Operating Instructions

Laboratory Furnaces (Muffle Furnaces)

L .../...

LE .../...

LT .../...

LV .../...

LVT .../...

-SKM -SW -HA

-> 10.2005

Original instructions

www.nabertherm.com

Made

in

Germany

2

Copyright

Copyright by

Nabertherm GmbH

Bahnhofstrasse 20

28865 Lilienthal

Federal Republic of Germany

Reg: M01.0032 ENGLISCH

Rev: 2014-06

No responsibility is accepted for the correctness of this information. We

reserve the right to make technical alterations.

3

1 Introduction ........................................................................................................................................................... 5

1.1 Product Description ........................................................................................................................................... 6

1.2 Overview of the Complete Furnace ................................................................................................................... 7

1.3 Safeguarding against Dangers Posed by Over-Temperature ............................................................................. 9

1.3.1 Key to the Model Names ............................................................................................................................ 10

1.4 Scope of Delivery ............................................................................................................................................ 11

2 Specifications ....................................................................................................................................................... 12

2.1 Warranty and Liability .................................................................................................................................... 16

3 Safety .................................................................................................................................................................... 17

3.1 Intended Use.................................................................................................................................................... 17

3.2 Requirements for the Furnace Operator .......................................................................................................... 18

3.3 Requirements for the Operating Personnel ...................................................................................................... 19

3.4 Protective Clothing .......................................................................................................................................... 20

3.5 Basic Measures During Normal Operation ..................................................................................................... 20

3.6 Basic Measures in Case of Emergency ........................................................................................................... 21

3.6.1 What to do in an Emergency ....................................................................................................................... 21

3.7 Basic Measures for Servicing and Maintenance.............................................................................................. 22

3.8 Environmental Regulations ............................................................................................................................. 22

3.9 Explanation of the Symbols and Warnings ..................................................................................................... 23

3.10 General Risks with the Furnace ....................................................................................................................... 26

4 Transportation, Installation, and Commissioning ............................................................................................ 27

4.1 Delivery ........................................................................................................................................................... 27

4.2 Unpacking ....................................................................................................................................................... 29

4.3 Transportation Securing Equipment/Packaging .............................................................................................. 31

4.4 Constructional and Connection Requirements ................................................................................................ 31

4.4.1 Installation (Furnace Location) ................................................................................................................... 31

4.5 Assembly, Installation, and Connection .......................................................................................................... 32

4.6 Assembly of a Vent ......................................................................................................................................... 32

4.6.1 Venting Exhaust Fumes .............................................................................................................................. 34

4.6.2 Connecting the Furnace to the Power Supply ............................................................................................. 35

4.6.3 Insertion of the Base Plate .......................................................................................................................... 37

4.7 Commissioning ............................................................................................................................................... 38

4.8 Recommendations for Heating the Furnace for the First Time ....................................................................... 39

4.9 Loading/Charging ........................................................................................................................................... 39

5 Operation ............................................................................................................................................................. 41

5.1 Operating Controller B 180/P 330 ................................................................................................................... 41

5.2 Operating Controller R 6 ................................................................................................................................. 42

5.3 Over-Temperature Limiter with Manual Reset and Adjustable Cut-Off Temperature ................................... 43

5.4 Air Inflow Lever ............................................................................................................................................. 44

6 Servicing, Cleaning, and Maintenance .............................................................................................................. 45

6.1 Shutting the System Down for Maintenance ................................................................................................... 46

6.2 Regular Maintenance of the Furnace ............................................................................................................... 47

6.3 Operating and Auxiliary Materials .................................................................................................................. 48

6.4 Cleaning Products ........................................................................................................................................... 48

4

7 Malfunctions ........................................................................................................................................................ 49

7.1 Replacing a Fuse ............................................................................................................................................. 50

7.1.1 Fuse Located Outside the Switchgear ......................................................................................................... 50

7.1.2 Fuse Located Inside the Switchgear ............................................................................................................ 51

7.2 Separate the Snap-In Coupling (Plug) from the Furnace Housing .................................................................. 53

8 Spare Parts/Wearing Parts ................................................................................................................................. 54

8.1 Electrical Schematics/Pneumatic Schematics ................................................................................................. 55

9 Nabertherm Service ............................................................................................................................................ 55

10 Shut-Down, Dismantling, and Storage............................................................................................................... 56

10.1 Environmental Regulations ............................................................................................................................. 56

10.2 Transportation/Return Transportation ............................................................................................................. 56

11 Declaration of Conformity .................................................................................................................................. 58

5

Pos: 1 /TD/Einleitung/Überschrift - Einleitung 1 @ 0\mod_ 116 7823212238_51.docx @ 5139 @ 1 @ 1

1 Introduction

Pos: 2 /TD/Einleitung/Öfen @ 0\mod_1158157227533_51.d ocx @ 2084 @ @ 1

Dear Customer,

Thank you for choosing a quality product from Nabertherm GmbH.

You can be proud that you have chosen a furnace which has been especially tailored to suit

your manufacturing and production conditions.

This product is characterized by

professional workmanship

high performance due to its high efficiency

high-quality insulation

low power consumption

low noise level

simple installation

easy to maintain

high availability of spare parts

Your Nabertherm Team

Note

These documents are intended only for buyers of our products and may not be copied or

disclosed to third parties without our written consent. (Law governing copyright and

associated protective rights, German Copyright Law from Sept. 9, 1965)

Protective Rights

Nabertherm GmbH owns all rights to drawings, other documents and authorizations, also in

case of applications for protective rights.

Note

All the figures in the instructions have a descriptive character; in other words, they do not

represent the exact details of the furnace.

Pos: 3 /TD/Einleitung/Die in der Anleitung gezeigten Abbi l dungen können abhängig von Funktion, Ausführung ... @ 24\mod_1337854352242_51.doc x @ 1616 05 @ @ 1

Note

The pictures contained in the instruction manual may contain inaccuracies in terms of the

function, design and furnace model.

Pos: 4 /TD/Einleitung/Produktbeschreibung/Öfen/ Überschrift - Produktbeschreibung 1.1 @ 0\mod_1167821 943807_51.docx @ 5103 @ 2 @ 1

6

1.1 Product Description

Pos: 5 /TD/Einleitung/Produktbeschreibung/Öfen/P r oduktbeschreibung-Laborofen L-LE-L(T)-LV ( T)-SKM-SW-HA @ 14\mod_1299596880427_51.docx @ 113276 @ @ 1

These laboratory furnaces are a high-quality product which will give you many years of

reliable service if they are properly cared for and maintained. One basic prerequisite is that

the furnace is used the way it was designed to be used.

During development and production a high priority was placed on safety, functionality and

economy.

Laboratory Furnaces are attractive thanks to their many advantages. These furnaces are

all-rounders for research and laboratory applications. They are made from expertly finished,

high-quality materials and are easy to operate. These furnaces are optimally designed for

incinerating and heat treatment. The very best insulation materials permit energy-saving

operation and fast heating times thanks to low heat storage and thermal conductivity.

Laboratory furnaces attain furnace chamber temperatures of max. 1100 °C (2012 °F), 1200

°C (2192 °F) or 1300 °C (2372 °F).

Other Characteristics of this Product are:

All the models have a high-quality, multi-layered and energy-saving thermal

insulation

Double-wall housing means low outer temperatures and solid stability. All furnaces

have housings made of textured stainless steel sheet.

Good temperature uniformity provided by special air supply and exhaust system for

models LV/LVT .../… and LT …/…HA. For models LV/LVT .../… the system

delivers more than 6 air changes a minute. The incoming air is pre-heated, so that a

good temperature uniformity is ensured.

There are furnaces with drop-down doors or lift doors

Ceramic heating plates with integrated heating wire, protected against splattering and

exhaust-air for models L/LT …/… and LV/LVT .../…

Model L/LT …/…/SW with scale and software (Controltherm MV) for annealing loss

specifications

All the models are equipped with a controller which provides considerable safety

against operator mistakes. The furnace chamber temperature is measured and

regulated by a long-life thermocouple (NiCr-Ni Tmax < 1100 °C or PtRh-Pt Tmax >

1100 °C).

Additional Equipment

Vent, vent with fan or catalytic converter.

Over-temperature limiter with adjustable shut-down temperature for thermal

protective class 2 as specified in EN 60519-2 to protect the furnace and the ware

against overheating.

Manual or automatic protective gas system Protective gas connection on the back side

of the furnace

Digital interface RS 422, for example, for process control and documentation

provided by Controltherm MV software package.

