Page 1

ST 360

NaceCare Solutions

1205 Britannia road east

Mississauga, Ontario, Canada

L4W 1C7

Toll Free: 1 800 387 3210

Toll Free Fax: 1 800 709 2896

Page 2

ST360_V05-2

TABLE OF CONTENTS

....................................................................................................................................................................... 1

TABLE OF CONTENTS ...................................................................................................................................2

DELIVERY OF THE MACHINE.........................................................................................................................3

INTRODUCTION..............................................................................................................................................3

TECHNICAL DATA ..........................................................................................................................................4

SYMBOLS USED ON THE MACHINE...............................................................................................................5

PREPARATION OF THE MACHINE .................................................................................................................6

MOVING THE MACHINE WHEN PACKED............................................................. 6

UNPACKING THE MACHINE....................................................................... 6

CONNECTING THE BATTERY CHARGER ............................................................ 7

RECHARGING THE BATTERIES ................................................................... 7

BATTERY LEVEL INDICATOR ..................................................................... 7

SQUEEGEE ................................................................................... 8

FITTING THE DISC BRUSH ....................................................................... 9

DETERGENT SOLUTION ......................................................................... 9

RECOVERY TANK .............................................................................. 9

GENERAL SAFETY RULES...........................................................................................................................10

CONTROLS ....................................................................................................................................................11

MAIN CONTROLS.............................................................................. 11

OPERATING THE GEAR LEVERS ................................................................. 13

SUCTION .................................................................................... 15

HORN....................................................................................... 15

SOLUTION LEVEL ............................................................................. 15

UPON COMPLETION OF WORK....................................................................................................................16

DAILY MAINTENANCE .................................................................................................................................. 17

CLEANING THE RECOVERY TANK ................................................................ 17

CLEANING THE SQUEEGEE ..................................................................... 17

REPLACING SQUEEGEE RUBBER BARS ........................................................... 18

RELEASING THE DISC BRUSH ................................................................... 18

CLEANING THE FILTER AND THE SOLUTION TANK................................................... 18

CLEANING THE SUCTION HOSE .................................................................. 19

CLEANING THE SUCTION MOTOR FILTER .......................................................... 19

OPERATION CONTROL ...............................................................................................................................20

NOT ENOUGH WATER ON THE BRUSH ............................................................ 20

MACHINE DOES NOT CLEAN EFFECTIVELY ........................................................ 20

SQUEEGEE DOES NOT DRY PERFECTLY .......................................................... 20

SUCTION DOES NOT WORK ..................................................................... 21

BRUSH MOTOR DOES NOT WORK ................................................................ 21

TRACTION MOTOR DOES NOT WORK ............................................................. 21

TOO MUCH FOAM FORMATION .................................................................. 21

THERMAL PROTECTIONS ....................................................................... 21

TRANSPORTING THE MACHINE........................................................................................................................................... 22

2

Page 3

ST360_V05-2

Delivery of the machine

When the machine is delivered, please check

immediately that all materials match the delivery

documents and that the machine has not been

damaged during transport. If so, ask your shipping

agent to assess the extent of the damage and

inform our customer care service at once. Prompt

and appropriate action is the only way to obtain the

missing parts and to be able to claim damages.

