Nabertherm LHT 17 LB, LHT 17 LB Speed, LHT 01/17, LHT 01/17 LB Speed, LHT 02/17 LB Speed Original Instructions Manual

...

Operating Instructions

High-Temperature Bottom Loading

Furnaces

LHT ../17 LB

LHT ../17 LB Speed

M01.0086 ENGLISCH

Original instructions

www.nabertherm.com

Made

in

Germany

Copyright

Copyright by

Nabertherm GmbH

Bahnhofstrasse 20

28865 Lilienthal

Federal Republic of Germany

Reg: M01.0086 ENGLISCH

Rev: 2017-12

No responsibility is accepted for the correctness of this information. We

reserve the right to make technical alterations.

2

1 Introduction ........................................................................................................................................................... 5

1.1 Product Description ........................................................................................................................................... 6

1.2 Overview of the Complete Furnace ................................................................................................................... 8

1.3 Safeguarding against Dangers from Excess Temperatures ............................................................................. 10

1.4 Key to the Model Names ................................................................................................................................. 11

1.5 Scope of Delivery ............................................................................................................................................ 11

2 Specifications ....................................................................................................................................................... 12

3 Warranty and Liability ....................................................................................................................................... 14

4 Safety .................................................................................................................................................................... 14

4.1 Defined Application ........................................................................................................................................ 14

4.2 Requirements for the Furnace Operator .......................................................................................................... 16

4.3 Requirements for the Operating Personnel ...................................................................................................... 17

4.4 Protective Clothing .......................................................................................................................................... 18

4.5 Basic Measures During Normal Operation ..................................................................................................... 19

4.6 Basic Measures in Case of Emergency ........................................................................................................... 19

4.6.1 What to Do in an Emergency ...................................................................................................................... 19

4.7 Basic Measures for Servicing and Maintenance.............................................................................................. 20

4.8 Environmental Regulations ............................................................................................................................. 21

4.9 Explanation of the Symbols and Warnings ..................................................................................................... 22

4.10 General Risks with the Furnace....................................................................................................................... 25

5 Transportation, Installation and Initial Start-Up ............................................................................................. 27

5.1 Delivery ........................................................................................................................................................... 27

5.2 Unpacking ....................................................................................................................................................... 29

5.3 Transport Securing Device/Packaging ............................................................................................................ 32

5.4 Constructional and Connection Requirements ................................................................................................ 32

5.4.1 Installation (Furnace Location) ................................................................................................................... 32

5.5 Assembly, Installation, and Connection .......................................................................................................... 35

5.5.1 Venting Exhaust Fumes .............................................................................................................................. 35

5.5.2 Connecting the Furnace to the Power Supply ............................................................................................. 36

5.5.3 Placing the Insulation in the Base Shell of the Lift Bottom ........................................................................ 37

6 Initial Start-Up .................................................................................................................................................... 38

6.1 Recommendations for Heating Up the Furnace for the First Time ................................................................. 39

7 Operation ............................................................................................................................................................. 42

7.1 Controller ........................................................................................................................................................ 42

7.2 Operation, Display and Switch Elements (depending on design) ................................................................... 42

7.2.1 Turning on the Controller/Furnace ............................................................................................................. 42

7.2.2 Turning off the Controller/Furnace ............................................................................................................. 43

8 Pre-Set Programs................................................................................................................................................. 43

8.1 Pre-Set Programs for Furnace Models with Speed Function........................................................................... 43

8.2 Pre-Set Programs for Furnace Models with and without Speed Function ....................................................... 47

8.2.1 Over-Temperature Limiter with Manual Reset and Adjustable CutoutTemperature (Additional Equipment)

.................................................................................................................................................................... 49

8.3 Loading/Charging ........................................................................................................................................... 50

8.4 Stackable Saggar ............................................................................................................................................. 51

3

9 Servicing, Cleaning, and Maintenance .............................................................................................................. 54

9.1 Furnace Insulation ........................................................................................................................................... 55

9.2 Shutting the System Down for Maintenance ................................................................................................ ... 55

9.3 Separate the Snap-In Coupling (Plug) from the Furnace Housing .................................................................. 56

9.4 Regular Maintenance of the Furnace ............................................................................................................... 56

9.5 Regular Maintenance Tasks – Electrical Testing ............................................................................................ 58

9.6 Regular Maintenance Tasks – Documentation ................................................................................................ 58

9.7 Checking the Heating Element Screws ........................................................................................................... 59

9.8 Cleaning Products ........................................................................................................................................... 61

10 Malfunctions ........................................................................................................................................................ 62

10.1 Error Messages of the Controller .................................................................................................................... 63

10.2 Warnings of the Controller .............................................................................................................................. 65

10.3 Malfunctions of the Switchgear ...................................................................................................................... 67

10.4 Controller Check List ...................................................................................................................................... 68

10.5 Lowering the Lift Unit - Emergency Hole ...................................................................................................... 70

11 Spare Parts/Wearing Parts ................................................................................................................................. 72

11.1 Electrical Schematics/Pneumatic Schematics ................................................................................................. 77

11.2 Removing and Installing Heating Elements .................................................................................................... 77

11.2.1 Tightening Torque for Screw Connections on Heating Elements .......................................................... 82

11.3 Replacing a Thermocouple .............................................................................................................................. 82

11.4 Repairing the Insulation .................................................................................................................................. 85

11.4.1 Replacing the Collar Insulation .............................................................................................................. 85

11.5 Separate the Snap-In Coupling (Plug) from the Furnace Housing .................................................................. 86

12 Accessories (Options) .......................................................................................................................................... 86

12.1 Electrical Schematics/Pneumatic Schematics ................................................................................................. 87

13 Nabertherm Service............................................................................................................................................. 87

14 Shut-Down, Dismantling, and Storage............................................................................................................... 88

14.1 Transportation/Return Transportation ............................................................................................................. 89

15 Declaration of Conformity .................................................................................................................................. 90

16 For Your Notes .................................................................................................................................................... 91

4

Note

These documents are intended only for buyers of our products and may not be copied or

disclosed to third parties without our written consent. (Law governing copyright and

associated protective rights, German Copyright Law from Sept. 9, 1965)

Protective Rights

Nabertherm GmbH owns all rights to drawings, other documents and authorizations, also

in case of applications for protective rights.

Note

All the figures in the instructions have a descriptive character; in other words, they do not

represent the exact details of the furnace.

Note

The pictures contained in the instruction manual may contain inaccuracies in terms of the

function, design and furnace model.

Pos: 1 /TD/Einleitung/Überschrift - Einl eitung 1 @ 0\mod_1167823212238_51. docx @ 5139 @ 1 @ 1

1 Introduction

Pos: 2 /TD/Einleitung/Einleitung_Öfen mit Luftaufnahmebild 2017 @ 151\mod _1490190055052_51.docx @ 626352 @ @ 1

Dear Customer,

Thank you for choosing a quality product from Nabertherm GmbH.

You can be proud that you have chosen a furnace which has been especially tailored to suit

your manufacturing and production conditions.

This product is characterized by

professional workmanship

high performance due to its high efficiency

high-quality insulation

low power consumption

low noise level

simple installation

easy to maintain

high availability of spare parts

Your Nabertherm Team

Pos: 3 /TD/Einleitung/Die in der Anleitu ng gezeigten Abbildungen können abhängi g von Funktion, ... Ofenmodell abweichen @ 24\mod_1337854352242_51.doc x @ 161605 @ @ 1

5

These electrically heated furnaces are a high-quality product which will give you many

years of reliable service if they are properly cared for and maintained. One basic

prerequisite is that the furnace is used the way it was designed to be used.

During development and production a high priority was placed on safety, functionality

and economy.

Pos: 4 /TD/Einleitung/Produktbeschreibu ng/Öfen/Überschrift - Produktbeschrei bung 1.1 @ 0\mod_1167821943807_51.doc x @ 5103 @ 2 @ 1

1.1 Product Description

Pos: 5 /TD/Einleitung/Produktbeschreibu ng/Öfen/Produktbeschreibung-Bei dies en elektrisch beheizten Öfen handelt es sic h um ein Qualitätsprodukt ... @ 15\m od_1305707254935_51.docx @ 117576 @ @ 1

Pos: 6 /TD/Einleitung/Produktbeschreibu ng/Öfen/Produktbeschreibung - Durch d en elektrisch angetriebenen Hubtisch wird die ..M01.0086 - Katalog @ 176\ mod_1511863833264_51.docx @ 721545 @ @ 1

The electrically operated lift bottom simplifies charging of high-temperature furnaces

considerably. The all-round heating inside the furnace ensures very even temperature

distribution. The sinter material is placed in saggars made from technical ceramic material.

Since the saggars can be stacked on top of each other, this guarantees a high degree of

Pos: 7 /TD/Einleitung/Produktbeschreibu ng/Öfen/Beim Ofenmodell LHT 01/17 können Chargenbehälter stapelbar für Beschic kung in bis zu zwei @ 184\ mod_1519289808530_51.docx @ 742270 @ @ 1

Pos: 8 /TD/Einleitung/Produktbeschreibu ng/Öfen/Aufgrund geringer Speicher wärme sind kurze Prozesszeiten realisierb ar. Diese Hochtemperatur-... @ 176\mo d_1511864826875_51.docx @ 721571 @ @ 1

Pos: 9 /TD/Einleitung/Produktbeschreibu ng/Öfen/Überschrift - Ofenmodell LHT .. /17 LB Speed (Einzug Mitte) @ 184\m od_1519295264148_51.docx @ 742608 @ @ 1

Pos: 10 /TD/Einleitung/Produktbeschreib ung/Öfen/Produktbeschreibung - Grund aufbau-Dieses Modell eignet sich aufgr und seiner speziellen Heizelemente @ 17 6\mod_1511865061863_51.docx @ 721 597 @ @ 1

Pos: 11 /TD/Einleitung/Produktbeschr eibung/Öfen/Überschrift - Zusätzlich zeic hnet sich dieses Produkt aus durch: @ 15\ mod_1305713428306_51.docx @ 11772 4 @ @ 1

Pos: 12 /TD/Einleitung/Produktbeschreib ung/Öfen/Produktbeschreibung - Hoch temperatur-Hubbodenofen - M01.0086 @ 184\mod_1519290482834_51.docx @ 742322 @ @ 1

Pos: 13 /TD/Einleitung/Produktbeschr eibung/Öfen/Überschrift - Zusatzausstattu ng (Einzug Mitte) @ 39\mod_1364984085 402_51.docx @ 221200 @ @ 1

Pos: 14 /TD/Einleitung/Produktbeschreib ung/Öfen/Produktbeschreibung - Te mperaturwählbegrenzer mit einstellbarer Abs chalttemperatur ... @ 116\mod_14593 32570794_51.docx @ 459785 @ @ 1

Pos: 15 /TD/Einleitung/Produktbeschreib ung/Öfen/Produktbeschreibung - Zubeh ör: Prozesssteuerung und -dokumentatio n über VCD-Softwarepaket zur Überw a @ 116\mod_1459332710604_51.doc x @ 459839 @ @ 1

productivity.

With the furnace model LHT 01/17, saggars can be stacked for charging on up to two

levels. With furnace model LHT 02/17, up to three levels.

Low storage heat allows short process times. These high-temperature bottom loading

furnaces reach a maximum temperature of 1650 °C (3002 °F).

Furnace model LHT ../17 LB Speed

Because of their special heating elements, these models are ideal for sintering translucent

zirconia. The electrically operated lift bottom simplifies charging of the furnace

considerably. The all-round heating inside the furnace ensures very even temperature

distribution. The furnaces also have a forced cooling feature. To cool the furnace, it is

opened gradually by the controller in relation to the program. Depending on the charge and

the saggar, overall cycle times of less than two hours can be achieved with this hightemperature furnace.