Base plates and catch basins to protect of the furnace and to enable easy charging

Rectangular container, stackable for charging on several levels

7

Pos: 6 /TD/Einleitung/Lieferumfang/Öfen/Übersc hr ift - Gesamtübersicht der Anlage @ 1\mod_1174302636992_5 1.docx @ 11332 @ 2 @ 1

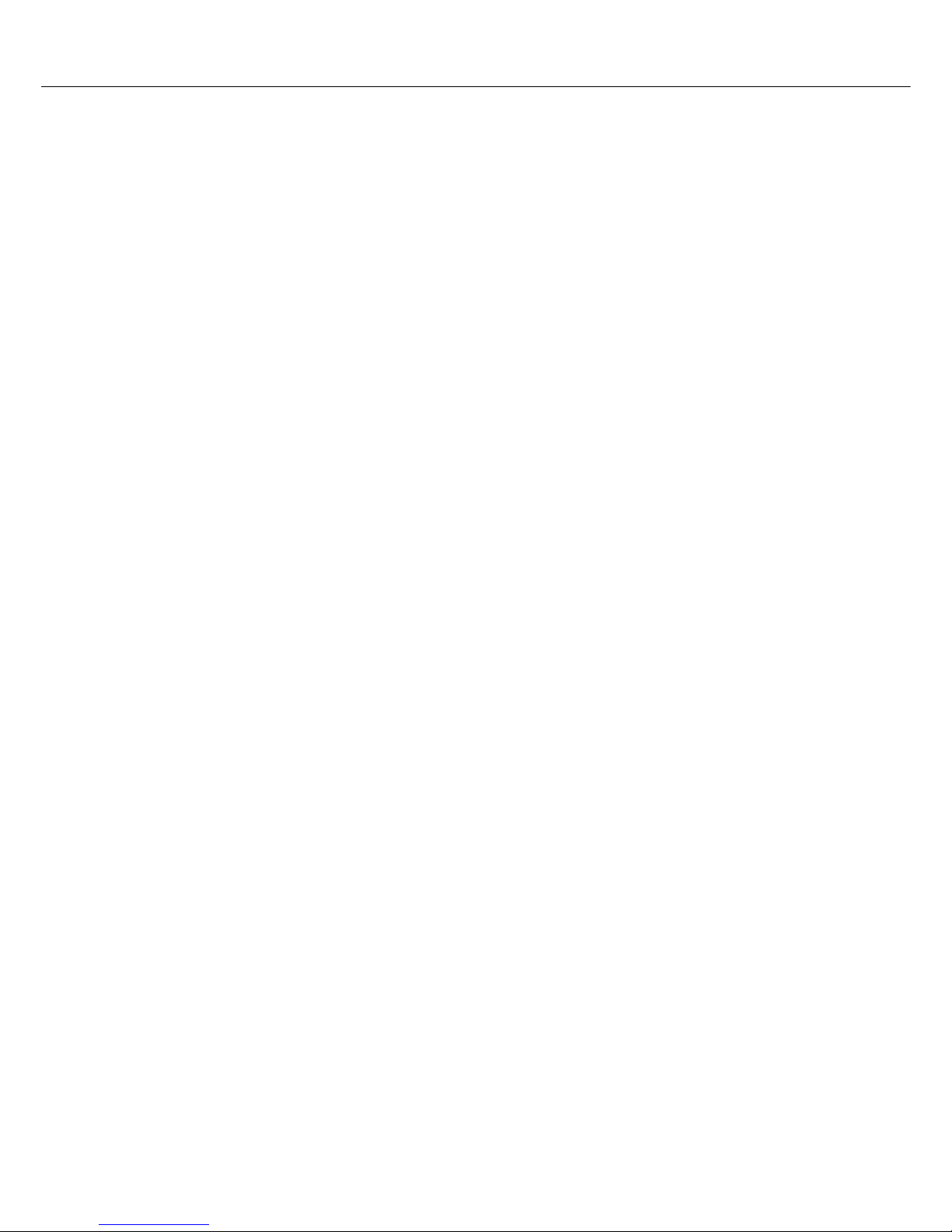

1.2 Overview of the Complete Furnace

Pos: 7 /TD/Einleitung/Lieferumfang/Öfen/Gesa mtübersicht Laborofen L-LE-L(T)-LV(T)-SKM-SW- HA @ 14\ mod_ 129 5003962965_51.docx @ 111859 @ @ 1

Furnace door

Handle

Furnace chamber

Air for the regulation of fresh air

Display

Controller

Power switch (ON/OFF)

Display

Controller

Power switch (ON/OFF)

Heating (ON/OFF)

Exhaust-air system

8

Fig. 1: Exa

m

Backup po

w

(lock for ba

c

for example

,

ple: Complet

e

er connectio

n

kup power c

o

for vent wit

h

e

overview o

f

D

nnection)

fan or gas s

u

various labo

r

Gas s

u

(addit

i

igital interfa

c

pply system

(

atory furnac

e

pply syste

m

i

onal equipm

e

V

(

Powe

r

Switchge

a

L

e RS 422 (op

additional eq

u

s

Scale

Ceramic die

Support plate

nt)

ent, vent wi

t

accessories)

Support die

line

r fan

ock

tion)

u

ipment)

in the furnac

e

h fan or catal

e

chamber

ytic converte

r

9

Pos: 8 /TD/Einleitung/Produktbeschreibung/Öfen/ Überschrift - Absicherung von Gefahren bei Übertemper atur @ 37\mod_1362489730884_51.docx @ 213987 @ 2 @ 1

Safety control circuit

1.3 Safeguarding against Dangers Posed by Over-Temperature

Pos: 9 /TD/Einleitung/Produktbeschreibung/Öfen/S i cherheitseinrichtung - Überwachung der Ofenraumte mperatur (TWB-TWW) - Beschreibung @ 37\mod_1362491214270 _51.docx @ 214092 @ @ 1

Over-temperature limiters with manual reset/with automatic reset to protect against overtemperature in the furnace chamber are available for Nabertherm GmbH furnaces either as

a standard feature (depending on the model series) or as additional equipment (customized

design).

The over-temperature limiter with manual reset/with automatic reset monitors the furnace

chamber temperature. The display shows the most recently set cut-off temperature. If the

furnace chamber temperature rises about the pre-set cut-off temperature the heating is shut

down to protect the furnace, the charge and/or the operating equipment.

Pos: 10 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Warnsymbol_Gefahr - Absic herung von Gefahren bei Übertemperatur am TWB-TWW @ 37\mod_136249 0404 893_51.docx @ 214067 @ @ 1

DANGER

• Danger caused by incorrectly entered cut-off

temperature at the over-temperature limiter with

manual reset/over-temperature limiter with automatic

reset.

• Mortal danger

• If, as a result of over-temperature from the charge and/or the

operating equipment, a charge is likely to be damaged at this preset cut-off temperature of the over-temperature limiter with

manual reset/over-temperature limiter with automatic reset, or if

the charge itself becomes a source of danger for the furnace or its

surroundings, the cut-off temperature must be reduced at the

over-temperature limiter with manual reset/automatic reset to the

maximum permissible value.

Pos: 11 /TD/Betrieb_Bedienung/Vor Inbetriebnahme des Ofens ist die Bedienungsanleitung... (TWB-TWW) - Text @ 37\mod_1362494080225_51.docx @ 214142 @ @ 1

Read the operating instructions of the over-temperature limiter with manual reset/with

automatic reset before starting the furnace. The safety sticker must be removed from the

over-temperature limiter with manual reset/with automatic reset. Any time a change is

made in the heat treatment program, the maximum permissible cut-off temperature (alarm

trigger temperature) at the over-temperature limiter with manual reset/with automatic reset

must be checked or re-entered.

Pos: 12 /TD/Betrieb_Bedienung/die maximale Solltemper atur des Wärmeprogramms Controller zwischen 5 °C und 30 °C (TW B- TWW) @ 39\mod_1363784610371_51.docx @ 218500 @ @ 1

We recommend setting the maximum setpoint temperature of the heating program in the

limiter between 5 °C and 30 °C, depending on the physical characteristics of the furnace,

below the trigger temperature of the over-temperature limiter with manual reset/with

automatic reset. This prevents an unwanted triggering of the over-temperature limiter with

manual reset/with automatic reset.