3

Page 4

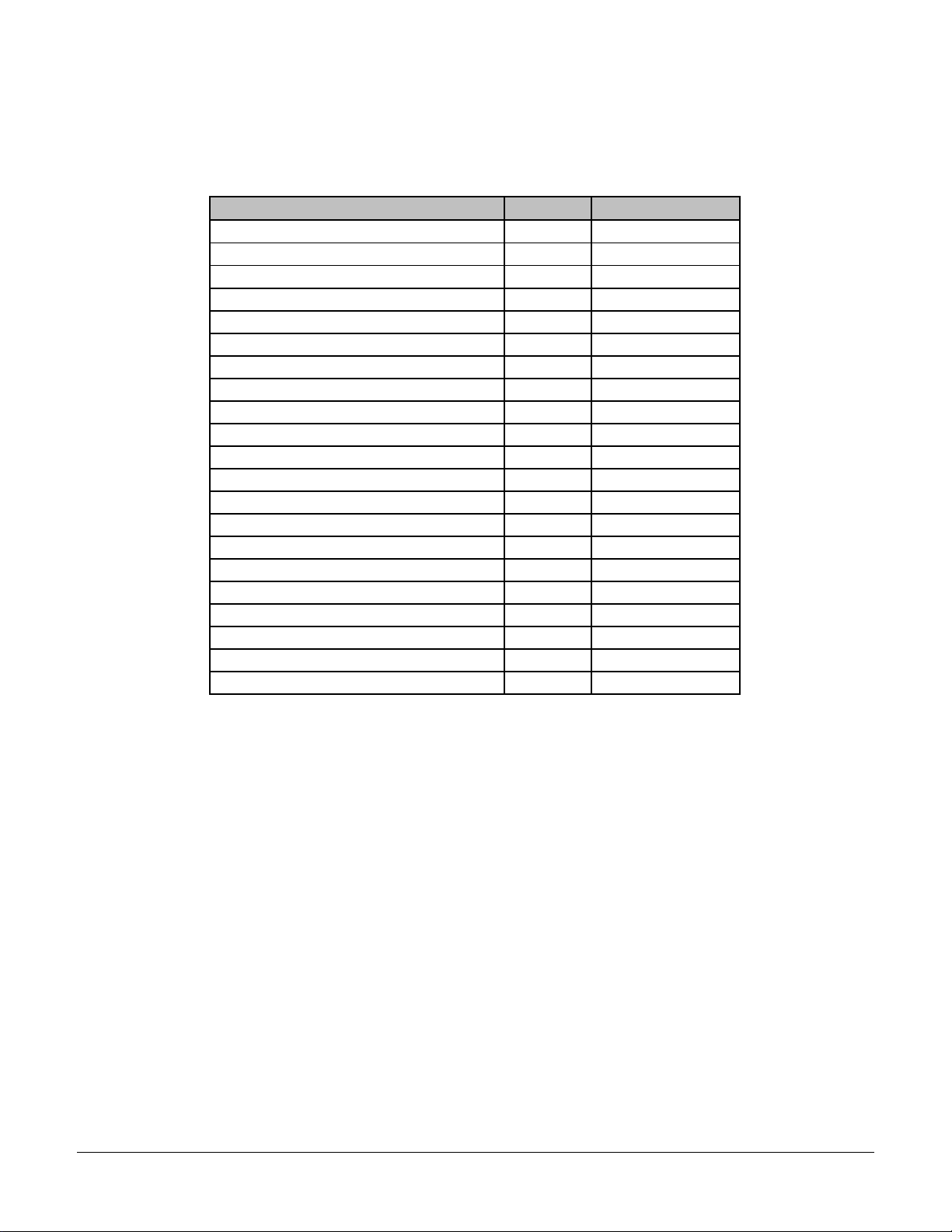

TECHNICAL DATA

4

ST360

TECHNICAL DATA UNIT

Working width Inches 21"

Squeegee width Inches 25.5"

Working capacity Sq feet/h 31,500

Brushes Inches 1 x 21"

Brush rpm RPM 200

Brush pressure LBS 100

Brush motor Volts V 24

Brush motor Watts W 400

Traction speed mph 0 - 4.5

Max grade capability % 10%

Suction motor Volts V 24

Suction motor Watts W 480

Solution tank Gallon 24

Recovery tank Gallon 27

Turning radius Inches 53"

Machine length Inches 48.5"

Machine width Inches 25.5"

Machine height Inches 62"

