Nabertherm Top 16/R, Top 60eco, Top 60Leco, Top 60/R, Top 100 LE Operating Instructions Manual

...Page 1

Operating Instructions

Top Loaders

Top ..., HO ..., F ...

M01.0062 ENGLISCH

Original instructions

www.nabertherm.com

Made

in

Germany

Page 2

2

Copyright

Copyright by

Nabertherm GmbH

Bahnhofstrasse 20

28865 Lilienthal

Federal Republic of Germany

Reg: M01.0062 ENGLISCH

Rev: 2017-05

No responsibility is accepted for the correctness of this information. We

reserve the right to make technical alterations.

Page 3

3

1 Introduction ........................................................................................................................................................... 5

1.1 Product Description ........................................................................................................................................... 6

1.2 Overview of the Complete Furnace ................................................................................................................... 7

1.2.1 Key to the Model Names .............................................................................................................................. 9

1.3 Scope of Delivery .............................................................................................................................................. 9

2 Specifications ....................................................................................................................................................... 10

2.1 Warranty and Liability .................................................................................................................................... 13

3 Safety .................................................................................................................................................................... 14

3.1 Explanation of the Symbols and Warnings ..................................................................................................... 14

3.2 Defined Application ........................................................................................................................................ 17

3.3 Requirements for the Furnace Operator .......................................................................................................... 18

3.4 Protective Clothing .......................................................................................................................................... 19

3.5 Basic Measures During Normal Operation ..................................................................................................... 20

3.6 Basic Measures in Case of Emergency ........................................................................................................... 20

3.6.1 What to Do in an Emergency ...................................................................................................................... 20

3.7 Basic Measures for Servicing and Maintenance.............................................................................................. 21

3.8 General Risks with the Furnace....................................................................................................................... 22

4 Transportation, Installation and Initial Start-Up ............................................................................................. 23

4.1 Delivery ........................................................................................................................................................... 23

4.2 Unpacking ....................................................................................................................................................... 24

4.3 Transport Securing Device/Packaging ............................................................................................................ 26

4.4 Constructional and Connection Requirements ................................................................................................ 26

4.4.1 Installation (Furnace Location) ................................................................................................................... 26

4.5 Assembly, Installation, and Connection .......................................................................................................... 28

4.5.1 Assembling the Base Extension (Accessory) .............................................................................................. 28

4.5.2 Assembling the Castors............................................................................................................................... 29

4.5.3 Assembling the Controller (Depending on the Model) ................................ ................................ ............... 31

4.5.4 Place the Controller in the Holder on the Furnace (model-related) ............................................................ 32

4.5.5 Assembling the Bypass Connection ............................................................................................................ 32

4.5.6 Venting Exhaust Fumes .............................................................................................................................. 33

4.5.7 Connecting the Furnace to the Power Supply ............................................................................................. 36

4.6 Initial Start-Up ................................................................................................................................................ 37

4.7 Recommendations for Heating Up the Furnace for the First Time ................................................................. 38

5 Operation ............................................................................................................................................................. 39

5.1 Controller ........................................................................................................................................................ 39

6 Operation, Display and Switch Elements (depending on design) .................................................................... 40

6.1 Turning on the Controller/Furnace .................................................................................................................. 40

6.2 Turning off the Controller/Furnace ................................................................................................................. 40

6.2.1 Handling the Controller .............................................................................................................................. 40

6.3 Opening and Closing the Lid .......................................................................................................................... 41

6.4 Fresh Air Valve ............................................................................................................................................... 43

6.5 Loading/Charging ........................................................................................................................................... 43

6.5.1 Tips for Potters............................................................................................................................................ 44

6.5.1.1 Preset programs for ceramic applications .......................................................................................... 44

6.5.2 Bisque Firing............................................................................................................................................... 47

Page 4

4

6.5.3 Glaze Firing ................................................................................................................................................ 47

6.5.4 Reduction Firing ......................................................................................................................................... 48

7 Servicing, Cleaning, and Maintenance .............................................................................................................. 48

7.1 Shutting Down the Furnace for Servicing, Cleaning, and Maintenance.......................................................... 48

7.2 Furnace Insulation ........................................................................................................................................... 48

7.3 Regular Maintenance of the Furnace ............................................................................................................... 49

7.4 Adjusting the Lid ............................................................................................................................................. 50

7.5 Adjusting the Tensioning Straps ..................................................................................................................... 52

7.6 Separate the Snap-In Coupling (Plug) from the Furnace Housing .................................................................. 52

7.7 Cleaning Products ........................................................................................................................................... 53

8 Malfunctions ........................................................................................................................................................ 53

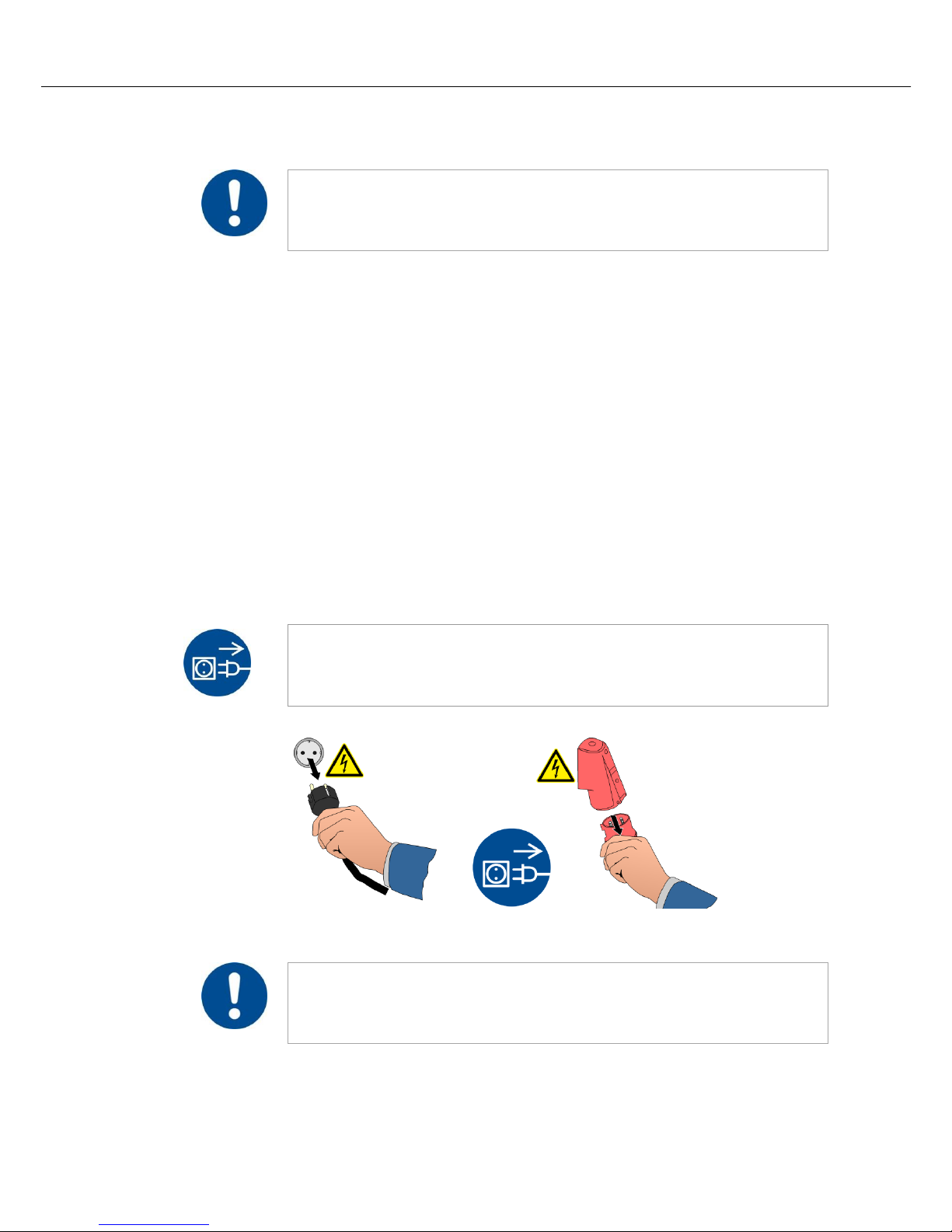

8.1 Error Messages of the Controller .................................................................................................................... 54

8.2 Warnings of the Controller .............................................................................................................................. 56

8.3 Malfunctions of the Switchgear ...................................................................................................................... 58

8.4 Controller Check List ...................................................................................................................................... 59

9 Spare Parts/Wearing Parts ................................................................................................................................. 61

9.1 Replacing a Heating Element .......................................................................................................................... 61

9.2 Replacing a Thermocouple .............................................................................................................................. 70

10 Accessories (Options) .......................................................................................................................................... 72

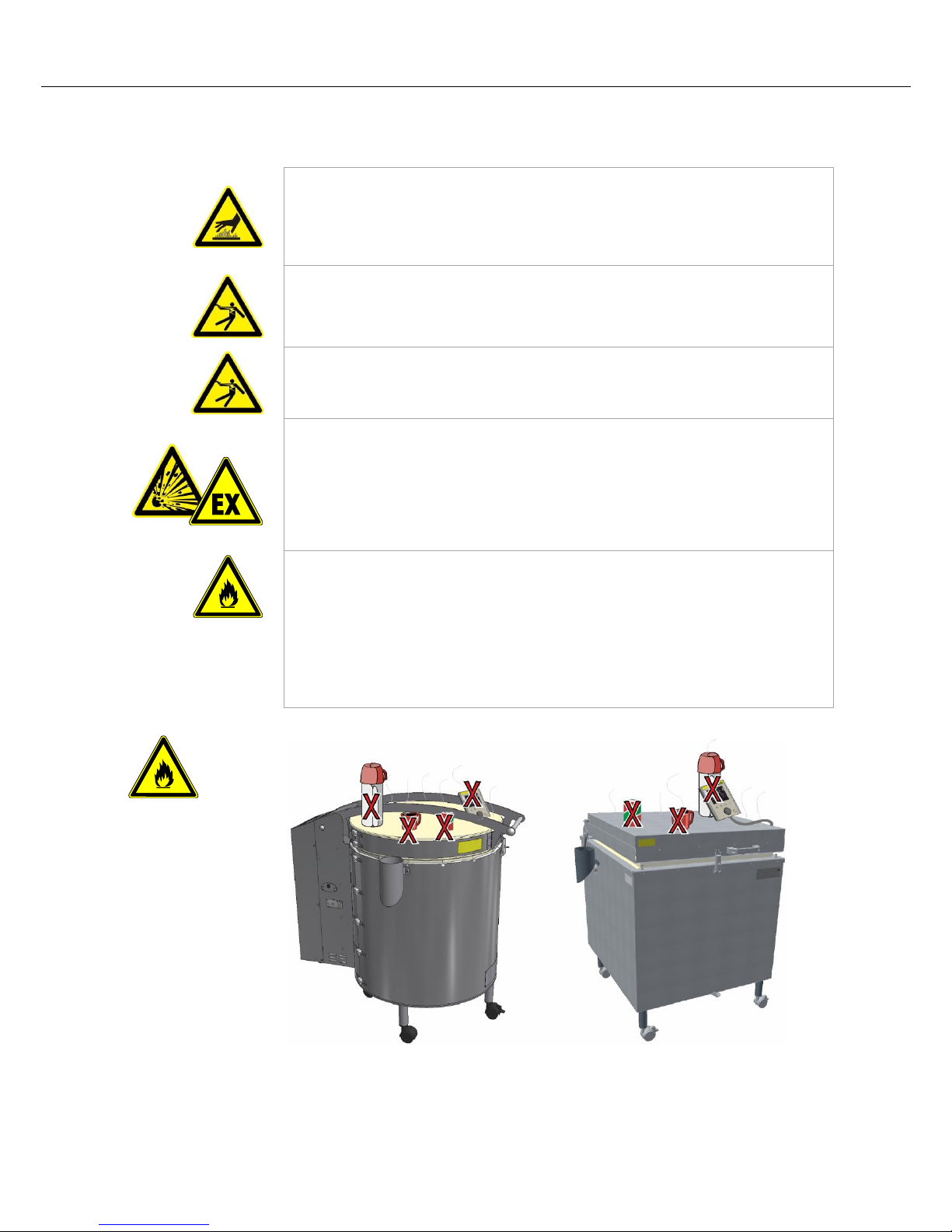

11 Electrical Connection (Circuit Diagram) .......................................................................................................... 73

12 Nabertherm Service............................................................................................................................................. 73

13 Shut-Down, Dismantling, and Storage............................................................................................................... 74

13.1 Environmental Regulations ............................................................................................................................. 74

13.2 Transportation/Return Transportation ............................................................................................................. 75

14 Declaration of Conformity .................................................................................................................................. 76

15 For Your Notes .................................................................................................................................................... 77

Page 5

5

Pos: 1 /TD/Einleitung/Überschrift - Einleit ung 1 @ 0\mod_1167823212238_51.doc x @ 5139 @ 1 @ 1

1 Introduction

Pos: 2 /TD/Einleitung/Einleitung_Öfen mit L uftaufnahmebild 2017 @ 151\mod_14 90190055052_51.docx @ 626352 @ @ 1

Dear Customer,

Thank you for choosing a quality product from Nabertherm GmbH.

You can be proud that you have chosen a furnace which has been especially tailored to suit

your manufacturing and production conditions.

