Nacecare TT 1117 / 100, TT 1120 / 100, TT 1117, TT 1120 Owner's Instructions Manual

TT 1117 / 100

TT 1120 / 100

TT 1120 TT 1117

Original Instructions - Warning! Read instructions before using the machine.

Attention - Lisez la notice avant d’utiliser la machine.

www.nacecare.com

Owner Instructions

Mode d’emploi

2

Index Page 2 Index Page 2

Machine overview Page 3 Description de la machine Page 3

Rating label / Personal

Protective Equipment /

Recycling

Page 4

Plaque signalétique/

Équipement de protection

individuelle/Recyclage

Page 15

Safety Precautions /

Specications

Page 5

Précautions à prendre/

Caractéristiques

Page 16

Machine set-up Page 7 Préparation de la machine Page18

Tilting the handle Page 7 Inclinaison de la poignée Page 18

Fitting the top tank Page 7 Montage du réservoir supérieur Page 18

Fitting the brush Page 7 Montage des brosses Page 18

Tipping the Brush deck Page 8 Inclinaison du plateau de brosses Page 19

Fitting the oor tool Page 8 Montage du suceur Page 19

Filling the clean-water tank Page 9

Remplissage du réservoir d’eau

propre

Page 20

Clean water level Page 9 Niveau d’eau propre Page 20

Control of Cleaning substances

(COSHH)

Page 9

Contrôle des substances de

nettoyage dangereuses pour la

santé (COSHH)

