Page 1

Operating Instructions

Chamber Furnaces for Annealing,

Hardening and Brazing

N 7/H - N 87/H

-> 01.2016

Original instructions

www.nabertherm.com

Made

in

Germany

Page 2

Copyright

Copyright by

Nabertherm GmbH

Bahnhofstrasse 20

28865 Lilienthal

Federal Republic of Germany

Reg: M01.0071 ENGLISCH

Rev: 2016-06

No responsibility is accepted for the correctness of this information. We

reserve the right to make technical alterations.

2

Page 3

1 Introduction ........................................................................................................................................................... 5

1.1 Product Description ........................................................................................................................................... 6

1.2 Overview of the Complete Furnace ................................................................................................................... 8

1.3 Safeguarding against Dangers Posed by Over-Temperature ........................................................................... 12

1.3.1 Key to the Model Names ............................................................................................................................ 13

1.4 Scope of Delivery ............................................................................................................................................ 13

2 Specifications ....................................................................................................................................................... 15

2.1 Warranty and Liability .................................................................................................................................... 16

3 Safety .................................................................................................................................................................... 16

3.1 Intended Use.................................................................................................................................................... 16

3.2 Requirements for the Furnace Operator .......................................................................................................... 18

3.3 Requirements for the Operating Personnel ...................................................................................................... 19

3.4 Protective Clothing .......................................................................................................................................... 20

3.5 Basic Measures During Normal Operation ..................................................................................................... 21

3.6 Basic Measures in Case of Emergency ........................................................................................................... 21

3.6.1 What to do in an Emergency ....................................................................................................................... 21

3.7 Basic Measures for Servicing and Maintenance.............................................................................................. 23

3.8 Environmental Regulations ............................................................................................................................. 24

3.9 Explanation of the Symbols and Warnings ..................................................................................................... 24

3.10 General Risks with the Furnace ....................................................................................................................... 28

4 Transportation, Installation, and Commissioning ............................................................................................ 30

4.1 Delivery ........................................................................................................................................................... 30

4.2 Unpacking (N 7/H - N 17/HR) ........................................................................................................................ 33

4.3 Unpacking (N 31/H - N 87/H) ......................................................................................................................... 34

4.4 Transportation Securing Equipment/Packaging .............................................................................................. 36

4.5 Constructional and Connection Requirements ................................................................................................ 36

4.5.1 Installation (Furnace Location) ................................................................................................................... 36

4.6 Assembly, Installation, and Connection .......................................................................................................... 38

4.6.1 Venting Exhaust Fumes .............................................................................................................................. 38

4.6.2 Insertion of the Base Plate .......................................................................................................................... 39

4.6.3 Assembling the Controller (Depending on the Model) ............................................................................... 40

4.7 Installation of an Extraction Flue, Extraction Flue with Fan or Extraction Flue with Fan and Catalyst

(Accessories for N 7/H – N 17/HR) .............................................................................................................................. 42

4.7.1 Connecting the Furnace to the Power Supply ............................................................................................. 43

4.8 Commissioning ............................................................................................................................................... 46

4.9 Loading/Charging ........................................................................................................................................... 47

4.10 Recommendations for Heating the Furnace for the First Time ....................................................................... 48

5 Operation ............................................................................................................................................................. 49

5.1 Controller ........................................................................................................................................................ 49

6 Operation, Display and Switch Elements (depending on design) .................................................................... 50

6.1 Turning on the Controller/Furnace .................................................................................................................. 50

6.2 Turning off the Controller/Furnace ................................................................................................................. 51

6.2.1 Handling the Controller .............................................................................................................................. 52

6.3 Opening and Closing the Door ........................................................................................................................ 52

6.3.1 Charging Plate ............................................................................................................................................ 53

3

Page 4

6.4 Operation with Heat Treatment Accessories ................................................................................................... 54

7 Servicing, Cleaning, and Maintenance .............................................................................................................. 55

7.1 Furnace Insulation ........................................................................................................................................... 56

7.2 Shutting Down the Furnace for Servicing, Cleaning, and Maintenance ......................................................... 57

7.3 Regular Maintenance Tasks for the Entire System ......................................................................................... 58

7.4 Regular Maintenance of the Furnace ............................................................................................................... 58

7.5 Regular Maintenance Tasks – Switchgear ...................................................................................................... 59

7.6 Regular Maintenance Tasks – Electrical Testing ............................................................................................ 61

7.7 Regular Maintenance Tasks – Documentation ................................................................................................ 62

7.8 Cleaning Products ........................................................................................................................................... 63

8 Malfunctions ........................................................................................................................................................ 64

8.1 Error Messages of the Controller .................................................................................................................... 64

8.2 Warnings of the Controller .............................................................................................................................. 67

8.3 Malfunctions of the Switchgear ...................................................................................................................... 68

8.4 Controller Check List ...................................................................................................................................... 70

9 Spare Parts/Wearing Parts ................................................................................................................................. 72

9.1 Replacing a Heating Element .......................................................................................................................... 76

9.2 Replacing a Thermocouple .............................................................................................................................. 81

9.3 Electrical Schematics/Pneumatic Schematics ................................................................................................. 83

10 Nabertherm Service ............................................................................................................................................ 83

11 Shut-Down, Dismantling, and Storage............................................................................................................... 84

11.1 Transportation/Return Transportation ............................................................................................................. 85

12 Declaration of Conformity .................................................................................................................................. 86

4

Page 5

Pos: 1 /TD/Einleitung/Überschrift - Einleitung 1 @ 0\ mod_1167823212238_51.docx @ 5139 @ 1 @ 1

1 Introduction

Pos: 2 /TD/Einleitung/Öfen @ 0\mod_1158157227533_51. d ocx @ 2084 @ @ 1

Dear Customer,

Thank you for choosing a quality product from Nabertherm GmbH.

You can be proud that you have chosen a furnace which has been especially tailored to suit

your manufacturing and production conditions.

This product is characterized by

professional workmanship

high performance due to its high efficiency

high-quality insulation

low power consumption

low noise level

simple installation

easy to maintain

high availability of spare parts

Your Nabertherm Team

Pos: 3 /TD/Einleitung/Die in der Anleitung gezeigte n Abbi ldungen können abhängig von Funktion, ... Ofenmodell abweichen @ 24\mod_1337854352242_51.docx @ 161605 @ @ 1

Note

These documents are intended only for buyers of our products and may not be copied or

disclosed to third parties without our written consent. (Law governing copyright and

associated protective rights, German Copyright Law from Sept. 9, 1965)

Protective Rights

Nabertherm GmbH owns all rights to drawings, other documents and authorizations, also in

case of applications for protective rights.

Note

All the figures in the instructions have a descriptive character; in other words, they do not

represent the exact details of the furnace.

Note

The pictures contained in the instruction manual may contain inaccuracies in terms of the

function, design and furnace model.

5

Page 6

Pos: 4 /TD/Einleitung/Produktbeschreibung/Öfen/ Überschrift - Produktbeschreibung 1.1 @ 0\mod_116 7821943807_51.docx @ 5103 @ 2 @ 1

1.1 Product Description

Pos: 5 /TD/Einleitung/Produktbeschreibung/Öfen/ Produktbeschreibung-Bei diesen elektri sch beheizten Öfen handelt es sich um ein Qualitätsproduk t ... @ 15\mod_1305707254935_51.docx @ 117576 @ @ 1

These electrically heated furnaces are a high-quality product which will give you many

years of reliable service if they are properly cared for and maintained. One basic

prerequisite is that the furnace is used the way it was designed to be used.

During development and production a high priority was placed on safety, functionality and

economy.

Pos: 6 /TD/Einleitung/Produktbeschreibung/Öfen/ Produktbeschreibung-Grundaufbau-Kam merof en N7/H - N 87/H_Dental und Laborbereich @ 123\mod_1465207 377133_51.docx @ 544234 @ @ 1

Pos: 7 /TD/Einleitung/Produktbeschreibung/ Öfen/ Überschrift - Zusätzlich zeichnet sich dieses Pr odukt aus durch: @ 15\mod_1305713428306_51.doc x @ 117724 @ @ 1

Pos: 8 /TD/Einleitung/Produktbeschreibung/Öfen/ Produktbeschreibung-Zusätzlich zeic hnet ...: Kammerofen N7/H - N 87/H (Modell 2015) - Katalog @ 123\mod_1465207169834_51.docx @ 544008 @ @ 1

Pos: 9 /TD/Einleitung/Produktbeschreibung/Öfen/ Produktbeschreibung-Zusätzlich zeic hnet ...: Kammerofen N7/H - N 87/H (Modell 2015) - Ofenspezifisch @ 123\mod_1465287126336_51.docx @ 545416 @ @ 1

Pos: 10 /TD/Einleitung/Produktbeschreibung/ Öfen/Überschrift - Zusatzausstattung (Einzug Mitte) @ 39\mod_1364984085402_51.docx @ 221200 @ @ 1

Pos: 11 /TD/Einleitung/Produktbeschreibung/ Öfen/Produktbeschreibung - Zusatzausstattung: Temperaturwählbegrenzer mit einstellbarer ... @ 116\mod_1459332570794 _51.docx @ 459785 @ @ 1

Pos: 12 /TD/Einleitung/Produktbeschreibung/ Öfen/Produktbeschreibung - Zubehör: Prozessste uer ung und -dokumentation über VCD-Softwarepaket zur Über wa @ 116\mod_1459332710604_51.docx @ 459839 @ @ 1

Pos: 13 /TD/Einleitung/Produktbeschreibung/ Öfen/Überschrift - Zubehör (Einzug Mitte) @ 36\mod_1359 971094458_51.docx @ 208406 @ @ 1

Pos: 14 /TD/Einleitung/Produktbeschreibung/ Öfen/Produktbeschreibung - Zubehör: Abzugskamin mit Ventilator oder Katalysator (nicht für N 31/H-N 87/ H) @ 123\mod_1465378085414_51.docx @ 546202 @ @ 1

Pos: 15 /TD/Einleitung/Produktbeschreibung/ Öfen/Produktbeschreibung - Zubehör: NTLog für Naber ther m-Controller: Aufzeichnen...Prozessdaten mit USB-S @ 123\mod_1465287433347_51.docx @ 545442 @ @ 1

Pos: 16 /TD/Einleitung/Produktbeschreibung/ Öfen/Produktbeschreibung - Zubehör: Chargierpla tte @ 123\mod_1465287709579_51.docx @ 545468 @ @ 1

Pos: 17 /TD/Einleitung/Produktbeschreibung/ Öfen/Produktbeschreibung - Zubehör: Glüh- und Härtef olien @ 123\mod_1465287729726_51.docx @ 545494 @ @ 1

Pos: 18 /TD/Einleitung/Produktbeschreibung/ Öfen/Produktbeschreibung - Zubehör: Begasungskäs ten für Schutzgasatmosphäre mit zusätzlichem Char gen therm @ 123\mod_1465287732847_51.docx @ 545520 @ @ 1

Pos: 19 /TD/Einleitung/Produktbeschreibung/ Öfen/Produktbeschreibung - Zubehör: Manuelles oder automatisches Begasungssystem. @ 116\mod_14593 32575272_51.docx @ 459812 @ @ 1

Pos: 20 /TD/Einleitung/Produktbeschreibung/ Öfen/Produktbeschreibung - Zubehör: Schutzgashär tesystem @ 123\mod_1465287735885_51.docx @ 545546 @ @ 1

These universal chamber furnaces with radiation heating are designed for tough heat

treatment applications. They are perfect for processes in toolmaking and in the hardening

shop, such as annealing, hardening and forging. A wide variety of accessories enables these

furnaces to be tailored to the relevant application.

Other Characteristics of this Product are:

Heating from three sides (both sides and the floor)

Heating elements on carrier tubes ensure free heat radiation and a long service life

Bottom heating protected by heat-resistant SiC tiles

Multi-layer insulation with high-quality refractory insulation inside the furnace

Exhaust air opening on the left side of the furnace, from N 31/H in the rear wall

Models N 7/H – N 17/HR are designed as tabletop models

Base included from model N 31/H

Parallel swing door, which opens downward; if required, also available with lift door

that opens upward (N 31/H to N 87/H)

Top part of door with stainless steel plates to prevent burning when the door is opened

at high temperatures (from model N 31/H)

Temperature uniformity according to DIN 17052-1 to +/- 10 °C

Door movement cushioned with gas springs (from model N 31/H)

Additional Equipment

Over-temperature limiter with adjustable cutout temperature for thermal protection

class 2 in accordance with EN 60519-2 as temperature limiter to protect the furnace

and load

Process control and documentation via VCD software package for monitoring,

documentation and control

Accessories

Extraction flue with fan or catalyst (not for model N 31/H – N 87/H)

NTLog for Nabertherm controller: Recording process data with a USB flash drive

Charging plate

Annealing and hardening foil

Protective gas boxes for protective gas atmosphere with additional charge

thermocouple Type K

Manual or automatic gas supply system

Protective gas hardening system

6

Page 7

Pos: 21 /TD/Einleitung/Produktbeschreibung/ Öfen/Produktbeschreibung - Zubehör: Digitales Temperaturmessgerät zur Messung der Temperatur im Begasun gs @ 123\mod_1465287738965_51.docx @ 545572 @ @ 1

Pos: 22 /TD/Einleitung/Produktbeschreibung/ Öfen/Produktbeschreibung - Zubehör: Rollengäng e @ 123\ mod_1465287743003_51.docx @ 545598 @ @ 1

Pos: 23 /TD/Einleitung/Produktbeschreibung/ Öfen/Produktbeschreibung - Zubehör: Kühlstation @ 123\ mod_1465288243136_51.docx @ 545624 @ @ 1

Digital temperature measurement device to measure the temperature in the protective

gas boxes

Roller conveyors

Cooling station

7

Page 8

Pos: 24 /TD/Einleitung/Lieferumfang/Öfen/Üb er schrift - Gesamtübersicht der Anlage @ 1\mod_1174302 6369 92_51.docx @ 11332 @ 2 @ 1