This product is characterized by

professional workmanship

high performance due to its high efficiency

high-quality insulation

low power consumption

low noise level

simple installation

easy to maintain

high availability of spare parts

Your Nabertherm Team

Note

These documents are intended only for buyers of our products and may not be copied or

disclosed to third parties without our written consent. (Law governing copyright and

associated protective rights, German Copyright Law from Sept. 9, 1965)

Protective Rights

Nabertherm GmbH owns all rights to drawings, other documents and authorizations, also

in case of applications for protective rights.

Note

All the figures in the instructions have a descriptive character; in other words, they do not

represent the exact details of the furnace.

Pos: 3 /TD/Einleitung/Die in der Anleitung g ezeigten Abbildungen können abhängig von Funktion, ... Ofenmodell abweichen @ 24\mod_1337854352242_51.doc x @ 161605 @ @ 1

Note

The pictures contained in the instruction manual may contain inaccuracies in terms of the

function, design and furnace model.

Page 6

6

Pos: 4 /TD/Einleitung/Produktbeschreibung/Öf en/Überschrift - Produktbeschreibung 1.1 @ 0\mod_1167821943807_51.doc x @ 5103 @ 2 @ 1

1.1 Product Description

Pos: 5 /TD/Einleitung/Produktbeschreibung/Öf en/Produktbeschreibung-Bei diese n elektrisch beheizten Öfen handelt es sic h um ein Qualitätsprodukt ... @ 15\mod_ 1305707254935_51.docx @ 117576 @ @ 1

These electrically heated furnaces are a high-quality product which will give you many

years of reliable service if they are properly cared for and maintained. One basic

prerequisite is that the furnace is used the way it was designed to be used.

During development and production a high priority was placed on safety, functionality

and economy.

Pos: 6 /TD/Einleitung/Produktbeschreibung/Öf en/Produktbeschreibung - Toplader T op/HO/F @ 104\mod_1443690280555_ 51.docx @ 412440 @ @ 1

Furnaces in the Top loader Top …, Top loader HO … and Fusing top loader F … series

are electrically heated furnaces for ceramics, glass fusing, glass and porcelain painting.

These furnace models have an appealing design, are lightweight and produce good firing

results. The right furnace for hobby artists or small workshops.

Pos: 7 /TD/Einleitung/Produktbeschreibung/Öf en/Überschrift - Zusätzlich zeichnet sic h dieses Produkt aus durch: @ 15\m od_1305713428306_51.docx @ 117724 @ @ 1

Other Characteristics of this Product are:

Pos: 8 /TD/Einleitung/Produktbeschreibung/Öf en/Produktbeschreibung-Zusätzlich zeic hnet ...: - Toplader Top/HO/F @ 104 \mod_1443691014021_51.docx @ 4124 66 @ @ 1

Heating elements embedded in grooves, heating from all sides

Top-quality heating elements, optimum wire gauge and length for long life

Solid state relays provide for low-noise heater operation

Rapid switching cycles result in precise temperature control

Type S thermocouple

Lid interlock safety switch

Multi-layered insulation for low power consumption and low exterior temperatures

Models Top 60eco ff. with special high-grade, energy-saving backing insulation

Lightweight refractory bricks inside furnace chamber for clean firing results

Housing made of sheets of textured stainless steel

Lid with adjustable quick-release lock and padlock hasp

Lid heating for direct radiation of the charge (fusing top loaders F 30 – F 220)

Wear-free lid seal (brick on brick)

Powerful gas dampers make lid opening very easy

Infinitely adjustable air inlet in opening in the furnace bottom for good ventilation and

short cooling times

Exhaust air outlet on furnace side with stub for pipe of diameter 80 mm

Lockable castors for easy transport of furnace without the need for lifting

Pos: 9 /TD/Einleitung/Produktbeschreibung/Öf en/Überschrift - Zusatzausstattung ( Einzug Mitte) @ 39\mod_13649840854 02_51.docx @ 221200 @ @ 1

Additional Equipment

Pos: 10 /TD/Einleitung/Produktbeschreibung/ Öfen/Produktbeschreibung-Zusatza usstattung-Toplader Top/HO/F (Modell 20 15) @ 105\mod_1444907338805_51.doc x @ 415268 @ @ 1

Bottom heating for very good temperature uniformity for Top 140 and Top 190

Two-zone control of heating via controller

Raised base for Top 45/ Top 60 and F 75/F 110

Page 7

7

Pos: 11 /TD/Einleitung/Lieferumfang/Öfen/Üb erschrift - Gesamtübersicht der Anl age @ 1\mod_1174302636992_51.doc x @ 11332 @ 2 @ 1

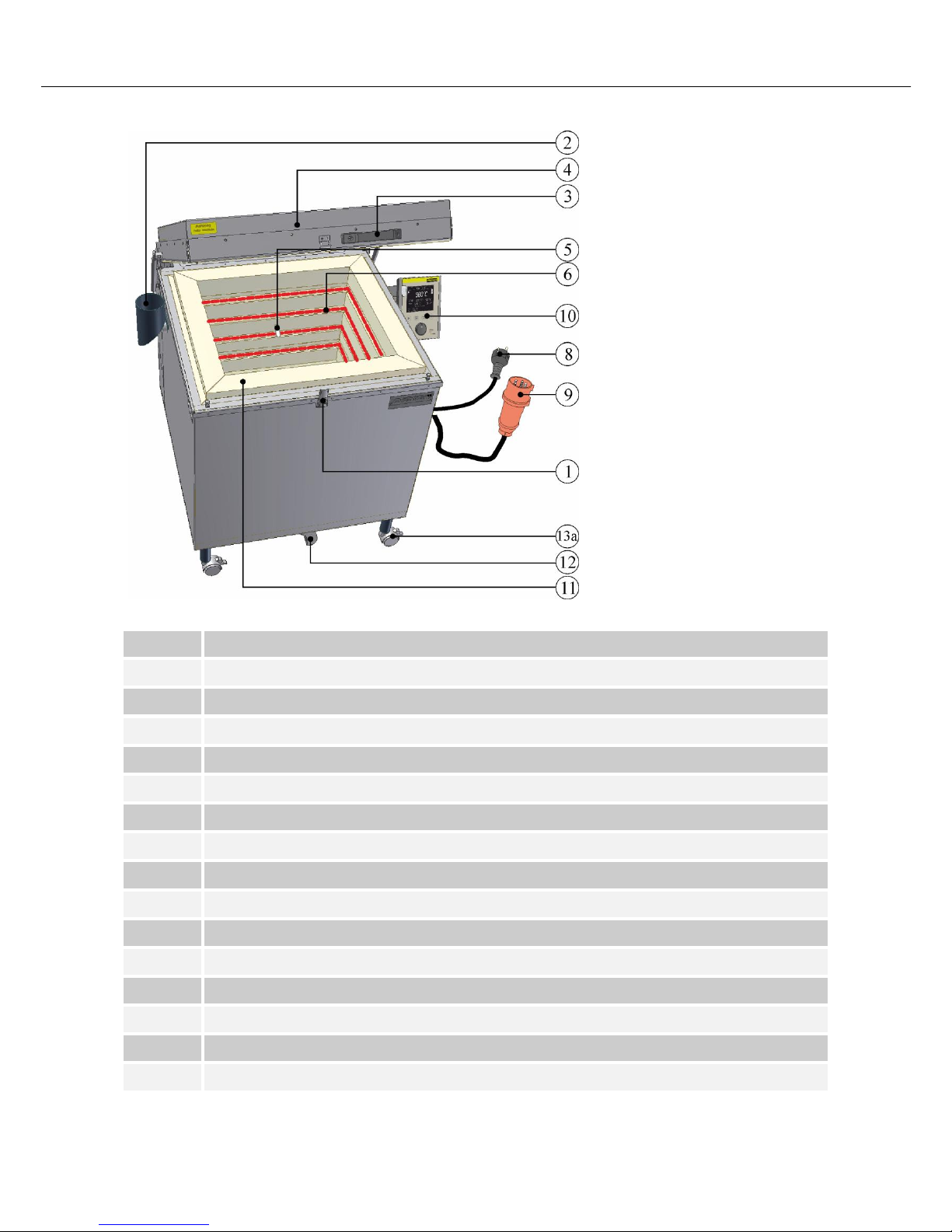

1.2 Overview of the Complete Furnace

Pos: 12 /TD/Einleitung/Lieferumfang/Öfen/G esamtübersicht Toplader Top und Fusing- Toplader F (Modell 2015) @ 155\ mod_1494222834615_51.docx @ 640316 @ @ 1

Example: Top loader model Top 60

Example: Lid from the fusing top loader Model F 30

Example: Fusing top loader Model F 220

Fig. 1: Example: Top loader model Top … and Fusing top loader Model F … (similar to picture)

Page 8

8

Pos: 13 /TD/Einleitung/Lieferumfang/Öfen/G esamtübersicht Toplader HO (Modell 2015) @ 155\mod_1494222849223_51.d ocx @ 640342 @ @ 1

Fig. 2: Example: Top loader Model HO 100 (similar to picture)

Pos: 14 /TD/Einleitung/Lieferumfang/Öfen/G esamtübersicht_M01.0062_Tabelle Nr. und Benennung der verbauten Teile - T op, F und HO @ 155\mod_1494223066 523_51.docx @ 640368 @ @ 1

No.

Designation

1

Adjustable lid closure

2

Bypass connection (Top + HO model only)

3

Handle

4

Lid 5 Thermocouple

6

Heating element

7

Power switch (to switch the furnace on and off)

8

Power plug (up to 3600 watts)

9

Power plug (from 5500 watts)

10

Controller

11

Insulation

12

Supply air valve

13

Castor with locking brake

13a

Castor (with locking brake from Model HO 70 + HO 100)

14

Lid heating (Fusing top loader F …)

Page 9

9

No.

Designation

15

Base frame (Model Top 220/Fusing top loader from Model F 75)

Pos: 15 /TD/Einleitung/Produktbeschreibung/ Öfen/Überschrift - Entschlüsselung d er Modellbezeichnung @ 2\mod_1184 245078907_51.docx @ 19775 @ 3 @ 1

1.2.1 Key to the Model Names

Pos: 16 /TD/Einleitung/Produktbeschreibung/ Öfen/Entschlüssellung der Modellbez eichnung Top, HO und F @ 13\mod_12 89220515672_51.docx @ 107253 @ @ 1

Example

Explanation

Top 60/Leco

Top = Top loader, round/oval

HO = Top loader, rectangular

F = Fusing top loader

Top 60/Leco

X = Liters furnace chamber (volume in liters)

Top 60/Leco

L = low

LE = low energy

R = rapid

Top 60/Leco

eco = economy

Pos: 17 /TD/Einleitung/Produktbeschreibung/ Öfen/Entschlüssellung der Modellbez eichnung Top, HO und F - Grafik (Mod ell 2015) @ 104\mod_1444119915280_51.d ocx @ 412700 @ @ 1

Fig. 3: Example: Model name (type plate)

Pos: 18 /TD/Einleitung/Lieferumfang/Öfen/Üb erschrift - Lieferumfang @ 0\mod_11 67822508130_51.docx @ 5112 @ 2 @ 1

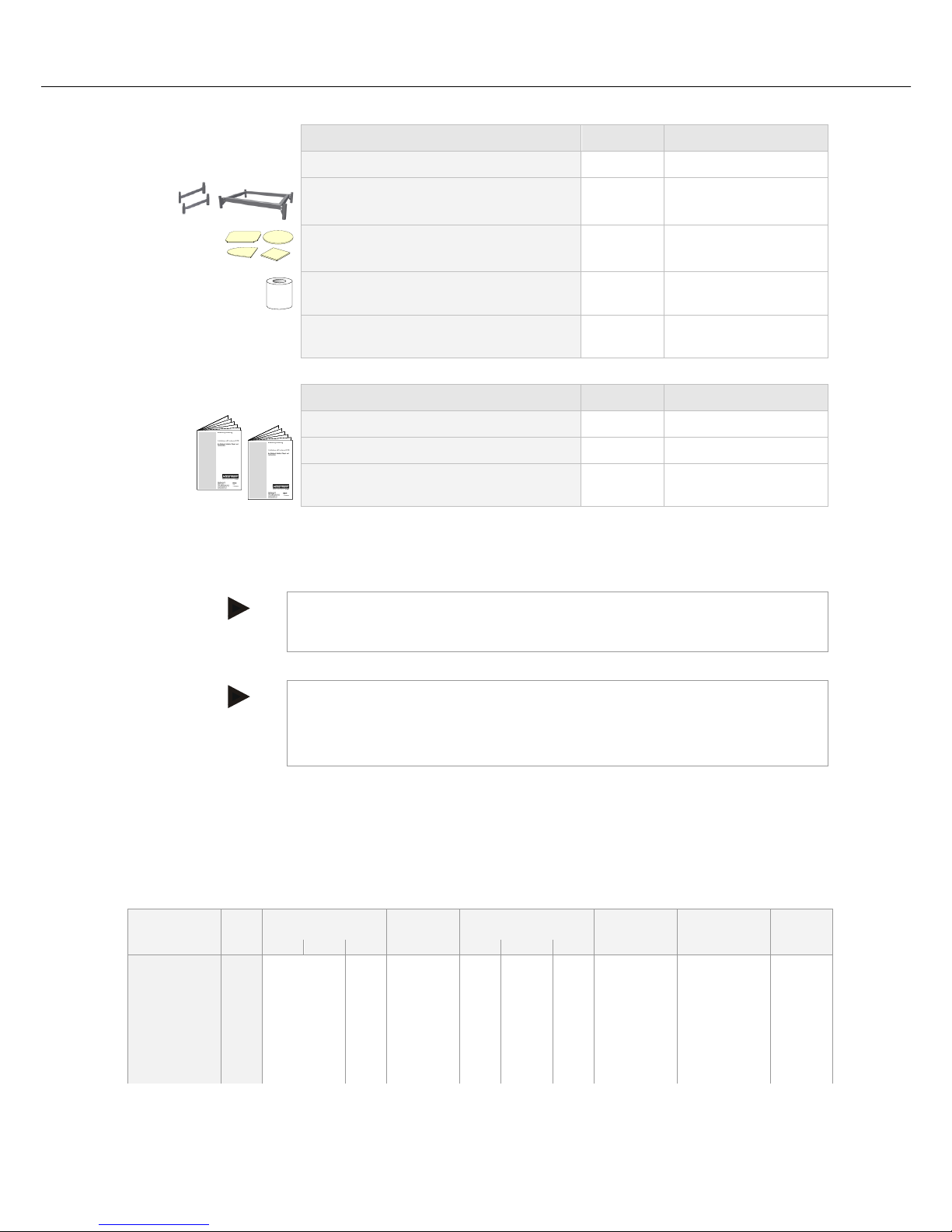

1.3 Scope of Delivery

Pos: 19 /TD/Einleitung/Lieferumfang/Öf en/Lieferumfang - Top-HO-F @ 156\mod_1 494507874135_51.docx @ 643000 @ @ 1