Page 20

Clean Water Tap On / Off Page 9

Robinet marche-arrêt de l’eau

propre

Page 20

Machine Operation Fonctionnement de la machine

Pre-cleaning advice Page 10 Pré-nettoyage Page 21

Pre-scrub mode Page 10 Prélavage Page 21

Lowering the oor tool Page 10 Abaissement du suceur Page 21

Break away oor tool feature Page 11

Fonction de détachement du

suceur

Page 22

Setting the cleaning controls Page 11

Utilisation des commandes de

nettoyage

Page 22

Regular Maintenance Entretien régulier

Tanks and Filters Page 12 Réservoirs et ltres Page 23

Changing the Floor Tool Blades Page 13

Démontage et nettoyage du

séparateur

Page 24

Trouble shooting Page 14 Dépannage Page 25

Recommended spare parts Page 14

Pièces de rechange

recommandées

Page 25

Wiring Diagrams Page 26 Schémas de câblage Page 26

Company addresses Page 28 Adresses de l’entreprise Page 32

3

Machine Overview

1

3

4

5

6

7

8

10

13

14

15 16

17

18

19

20

21

11

2

22

9

12

13

19

Description de la machine

1. Panneau de commande de l’opérateur 12. Commutateur marche-arrêt

2. Séparateur 13. Levier marche-arrêt

3. Réservoir supérieur (eau sale) 14. Point de remplissage du réservoir d’eau propre

4. Tuyau de vidange de l'eau sale 15. Tuyau d’aspiration du suceur

5. Réservoir inférieur (eau propre) 16. Tuyau d’aspiration

6. Goupille de verrouillage de plateau 17. Tuyau de vidange et niveau de remplissage du réservoir d'eau propre

7. Plateau de brosses 18. Levier de levage du suceur

8. Levier de positionnement de poignée 19. Boutons de retenue du suceur

9. Commutateur de l'aspiration 20. Suceur semi-parabolique

10. Commutateur de la pompe 21. Filtre d'eau propre

11. Voyant d'alimentation 22. Brosse

Machine Overview

1. Operator control panel 12. On / Off Switch

2. Separator 13. On / Off lever

3. Top tank (waste water) 14. Clean water tank ll point

4. Waste water emptying hose 15. Floor tool vacuum hose

5. Bottom tank (clean water) 16. Vacuum hose

6. Deck locking pin 17. Clean water tank emptying hose & ll level

7. Brush deck 18. Floor Tool Lifting lever

8. Handle position lever 19. Floor tool retaining knobs

9. Vacuum switch 20. Semi parabolic oor-tool

10. Pump switch 21. Clean Water Filter

11. Power Ligh 22. Brush

4

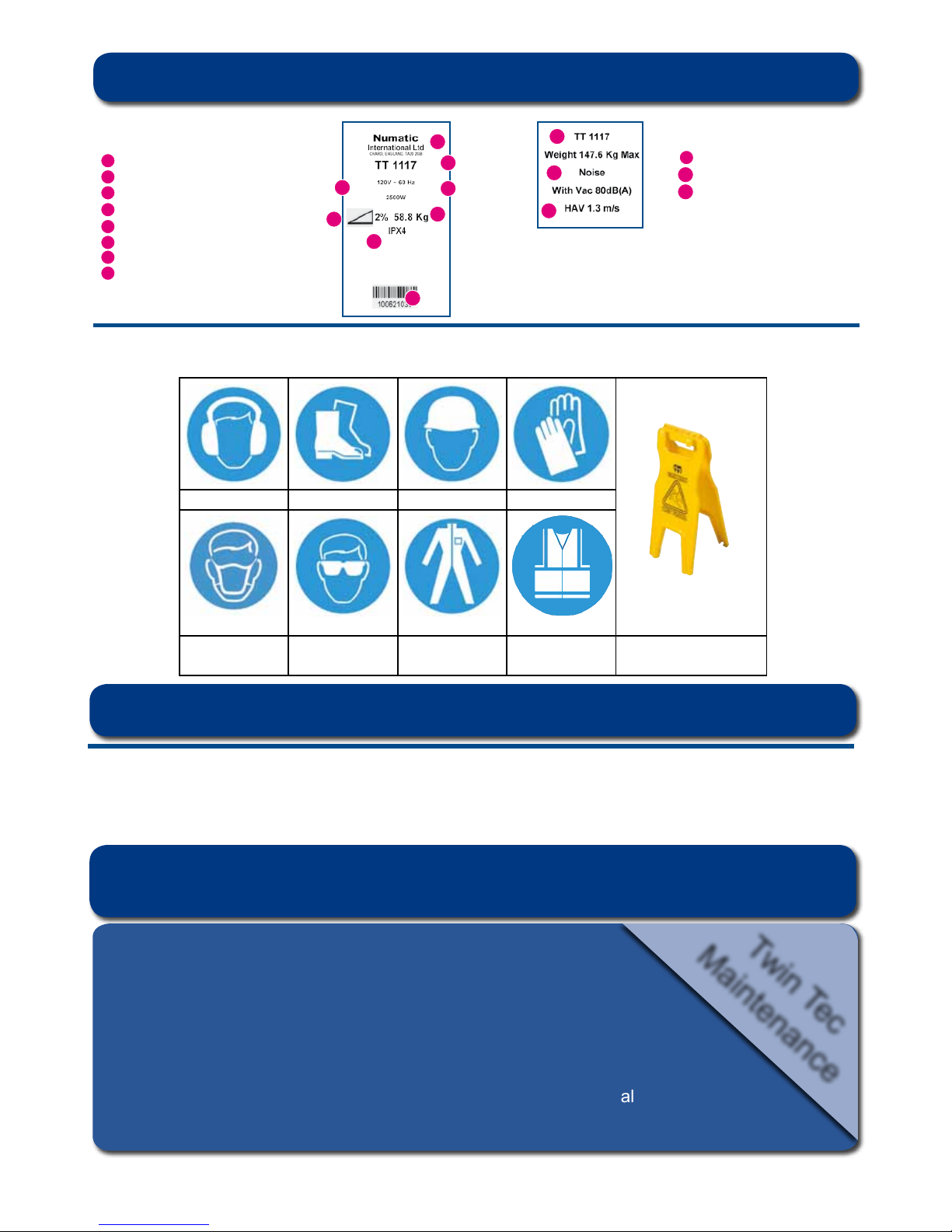

Rating Label

Safety Critical Component

Mains lead:

SJTW x 14 AWG x 3 core

About the Machine

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

Company Name & Address

Machine Description

Voltage Frequency

Power rating

Max Gradient

Weight (ready to use)

Splash Proof Rating

Machine yr/wk Serial number

Failure to rectify the problem or in the event of a breakdown contact your Nacecare dealer or the

Nacecare Technical help line 900 1 905 795 0038

10

10

11

11

Machine Description

Noise Rating

Hand Arm Vibration

Ear Protection Safety Footwear Head Protection Safety Gloves

Dust/Allergens

Protection

Eye Protection Protective

Clothing

Hi-Vis Jacket

Caution

wet oor sign

Note:

A risk assessment should be conducted to determine which PPE should be worn.

