Page 1

USE AND MAINTENANCE INSTRUCTIONS FOR

THE SELF-CONTAINED CLEANING MACHINE

AVB4X

READ THESE INSTRUCTIONS CAREFULLY BEFORE USING THE MACHINE

1205 Britannia Road East

Mississauga, Ontario, Canada L4W IC7

Tel: 905 795 0122

Toll Free: 1 800 387 3210

Fax: 1 800 709 2896

Page 2

2

Generalities

The body of the carpet cleaning machine Sharon-Brush is composed by two high-density

polyethylene tanks, kept together with elastic hooks. The upper tank is meant to contain the dirty

water sucked from the carpet, while the lower tank is meant to contain clean water and detergent. The

lower tank also contains the vacuum motor, the pump and the control panel. The vacuum head, the

spray nozzle and the rotating brush are situated below the lower tank.

Safety instructions (read carefully)

Every electrical device must be used for its particular function only, respecting the manufacturer’s

instructions. Failure to adhere to the instructions could result in serious person injury, electric shock,

fire or explosion.

The nowadays machines are normally produced according to the accident prevention regulations and

are often homologated by qualified institutes for the safety, but nobody and nothing can save

irresponsible users from danger.

Please, read carefully the following points and be sure to understand everything before using the

machines. The following information signals potentially dangerous conditions to the operator or

equipment.

WARNING: Fire or Explosion Hazard.

Do not spray water near electrical outlets.

Do not use the machine to spray or to suck dust, corrosive liquids (acids or bases) and explosive

or inflammable liquids.

Do not use the machine in an explosive atmosphere. This machine is not equipped with an

explosion proof motor. The electric motor will spark when powered on which could cause a flash

fire or explosion if machine is used in an area where flammable vapors/liquids or combustible

dusts are present.

Never use flammable liquids or operate machine in or near flammable liquids, vapors or

combustible dusts.

Page 3

3

WARNING: Electrical Hazard.

Before putting the machine’s plug in the current socket, check that the voltage available is the

same indicated on the label of the machines.

Be sure that the electrical system is well earthed and that it has a safety differential switch.

Verify that the cable plug is complying with the outlet.

Do not modify plug.

Do not use adapters or multiple sockets, without knowing the electrical input of each user.

If any electrical extension is used, check that it corresponds to the absorbed power of the machine

and that the connection of the plug with the socket is complying and sealed.

Take care of the electrical cable. It must be integral and protected from water, tears and chemical

agents. Do not repair the cable in case of tears, but replace it with a new one. The cable must be

replaced by the manufacturer or its service agent or a similarly qualified person in order to avoid a

hazard.

Do not pull the cable to drag the machine or to pull the plug out.

Pull the plug out only when the machine is switched off.

Do not handle the plug with wet hands.

Unplug cable before servicing machine.

FOR SAFETY:

Do not let the machine being used by children and people unable to understand the danger

connected with the use of electrical power.

Do not bring the end of the suction hose or one of the accessories near your face or others’,

particularly near ears and eyes: the sucked air could seriously damage them.

If the machine is used as a wet vacuum cleaner, you must check the level of water in the recovery

tank, in order to prevent water from being sucked by the vacuum motor.

If the chemical you are using produces foam, or if you are cleaning carpet previously treated with

shampoo, you must put some antifoaming liquid into the recovery tank. In the long run, the foam

sucked by the motor can damage it.

In case of abnormal working (very noisy motor, not running pump, extreme temperature rise, or

other suspicious signals) switch off the machine and pull the plug out.

If foam or liquid escapes from the machine, switch machine off immediately.

After using, store the machine, well cleaned, in a cool and dry place.

The manufacturer cannot be held responsible for any damage/injury caused to persons or property,

because of the incorrect use of the machine due to procedures being used which are not specified in

this instruction manual.

Attention: all the electrical repairs must be performed by qualified personal only!

PROTECT THE ENVIRONMENT

Please dispose of packaging materials and old machine components in a safe

environmentally way according to your local waster disposal regulations.

Always remember to recycle.

Page 4

4

Preparation for Work

The carpet cleaning machine Sharon-Brush is designed to clean large areas of carpet and hard floor,

even without using external accessories, since the washing device is situated below the body of the

machine (see paragraph Use as a Self-contained Machine).

It is also possible to clean upholstery, inside of cars or hard-to-reach areas, by using additional

accessories, which must be connected to the machine with connecting hoses (see paragraph Use

with Accessories).