The scope of delivery includes:

Furnace components

Quantity

Comment

-Furnace model Top …,

-Furnace model HO … or

-Furnace model F …

1 x

Nabertherm GmbH

Power cable1)

1 x

Nabertherm GmbH

Bypass connection1)

(for furnace models Top and HO)

1 x

Nabertherm GmbH

Ceramic shelves

(691600956 – 80x80x10 mm)

3 x

Nabertherm GmbH

Castors

4 to 6x3)

Nabertherm GmbH

Hex key1)

(for furnace models Top and F)

1 x

Nabertherm GmbH

Top 160 SN 123456 2017

TOP1603BN1 1320 °C

-

-

400 V 3/N/PE~

-

50/60 Hz

13,0/13,0/13,0 A

9,0 kW

Page 10

10

Furnace components

Quantity

Comment

Accessories:

Adjustable base1) (for furnace models

Top 45/60 or F 75/F 110)

1 x

Nabertherm GmbH

Shelve/s2) for furnace models Top, HO and F

4)

Nabertherm GmbH

Props

2)

4)

Nabertherm GmbH

Other components, variable depending on

the particular furnace

- - -

See the shipping

documents

Document type

Quantity

Comment

Furnace operating manual

1 x

Nabertherm GmbH

Controller operating manual

1 x

Nabertherm GmbH

Other documents, variable depending on the

particular furnace

- - -

1) in delivery scope depending on the design/furnace model

2) in delivery scope as required, see shipping documents

3) quantity depends on furnace model

4) quantity as required, see shipping documents

Note

Store all documents carefully. All the functions of this furnace were tested during

manufacturing and prior to shipping.

Pos: 20 /TD/Betrieb_Bedienung/Die mitgelief erten Unterlagen beinhalten nicht zwangsl äufig elektrische Schaltpläne bzw. Pneu ma ... @ 47\mod_1380028074616_ 51.docx @ 247668 @ @ 1

Note

The documents included do not always contain the electrical schematics and pneumatic

diagrams.

If you need the respective diagrams, they can be ordered from Nabertherm Service.

Pos: 21 /TD/Einleitung/Technische Daten/Ö fen/Überschrift - Technische Daten - mit Hinweis @ 0\mod_1167822840737_51. docx @ 5121 @ 1 @ 1

2 Specifications

Electrical specifications are on the type plate located on the side of the furnace.

Pos: 22 /TD/Einleitung/Technische Daten/Ö fen/Modell-Tabelle für Top-Öfen - 1 (M odell 2015) 1200 °C und 1320°C @ 15 5\mod_1493981954113_51.docx @ 64028 6 @ @ 1

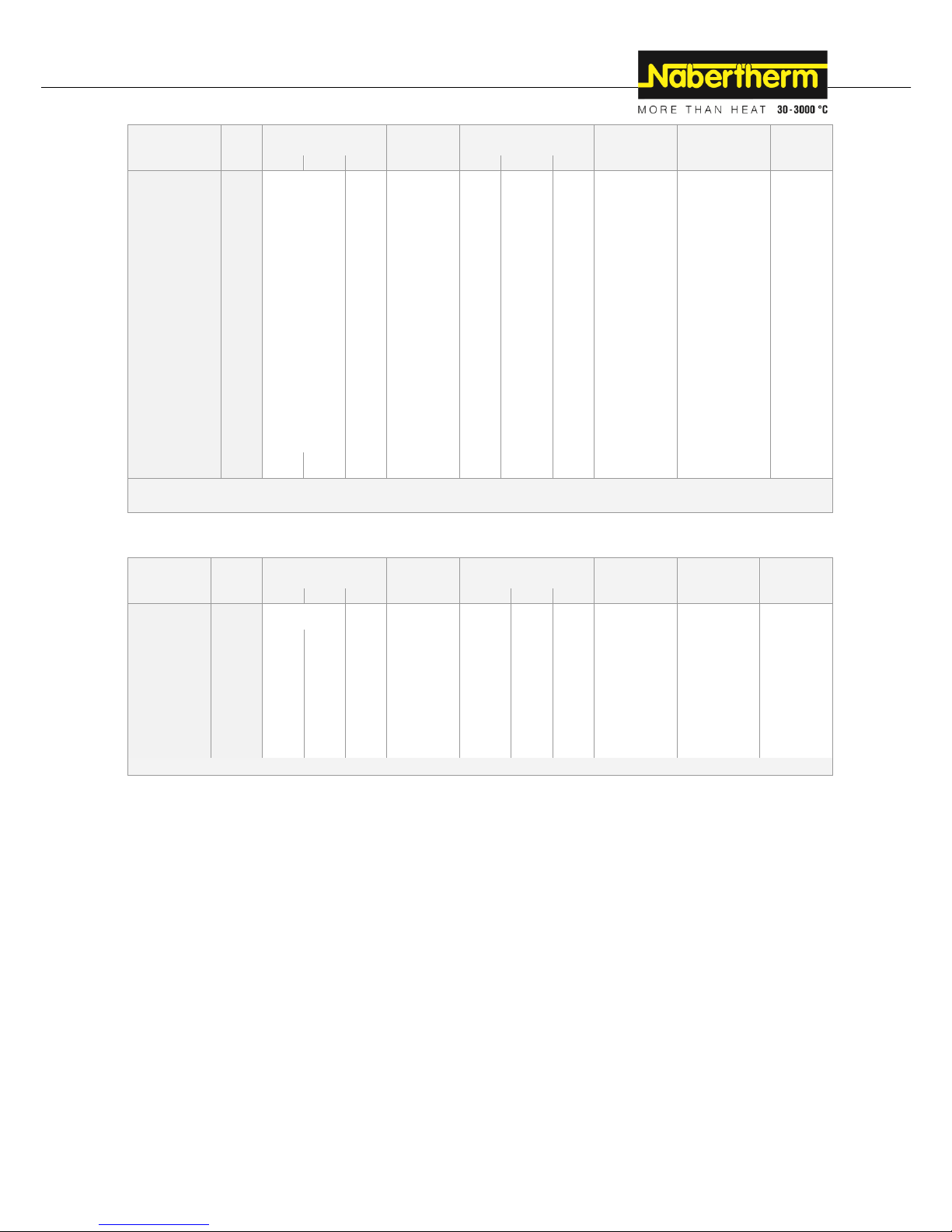

Furnace model Top

Model

Tmax

Inner dimensions in

mm

Volume

Outer dimensions in

mm

Connected

load

Electrical

connection

Weight

°C w d h in l W D H kW

in kg

Top 16/R

1320

Ø 290

230

16

440

650

530

2.6

1-phase

32

Top 45eco

1320

Ø 410

340

45

580

880

760

2.9

1-phase

62

Top 45

1320

Ø 410

340

45

580

880

760

3.6

1-phase

62

Top 45/R

1320

Ø 410

340

45

580

880

760

5.5

3-phase1

62

Top 60

1200

Ø 410

460

60

580

870

870

3.6

1-phase

72

Page 11

11

Model

Tmax

Inner dimensions in

mm

Volume

Outer dimensions in

mm

Connected

load

Electrical

connection

Weight

°C w d h in l W D H kW

in kg

Top 60Leco

1200

Ø 410

460

60

580

870

870

2.9

1-phase

72

Top 60eco

1320

Ø 410

460

60

580

870

870

3.6

1-phase

72

Top 60/R

1320

Ø 410

460

60

580

870

870

5.5

3-phase1

72

Top 80

1320

Ø 480

460

80

660

950

890

5.5

3-phase1

100

Top 100 LE

1320

Ø 480

570

100

660

970

1000

6.0

1-phase2

102

Top 100

1320

Ø 480

570

100

660

970

1000

7.0

3-phase

102

Top 130

1320

Ø 590

460

130

770

1090

920

9.0

3-phase

110

Top 140 LE

1320

Ø 550

570

140

730

1040

1020

6.0

1-phase2

124

Top 140

1320

Ø 550

570

140

730

1040

1020

9.0

3-phase

124

Top 160

1320

Ø 590

570

160

770

1090

1030

9.0

3-phase

130

Top 190

1320

Ø 590

690

190

770

1090

1150

11.0

3-phase

146

Top 220

1320

930

590

460

220

1100

1030

930

15.0

3-phase

150

1

Heating only between two phases

2

Fusing of 32 A if connected to 230 V

Pos: 23 /TD/Einleitung/Technische Daten/Ö fen/Modell-Tabelle für F-Öfen - 1 @ 13 \mod_1289317404179_51.docx @ 1074 19 @ @ 1

Furnace model F

Model

Tmax

Inner dimensions in

mm

Floor

space

Outer dimensions in

mm

Connected

load

Electrical

connection

Weight

°C w d h in m2

W D H

kW

in kg

F 30

950

Ø 410

230

0.13

650

800

500

2.0

1-phase

50

F 75 L

950

750

520

230

0.33

950

880

680

3.6

1-phase

80

F 75

950

750

520

230

0.33

950

880

680

5.5

3-phase

80

F 110 LE

950

930

590

230

0.47

1120

950

680

6.0

1-phase1

95

F 110

950

930

590

230

0.47

1120

950

680

7.5

3-phase

95

F 220

950

930

590

460

0.47

1120

950

910

15.0

3-phase

115

1

Fusing of 32 A if connected to 230 V

Page 12

12

Pos: 24 /TD/Einleitung/Technische Daten/Ö fen/Modell-Tabelle für Top und F-Öfen - Z eichnung (Modell 2015) @ 104\mod_1444133795 726_51.docx @ 412726 @ @ 1

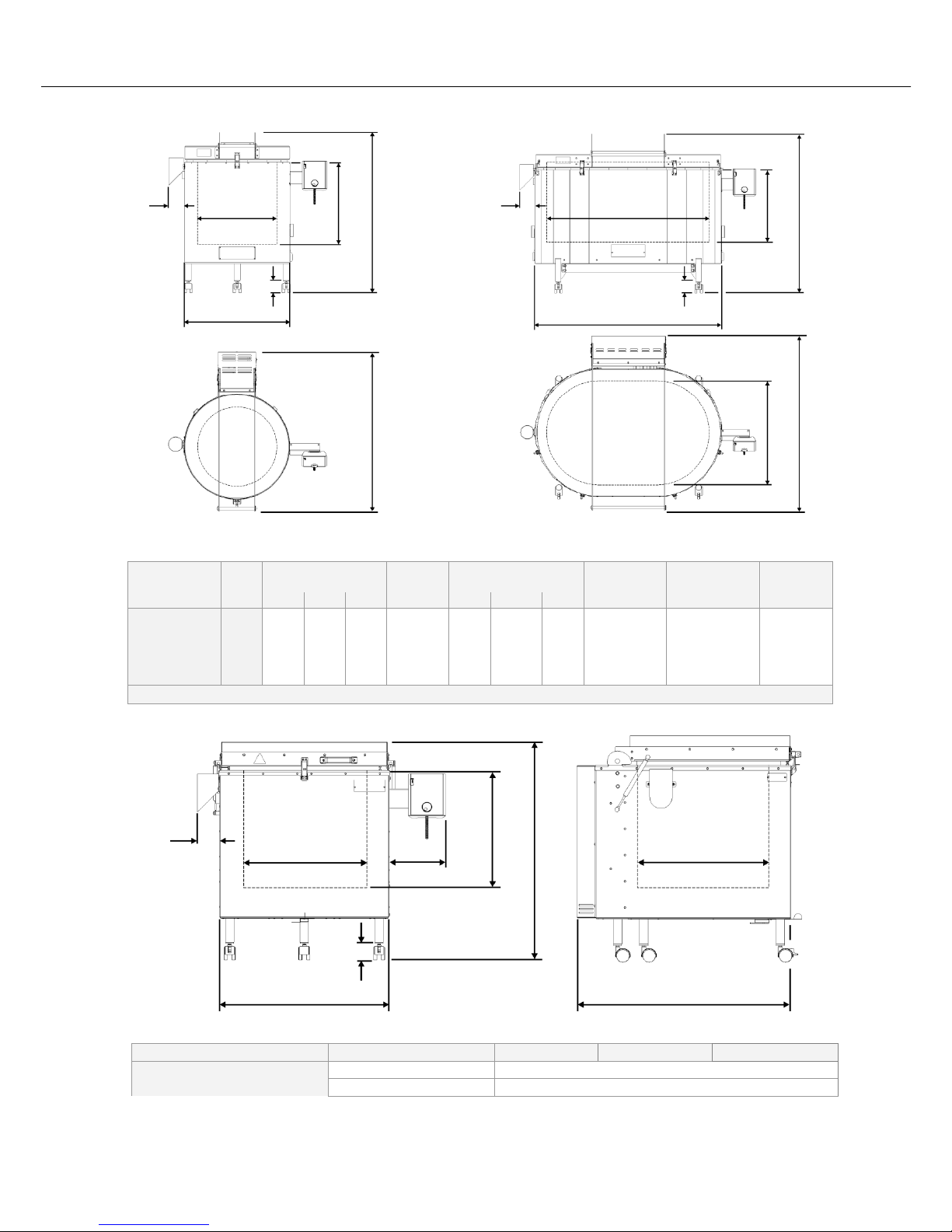

Fig. 4: Top 16 – 190 / F 30 Top 220 / F 75 – F 22

Pos: 25 /TD/Einleitung/Technische Daten/Ö fen/Modell-Tabelle für HO-Öfen - 1 @ 13\mod_1289317 483630_51.docx @ 107442 @ @ 1