Batteries (No.) V/AH 24/240AH 4x6V

Battery weight Lbs 71lbs x 4

Machine weight without batteries Lbs 496

ST360_V05-2

Page 5

ST360_V05-2

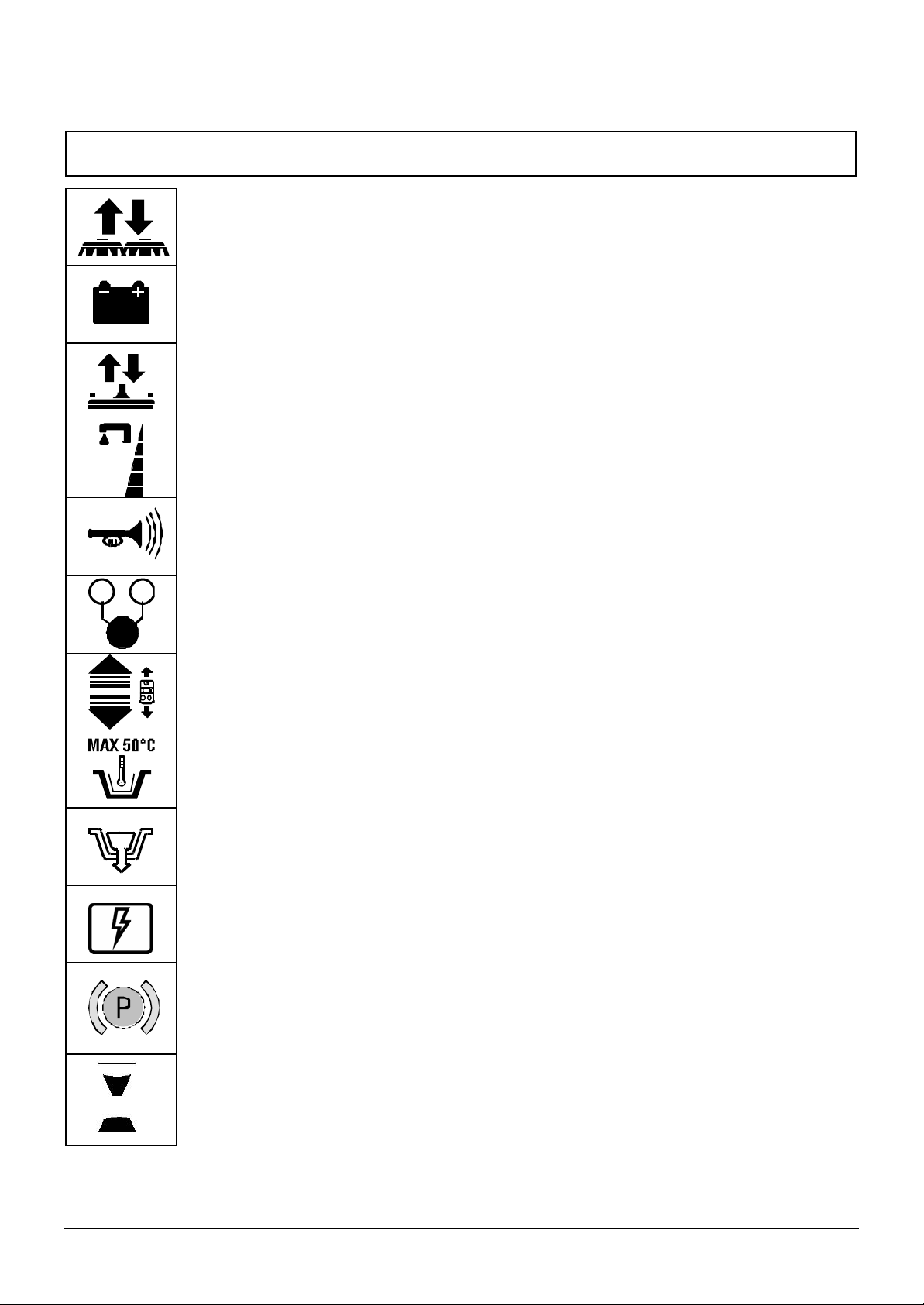

SYMBOLS USED ON THE MACHINE

Symbol for brush head up/down.

It indicates the brush head up/down pedal.

Symbol for battery charge level.

Symbol for squeegee up/down.

It indicates the up/down pedal of the squeegee.

Symbol for water flow.

Symbol for the horn button.

OFF/0 ON/1

Symbol for on/off switch.

Symbol for forward and reverse switch.

Its position shows the direction of the machine, either forwards or reverse.

Symbol for maximum temperature of solution.

Symbol for drain hose on the recovery tank.