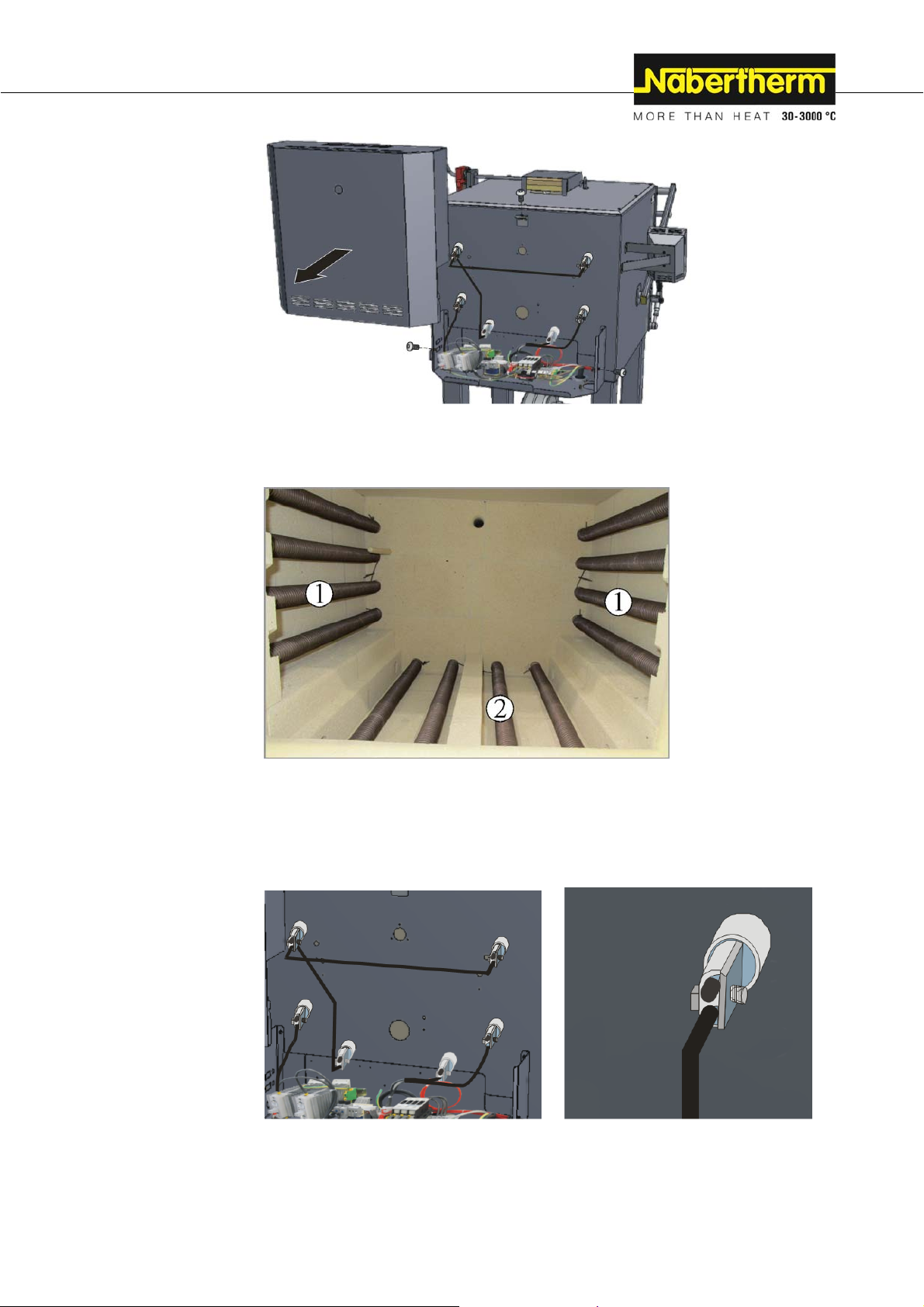

1.2 Overview of the Complete Furnace

Pos: 25 /TD/Einleitung/Lieferumfang/Öfen/Üb er schrift - Ofenmodell N 7/H - N 17/HR (Einzug links) @ 122\mod_146 4942440905_51.docx @ 543106 @ @ 1

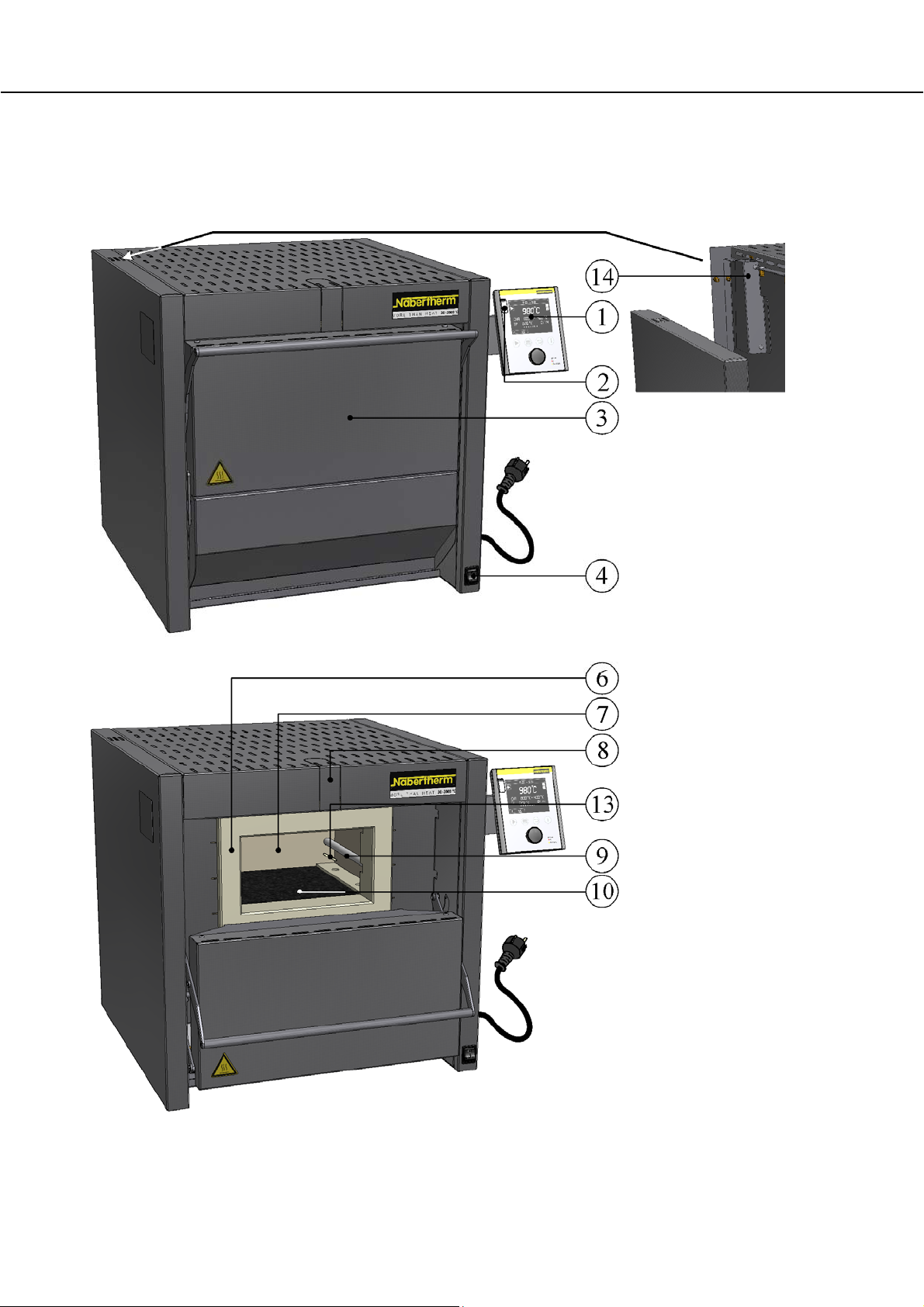

Furnace model N 7/H – N17/HR (similar to picture)

Pos: 26 /TD/Einleitung/Lieferumfang/Öfen/Ge sa mtübersicht Kammerofen N 7/H (Modell 2015) @ 123\mod_1464 942615333_51.docx @ 543132 @ @ 1

Fig. 1: Overview: Example shows chamber furnace N 7/H (table-top model) (similar to picture)

8

Page 9

Pos: 27 /TD/Einleitung/Lieferumfang/Öfen/Üb er schrift - Ofenmodell N 31/H - N 87/H (Einzug links) @ 123\mod_14 64942752748_51.docx @ 543184 @ @ 1

Furnace model N 31/H - N 87/H (similar to picture)

Pos: 28 /TD/Einleitung/Lieferumfang/Öfen/Ge sa mtübersicht Kammerofen N 41/H (Modell 2015) @ 123\mod_146 4942670128_51.docx @ 543158 @ @ 1

Fig. 2: Overview: Example chamber furnace N 41/H (similar to picture)

9

Page 10

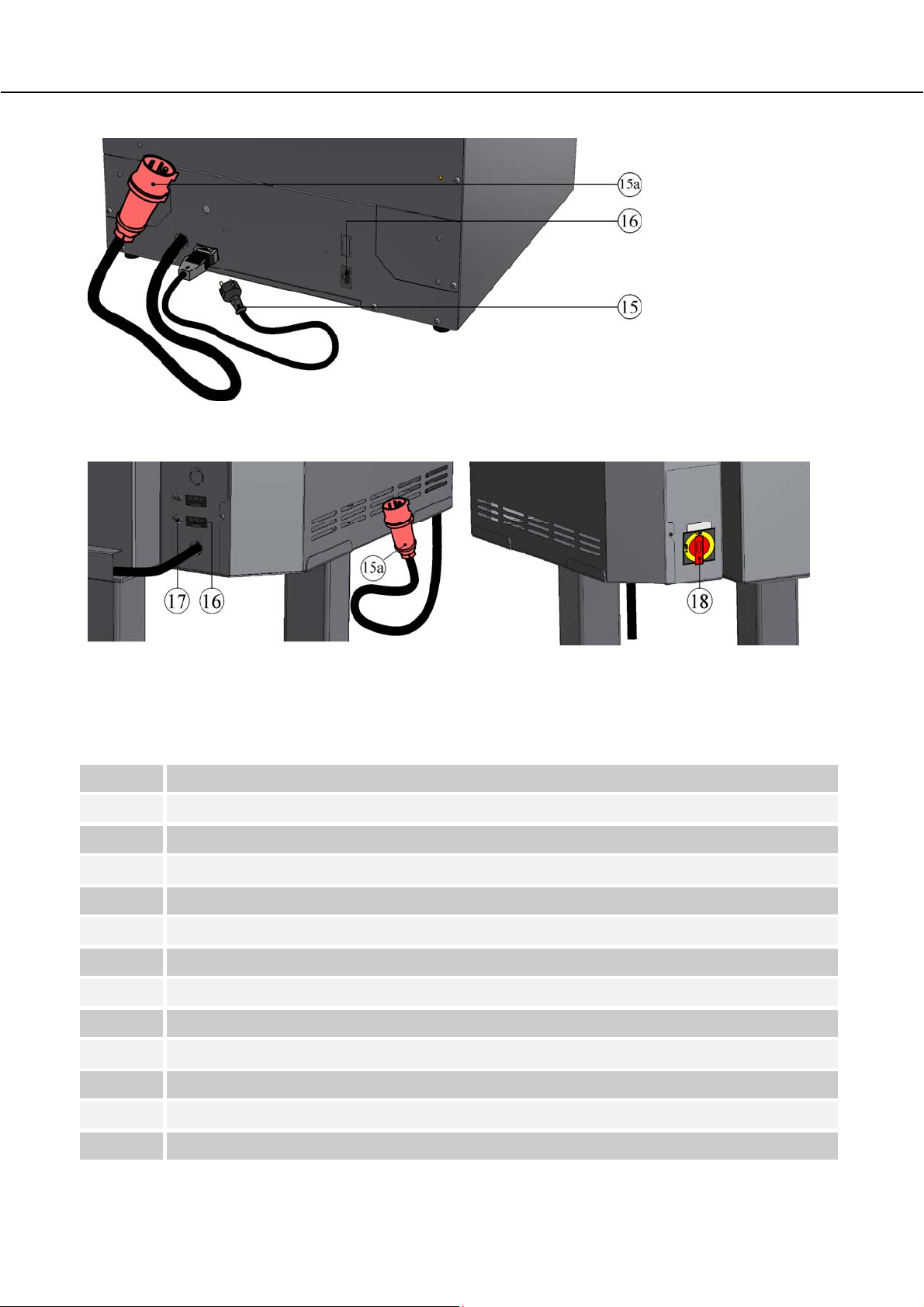

Pos: 29 /TD/Einleitung/Lieferumfang/Öfen/Ge sa mtübersicht Rückansicht N 7/H - N 17/HR - Kammerofen (Model l 201 5) @ 123\mod_1464951930103_51.docx @ 543370 @ @ 1