Furnace model HO

Model

Tmax

Inner dimensions in

mm

Volume

Outer dimensions in

mm

Connected

load

Electrical

connection

Weight

°C w d h in l W D H kW

in kg

HO 70/L

1200

440

380

420

70

640

770

780

3.6

1-phase

120

HO 70/R

1300

440

380

420

70

640

770

780

5.5

3-phase1

120

HO 100

1300

480

430

490

100

680

820

850

5.5

3-phase1

160

1

Heating only between two phases

Pos: 26 /TD/Einleitung/Technische Daten/Ö fen/Modell-Tabelle für HO-Öfen - Zeich nung (Modell 2015) @ 104\mod_144413 4039128_51.docx @ 412752 @ @ 1

Fig. 5: Dimensions of model HO

Pos: 27 /TD/Einleitung/Technische Daten/Ö fen/Tabelle für alle Top-HO und F-Öf en - 1 @ 13\mod_1289381485867_51.d ocx @ 107493 @ @ 1

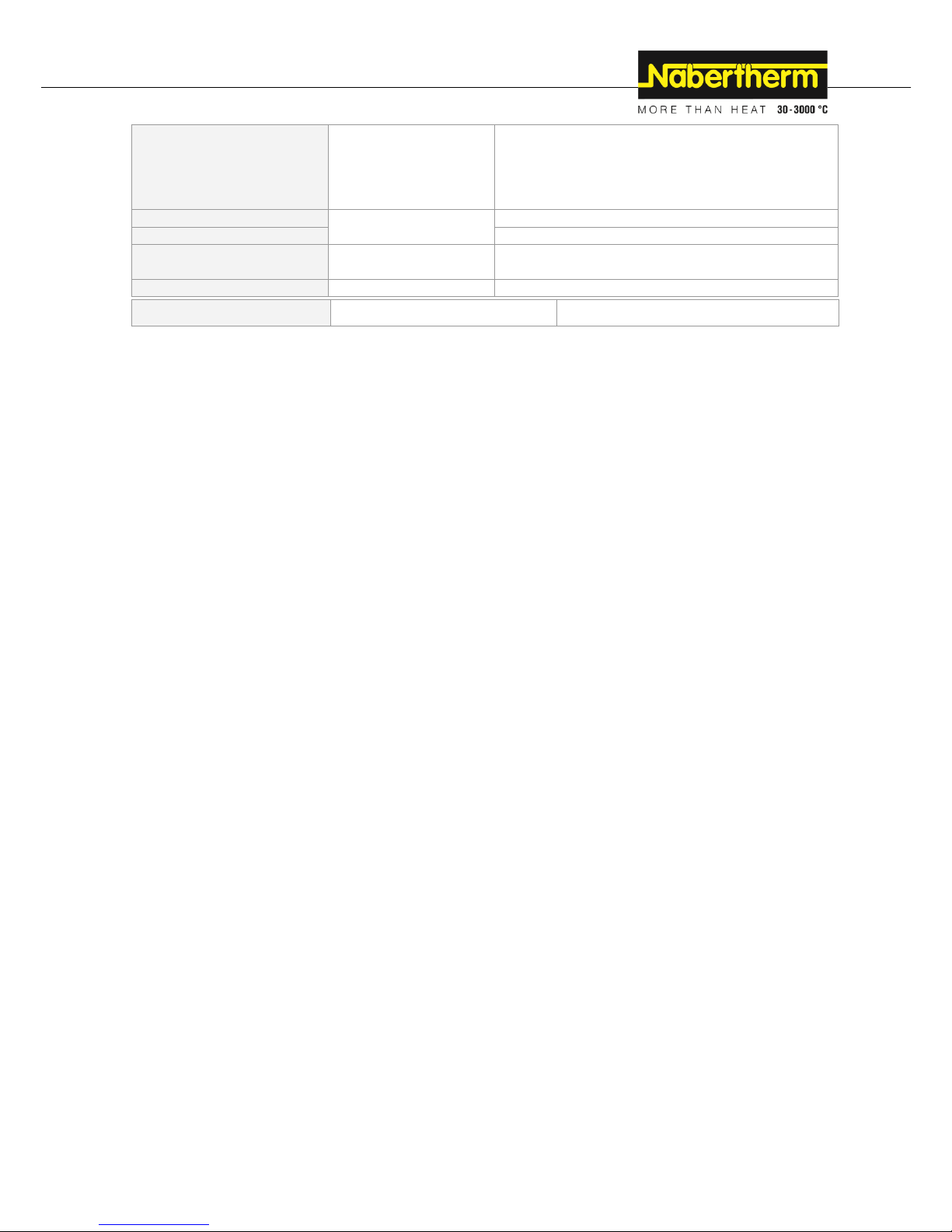

Electrical connection

Voltage (V)

1-phase:

3-phase:

Special voltage:

Furnace model

See type plate on furnace

Frequency:

50 or 60 Hz

W

D

H w h d W D Ø h H

90

90

65

65

W

D

H w h

d

65

90

200

Page 13

13

Thermal protection class

Furnaces:

according to DIN EN 60519-2

without safety controller: Class 0

(in case of fault, no protection for furnace or charge)

with safety controller: Class 2

(in case of fault, furnace and charge protected)

Protection rating

Furnaces:

1

Protection type

IP20

Ambient conditions for

electrical equipment

Temperature:

Humidity:

+5 °C to +40 °C

max. 80 % non condensing

Weights

Furnace with accessories

Varies (see shipping documents)

Pos: 28 /TD/Einleitung/Technische Daten/Ö fen/Tabelle Dauerschalldruckpegel < 80 d B(A) - 2 @ 1\mod_1170750985488_5 1.docx @ 8913 @ @ 1

Emissions

Continuous sound pressure level:

< 80 dB(A)

Pos: 29 /TD/Einleitung/Gewährleistung_Haft ung/Überschrift - Gewährleistung und H aftung 1.1 @ 0\mod_1167822979492_ 51.docx @ 5130 @ 2 @ 1

2.1 Warranty and Liability

Pos: 30 /TD/Einleitung/Gewährleistung_Haft ung/Öfen und Schaltanlagen - Gewä hrleistung und Haftung @ 0\mod_1157536 440972_51.docx @ 1569 @ @ 1

§

As regards warranty and liability, the normal Nabertherm warranty terms apply,

unless individual terms and conditions have been agreed. However, the following

conditions also apply:

Warranty and liability claims for personal injury or damage to property shall be excluded if

they are attributable to one or more of the following causes:

All persons involved in operation, installation, maintenance, or repair of the furnace

must have read and understood the operating instructions. No liability will be accepted

for damage or disruption to operation resulting from non-compliance with the

operating instructions.

Not using the furnace as intended

Improper installation, start-up, operation, or maintenance of the furnace,

Operation of the furnace with defective safety equipment or improperly installed or

non-functioning safety and protective equipment

Not observing the information in the operating instructions with respect to

transportation, storage, installation, start-up, operation, maintenance, or equipping the

furnace

Making unauthorized changes to the furnace

Making unauthorized changes to the operating parameters

Making unauthorized changes to the parameterization, the settings, or the program

Nabertherm accepts absolutely no liability for damage caused by using parts that are

not original Nabertherm parts. Original parts and accessories are designed especially

for Nabertherm furnaces. Replace parts only with original Nabertherm parts.

Otherwise the warranty will be void.

Catastrophes due to third-party causes and force majeure

Page 14

14

Pos: 31 /TD/Sicherheit/Überschrift - Sic herheit @ 0\mod_1158843961540_51.doc x @ 3103 @ 1 @ 1

3 Safety

Pos: 32 /TD/Sicherheit/Sicherheitssymbole/ Warnhinweise-ISO-ANSI/Erläuterung AN SI Z535.6 @ 8\mod_124332355888 1_51.docx @ 57444 @ 2 @ 1