Symbol for fuse panel

Symbol for levers in brake position

Symbol for the hourmeter

5

Page 6

ST360_V05-2

PREPARATION OF THE MACHINE

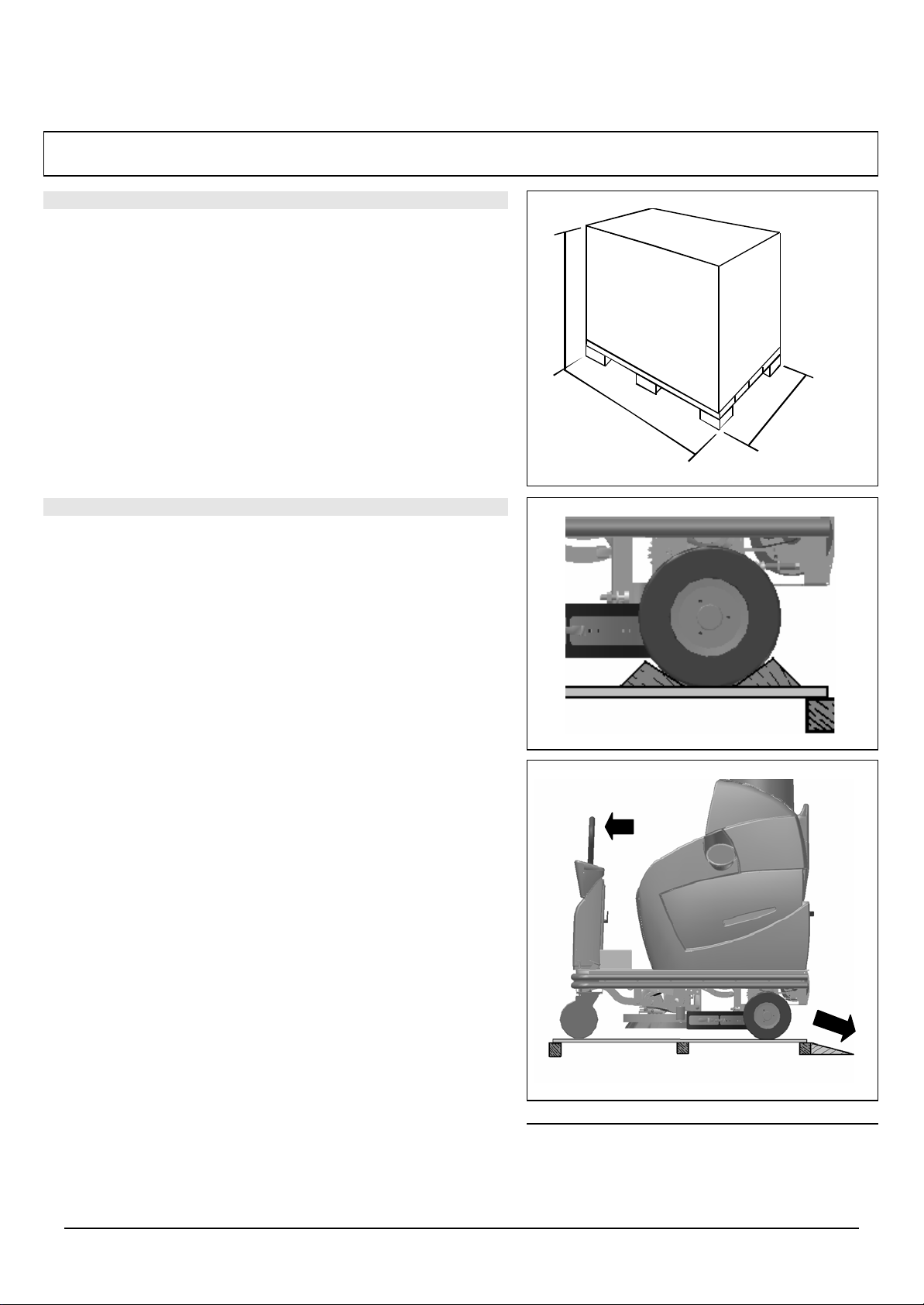

MOVING THE MACHINE WHEN PACKED

The machine comes in special packaging which includes a

platform for fork -lift transport. Do not place skids one on top

of the other.

The overall weight is 540Lbs.

Packing size is:

A : 60"

B : 29"

C : 52.5"

A

C B

UNPACKING THE MACHINE

Remove the box.

The machine is fixed to the skid by wheel -blocks.

Remove the wheel blocks.

Push the machine backwards off of the skid using a ramp.

Avoid hitting the brush head on the skid.

Keep the skid for future transport.

The suction head, is located inside the

battery compartment.

NOTE: to move the machine without batteries push the

drive levers forward.