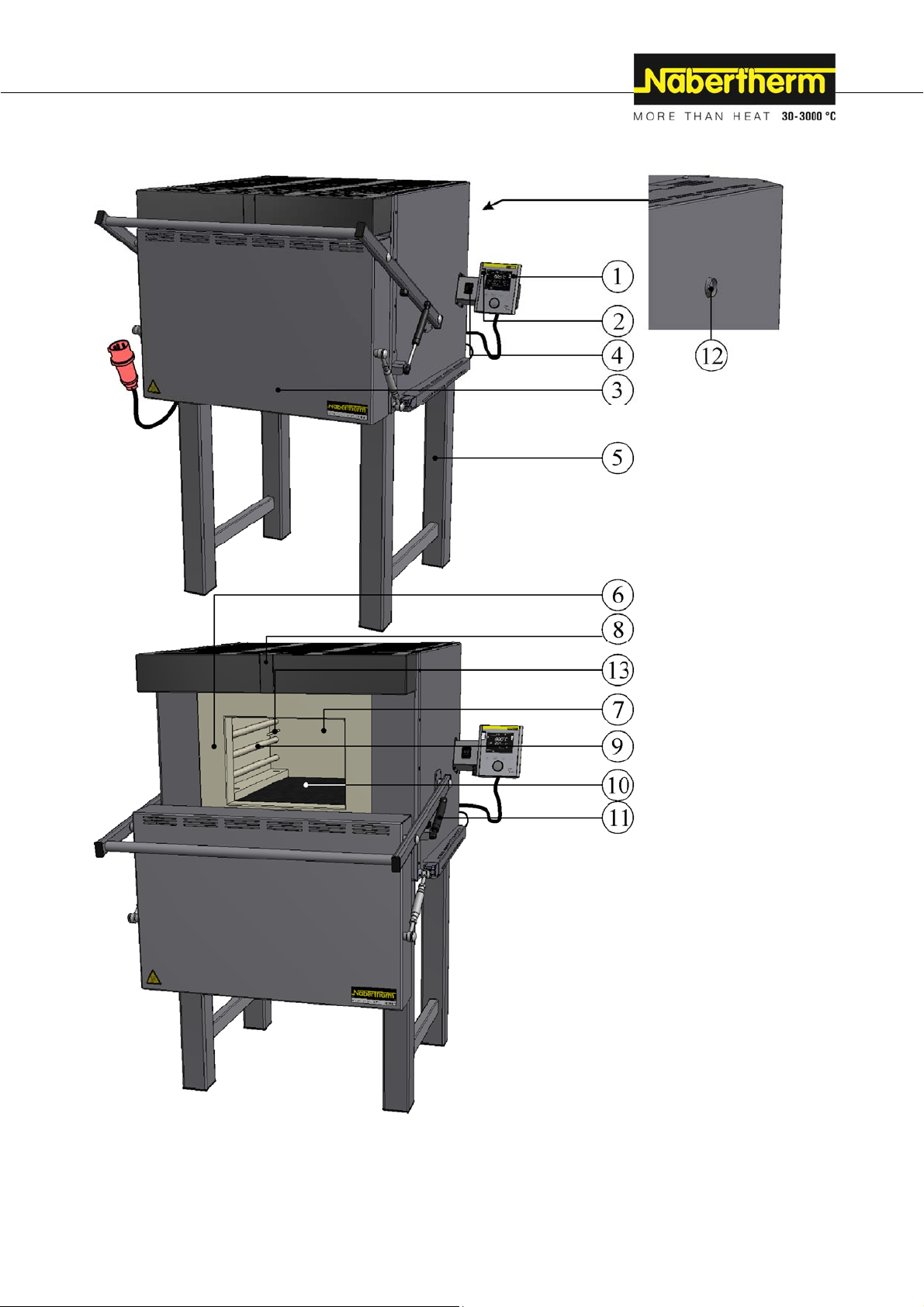

Fig. 3: Chamber furnace, rear view N 7/H – N 17/HR (similar to picture)

Pos: 30 /TD/Einleitung/Lieferumfang/Öfen/Ge sa mtübersicht Rückansicht N 31/H - N 87/H - Kammerofen (Modell 20 15) @ 123\mod_1465198382694_51.docx @ 543982 @ @ 1

Furnace model N 31/H – N 87/H with power supply

cable (depending on connection voltage)

Furnace model N 31/H – N 87/H with fixed

power connection and main switch (depending on

connection voltage)

Fig. 4: Chamber furnace, rear view N 31/H – N 87/H (similar to picture)

Pos: 31 /TD/Einleitung/Lieferumfang/Öfen/Ge sa mtübersicht_M01.0071_Tabelle Nr. und Benennung der verbauten Teile für N 7H - N87/H @ 122\mod_1464256548621_51. doc x @ 541668 @ @ 1

No. Name

1

2

3

4

5

6

7

8

9

10

Controller B400/C440/P470 (depending on model)

USB interface (NTLog for Nabertherm Controller: Recording Process Data with a USB Flash Drive)

Parallel swing door, opens downward

Power switch with integrated fuse (switching furnace on/off)

Base included from model N 31/H

Multi-layer insulation with high-quality refractory insulation inside the furnace

Furnace chamber

Opening for a gas supply system (remove perforation)

Heating elements on carrier tubes ensure free heat radiation and a long service life

Bottom heating protected by heat-resistant SiC tiles

11

12

10

Door movement cushioned with gas springs (from model N 31/H – N 87/H)

Exhaust air opening

Page 11

No. Name

13

14

15

15a

16

17

18

Pos: 32 /TD/Einleitung/Produktbeschreibung/ Öfen/Überschrift - Zusatzausstattung (Einzug lin ks) @ 36\mod_1360061559626_51.docx @ 208485 @ @ 1

Additional Equipment

Pos: 33 /TD/Einleitung/Lieferumfang/Öfen/Ge sa mtübersicht Zusatzausstattung_Zubehör: TW B-TWW_B410_C450_P480 (Modell 2015) @ 116\mod_145881006085 9_51.docx @ 458551 @ @ 1

Thermocouple

Extraction flue (Model N 7/H – N 17/HR)

Power plug with snap-in coupling (to 3600 watts)

CEE power plug (from 3600 watts) (depending on connection voltage)

Additional power connection (for accessories)

Fuse for additional power connection (for accessories)

Main switch (depending on connection voltage)

Fig. 5: Example (similar to picture)

Pos: 34 /TD/Einleitung/Produktbeschreibung/ Öfen/Überschrift - Zubehör (Einzug links) @ 53\mod_138 9868020284_51.docx @ 263175 @ @ 1

Accessories

Pos: 35 /TD/Einleitung/Lieferumfang/Öfen/Ge sa mtübersicht Zusatzausstattung_Zubehör: A bzugsk amine_Katalysatoren (N 7/H - N 17/HR) @ 123\mod_146537 8887405_51.docx @ 546228 @ @ 1

Over-temperature limiter with adjustable cutout

temperature for thermal protection class 2 in accordance

with EN 60519-2 as temperature limiter to protect the

furnace and load

Extraction flue with fan, to improve extraction of

exhaust gases from the furnace. Can be switched with

Controller B400 - P480, depending on the program (only

for N 7/H – N 17/HR)

Catalyst to clean organic components in the exhaust air. The

organic components are catalytically incinerated at approx.

600 °C; i.e. separated into carbon dioxide and steam. This

largely eliminates smells. With Controllers B400 - C440, the

catalyst can be switched in relation to the program (only for

N 7/H – N 17/HR)

*Note: If other controllers are used, an adapter cable must be ordered for connection to a separate socket. The device is

activated when it is plugged in.

Fig. 6: Example: (similar to picture)

11

Page 12

Pos: 36 /TD/Einleitung/Produktbeschreibung/ Öfen/Überschrift - Absicherung von Gefahren bei Übert emperatur @ 37\mod_1362489730884_51.docx @ 213987 @ 2 @ 1

Safety control circuit

1.3 Safeguarding against Dangers Posed by Over-Temperature

Pos: 37 /TD/Einleitung/Produktbeschreibung/ Öfen/Sicherheitseinrichtung - Überwachung der Ofenr aumtemperatur (TWB-TWW) - Beschreibung @ 37\mod_1 3624 91214270_51.docx @ 214092 @ @ 1

Over-temperature limiters with manual reset/with automatic reset to protect against overtemperature in the furnace chamber are available for Nabertherm GmbH furnaces either as

a standard feature (depending on the model series) or as additional equipment (customized

design).

The over-temperature limiter with manual reset/with automatic reset monitors the furnace

chamber temperature. The display shows the most recently set cut-off temperature. If the

furnace chamber temperature rises about the pre-set cut-off temperature the heating is shut

Pos: 38 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Warnsymbol_Gefahr - Absicherung von Gefahren bei Übertemperatur am TWB- TWW @ 37\mod_1362490404893_51.docx @ 214067 @ @ 1

down to protect the furnace, the charge and/or the operating equipment.

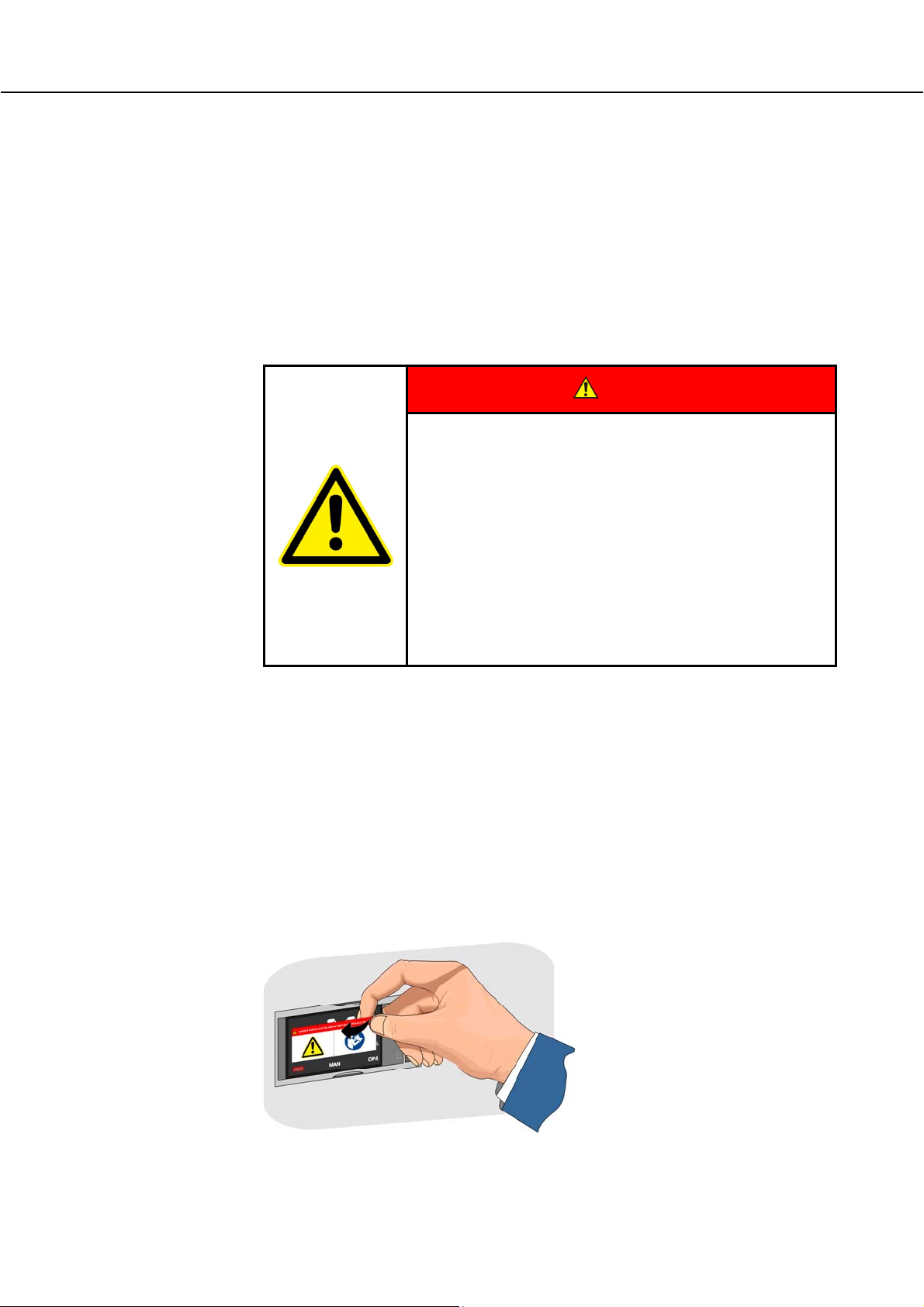

DANGER

• Danger caused by incorrectly entered cut-off

temperature at the over-temperature limiter with

manual reset/over-temperature limiter with automatic

reset.

• Mortal danger

• If, as a result of over-temperature from the charge and/or the

operating equipment, a charge is likely to be damaged at this preset cut-off temperature of the over-temperature limiter with

manual reset/over-temperature limiter with automatic reset, or if

the charge itself becomes a source of danger for the furnace or its

surroundings, the cut-off temperature must be reduced at the

over-temperature limiter with manual reset/automatic reset to the

maximum permissible value.

Pos: 39 /TD/Betrieb_Bedienung/Vor Inbetriebnah me d es Ofens ist die Bedienungsanleitung... (TWB-TWW) - Text @ 37\mod_1362494080225_51.docx @ 214142 @ @ 1

Pos: 40 /TD/Betrieb_Bedienung/die maximale Sollt em per atur des Wärmeprogramms Controller zwischen 5 °C und 30 °C ( TWB-TWW) @ 39\mod_1363784610371_51.docx @ 218500 @ @ 1

Pos: 41 /TD/Betrieb_Bedienung/Aufkleber vom TWB/ TWW abziehen - Grafik @ 37\mod_1362492020088_51.docx @ 214117 @ @ 1

Read the operating instructions of the over-temperature limiter with manual reset/with

automatic reset before starting the furnace. The safety sticker must be removed from the

over-temperature limiter with manual reset/with automatic reset. Any time a change is

made in the heat treatment program, the maximum permissible cut-off temperature (alarm

trigger temperature) at the over-temperature limiter with manual reset/with automatic reset

must be checked or re-entered.

We recommend setting the maximum setpoint temperature of the heating program in the

limiter between 5 °C and 30 °C, depending on the physical characteristics of the furnace,

below the trigger temperature of the over-temperature limiter with manual reset/with

automatic reset. This prevents an unwanted triggering of the over-temperature limiter with

manual reset/with automatic reset.