The following steps explain the necessary operations to prepare the machine for use:

1. Put the machine in the normal working position and regulate the height of the handle.

2. Fill in the lower tank (solution tank) with cold or warm water, through the filling hole, adding a 5%

of not-foaming detergent (1/2 liter each 10 liters). Higher concentrations can be used in case of

particularly dirty surfaces.

Attention: wool carpet must be washed with cold water only!

While filling the lower tank, pay attention to avoid overfilling the tank and to prevent water from going

outside the appropriate filling hole. Always keep in mind the dangers connected with the use of

electrical device.

3. Close the filling hose with the cap.

4. Insert the plug of the cable into a wall socket (see Safety Regulations).

Page 5

5

Use as a Self-contained Machine

In this modality the machine washes and dries with the spray nozzle and the vacuum head which are

situated below the body of the machine.

To switch on the machine you must act on the switches on the control panel:

1. Set to position "I" the switch of the vacuum motor.

2. Set to position "I" the pump switch. In this way the solution pump works only while you rotate

the hand grip of the machine.

3. To clean carpets, rotate the lever on the vacuum head towards the right side. To clean hard

floors, rotate it towards the left side.

4. To activate the rotating brush switch on the power brush motor, act on the

correspondent luminous switch, located in the nearby of the vacuum head.

Attention: Do not use the machine as a vacuum cleaner!

Do not let the pump function without water! Check periodically the level of water in the lower tank,

while using the machine. As soon as it becomes empty you must switch off the machine, empty the

upper tank (which then will be full) and fill again the lower tank before activating the pump.

Attention: Keep an adequate distance from other people. Pay attention to any object that could hit by

the machine. Never leave the machine unguarded.