PPE

(Personal protective equipment) that may be required for certain operations).

9

Daily

Keep the machine clean

Ensure brushes/ pads/ squeegee/ lters are in good condition

Check for any worn or damaged parts and replace immediately

Drain and rinse dirty water tank after every use

Store machine with brush deck secured in tilted position

Weekly – as daily and –

Check brush or pad and skirt and rinse

Check oor tool blades for wear and wipe clean

Clean separator assembly including lter and check condition of seal

Flush out system with clean water and clean lters

Do not steam clean or pressure wash

Twin Tec

Maintenance

5

As with all electrical equipment care and attention must be exercised at all times during its use, in addition

to ensuring that routine and preventative maintenance is carried out periodically in order to ensure its safe

operation.

Failure to carry out maintenance as necessary, including the replacement of parts to the correct standard could render

this equipment unsafe and the manufacturer can accept no responsibility or liability in this respect.

When ordering spare parts always quote the Model Number / Serial Number specied on the Rating Plate.

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

This machine is not suitable for picking-up hazardous dust.

Do not use on surfaces having a gradient exceeding that marked on the appliance.

The machine is not to be stored outdoors in wet conditions.

This machine is for indoor use only.

Read the instruction manual before using the appliance.

This product meets the requirements of CAN / CSA IEC 60335-2-72

NOTES

This machine is also suitable for commercial use, for example in hotels, schools, hospitals, factories, shops and

ofces for other than normal housekeeping purposes.

• Ensure only competent persons unpack/assemble the machine.

• Keep your machine clean.

• Keep your brushes in good condition.

• Replace any worn or damaged parts immediately.

• Regularly examine the power cord for damage, such as cracking or ageing. If damage is found,

replace the cord before further use.

• Only replace the power cord with the correct Numatic approved replacement parts.

• Ensure that the work area is clear of obstructions and / or people.

• Ensure that the working area is well illuminated.

• Pre-sweep the area to be cleaned.

• Use steam cleaners or pressure washers to clean the machine or use in the rain.

• Attempt machine maintenance or cleaning unless the power plug has been removed from the supply

outlet.

• Allow any inexperienced repairs. Call the experts

• Strain cable or try to unplug by pulling on cable.

• Leave the brush pad on the machine when not in use.

• Allow the machine to be used by inexperienced or un-authorised operators or without appropriate training.

• Use the machine without the solution tanks properly positioned on the machine, as shown in the instructions.

• Expect the machine to provide trouble-free, reliable operation unless maintained correctly.

• Lift or pull the machine by any of the operating triggers - Use the main handle.

• Remove the handle from the machine except for service and repair.

• Use on surfaces having a gradient exceeding that marked on the machine.

ORIGINAL INSTRUCTIONS

READ MANUAL BEFORE USE

Information for Scrubber Dryer

Component Interval Inspect for

Charging Lead DAILY Scufng, cracks, splits, conductors showing

Brushes DAILY Bristle damage, wear, drive collar wear

Squeegee Blade BEFORE EACH USE Wear, cracks, splits

Filters BEFORE EACH USE Clogging and debris retention

Tanks AFTER EACH USE Rinse dirty water tank after use

WARNING

CAUTION

DO

DON’T

6

Do not use on surfaces have a gradient exceeding that marked on the machine.

Only use brushes provided with the appliance or those specied in the instruction manual.

The use of other brushes may impair safety.

A full range of brushes and accessories are available for this product.

Only use brushes or pads which are suitable for the correct operation of the machine for the specic task being

performed.

It is essential that this equipment is correctly assembled and operated in accordance with current safety regulations.

When using the equipment always ensure that all necessary precautions are taken to guarantee the safety of the

operator and any other persons who may be affected.

Wear non-slip footwear when scrubbing. Use a respiratory mask in dusty environments.

The machine, while charging, must be positioned so that the mains plug is easily accessible.