6

Page 7

ST360_V05-2

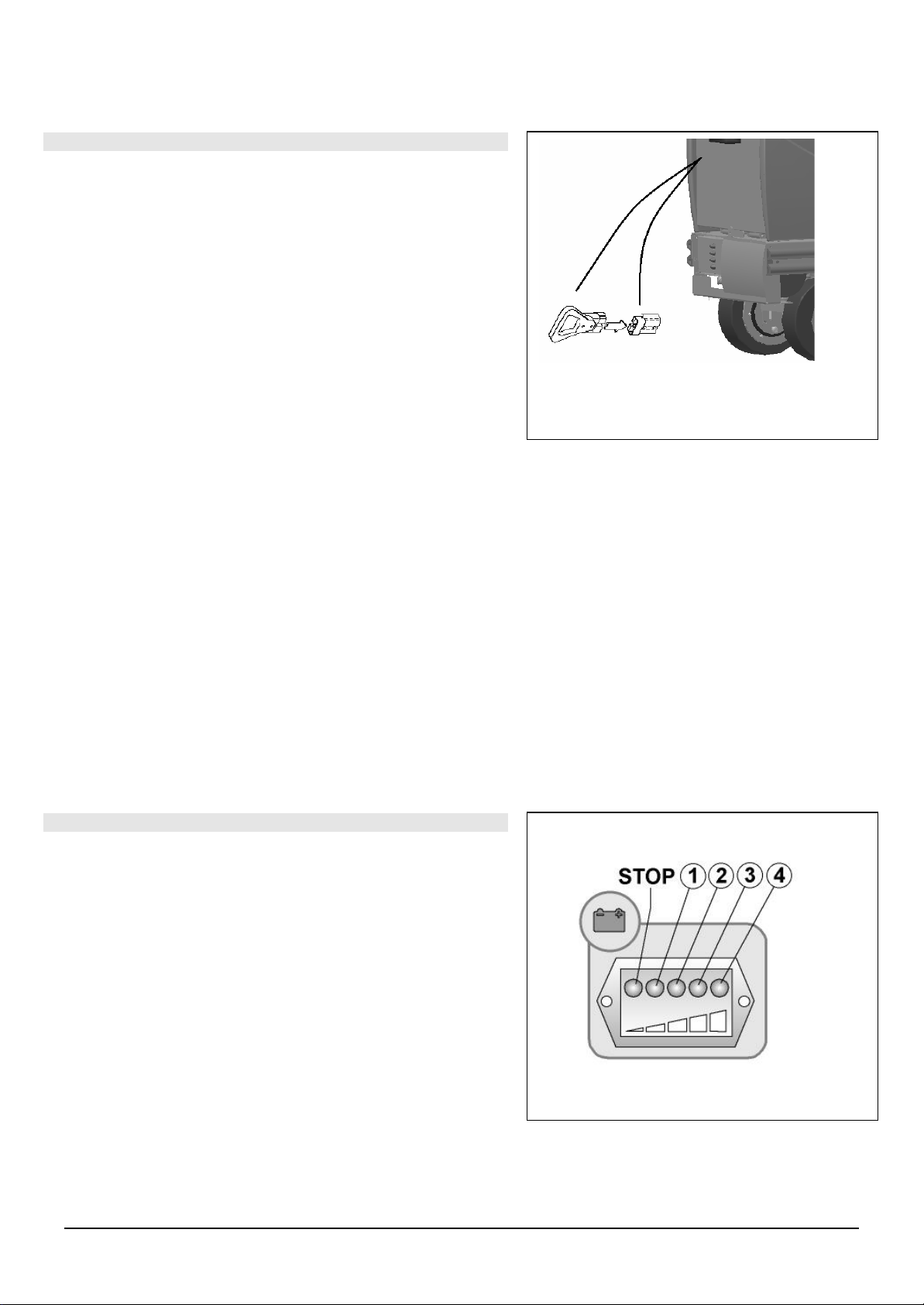

CONNECTING THE BATTERY CHARGER

The connectors are fitted on the battery compartment. Plug the

connector of the battery charger cables into the socket on battery

compartment. The battery connector is delivered inside the bag

where you found this instruction booklet.

BATTERY LEVEL INDICATOR

The battery level indicator is operated by a microprocessor. The

LEDs display the approximate level of charge:

4 = max. charge level, 3 = ¾ charge level,

2 = ½ charge level, 1 = ¼ charge level,

0 = flat batteries (blinking light).

ATTENTION: a few seconds after the “=” is shown, the brush

motor switches off automatically. However, with the residual

charge, the floor can be dried before recharging

7

Page 8

17¾”

-

17 ¾”

+

-

+

+

-

+

TO MACHINE

-

REAR OF BATTERY BOX

NOTE: Battery box will accept Trojan T125 Batteries (10 3/8” L x 7 3/8” W)

Page 9

8

PREPARATION OF THE MACHINE

1 2

1

ST360_V05-2

SQUEEGEE

The squeegee is supplied already assembled on the machine and with the

adjustments made during machine testing.

When operating the machine, the rear rubber should be slightly tilted back

5mm all along its length. you can use the squeegee on all 4 edges before

replacing it with a new one.

To adjust the squeegee blade down, just tilt back the squeegee body by

turning the knobs counter-clockwise. To adjust the squeegee blade up,

turn the knobs clock-wise. When adjustment is completed, thighen the lock-nut.

To release the squeegee from the machine, use the lever (1) and the

squeegee is immediately released from its holder. Disconnect the

suction hose and push it towards the inside of the machine to release the

opposite side.

Page 10

9

PREPARING THE MACHINE

ST360_V05-2

FITTING THE DISC BRUSH

1. With the brush head lifted, centre the brush under the brush deck

2. When lowering the brush head, the brush will lock automatically.

DETERGENT SOLUTION

Fill up the solution tank with fresh water at a temperature not

exceeding 50 °C and add the liquid detergent according to the

concentrations and instructions that are provided by the

manufacturer.

NOTE: Always use low-foam detergents. To be sure to avoid any

foam formation, before starting to operate, pour a minimum quantity

of antifoaming agent into the recovery tank. Do not ever use pure

acids.

RECOVERY TANK

Make sure the vacuum unit is properly fitted and the drain hose

cap is closed.

Page 11

10

GENERAL SAFETY RULES

ST360_V05-2

Keep to the following rules in order to prevent any operator injury or machine damage.

r Read thoroughly the labels on the machine, do not cover them for any reason and replace them immediately if

they are damaged

r The machine should be operated only by authorised and trained personnel

r When operating the machine, beware of other people and especially to children

r Do not mix different types of detergent in order to prevent formation of harmful gases

r No Do not place any liquid container onto the machine

r Storage temperature should be between -25°C and +55°C

r The optimum operating temperature should be between 0°C and 40°C

r The humidity level should be between 30 and 95%

r Do not operate the machine in explosive environment

r Do not use the machine as means of transport

r Do not use any acid solution which could damage the machine

r Stop brush rotation when the machine is not moving to prevent floor damag e

r Avoid suction of inflammable liquids

r In the event of fire, use powder extinguishers. Do not use water.