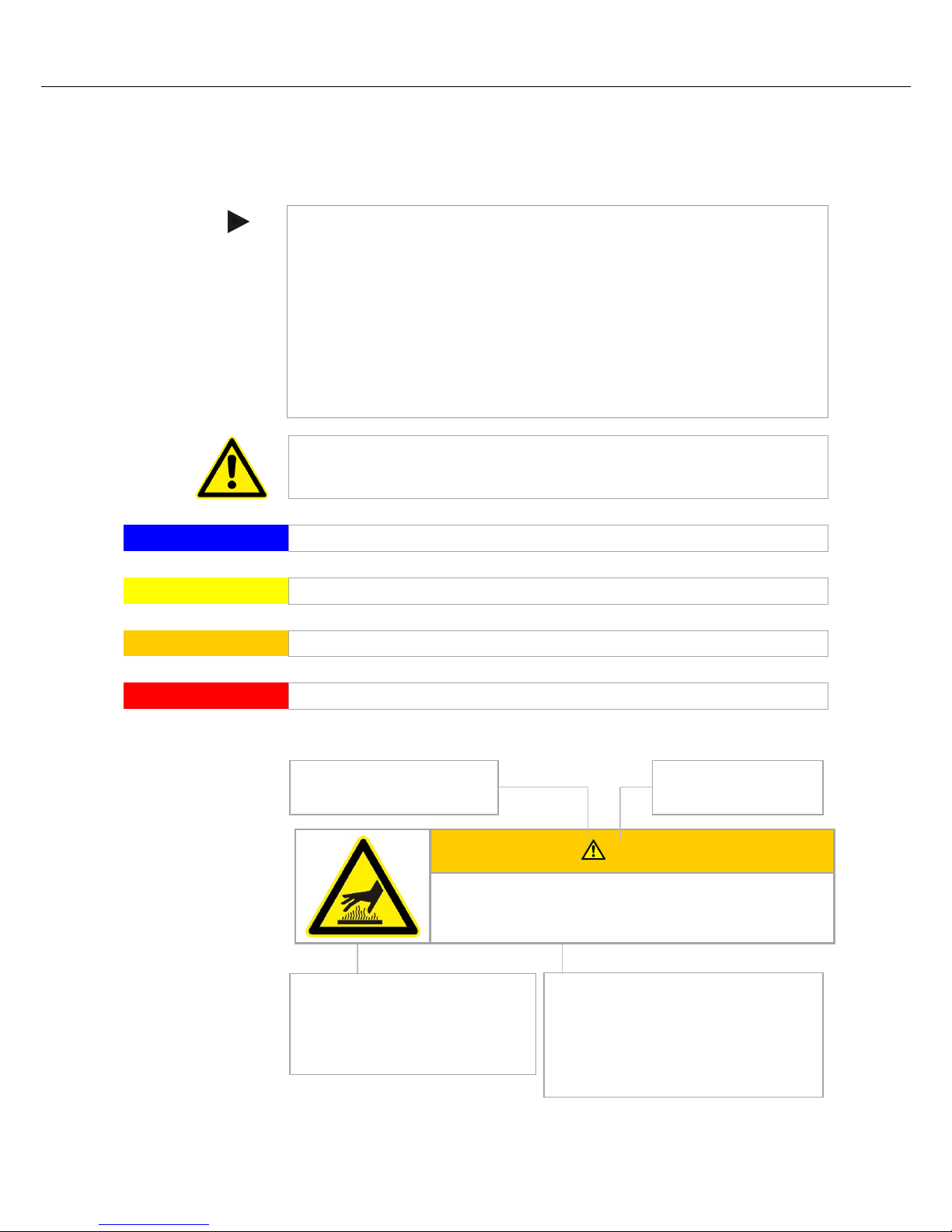

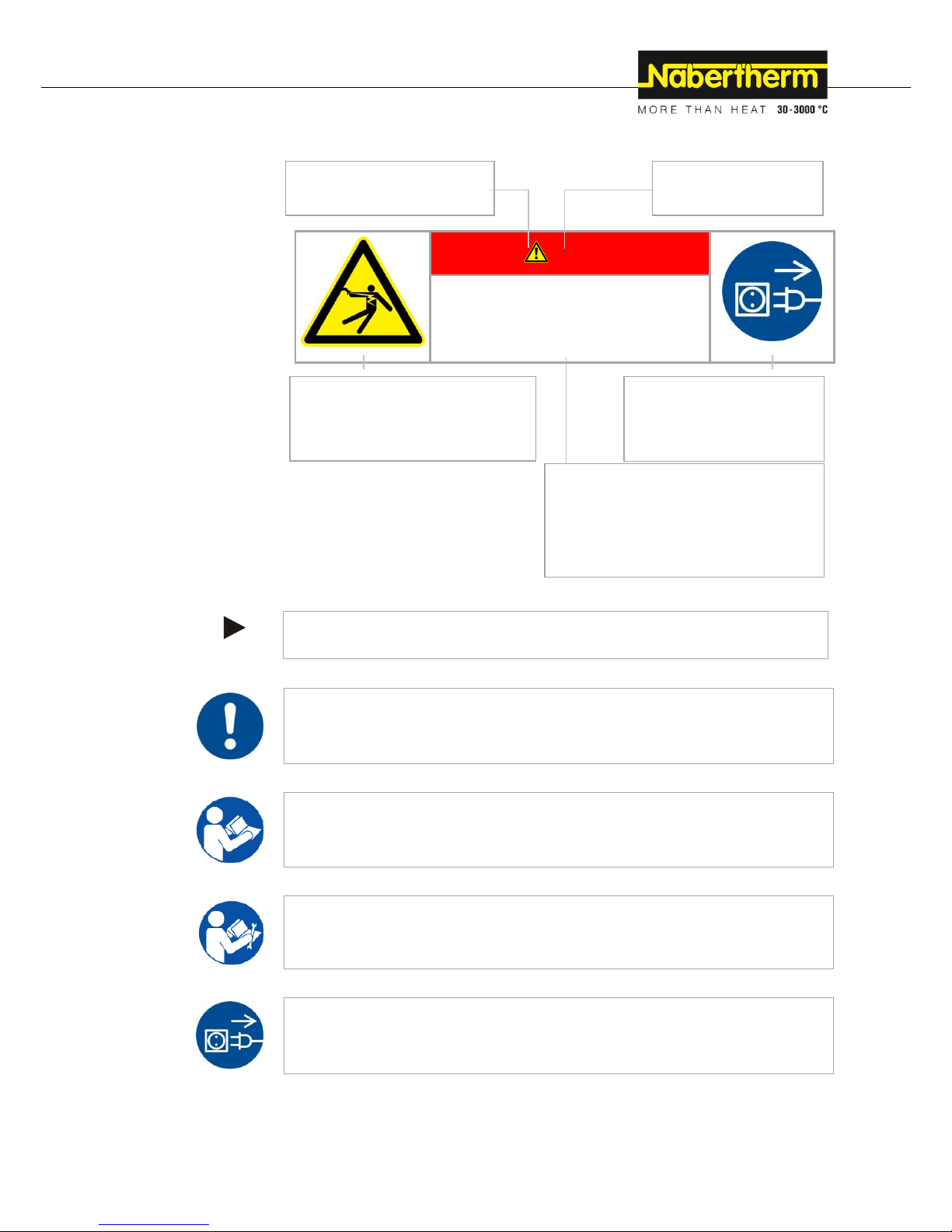

3.1 Explanation of the Symbols and Warnings

Note

In the following operating instructions, specific warnings are given to draw attention to

residual risks that cannot be avoided when the furnace is operating. These residual risks

include dangers for humans/products/ the furnace, and the environment.

The symbols used in the operating instructions are especially intended to draw attention to

safety information.

The symbols used cannot replace the text of the safety information. Therefore, always

read the entire text.

Graphic symbols correspond to ISO 3864. In accordance with the American National

Standard Institute (ANSI) Z535.6 the following warning information and words are used

in this document:

The general hazard symbol, in combination with the words CAUTION, WARNING and

DANGER warns about the risk of serious injury. Observe the following information to

prevent injury or death.

NOTE

Refers to a hazard that could damage or destroy the equipment.

CAUTION

Refers to a hazard with a minor or medium risk of injury.

WARNING

Refers to a hazard that could cause death, serious or irreversible injury.

DANGER

Refers to a hazard that could directly cause death, serious or irreversible injury.

Structure of the Warning: All Warnings are Structured as Follows

WARNING

• Type and source of the danger

• Consequences of non-compliance

• Action to prevent danger

Hazard Symbol

Indicates the risk of injury

Signal Word

Classifies the danger

Graphical Symbols (optional)

According to ISO 3864:

Consequences, measures, and

prohibitions

Reference Texts:

• Type and source of the danger

• Possible consequences of non-

compliance

• Measures/Prohibitions

Page 15

15

or

DANGER

• Type and source of the danger

• Consequences of non-compliance

• Action to prevent danger

Pos: 33 /TD/Sicherheit/Sicherheitssymbole/ Warnhinweise-ISO-ANSI/Überschrift - Hin weissymbole in der Anleitung (Einzug Mit te) @ 9\mod_1247053429626_51.d ocx @ 62751 @ @ 1

Information Symbols in the Instructions:

Pos: 34 /TD/Sicherheit/Sicherheitssymbole/ Warnhinweise-ISO-ANSI/Hinweis - U nter diesem Symbol erhalten Sie Anweisu ngshinweise und ... @ 9\mod_124705393 2311_51.docx @ 62785 @ @ 1

Note

Below this symbol you will find instructions and particularly useful information.

Pos: 35 /TD/Sicherheit/Sicherheitssymbole/ Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Gebot - Gebotszeichen - Wichtige Gebote sind zu befolgen @ 9\ mod_1247056175982_51.docx @ 62853 @ @ 1

Rule - Rule Sign

This symbol draws attention to important rules that must be observed. Rule signs protect

people against injury and show what is to be done in certain situations.

Pos: 36 /TD/Sicherheit/Sicherheitssymbole/ Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Gebot - Wichtige Inform ation für den Bediener @ 9\mod_124705 3200729_51.docx @ 62717 @ @ 1

Rule – Important Information for Operators

This symbol draws the operator's attention to important information and operating

instructions that must be observed.

Pos: 37 /TD/Sicherheit/Sicherheitssymbole/ Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Gebot - Wichtige Inform ation für das Wartungspersonal @ 9\m od_1247053206042_51.docx @ 62734 @ @ 1

Rule – Important Information for Maintenance Personnel

This symbol draws the maintenance personnel's attention to important operating and

maintenance instructions (service) that must be observed.

Pos: 38 /TD/Sicherheit/Sicherheitssymbole/ Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Gebot - Netzstecker zieh en @ 9\mod_1247055471526_51.docx @ 62836 @ @ 1

Rule – Pull Out the Power Plug

This symbol tells the operator to pull out the power plug.

Graphical Symbols (optional)

According to ISO 3864:

Consequences, measures, and

prohibitions

Reference Texts:

• Type and source of the danger

• Possible consequences of non-compliance

• Measures/prohibitions

Graphical Symbols

(optional) According to ISO

3864:

Instructions or prohibitions

Hazard Symbol

Indicates the risk of injury

Signal Word

Classifies the danger

Page 16

16

Pos: 39 /TD/Sicherheit/Sicherheitssymbole/ Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Gebot - Anheben mit mehreren Personen @ 9\mod_1247063058 002_51.docx @ 62938 @ @ 1

Rule – Lift only with Several People

This symbol draws the personnel's attention to the fact that this device may only be lifted

and moved to its final destination by several people.

Pos: 40 /TD/Sicherheit/Sicherheitssymbole/ Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Warnung - Heiße Oberflä che - Oberfläche nicht berühren @ 9\ mod_1247054774780_51.docx @ 62802 @ @ 1

Warning – Hot Surface, Do Not Touch

This symbol warns the operator that the surface is hot and should not be touched.

Pos: 41 /TD/Sicherheit/Sicherheitssymbole/ Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Warnung - elektrischer Schlag - zur Vermeidung Anweisung folg en @ 9\mod_1247055093892_51.docx @ 62819 @ @ 1

Warning – Danger of Electric Shock

This symbol warns the operator that there is a risk of an electric shock if the following

warnings are not heeded.

Pos: 42 /TD/Sicherheit/Sicherheitssymbole/ Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Warnung - Heben schwer er Lasten @ 9\mod_1247059891358_5 1.docx @ 62887 @ @ 1

Warning – Danger if Heavy Loads are Lifted

This symbol warns the operator of the potential dangers of lifting heavy loads. Ignoring

this can lead to injury.

Pos: 43 /TD/Sicherheit/Sicherheitssymbole/ Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Warnung - Brandgefa hr @ 9\mod_1251445272822_51.docx @ 6 5437 @ @ 1

Warning – Fire Danger

This symbol warns operators of the danger of fire if the following information is not

followed.

Pos: 44 /TD/Sicherheit/Sicherheitssymbole/ Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Gefahr - nicht mit Wasser überschütten @ 9\mod_124782641 0886_51.docx @ 63819 @ @ 1

Prohibited – Important Information for Operators

This symbol warns the operator that water or cleaning products must NOT be poured over

the objects. A high-pressure cleaning device must also not be used.

Pos: 45 /TD/Sicherheit/Sicherheitssymbole/ Warnhinweise-ISO-ANSI/Überschrift - Warnhinweissymbole an der Anlage @ 9\mod_1247053700273_51.docx @ 627 68 @ @ 1

Warning Signs on the Furnace:

Pos: 46 /TD/Sicherheit/Sicherheitssymbole/ Warnhinweise-ISO-ANSI/Piktogram m an der Anlage - Warnung - Gefahr vor h eißer Oberfläche und Verbrennung @ 9\ mod_1247052957145_51.docx @ 62700 @ @ 1

Warning – Hot Surface, Danger of Burning – Do Not Touch

You may not always realize that surfaces, such as furnace components, furnace walls,

doors and materials, and even liquids are hot. Do not touch the surface.

Pos: 47 /TD/Sicherheit/Sicherheitssymbole/ Warnhinweise-ISO-ANSI/Piktogram m an der Anlage - Warnung - Gefahren durch elektrischen Strom @ 9\mod_12470 52639824_51.docx @ 62683 @ @ 1

Warning – Danger of Electric Shock!

Warning, dangerous electric voltage

Page 17

17

Pos: 48 /TD/Sicherheit/Sicherheitssymbole/ Warnhinweise-ISO-ANSI/Warnsymbol_ Gefahr - Gefahr durch fehlende oder nic ht korrekt angeschlossene Erdung an ... @ 85\mod_1423745935634_51.docx @ 359461 @ @ 1

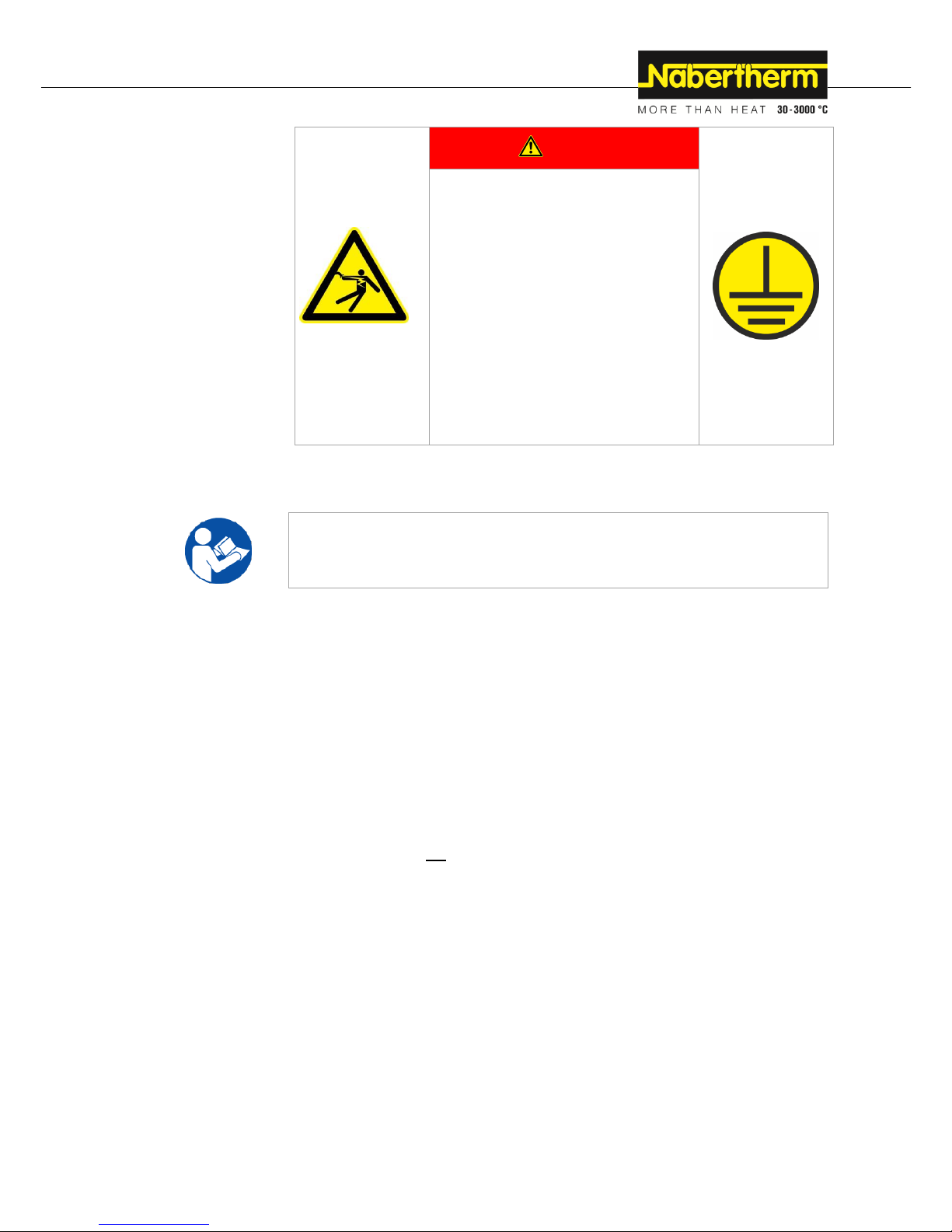

DANGER

• Danger from electrocution

• If there is no earth connection, or the

earth connection is poorly connected,

the result may be a deadly electrical

shock.