When cleaning, servicing or maintaining the machine, replacing parts or converting to another function the power

source shall be switched off.

Mains operated machines shall be disconnected by removing the power plug, and battery operated machines shall be

disconnected by switching off the isolating key.

Machines left unattended shall be secured against unintentional movement.

Operators shall be adequately instructed as to the correct use of the machine.

WARNING

Data

Brush Motor Vac Motor Power Sound

Pressure

Speed Brush Dimensions

1500W 1000W 120v 60Hz 80 dB(A) 60Hz = 180rpm 17” Width - 18.5”

Length - 44.5”

Height - 46.5”

Gross Weight

Full

Protection Class Hand Arm

Vibration

Pad Net Weight Cleaning

Range

Water Capacity

214 lbs Class 1 1.4 +/- 0.05ms² 17” 125.5 lbs 1653” 10.5 gal

TT 1117

Brush Motor Vac Motor Power Sound

Pressure

Speed Brush Dimensions

1500W 1000W 120v 60Hz 80 dB(A) 60Hz = 180rpm 20” Width - 22.5”

Length - 44.5”

Height - 46.5”

Gross Weight

Full

Protection Class Hand Arm

Vibration

Pad Net Weight Cleaning

Range

Water Capacity

214 lbs Class 1 1.4 +/- 0.05ms² 20” 125.5 lbs 1653” 10.5 gal

TT 1120

7

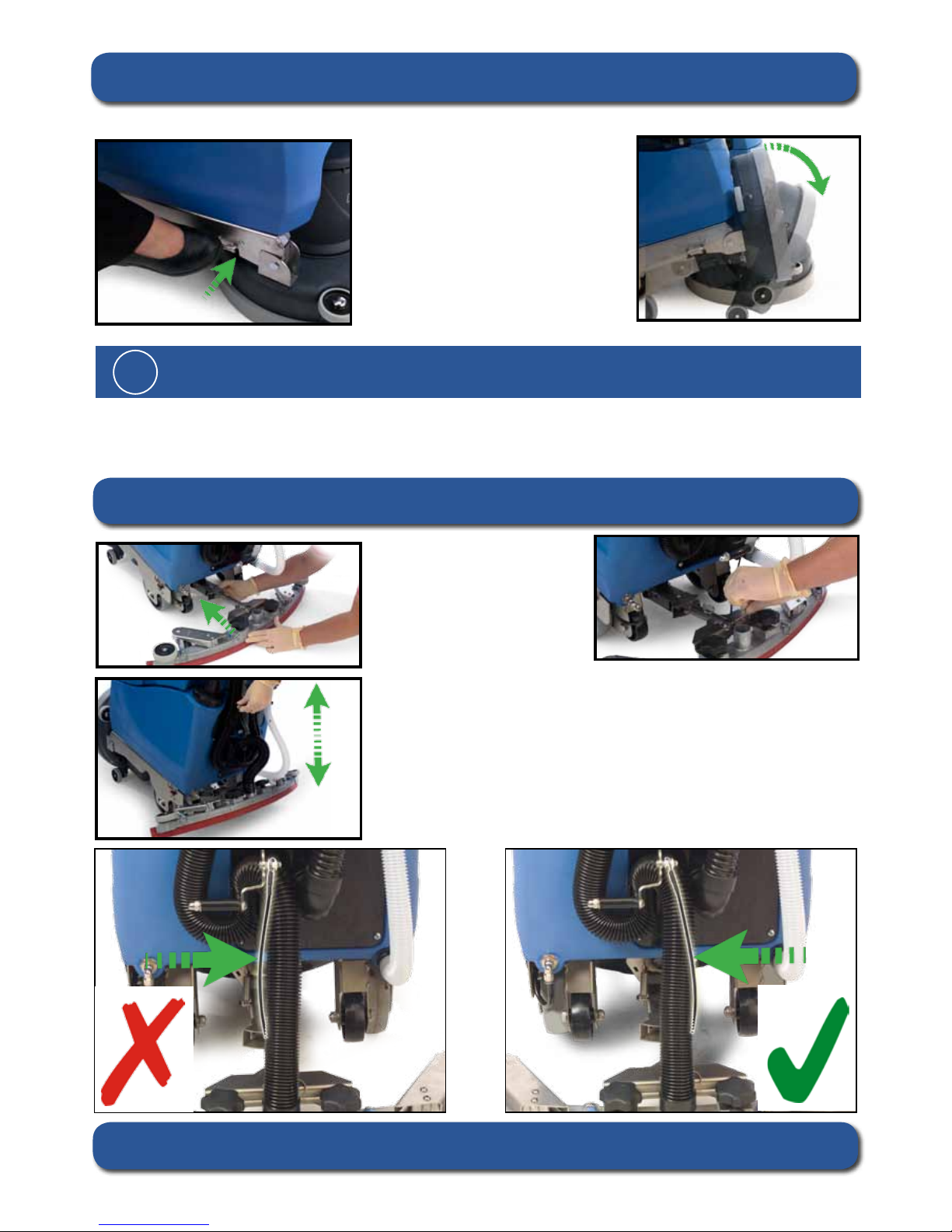

Machine Set Up

Please read before commencing any operation.

After the removal of all the packaging, carefully open and check the contents.

!

Fit the top tank to the machine

(g 3).

Fit both the vacuum hose and the

oor tool hose to the separator

(g 4).

Fitting top tank

Fitting the brush

Featuring the Nulock brush system.

The brush is simply pushed and twisted to lock, making tting and removal a simple process.

The Pad is retained using Numatic’s own PadLoc system. (Ask your supplier for details)

Only use manufacturer supplied brushes / pads.

TT 1117 requires a 17” brush or pad.

TT 1120 requires a 17” brush or pad

Safety gloves are recommended for the changing of used brushes.

Fit the brush /pad to the drive chuck,

twist to lock the brush

(Fig 5) / pad in place (Fig 6).

Fig 6

Fig 5

!

Tilting the handle

Using the handle position lever

(g 1).

Move the handle into the upright

position (g 2).

Fig 1 Fig 2

Fig 3 Fig 4

8

Machine Set-Up