Description and function, see the

Operating Instructions of the overtemperature limit controller/guard

12

Fig. 7: Removing the sticker (similar to picture)

Page 13

Pos: 42 /TD/Einleitung/Produktbeschreibung/ Öfen/Überschrift - Entschlüsselung der Modellbez eichnung @ 2\mod_1184245078907_51.docx @ 19775 @ 3 @ 1

1.3.1 Key to the Model Names

Pos: 43 /TD/Einleitung/Produktbeschreibung/ Öfen/Entschlüssellung der Modellbezeichnung Ka mmerofen N 7/H - N 87/H (Modell 2015) @ 123\mod_1465208363287_51. docx @ 544390 @ @ 1

Example Explanation

N 41/H

N = Chamber furnace

N 41/H

7 = 9 liter furnace (volume in l)

11 = 11 liter furnace (volume in l)

17 = 17 liter furnace (volume in l)

25 = 25 liter furnace (volume in l)

31 = 31 liter furnace (volume in l)

41 = 41 liter furnace (volume in l)

61 = 61 liter furnace (volume in l)

87 = 87 liter furnace (volume in l)

N 41/HR

Pos: 44 /TD/Einleitung/Produktbeschreibung/ Öfen/Entschlüssellung der Modellbezeichnung N7/ H - N 87/H - Grafik @ 123\mod_1465210929875_51.docx @ 544572 @ @ 1

Pos: 45 /TD/Einleitung/Lieferumfang/Öfen/Über schrift - Lieferumfang @ 0\mod_1167822508130_51. docx @ 5112 @ 2 @ 1

13 = Tmax. 1300 °C (2372 F)

H = High temperature Tmax. 1280 °C (2336 F)

R = Increased power

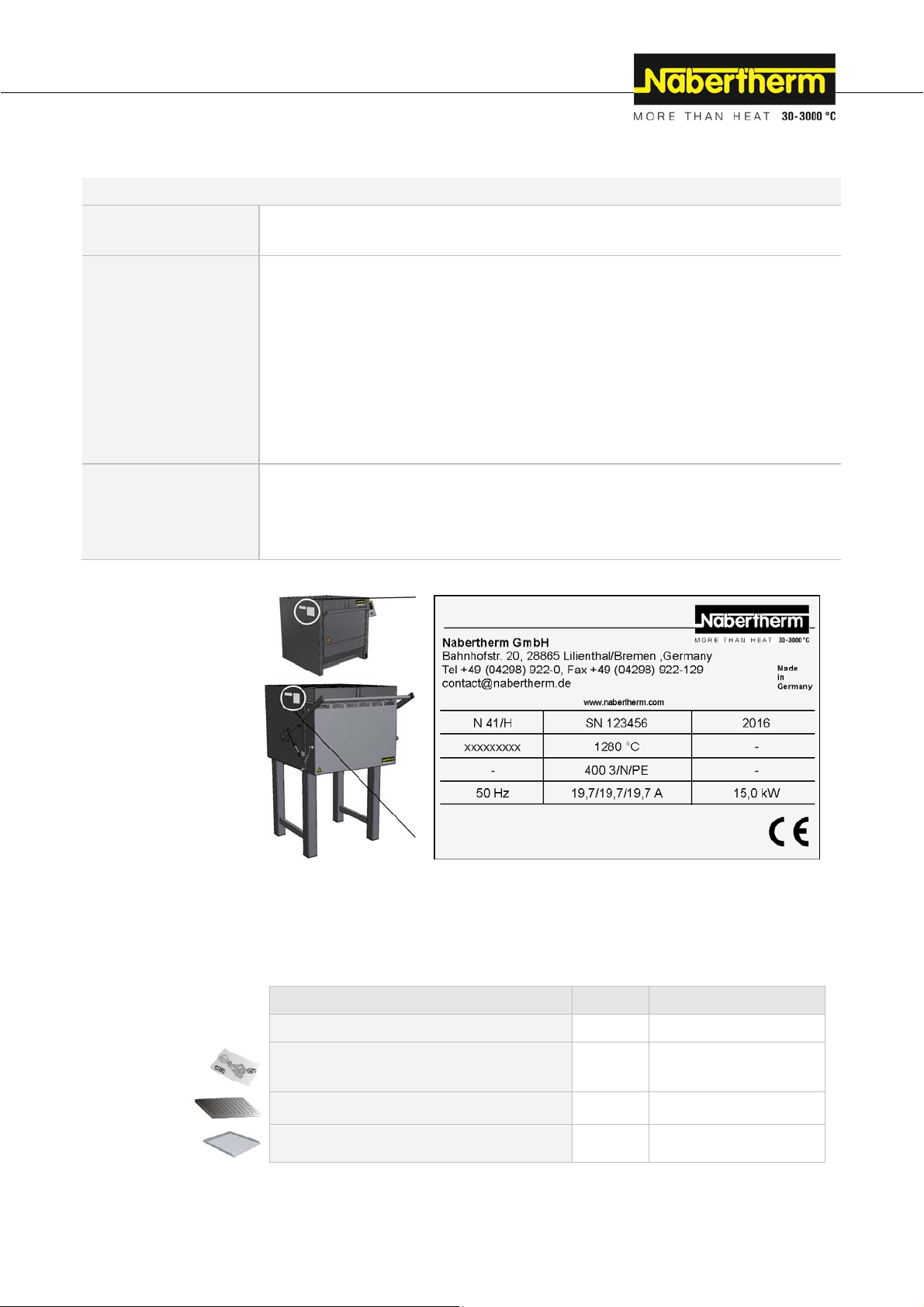

Fig. 8: Example model designation (type plate)

1.4 Scope of Delivery

Pos: 46 /TD/Einleitung/Lieferumfang/Öfen/Lief er umfang - Kammerofen N7/H - N 87/H (Modell 2015) @ 123\mod_146521 1806141_51.docx @ 544706 @ @ 1

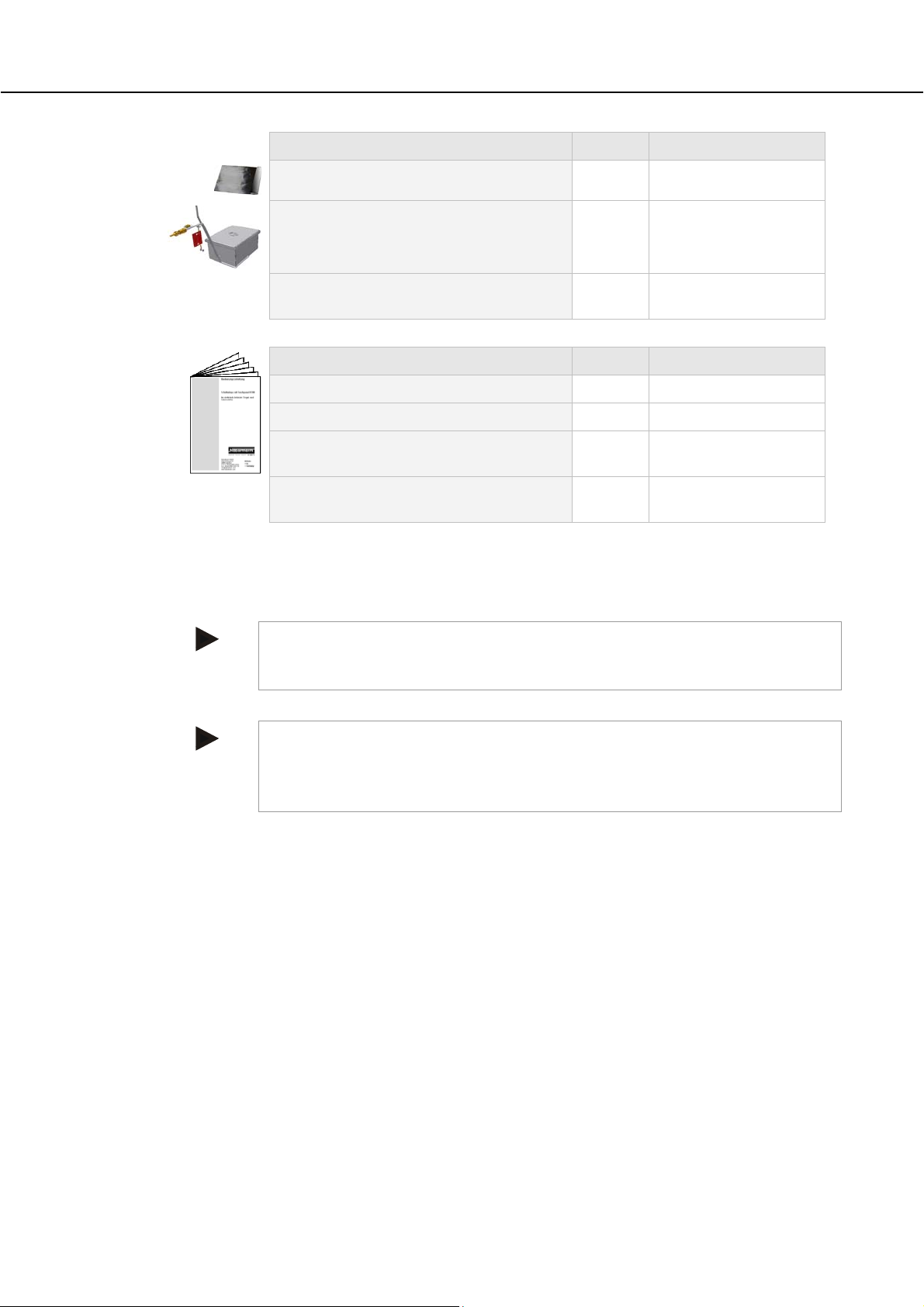

The scope of delivery includes:

System components Quantity Comment

Chamber furnace 1 x Nabertherm GmbH

Power cable1) 1 x Nabertherm GmbH

SiC floor plate 1 x Nabertherm GmbH

Charging plate2) 1 x Nabertherm GmbH

13

Page 14

System components Quantity Comment

)

Annealing and hardening foil2)

4

Nabertherm GmbH

Protective gas box1) 1 x Nabertherm GmbH

Other components, variable depending on the

- - - See shipping documents

particular design

Document type Quantity Comment

Operating Instructions 1 x Nabertherm GmbH

Operating Manual for Controller 1 x Nabertherm GmbH

Pos: 47 /TD/Betrieb_Bedienung/Die mitgelieferte n Unterlagen beinhalten nicht zwangsläufig elektr ische Schaltpläne bzw. Pneuma ... @ 47\mod_13800280746 16_51.docx @ 247668 @ @ 1

Pos: 48 /TD/Einleitung/Technische Daten/Öfen/ Üb er schrift - Technische Daten - mit Hinweis @ 0\mod_116782 2840 737_51.docx @ 5121 @ 1 @ 1

Operating Instructions for

Protective Gas and Carburization Systems1)

Other documents, variable depending on the

1 x Nabertherm GmbH

1 x

particular design

1)

included with delivery depending on design/furnace model

2)

included with delivery if required, see shipping documents

3)

quantity depends on furnace model

4)

quantity as required, see shipping documents

Note

Store all documents carefully. All the functions of this furnace were tested during

manufacturing and prior to shipping.

Note

The documents included do not always contain the electrical schematics and pneumatic

schematics.

If you need the respective schematics they can be ordered from Nabertherm Service.

14

Page 15

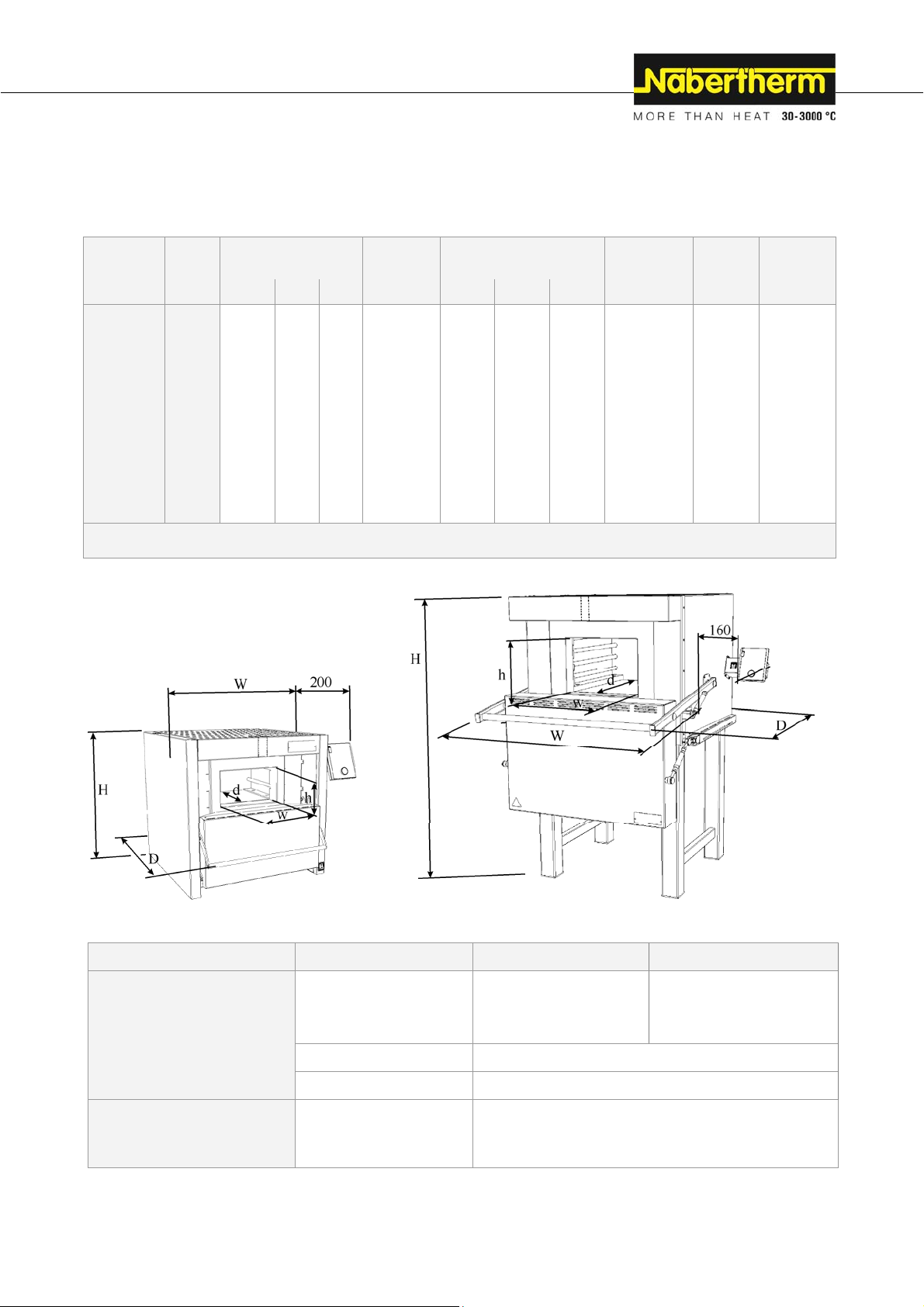

2 Specifications

Electrical specifications are on the type plate located on the side of the furnace.