Other Characteristics of this Product are:

Tmax 1650 °C (3002 °F)

High quality molybdenum disilicide heating elements offer the best possible

protection against chemical interactions between the charge and the heating elements

Only insulation materials that are not classified as carcinogenic according to

TRGS 905, Class 1 or 2 are used

Outstanding temperature uniformity due to the all-round heating inside the furnace

Precise, electric tooth belt drive of the lift bottom with button controls; the furnace can

be opened automatically for forced cooling

Housing made of sheets of textured stainless steel

Exhaust air opening in the roof

Type S thermocouples

Controller P480

Equipped with an optional drying function. At the start of the program, the bottom

moves to the drying position and closes automatically at 500 °C (932 °F)

Delivery includes a starter set saggar for charging zirconia work (starter set included

with delivery of model LHT ../17 LB Speed)

Additional Equipment

Over-temperature limiter with adjustable cutout temperature for thermal protection

class 2 in accordance with EN 60519-2 as temperature limiter to protect the furnace

and load

Process control and documentation via VCD software package for monitoring,

documentation and control

6

Pos: 16 /TD/Einleitung/Produktbeschreib ung/Öfen/Produktbeschreibung - Zusatz ausstattung: Ethernet Schnittstelle für Üb erwachungssoftware VCD @ 150\mod _1489393775988_51.docx @ 623916 @ @ 1

Pos: 17 /TD/Einleitung/Produktbeschreib ung/Öfen/Überschrift - Zubehör (Einzug Mit te) @ 36\mod_1359971094458_51. docx @ 208406 @ @ 1

Pos: 18 /TD/Einleitung/Produktbeschreib ung/Öfen/Produktbeschreibung-Zubehör - Chargenbehälter stapelbar für Beschic kung in mehreren Ebenen @ 176\mod_ 1511871442772_51.docx @ 721675 @ @ 1

Ethernet interface for VCD monitoring software

Accessories

Stackable charge saggars for multilevel loading

7

Pos: 19 /TD/Einleitung/Lieferumfang/Öf en/Überschrift - Gesamtübersicht der Anl age @ 1\mod_1174302636992_51.doc x @ 11332 @ 2 @ 1

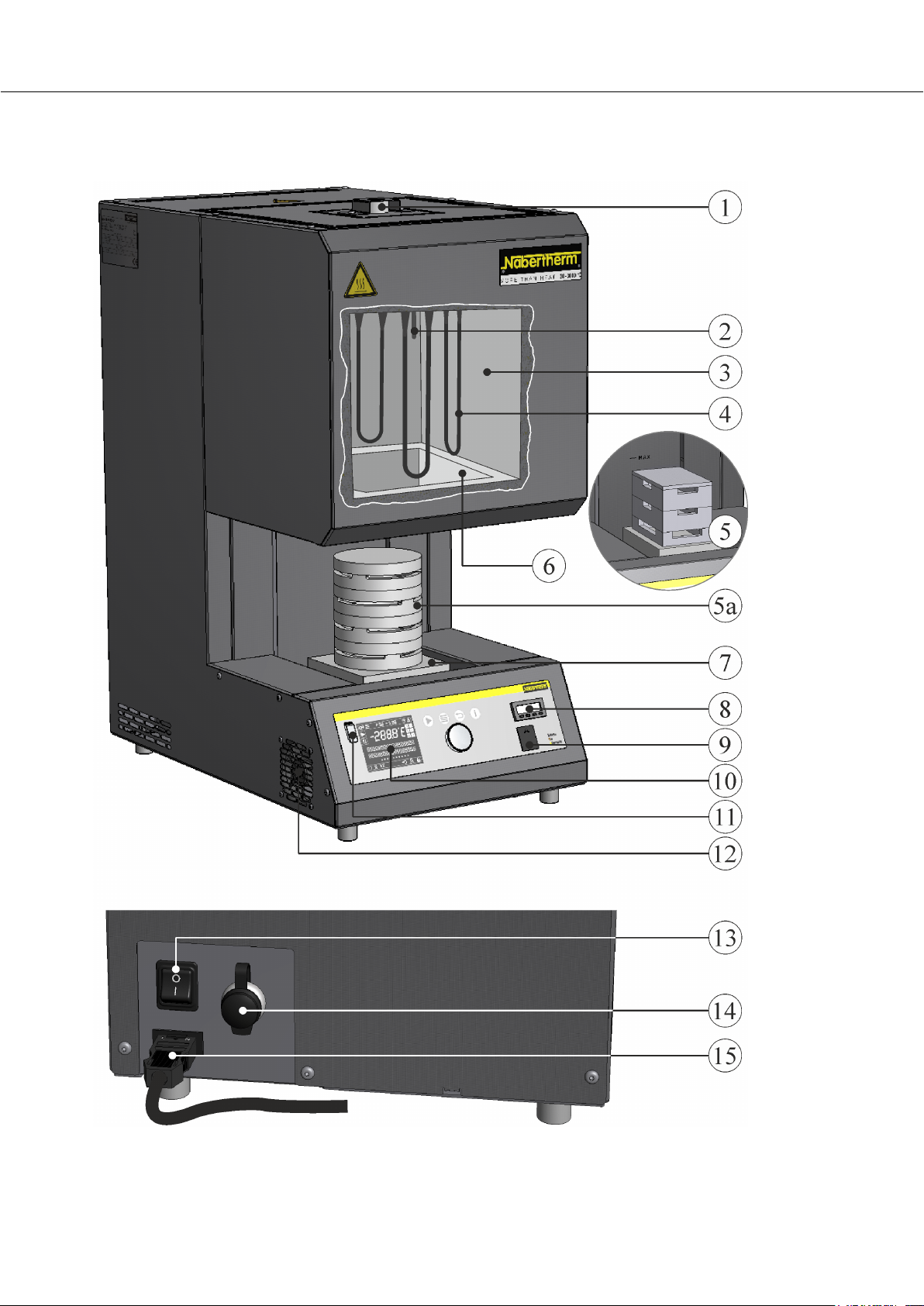

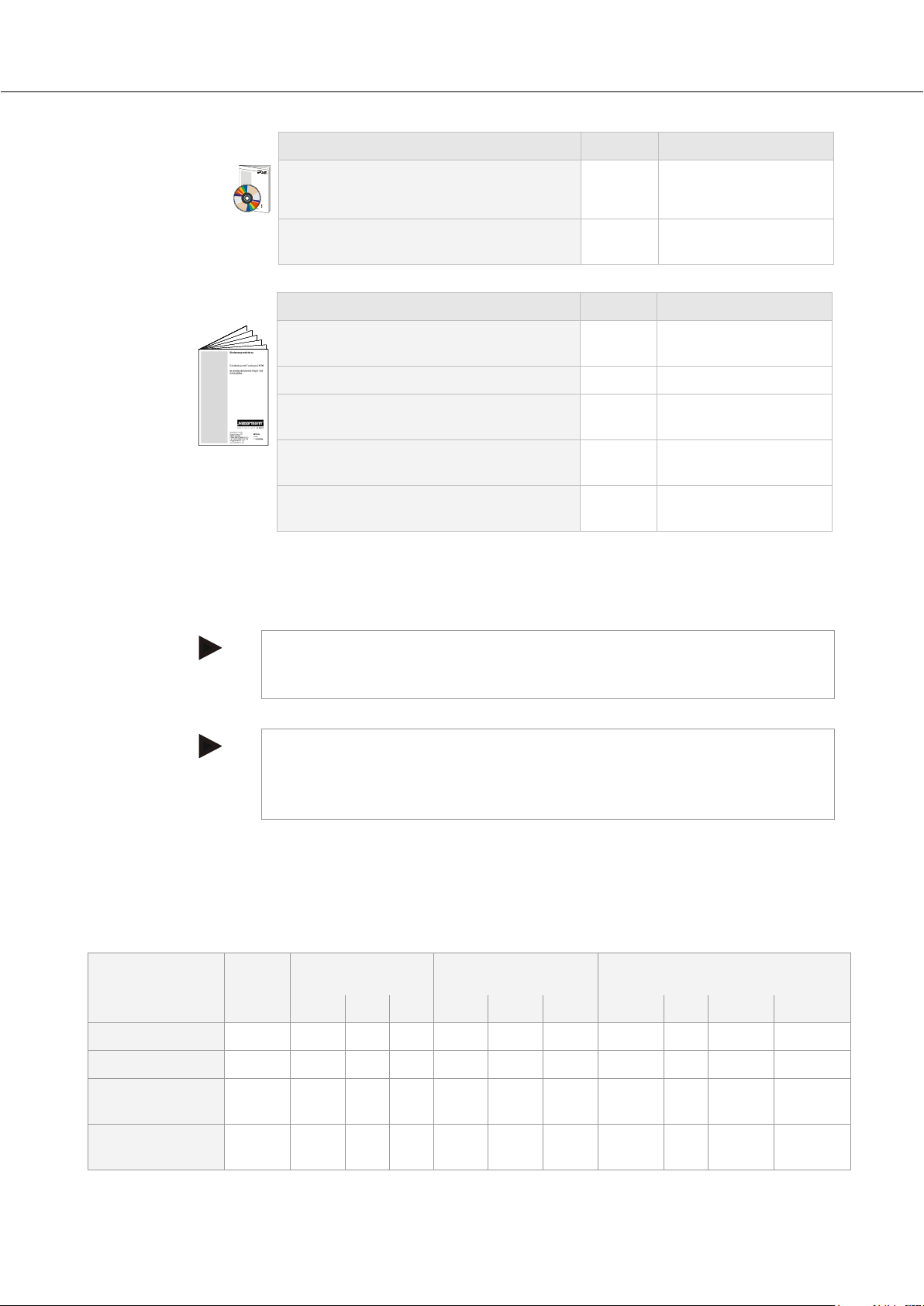

1.2 Overview of the Complete Furnace

Pos: 20 /TD/Einleitung/Lieferumfang/Öf en/Gesamtübersicht LHT - Hochtemperat ur-Hubbodenofen LHT ../.. LB Speed - M 01.0086 @ 176\mod_1511872528176 _51.docx @ 721701 @ @ 1

Fig. 1: Complete overview: The figure shows a model with over-temperature limiter and Ethernet interface as

accessories (similar to picture)

8

No.

Name

1

Exhaust air tube

2

Thermocouple type S

3

Oven chamber

4

Heating elements made from molybdenum disilicide

5

Rectangular saggar with lid for model LHT 01/17

5a

Round saggar with spacer ring for model LHT 02/17

6

Collar insulation

7

Lift bottom with floor insulation

8

Over-temperature limiter with manual reset for thermal protection class 2 in accordance with EN 60519-2 as

a temperature limiter to protect the furnace and the load (accessory)

9

Rocker switch to control the lift bottom

10

Controller P480

11

USB interface

12

Fan

13

Power switch (ON/OFF)

14

Ethernet interface (accessory)

15

Power plug with snap-in coupling

Rectangular saggars

For optimum utilization of the furnace chamber, the

material is placed in ceramic saggars. Saggars can be

stacked in several levels, depending on the furnace

model. The saggars have slits to allow the air to

circulate. The top saggar should be closed with a

ceramic lid.

Pos: 21 /TD/Einleitung/Lieferumfang/Öf en/Gesamtübersicht_M01.0086_Tabelle Nr. und Benennung der verbauten Teile für LHT../.. LB Speed @ 184\mod_1519 290628074_51.docx @ 742348 @ @ 1

Pos: 22 /TD/Einleitung/Produktbeschreib ung/Öfen/Überschrift - Zubehör (Einzug li nks) @ 53\mod_1389868020284_51.doc x @ 263175 @ @ 1

Accessories

Pos: 23 /TD/Einleitung/Lieferumfang/Öf en/Überschrift - Ofenmodell LHT 01/17 ( Einzug links) @ 184\mod_1519290967 565_51.docx @ 742374 @ @ 1

Furnace model LHT 01/17

Pos: 24 /TD/Einleitung/Lieferumfang/Öf en/Überschrif - (Starterset im Lieferumf ang bei Modell LHT ../17 LB Speed enthalt en) (Einzug links) @ 184\mod_1519291 669272_51.docx @ 742426 @ @ 1

(Starter set included with delivery of model LHT ../17 LB Speed)

Pos: 25 /TD/Einleitung/Lieferumfang/Öf en/Gesamtübersicht Zusatzausstattung_Zub ehör: Eckige Chargenbehälter mit Deckel @ 179\mod_1515761890235_51.d ocx @ 730938 @ @ 1

Fig. 2: Rectangular saggar with lid (similar to picture)

9

Round saggar

Saggars are recommended when working with

zirconium oxide. A saggar consists of the sintering

bowl as the bottom part and the spacer ring with

ventilation openings. The material is very resistant to

temperature changes and can also be used with short

heating and cooling times.

DANGER

• Danger caused by incorrectly entered cut-off temperature at

the over-temperature limiter/over-temperature limiter with

motor driven reset

• Risk of fatal injury

• If, as a result of over-temperature from the charge and/or the

operating equipment, a charge is likely to be damaged at this preset cut-off temperature of the over-temperature limiter/overtemperature limiter with motor driven reset, or if the charge itself

becomes a source of danger for the furnace or its surroundings,

the cut-off temperature must be reduced on the over-temperature

limiter/over-temperature limiter with motor driven reset to the

maximum permissible value.

Pos: 26 /TD/Einleitung/Lieferumfang/Öf en/Überschrift - Ofenmodell LHT 02/17 ( Einzug links) @ 184\mod_1519291012 848_51.docx @ 742400 @ @ 1

Furnace model LHT 02/17

Pos: 27 /TD/Einleitung/Lieferumfang/Öf en/Überschrif - (Starterset im Lieferumf ang bei Modell LHT ../17 LB Speed enthalt en) (Einzug links) @ 184\mod_1519291 669272_51.docx @ 742426 @ @ 1

(Starter set included with delivery of model LHT ../17 LB Speed)

Pos: 28 /TD/Einleitung/Lieferumfang/ Öfen/Gesamtübersicht Zusatzausstattung _Zubehör: Runde Chargenbehälter @ 1 45\mod_1481117570454_51.docx @ 6 07622 @ @ 1

Fig. 3: Round saggar (similar to picture)

Pos: 29 /TD/Einleitung/Produktbeschreib ung/Öfen/Überschrift - Absicherung von Gefahren bei Übertemperatur @ 37\mo d_1362489730884_51.docx @ 213987 @ 2 @ 1

Safety control circuit

1.3 Safeguarding against Dangers from Excess Temperatures

Pos: 30 /TD/Einleitung/Produktbeschreib ung/Öfen/Sicherheitseinrichtung - Über wachung der Ofenraumtemperatur (T WB-TWW) - Beschreibung @ 37\mod_1362 491214270_51.docx @ 214092 @ @ 1

Over-temperature limiters and over-temperature limiters with automatic reset to protect

against over-temperature in the furnace are available for Nabertherm GmbH furnaces either

as a standard feature (depending on the model series) or as additional equipment

(customized design).

Over-temperature limiters and over-temperature limiters with automatic reset monitor the

furnace temperature. The display shows the most recently set cut-off temperature. If the

furnace temperature rises above the pre-set cut-off temperature, the heating is shut down to

Pos: 31 /TD/Sicherheit/Sicherheitssymbol e/Warnhinweise-ISO-ANSI/Warnsymb ol_Gefahr - Absicherung von Gefahren b ei Übertemperatur am TWB-TWW @ 37\ mod_1362490404893_51.docx @ 2140 67 @ @ 1

protect the furnace, the charge and/or the operating equipment.