• Do not insert any metallic objects such as

thermocouples, sensors or tools into the

furnace chamber without having

previously ensured that the plant has been

correctly earthed. Entrust the job of

making a earth connection between the

object and the furnace housing to a

qualified electrical technician. Any

objects inserted into the furnace must be

inserted only through those openings

intended for this purpose.

Pos: 49 /TD/Sicherheit/Überschrift - Besti mmungsgemäße Verwendung @ 0\ mod_1167823503921_51.docx @ 5148 @ 2 @ 1

3.2 Defined Application

Pos: 50 /TD/Sicherheit/Bestimmungsgemäß e Verwendung allgemeiner Ofen-Anlage n - Teil 1 @ 45\mod_137723815939 1_51.docx @ 241740 @ @ 1

Safety

The Nabertherm furnace was designed and built in conformance with a careful selection

of the applicable harmonized standards and other technical specifications. Hence, it

corresponds to the state of the art and assures the greatest degree of safety.

Pos: 51 /TD/Sicherheit/Bestimmungsgemäß e Verwendung Top-HO und F-Öfen @ 13\mod_1289384913818_51.docx @ 107516 @ @ 1

Furnaces in the Top and HO series are electrically heated furnaces for firing ceramics,

glass fusing, glass and porcelain painting. Furnaces in the F series are for glass fusing, glass

and porcelain painting.

Pos: 52 /TD/Sicherheit/Überschrift - Nicht b estimmungsgemäß ist: (Einzug Mitte) @ 80\mod_1418806747958_51.docx @ 3 47220 @ @ 1

Improper furnace operation:

Pos: 53 /TD/Sicherheit/Eine andere oder darüber hinausgehende Benutzung, wie z. B. die Verarbeitung ... @ 45\mod_137 7242071687_51.docx @ 242040 @ @ 1

Safety

Any other use, such as processing of products other than those for which the furnace

was intended as well as handling hazardous materials or materials dangerous to health

is deemed IMPROPER and such uses must be approved in writing by Nabertherm.

Pos: 54 /TD/Sicherheit/dieser Ofen ist NICHT dafür bestimmt durch Personen (einschließlic h Kinder) mit eingeschränkten ... @ 45\mod_1377501786408_51.docx @ 24249 0 @ @ 1

This furnace is NOT used by certain persons (including children) with restricted

physical, sensorial or mental capabilities or who have insufficient experience

and/or insufficient knowledge, unless they are supervised by a person who is

responsible for their safety or are instructed in how to use the furnace. Children

should be supervised to make sure that they do not play with the furnace.

Pos: 55 /TD/Sicherheit/Der Ofen ist nicht für die Erwärmung von Nahrungsmitteln zum Verzehr zu verwenden. @ 53\mod_1 389787274556_51.docx @ 262780 @ @ 1

The furnace must not not be used for heating food.

Pos: 56 /TD/Sicherheit/Veränderungen am Of en, müssen mit Nabertherm schriftlich a bgestimmt werden ... @ 45\mod_13 77243398694_51.docx @ 242240 @ @ 1

The set-up instructions and safety regulations must be followed, otherwise the furnace

will be considered improperly used, effectively cancelling any claims against

Nabertherm GmbH. The EC Declaration of Conformity will cease to be valid if any

modifications are made to the machine without our approval.

Pos: 57 /TD/Sicherheit/Die Aufstellhinweise und Sicherheitsbestimmungen sind einz uhalten, andernfalls gilt der Ofen als ... @ 45\mod_1377243410507_51.docx @ 242265 @ @ 1

The set-up instructions and safety regulations must be followed, otherwise the furnace

will be considered improperly used, effectively cancelling any claims against

Nabertherm GmbH.

Pos: 58 /TD/Sicherheit/Der Betrieb mit Kr aftquellen, Produkten, Betriebsmitteln, Hilfssto ffen, Lösungsmitteln ... - 2 @ 53\ mod_1389787294041_51.docx @ 262830 @ @ 1

Operation with power sources, products, operating equipment, auxiliary materials,

solvents, etc., which are listed as hazardous or which may in any way harm the health

of the personnel operating the furnace is prohibited.

Page 18

18

Pos: 59 /TD/Sicherheit/Überschrift - Für hieraus resultierende Schäden haftet der Betreiber (Einzug Mitte) @ 10\mod_125 6731411117_51.docx @ 68223 @ @ 1

The operator is liable for any resulting damages.

Pos: 60 /TD/Sicherheit/Das Betreiben des Ofens ist nur nach der in dieser Betriebs anleitung beschriebenen Vorgehensweise .. @ 53\mod_1389787305804_51.docx @ 262855 @ @ 1

The furnace may only be operated in the manner described in these operating

instructions, i.e., the operating instructions must be completely read and understood.

Pos: 61 /TD/Sicherheit/Von den im Ofen ei ngesetzten Materialien bzw. Ausgasunge n können sich unter Umständen Schadstoff e .. @ 45\mod_137724339221 7_51.docx @ 242065 @ @ 1

Under certain circumstances gases or materials may be released from the materials in

the furnaces that settle on the insulation or the heating elements and destroy them. If

applicable, read the labels and instructions on the packaging of materials that

you use.

Pos: 62 /TD/Sicherheit/Die Aufstellhinweise und Sicherheitsbestimmungen sind einz uhalten, andernfalls gilt der Ofen als ... @ 45\mod_1377243410507_51.docx @ 242265 @ @ 1

The set-up instructions and safety regulations must be followed, otherwise the furnace

will be considered improperly used, effectively cancelling any claims against

Nabertherm GmbH.

Pos: 63 /TD/Sicherheit/Das Öffnen des Ofens i m heißen Zustand über 200 °C (392 °F) kann zu einem erhöhtem Verschleiß ... @ 39\mod_1364289911635_51.docx @ 219945 @ @ 1

Opening the furnace while it is still hot, over 200 °C (392 °F), can lead to increased

wear of the following components: insulation, door seal, heating elements and furnace

housing. No liability shall be accepted for any damage to the goods or the furnace

resulting from non-compliance with this warning.

Pos: 64 /TD/Allgemeine Hinweise (für alle Anleitungen)/Hinweis - Dieser Ofen ist für die private und gewerbliche Anwendung ... Der Ofen ist nicht für ... @ 45\mod_1 377239313841_51.docx @ 241765 @ @ 1

Safety

This furnace was designed for private and commercial use. The furnace is NOT to be

used for heating food, animals, wood, grains, etc.

The furnace must NOT be used to heat the workplace.

Do NOT use the furnace to melt ice or for similar purposes.

Do NOT use the furnace as a clothes dryer.

Pos: 65 /TD/Allgemeine Hinweise (für alle Anleitungen)/Hinweis - Es gelten die Sic herheitshinweise der einzelnen Kapitel. @ 34\mod_1357906319399_51.docx @ 203020 @ @ 1

Note

See safety instructions in the individual sections.

Pos: 66 /TD/Allgemeine Hinweise (für alle Anleitungen)/Hinweis - Dieser Ofen verfügt über keine Sicherheitstechnik für Pr ozesse, ..-nicht brennbare Gase @ 8\mo d_1235038699771_51.docx @ 51483 @ @ 1

Note

The furnace must not be operated with explosive gases or mixtures or with

explosive gases or mixtures that form during the process.

This furnace has no safety technology for processes in which combustible mixtures

can form, such as debinding.

If the furnace is to be used for such processes, the concentration of organic gases must

never exceed 3 % of the lower explosive limit (LEL) in the furnace. This requirement

not only applies to normal operation, but also especially to exceptions, such as process

malfunctions (e.g. due to the breakdown of a unit, etc.). Ensure adequate extraction

and ventilation of the furnace.

Nabertherm offers a wide range of furnaces that were especially developed for processes

with flammable gases.

Pos: 67 /TD/Allgemeine Hinweise (für alle Anleitungen)/Hinweis - Dieses Produ kt entspricht nicht der ATEX-Richtlinie und darf nicht ..-nicht brennbare Gase @ 2\m od_1184228756893_51.docx @ 19686 @ @ 1

Note

This product does not comply with the ATEX Directive and may not be used in

ignitable atmospheres. The system must not be operated with explosive gases or

mixtures and it must be ensured that explosive gases or mixtures do not form during

the process.

Pos: 68 /TD/Sicherheit/Überschrift - Anf orderungen an den Betreiber der Anlage @ 0\mod_1167823775531_51.docx @ 515 7 @ 2 @ 1

3.3 Requirements for the Furnace Operator

Pos: 69 /TD/Sicherheit/Anforderungen an de n Betreiber der Anlage - Die Aufstell hinweise und Sicherheits ... (Ofen) @ 45\ mod_1377241972892_51.docx @ 242015 @ @ 1

The set-up instructions and safety regulations must be followed, otherwise the furnace

will be deemed to have been used improperly, effectively cancelling any claims against

Nabertherm GmbH.

Page 19

19

This level of safety can be achieved only if all the necessary measures have been taken. It

depends on the furnace operator's diligence in planning these measures and controlling how

they are carried out.

Pos: 70 /TD/Sicherheit/Überschrift - Der Betreiber muss sicherstellen, dass @ 45\ mod_1377501770051_51.docx @ 24246 5 @ @ 1

The operator must ensure that

Pos: 71 /TD/Sicherheit/dieser Ofen ist NICHT dafür bestimmt durch Personen (einschließlic h Kinder) mit eingeschränkten ... @ 45\mod_1377501786408_51.docx @ 24249 0 @ @ 1

This furnace is NOT used by certain persons (including children) with restricted

physical, sensorial or mental capabilities or who have insufficient experience

and/or insufficient knowledge, unless they are supervised by a person who is

responsible for their safety or are instructed in how to use the furnace. Children

should be supervised to make sure that they do not play with the furnace.

Pos: 72 /TD/Sicherheit/beim Brennen von K eramik, des Tones bzw. der Glasur können ... @ 45\mod_1377501792291_51.d ocx @ 242515 @ @ 1

When ceramics, clay, or glaze are fired, they can emit gases and vapors that are

harmful to your health. It is therefore necessary to make sure that the "exhaust gases"

emitted from the exhaust air opening are directed outdoors in a suitable manner

(ventilate the working area). If adequate ventilation cannot be ensured at the working

area, the "exhaust gases" must be removed via a pipe (see "venting exhaust fumes").

Pos: 73 /TD/Sicherheit/von den Materialien, die in dem Ofen eingesetzt werden, muss bekannt sein, ob sie ... @ 45\mod _1377501799794_51.docx @ 242540 @ @ 1

Before placing materials in the furnace, check whether they could harm or destroy the

insulation or the heating elements. Materials that could damage the insulation include:

alkalis, alkaline earths, metal vapors, metal oxides, chlorine compounds, phosphorous

compounds, and halogens. If applicable, read the labels and instructions on the

packaging of materials that you use.

Pos: 74 /TD/Sicherheit/die Anlage nur in ei nwandfreiem, funktionstüchtigem ... - di eses Personal regelmäßig in allen... @ 4 5\mod_1377501806506_51.docx @ 242 565 @ @ 1

The furnace is operated only in a perfect operating condition and, in particular, that

the functions of the safety components are checked regularly.

Necessary personal protective equipment is available. Example: protective gloves,

suitable apron, etc.

This instruction manual is to be kept beside the furnace. These instructions must be

available at all times for anyone working with or on the furnace;

All the safety and operating instruction signs on the furnace can be read properly.

Damaged or unreadable signs must be replaced immediately,

Personnel are informed regularly about all issues involving occupational safety and

environmental protection and are familiar with all the operating instructions,

especially those involving safety,

Pos: 75 /TD/Sicherheit/Bei gewerblicher Nu tzung: Beachten Sie die für Ihr Land gültige n Sicherheitsvorschriften ... @ 45\m od_1377501814270_51.docx @ 242590 @ @ 1

If the furnace is used commercially:

Observe the safety regulations applicable in your country. In Germany, the furnace

must be checked by a qualified electrician at defined intervals in accordance with a

regulation issued by the employers' accident insurance fund.

Pos: 76 /TD/Allgemeine Hinweise (für all e Anleitungen)/Hinweis - In Deutschland ist die allgemeine Unfallverhütungsvorschrif t zu beachten. @ 3\mod_1193667801 739_51.docx @ 26122 @ @ 1

a

Note

In Germany, the general accident protection guidelines must be observed. The accident

prevention regulations applicable in the country where the furnace is installed must be

observed.

Pos: 77 /TD/Sicherheit/Überschrift - Schu tzkleidung @ 0\mod_1167825795750_51. docx @ 5175 @ 2 @ 1

3.4 Protective Clothing

Pos: 78 /TD/Sicherheit/Schutzkleidung - Hi tzebeständige Handschuhe tragen @ 9\ mod_1246542013306_51.docx @ 6247 3 @ @ 1

Wear heat-resistant gloves to protect your hands.

Page 20

20

Pos: 79 /TD/Sicherheit/Überschrift - Grun dlegende Maßnahmen bei Normalbetrieb @ 0\mod_1167825919827_51.docx @ 5 184 @ 2 @ 1

3.5 Basic Measures During Normal Operation

Pos: 80 /TD/Sicherheit/Grundlegende Maßn ahmen bei Normalbetrieb Top-HO un d F Öfen @ 13\mod_1289395735652_51.d ocx @ 107562 @ @ 1

Risks during normal operation

Before switching the furnace on, check and ensure that only authorized persons are in the

working area of the furnace and that no one can be injured as a result of operating the

furnace.

Each time, before starting production check and ensure that all the safety equipment

functions as intended (for example, that the contact safety switch switches the heating off

when the lid is opened).

Before starting production each time, check the furnace for obvious damage and ensure that

it is operated only in a perfect condition. Report any defects to Nabertherm Service

immediately.