Page 6

6

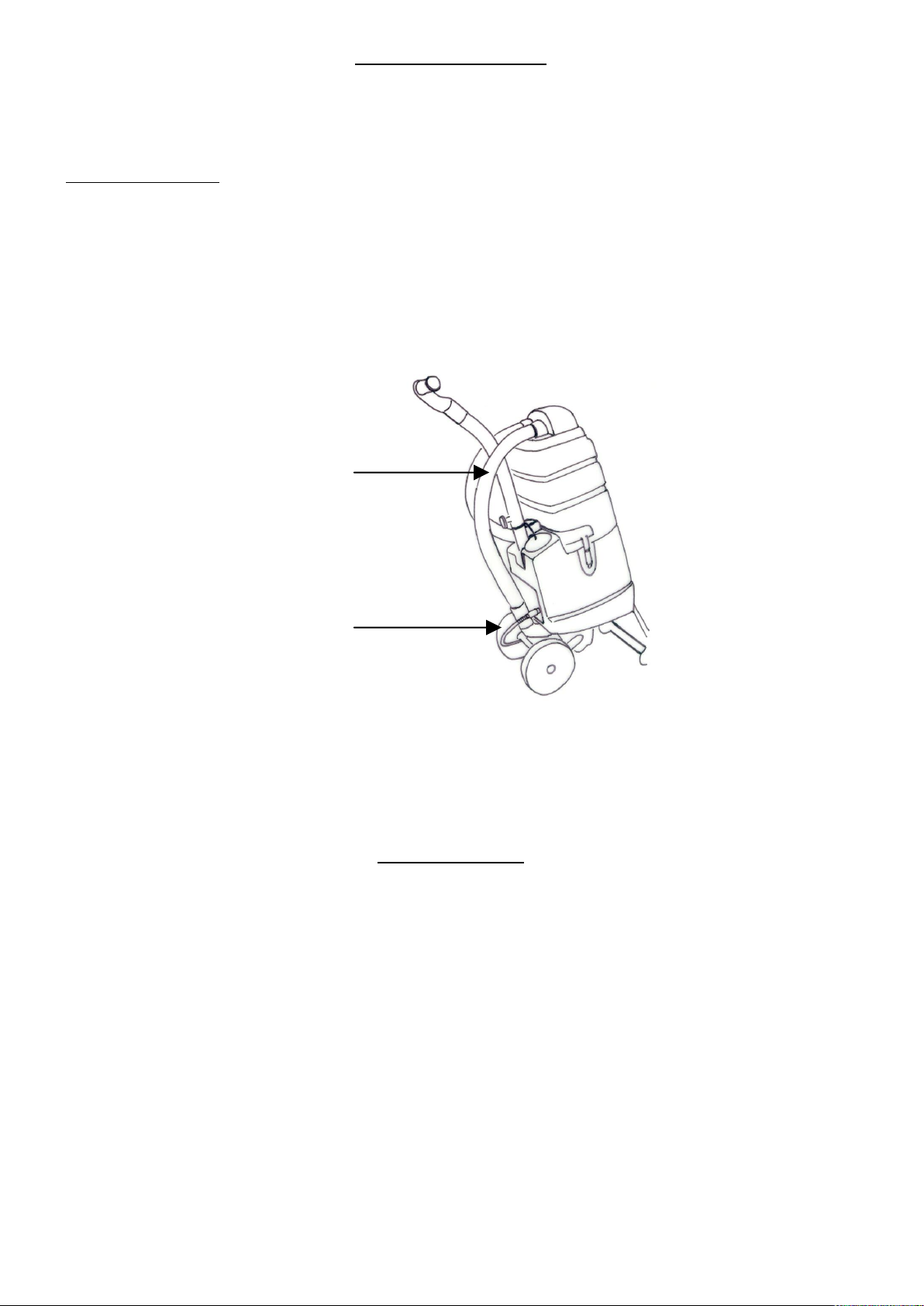

Vacuum hose

Solution hose

Use with Accessories

In this modality the machine works as a classical extractor, for which you clean a surface by using

accessories which are external to the machine body.

After filling the tanks with solution and inserting the plug in the wall outlet (see the Paragraph

Preparation for work), you need to perform the following operations:

1. Connect the machine to the wand or to the hand-tool using the solution and the vacuum

hoses. To connect the hoses to the machine, remove the vacuum hose, which connects the

upper tank to the vacuum head, and the solution hose, which connects the pump to the

spraying nozzle, situated under the machine. By doing so, Sharon-Brush becomes a classical

carpet extractor. At this point it is possible to connect the accessories to the machine, through

the special connecting hoses.

2. Switch on the vacuum motor by setting their switch to position "I", and the pump by setting the

switches to position "II". In this way the solution pump always works and it is not necessary to

keep pressed the control lever situated on the control panel.

3. To spray water you need to press the lever situated on the handle of the accessory.

Working method

As regards the use as a self-contained machine, considering a rectangular surface, we suggest you to

proceed in parallel stripes, spraying and sucking the solution at the same time. Proceed at a speed

suitable with the dirt of the surface. In case of persistent spots, you can apply locally a pure

detergent. There are also spray bottles on market, with detergents, which are specific for a particular

kind of spot. Choose high-quality detergents only in order to avoid any damage to the surface. Always

make a test in an area where an eventual damage is less visible.

Page 7

7

Maintenance

The model Sharon-Brush is a professional machine. The warranty on these machine is of 1 year and

regards the faults due to manufacturing defects. The faults due to improper use are not covered by

warranty. For further details regarding warranty, contact the distributor supplying the machine.

For a good preservation and a long duration of the machine, observe the following advice:

1. After every use, before storing the machine, remove all the water from the solution and the

recovery tank. Put some liters of clean water into the solution tank and use the pump only,

pressing the lever of the solution valve. This operation is useful to clean the internal parts of the

pump, of the couplings and nozzles, removing the detergent residues.

2. After every use, store the machine in a cool and dry place with the cover open, to avoid that

humidity inside the recovery tank can condensate on the internal parts of the vacuum motor,

therefore damaging it. The damage provoked by humidity that condenses on the motor (like the

damage caused by the foam sucked by the motor) is not covered by warranty.

3. Periodically clean the water filter, extracting it from the machine and rinsing it under current water.

4. Check and periodically clean the filters of the vacuum motor, that are located in the transparent

cover of the recovery thank.

5. Eliminate the lime that in time deposits inside the hydraulic circuit of the machine, by putting some

anti-lime solution in the solution tank and leave it for some hours. Then empty the tank and rinse.

It is enough to perform this operation every 6-8 months.

6. Periodically check the consume of the carbon brushes of the vacuum motor and of the brush

motor. This check should be done after 500 working hours. Consumed carbon brushed may result

in a damage to vacuum motor or pump, which are not covered by warranty. The check of carbon

brushes should be done by technical personnel.

7. Periodically check that the brush rotates without problems, eliminating the causes which prevent a

free rotation. In case of difficulties, contact the technical assistance.

Loading...

Loading...