Pos: 32 /TD/Betrieb_Bedienung/Vor Inbetri ebnahme des Ofens ist die Bedienungsa nleitung... (TWB-TWW) - Text @ 37\ mod_1362494080225_51.docx @ 2 14142 @ @ 1

Read the operating instructions of the over-temperature limiter/over-temperature limiter

with automatic reset before starting the furnace. The safety sticker must be removed from

the over-temperature limiter/over-temperature limiter with automatic reset. When a change

is made in the heat treatment program, the maximum permissible cut-off temperature

(alarm trigger temperature) on the over-temperature limiter/over-temperature limiter with

Pos: 33 /TD/Betrieb_Bedienung/die m aximale Solltemperatur des Wärmeprogram ms Controller zwischen 5 °C und 30 °C (TW B-TWW) @ 39\mod_136378461037 1_51.docx @ 218500 @ @ 1

automatic reset must be checked or re-entered.

Depending on the physical characteristics of the furnace, we recommend that you set the

maximum target temperature of the heating program in the controller between 5 °C and

30 °C below the trigger temperature of the over-temperature limiter/over-temperature

limiter with automatic reset. This prevents unwanted triggering of the over-temperature

limiter/over-temperature limiter with automatic reset.

10

Description and function, see the

Operating Instructions of the overtemperature limiter/over-temperature

limiter with automatic reset.

Example

Explanation

LHT 01/17 LB

LHT = Laboratory High-Temperature bottom loading furnace tabletop model

LHT 01/17 LB

01 = 1-liter furnace chamber (volume in liters)

02 = 2-liter furnace chamber (volume in liters)

LHT 01/17 LB

17 = Tmax 1650 °C (3002 °F)

LHT 01/17 LB

LB = Lift Bottom

LHT 01/17 LB Speed

Speed = Model is equipped with forced cooling

System components

Quantity

Comment

High-temperature bottom loading furnace

1 x

Nabertherm GmbH

Allen key

1 x

Nabertherm GmbH

Saggar (starter set), rectangular or round

depending on furnace model

1)5)

1 x

Nabertherm GmbH

Power cable1)

1 x

Nabertherm GmbH

Pos: 34 /TD/Betrieb_Bedienung/Aufkleber vom TWB/TWW abziehen - Grafi k @ 37\mod_1362492020088_51.docx @ 2 14117 @ @ 1

Pos: 35 /TD/Einleitung/Produktbeschreib ung/Öfen/Überschrift - Entschlüsselung der Modellbezeichnung @ 2\mod_1184 245078907_51.docx @ 19775 @ 2 @ 1

Fig. 4: Removing the sticker (similar to picture)

1.4 Key to the Model Names

Pos: 36 /TD/Einleitung/Produktbeschreib ung/Öfen/Entschlüssellung der Modellbez eichnung Hochtemperatur-Hubbuden ofen - M01.0086 @ 184\mod_15192919 48379_51.docx @ 742452 @ @ 1

Pos: 37 /TD/Einleitung/Produktbeschreib ung/Öfen/Typenschild Hochtemperatur-H ubbodenofen - M01.0086 @ 177\mo d_1512378981532_51.docx @ 723642 @ @ 1

Pos: 38 /TD/Einleitung/Lieferumfang/Öf en/Überschrift - Lieferumfang @ 0\mod _1167822508130_51.docx @ 5112 @ 2 @ 1

Fig. 5: Example model designation (type plate)

1.5 Scope of Delivery

Pos: 39 /TD/Einleitung/Lieferumfang/Öf en/Lieferumfang - Hochtemperatur-Hubb odenofen - M01.0086 @ 184\mod_1519 292346382_51.docx @ 742478 @ @ 1

The scope of delivery includes:

11

System components

Quantity

Comment

Process documentation VCD software

package2

1 x

Nabertherm GmbH

Other components, variable depending on the

model

- - -

See shipping documents

Document type

Quantity

Comment

Instruction manual for high-temperature

bottom loading furnace

1 x

Nabertherm GmbH

Operating manual for controller

1 x

Nabertherm GmbH

Operating manual for over-temperature

limiter1)

1 x

Nabertherm GmbH

Operating instructions for VCD software

package2)

1 x

Nabertherm GmbH

Other documents, variable depending on the

particular design

1 x

Note

Store all documents carefully. All the functions of this furnace were tested during

manufacturing and prior to shipping.

Note

The documents included do not always contain the electrical schematics and pneumatic

diagrams.

If you need the respective diagrams, they can be ordered from Nabertherm Service.

Electrical specifications are on the type plate located on the side of the furnace.

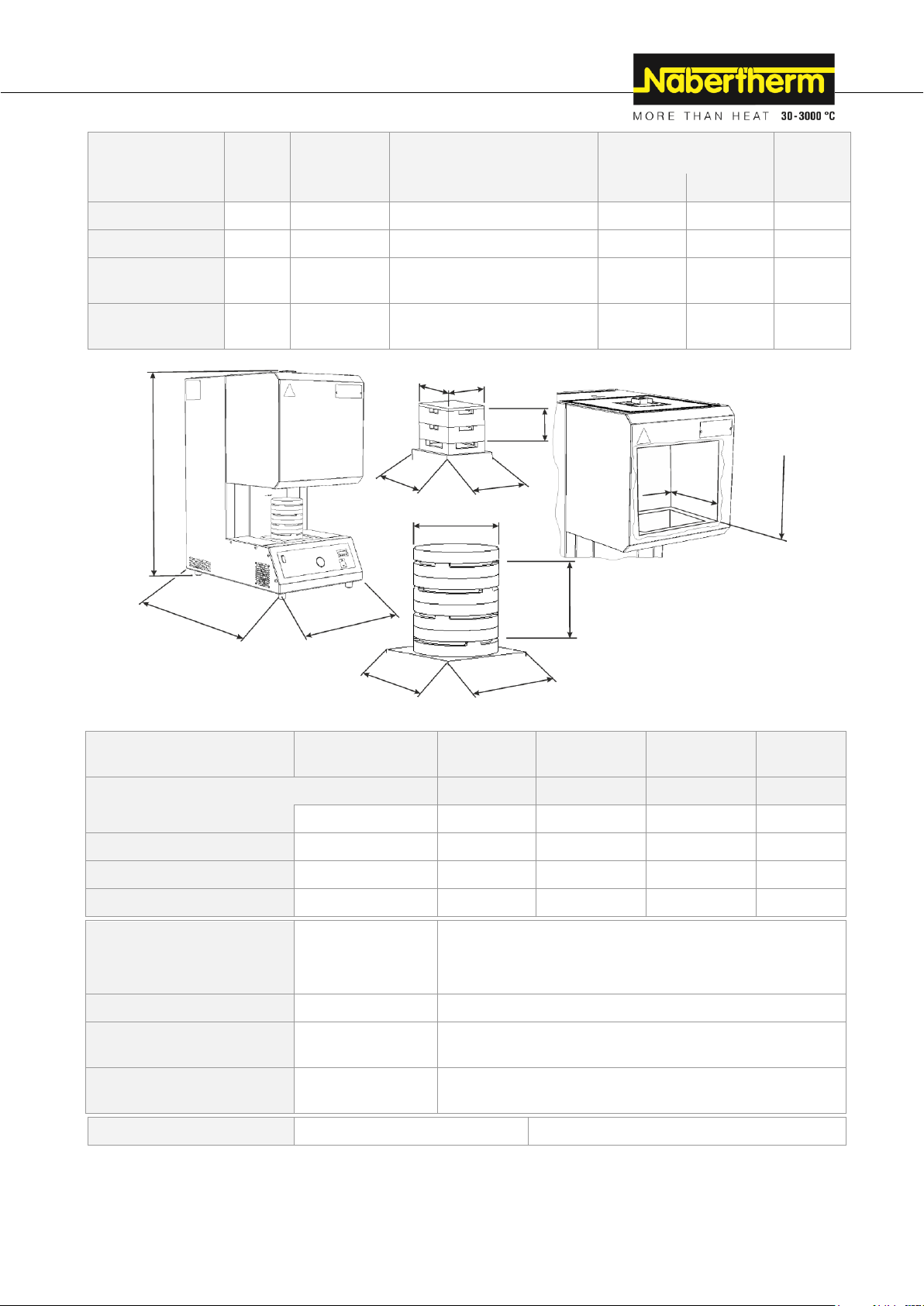

Model

Tmax

Inner dimensions

in mm

Outer dimensions

in mm

Work space in mm (corresponds to saggar

with spacer 20 mm above the floor)

°C w d h W D H

w1 Ø d1

h1

LHT 01/17 LB

1650

145

180

100

350

590

680

75 110

65

LHT 02/17 LB

1650

185

180

185

390

590

765

115 105

LHT 01/17 LB

Speed

1650

145

180

100

350

590

680

75 110

65

LHT 02/17 LB

Speed

1650

185

180

185

390

590

765

115 105

Betriebsanleitung

Made

in

Germany

Prozessdokumentation

Controltherm MV

Pos: 40 /TD/Betrieb_Bedienung/Die mitg elieferten Unterlagen beinhalten nicht z wangsläufig elektrische Schaltpläne bzw. P neuma ... @ 47\mod_138002807461 6_51.docx @ 247668 @ @ 1

Pos: 41 /TD/Einleitung/Technische Dat en/Öfen/Überschrift - Technische Daten - mit Hinweis @ 0\mod_1167822840737 _51.docx @ 5121 @ 1 @ 1

2 Specifications

Pos: 42 /TD/Einleitung/Technische Dat en/Öfen/Modell-Tabelle für Hochtemperatur- Hubbodenofen - M01.0086 - 1 @ 18 4\mod_1519292775469_51.docx @ 742 504 @ @ 1

1)

included with delivery depending on design/furnace model

2)

included with delivery if required, see shipping documents

3)

quantity depends on furnace model

4)

quantity as required, see shipping documents

5)

starter set included with delivery of model LHT ../17 LB Speed

12

Model

Volume

Weight

Minutes to Tmax

Area of lift bottom

Maximum

units

in L

in kg

b2

t2

LHT 01/17 LB

1

40

85

95

130

30

LHT 02/17 LB

2

50

75

135

135

75

LHT 01/17 LB

Speed

1

40

85

95

130

30

LHT 02/17 LB

Speed

2

50

75

135

135

75

Model

Electrical

Connection:

Voltage

Electric

current

Connected

load

Frequency

in V

in A

kW

in Hz

LHT 01/17 LB

1-phase: (1/N/PE)

220 - 240

9.7

2.2

50/60

LHT 02/17 LB

1-phase: (1/N/PE)

220 - 240

15.5

3.4

50/60

LHT 01/17 LB Speed

1-phase: (1/N/PE)

220 - 240

9.7

2.2

50/60

LHT 02/17 LB Speed

1-phase: (1/N/PE)

220 - 240

15.5

3.4

50/60

Thermal protection class

Furnaces:

according to DIN EN 60519-2

without safety controller: Class 0

with safety controller: Class 2

Protection type

Furnaces

IP20

Ambient conditions for

electrical equipment

Temperature:

Humidity:

+5 °C to + 40 °C

max. 80% non-condensing

Weights

Furnace with

accessories

Depends on design (see shipping documents)

Emissions

Continuous sound pressure level:

< 80 dB(A)

W

D

Ø

h H d w w2

d2

h1

h1

w1

d1

w2

d2

Pos: 43 /TD/Einleitung/Technische Daten /Öfen/Modell-Maße für Hochtemperatur- Hubbodenofen - M01.0086 - Grafik @ 177\mod_1512383801723_51.docx @ 72 3720 @ @ 1

Fig. 6: Dimensions

Pos: 44 /TD/Einleitung/Technische Daten /Öfen/Tabelle techn. Daten für alle Hochte mperatur-Hubbodenofen - M01.0086 - 1 @ 184\mod_1519293798063_51.docx @ 742530 @ @ 1

Pos: 45 /TD/Einleitung/Technische Daten /Öfen/Tabelle techn. Daten für alle Hochte mperatur-Hubbodenöfen - M01.0086 - 2 @ 177\mod_1512389194706_51.d ocx @ 723772 @ @ 1

Pos: 46 /TD/Einleitung/Technische Daten /Öfen/Tabelle Dauerschalldruckpegel < 80 dB(A) - 2 @ 1\mod_1170750985488 _51.docx @ 8913 @ @ 1

13

§

As regards warranty and liability, the normal Nabertherm warranty terms apply,

unless individual terms and conditions have been agreed. However, the following

conditions also apply:

The Nabertherm furnace was designed and built in conformance with a careful selection

of the applicable harmonized standards and other technical specifications. Hence, it

corresponds to the state of the art and assures the greatest degree of safety.

Only materials whose characteristics and melting temperatures are known may be heated.

Consult any available safety-related material data sheets.

Pos: 47 /TD/Einleitung/Gewährleistung_Ha ftung/Überschrift - Gewährleistung und H aftung 1.1 @ 0\mod_116782297949 2_51.docx @ 5130 @ 1 @ 1

3 Warranty and Liability

Pos: 48 /TD/Einleitung/Gewährleistung_Ha ftung/Öfen und Schaltanlagen - Gew ährleistung und Haftung @ 0\mod_11 57536440972_51.docx @ 1569 @ @ 1

Warranty and liability claims for personal injury or damage to property shall be excluded if

they are attributable to one or more of the following causes:

All persons involved in operation, installation, maintenance, or repair of the furnace

must have read and understood the operating instructions. No liability will be accepted

for damage or disruption to operation resulting from non-compliance with the

operating instructions.

Not using the furnace as intended

Improper installation, start-up, operation, or maintenance of the furnace,

Operation of the furnace with defective safety equipment or improperly installed or

non-functioning safety and protective equipment

Not observing the information in the operating instructions with respect to

transportation, storage, installation, start-up, operation, maintenance, or equipping the

furnace

Making unauthorized changes to the furnace

Making unauthorized changes to the operating parameters

Making unauthorized changes to the parameterization, the settings, or the program

Nabertherm accepts absolutely no liability for damage caused by using parts that are

not original Nabertherm parts. Original parts and accessories are designed especially

for Nabertherm furnaces. Replace parts only with original Nabertherm parts.