r Do not bump against shelving or scaffolding to prevent any risk of object falling

r Adjust operating speed to wheel grip conditions

r Do not exceed the m aximum stated gradient to avoid instability

r When the machine is parked, take the key out

r The machine has to scrub and dry at the same time. If otherwise operated, cleaning tasks should only take

place in areas that are restricted to authorised personnel. Mark the wet floor areas with proper signs

r Should any anomalies be detected in machine operation, make sure they are not due to lack of ordinary

maintenance. Otherwise, ask the Fimap customer care service for assistance.

r Should any part be replaced, ask an authorised dealer and/or retailer for ORIGINAL spare parts.

r For any maintenance procedure, unplug the machine from the mains supply.

r Do not remove any protection which requires the use of tools to be removed

r Do not wash the machine with direct jets of water or under pressure, nor with corrosive substances.

r Every 200 operating hours have the machine checked by a Fimap customer care service

r The machine doesn’t cause any harmful vibration

r In order to prevent the solution tank filter from developing scaly deposits, do not pour in the detergent solution

hours before operating it.

r Before operating the machine, make sure that all caps and covers are properly positioned as indicated in this

operator’s manual.

r Before lifting the recovery tank, make sure it is empty.

r Dispose of any consumables in strict accordance with the relevant regulations in force.

r When, after years of valuable usage, you have to dispose of your FIMAP machine, make sure you dispose

correctly of all the materials it consists of, especially oils, batteries and electrical components considering that

the machine itself has been manufactured with completely recyclable materials.

r Attention: reconnect all electric connections after every maintenance procedure.

r The machine is not intended for children nor for unsupervised use by persons whose physical, sensory or

mental conditions could make the use of the machine unsafe. Keep the machine away from children.

Page 12

11

CONTROLS

2 1

3 6

7

9 8

10

11

10

ST360_V05-2

MAIN CONTROLS

1. Horn

2. Digital hourmeter

3. Battery level indicator

4. On/Off key switch

5. Forward/reverse switch

6. Forward/reverse levers

7. Solution lever

4

5

8. Squeegee control pedal: the

squeegee is working when the

pedal is lifted.

9. Pedal for right wheel directional

lock.

10. Brush control pedal, the brush is

working when the pedal is lifted.

11. Pedal for left wheel directional

lock.

12. Button to de-activate the vacuum motor.

Page 13

ST360_V05-2

OPERATING

Follow the operations as instructed under PREPARATION OF THE

MACHINE

1. Plug in the battery connector

2. Sit on the seat

3. Turn the key switch on.

4. Drop the brush deck down and the vacuum motor will start

automatically.

5. Open the tap by turning the knob counter clock-wise. Water only

flows when the brush motor is on.

6. To lower the brush head, push the pedal left and up. Brush and

suction start automatically. For higher pad pressure, lift the pedal

further until it locks in place. To lift the brush head, push the

pedal down until it locks in place.

7. To lower the squeegee, push the pedal right and up. To lift it, press

the pedal down until it locks in place.

12

Page 14

1

ST360_V05-2

OPERATING

OPERATING THE DRIVE LEVERS

Each lever is directly connected to the corresponding traction wheel

(right lever with right wheel and vice-versa).

Operating in forward gear:

1. Press the forward switch on the instrument board

2. Push both levers forwards simultaneously

To turn right, move the left lever fo rwards and the right one

backwards.

To turn left, move the right lever forwards and the left one backwards

To brake, pull back both levers simultaneously.

Operating in reverse gear:

1. Press the switch on the instrument board

2. Push both levers forward simultaneously

13

Page 15

14

ST360_V05-2

To turn right, move the left lever forwards and the right one

backwards.

To turn left, move the right lever forwards and the left one backwards.

These pedals are meant to lock the direction of the front wheels to

ensure straig ht drive when operating in forward or reverse gear.

NOTE: the machine is fitted with a deadman microswitch. The

machine does not works if the operator is not seated properly.

Page 16

1

ST360_V05-2

OPERATING

SUCTION

The vacuum motor starts automatically as the squeegee is lowered.

The motor does not switch off automatically when the squeegee is

lifted to prevent any water leaking from the suction hose. Wait a few

seconds and press the button (1) on the vacuum unit.

HORN

The machine is fitted with a horn switch. To sound the horn, press the

button as shown in the picture.

SOLUTION LEVEL

The solution tank has 3 water level indicators:

MIN

MED

MAX

MAX

MED

MIN

15

Page 17

16

UPON COMPLETION OF WORK

ST360_V05-2

Upon completion of work and prior to any type of maintenance

procedure, carry out the following operations:

1. Close the water valve

2. Lift the brush head

3. Lift the squeegee

4. Switch the suction motor off

5. Take the machine where you intend to drain the water out

6. Turn the key to “OFF”

Take the hose off the hook, unscrew the drain plug and empty the

recovery tank. To make this operation easier, keep the hose

higher than the tank water level with one hand and with the other

hand unscrew the knob and take off the cap. By slowly lowering the

hose, the liquid will come out at the desired speed. Do this only when

wearing protection gloves to prevent contact with dangerous

solutions.