Pos: 13 /TD/Betrieb_Bedienung/Aufkleber vom TWB/TWW abziehen - Grafik @ 37\mod_1362492020088_51.docx @ 214117 @ @ 1

Description and function, see the

Operating Instructions of the overtemperature limit controller/guard

Fig. 2: Removing the sticker

10

Pos: 14 /TD/Einleitung/Produktbeschreibung/ Öfen/ Überschrift - Entschlüsselung der Modellbezeic hnung @ 2\ mod

_

1.3.1 Ke

Pos: 15 /TD/Einleitung/Produktbeschreibung/ Öfen/ Entschlüssellung der Modellbezeichnung Laborofen L- LE-L(T)-L

V

Example

LT 9/11SK

M

LT 9/11SK

M

LT 9/11SK

M

LT 9/11SK

M

Pos: 16 /TD/Einleitung/Lieferumfang/Öfen/Über sc hrift - Lieferumfang @ 0\mod_1167822508130_51.doc x @ 5112

@ _

1184245078907_51.docx @ 19775 @ 3 @ 1

y to the

M

V

(T)-SKM-SW-HA @ 14\mod_1299593606987_51.docx @ 113253 @ @ 1

@

2 @ 1

odel Na

m

Explanati

o

L = L

a

LE = L

a

LT = L

a

LV = L

a

LVT = L

a

1 = 1

-

2 = 2

-

3 = 3

-

4 = 4

-

5 = 5

-

6 = 6

-

9 = 9

-

14 = 14-l

i

15 = 15-l

i

24 = 24-l

i

40 = 40-l

i

11 = Tmax

12 = Tmax

13 = Tmax

HA =

L

SKM =

F

SW =

S

Fig. 3: Exa

m

es

n

boratory fur

n

boratory fur

n

boratory fur

n

boratory inci

n

boratory inci

n

liter furnace

c

liter furnace

c

liter furnace

c

liter furnace

c

liter furnace

c

liter furnace

c

liter furnace

c

i

ter furnace c

h

i

ter furnace c

h

i

ter furnace c

h

i

ter furnace c

h

1100 °C (20

1

1200 °C (21

9

1300 °C (23

7

aboratory f

u

urnace cha

m

cale furnace

ple: Model

d

ace with dro

p

ace econom

y

ace with lift

d

nerator with

d

nerator with l

c

hamber (vol

u

c

hamber (vol

u

c

hamber (vol

u

c

hamber (vol

u

c

hamber (vol

u

c

hamber (vol

u

c

hamber (vol

u

amber (volu

m

amber (volu

m

amber (volu

m

amber (volu

m

2 °F)

2 °F)

2 °F)

rnace with re

c

ber made of

c

with support

d

esignation (

t

-down door

series

oo

r

rop-down do

ift doo

r

me in L)

me in L)

me in L)

me in L)

me in L)

me in L)

me in L)

e in L)

e in L)

e in L)

e in L)

irculating ai

r

eramic muff

l

frame and sc

a

ype plate)

www.naberthe

r

LT 9/11S

K

LC011H6S

N

230 V 1/N/

P

fan in the ba

c

e

le

m.de

M

E~ 15.2 A

ck wall

Made

SN

x

1100 °C

50/60 Hz 3.5

k

in German

y

xxxxx

2011

W

1.4 Sco

Pos: 17 /TD/Einleitung/Lieferumfang/Öfen/Liefer u mfang - Laborofen L-LE-L(T)-LV(T)-SKM-SW-HA @ 14\mod_129

9

Pos: 18 /TD/Betrieb_Bedienung/Die mitgelieferten Unt erlagen beinhalten nicht zwangsläufig elektrisc he Schaltplän

e

pe of Deli

9

662508331_51.docx @ 113310 @ @ 1

e

bzw. Pneuma ... @ 47\mod_1380028074616_51.docx @ 247668 @ @ 1

B

e

t

r

i

e

b

s

a

n

l

e

i

t

u

n

P

r

o

z

e

s

s

d

o

k

u

m

e

n

t

a

t

i

o

C

o

n

t

r

o

l

t

h

e

r

m

M

V

very

The scop

e

Furnace

Laborato

Power c

a

Vent ) 2)

Vent wit

h

Catalytic

Ceramic

Ceramic

Steel cat

c

Base Pla

t

Gas sup

p

Scale 2)

Process

d

Controlt

h

Other co

m

p

articula

r

Docume

n

Instructi

o

Operatin

g

Operatin

g

gas supp

l

Operatin

g

Controlt

h

Other do

c

p

articula

r

1) = in s

c

2) = in s

c

3) = qua

n

4) = qua

n

Caution

Make sure

t

tested duri

n

Note

The docu

m

schematics

.

If you nee

d

n

g

M

a

d

e

i

n

G

e

r

m

a

n

y

o

n

of deliver

y

components

r

y furnace 1)

ble 1)

fan 1) 2)

converter 1)

2

ribbed plate

ceramic catc

h

h basin

e 1)

ly system 2)

ocumentatio

n

erm MV sof

t

ponents, va

r

furnace

t type

n Manual La

b

Instructions

Instructions

y system 1)

Instructions

erm MV sof

t

uments, vari

a

furnace

ope of deliv

e

ope of deliv

e

tity depends

tity depends

t

hat all docu

m

g manufactu

r

ents included

the respectiv

includes:

2)

basin

ware packag

e

iable depend

i

b

oratory Fur

n

for Controll

e

ware packag

e

a

ble dependi

n

ry depends o

n

ry depend o

n

on furnace

m

on on need,

s

ents are care

f

ing and prior

do not alwa

y

e schematics

Q

111

431

1

1) 2)

1

ng on the

-

Q

ace 1)

1

r 1)

1

1

1)

1

g on the

-

design/furn

a

need, see shi

p

odel

ee shipping p

f

ully stored.

A

to shipping.

s contain the

e

t

hey can be o

r

uantity C

x

N

x

N

x

)

)

x

N

x

N

x

N

- - C

pa

uantity C

x

N

x

N

x

N

x

N

- -

ce model

ping papers

a

pers

ll the functi

o

lectrical sch

e

dered from

N

omment

abertherm G

m

abertherm G

m

abertherm G

m

abertherm G

m

abertherm G

m

onsult the shi

pers

omment

abertherm G

m

abertherm G

m

abertherm G

m

abertherm G

m

ns of this fur

n

matics and p

n

abertherm S

e

1

1

bH

bH

bH

bH

bH

p

ping

bH

bH

bH

bH

ace were

n

eumatic

rvice.

12

Pos: 19 /TD/Einleitung/Technische Daten/Öfen/Über schrift - Technische Daten - mit Hinweis @ 0\mod_1167822840737_ 51.docx @ 5121 @ 1 @ 1

2 Specifications

Electrical specifications are on the type plate located on the side of the furnace.

Pos: 20 /TD/Einleitung/Technische Daten/Öfen/Mode ll Muffelofen Klapptür -Tabelle für L 3/11 - L 40/11 bis L 1/12 - L 40/ 12 @ 14\mod_1294910652628_51.docx @ 111513 @ @ 1