Otherwise the warranty will be void.

Pos: 49 /TD/Sicherheit/Überschrift - Sic herheit @ 0\mod_1158843961540_51.doc x @ 3103 @ 1 @ 1

Catastrophes due to third-party causes and force majeure

4 Safety

Pos: 50 /TD/Sicherheit/Überschrift - B estimmungsgemäße Verwendung @ 0\ mod_1167823503921_51.docx @ 5148 @ 2 @ 1

4.1 Defined Application

Pos: 51 /TD/Sicherheit/Bestimmungsgem äße Verwendung allgemeiner Ofen-A nlagen_Materialien - Teil 1 @ 24\mod_13 37938775936_51.docx @ 161920 @ @ 1

Safety

Pos: 52 /TD/Sicherheit/Bestimmungsgem äße Verwendung zum Sintern von Technisc her Keramik ... Brücken und Kronen aus Zirkonox @ 46\mod_13777647087 84_51.docx @ 243590 @ @ 1

Pos: 53 /TD/Sicherheit/Der Einsatz vo n Färbelösungen kann zu einem überpro portionalen Verschleiß der Heizelement e führen... @ 43\mod_1371115299588_51.d ocx @ 233530 @ @ 1

it

Furnaces in this series are suitable for sintering technical ceramic pieces such as bridges

and crowns made of zirconium oxide.

The use of paint solvents can lead to accelerated wear of the heating elements. If solvents

are used, good pre-drying is necessary to minimize their impact on the heating elements.

14

Note

The furnace must not be operated with explosive gases or mixtures or with

explosive gases or mixtures that form during the process.

This furnace has no safety technology for processes in which combustible mixtures

can form, such as debinding.

If the furnace is to be used for such processes, the concentration of organic gases must

never exceed 3 % of the lower explosive limit (LEL) in the furnace. This requirement

not only applies to normal operation, but also especially to exceptions, such as process

malfunctions (e.g. due to the breakdown of a unit, etc.). Ensure adequate extraction

and ventilation of the furnace.

Nabertherm offers a wide range of furnaces that were especially developed for processes

with flammable gases.

Operation with power sources, products, operating equipment, auxiliary materials, etc.,

which are listed as hazardous or which may in any way harm the health of the operator is

prohibited.

The furnace must not be filled with materials or substances that release explosive gases or

vapors. Only materials and substances whose properties are known may be used.

Caution

Continuous operation at maximum temperature can lead to increased wear of the heating

elements and the insulation material. We recommend operating at approx. 50 °C below

the maximum temperature.

- This furnace was designed for commercial use. The furnace is not designed

for heating food, animals, wood, grain, etc.

- The furnace must not be used to heat the workplace.

- Do not use the furnace to melt ice or for similar purposes.

- Do not use the furnace as a clothes dryer.

Pos: 54 /TD/Allgemeine Hinweise (für all e Anleitungen)/Hinweis - Dieser Ofen verfügt über keine Sicherheitstechnik für Pr ozesse, ..- Zeitpunkt 3 % der @ 8\mo d_1235038699771_51.docx @ 51483 @ @ 1

Pos: 55 /TD/Sicherheit/Überschrift - Nic ht bestimmungsgemäß ist: (Einzug Mitte) @ 80\mod_1418806747958_51.docx @ 347220 @ @ 1

Pos: 56 /TD/Sicherheit/Eine andere oder darüber hinausgehende Benutzung, wie z. B. die Verarbeitung ... @ 45\mod_137 7242071687_51.docx @ 242040 @ @ 1

Safety

Pos: 57 /TD/Sicherheit/Von den im Ofen eingesetzten Materialien bzw. Ausgasunge n können sich unter Umständen Schadst offe .. @ 45\mod_137724339 2217_51.docx @ 242065 @ @ 1

Pos: 58 /TD/Sicherheit/Bei Öfen mit T emperaturwählbegrenzer muss die Abschal ttemperatur so eingestellt werden ... @ 45\ mod_1377244417122_51.docx @ 2 42390 @ @ 1

Pos: 59 /TD/Sicherheit/Geht von der Charg e durch Übertemperatur die Gefahr aus , dass bei dieser voreingestellten ... TWB @ 53\mod_1389787246569_51.docx @ 262755 @ @ 1

Pos: 60 /TD/Sicherheit/Die Aufstellhinw eise und Sicherheitsbestimmungen sind ei nzuhalten, andernfalls gilt der Ofen als ... @ 45\mod_1377243410507_51.docx @ 242 265 @ @ 1

Pos: 61 /TD/Sicherheit/Der Betrieb mit Kr aftquellen, Produkten, Betriebsmitteln, Hilfss toffen usw., ... - mit Symbol @ 45 \mod_1377241083975_51.docx @ 2 41990 @ @ 1

Improper furnace operation:

Any other use, such as processing of products other than those for which the furnace

was intended as well as handling hazardous materials or materials dangerous to health

is deemed IMPROPER and such uses must be approved in writing by Nabertherm.

Under certain circumstances gases or materials may be released from the materials in

the furnaces that settle on the insulation or the heating elements and destroy them. If

applicable, read the labels and instructions on the packaging of materials that

you use.

Furnaces with over-temperature limit controllers must have their shut-down

temperatures set to prevent any overheating of the material.

If as a result of excessive heat the batch is likely to be damaged by the pre-set cut-out

temperature of the over-temperature limit controller or that the batch itself becomes a

source of danger for the furnace or its surroundings, the temperature setting on the

over-temperature limit controller must be reduced to the maximum permissible

value.

The set-up instructions and safety regulations must be followed, otherwise the furnace

will be considered improperly used, effectively cancelling any claims against

Nabertherm GmbH.

Pos: 62 /TD/Allgemeine Hinweise (für all e Anleitungen)/Hinweis - Dauerhafter Betrieb bei maximaler Temperatur kann z u erhöhtem Verschleiß an Heizelementen @ 17\mod_1310050610942_51.doc x @ 123376 @ @ 1

Pos: 63 /TD/Allgemeine Hinweise (für all e Anleitungen)/Hinweis - Dieser Ofen ist für die gewerbliche Anwendung ... Der O fen ist nicht für die Erwärmung ... @ 19\ mod_1315980979500_51.docx @ 13454 8 @ @ 1

15

Caution

Applicable safety instructions are contained in individual chapters.

Note

Depending on use, wearing parts, such as heating elements and insulation material, can be

subject to increased wear. Service life, the process, and the type of use are also dependent

on the usage frequency and can, therefore, cause increased wear of heating elements and

insulation material. Heating may discolor stainless steel sheet (especially if the furnace is

opened while hot), but this does not impair the functionality of the furnace.

Note

This product does not comply with the ATEX Directive and may not be used in

ignitable atmospheres. The system must not be operated with explosive gases or

mixtures and it must be ensured that explosive gases or mixtures do not form during

the process.

The set-up instructions and safety regulations must be followed, otherwise the furnace

will be deemed to have been used improperly, effectively cancelling any claims against

Nabertherm GmbH.

This level of safety when operating the furnace can be achieved only if all the necessary

measures have been taken. It depends on the furnace operator's diligence in planning these

measures and controlling how they are carried out.

Pos: 64 /TD/Sicherheit/Überschrift - Für hieraus resultierende Schäden haftet der Betreiber (Einzug Mitte) @ 10\mod_125 6731411117_51.docx @ 68223 @ @ 1

Pos: 65 /TD/Sicherheit/Das Betreiben des Ofens ist nur nach der in dieser Betriebs anleitung beschriebenen Vorgehensweise .. @ 53\mod_138978730580 4_51.docx @ 262855 @ @ 1

Pos: 66 /TD/Sicherheit/Veränderungen a m Ofen, müssen mit Nabertherm schriftlich abgestimmt werden ... @ 45\mod_13 77243398694_51.docx @ 242240 @ @ 1

Pos: 67 /TD/Sicherheit/Es dürfen nur die M aterialien eingesetzt werden, deren Eige nschaften und Schmelztemperaturen ... @ 49\mod_1385394498752_51.doc x @ 254350 @ @ 1

Pos: 68 /TD/Sicherheit/Das Öffnen des O fens im heißen Zustand über 200 °C (392 °F) kann zu einem erhöhtem Verschleiß . .. @ 39\mod_1364289911635_51.doc x @ 219945 @ @ 1

Pos: 69 /TD/Sicherheit/Dieser Ofen ist NICH T dafür bestimmt durch Personen (einschli eßlich Kinder) mit eingeschränkten ... @ 45\mod_1377501786408_51.docx @ 2 42490 @ @ 1

Pos: 70 /TD/Transport_Montage_Inbetrieb nahme/Erstinbetriebnahme/Hinweis - Verschleißteile wie Heizelemente und Isoli ermaterialien unterliegen in Abhängigkeit der je @ 166\mod_1505112276697_5 1.docx @ 677058 @ @ 1

The operator is liable for any resulting damages.

The furnace may only be operated in the manner described in these operating

instructions, i.e., the operating instructions must be completely read and understood.

The set-up instructions and safety regulations must be followed, otherwise the furnace

will be considered improperly used, effectively cancelling any claims against

Nabertherm GmbH. The EC Declaration of Conformity will cease to be valid if any

modifications are made to the machine without our approval.

Only materials whose characteristics and melting temperatures are known may be

heated. Consult any available safety data sheets of the materials. Any other use

beyond this is improper, including the processing of products other than those for

which the furnace was intended as well as handling hazardous materials or materials

dangerous to health, and must be approved in writing by the manufacturer Nabertherm

GmbH.

Opening the furnace while it is still hot, over 200 °C (392 °F), can lead to increased

wear of the following components: insulation, door seal, heating elements and furnace

housing. No liability shall be accepted for any damage to the goods or the furnace

resulting from non-compliance with this warning.

This furnace is NOT used by certain persons (including children) with restricted

physical, sensorial or mental capabilities or who have insufficient experience

and/or insufficient knowledge, unless they are supervised by a person who is

responsible for their safety or are instructed in how to use the furnace. Children

should be supervised to make sure that they do not play with the furnace.

Pos: 71 /TD/Allgemeine Hinweise (für all e Anleitungen)/Hinweis - Dieses Produ kt entspricht nicht der ATEX-Richtlinie un d darf nicht ..-nicht brennbare Gase @ 2\ mod_1184228756893_51.docx @ 1968 6 @ @ 1

Pos: 72 /TD/Sicherheit/Überschrift - A nforderungen an den Betreiber der Anlage @ 0\mod_1167823775531_51.docx @ 5157 @ 2 @ 1

4.2 Requirements for the Furnace Operator

Pos: 73 /TD/Sicherheit/Anforderungen an d en Betreiber der Anlage - RHTH, RHTC , LHT, RT - Rohröfen @ 2\mod_1184 570280797_51.docx @ 19913 @ @ 1

16

Note

In Germany, the general accident protection guidelines must be observed. The accident

prevention regulations applicable in the country where the furnace is installed must be

observed.

All persons involved in operation, installation, maintenance, or repair of the furnace must

have read and understood the operating instructions. No liability will be accepted for

damage or disruptions to operation resulting from non-compliance with the operating

instructions.

Pos: 74 /TD/Sicherheit/Der Einsatz vo n Färbelösungen kann zu einem überpro portionalen Verschleiß der Heizelemente f ühren... @ 43\mod_1371115299588_51.d ocx @ 233530 @ @ 1

it

Pos: 75 /TD/Allgemeine Hinweise (für all e Anleitungen)/Hinweis - In Deutschla nd ist die allgemeine Unfallverhütungsvorschrif t zu beachten. @ 3\mod_119366780 1739_51.docx @ 26122 @ @ 1

a

The Operator must ensure that

all harmful gases are removed from the workplace, for example by an extraction

system,

the extraction system is switched on,

the workplace is properly ventilated,

the furnace is operated only in a perfect operating condition and, in particular, that the

functions of the safety components are checked regularly.

the required personal protective equipment is available for and used by the operating,

maintenance, and repair personnel.

these operating instructions, including the supplier documentation, are kept near the

furnace. These instructions must be available at all times for anyone working with or

on the furnace;

all the safety and operating instruction signs on the furnace can be read properly.

Damaged or unreadable signs must be replaced immediately,

furnace personnel are informed regularly about all issues involving occupational

safety and environmental protection and are familiar with all the operating

instructions, especially those involving safety,

a risk assessment is carried out (in Germany, covered of the Occupational Safety Act)

to determine any other hazards that may result from the working conditions particular

to the furnace's location,

all other instructions and safety guidelines that have been determined in a risk

assessment for the workplace are compiled in an operation manual (in Germany,

covered of the Ordinance Regulating the Use of Operating Equipment).

Only sufficiently qualified and authorized personnel may operate, maintain and repair

the system. This personnel must be trained in how to operate the furnace and must

confirm their participation in the training with a personal signature. The training

program must be documented in detail. In case an operator is replaced, additional

training must also take place. The additional training may only be performed by

authorized, trained individuals familiar with the system. The additional training must

be painstakingly documented and participation must be evidenced by the names and

signatures of the participating employees.

The use of paint solvents can lead to accelerated wear of the heating elements. If solvents

are used, good pre-drying is necessary to minimize their impact on the heating elements.

Pos: 76 /TD/Sicherheit/Überschrift - A nforderungen an das Bedienpersonal @ 0\mod_1167825643423_51.docx @ 516 6 @ 2 @ 1

4.3 Requirements for the Operating Personnel

Pos: 77 /TD/Sicherheit/Anforderungen an d as Bedienpersonal @ 0\mod_115821 8663482_51.docx @ 2155 @ @ 1

Only adequately qualified and authorized persons may operate, maintain, and repair the

system.