Fitting the Floor Tool

The oor tool has been designed for quick tting, allowing easy squeegee blade replacement and a safety knock-off

feature if the oor tool gets snagged, whilst in transit.

Raise the oor tool for transit or lower for cleaning operation using the lifting

handle tted to the back of the machine (Fig 11).

For tting the oor tool blades (See Page 10)

Note:

It is easier to t the oor-tool if the weight of the machine is resting on the brush. Ensure the brush is tted rst.

Fig 11

Fig 10

Fig 9

Fit the oor tool and retain using

the detent pin (g 9).

The lifting strap is held by a

detent pin (Fig 10).

Note:

Raise oor-tool again before driving to the cleaning area

Tipping the Brush Deck

To tip the deck into the down position

(Operating mode). Press in the brush

deck locking bar (Fig 7) and rotate the

brush deck (Fig 8).

To change to brush deck up position,

(Transit mode) simply lift the deck and

the sprung loaded locking bar will active

to hold the deck up.

Fig 8

Fig 16

ALWAYS ENSURE THAT THE MACHINE IS SWITCHED OFF

BEFORE MAKING ANY ADJUSTMENTS

!

Fig 7

9

The water level in the clean water tank can be seen using the clean-water clear

dump hose tted to the rear of the machine.

The clean water bottom tank holds 11 gal.

Machine Set-Up

Control of Substances Hazardous to Health (COSHH)

For best results use a non-foaming type of chemical, dilute to the manufacturers specication.

For further guidance on hazardous substances refer to health and safety instructions online.

Important

Do not operate machine unless the Operator Manual has been read and fully understood.

!

!

WHEN HANDLING AND MIXING CHEMICALS.

Always ensure that chemical manufacturers safety guidelines are followed.

Only use chemicals recommended for use in auto scrubber-dryers.

! !

Note.

Great care must be taken to ensure that contaminants (leaves,hair, dirt, etc) are not allowed to enter the

clean-water during the lling process.

If using a bucket or similar, ensure it is always clean and free from debris.

Clean water level

The TT Range are all equipped with a 11 gal, clean-water tank allowing large areas to be cleaning in a single ll.