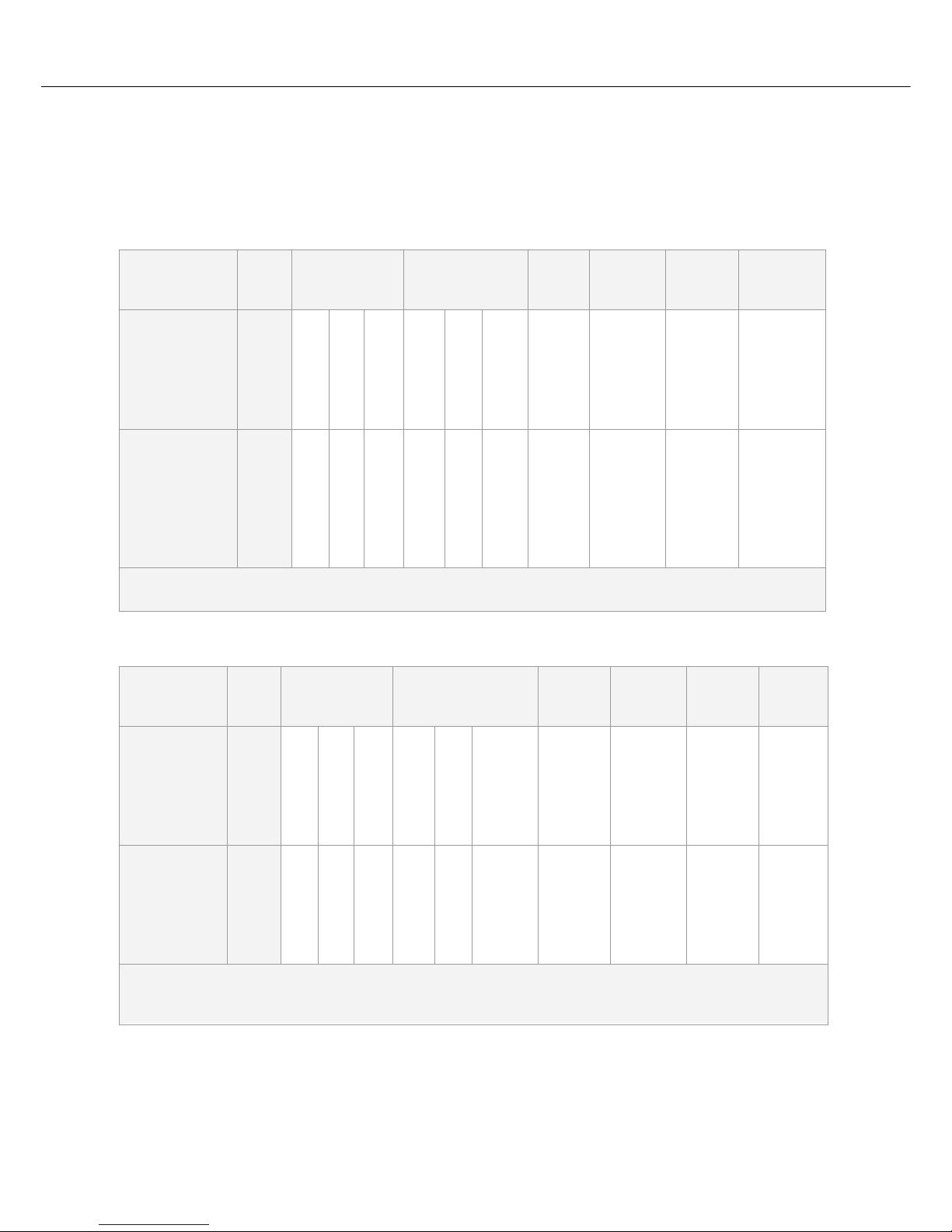

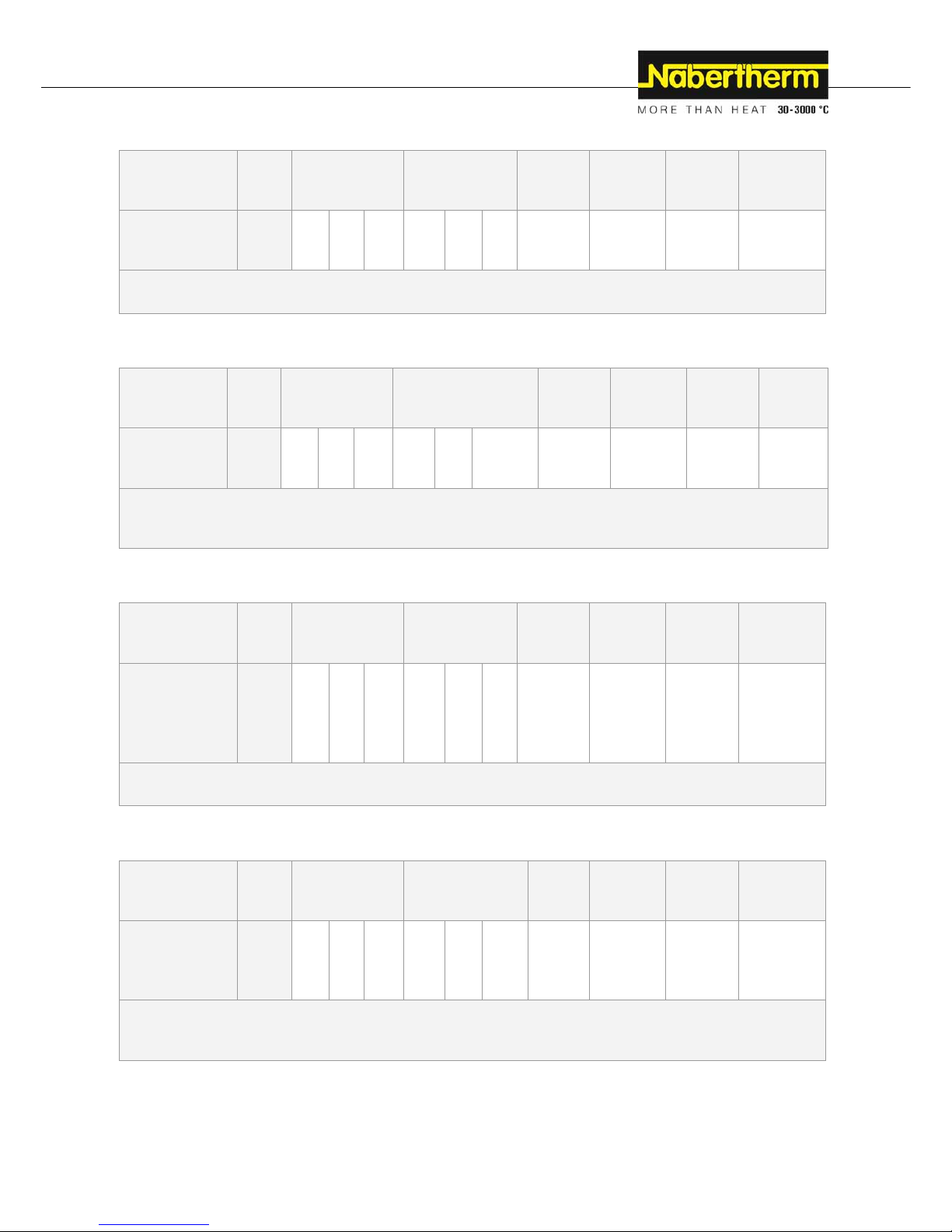

Muffle Furnace

Model

Drop-Down Door

Tmax

°C

Dimensions

Interior in mm

w d h

Dimensions

Outer in mm

W D H

Volume

in l

Heating

power in

kW*

Weight

kg

Minutes

to

Tmax1

L 3/11 1100 160 140 100 380 370 420 3 1.2 20 60

L 5/11 1100 200 170 130 440 470 520 5 2.4 35 60

L 9/11 1100 230 240 170 480 550 570 9 3.0 45 75

L 15/11 1100 230 340 170 480 650 570 15 3.5 55 90

L 24/11 1100 280 340 250 560 660 650 24 4.5 75 95

L 40/11 1100 320 490 250 600 790 650 40 6.0 95 95

L 1/12 1200 90 115 110 250 265 340 1 1.5 10 25

L 3/12 1200 160 140 100 380 370 420 3 1.2 20 75

L 5/12 1200 200 170 130 440 470 520 5 2.4 35 75

L 9/12 1200 230 240 170 480 550 570 9 3.0 45 90

L 15/12 1200 230 340 170 480 650 570 15 3.5 55 105

L 24/12 1200 280 340 250 560 660 650 24 4.5 75 110

L 40/12 1200 320 490 250 600 790 650 40 6.0 95 110

1

for connection to 230 V 1/N/PE or 400 V 3/N/PE

*Depending on furnace design connected load might be higher

Pos: 21 /TD/Einleitung/Technische Daten/Öfen/Mode ll Muffelofen Hubtür -Tabelle für LT 3/11 - LT 40/11 bis LT 3/12 - LT 40/ 12 @ 14\ mod_1294933924209_51.docx @ 111553 @ @ 1

Muffle Furnace

Model

Lift Door

Tmax

°C

Dimensions

Interior in mm

w d h

Dimensions

Outer in mm

W D H+Ha2

Volume

in l

Heating

power in

kW*

Weight

kg

Minutes

to

Tmax1

LT 3/11 1100 160 140 100 380 370 420+165 3 1.2 20 60

LT 5/11 1100 200 170 130 440 470 520+220 5 2.4 35 60

LT 9/11 1100 230 240 170 480 550 570+290 9 3.0 45 75

LT 15/11 1100 230 340 170 480 650 570+290 15 3.5 55 90

LT 24/11 1100 280 340 250 560 660 650+335 24 4.5 75 95

LT 40/11 1100 320 490 250 600 790 650+335 40 6.0 95 95

LT 3/12 1200 160 140 100 380 370 420+165 3 1.2 20 75

LT 5/12 1200 200 170 130 440 470 520+220 5 2.4 35 75

LT 9/12 1200 230 240 170 480 550 570+290 9 3.0 45 90

LT 15/12 1200 230 340 170 480 650 570+290 15 3.5 55 105

LT 24/12 1200 280 340 250 560 660 650+335 24 4.5 75 110

LT 40/12 1200 320 490 250 600 790 650+335 40 6.0 95 110

1

for connection to 230 V 1/N/PE or 400 V 3/N/PE

2

incl. opened lift door

*Depending on furnace design connected load might be higher

Pos: 22 /TD/Einleitung/Technische Daten/Öfen/Mode ll Muffelofen Klapptür -Tabelle für L 5/13 - L 15/13 @ 14\mod_129499 1083275_51.docx @ 111629 @ @ 1