These personnel are informed regularly about all issues involving occupational safety and

environmental protection and are familiar with all the operating instructions, especially

those involving safety,

17

DANGER

• Danger caused by incorrectly entered cut-off temperature at

the over-temperature limiter/over-temperature limiter with

motor driven reset

• Risk of fatal injury

• If, as a result of over-temperature from the charge and/or the

operating equipment, a charge is likely to be damaged at this preset cut-off temperature of the over-temperature limiter/overtemperature limiter with motor driven reset, or if the charge itself

becomes a source of danger for the furnace or its surroundings,

the cut-off temperature must be reduced on the over-temperature

limiter/over-temperature limiter with motor driven reset to the

maximum permissible value.

Wear protective clothing

Wear a full face protection visor that is resistant to heat or splattering

Pos: 78 /TD/Sicherheit/Sicherheitssymbol e/Warnhinweise-ISO-ANSI/Warnsymb ol_Gefahr - Absicherung von Gefahren b ei Übertemperatur am TWB-TWW @ 37\ mod_1362490404893_51.docx @ 2140 67 @ @ 1

Only trained personnel may operate the control and safety equipment.

The Operator Should Complete these Details:

Operator

_______________________________________________________________

The furnace may only be transported by

_______________________________________________________________

The furnace may only be installed by

_______________________________________________________________

The furnace may only be commissioned by

_______________________________________________________________

Initial instructions may only be given by

_______________________________________________________________

Malfunctions may only be rectified by

_______________________________________________________________

The furnace may only be maintained by

_______________________________________________________________

The furnace may only be cleaned by

_______________________________________________________________

The furnace may only be serviced by

_______________________________________________________________

The furnace may only be repaired by

_______________________________________________________________

The furnace may only be shut down by

_______________________________________________________________

Pos: 79 /TD/Sicherheit/Überschrift - Sc hutzkleidung @ 0\mod_1167825795750 _51.docx @ 5175 @ 2 @ 1

4.4 Protective Clothing

Pos: 80 /TD/Sicherheit/Schutzkleidung - Schutzkleidung tragen @ 5\mod_122 0274995030_51.docx @ 42108 @ @ 1

Pos: 81 /TD/Sicherheit/Schutzkleidung - Gesichtsschutz- (Schutz vor Hitze un d Spritzer) @ 95\mod_1434960421391_51.d ocx @ 390332 @ @ 1

18

Wear heat-resistant gloves to protect your hands.

Risks during Normal Operation!

Before switching the furnace on, check and ensure that only authorized persons are in the

working area of the furnace and that no one can be injured as a result of operating the

furnace.

Note

The power plug is to be pulled out to stop the furnace in case of an emergency.

Therefore, the power plug must be accessible at all times when the furnace is operating so

that it can be pulled out quickly in case of an emergency.

Pos: 82 /TD/Sicherheit/Schutzkleidung - Hitzebeständige Handschuhe tragen @ 9\mod_1246542013306_51.docx @ 624 73 @ @ 1

Pos: 83 /TD/Sicherheit/Überschrift - Gru ndlegende Maßnahmen bei Normalbetri eb @ 0\mod_1167825919827_51.docx @ 5184 @ 2 @ 1

4.5 Basic Measures During Normal Operation

Pos: 84 /TD/Sicherheit/Grundlegende Maß nahmen bei Normalbetrieb (LHT ../..-Tisc hmodell) @ 32\mod_13522951916 92_51.docx @ 191520 @ @ 1

Before starting production each time, check and ensure that all the safety equipment works

properly.

Before starting production each time, check the furnace for obvious damage and ensure that

it is operated only in a perfect condition. Report any defects to a supervisor immediately.

Before starting production each time, remove all materials and objects that are not needed

for production from the working area.

At Least once every Day (see also Servicing and Maintenance) Check the Following:

Check the furnace for obvious external damage,

Check all hydraulic or pneumatic hoses, make sure that they are not leaking and that

they are connected properly (if applicable),

Check all gas and oil lines, make sure that they are not leaking and that they are

connected properly (if applicable),

Pos: 85 /TD/Sicherheit/Überschrift - Gru ndlegende Maßnahmen im Notfall @ 1\m od_1170943369267_51.docx @ 9093 @ 2 @ 1

Check that the fan works properly (if applicable)

4.6 Basic Measures in Case of Emergency

Pos: 86 /TD/Sicherheit/Überschrift - V erhalten im Notfall @ 1\mod_11709499048 55_51.docx @ 9123 @ 3 @ 1

4.6.1 What to Do in an Emergency

Pos: 87 /TD/Allgemeine Hinweise (für all e Anleitungen)/Hinweis - Das Stillsetze n im Notfall ist vorgesehen durch Ziehen d es Netzsteckers. @ 6\mod_12220628 36860_51.docx @ 42829 @ @ 1

Pos: 88 /TD/Sicherheit/Grundlegende Maß nahmen im Notfall - Netzstecker zie hen (alle Anleitungen) - Grafik @ 36\mo d_1360079722854_51.docx @ 208920 @ @ 1

Fig. 7: Pull the power plug (similar to picture)

19

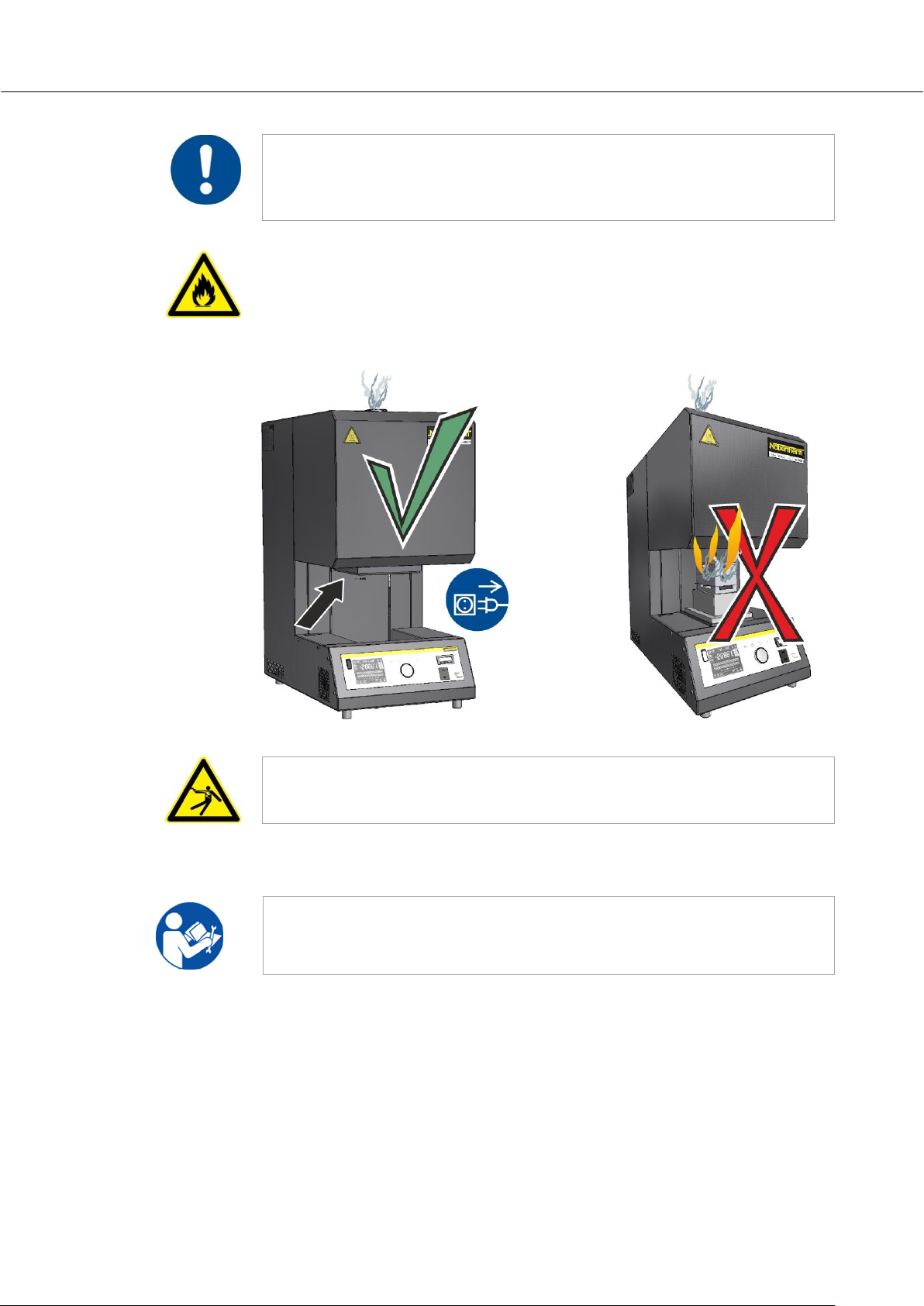

Risks during Normal Operation!

Switch the furnace off immediately in case of unexpected occurrences in the furnace (e.g.

a lot of smoke or unusual smells). Wait until the furnace has cooled naturally to room

temperature.

Warning - General hazards!

If unusual processes are occurring in the furnace (e.g., emission of heavy smoke or strong

odors), do not open the furnace. Doing so creates a fire or explosion hazard. Wait until

the furnace has naturally cooled down to room temperature.

Warning – Danger of Electric Shock!

Work on the electrical equipment may be done only by qualified, authorized electricians.

Maintenance work must be performed only by authorized persons, observing the

maintenance instructions and the accident prevention regulations. We recommend that

maintenance and repair work be carried out by the service team of Nabertherm GmbH.

Non-compliance may cause injuries, death, or considerable damage to property.

Pos: 89 /TD/Allgemeine Hinweise (für all e Anleitungen)/Warnung - Bei unerwarteten Vorgä ngen im Ofen (z.B. starke Rauchentwic klung oder Geruchsbelästigung) @ 4\m od_1205306579737_51.docx @ 34218 @ @ 1

Pos: 90 /TD/Allgemeine Hinweise (für all e Anleitungen)/Warnung - Bei unerwart eten Vorgängen darf der Ofen nicht geöffn et werden @ 7\mod_1232553819617_5 1.docx @ 48258 @ @ 1

Pos: 91 /TD/Allgemeine Hinweise (für all e Anleitungen)/Warnung - Bei unerwart eten Vorgängen darf der Ofen nicht geöffn et werden - M01.0086 - Grafik @ 178\m od_1512996929131_51.docx @ 7261 03 @ @ 1

Pos: 92 /TD/Allgemeine Hinweise (für all e Anleitungen)/Warnung - Arbeiten an d er elektrischen Ausrüstung dürfen nur vo n ... @ 2\mod_1184228021019_51.doc x @ 19673 @ @ 1

Pos: 93 /TD/Sicherheit/Überschrift - Gru ndlegende Maßnahmen bei Wartung und Instandhaltung @ 0\mod_1167826060 620_51.docx @ 5193 @ 2 @ 1

4.7 Basic Measures for Servicing and Maintenance

Pos: 94 /TD/Sicherheit/Grundlegend e Maßnahmen bei Wartung und Instandhalt ung @ 0\mod_1158222458436_51.doc x @ 2188 @ @ 1

Pos: 105 /TD/Sicherheit/Grundlegende Maß nahmen bei Wartung und Instandhaltung @ 0\mod_1158222458436_51.doc x @ 2188 @ @ 1

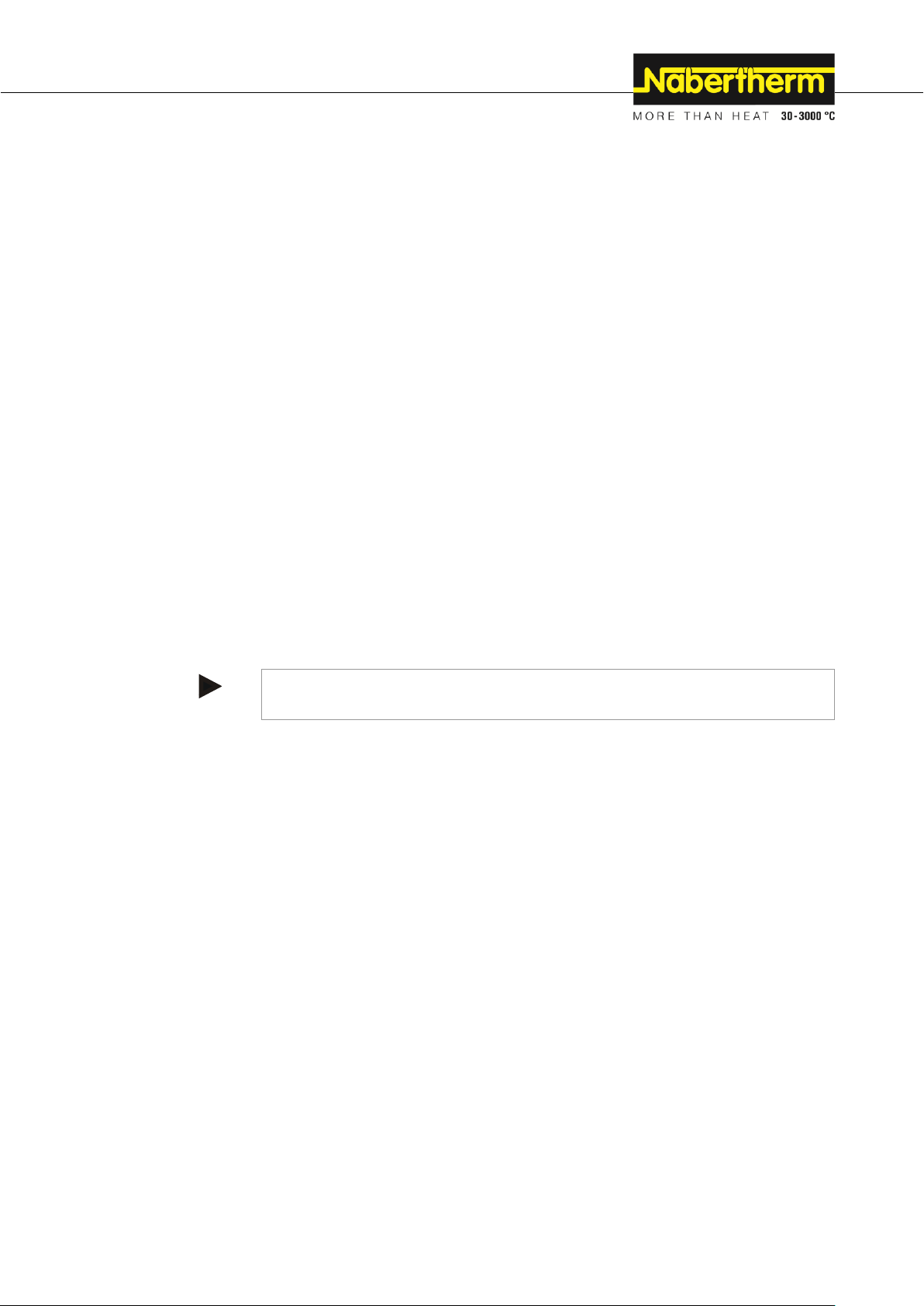

Switch off the system and make sure it cannot be switched on again inadvertently (lock the

main switch and secure it with a padlock), or pull out the power plug.