Before starting production each time, remove all materials and objects that are not needed

for production from the working area.

At least once every day (see also Servicing and Maintenance) check the following:

Check the furnace for obvious external damage (visual check), for example insulation,

heating elements, power cable, exhaust gas system, if applicable.

Check that all safety equipment is functioning (for example, that the contact safety

switch switches the heating off when the door is opened).

Pos: 81 /TD/Sicherheit/Überschrift - Grun dlegende Maßnahmen im Notfall @ 1\mo d_1170943369267_51.docx @ 9093 @ 2 @ 1

3.6 Basic Measures in Case of Emergency

Pos: 82 /TD/Sicherheit/Überschrift - Verh alten im Notfall @ 1\mod_11709499048 55_51.docx @ 9123 @ 3 @ 1

3.6.1 What to Do in an Emergency

Pos: 83 /TD/Allgemeine Hinweise (für alle Anleitungen)/Hinweis - Das Stillsetzen i m Notfall ist vorgesehen durch Ziehen des Netzsteckers. @ 6\mod_122206283686 0_51.docx @ 42829 @ @ 1

Note

The power plug is to be pulled out to stop the furnace in case of an emergency.

Therefore, the power plug must be accessible at all times when the furnace is operating so

that it can be pulled out quickly in case of an emergency.

Pos: 84 /TD/Sicherheit/Grundlegende Maß nahmen im Notfall - Netzstecker ziehen ( alle Anleitungen) - Grafik @ 36\mod_1 360079722854_51.docx @ 208920 @ @ 1

Fig. 6: Pull the power plug (similar to picture)

Pos: 85 /TD/Allgemeine Hinweise (für alle Anleitungen)/Warnung - Bei unerwarteten Vorgänge n im Ofen (z.B. starke Rauchentwicklung oder Geruchsbelästigung) @ 4\mod_1 205306579737_51.docx @ 34218 @ @ 1

Risks during Normal Operation!

Switch the furnace off immediately in case of unexpected occurrences in the furnace (e.g.

a lot of smoke or unusual smells). Wait until the furnace has cooled naturally to room

temperature.

Page 21

21

Pos: 86 /TD/Allgemeine Hinweise (für alle Anleitungen)/Warnung - Bei unerwartet en Vorgängen darf der Ofen nicht geöffnet ...- Grafik Top_HO_F (Modell 2015) @ 1 04\mod_1444049593859_51.docx @ 412601 @ @ 1

In case of fire, keep

lid closed.

Immediately remove

the power plug.

Keep doors and

windows closed. This

prevents smoke

spreading.

Immediately notify

the fire service,

regardless of the

extent of the fire.

When you phone the

fire service, remain

calm and speak

clearly.

Pos: 87 /TD/Sicherheit/Sicherheitssymbole/ Warnhinweise-ISO-ANSI/Warnsymbol_ Gefahr - Elektrischer Schlag - Piktogram m elektr. Schlag - Netzstecker ziehen @ 9\ mod_1247472185096_51.docx @ 6 3063 @ @ 1

DANGER

• Danger of electric shock.

• Risk of fatal injury.

• Work on electrical

equipment may be carried out only by

qualified electricians

or by trained personnel authorized by

Nabertherm.

• Before starting work, pull out the

power plug

Pos: 88 /TD/Sicherheit/Überschrift - Grun dlegende Maßnahmen bei Wartung und Ins tandhaltung @ 0\mod_116782606062 0_51.docx @ 5193 @ 2 @ 1

3.7 Basic Measures for Servicing and Maintenance

Pos: 89 /TD/Sicherheit/Grundlegende Maß nahmen bei Wartung und Instandhaltung T op, HO und F - Öfen @ 13\mod_1291 107854956_51.docx @ 109556 @ @ 1

Maintenance work must be performed by authorized persons, following the maintenance

instructions and the accident prevention regulations. We recommend that the maintenance

and repair work be carried out by the service team of Nabertherm GmbH. Noncompliance may cause injuries, death, or considerable damage to property.

Switch the furnace off at the power supply and pull out the plug.

The furnace must be completely empty.

When cleaning furnaces, control cabinets, or electrical equipment housings, never spray

them with water.

When maintenance or repair work has been completed, before recommencing production

ensure the following:

Check that loosened screw connections/tensioning straps have been re-tightened,

Reinstall protective equipment, screens, and filters If applicable),

Remove all material, tools, and other equipment used for the maintenance or repair

work from the working area of the furnace,

Power cables may be replaced only with similar, approved cables.

Page 22

22

Pos: 90 /TD/Sicherheit/Überschrift - Allge meine Gefahren an der Anlage @ 0\m od_1168596796288_51.docx @ 6014 @ 2 @ 1

3.8 General Risks with the Furnace

Pos: 91 /TD/Sicherheit/Allgemeine Gefahren ( Verbrennung, Quetschen, Strom) - T op, HO und F @ 13\mod_12894667661 04_51.docx @ 107663 @ @ 1

• Bypass connection/exhaust air pipe/lid/handle all become hot when the furnace is

operating.

• Danger of burning.

• Do NOT touch the bypass connection/exhaust air pipe/lid/handle when the furnace is

operating.

• Do not insert objects into the openings in the furnace housing, the exhaust air holes

or the cooling slits of the switchgear or the furnace.

• Danger of electric shock.

• Do NOT insert any objects.

• Danger of electric shock

• Risk of fatal injury

• The furnace must NOT become wet during operation or maintenance

• Danger of explosion from materials in the furnace

• Risk of fatal injury

• Do NOT insert explosive substances into the furnace when it has reached its operating

temperature.

• NO explosive dusts or solvent-air mixtures inside the furnace.

• Do NOT operate the furnace in areas where there is a risk of explosion.

• NO explosive dusts or solvent-air mixtures in the surrounding area.

• Fire hazard if an extension cable is used

• Risk of fatal injury

With 230 V furnace models make sure that:

• The distance between the circuit breaker and the power socket that the furnace is

connected to

is as short as possible.

• NO power board or extension cable is used between the power socket and the

furnace.

Pos: 92 /TD/Sicherheit/Warnung - Es dürfen keine Gegenstände auf dem To p-HO und F Ofen abgelegt/abgestellt - Grafi k @ 104\mod_1444052645305_51.doc x @ 412627 @ @ 1

Risks during normal

operation

Do not place objects

on top of the furnace.

There is a risk of fire

or explosion.

Page 23

23

Pos: 93 /TD/Transport_Montage_Inbetrieb nahme/Erstinbetriebnahme/Überschrift - Tr ansport, Montage und Erstinbetriebn ahme @ 0\mod_1158844227416_51.doc x @ 3112 @ 1 @ 1

4 Transportation, Installation and Initial Start-Up

Pos: 94 /TD/Transport_Montage_Inbetrieb nahme/Erstinbetriebnahme/Überschrift - Anlieferung @ 0\mod_1167826534889_ 51.docx @ 5220 @ 2 @ 1

4.1 Delivery

Pos: 95 /TD/Transport_Montage_Inbetrieb nahme/Erstinbetriebnahme/Anlieferung T op, HO und F Öfen - (Hinweise allgemein) @ 13\mod_1289468478869_51.docx @ 1076 86 @ @ 1

Check that everything is complete

Compare the delivered items with the delivery note and the purchase order documents.

Immediately notify the carrier and Nabertherm GmbH of any missing or damaged parts, as

complaints at a later date cannot be acknowledged.

Danger of injury

When the furnace is being lifted, parts of the furnace or the furnace itself could topple over,

slip, or fall. Before the furnace is lifted, make sure no one is in the working area.

Appropriate protective gloves must be worn.

Safety Instructions

Industrial trucks (e.g.: crane/pallet truck) must be operated only by authorized

personnel. The operator bears sole responsibility for safe operation and the load.

Use only lifting equipment with sufficient load-bearing capacity.

When the furnace is being lifted, make sure that the ends of the forks or the load do

not catch on neighboring goods. Use a crane to move tall parts, such as control

cabinets.

Lifting gear must be attached only to positions that have been designated for this

purpose.

Attachments, piping, or cable conduits must never be used to affix lifting gear.

Attach transportation equipment only to positions intended for this purpose.

Note

Wear protective gloves when installing the furnace.

Risks during normal operation

Suspended loads are dangerous. Working beneath a suspended load is prohibited. There is

a risk of fatal injury.

Note

Safety and accident prevention guidelines applicable for forklift trucks must be followed.

Pos: 96 /TD/Transport_Montage_Inbetrieb nahme/Erstinbetriebnahme/Anlieferung - Öfen mit einem Hubwagen transportier en @ 2\mod_1184672460200_51.docx @ 20000 @ @ 1

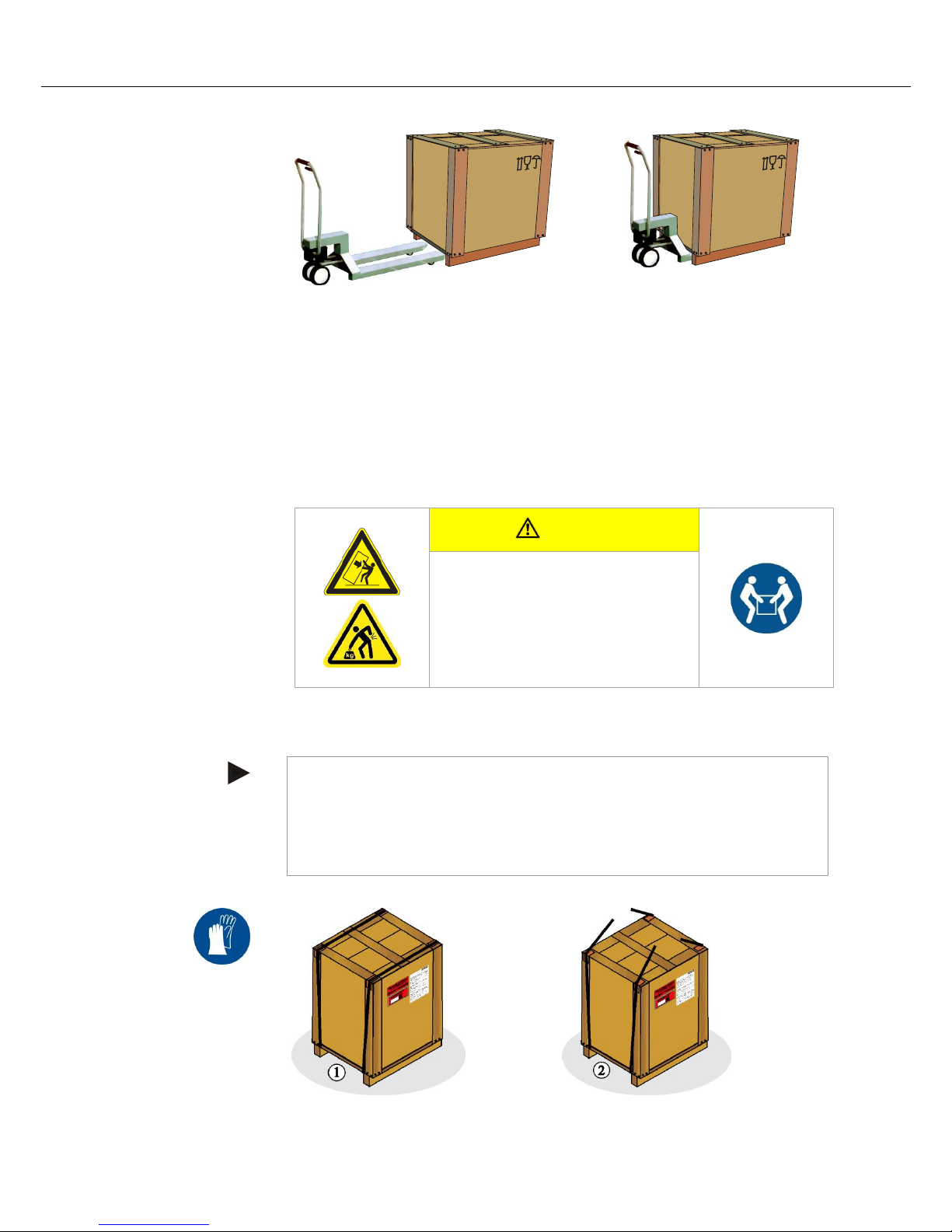

Transportation with a Pallet Truck

Observe the maximum permitted capacity of the pallet truck.

1. Our furnaces are delivered ex works on wooden frames to facilitate unloading.

Transport the furnace in its original packaging and with suitable equipment to

prevent any damage. Remove the packaging only when the furnace is in its final

location. When transporting the furnace, make sure it is secured against sliding,

toppling over, and damage. The furnace should be transported and installed by at

least two persons. Do not store the furnace in damp rooms or outdoors.

2. Push the pallet truck underneath the transportation frame. Make sure that the pallet

truck is completely beneath the frame. Pay attention to neighboring goods.

Page 24

24

Fig. 7: Pallet truck is pushed completely beneath the transportation frame

3. Lift the furnace carefully and pay attention to its center of gravity. When the furnace

is being lifted, make sure that the ends of the forks or the load do not catch on

neighboring goods.

4. Make sure that the furnace is balanced safely; if not, attach securing equipment.

Push the furnace carefully, slowly and with the pallet truck at its lowest position. Do

not transport the furnace on inclines.

5. Carefully lower the furnace at its final position. Pay attention to neighboring goods.

Try not to set it down too abruptly.

Pos: 97 /TD/Sicherheit/Sicherheitssymbol e/Warnhinweise-ISO-ANSI/Warnsymbol_ Vorsicht - Rutschen/Kippen des Gerätes - Piktogramm Kippen/Heben/Anheben @ 9\mod_1247064081950_51.docx @ 62 955 @ @ 1

CAUTION

• Device may slip or topple over.