13

Muffle Furnace

Model

Drop-Down Door

Tmax

°C

Dimensions

Interior in mm

w d h

Dimensions

Outer in mm

W D H

Volume

in l

Heating

power in

kW*

Weight

kg

Minutes

to

Tmax1

L 5/13 1300 200 170 130 440 470 520 5 2.4 45 45

L 9/13 1300 230 240 170 480 550 570 9 3.0 50 50

L 15/13 1300 230 340 170 480 650 570 15 3.5 60 60

1

for connection to 230 V 1/N/PE or 400 V 3/N/PE

*Depending on furnace design connected load might be higher

Pos: 23 /TD/Einleitung/Technische Daten/Öfen/Mode ll Muffelofen Hubtür -Tabelle für LT 5/13 - LT 15/13 @ 14\mod_12949 9104 0209_51.docx @ 111583 @ @ 1

Muffle Furnace

Model

Lift Door

Tmax

°C

Dimensions

Interior in mm

w d h

Dimensions

Outer in mm

W D H+Ha2

Volume

in l

Heating

power in

kW*

Weight

kg

Minutes

to

Tmax1

LT 5/13 1300 200 170 130 440 470 520+220 5 2.4 42 45

LT 9/13 1300 230 240 170 480 550 570+290 9 3.0 60 50

LT 15/13 1300 230 340 170 480 650 570+290 15 3.5 70 60

1

for connection to 230 V 1/N/PE or 400 V 3/N/PE

2

incl. opened lift door

*Depending on furnace design connected load might be higher

Pos: 24 /TD/Einleitung/Technische Daten/Öfen/Mode ll Kompakt-Muffelofen Klapptür -Tabelle für LE 1/11 - LE 14/11 @ 14\mod_1294992044264_51.docx @ 111652 @ @ 1

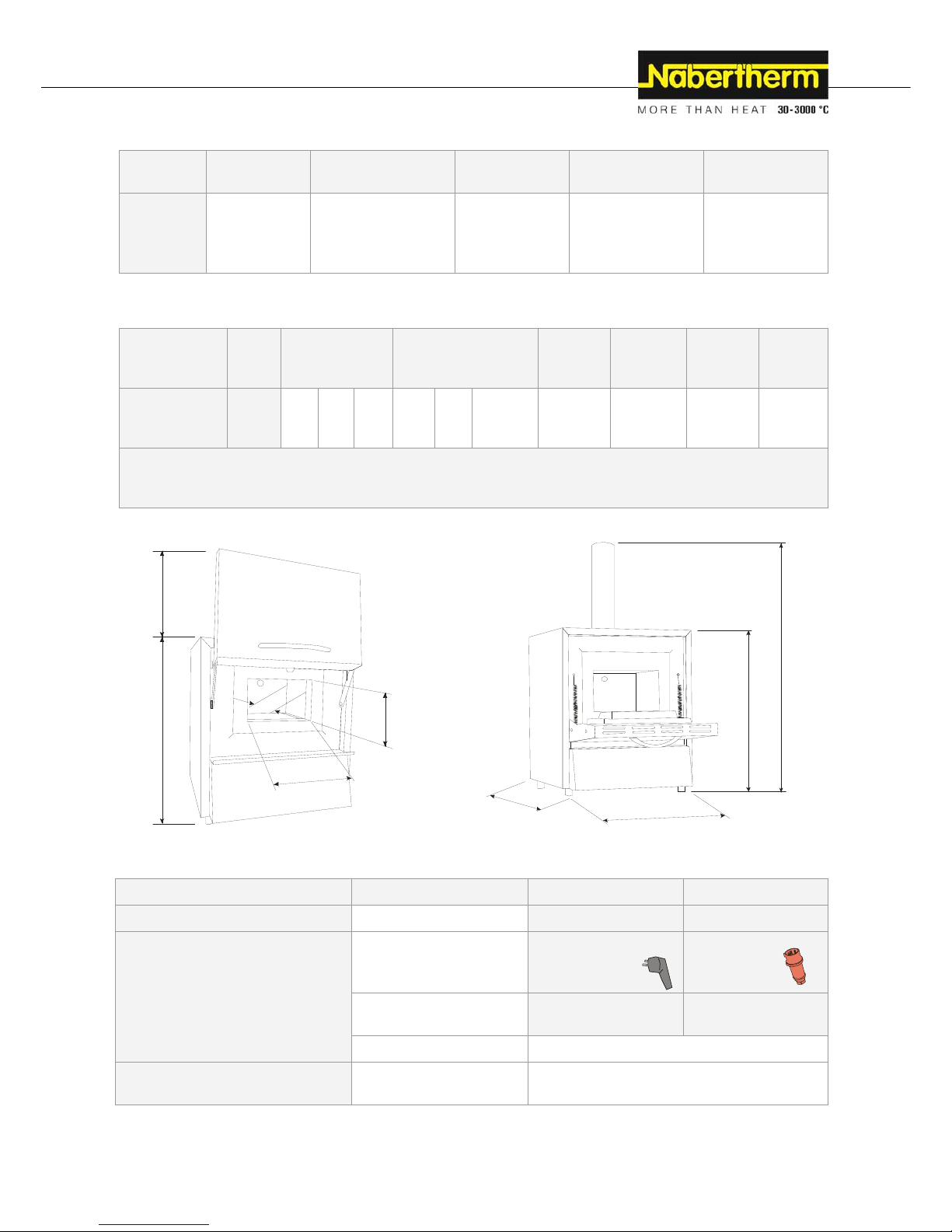

Compact Muffle Furnace

Model

Drop-Down Door

Tmax

°C

Dimensions

Interior in mm

w d h

Dimensions

Outer in mm

W D H

Volume

in l

Heating

power in

kW*

Weight

kg

Minutes

to

Tmax1

LE 1/11 1100 90 115 110 250 265 340 1 1.5 10 10

LE 2/11 1100 110 180 110 275 380 350 2 1.8 10 25

LE 4/11 1100 170 200 170 335 400 410 4 1.8 15 35

LE 6/11 1100 170 200 170 510 400 320 6 1.8 18 35

LE 14/11 1100 220 300 220 555 500 370 14 2.9 25 40

1

for connection to 230 V 1/N/PE or 400 V 3/N/PE

*Depending on furnace design connected load might be higher

Pos: 25 /TD/Einleitung/Technische Daten/Öfen/Mode ll Veraschungsofen Klapptür -Tabelle für LV 3/11 - LV 15/ 11 @ 14\ mod_1294992766140_51.docx @ 111675 @ @ 1

Incinerator

Model

Drop-Down Door

Tmax

°C

Dimensions

Interior in mm

w d h

Dimensions

Outer in mm

W D Hb2

Volume

in l

Heating

power in

kW*

Weight

kg

Minutes

to

Tmax1

LV 3/11 1100 160 140 100 380 370 750 3 1.2 20 120

LV 5/11 1100 200 170 130 440 470 850 5 2.4 35 120

LV 9/11 1100 230 240 170 480 550 900 9 3.0 45 120

LV 15/11 1100 230 340 170 480 650 900 15 3.5 55 120

1

for connection to 230 V 1/N/PE or 400 V 3/N/PE

2

incl. exhaust air pipe (Ø 80 mm)

*Depending on furnace design connected load might be higher

14

Pos: 26 /TD/Einleitung/Technische Daten/Öfen/Mode ll Veraschungsofen Hubtür -Tabelle für LVT 3/11 - LVT 15/11 @ 14\mod_1 294992895007_51.docx @ 111698 @ @ 1

Incinerator

Model

Lift Door

Tmax

°C

Dimensions

Interior in mm

w d h

Dimensions

Outer in mm

W D Hb2

Volume

in l

Heating

power in

kW*

Weight

kg

Minutes

to

Tmax1

LVT 3/11 1100 160 140 100 380 370 750 3 1.2 20 120

LVT 5/11 1100 200 170 130 440 470 850 5 2.4 35 120

LVT 9/11 1100 230 240 170 480 550 900 9 3.0 45 120

LVT 15/11 1100 230 340 170 480 650 900 15 3.5 55 120

1

for connection to 230 V 1/N/PE or 400 V 3/N/PE

2

incl. exhaust air pipe (Ø 80 mm)

*Depending on furnace design connected load might be higher

Pos: 27 /TD/Einleitung/Technische Daten/Öfen/Mode ll Muffelofen mit Keramikmuffel Klapptür/Hubtür - Tabelle für L 9/11/SKM - LT 9/11/SKM @ 14\mod_1294994910658_51.doc x @ 111721 @ @ 1