Clear an adequate area around the system to facilitate the repair work.

Suspended loads are dangerous. Working beneath a suspended load is prohibited. There is a

risk of fatal injury.

Relieve the pressure on hydraulic and pneumatic equipment before carrying out

maintenance or repair work. (if applicable).

When cleaning furnaces, control cabinets, or electrical equipment housings, never spray

them with water.

When maintenance or repair work has been completed, before recommencing production

20

Note

The operator must ensure that national environmental regulations are observed.

ensure the following:

Check that loosened screw connections have been re-tightened,

Reinstall protective equipment, screens, and filters,

Remove all material, tools, and other equipment used for the maintenance or repair

work from the working area of the system,

Remove any liquids that have leaked,

Check that all safety functions (e.g. EMERGENCY STOP button) work properly,

Pos: 95 /TD/Sicherheit/Lüfter auf Fun ktion prüfen (wenn bei Anlage vorhanden) @ 5 0\mod_1385451942691_51.docx @ 254780 @ @ 1

Pos: 96 /TD/Sicherheit/Überschrift - Um weltschutzvorschriften @ 0\mod_116782 6189237_51.docx @ 5202 @ 2 @ 1

Power cables may be replaced only with similar, approved cables

Check that the fan works properly (if applicable)

4.8 Environmental Regulations

Pos: 97 /TD/Sicherheit/Umweltschutz vorschriften Schmierfette-Hydrauliköl-Kühl mittel @ 0\mod_1158223424304_51.doc x @ 2199 @ @ 1

All statutory duties regarding waste avoidance, proper recycling, and disposal must be

observed when work is carried out on and with the furnace.

Problem materials that are no longer needed, such as lubricants or batteries, must not be

placed in normal waste disposal systems or allowed to enter the sewage system.

During installation, repair, and maintenance work, substances that are hazardous to water,

such as

lubricating grease and oils

hydraulic oils

refrigerants

solvent-based cleaning fluids must not be allowed to contaminate the soil or enter the

sewage system.

These substances must be stored, transported, collected, and disposed of in suitable

containers.

Pos: 98 /TD/Sicherheit/Umweltschutz vorschriften Elektronische Bauteile-Isolieru ng-Altmetall @ 4\mod_1205143314853 _51.docx @ 32563 @ @ 1

When it is delivered, this furnace contains no substances that make a hazardous waste

classification necessary. However, residues of process materials may accumulate in the

furnace insulation during operation. These may be hazardous to health and/or the

environment.

Dismantle the electronic components and dispose of them as electric scrap.

Remove the insulation and dispose of it as hazardous waste (see “Servicing, Cleaning,

and Maintenance with Ceramic Fiber Material”).

Dispose of the housing as scrap metal.

Contact the responsible disposal company to dispose of the materials listed above.

21

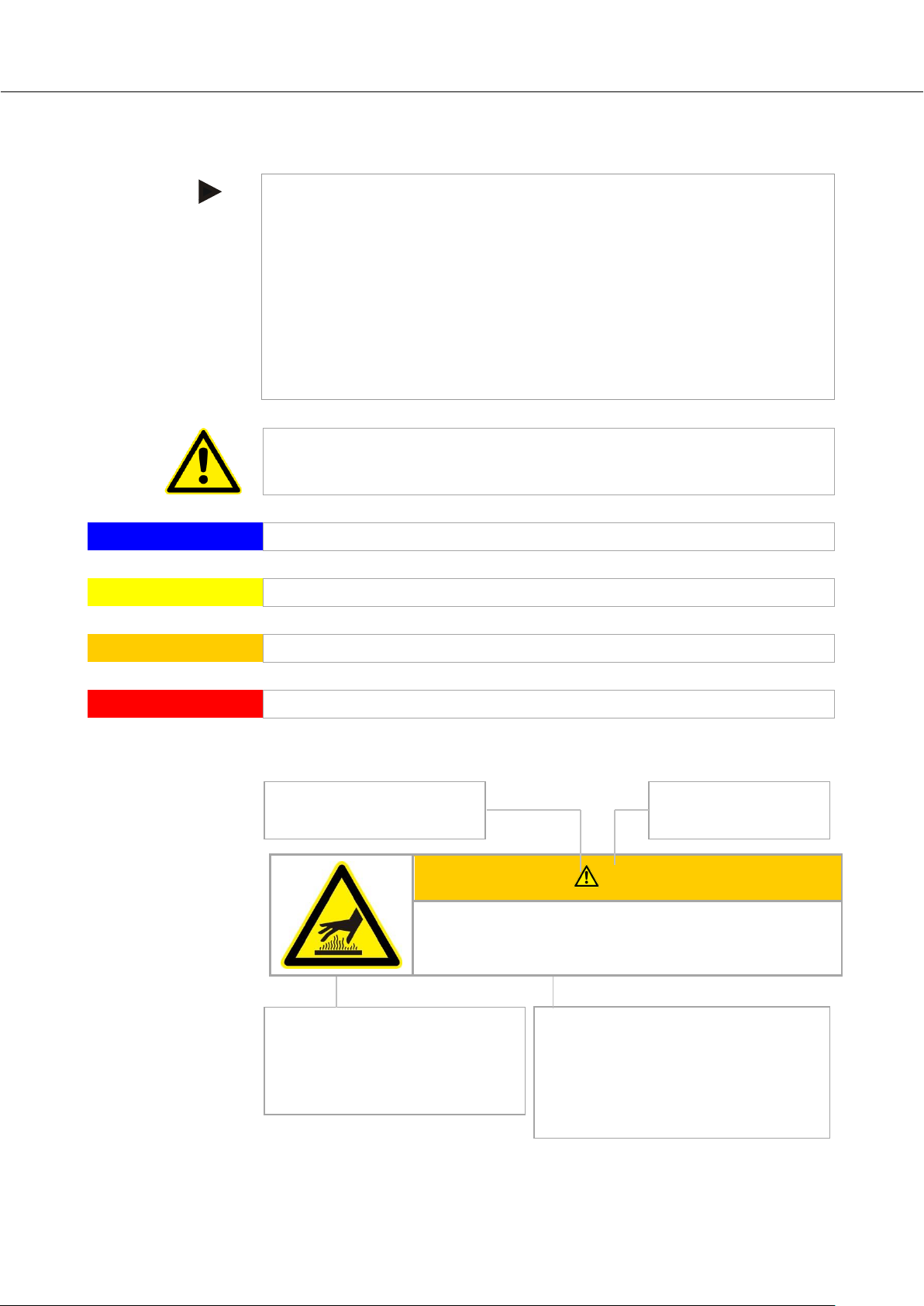

Note

In the following operating instructions, specific warnings are given to draw attention to

residual risks that cannot be avoided when the furnace is operating. These residual risks

include dangers for humans/products/ the furnace, and the environment.

The symbols used in the operating instructions are especially intended to draw attention to

safety information.

The symbols used cannot replace the text of the safety information. Therefore, always

read the entire text.

Graphic symbols correspond to ISO 3864. In accordance with the American National

Standard Institute (ANSI) Z535.6 the following warning information and words are used

in this document:

The general hazard symbol, in combination with the words CAUTION, WARNING and

DANGER warns about the risk of serious injury. Observe the following information to

prevent injury or death.

NOTE

Refers to a hazard that could damage or destroy the equipment.

CAUTION

Refers to a hazard with a minor or medium risk of injury.

WARNING

Refers to a hazard that could cause death, serious or irreversible injury.

DANGER

Refers to a hazard that could directly cause death, serious or irreversible injury.

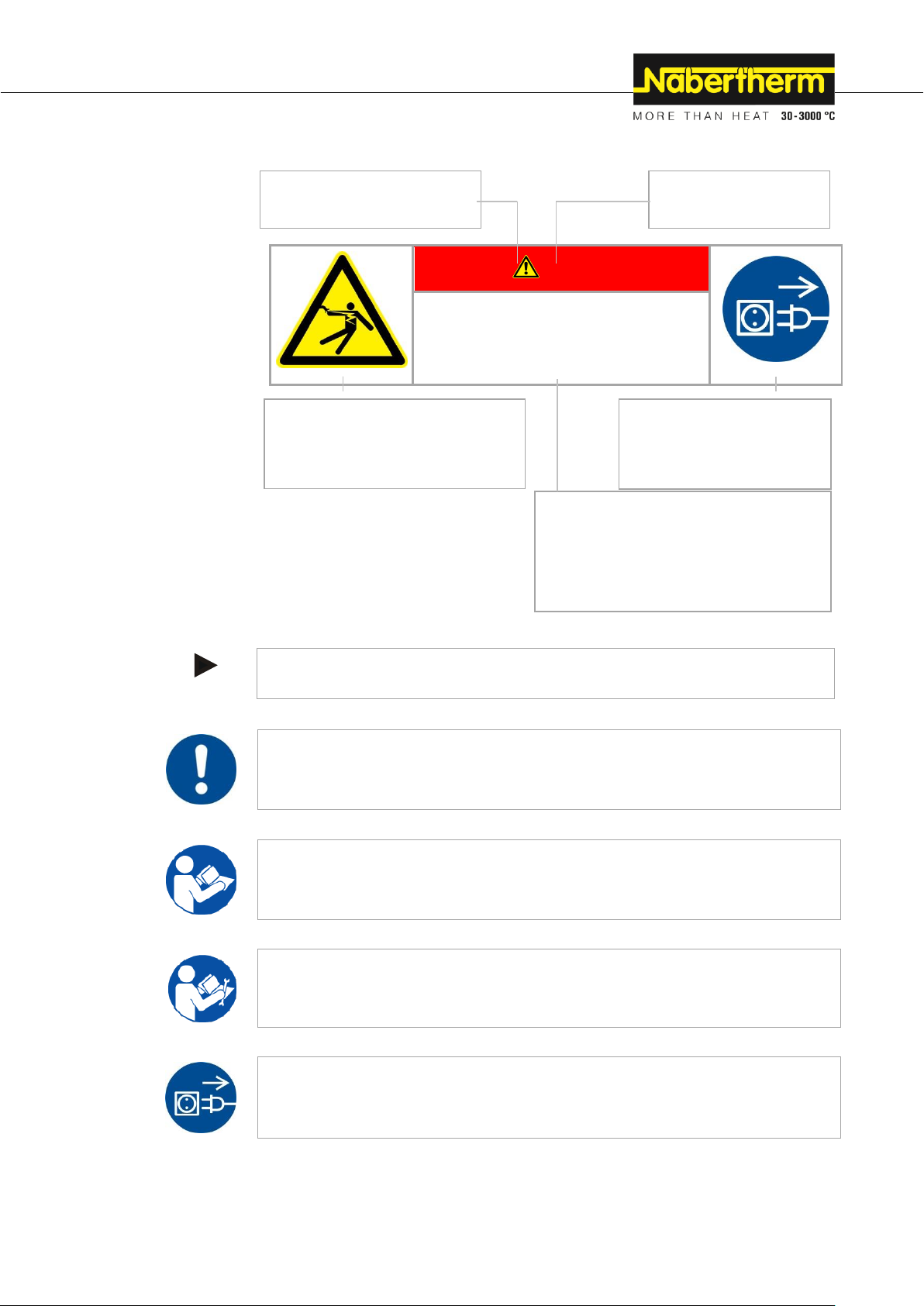

WARNING

• Type and source of the danger

• Consequences of non-compliance

• Action to prevent danger

Hazard Symbol

Indicates the risk of injury

Signal Word

Classifies the danger

Graphical Symbols (optional)

According to ISO 3864:

Consequences, measures, and

prohibitions

Reference Texts:

• Type and source of the danger

• Possible consequences of non-

compliance

• Measures/Prohibitions

Pos: 99 /TD/Sicherheit/Sicherheitssymbol e/Warnhinweise-ISO-ANSI/Erläuteru ng ANSI Z535.6 @ 8\mod_124332355888 1_51.docx @ 57444 @ 2 @ 1

4.9 Explanation of the Symbols and Warnings

Structure of the Warning: All Warnings are Structured as Follows

22

DANGER

• Type and source of the danger

• Consequences of non-compliance

• Action to prevent danger

Note

Below this symbol you will find instructions and particularly useful information.