Pos: 49 /TD/Einleitung/Technische Daten/Öfen/ Mo de ll-Tabelle für Kammeröfen N 7/H - N 87/H (Modell 2015) @ 123\mod_1 465223703739_51.docx @ 545336 @ @ 1

Model Tmax Inner dimensions in

mm

°C w d h in l W D H in kW in kg

N 7/H1 1280 250 250 140 9 600 650 600 3,0 60 180

N 11/H1 1280 250 350 140 11 600 750 600 3,5 70 180

N 11/HR1 1280 250 350 140 11 600 750 600 5,5 70 120

N 17/HR1 1280 250 500 140 17 600 900 600 6,4 90 120

N 31/H 1280 350 350 250 31 880 1100 1340 15,0 210 105

N 41/H 1280 350 500 250 41 880 1250 1340 15,0 260 120

N 61/H 1280 350 750 250 61 880 1500 1340 20,0 400 120

Volume Outer dimensions in mm Heating

power

Weight Minutes

to Tmax2

N 87/H 1280 350 1000 250 87 880 1750 1340 25,0 480 120

1

table-top model

2

If connected at 230 V 1/N/PE rsp. 400 V 3/N/PE

Pos: 50 /TD/Einleitung/Technische Daten/Öfen/ Ma ß e des Ka mmerofens N 7/H - N 87/H (Modell 2015) - Grafik @ 123\mod_14652239 74241_51.docx @ 545362 @ @ 1

Fig. 9: Dimensions

Pos: 51 /TD/Einleitung/Technische Daten/Öfen/ Tabe lle Technische Daten für Ofenmodell Kammerofen N7/H - N 87/ H (Modell 2015) @ 123\mod_1465225518930_51.docx @ 54538 8 @ @ 1

Electrical connection 1-phase: 3-phase:

1

, N 17/HR1

Furnace model

N 7/H

N 11/H

N 11/HR

N 31/H, N 41/H

N 61/H, N 87/H

Thermal protection class

Voltage (V): See type plate on furnace

Frequency (Hz): See type plate on furnace

according to DIN EN 60519-2

Furnaces:

without safety controller: Class 0

with safety controller: Class 2

15

Page 16

Protection rating

Furnaces:

Protection type

Ambient conditions for

electrical equipment

Weights

Pos: 52 /TD/Einleitung/Technische Daten/Öfen/ Tabe lle Dauerschalldruckpegel < 80 dB(A) - 2 @ 1\mod_1170750 985 488_51.docx @ 8913 @ @ 1

Temperature: Humidity:

Furnace with accessories Varies (see shipping documents)

Emissions

Pos: 53 /TD/Einleitung/Technische Daten/Öfen/ Lege nde: 1Heizung nur zwischen zwei Phasen @ 77\mod_1415782894 129_51.docx @ 338720 @ @ 1

1

Heating only between two phases

Pos: 54 /TD/Einleitung/Gewährleistung_Haftu ng/ Überschrift - Gewährleistung und Haftung 1.1 @ 0\mod_11 67822979492_51.docx @ 5130 @ 2 @ 1

2.1 Warranty and Liability

Pos: 55 /TD/Einleitung/Gewährleistung_Haftung/ Öfen und Schaltanlagen - Gewährleistung und Haftung @ 0\ m od_1 157536440972_51.docx @ 1569 @ @ 1

As regards warranty and liability, the normal Nabertherm warranty terms apply,

unless individual terms and conditions have been agreed. However, the following

conditions also apply:

Warranty and liability claims for personal injury or damage to property shall be excluded if

they are attributable to one or more of the following causes:

Everyone involved in operation, installation, maintenance, or repair of the furnace

must have read and understood the operating instructions. No liability will be accepted

for damage or disruptions to operation resulting from non-compliance with the

operating instructions.

Not using the furnace as intended,

Improper installation, start-up, operation, or maintenance of the furnace,

Operation of the furnace with defective safety equipment or improperly installed or

non-functioning safety and protective equipment,

Not observing the references in the operating instructions to transportation, storage,

installation, start-up, operation, maintenance, or equipping the furnace,

Making unauthorized changes to the furnace,

Making unauthorized changes to the operating parameters,

Making unauthorized changes to the parameterization, the settings, or the program,

Original parts and accessories are designed especially for Nabertherm furnaces.

Replace parts only with original Nabertherm parts. Otherwise the warranty will be

void. Nabertherm accepts absolutely no liability for damage caused by using parts that

are not original Nabertherm parts.

Catastrophes due to third-party causes and force majeure.

Pos: 56 /TD/Sicherheit/Überschrift - Sicher heit @ 0\mod_1158843961540_51.docx @ 3103 @ 1 @ 1

§

1

IP20

+5 °C to + +40 °C

max. 80% non-condensing

Continuous sound pressure

level:

< 80 dB(A)

3 Safety

Pos: 57 /TD/Sicherheit/Überschrift - Bestimmung sge mäße Verwendung @ 0\mod_1167823503921_51.docx @ 5148 @ 2 @ 1

3.1 Intended Use

Pos: 58 /TD/Sicherheit/Bestimmungsgemäße Verwendun g allgemeiner Ofen-Anlagen_Materialien - Teil 1 @ 24\ mod_1337938775936_51.docx @ 161920 @ @ 1

Safety

Pos: 59 /TD/Sicherheit/Bestimmungsgemäße Verwendun g Kammeröfen - N 7/H - N87/H (Dental_Labor_Thermprozess) @ 123\ mod_1465289960174_51.docx @ 545650 @ @ 1

16

The Nabertherm furnace was designed and built in conformance with a careful selection of

the applicable harmonized standards and other technical specifications. Hence, it

corresponds to the state of the art and assures the greatest degree of safety.

Only materials whose characteristics and melting temperatures are known may be heated.

Consult any available safety-related material data sheets.

These universal chamber furnaces with radiation heating are designed for tough heat

treatment applications. They are perfect for processes in toolmaking and in the hardening

Page 17

Pos: 60 /TD/Sicherheit/Von den im Ofen eingesetzten Mater ialien bzw. Ausgasungen können sich unter Umständen Sc hadstoffe .. @ 45\mod_1377243392217_51.docx @ 242065 @ @ 1

Pos: 61 /TD/Sicherheit/Es dürfen nur die Materialien ein gesetzt werden, deren Eigenschaften und Schmelzte mperaturen ... @ 49\mod_1385394498752_51.docx @ 254350 @ @ 1

Pos: 62 /TD/Sicherheit/Eine andere oder darüber hinausg ehende Benutzung, wie z.B. die Verarbeitung ... @ 45\mod_1377242071687_51.docx @ 242040 @ @ 1

Safety

Pos: 63 /TD/Sicherheit/Bei Öfen mit Temperaturwählbegrenzer muss die Abschalttemperatur so eingestellt werden ... @ 45\mod_1377244417122_51.docx @ 242390 @ @ 1

Pos: 64 /TD/Sicherheit/Veränderungen am Ofen, müssen mit Nabertherm schriftlich abgestimmt werden ... @ 45\mod_1377243398694_51. docx @ 242240 @ @ 1

Pos: 65 /TD/Sicherheit/Die Aufstellhinweise und Si cherheitsbestimmungen sind einzuhalten, ander nfalls gilt der Ofen als ... @ 45\mod_1377243410507_51.docx @ 242265 @ @ 1

Pos: 66 /TD/Sicherheit/Das Öffnen des Ofens im heißen Zusta nd über 200 °C (392 °F) kann zu einem erhöhtem Verschleiß ... @ 39\mod_1364289911635_51.docx @ 219945 @ @ 1

Pos: 67 /TD/Sicherheit/Der Betrieb mit Kraftquel len, Produkten, Betriebsmitteln, Hilfsstoffen us w., ... @ 45\mod_1377241083975_51.docx @ 241990 @ @ 1

Pos: 68 /TD/Allgemeine Hinweise (für alle Anleitungen) /Hinweis - Dieser Ofen ist für die gewerbliche Anwendung ... Der Ofen ist nicht für die Erwärmung ... @ 19\mod_1315980979500_51.docx @ 134548 @ @ 1

shop, such as annealing, hardening and forging. A wide variety of accessories enables these

furnaces to be tailored to the relevant application.

Under certain circumstances gases or materials may be released from the materials in

the furnaces that settle on the insulation or the heating elements and destroy them. If

applicable, read the labels and instructions on the packaging of materials that

you use.

Only materials whose characteristics and melting temperatures are known may be

heated. Consult any available safety data sheets of the materials. Any other use

beyond this is improper, including the processing of products other than those for

which the furnace was intended as well as handling hazardous materials or materials

dangerous to health, and must be approved in writing by the manufacturer Nabertherm

GmbH.

Any other use, such as processing of products other than those for which the furnace

was intended as well as handling hazardous materials or materials dangerous to health

is deemed IMPROPER and such uses must be approved in writing by Nabertherm.

Furnaces with over-temperature limit controllers must have their shut-down

temperatures set to prevent any overheating of the material.

The set-up instructions and safety regulations must be followed, otherwise the furnace

will be considered improperly used, effectively cancelling any claims against

Nabertherm GmbH. The EC Declaration of Conformity will cease to be valid if any

modifications are made to the machine without our approval.

The set-up instructions and safety regulations must be followed, otherwise the furnace

will be considered improperly used, effectively cancelling any claims against

Nabertherm GmbH.

Opening the furnace while it is still hot, over 200 °C (392 °F), can lead to increased

wear of the following components: insulation, door seal, heating elements and furnace

housing. No liability shall be accepted for any damage to the goods or the furnace

resulting from non-compliance with this warning.

Operation with power sources, products, operating equipment, auxiliary materials, etc.,

which are listed as hazardous or which may in any way harm the health of the operator is

prohibited.

The furnace must not be filled with materials or substances that release explosive gases or

vapors. Only materials and substances whose properties are known may be used.

- This furnace was designed for commercial use. The furnace is not designed

for heating food, animals, wood, grain, etc.

- The furnace must not be used to heat the workplace.

- Do not use the furnace to melt ice or for similar purposes.

- Do not use the furnace as a clothes dryer.

Caution

Applicable safety instructions are contained in individual chapters.

17

Page 18

Pos: 69 /TD/Sicherheit/Überschrift - Für hier aus r esultierende Schäden haftet der Betreiber @ 10\mod_125673 1411117_51.docx @ 68223 @ @ 1

Pos: 70 /TD/Allgemeine Hinweise (für alle Anleitungen) /Hinweis - Dieser Ofen verfügt über keine Sicherhei t stechnik für Prozesse, ..-nicht brennbare Gase @ 8\ mo d_12 35038699771_51.docx @ 51483 @ @ 1

Pos: 71 /TD/Allgemeine Hinweise (für alle Anleitungen) /Hinweis - Dieses Produkt entspricht nicht der ATEX- Richtlinie und darf nicht ..-nicht brennbare Gase @ 2\ mod_1184228756893_51.docx @ 19686 @ @ 1

The operator is liable for any resulting damages.

Caution

Operating the furnace with explosive gases or mixtures, including explosive gases or

mixtures created as a result of heating/drying, is prohibited.

This furnace features no safety technology for processes which produce combustible

mixtures, for example debinding.

If the furnace is still used for such processes despite this fact, the concentration of organic

gas mixtures in the furnace must never exceed 3% of the lower explosion limit (LEL). This

pre-requisite applies not only to normal operation but, in particular, to exceptional

situations such as process disruptions (caused, for example, by the failure of a power unit).

You must ensure that the furnace is adequately ventilated and vented.

Nabertherm offers a broad range of furnaces which were especially developed for processes

involving the use of combustible gas mixtures.

Note

This product does not comply with the ATEX Directive and may not be used in ignitable

atmospheres. It must not be operated with explosive gases or mixtures or during processes

where explosive gases or mixtures are produced.

Pos: 72 /TD/Sicherheit/Überschrift - Anfor derungen an den Betreiber der Anlage @ 0\mod_1167823775531_51.doc x @ 5157 @ 2 @ 1

3.2 Requirements for the Furnace Operator

Pos: 73 /TD/Sicherheit/Anforderungen an den Betreiber der Anlage - RHTH, RHTC, LHT, RT - Rohröfen @ 2\mod_1184570280797 _51.docx @ 19913 @ @ 1

The set-up instructions and safety regulations must be followed, otherwise the furnace will

be deemed to have been used improperly, effectively cancelling any claims against

Nabertherm GmbH.

This level of safety when operating the furnace can be achieved only if all the necessary

measures have been taken. It depends on the furnace operator's diligence in planning these

measures and controlling how they are carried out.

The operator must ensure that

all harmful gases are removed from the workplace, for example by an extraction

system,

the extraction system is switched on,

the workplace is properly ventilated,

the furnace is operated only in a perfect operating condition and, in particular, that the

functions of the safety components are checked regularly.

the required personal protective equipment is available for and used by the operating,

maintenance, and repair personnel.

these operating instructions, including the supplier documentation, are kept near the

furnace. These instructions must be available at all times for anyone working with or

on the furnace;

all the safety and operating instruction signs on the furnace can be read properly.

Damaged or unreadable signs must be replaced immediately,

furnace personnel are informed regularly about all issues involving occupational

safety and environmental protection and are familiar with all the operating

instructions, especially those involving safety,

a risk assessment is carried out (in Germany, covered of the Occupational Safety Act)

to determine any other hazards that may result from the working conditions particular

to the furnace's location,

18

Page 19

Pos: 74 /TD/Sicherheit/Anforderungen an den Betreiber der Anlage - Betrieb des Ofens @ 30\mod_1349086871519_51. doc x @ 184910 @ @ 1

Pos: 75 /TD/Allgemeine Hinweise (für alle Anleitungen) /Hinweis - Bei Verwendung von Begasungskästen wird ei ne A r beitstemperatur bis zu 1100 °C (2012 °F)... @ 123\mod_14 6529 0938112_51.docx @ 545676 @ @ 1

all other instructions and safety guidelines that have been determined in a risk

assessment for the workplace are compiled in an operation manual (in Germany,

covered of the Ordinance Regulating the Use of Operating Equipment).

Only sufficiently qualified and authorized personnel may operate, maintain and repair

the system. This personnel must be trained in how to operate the furnace and must

confirm their participation in the training with a personal signature. The training

program must be documented in detail. In case an operator is replaced, additional

training must also take place. The additional training may only be performed by

authorized, trained individuals familiar with the system. The additional training must

be painstakingly documented and participation must be evidenced by the names and

signatures of the participating employees.

Operating the Furnace

Operating the furnace with explosive gases or mixtures, i.e., including any explosive

gases or mixtures created as a result of heating/drying, is prohibited.

A furnace opened while still hot radiates enormous heat energy, which can cause

burns.

Working with the furnace, for example opening the furnace door, etc., is only

permissible when the whole space needed for the door to swing out, the danger zone,

is visible to the operator.

When working at the furnace with high temperatures, the appropriate protective

clothing and protective goggles must be worn.

Danger! Risk of burns:

Several spots on the housing and components of the control box can become hot

enough during normal operation to cause skin burns.

When the vent supports are hot, touching them will lead to burns.