Muffle Furnace

Model

Drop-Down

Door/

Lift Door

Tma

x

°C

Dimensions

Interior in mm

w d h

Dimensions

Outer in mm

W D H+Ha2

Volume

in l

Heating

power in

kW*

Weight

kg

Minutes

to

Tmax1

L 9/11/SKM 1100 230 240 170 480 550 570 9 3.0 50 90

LT 9/11/SKM 1100 230 240 170 480 550 570+290 9 3.0 50 90

1

for connection to 230 V 1/N/PE or 400 V 3/N/PE

2

incl. opened lift door

*Depending on furnace design connected load might be higher

Pos: 28 /TD/Einleitung/Technische Daten/Öfen/Mode ll Muffelofen mit Klapptür und Waage -Tabelle für L 9/11/SW - L 9/ 12/SW @ 14\mod_1294995752712_51.docx @ 111744 @ @ 1

Muffle Furnace

Model

Drop-Down

Door

Tmax

°C

Dimensions

Interior in mm

w d h

Dimensions

Outer in mm

W D H

Volume

in l

Heating

power in

kW*

Weight

kg

Minutes

to

Tmax1

L 9/11/SW 1100 230 240 170 480 550 800 9 3.0 55 75

L 9/12/SW 1200 230 240 170 480 550 800 9 3.0 55 90

1

for connection to 230 V 1/N/PE or 400 V 3/N/PE

*Depending on furnace design connected load might be higher

Pos: 29 /TD/Einleitung/Technische Daten/Öfen/Mode ll Muffelofen mit Hubtür und Waage -Tabelle für LT 9/11/SW - LT 9/12/ SW @ 14\mod_1294996314888_51.docx @ 111767 @ @ 1

Muffle Furnace

Model

Drop-Down

Door

Tmax

°C

Dimensions

Interior in mm

w d h

Dimensions

Outer in mm

W D H+Ha2

Volume

in l

Heating

power in

kW*

Weight

kg

Minutes

to

Tmax1

LT 9/11/SW 1100 230 240 170 480 550 800+290 9 3.0 55 75

LT 9/12/SW 1200 230 240 170 480 550 800+290 9 3.0 55 90

1

for connection to 230 V 1/N/PE or 400 V 3/N/PE

2

incl. opened lift door

*Depending on furnace design connected load might be higher

Pos: 30 /TD/Einleitung/Technische Daten/Öfen/Mode ll Waage für Muffelofen L/LT 9/11-12/SW -Tabelle für EW- 2200/4200/6200/12000 @ 14\mod_1294996701851_51.docx @ 111790 @ @ 1

15

Scale

Type Readability

in g

Weight Range

in g

Stamp Weight

in g

Calibration Value

in g

Minimum Load

in g

EW-2200 0.01 2200 incl. plunger 850 0.1 0.5

EW-4200 0.01 4200 incl. plunger 850 0.1 0.5

EW-6200 0.01 6200 incl. plunger 850 - 1.0

EW-12000 0.10 12000 incl. plunger 850 1.0 5.0

Pos: 31 /TD/Einleitung/Technische Daten/Öfen/Mode ll Muffelofen Hubtür -Tabelle für LT 5/11HA - LT 15/11HA @ 14\mod_1294 997879629_51.docx @ 111813 @ @ 1

Muffle Furnace

Model

Lift Door

Tmax

°C

Dimensions

Interior in mm

w d h

Dimensions

Outer in mm

W D H+Ha2

Volume

in l

Heating

power in

kW*

Weight

kg

Minutes

to

Tmax1

LT 5/11HA 1100 200 160 130 440 470 520+220 5 2.4 36 60

LT 9/11HA 1100 230 230 170 480 550 570+290 9 3.0 46 60

LT 15/11HA 1100 230 330 170 480 650 570+290 15 3.5 56 75

1

for connection to 230 V 1/N/PE or 400 V 3/N/PE

2

incl. opened lift door

*Depending on furnace design connected load might be higher

Pos: 32 /TD/Einleitung/Technische Daten/Öfen/Mode ll-Tabelle für Laboröfen L-LE-L(T)-LV(T)-SKM-SW -HA - Grafik - 1 @ 14\mod_1300087573327_51.docx @ 113363 @ @ 1

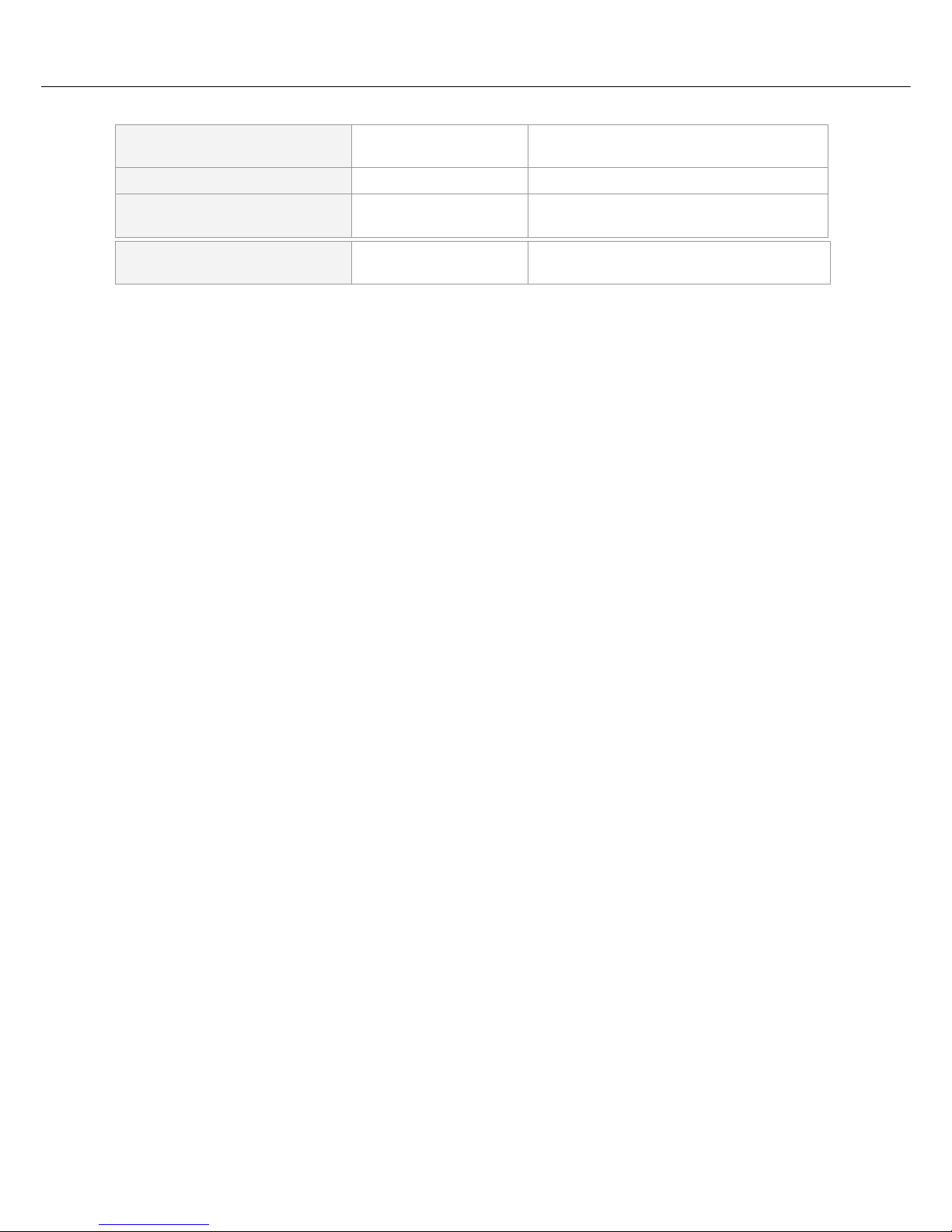

Fig. 4: Dimensions

Pos: 33 /TD/Einleitung/Technische Daten/Öfen/Tabe lle für Laboröfen L/LT/LE/LV/LVT/ - Öfen - 1 @ 14\mod_12950010508 44_51.docx @ 111836 @ @ 1

Electrical connection

1-phase: (1 N/PE) 3-phase: (3 N/PE)

Model:

to 3.6 kW from 4.5 kW

Power plug

Protective contact plug

(with snap-in socket)

CEE plug

Voltage:

110 V – 240 V

220 V – 240 V

380 V – 480 V

Frequency: 50 or 60 Hz

Heating output in kW: see section "Specifications" or type plate on the

furnace

w

d

D

h

Hb

H

Ha

W

H

16

Thermal protection class

Furnaces:

as specified in DIN EN 60519-2

without safety controller Class 0

Protective type

Furnaces: IP20

Ambient conditions for electrical

equipment

Temperature: Humidity: +5 °C to + 40 °C max. 80 % not

condensing

Pos: 34 /TD/Einleitung/Technische Daten/Öfen/Tabe lle Dauerschalldruckpegel < 80 dB(A) - 2 @ 1\mod_1170750985488_ 51.docx @ 8913 @ @ 1