When the machine is not operating lift the squeegee to prevent

rubber bars from losing their shape.

Release the brush and clean it with a hose (For brush release,

see the following chapter “BRUSH RELEASE”).

Page 18

ST360_V05-2

DAILY MAINTENANCE

CLEANING THE RECOVERY TANK

Empty the tank through the drain hose. Turn the knob a few turns to

unscrew it and remove the plug.

CLEANING THE SQUEEGEE

Clean the squeegee with a hose. Check for rubber blade wear

conditions and, if necessary, turn or replace them. Accurate cleaning of

the whole suction assembly ensures longer suction motor life.

17

Page 19

DAILY MAINTENANCE

1 3

2 4

ST360_V05-2

REPLACING SQUEEGEE RUBBER BARS

If the squeegee blades are worn out and do not dry properly,

change the drying side as follows:

Pull the squeegee assembly out as illustrated un der

“PREPARATION OF THE MACHINE”

Unlock the clamp (1) between the two rear blades

Pull out the blades (2/3) and the rubber bar (4)

Flip the rubber blade or, if necessary, replace it

Adjust squeegee height as illustrated under “HEIGHT

ADJUSTMENT OF THE SQUEEGEE SUPPORT” at chapter

“PREPARATION OF THE MACHINE”

Reassemble it all by following the above procedure in reverse

RELEASING THE DISC BRUSH

1. Turn the key to “OFF” and remove it from the instrument board.

(releasing the brush when the machine is on may cause serious

injury)

2. Disconnect the battery connector

3. Lift the brush head

4. Keeping the brush head lifted, rotate the brush to release it

from the brush holder plate as illustrated in the picture.

CLEANING THE FILTER AND THE SOLUTION TANK

Close the solution tap:

1. Unscrew the solution filter to empty the tank

2. Remove the cartridge and clean it

Reassemble it all by following the above procedure the other way

round

18

Page 20

WEEKLY MAINTENANCE

2

ST360_V05-2

CLEANING THE SUCTION HOSE

1. In case of po or suction, make sure the suction hose is not

clogged. Clean it with a garden hose from where

the hose is connected to the tank.

CLEANING THE SUCTION MOTOR FILTER

1. Disconnect the main connector between the suction cover and the

recovery tank

2. Remove the suction unit from the tank.

3. With a circular movement, remove the black cover (1).

4. Remove the filter (2) and clean it thoroughly with a garden hose.

5. Reassemble it all by following the above procedure in reverse

1

19

Page 21

20

OPERATION CONTROL

ST360_V05-2

NOT ENOUGH WATER ON THE BRUSH

1. Make sure the tap is open

2. Make sure there is water in the solution tank

3. Clean the solution filter

MACHINE DOES NOT CLEAN EFFECTIVELY

1. Check for brush wear and, if necessary, replace it (the brush should

be replaced as the bristles are about 15 mm long).

2. Use another type of brush and not the standard one. For cleaning

tasks on floors with stubborn dirt, special brushes are

recommended, which can be supplied on request according to

individual requirements.

SQUEEGEE DOES NOT DRY PERFECTLY

1. Make sure the squeegee is clean

2. Adjust the height of the squeegee support (see under

“PREPARATION OF THE MACHINE”)

3. Clean the whole suction unit (see under “WEEKLY

MAINTENANCE”)

4. Replace the rubber blades, if worn out

Page 22

21

OPERATION CONTROL

ST360_V05-2

SUCTION DOES NOT WORK

1. Make sure the connector of the suction unit is properly connected.

2. Make sure that thermal protection has not been activated (see

under THERMAL PROTECTION).

BRUSH MOTOR DOES NOT WORK

1. Make sure the brush head was lowered.

2. Make sure that batteries are charged by checking on the indicator.

3. Make sure that thermal protection has not been activated (see

under THERMAL PROTECTION).

TRACTION MOT OR DOES NOT WORK

4. Make sure that batteries are charged by checking the indicator.

1. Make sure that thermal protection has not been activated (see

under THERMAL PROTECTION).

TOO MUCH FOAM FORMATION

Make sure that low-foam detergent has been used. If necessary, add a

minimal quantity of antifoaming agent into the recovery tank.

Keep in mind that there is more foam formation when the floor is not

very dirty. In this event, use a more diluted detergent solution.