Note

If the protective gas boxes are used, a working temperature to 1100 °C (2012 °F) is

recommended; with working temperatures to 1150 °C (2102 °F) the boxes will suffer

increased wear.

Pos: 76 /TD/Allgemeine Hinweise (für alle Anleitungen) /Hinweis - In Deutschland ist die allgemeine Unfa ll ver hütungsvorschrift zu beachten. @ 3\mod_1193667 801739_51.docx @ 26122 @ @ 1

a

Note

In Germany, the general accident protection guidelines must be observed. The national

accident prevention regulations of the country of operation apply.

Pos: 77 /TD/Sicherheit/Überschrift - Anfor derungen an das Bedienpersonal @ 0\mod_1167825643423_51.doc x @ 5166 @ 2 @ 1

3.3 Requirements for the Operating Personnel

Pos: 78 /TD/Sicherheit/Anforderungen an das Bedienper s onal @ 0\mod_1158218663482_51.docx @ 2155 @ @ 1

Everyone involved in operation, installation, maintenance, or repair of the furnace must

have read and understood the operating instructions. No liability will be accepted for

damage or disruptions to operation resulting from non-compliance with the operating

instructions.

Only adequately qualified and authorized persons may operate, maintain, or repair the

furnace.

Operating personnel are instructed regularly in all aspects of occupational safety and

environmental protection and are familiar with all the operating instructions, in particular,

safety instructions.

Only trained personnel may operate the control and safety equipment.

The operator should complete these details:

Operator

19

Page 20

Pos: 79 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Warnsymbol_Gefahr - Absicherung von Gefahren bei Übertemperatur am TWB- TWW @ 37\mod_1362490404893_51.docx @ 214067 @ @ 1

_______________________________________________________________

The furnace may only be transported by

_______________________________________________________________

The furnace may only be installed by

_______________________________________________________________

The furnace may only be commissioned by

_______________________________________________________________

Initial instructions may only be given by

_______________________________________________________________

Malfunctions may only be rectified by

_______________________________________________________________

The furnace may only be maintained by

_______________________________________________________________

The furnace may only be cleaned by

_______________________________________________________________

The furnace may only be serviced by

_______________________________________________________________

The furnace may only be repaired by

_______________________________________________________________

The furnace may only be shut down by

_______________________________________________________________

Pos: 80 /TD/Sicherheit/Überschrift - Schutzklei du ng @ 0\mod_1167825795750_51.docx @ 5175 @ 2 @ 1

3.4 Protective Clothing

Pos: 81 /TD/Sicherheit/Schutzkleidung -Gesichts schutz-Handschuhe-Stiefel @ 5\mod_12113759853 20_51.docx @ 37168 @ @ 1

When close to furnaces, heat treatment accessories and similar components, wear protective

clothing that is resistant to heat and splashes of quenching media.

Wear a full-face mask that is resistant to heat and splashes of quenching media.

DANGER

• Danger caused by incorrectly entered cut-off

temperature at the over-temperature limiter with

manual reset/over-temperature limiter with automatic

reset.

• Mortal danger

• If, as a result of over-temperature from the charge and/or the

operating equipment, a charge is likely to be damaged at this preset cut-off temperature of the over-temperature limiter with

manual reset/over-temperature limiter with automatic reset, or if

the charge itself becomes a source of danger for the furnace or its

surroundings, the cut-off temperature must be reduced at the

over-temperature limiter with manual reset/automatic reset to the

maximum permissible value.

20

Page 21

Protect your hands when handling heat treatment accessories and similar components by

wearing heat-resistant gloves.

Protect your hands when cutting annealing and hardening foil/annealing envelopes by

wearing firm gloves.

Wear safety boots to protect your feet.

Pos: 82 /TD/Sicherheit/Überschrift - Grundlegende Maßnahmen bei Normalbetrieb @ 0\mod_1167825919827_51. docx @ 5184 @ 2 @ 1

3.5 Basic Measures During Normal Operation

Pos: 83 /TD/Sicherheit/Grundlegende Maßnahmen bei Norm al betrieb (LHT ../..-Tischmodell) @ 32\mod_1352295191692_51.docx @ 191520 @ @ 1

Risks during Normal Operation!

Before switching the furnace on, check and ensure that only authorized persons are in the

working area of the furnace and that no one can be injured as a result of operating the

furnace.

Before starting production each time, check and ensure that all the safety equipment works

properly.

Before starting production each time, check the furnace for obvious damage and ensure that

it is operated only in a perfect condition. Report any defects to a supervisor immediately.

Before starting production each time, remove all materials and objects that are not needed

for production from the working area.

At least once every day (see also Servicing and Maintenance) check the following:

Check the furnace for obvious external damage,

Check all hydraulic or pneumatic hoses, make sure that they are not leaking and that

they are connected properly (if applicable),

Check all gas and oil lines, make sure that they are not leaking and that they are

connected properly (if applicable),

Check that the fan works properly (if applicable)

Pos: 84 /TD/Sicherheit/Überschrift - Grundlegende Maßnahmen im Notfall @ 1\mod_1170943369267_51.doc x @ 9093 @ 2 @ 1

3.6 Basic Measures in Case of Emergency

Pos: 85 /TD/Sicherheit/Überschrift - Verhalten im No tf al l @ 1\mod_1170949904855_51.docx @ 9123 @ 3 @ 1

3.6.1 What to do in an Emergency

Pos: 86 /TD/Allgemeine Hinweise (für alle Anleitungen) /Überschrift - Öfen mit Netzstecker (Einzug links) @ 7\mod_1232450264630_51.docx @ 48098 @ @ 1

Furnaces with power plug

Pos: 87 /TD/Allgemeine Hinweise (für alle Anleitungen) /Hinweis - Das Stillsetzen im Notfall ist vorgeseh en durch Ziehen des Netzsteckers. @ 6\mod_1222062836860 _51.docx @ 42829 @ @ 1

Note

The power plug is to be pulled out to stop the furnace in case of an emergency.

Therefore, the power plug must be accessible at all times when the furnace is operating so

that it can be pulled out quickly in case of an emergency.

21

Page 22

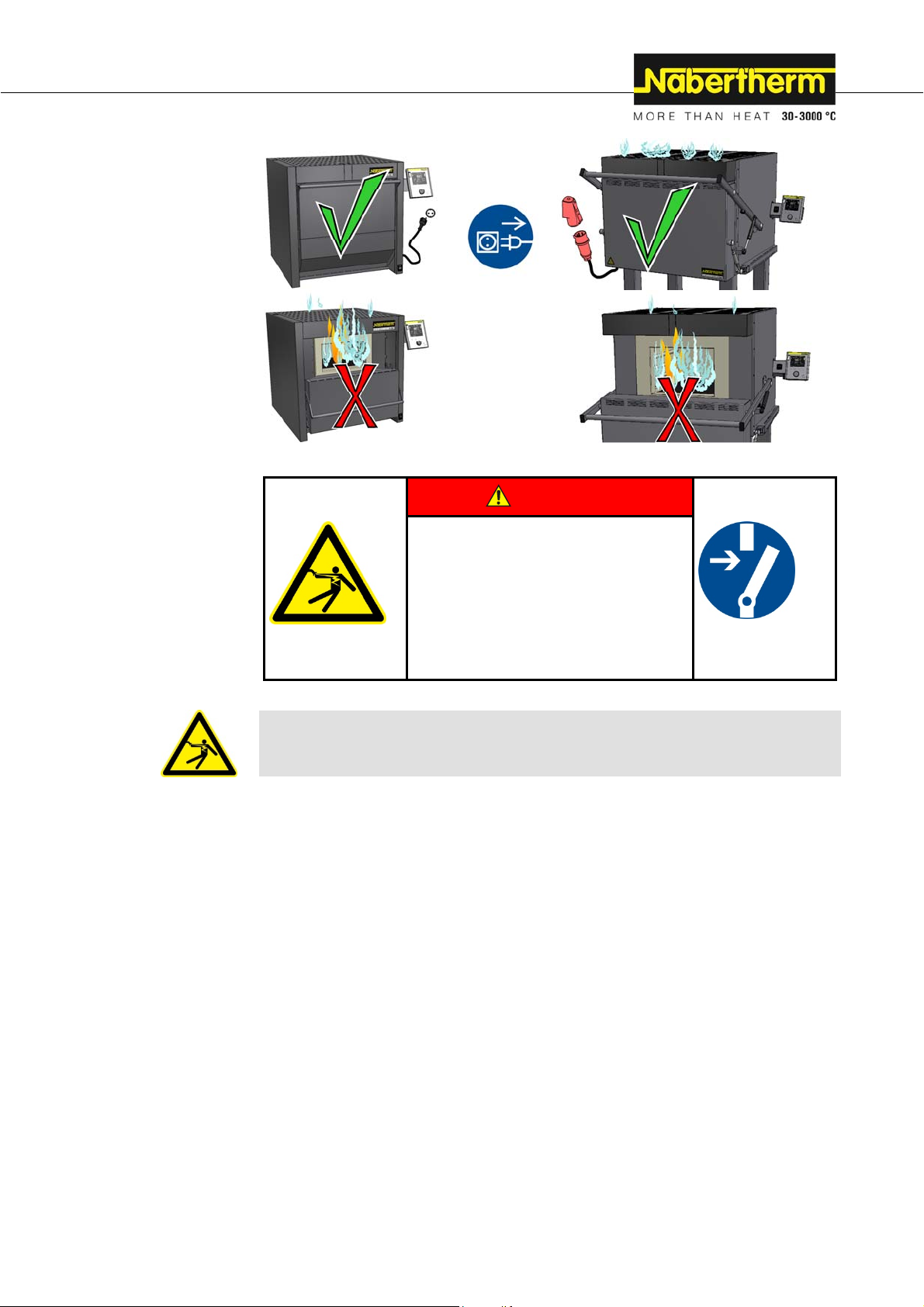

Pos: 88 /TD/Sicherheit/Grundlegende Maßnahmen im Notf a ll - Netzstecker ziehen (alle Anleitungen) - Graf ik @ 36\mod_1360079722854_51.docx @ 208920 @ @ 1

Fig. 10: Pull the power plug (similar to picture)

Pos: 89 /TD/Allgemeine Hinweise (für alle Anleitungen) /Überschrift - Öfen mit Hauptschalter (Einzug li nks) @ 7\mod_1232450214124_51.docx @ 48083 @ @ 1

Furnaces with main switch

Pos: 90 /TD/Allgemeine Hinweise (für alle Anleitungen) /Hinweis - Schalten Sie im Notfall sofort den Ofen am Haup tsc halter (Stellung „O“) spannungsfrei @ 2\mod_1184230 771480_51.docx @ 19710 @ @ 1

I ON

Note

In an emergency, immediately switch off the voltage supply to the furnace at the main

O OFF

switch (position "O/OFF"). Wait until the furnace chamber and attaching parts have cooled

to room temperature.

Pos: 91 /TD/Sicherheit/Grundlegende Maßnahmen im Notf a ll - Anlage über den Hauptschalter ... (alle Anleitungen) - Grafik @ 121\mod_1463732481989_51.docx @ 475758 @ @ 1

Pos: 92 /TD/Allgemeine Hinweise (für alle Anleitungen) /Warnung - Bei unerwarteten Vorgängen im Ofen (z.B. star ke Rauchentwicklung oder Geruchsbelästigung) @ 4\mod_ 1205 306579737_51.docx @ 34218 @ @ 1

22

Fig. 11: Disconnect power to the system using the main switch (similar to picture)

Risks during Normal Operation!

Switch the furnace off immediately in case of unexpected occurrences in the furnace (e.g. a

lot of smoke or unusual smells). Wait until the furnace has cooled naturally to room

temperature.

Page 23

Pos: 93 /TD/Allgemeine Hinweise (für alle Anleitungen) /Warnung - Bei unerwarteten Vorgängen darf der Ofen nic ht geöffnet werden - Grafik N 7/H - N 87/H @ 123\mod_1465292169374_51. d ocx @ 545702 @ @ 1

In case of a fire, keep

the door closed. This

will allow you to

prevent the spread of

smoke and keep out a

supply of oxygen.

Pos: 94 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Warnsymbol_Gefahr - Elektrischer Schlag - Piktogramm elektr. Schlag- Fr eischalten @ 11\mod_1263372988761_51.docx @ 70523 @ @ 1

DANGER

• Danger from electric shock.

• Danger to life.

• Work on the electrical

equipment may be performed

only by qualified electricians

or by technicians authorized

by Nabertherm.

• Disconnect the furnace

Pos: 95 /TD/Allgemeine Hinweise (für alle Anleitungen) /Warnung - Arbeiten an der elektrischen Ausrüstung dür f en nur von ... @ 2\mod_1184228021019_51.docx @ 19673 @ @ 1

Warning - Danger of Electric Shock!

Work on the electrical equipment may be done only by qualified, authorized electricians.

Pos: 96 /TD/Sicherheit/Überschrift - Grundlegende Maßnahmen bei Wartung und Instandhaltung @ 0\mod_11678260 60620_51.docx @ 5193 @ 2 @ 1

3.7 Basic Measures for Servicing and Maintenance

Pos: 97 /TD/Sicherheit/Grundlegende Maßnahmen bei W artung und Instandhaltung @ 0\mod_1158222458436_51.doc x @ 2188 @ @ 1

Maintenance work must be performed by authorized persons following the maintenance

instructions and the accident prevention regulations. We recommend that the maintenance

and repair work be carried out by the service team of Nabertherm GmbH. Non-compliance

may cause injuries, death, or considerable damage to property.

Switch off the furnace and make sure it cannot be switched on again inadvertently (lock the

main switch and secure it with a padlock), or pull out the power plug.

Clear an adequate area around the furnace to facilitate the repair work.

Suspended loads are dangerous. Working beneath a suspended load is prohibited. There is a

risk of fatal injury.

Relieve the pressure on hydraulic or pneumatic equipment before carrying out maintenance

or repair work (if applicable).

When cleaning furnaces, control cabinets, or electrical equipment housings, never spray

them with water.

When maintenance or repair work has been completed, before recommencing production

ensure the following:

Check that loosened screw connections have been re-tightened,

23

Page 24

Reinstall protective equipment, screens, and filters,

Remove all material, tools, and other equipment used for the maintenance or repair

work from the working area of the furnace,

Remove any liquids that have leaked,

Check that all safety functions (e.g. emergency stop button) work properly,

Pos: 98 /TD/Sicherheit/Überschrift - Umweltschutz vorschriften @ 0\mod_1167826189237_51.doc x @ 5202 @ 2 @ 1

Power cables may be replaced only with similar, approved cables.