Emissions

Continuous sound pressure

level:

< 80 dB(A)

Pos: 35 /TD/Einleitung/Gewährleistung_Haftung/ Überschrift - Gewährleistung und Haftung 1.1 @ 0\mod_116782 2979492_51.docx @ 5130 @ 2 @ 1

2.1 Warranty and Liability

Pos: 36 /TD/Einleitung/Gewährleistung_Haftung/ Öfe n und Schaltanlagen - Gewährleistung und Haftung @ 0\mod_1157 536440972_51.docx @ 1569 @ @ 1

§

As regards warranty and liability, the normal Nabertherm warranty terms apply,

unless individual terms and conditions have been agreed. However, the following

conditions also apply:

Warranty and liability claims for personal injury or damage to property shall be excluded if

they are attributable to one or more of the following causes:

Everyone involved in operation, installation, maintenance, or repair of the furnace

must have read and understood the operating instructions. No liability will be accepted

for damage or disruptions to operation resulting from non-compliance with the

operating instructions.

Not using the furnace as intended,

Improper installation, start-up, operation, or maintenance of the furnace,

Operation of the furnace with defective safety equipment or improperly installed or

non-functioning safety and protective equipment,

Not observing the references in the operating instructions to transportation, storage,

installation, start-up, operation, maintenance, or equipping the furnace,

Making unauthorized changes to the furnace,

Making unauthorized changes to the operating parameters,

Making unauthorized changes to the parameterization, the settings, or the program,

Original parts and accessories are designed especially for Nabertherm furnaces.

Replace parts only with original Nabertherm parts. Otherwise the warranty will be

void. Nabertherm accepts absolutely no liability for damage caused by using parts that

are not original Nabertherm parts.

Catastrophes due to third-party causes and force majeure.

17

Pos: 37 /TD/Sicherheit/Überschrift - Sicherhei t @ 0\mod_1158843961540_51.docx @ 3103 @ 1 @ 1

3 Safety

Pos: 38 /TD/Sicherheit/Überschrift - Bestimmungsge mäße Verwendung @ 0\mod_1167823503921_51.docx @ 5148 @ 2 @ 1

3.1 Intended Use

Pos: 39 /TD/Sicherheit/Bestimmungsgemäße Verwendung L HT-Hochtemperaturöfen (Tischmodell) @ 2\mod_1182347443 948_51.docx @ 18724 @ @ 1

Safety

This Nabertherm system was designed and manufactured after careful selection of the

harmonized standards to be observed as well as other technical specifications. It therefore

corresponds to the state of the art, ensuring the highest possible degree of safety.

Only materials with known characteristics and melting temperatures may be used. Check

the material safety data sheets if necessary.

Use of the furnace for any other purpose whatsoever such as processing

products other than those intended or handling hazardous substances or

substances posing a health hazard constitutes improper use and must be

agreed upon with Nabertherm in writing.

Whether or not the materials used in the furnace can potentially corrode or destroy

the insulation or heating elements must be ascertained.

For furnaces with over-temperature limiters, the cutoff temperature must be set to prevent

overheating of the material.

Modifications to system equipment must be agreed upon with

Nabertherm in writing. It is not permitted to remove, bypass, or shut down safety devices.

The installation instructions and safety guidelines must be observed. Otherwise, the furnace

will not be considered as being used as designated, and all claims against Nabertherm

GmbH will be void.

Opening the furnace when hot (temperature greater than 200/392 °C/°F) can lead to

accelerated wear of the following components: insulation, heating elements, and furnace

housing.

Operating with power sources, products, operating equipment, additives,

etc. that are subject to the Ordinance on Hazardous Substances or cause

risks to the health of operating personnel in any way is not permitted.

- This furnace is designed for commercial use. The furnace must not be used

for heating food, animals, wood, grain, etc.

- The furnace must not be used as a workplace heater.

- Do not use the furnace to melt ice or similar materials.

- Do not use the furnace as a clothes dryer.

Note

See safety instructions in the individual sections.

18

Pos: 40 /TD/Allgemeine Hinweise (für alle Anleitungen)/ Hinweis - Dieser Ofen verfügt über keine Sicherheitstechni

k

Pos: 41 /TD/Allgemeine Hinweise (für alle Anleitungen)/ Hinweis - Dieses Produkt entspricht nicht der ATEX-Ric htli

n

Pos: 42 /TD/Sicherheit/Überschrift - Anforder ungen an den Betreiber der Anlage @ 0\mod_1167823775531_51.do

c

3.2 Req

Pos: 43 /TD/Sicherheit/Anforderungen an den Betreiber der Anlage - RHTH, RHTC, LHT, Rohröfen @ 2\mod_1184

k

für Prozesse, ..-nicht brennbare Gase @ 8\mod_12350 3869 9771_51.docx @ 51483 @ @ 1

n

ie und darf nicht ..-nicht brennbare Gase @ 2\mod_1184228 756893_51.docx @ 19686 @ @ 1

c

x @ 5157 @ 2 @ 1

uirement

s

4

570280797_51.docx @ 19913 @ @ 1

Caution

Operating

t

mixtures c

r

This furna

c

mixtures,

fo

If the furn

a

gas mixtur

e

pre-requisi

t

situations

s

You must

e

N

aberther

m

involving t

h

Note

This produ

c

atmospher

e

where expl

o

for the

F

The set-up

b

e deemed

N

aberther

m

This level

o

measures h

measures a

n

The oper

a

al

l

sy

th

e

th

e

th

e

th

e

th

eop

th

e

th

ewi

al

lDa

fu

rsafins

a

rOcwo

al

lass

he furnace w

i

eated as a res

e features no

r example d

e

ce is still use

d

s in the furn

a

e applies not

uch as p

r

oce

s

nsure that th

e

offers a bro

a

e use of co

m

t does not c

o

s. It must not

sive gases o

r

urnace O

instructions a

n

to have been

u

GmbH.

f safety whe

n

a

ve been tak

e

d controllin

g

tor must e

n

harmful gas

e

s

tem,

extraction s

y

workplace i

s

furnace is o

p

functions of

required pe

r

erating, main

t

se operating

furnace. Th

e

th or on the f

u

the safety an

maged or un

r

nace person

n

ety and envi

r

tructions, es

p

isk assessme

n

cupational S

a

rking condit

i

other instruc

t

essment for

t

th explosive

g

ult of heating

safety techn

o

binding.

for such pr

o

ce must neve

only to norm

a

s disruptions

furnace is a

d

d range of f

u

bustible gas

m

mply with th

e

be operated

w

mixtures ar

e

perator

nd safety reg

u

used improp

e

operating th

e

n. It depends

how they ar

e

sure that

s are remove

d

stem is swit

c

properly ve

n

erated only i

n

the safety co

m

sonal protect

i

tenance, and

r

instructions,

i

se instructio

n

rnace;

d operating i

n

eadable sign

s

el are inform

e

onmental pr

o

ecially those

t is carried o

u

fety Act) to

d

ons particula

r

tions and saf

e

he workplac

e

ases or mixt

u

/drying, is pr

o

logy for proc

cesses despit

e

r exceed 3%

o

l operation

b

(caused, for

e

equately ven

t

rnaces which

ixtures.