Rule - Rule Sign

This symbol draws attention to important rules that must be observed. Rule signs protect

people against injury and show what is to be done in certain situations.

Rule – Important Information for Operators

This symbol draws the operator's attention to important information and operating

instructions that must be observed.

Rule – Important Information for Maintenance Personnel

This symbol draws the maintenance personnel's attention to important operating and

maintenance instructions (service) that must be observed.

Rule – Pull Out the Power Plug

This symbol tells the operator to pull out the power plug.

Graphical Symbols (optional)

According to ISO 3864:

Consequences, measures, and

prohibitions

Reference Texts:

• Type and source of the danger

• Possible consequences of non-compliance

• Measures/prohibitions

Graphical Symbols

(optional) According to ISO

3864:

Instructions or prohibitions

Hazard Symbol

Indicates the risk of injury

Signal Word

Classifies the danger

Pos: 100 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Überschrift - Hinweissymbole in der Anleitung (Einz ug Mitte) @ 9\mod_1247053429626_5 1.docx @ 62751 @ @ 1

Pos: 101 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Hinweis - Unter diesem Symbol erhalten Sie Anweis ungshinweise und ... @ 9\mod_124 7053932311_51.docx @ 62785 @ @ 1

or

Information Symbols in the Instructions:

Pos: 102 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Gebot - Gebotszeich en - Wichtige Gebote sind zu befolgen @ 9\mod_1247056175982_51.docx @ 62 853 @ @ 1

Pos: 103 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Gebot - Wichtige Infor mation für den Bediener @ 9\mod_ 1247053200729_51.docx @ 62717 @ @ 1

Pos: 104 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Gebot - Wichtige Infor mation für das Wartungspersonal @ 9\mod_1247053206042_51.docx @ 62734 @ @ 1

Pos: 105 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Gebot - Netzstec ker ziehen @ 9\mod_1247055471526_51.d ocx @ 62836 @ @ 1

23

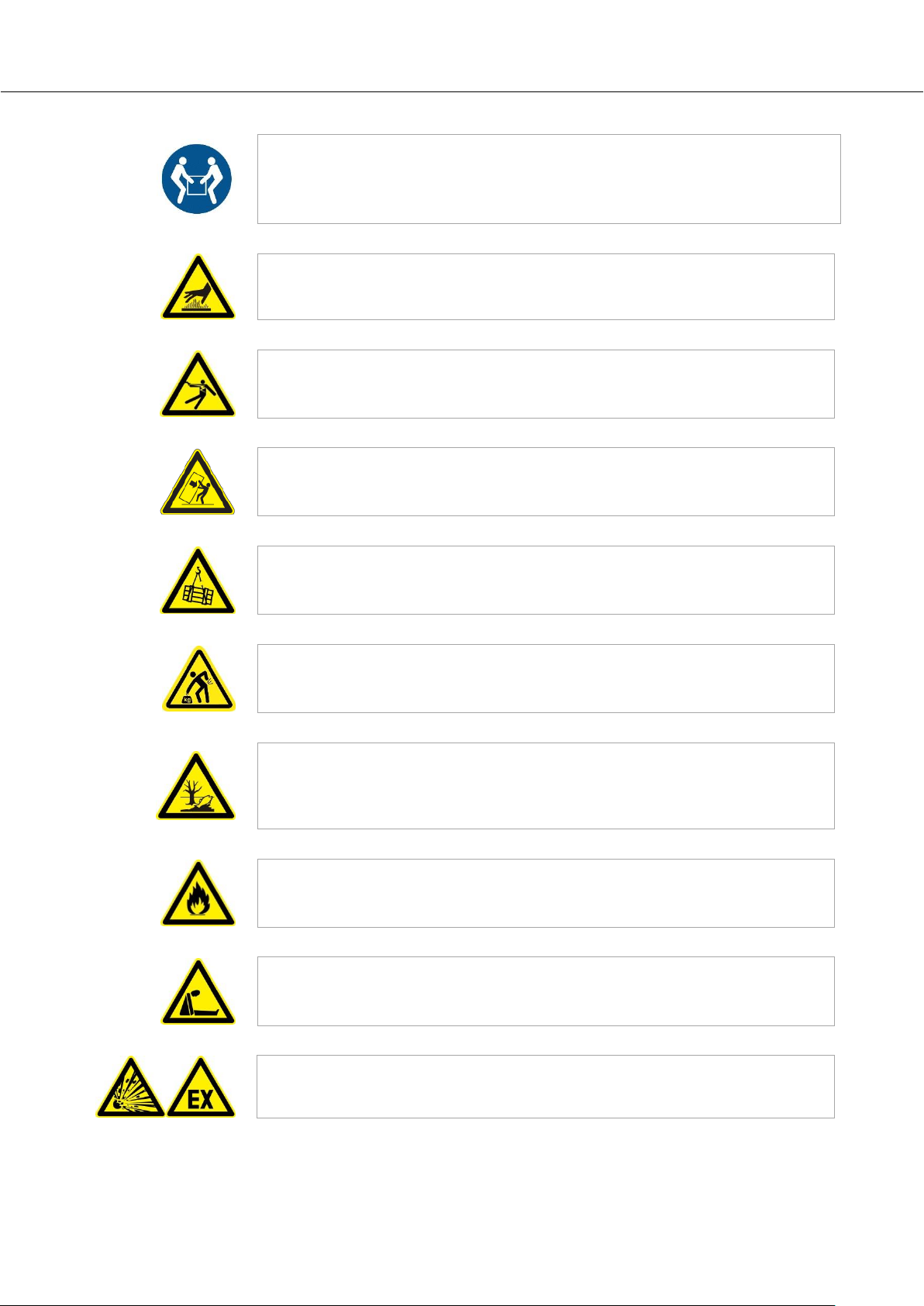

Rule – Lift only with Several People

This symbol draws the personnel's attention to the fact that this device may only be lifted

and moved to its final destination by several people.

Warning – Hot Surface, Do Not Touch

This symbol warns the operator that the surface is hot and should not be touched.

Warning – Danger of Electric Shock

This symbol warns the operator that there is a risk of an electric shock if the following

warnings are not heeded.

Warning – Risk of Device Toppling Over

This symbol tells the operator that there is a risk of the device toppling over if the

following warnings are not heeded.

Warning – Suspended Load

This symbol warns the operator of potential dangers of suspended loads. Working below a

suspended load is strictly forbidden. Ignoring this can lead to fatal injury.

Warning – Danger if Heavy Loads are Lifted

This symbol warns the operator of the potential dangers of lifting heavy loads. Ignoring

this can lead to injury.

Warning – Risk to the Environment

This symbol warns the operator of the risk to the environment if the following information

is not heeded. The operator must ensure that national environmental regulations are

observed.

Warning – Fire Danger

This symbol warns operators of the danger of fire if the following information is not

followed.

Warning – Suffocation from Lack of Oxygen

This symbol warns the operator of the possibility of suffocating from lack of oxygen.

Ignoring this can lead to suffocation

Warning – Risk of Explosive Substances or Explosive Atmosphere

These symbols warn the operator of explosive substances or an explosive atmosphere

Pos: 106 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Gebot - Anheben mit mehreren Personen @ 9\mod_12470 63058002_51.docx @ 62938 @ @ 1

Pos: 107 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Warnung - Heiße O berfläche - Oberfläche nicht berühren @ 9\ mod_1247054774780_51.docx @ 628 02 @ @ 1

Pos: 108 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Warnung - elektrisch er Schlag - zur Vermeidung Anweisung folgen @ 9\mod_1247055093892_51.d ocx @ 62819 @ @ 1

Pos: 109 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Warnung - Umkippe n des Gerätes @ 9\mod_124705919837 2_51.docx @ 62870 @ @ 1

Pos: 110 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Warnung - Sch webende Lasten @ 9\mod_1251450500309 _51.docx @ 65454 @ @ 1

Pos: 111 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Warnung - Heben sc hwerer Lasten @ 9\mod_12470598913 58_51.docx @ 62887 @ @ 1

Pos: 112 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Warnung - Umweltge fährdung @ 9\mod_1247060443419_ 51.docx @ 62904 @ @ 1

Pos: 113 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Warnung - Brandg efahr @ 9\mod_1251445272822_51.doc x @ 65437 @ @ 1

Pos: 114 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Warnung - Ersticku ngsgefahr @ 16\mod_1307435027242_5 1.docx @ 118628 @ @ 1

Pos: 115 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Warnung - Explosi onsgefährliche Stoffe @ 9\mod_12470611 48859_51.docx @ 62921 @ @ 1

24

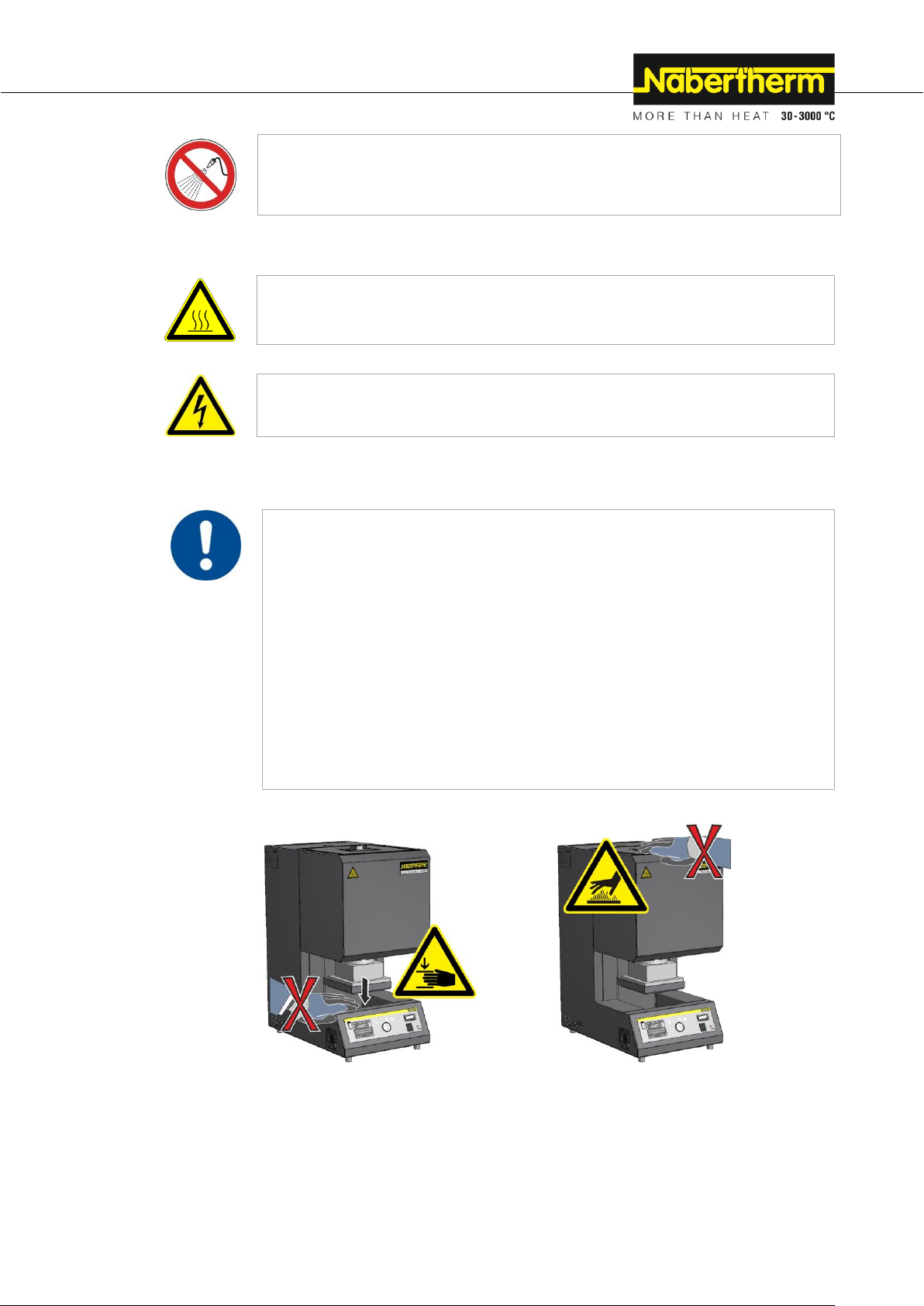

Prohibited – Important Information for Operators

This symbol warns the operator that water or cleaning products must NOT be poured over

the objects. A high-pressure cleaning device must also not be used.

Warning – Hot Surface, Danger of Burning – Do Not Touch

You may not always realize that surfaces, such as furnace components, furnace walls,

doors and materials, and even liquids are hot. Do not touch the surface.

Warning – Danger of Electric Shock!

Warning, dangerous electric voltage

Warning – General hazards

Risk of burning on the furnace housing

Risk of burning on the exhaust tubes

Risk of crushing from moving parts (lift bottom)

Live parts contain dangerous electrical voltages.

Operate the furnace only with fully installed and closed cover panels.

No objects should be inserted into openings in the furnace housing, exhaust tubes or

cooling slits of the switchgear or furnace. Ignoring this warning can result in electric

shock.

Risk of fire if using an extension cable:

If an extension cable or a power board is used, its maximum electrical load must not be

exceeded. Do not operate the furnace with an extension cable if you are not sure if

grounding is guaranteed.