3.8 Environmental Regulations

Pos: 99 /TD/Sicherheit/Umweltschutzvorschr iften Schmierfette-Hydrauliköl-Kühlmitte l @ 0\ mod_1158223424304_51.docx @ 2199 @ @ 1

All statutory duties regarding waste avoidance, proper recycling, and disposal must be

observed when work is carried out on and with the furnace.

Problem materials that are no longer needed, such as lubricants or batteries, must not be

placed in normal waste disposal systems or allowed to enter the sewage system.

During installation, repair, and maintenance work, substances that are hazardous to water,

such as

lubricating grease and oils

hydraulic oils

refrigerants

solvent-based cleaning fluids must not be allowed to contaminate the soil or enter the

sewage system.

These substances must be stored, transported, collected, and disposed of in suitable

containers.

Note

The operator must ensure that national environmental regulations are observed.

Pos: 100 /TD/Sicherheit/Umweltschutzvorschr iften Elektronische Bauteile-Isolierung-A l tmetall @ 4\mod_1205143314853_51.docx @ 32563 @ @ 1

When it is delivered, this furnace contains no substances that make a hazardous waste

classification necessary. However, residues of process materials may accumulate in the

furnace insulation during operation. These may be hazardous to health and/or the

environment.

Dismantle the electronic components and dispose of them as electric scrap.

Remove the insulation and dispose of it as hazardous waste (See Servicing, Cleaning,

and Maintenance with Ceramic Fiber Material)

Dispose of the housing as scrap metal.

Pos: 101 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Erläuterung ANSI Z535.6 @ 8\ mod_1243323558881_51.docx @ 57444 @ 2 @ 1

3.9 Explanation of the Symbols and Warnings

Note

In the following operating instructions, specific warnings are given to draw attention to

residual risks that cannot be avoided when the furnace is operating. These residual risks

include dangers for humans/products/ the furnace, and the environment.

The symbols used in the operating instructions are especially intended to draw attention to

safety information.

The symbols used cannot replace the text of the safety information. Therefore, always read

the entire text.

Graphic symbols correspond to ISO 3864. In accordance with the American National

Standard Institute (ANSI) Z535.6 the following warning information and words are used in

this document:

24

Page 25

The general hazard symbol, in combination with the words CAUTION, WARNING and

DANGER warns about the risk of serious injury. Observe the following information to

prevent injury or death.

NOTICE

Refers to a hazard that could damage or destroy the equipment.

CAUTION

Refers to a hazard with a minor or medium risk of injury.

WARNING

Refers to a hazard that could cause death, serious or irreversible injury.

DANGER

Refers to a hazard that could directly cause death, serious or irreversible injury.

25

Page 26

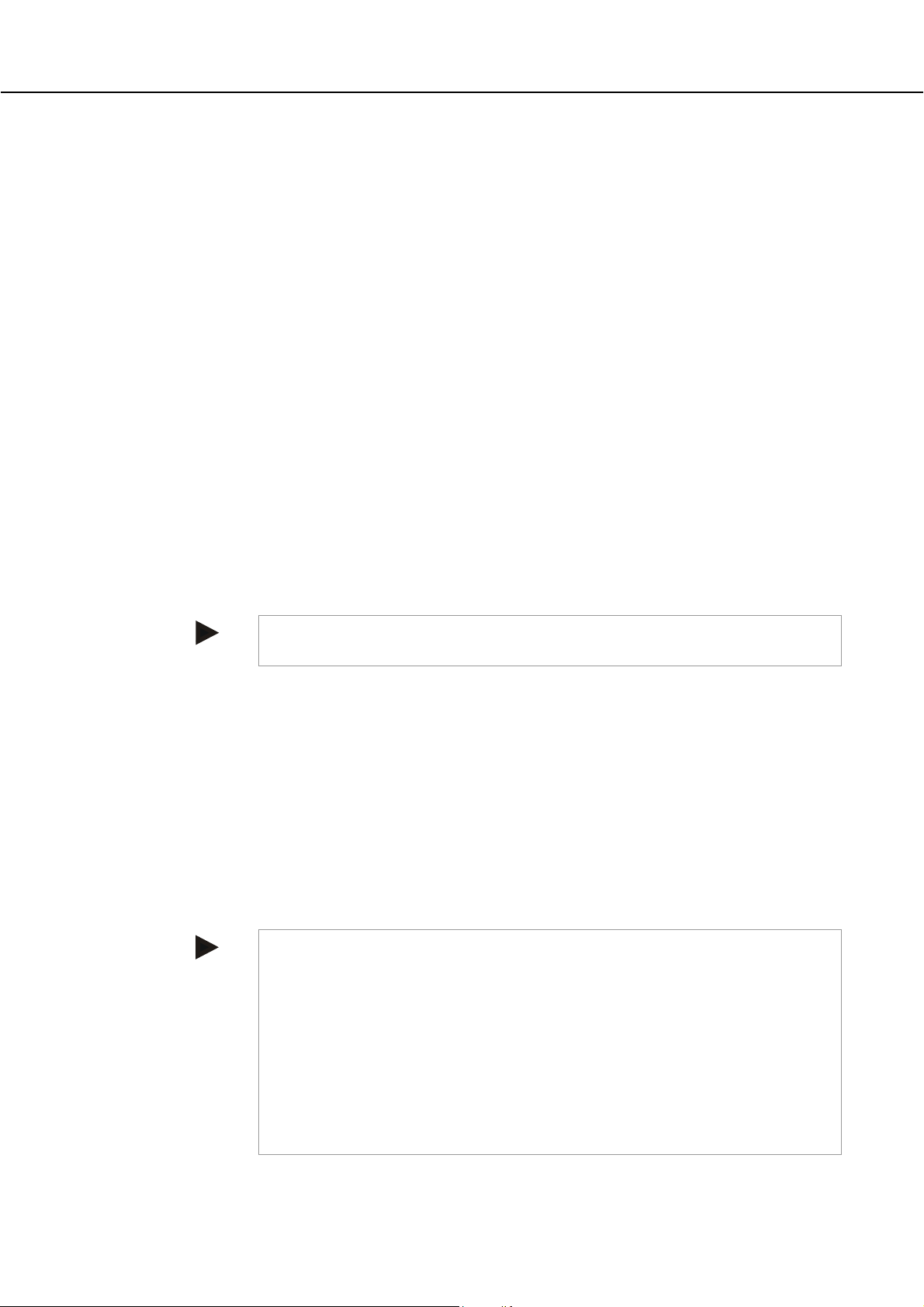

Structure of the Warning: All Warnings are Structured as Follows

Hazard symbol

Indicates the risk of injury

Signal word

Classifies the danger

WARNING

• Type and source of the danger

• Consequences of non-compliance

• Action to prevent danger

Graphical symbols (optional)

according to ISO 3864:

Consequences, measures, and

prohibitions

Reference texts:

• Type and source of the danger

• Possible consequences of noncompliance

• Measures/Prohibitions

or

Hazard symbol

Indicates the risk of injury

Signal word

Classifies the danger

Pos: 102 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Überschrift - Hinweis sy mbole in der Anleitung @ 9\mod_1247053429626_51.doc x @ 62751 @ @ 1

Pos: 103 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Hinweis - Unter diesem Sy mb ol er halten Sie Anweisungshinweise und ... @ 9\mod_1247053932311_51.docx @ 62785 @ @ 1

DANGER

• Type and source of the danger

• Consequences of non-compliance

• Action to prevent danger

Graphical symbols (optional)

according to ISO 3864:

Consequences, measures, and

prohibitions

Graphical symbols

(optional) according to ISO

3864:

Instructions or prohibitions

Reference texts:

• Type and source of the danger

• Possible consequences of noncompliance

• Measures/prohibitions

Information Symbols in the Instructions:

Note

Below this symbol you will find instructions and particularly useful information.

26

Page 27

Pos: 104 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleit ung - Gebot - Gebotszeichen - Wichtige Gebote sind zu befo lgen @ 9\ mod_1247056175982_51.docx @ 62853 @ @ 1

Pos: 105 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleit ung - Gebot - Wichtige Information für den Bediener @ 9\mod_124 7053200729_51.docx @ 62717 @ @ 1

Pos: 106 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleit ung - Gebot - Wichtige Information für das Wartungsperson al @ 9\mod_1247053206042_51.docx @ 62734 @ @ 1

Pos: 107 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleit ung - Gebot - Netzstecker ziehen @ 9\mod_1247055471526_5 1. docx @ 62836 @ @ 1

Rule - Rule Sign

This symbol draws attention to important rules that must be followed. Rule signs protect

people against injury and show what is to be done in certain situations.

Rule - Important Information for Operators

This symbol draws the operator's attention to important information and operating

instructions that must be followed.

Rule - Important Information for Maintenance Personnel

This symbol draws the maintenance personnel's attention to important operating and

maintenance instructions (service) that must be followed.

Rule - Pull Out the Power Plug

This symbol tells the operator to pull out the power plug.

Pos: 108 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleit ung - Gebot - Anlage spannungsfrei schalten @ 11\mod_1263 373877432_51.docx @ 70540 @ @ 1

Pos: 109 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleit ung - Gebot - Anheben mit mehreren Personen @ 9\mod_1247063058 002_51.docx @ 62938 @ @ 1

Pos: 110 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleit ung - Warnung - Quetschgefahr @ 10\mod_1256733173584_51. docx @ 68239 @ @ 1

Pos: 111 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleit ung - Warnung - Heiße Oberfläche - Oberfläche nicht berühr en @ 9\mod_1247054774780_51.docx @ 62802 @ @ 1

Pos: 112 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleit ung - Warnung - elektrischer Schlag - zur Vermeidung Anweisu ng folgen @ 9\mod_1247055093892_51.docx @ 62819 @ @ 1

Pos: 113 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleit ung - Warnung - Umkippen des Gerätes @ 9\mod_1247059198372_ 51.docx @ 62870 @ @ 1

Mandatory rule - Disconnect the furnace

This symbol informs the operator that before beginning any work the furnace must be

disconnected from the power supply and the applicable safety rules and accident prevention

regulations must be observed.

Rule - Lift only with Several People

This symbol draws the personnel's attention to the fact that this device may only be lifted

and moved to its final destination by several people.

Caution – Fingers or Hands May Be Crushed

This symbol warns the operator of the potential for fingers or hands to be crushed. Ignoring

this can lead to injury.

Warning - Hot Surface, Do Not Touch

This symbol warns the operator that the surface is hot and should not be touched.

Warning - Danger of Electric Shock

This symbol warns the operator that there is a risk of an electric shock if the following

warnings are not heeded.

Warning – Risk of Device Toppling Over

This symbol tells the operator that there is a risk of the device toppling over if the following

warnings are not heeded.

27

Page 28

Pos: 114 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleit ung - Warnung - Schwebende Lasten @ 9\mod_1251450500309_51.doc x @ 65454 @ @ 1

Pos: 115 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleit ung - Warnung - Heben schwerer Lasten @ 9\mod_1247059891358_5 1.docx @ 62887 @ @ 1

Pos: 116 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleit ung - Warnung - Umweltgefährdung @ 9\mod_1247060443419_51. docx @ 62904 @ @ 1

Pos: 117 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleit ung - Warnung - Brandgefahr @ 9\mod_1251445272822_51.doc x @ 65437 @ @ 1

Pos: 118 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleit ung - Warnung - Explosionsgefährliche Stoffe @ 9\ mod_1247061148859_51.docx @ 62921 @ @ 1

Warning – Suspended Load

This symbol warns the operator of potential dangers of suspended loads. Working below a

suspended load is strictly forbidden. Ignoring this can lead to fatal injury.

Warning – Danger if Heavy Loads Are Lifted

This symbol warns the operator of the potential dangers of lifting heavy loads. Ignoring this

can lead to injury.

Warning – Risk to the Environment

This symbol warns the operator of the risk to the environment if the following information

is not heeded. The operator must ensure that national environmental regulations are

observed.

Warning - Fire Danger

This symbol warns operators of the danger of fire if the following information is not

followed.

Warning – Risk of Explosive Substances or Explosive Atmosphere

These symbols warn the operator of explosive substances or an explosive atmosphere

Pos: 119 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleit ung - Gefahr - nicht mit Wasser überschütten @ 9\mod_12478 26410886_51.docx @ 63819 @ @ 1

Prohibited - Important Information for Operators

This symbol warns the operator that water or cleaning products must NOT be poured over

the objects. A high-pressure cleaning device must also not be used.