• Damage to the device.

• Risk of injury from lifting

heavy loads.

• Transport device only in original

packaging.

• Several people must carry the device.

Pos: 98 /TD/Transport_Montage_Inbetrieb nahme/Erstinbetriebnahme/Überschrift - Auspacken @ 2\mod_118473951798 5_51.docx @ 20013 @ 2 @ 1

4.2 Unpacking

Pos: 99 /TD/Allgemeine Hinweise (für alle Anleitungen)/Hinweis - Allgemeiner Hi nweis zur Verpackung (z.B. Laboröfen) @ 3\mod_1192437185846_51.docx @ 235 09 @ @ 1

Note

The furnace packaging prevents damage during transportation. Make sure that you

remove all packaging material (also inside the Furnace Chamber). Keep the packaging

and transportation securing equipment in case it is needed for future transportation or

storage.

At least two people are needed to carry/transport the furnace, more for larger furnaces.

Pos: 100 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Auspacken Troc kenschrank TR ... - Teil 1 @ 9\ mod_1246978000133_51.docx @ 62643 @ @ 1

Wear protective

gloves

Page 25

25

1. Check the transportation packaging for any signs of damage.

2. Remove straps from the transportation packaging.

3. Loosen the screws and remove the wooden frame from the cardboard box (if

applicable)

Pos: 101 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Auspacken To p und F Öfen - Teil 2 @ 156\mod_1 494510779792_51.docx @ 643026 @ @ 1

4. Carefully lift the cardboard box and remove it from the pallet. Compare the

delivered items with the delivery note and the order documents, see "Delivery".

5. The pallet contains a packaging unit for accessories (Example: power cable, bypass

connection, ceramic shelves, castors and tools to assemble the castors and the bypass

connection).

6. Remove the top protective film (A) from the furnace.

7. To carry the furnace, place your hands beneath the furnace on the side (near the feet)

and make sure that you have a good grip. Wear protective gloves when installing

the furnace. Keeping your back straight, lift the furnace from the pallet and

Page 26

26

carefully lower it at the point where it is to be installed. The furnace should be

transported by at least 2 people.

8. Remove the protective film that protects the insulation between the furnace and the

lid. (A) Make sure that you remove all the packaging material. Keep the packaging

and transportation securing material (if applicable) in case it is needed for future

transportation or storage of the furnace.

Pos: 102 /TD/Sicherheit/Sicherheitssymbol e/Warnhinweise-ISO-ANSI/Warnsymbol _Vorsicht - Rutschen/Kippen des Geräte s - Piktogramm Kippen/Heben/Anheben @ 9\mod_1247064081950_51.docx @ 6 2955 @ @ 1

CAUTION

• Device may slip or topple over.

• Damage to the device.

• Risk of injury from lifting

heavy loads.

• Transport device only in original

packaging.

• Several people must carry the device.

Pos: 103 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Überschrift - Transportsicherung/Verpackung @ 0\m od_1167826775847_51.docx @ 5229 @ 2 @ 1

4.3 Transport Securing Device/Packaging

Pos: 104 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Verpackung - Allgemeine Hinweise zur Verpackung - keine spezielle Transportsicherung @ 1\ mod_1171004073117_51.docx @ 9 153 @ @ 1

Note

No special transportation securing equipment is available for this furnace

The furnace packaging prevents damage during transportation. Make sure that you remove

all packaging material (also inside the Furnace Chamber). All packaging material can be

recycled. The packaging was designed so that no special description is necessary.

Pos: 105 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Verpackung - Allgemeine Hinweise zur Verpackung - Kinder und Verpackungsmaterial @ 13\mod_ 1290686355811_51.docx @ 109504 @ @ 1

Safety Information

Do not allow children to play with packaging parts. They are at risk of suffocation from

folding boxes and plastic film.

Pos: 106 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Überschrift - Bauliche- und Anschlussvoraussetzu ngen @ 0\mod_1167826890943_51.docx @ 5238 @ 2 @ 1

4.4 Constructional and Connection Requirements

Pos: 107 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Überschrift - Aufstellung (Standort des Ofens) @ 2\ mod_1184848718972_51.docx @ 20166 @ 3 @ 1

4.4.1 Installation (Furnace Location)

Pos: 108 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Standort ein es Top, HO und F - Ofens @ 13\mod_1 289479898145_51.docx @ 107732 @ @ 1

When the furnace is being installed, these safety instructions must be followed:

The furnace must be installed in a dry room as stated in the safety instructions.

Page 27

27

The surface (floor or bench) where the furnace is to be installed must be level to

permit the furnace to stand upright. Place the furnace on a non flammable surface

(fire safety class A DIN 4102 – Example: concrete, tiles, glass, aluminum or steel) so

that any hot material falling from the furnace cannot ignite the surface.

The load-bearing capacity of the bench (e.g. bench-top model Top 16/R) must be

sufficient to take the weight of the furnace and accessories.

Non-flammable surface

Top 16/R Bench (accessory)

Fig. 8: Example: Non flammable surface (similar to picture)

In spite of its good insulation, the furnace radiates heat from its outer surfaces. If

necessary, this heat must be dissipated (contact a ventilation engineer if necessary).

Flammable materials must be kept at least 0.5 m (safety distance S) away from the

furnace. In some cases, the distance must be greater because of specific local conditions.

The minimum distance between the furnace and non-flammable materials may be reduced

to 0.2 m at the sides. If the charge emits gases or vapors, ensure adequate ventilation at the

installation site and/or a suitable exhaust air venting system. If required, the customer must

provide a suitable vent for combustion exhaust gases.

Fig. 9: Minimum safety distance to flammable materials (similar to picture)

Pos: 109 /TD/Sicherheit/Sicherheitssymbol e/Warnhinweise-ISO-ANSI/Warnsymbol _Gefahr - Brandgefahr - Piktogramm Br andgefahr @ 9\mod_1247148035738_5 1.docx @ 63010 @ @ 1

DANGER

• Risk of fire, danger to health

• Risk of fatal injury

• Adequate ventilation must be ensured at the

installation location to remove exhaust heat and exhaust gases

Page 28

28

Pos: 110 /TD/Allgemeine Hinweise (für alle A nleitungen)/Hinweis - Vor Inbetriebna hme des Ofens sollte dieser 24 Stunden am Aufstellungsort akklimatisiert .. @ 3\m od_1195568014336_51.docx @ 2787 1 @ @ 1

Note

Before starting the furnace for the first time, allow it to acclimatize at its installation

location for 24 hours.

Pos: 111 /TD/Sicherheit/Sicherheitssymbol e/Warnhinweise-ISO-ANSI/Warnsymbol _Gefahr - Gefahren durch automatisch e Löscheinrichtungen (Wasser_Löschgas) @ 55\mod_1391587048048_51.docx @ 269740 @ @ 1

DANGER

• Danger associated with the use of an automatic extinguishing

system

• Danger to life from electrocution through wetness,

suffocation caused by extinguishing gas, etc.

• If automatic extinguishing systems are in place to fight fires and

protect the building, e.g. sprinkler systems, care must be taken

during their planning and installation that no additional hazards are

created, for example by extinguishing a pilot light, mixing

hardening oil and extinguishing water, shutdown of electrical

equipment, etc.

Pos: 112 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Überschrift - Montage, Installation und Anschluss @ 0\mod_1167827976269_51.docx @ 5 292 @ 2 @ 1

4.5 Assembly, Installation, and Connection

Pos: 113 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Überschrift - Montage der Untergestellerhöhung (Zub ehör-Untergestellerhöhung) @ 13\ mod_1290432714317_51.docx @ 108766 @ 3 @ 1

4.5.1 Assembling the Base Extension (Accessory)

Pos: 114 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Überschrift - Untergestellerhöhung Fusing-Toplad er Modell F … (Ei nzug Mitte) @ 156\mod_149 4576617483_51.docx @ 643166 @ @ 1

Base Extension for Fusing Top Loader Model F …

Pos: 115 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Das als Zube hör enthaltene Untergestell aus der Verpac kungseinheit entnehmen und Einzel teile mit der @ 156\mod_149457688399 5_51.docx @ 643218 @ @ 1

Remove the base from the packaging and compare the parts with the list below.

Pos: 116 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Einzelteile d es Untergestells - (Toplader Modell F) - T abelle @ 156\mod_1494576888683_51. docx @ 643244 @ @ 1

No.

Quantity

Name

1

2

Brace, long

2

2

Brace, short

3

4

Feet with castors, two with locking brake

4

8

Collar screw M8

5

1

Open-end wrench

Pos: 117 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Einzelteile d es Untergestells - (Toplader Modell F) - Grafik @ 156\mod_1494576893167_51. docx @ 643270 @ @ 1

Fig. 10: Parts of the base (similar to picture)

Pos: 118 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Einen Fuß (3) mit zwei Schrauben (4) (mit je einer lang en (1) und einer kurzen (2) Strebe) m ontieren @ 156\mod_1494576898855_5 1.docx @ 643296 @ @ 1

Assemble one foot (3) with two screws (4) (with one long (1) and one short (2) brace).

Loosely tighten the screws with the supplied tool (5).

Pos: 119 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Umlaufend di e anderen Füße und Streben ergänzen. Bei Montage aller Füße und Streben Sc hrauben fest @ 156\mod_14945769 04746_51.docx @ 643322 @ @ 1

Assemble the other feet and braces. When all the feet and braces are assembled,

tighten the screws.

1

2

3

4

5

Page 29

29

Pos: 120 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Es sind die vorh er gelösten Transportrollen unter die F üße zu montieren (siehe Kapitel „M ontage der @ 15 6\mod_14945 83567113_51.docx @ 643798 @ @ 1

Screw the castors that you removed on to the bottom of the feet (see “Assembling the

Castors”).

Pos: 121 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Ofen vorsichtig auf das Gestell stellen. Schutzhandsc huhe tragen und den Ofen nur von der Bodenun.. @ 156\mod_149457695631 1_51.docx @ 643374 @ @ 1

Carefully place the furnace on to the frame. Wear protective gloves and lift the

furnace only by the base. At least two people are needed to lift the furnace, more for

heavier furnaces.

Pos: 122 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Überschrift - Untergestellerhöhung Toplader Modell T op … (Einzug Mi tte) @ 156\ mod_1494576650581_51.docx @ 643 192 @ @ 1

Base Extension Top Loader Model Top …

Pos: 123 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Das als Zu behör enthaltene Untergestell aus der Verpac kungseinheit entnehmen und Einzel teile mit der @ 156\mod_149457688399 5_51.docx @ 643218 @ @ 1

Remove the base from the packaging and compare the parts with the list below.

Pos: 124 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Einzelteile d es Untergestells - (Modell Top) - Tabell e @ 156\mod_1494577363935_51.doc x @ 643436 @ @ 1

No.

Quantity

Name

3

2

Base extension Top 45/Top 60

Pos: 125 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Montage der U ntergestellerhöhung (gesteckte Version) - (Modell Top) - Grafik @ 156\mod_ 1494583436720_51.docx @ 643772 @ @ 1

Fig. 11: Assembling the base extension (similar to picture)

Pos: 126 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Transportroll en (1) durch kräftiges ziehen nach unten lös en. @ 157\mod_1495005522554_5 1.docx @ 645291 @ @ 1

To remove the castors (1) pull them firmly downwards.

Pos: 127 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Hülsen (2) (befi ndlich an den Füßen des Ofens) mit zu m Beispiel einem breiten Flachschra ubendreher @ 156\mod_1494577377404 _51.docx @ 643514 @ @ 1

Carefully loosen the sleeves (2) (on the furnace feet) with a wide screwdriver and

hammer for example.

Pos: 128 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Beide Unterge stellerhöhungen (3) auf die Füße des Of ens aufstecken. Auf festen Sitz der Unt ergeste.. @ 156\mod_1494577382138 _51.docx @ 643540 @ @ 1

Insert the two base extensions (3) on to the furnace feet. Make sure that the base

extension sits firmly.

Pos: 129 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Es sind die vorh er gelösten Transportrollen unter die F üße zu montieren (siehe Kapitel „M ontage der @ 15 6\mod_14945 83567113_51.docx @ 643798 @ @ 1

Screw the castors that you removed on to the bottom of the feet (see “Assembling the

Castors”).

Pos: 130 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Überschrift - Montage der Transportrollen @ 13\ mod_1289819020312_51.docx @ 107922 @ 3 @ 1

4.5.2 Assembling the Castors

Pos: 131 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Die im Liefer umfang befindlichen Transportrollen sind bz w. können wenn erforderlich an de n Füßen des @ 156\mod_14943330072 43_51.docx @ 642306 @ @ 1

If required, the castors that are delivered can be attached to the furnace feet. We

recommend that the castors with the locking brake are attached to the front of the furnace.

The number of castors depends on the number of feet and varies depending on the furnace

model. Furnace model Top 16/R (bench-top model) is delivered without castors. Wear

protective gloves when assembling the castors or when lifting the furnace. Only lift the

furnace from the base. The furnace must NOT be placed on its side, as this will damage

the insulation and heating elements and thus destroy the furnace. Nabertherm accepts

no liability for damage resulting from assembly of the castors.

Pos: 132 /TD/Transport_Montage_Inbetrie bnahme/Erstinbetriebnahme/Die im Liefer umfang enthaltenen Transportrollen kö nnen bei Bedarf unter die Füße des Ofens ges teckt @ 156\mod_1494583 860722_51.docx @ 643824 @ @ 1

If required, the supplied castors can be inserted under the feet of the furnace.

Page 30