Risk of crushing when the lift bottom is

being lowered

Risk of burning at the exhaust tubes on the

top of the furnace

Pos: 116 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Gefahr - nicht mit W asser überschütten @ 9\mod_12478264 10886_51.docx @ 63819 @ @ 1

Pos: 117 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Überschrift - Warnhinweissymbole an der Anlag e @ 9\mod_1247053700273_51.docx @ 62 768 @ @ 1

Pos: 118 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Piktogram m an der Anlage - Warnung - Gefahr vor heißer Oberfläche und Verbrennung @ 9\ mod_1247052957145_51.docx @ 627 00 @ @ 1

Pos: 119 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Piktogram m an der Anlage - Warnung - Gefahren durch elektrischen Strom @ 9\mod_1247 052639824_51.docx @ 62683 @ @ 1

Pos: 120 /TD/Sicherheit/Überschrift - Allgemeine Gefahren an der Anlage @ 0\ mod_1168596796288_51.docx @ 6014 @ 2 @ 1

Warning Signs on the Furnace:

4.10 General Risks with the Furnace

Pos: 121 /TD/Sicherheit/Allgemeine Gefa hren (Verbrennung, Quetschen, Strom) - LHT ../17 LB Speed @ 178\mod_1 512998598431_51.docx @ 726129 @ @ 1

Pos: 122 /TD/Allgemeine Hinweise (für alle Anleitungen)/Allgemeine Gefahren a m Hochtemperatur-Hubbodenofen - M 01.0086 - Grafik @ 178\mod_15130002 37878_51.docx @ 726255 @ @ 1

25

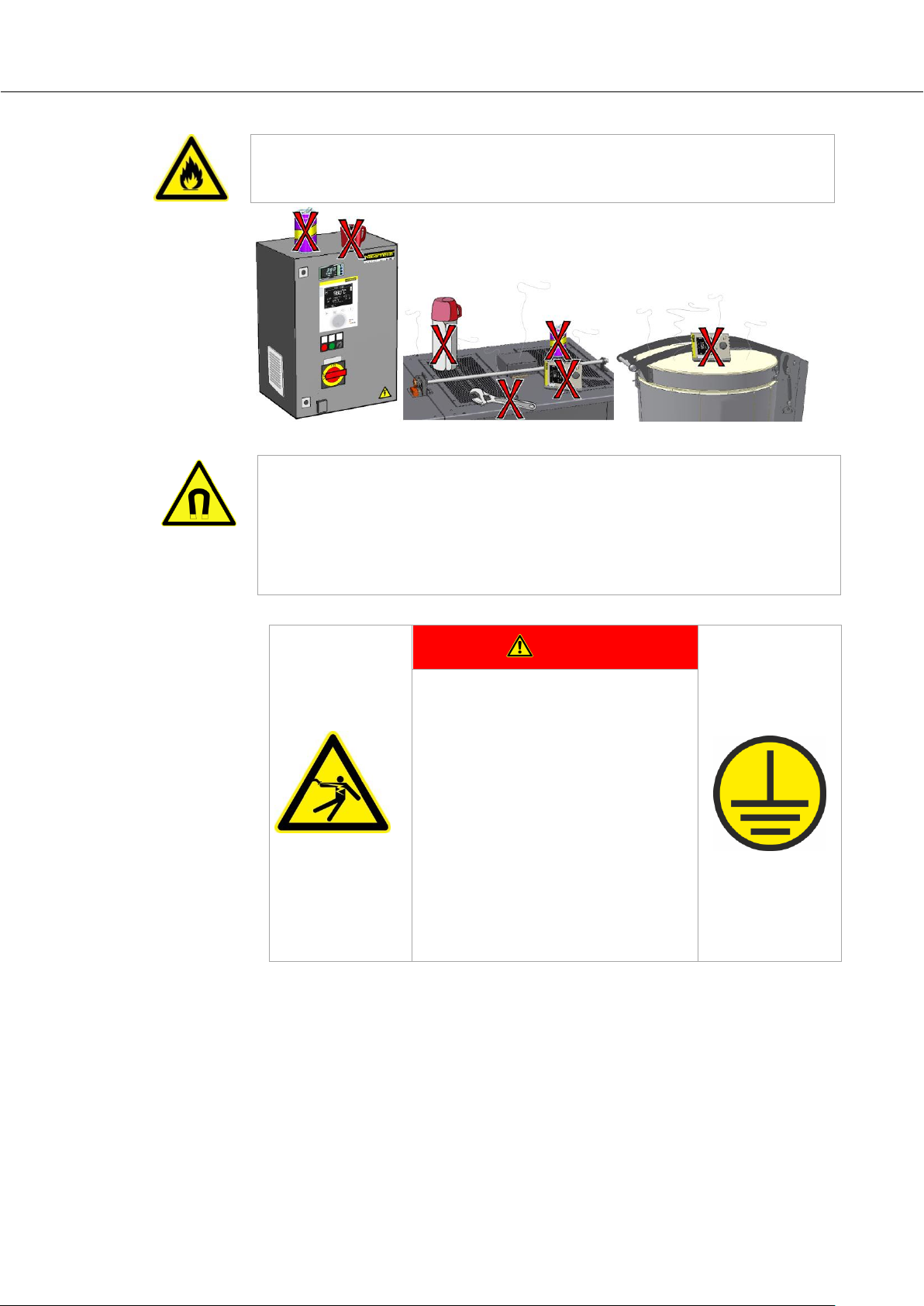

Warning – General Hazards

No objects may be placed or set down on the furnace or switchgear. There is a risk of fire or

explosion.

Warning – Influence on Implants from Electromagnetic Fields

It can be assumed that there is no risk from electromagnetic fields. Deviating from this,

there may be a risk for people with active implants (such as a pacemaker, insulin pump) and

passive implants, as the function of the implant may be affected also with a field strength

below the permissible threshold. Proper function must be ensured on the basis of the

technical specifications of the implant through an individual assessment by a suitable expert

(for example, an occupational physician).

DANGER

• Danger from electrocution

• If there is no earth connection, or the

earth connection is poorly connected,

the result may be a deadly electrical

shock.

• Do not insert any metallic objects such as

thermocouples, sensors or tools into the

furnace chamber without having

previously ensured that the plant has been

correctly earthed. Entrust the job of

making a earth connection between the

object and the furnace housing to a

qualified electrical technician. Any

objects inserted into the furnace must be

inserted only through those openings

intended for this purpose.

Pos: 123 /TD/Allgemeine Hinweise (für alle Anleitungen)/Warnung - Es dürfe n keine Gegenstände auf den/der Ofe n/Schaltanlage abgelegt/abgestellt werden... @ 4\mod_1203924555465_51.doc x @ 31568 @ @ 1

Pos: 124 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Piktogram m in der Anleitung - Warnung - vor elektro magnetische Felder (Implantat-Herzschri ttmacher) @ 116\mod_14594946685 52_51.docx @ 460673 @ @ 1

Pos: 125 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Warnsym bol_Gefahr - Gefahr durch fehlende oder nicht korrekt angeschlossene Erdung a n ... @ 85\mod_1423745935634_51.docx @ 359461 @ @ 1

26

DANGER

• Danger caused by incorrectly entered cut-off temperature at

the over-temperature limiter/over-temperature limiter with

motor driven reset

• Risk of fatal injury

• If, as a result of over-temperature from the charge and/or the

operating equipment, a charge is likely to be damaged at this preset cut-off temperature of the over-temperature limiter/overtemperature limiter with motor driven reset, or if the charge itself

becomes a source of danger for the furnace or its surroundings,

the cut-off temperature must be reduced on the over-temperature

limiter/over-temperature limiter with motor driven reset to the

maximum permissible value.

Risks during Normal Operation!

Suspended loads are dangerous. Working beneath a suspended load is prohibited. There is

a risk of fatal injury.

Pos: 126 /TD/Sicherheit/Sicherheitss ymbole/Warnhinweise-ISO-ANSI/Warnsym bol_Gefahr - Absicherung von Gefahren bei Übertemperatur am TWB-TWW @ 3 7\mod_1362490404893_51.docx @ 214 067 @ @ 1

Pos: 127 /TD/Transport_Montage_Inb etriebnahme/Erstinbetriebnahme/Überschrift - Transport, Montage und Erstinbetrie bnahme @ 0\mod_1158844227416_51.d ocx @ 3112 @ 1 @ 1

5 Transportation, Installation and Initial Start-Up

Pos: 128 /TD/Transport_Montage_Inb etriebnahme/Erstinbetriebnahme/Überschrift - Anlieferung @ 0\mod_116782653488 9_51.docx @ 5220 @ 2 @ 1

5.1 Delivery

Pos: 129 /TD/Transport_Montage_Inb etriebnahme/Erstinbetriebnahme/Anlieferung - (Hinweise allgemein) @ 0\mod_11 58233508887_51.docx @ 2223 @ @ 1

Check that Everything is Complete

Compare the delivered items with the delivery note and the purchase order documents.

Immediately notify the carrier and Nabertherm GmbH of any missing or damaged parts, as

complaints at a later date cannot be acknowledged.

Danger of Injury

When the furnace is being lifted, parts of the furnace or the furnace itself could topple over,

slip, or fall. Before the furnace is lifted, make sure no one is in the working area. Wear

safety footwear and a hard hat.

Safety Instructions

Forklifts must be operated only by authorized personnel. The operator bears sole

responsibility for safe operation and the load

When the furnace is being lifted, make sure that the ends of the forks or the load do

not catch on neighboring goods. Use a crane to move tall parts, such as control

cabinets.

Use only lifting equipment with sufficient load-bearing capacity

Lifting gear must be attached only to positions that have been designated for this

purpose

Attachments, piping, or cable conduits must never be used to affix lifting gear

Unpackaged parts should only be lifted with ropes or straps

Attach transportation equipment only to positions intended for this purpose.

Lifting and securing equipment must conform to the provisions contained in accident

prevention regulations

Consider the weight of the furnace when choosing lifting and securing equipment.

(see Specifications)

Stainless steel parts (including mounting elements) must always be kept separate from

unalloyed steel parts

Do not remove corrosion protection until immediately prior to assembly

27

Note

Safety and accident prevention guidelines applicable for forklift trucks must be followed.

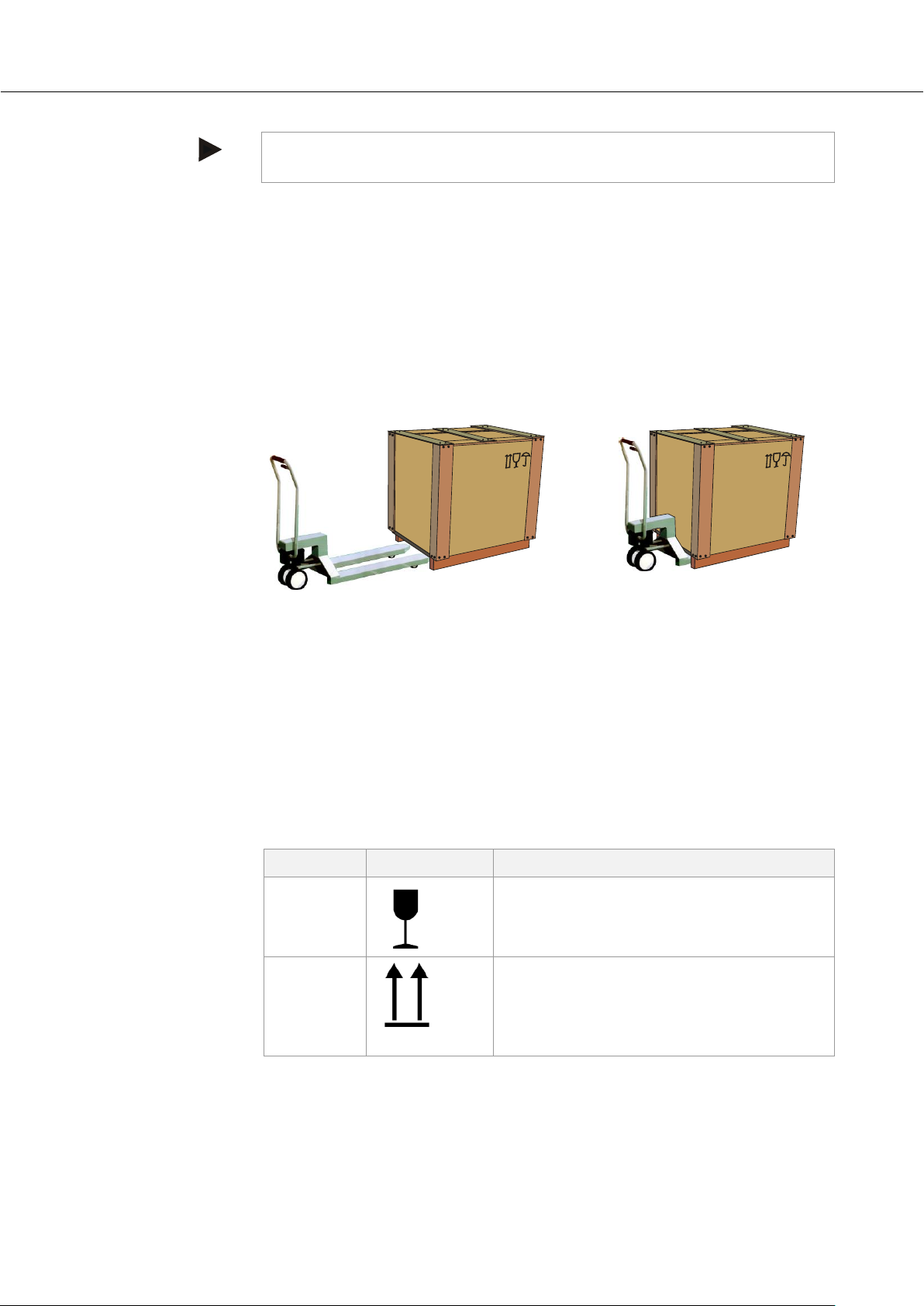

Description

Symbol

Explanation

Fragile

This symbol is to be attached to fragile goods.

Goods marked like this are to be handled carefully

and must not be thrown or tied up.

This side up

The freight must be transported, transshipped, and

stored in such a way that the arrows point upward.