Pos: 120 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Überschrift - Wa r nhinweissymbole an der Anlage @ 9\mod_1247053700273_51.doc x @ 62768 @ @ 1

Pos: 121 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm an der Anlage - W arnung - Gefahr vor heißer Oberfläche und Verbrennung @ 9\mod_124 7052957145_51.docx @ 62700 @ @ 1

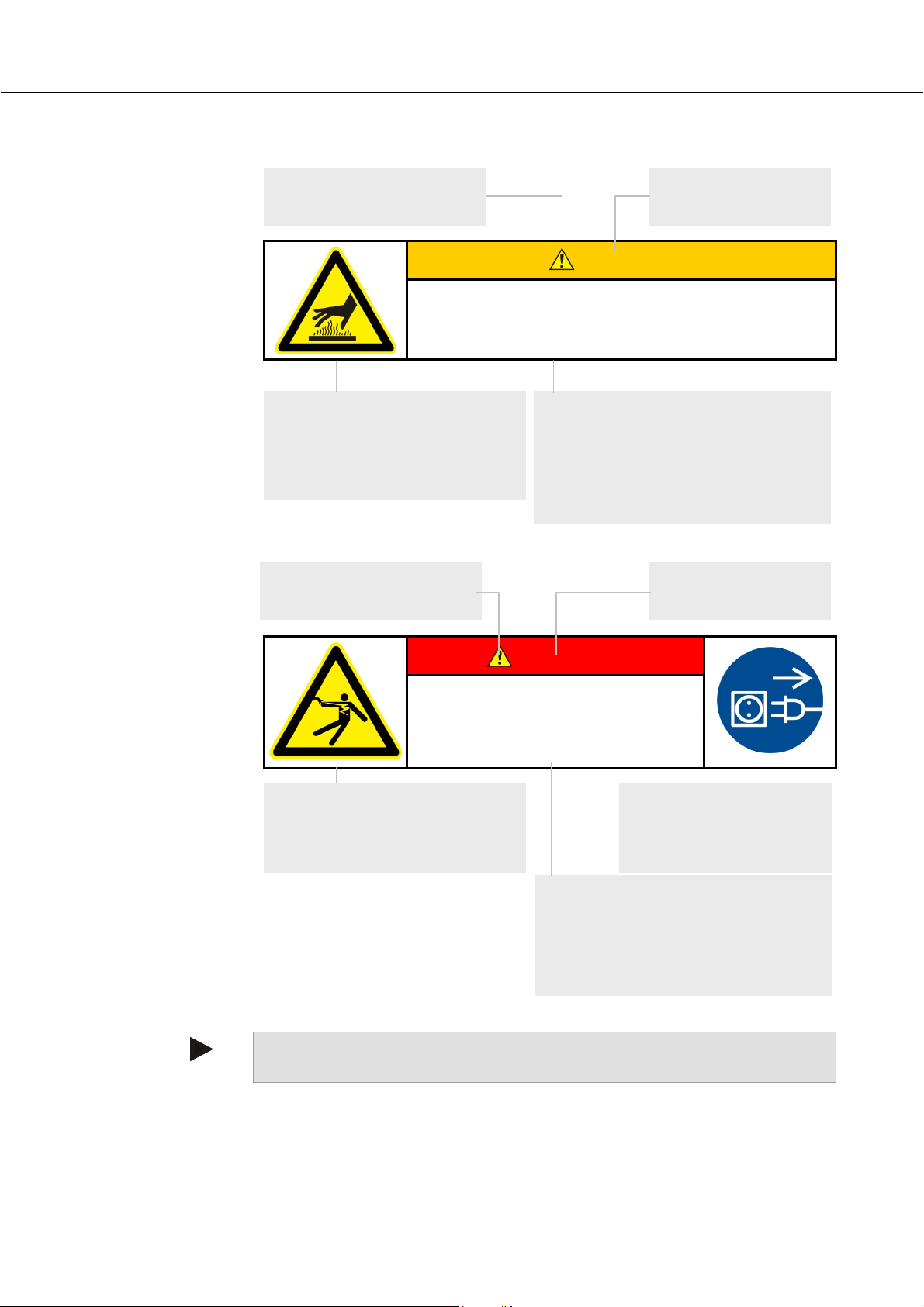

Warning Signs on the Furnace:

Warning - Hot Surface, Danger of Burning – Do Not Touch

You may not always realize that surfaces, such as furnace components, furnace walls, doors

and materials, and even liquids are hot. Do not touch the surface.

Pos: 122 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm an der Anlage - W arnung - Gefahren durch elektrischen Strom @ 9\mod_124705 263 9824_51.docx @ 62683 @ @ 1

Warning - Danger of Electric Shock!

Warning, dangerous electric voltage

Pos: 123 /TD/Sicherheit/Überschrift - Allgemeine Gefahren an der Anlage @ 0\mod_1168596796288_51.doc x @ 6014 @ 2 @ 1

3.10 General Risks with the Furnace

Pos: 124 /TD/Sicherheit/Allgemeine Gefahren (Ver br ennung, Quetschen, Strom) - LHT-Laboröfen/Kammeröf en @ 126\mod_1467703074637_51.docx @ 554246 @ @ 1

Warning! General Hazards!

Risk of burning on the furnace housing

The door handle/grip can become very hot during operation; wear gloves.

Risk of crushing on moving parts (door hinge)

The switchgear cabinet (if present) and the terminal boxes on the system contain dangerous

28

Page 29

electrical voltages.

Do not insert any objects into the openings on the furnace housing, exhaust air holes, or

cooling slots on the switchgear or furnace (if present). This poses a risk of electric shock.

Fire hazard if an extension cable is used:

With 230 V furnace models make sure that:

On use of an extension cable or a multipoint socket, the maximum electrical rating must not

be exceeded. Do not use the furnace with an extension cable if you are uncertain whether

grounding is guaranteed.

Pos: 125 /TD/Allgemeine Hinweise (für alle Anleitungen) /Warnung - Es dürfen keine Gegenstände auf den/der Ofen/S c haltanlage abgelegt/abgestellt werden... @ 4\mod_1203924555465_51. docx @ 31568 @ @ 1

Pos: 126 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Warnsymbol_Gefahr - Gefahr durch fehlende oder nicht korrekt angeschlossen e Erdung an ... @ 85\mod_1423745935634_51.docx @ 359461 @ @ 1

Warning! General Hazards!

No objects may be placed or set down on the furnace or switchgear. Doing so creates a fire

or explosion hazard.

DANGER

• Danger from electrocution

• If there is no earth connection, or the

earth connection is poorly connected, the

result may be a deadly electrical shock.

• Do not insert any metallic objects such as

thermocouples, sensors or tools into the

furnace chamber without having previously

ensured that the plant has been correctly

earthed. Entrust the job of making a earth

connection between the object and the

furnace housing to a qualified electrical

technician. Any objects inserted into the

furnace must be inserted only through those

openings intended for this purpose.

29

Page 30

Pos: 127 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Warnsymbol_Gefahr - Absicherung von Gefahren bei Übertemperatur am TWB-TWW @ 37\ mod_1362490404893_51.docx @ 214067 @ @ 1

DANGER

• Danger caused by incorrectly entered cut-off

temperature at the over-temperature limiter with

manual reset/over-temperature limiter with automatic

reset.

• Mortal danger

• If, as a result of over-temperature from the charge and/or the

operating equipment, a charge is likely to be damaged at this preset cut-off temperature of the over-temperature limiter with

manual reset/over-temperature limiter with automatic reset, or if

the charge itself becomes a source of danger for the furnace or its

surroundings, the cut-off temperature must be reduced at the

over-temperature limiter with manual reset/automatic reset to the

maximum permissible value.

Pos: 128 /TD/Transport_Montage_Inbetriebnahme/Er stinbetriebnahme/Überschrift - Transpor t, Montage und Erstinbetriebnahme @ 0\mod_115884422741 6_51.docx @ 3112 @ 1 @ 1

4 Transportation, Installation, and Commissioning

Pos: 129 /TD/Transport_Montage_Inbetriebnahme/Er stinbetriebnahme/Überschrift - Anli ef erung @ 0\mod_1167826534889_51.docx @ 5220 @ 2 @ 1

4.1 Delivery

Pos: 130 /TD/Transport_Montage_Inbetriebnahme/Er stinbetriebnahme/Anlieferung - (Hinweise a l lgemein) @ 0\mod_1158233508887_51.docx @ 2223 @ @ 1

Check that Everything is Complete

Compare the delivered items with the delivery note and the purchase order documents.

Immediately notify the carrier and Nabertherm GmbH of any missing or damaged parts, as

complaints at a later date cannot be acknowledged.

Danger of Injury

When the furnace is being lifted, parts of the furnace or the furnace itself could topple over,

slip, or fall. Before the furnace is lifted, make sure no one is in the working area. Wear

safety footwear and a hard hat.

Safety Instructions

Forklifts must be operated only by authorized personnel. The operator bears sole

responsibility for safe operation and the load.

When the furnace is being lifted, make sure that the ends of the forks or the load do

not catch on neighboring goods. Use a crane to move tall parts, such as control

cabinets.

Use only lifting equipment with sufficient load-bearing capacity.

Lifting gear must be attached only to positions that have been designated for this

purpose.

Attachments, piping, or cable conduits must never be used to affix lifting gear.

Unpackaged parts should only be lifted with ropes or straps.

Attach transportation equipment only to positions intended for this purpose.

Lifting and securing equipment must conform to the provisions contained in accident

prevention regulations.

Consider the weight of the furnace when choosing lifting and securing equipment.

(see Specifications)

Stainless steel parts (including mounting elements) must always be kept separate from

unalloyed steel parts.

Do not remove corrosion protection until immediately prior to assembly.

30

Page 31

Pos: 131 /TD/Transport_Montage_Inbetriebnahme/Er stinbetriebnahme/Anlieferung - Öfen mit eine m Hu b wagen transportieren @ 2\mod_1184672460200_51.doc x @ 20000 @ @ 1

Risks during Normal Operation!

Suspended loads are dangerous. Working beneath a suspended load is prohibited. There is a

risk of fatal injury.

Note

Safety and accident prevention guidelines applicable for forklift trucks must be followed.

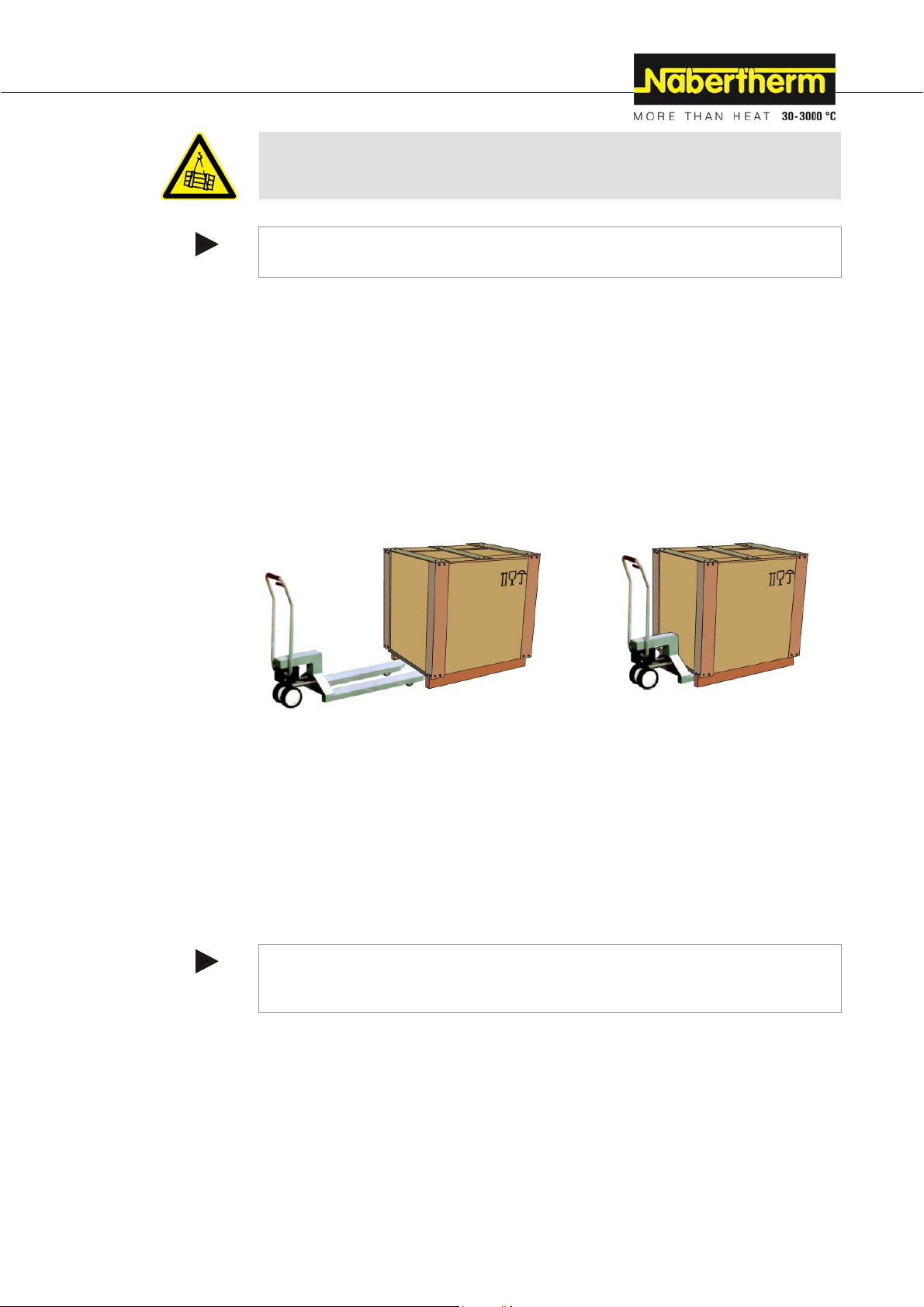

Transportation with a Pallet Truck

Observe the maximum permitted capacity of the pallet truck.

1. Our furnaces are delivered ex works on wooden frames to facilitate unloading.

Transport the furnace in its original packaging and with suitable equipment to

prevent any damage. Remove the packaging only when the furnace is in its final

location. When transporting the furnace, make sure it is secured against sliding,

toppling over, and damage. The furnace should be transported and installed by at

least two persons. Do not store the furnace in damp rooms or outdoors.

2. Push the pallet truck underneath the transportation frame. Make sure that the pallet

truck is completely beneath the frame. Pay attention to neighboring goods.

Fig. 12: Pallet truck is pushed completely beneath the transportation frame

3. Lift the furnace carefully and pay attention to its center of gravity. When the furnace

is being lifted, make sure that the ends of the forks or the load do not catch on

neighboring goods.

4. Make sure that the furnace is balanced safely; if not, attach securing equipment.

Push the furnace carefully, slowly and with the pallet truck at its lowest position. Do

not transport the furnace on inclines.

5. Carefully lower the furnace at its final position. Pay attention to neighboring goods.

Try not to set it down too abruptly.

Pos: 132 /TD/Allgemeine Hinweise (für alle Anleitungen) /Hinweis - In Deutschland ist die allgemeine Unfal lverhütungsvorschrift zu beachten. @ 3\mod_119366 7801739_51.docx @ 26122 @ @ 1

a

Note

In Germany, the general accident protection guidelines must be observed. The national

accident prevention regulations of the country of operation apply.

31

Page 32

Pos: 133 /TD/Sicherheit/Sicherheitssymbole/ W arnhinweise-ISO-ANSI/Warnsymbol_Vorsic ht - Rutschen/Kippen des Gerätes - Piktogramm Kippen/ Heben/Anheben @ 9\mod_1247064081950_51.doc x @ 62955 @ @ 1

Pos: 134 /TD/Transport_Montage_Inbetriebnahme/E r stinbetriebnahme/Legende für Packstücke z.B . zerbrechlich @ 1\mod_1173776713307_51.doc x @ 1074 6 @ @ 1

CAUTION

• Device may slip or topple over.

• Damage to the device.

• Risk of injury from lifting

heavy loads.