Filling the clean-water tank

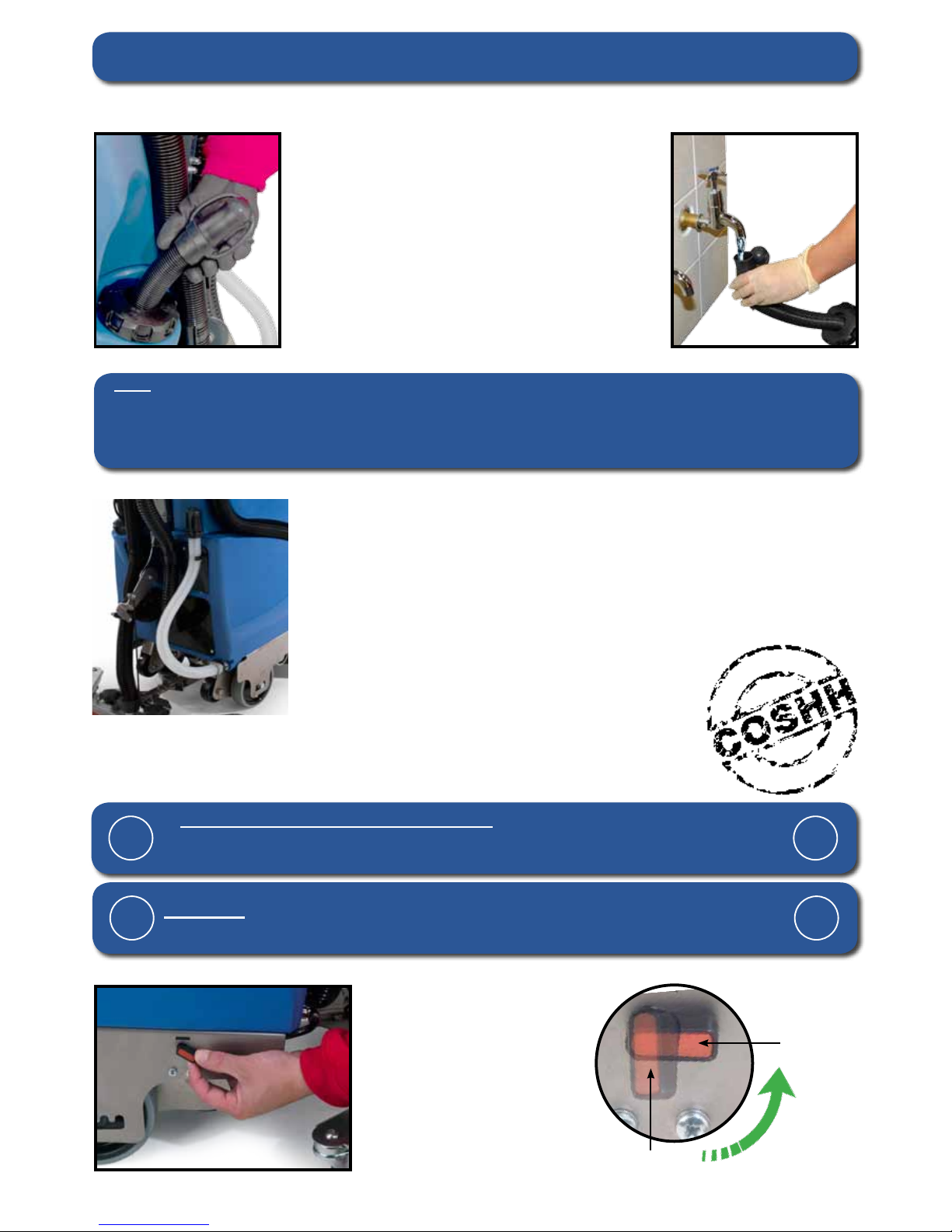

To ll the clean-water tank, use the FLEXI - FILL

pipe from either a tap or hose pipe (Fig 12).

The large cap can also be unscrewed for lling

from a bucket or suitable

container.

Fill the clean water tank to a maximum of 11 gal,

including cleaning chemicals if required.

Follow chemical manufacturing guide lines.

The clear Dump hose at the rear of the machine can be used to see the level of the clean water.

Fig 12

Turn on the clean water tap

On

Off

Clean water tap

Loading...

Loading...