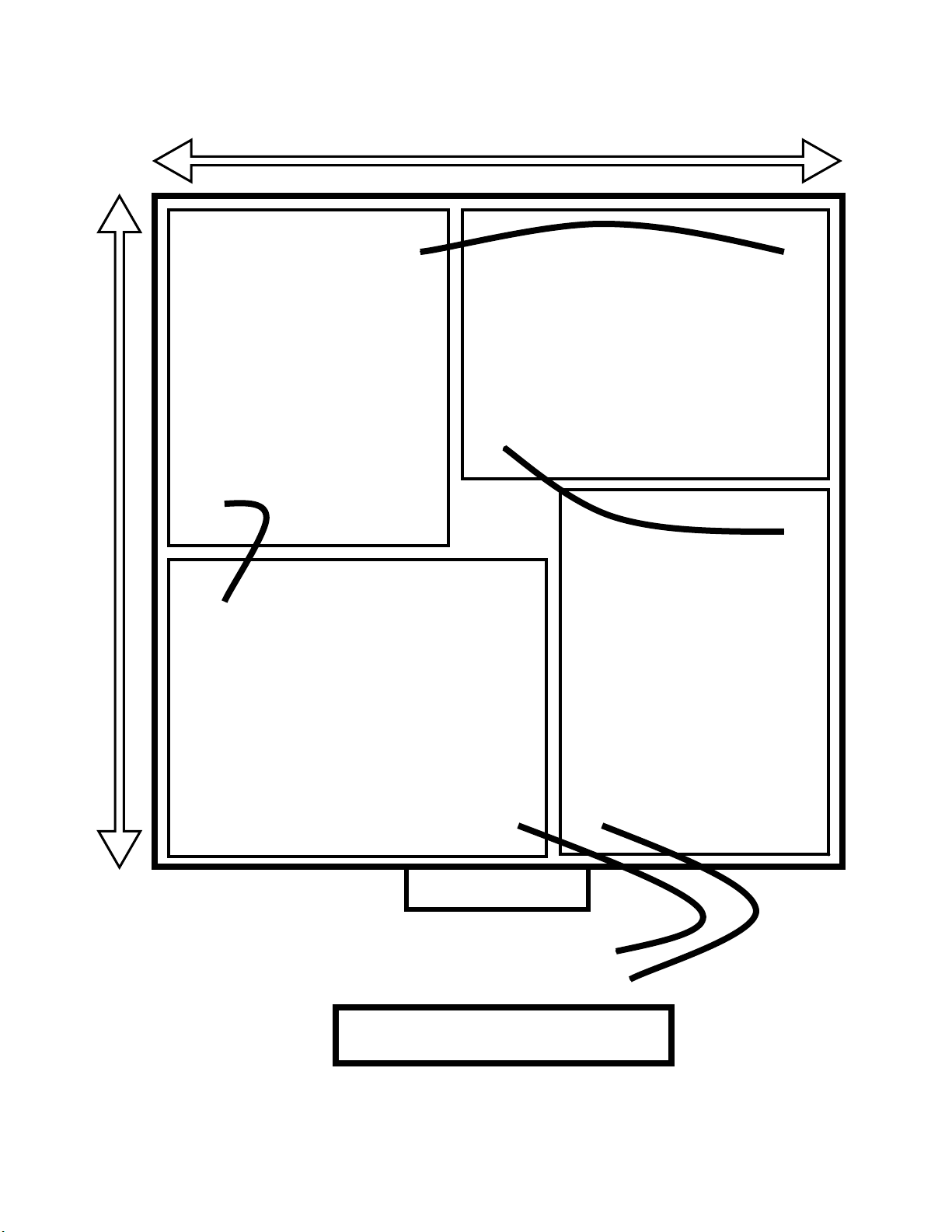

THERMAL PROTECTIONS

There is a THERMAL PROTECTION system for the following

functions:

1. Main.

2. Suction.

3. Brushes.

4. Traction.

Should any of these functions stop, resume operation by pressing the

relevant button.

The breaker panel is built-in to the rear left of the machine.

1

2

3

4

Page 23

ST360 LOADING AND UNLOADING USING A RAMP

23 ST360_V05-2

When going down a ramp with the ST360, always go down the

ramp forwards.

Note: If you must unload the

machine in reverse, stand in

front of the machine and pull

the drive levers towards you.

Push the machine down the

ramp in reverse while

continuing to hold the drive

levers. Never

machine down a ramp in

reverse. Also, ensure that the

battery box is well secured

drive the

Never attempt to drive down a ramp backwards with the ST360.

If the brakes are applied while driving down a ramp in reverse,

the machine may tip and cause serious injury to the operator and

bystanders.

Page 24

ST360 TRANSPORT INSTRUCTIONS

24 ST360_V05-2

When transporting the ST360, to prevent any damage to the machine follow these

guidelines:

1. Make sure that both the solution and recovery tanks are empty.

2. Ensure the machine is strapped down and well secured inside the trailer.

3. Remove the vacuum head to prevent any possible damage.

4. Transport the battery box and trolley separately, or put one strap around the entire

machine (from front to back) to prevent the battery box from coming loose during

transport.

5. If transporting the battery box on the trolley, lock the trolley wheels and ensure

the trolley is well secured in the trailer.

6. Ensure that the brakes on the machine are in the locked position using the locking

rod provided with the machine.

Loading...

Loading...