ATEX Dire

c

ith explosiv

e

produced.

lations must

rly, effective

l

e

furnace can

on the furnac

carried out.

from the w

o

hed on,

tilated,

n

a perfect o

p

ponents are

ve equipmen

t

epair person

n

ncluding the

s must be av

a

struction sig

n

must be repl

d regularly

a

tection and a

r

involving sa

f

t (in Germa

n

etermine an

y

to the furna

c

ty guidelines

are compile

d

res, includin

g

hibited.

e

sses which

p

this fact, the

f the lower e

x

u

t, in particul

xample, by t

h

ilated and ve

n

were especia

l

tive and ma

y

gases or mi

x

b

e followed,

o

y cancelling

a

be achieved

o

operator's d

i

rkplace, for

e

erating condi

t

checked reg

u

is available

f

el.

upplier docu

m

ilable at all

t

i

s on the furn

a

a

ced immedi

a

b

out all issue

s

e familiar wi

t

ty,

y, covered b

y

other hazard

s

e's location,

that have bee

n

in an operati

g

explosive g

a

roduce comb

u

concentratio

n

x

plosion limi

t

ar, to excepti

o

e failure of a

n

ted.

l

ly developed

not

b

e used

i

tures or duri

n

therwise the

ny claims ag

a

nly if all the

i

ligence in pl

a

xample by a

n

t

ion and, in p

a

larly.

or and used

b

mentation, ar

e

mes for anyo

ce can be re

a

tely,

s involving o

c

h all the ope

r

Section 5 of

s that may re

s

n determined

on manual (i

n

ses or

stible

of organic

(LEL). This

nal

power unit).

for processe

s

n ignitable

g processes

furnace will

inst

n

ecessary

nning these

extraction

rticular, that

y the

kept near

n

e working

d properly.

cupational

ating

the

ult from the

in a risk

Germany,

Pos: 44 /TD/Allgemeine Hinweise (für alle Anleitungen)/ Hinweis - In Deutschland ist die allgemeine Unfallverhü tung

a

Pos: 45 /TD/Sicherheit/Überschrift - Anforder ungen an das Bedienpersonal @ 0\mod_1167825643423_51.docx @

3.3 Req

Pos: 46 /TD/Sicherheit/Anforderungen an das Bedienpers onal @ 0\mod_1158218663482_51.docx @ 2155 @ @

1

g

svorschriften VBG bzw. BGZ zu beachten. @ 3\mod_1193667801 739_ 51.docx @ 26122 @ @ 1

5166 @ 2 @ 1

uirement

s

1

co

E

q

O

nrepantraad

peadev

Note

In German

y

The nation

a

for the

O

Everyone i

n

have read

a

damage or

d

instruction

s

Only adeq

u

furnace.

Operating

p

environme

n

safety instr

u

Only train

e

The oper

a

Oper

a

__

The f

u

__

The f

u

__

The f

u

__

Initia

l

__

Malf

u

__

The f

u

__

The f

u

__

The f

u

__

The f

u

__

The f

u

__

vered by Sec

t

uipment).

ly sufficientl

y

air the syste

m

d must confir

m

ining progra

m

ditional train

i

rformed by a

u

ditional train

i

idenced by t

h

, the general

l accident pr

e

perating

volved in op

nd understoo

d

d

isruptions to

.

ately qualifie

ersonnel are

tal protectio

n

ctions.

d personnel

m

tor should

tor

__________

_

rnace may o

n

__________

_

rnace may o

n

__________

_

rnace may o

n

__________

_

instructions

m

__________

_

nctions may

o

__________

_

rnace may o

n

__________

_

rnace may o

n

__________

_

rnace may o

n

__________

_

rnace may o

n

__________

_

rnace may o

n

__________

_

ion 6 of the

O

y qualified a

n

. This perso

n

their partic

must be do

c

ng must also

thorized, tra

i

ng must be p

a

e names and

s

accident prot

e

vention regu

l

Personn

e

eration, insta

l

the operati

n

operation re

s

d and authori

z

instructed re

g

and are fam

i

ay operate t

h

complete t

h

__________

_

ly be transp

o

__________

_

ly be install

e

__________

_

ly be commi

s

__________

_

ay only be

g

__________

_

nly be rectif

i

__________

_

ly be mainta

i

__________

_

ly be cleane

d

__________

_

ly be service

__________

_

ly be repaire

d

__________

_

ly be shut d

o

__________

_

rdinance Re

g

d authorized

p

nel must be

t

ipation in the

umented in

d

take place. T

h

ned individu

a

instakingly

d

ignatures of

t

ction guideli

ations of the

l

lation, maint

e

g instruction

s

ulting from

n

ed persons

m

ularly in all

a

liar with all t

h

e control and

ese detail

s

__________

_

rted by

__________

_

d by

__________

_

sioned by

__________

_

iven by

__________

_

ed by

__________

_

ned by

__________

_

by

__________

_

d by

__________

_

by

__________

_

wn by

__________

_

ulating the U

p

ersonnel ma

y

rained in ho

w

training with

etail. In case

a

e additional

t

ls familiar w

i

ocumented a

n

he participati

n

n

es of VBG

o

c

ountry of op

nance, or rep

.

N

o liability

w

on-complian

c

ay operate,

m

spects of occ

u

e operating i

n

safety equip

m

:

_

_________

_

_

_________

_

_

_________

_

_

_________

_

_

_________

_

_

_________

_

_

_________

_

_

_________

_

_

_________

_

_

_________

_

_

_________

_

se of Operati

n

y

operate, m

a

to operate t

h

a personal si

g

a

n operator is

raining may

o

th the syste

m

d participati

o

ng employee

s

r BGZ must

b

eration apply

.

air of the fur

n

will be accep

t

e with the op

aintain, or r

e

pational saf

e

nstructions, i

n

ent.

__________

_

__________

_

__________

_

__________

_

__________

_

__________

_

__________

_

__________

_

__________

_

__________

_

__________

_

1

9

g

intain and

e furnace

nature. The

replaced,

nly be

. The

n must be

.

e observed.

ace must

ed for

erating

pair the

ty and

particular,

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

20

Pos: 47 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Warnsymbol_Gefahr - Absic herung von Gefahren bei Übertemperatur am TWB-TWW @ 37\mod_136249 0404 893_51.docx @ 214067 @ @ 1

DANGER

• Danger caused by incorrectly entered cut-off

temperature at the over-temperature limiter with

manual reset/over-temperature limiter with automatic

reset.

• Mortal danger

• If, as a result of over-temperature from the charge and/or the

operating equipment, a charge is likely to be damaged at this preset cut-off temperature of the over-temperature limiter with

manual reset/over-temperature limiter with automatic reset, or if

the charge itself becomes a source of danger for the furnace or its

surroundings, the cut-off temperature must be reduced at the

over-temperature limiter with manual reset/automatic reset to the

maximum permissible value.

Pos: 48 /TD/Sicherheit/Überschrift - Schutzkleidu ng @ 0\mod_1167825795750_51.docx @ 5175 @ 2 @ 1

3.4 Protective Clothing

Pos: 49 /TD/Sicherheit/Schutzkleidung - Schutzkleid ung tragen @ 5\mod_1220274995030_51.docx @ 42108 @ @ 1

Wear protective clothing

Pos: 50 /TD/Sicherheit/Schutzkleidung - Hitzebeständi g e Handschuhe tragen @ 9\mod_1246542013306_51.doc x @ 62473 @ @ 1

Wear heat-resistant gloves to protect your hands.

Pos: 51 /TD/Sicherheit/Schutzkleidung - Schutzbril le tragen @ 5\mod_1220273954830_51.docx @ 42086 @ @ 1

Wear protective goggles.

Pos: 52 /TD/Sicherheit/Überschrift - Grundlegende Maß nah men bei Normalbetrieb @ 0\mod_1167825919827_51.doc x @ 5184 @ 2 @ 1

3.5 Basic Measures During Normal Operation

Pos: 53 /TD/Sicherheit/Grundlegende Maßnahmen bei Normal betrieb (LHT ../..-Tischmodell) (2012-11-07 14:33:12) @ 3\mod_1195478872113_51.docx @ 27827 @ @ 1

Risks during Normal Operation!

Before switching the furnace on, check and ensure that only authorized persons are in the

working area of the furnace and that no one can be injured as a result of operating the

furnace.

Before starting production each time, check and ensure that all the safety equipment works

properly.

Before starting production each time, check the furnace for obvious damage and ensure that

it is operated only in a perfect condition. Report any defects to a supervisor immediately.

Before starting production each time, remove all materials and objects that are not needed

for production from the working area.

At least once every day (see also Servicing and Maintenance) check the following:

Check the furnace for obvious external damage,

21

Check that all safety equipment is working as intended (e.g. emergency stop button),

Check all hydraulic or pneumatic hoses, make sure that they are not leaking and that

they are connected properly (if applicable),

Check all gas and oil lines, make sure that they are not leaking and that they are

connected properly (if applicable),

Check that the fan works properly (if applicable)

Pos: 54 /TD/Sicherheit/Überschrift - Grundlegende Maß nah men im Notfall @ 1\mod_1170943369267_51.docx @ 9093 @ 2 @ 1

3.6 Basic Measures in Case of Emergency

Pos: 55 /TD/Sicherheit/Überschrift - Verhalten im Notf al l @ 1\mod_1170949904855_51.docx @ 9123 @ 3 @ 1

3.6.1 What to do in an Emergency

Pos: 56 /TD/Allgemeine Hinweise (für alle Anleitungen)/ Hinweis - Das Stillsetzen im Notfall ist vorgesehen durc h Ziehen des Netzsteckers. @ 6\mod_1222062836860_51.doc x @ 42829 @ @ 1

Note

The power plug is to be pulled out to stop the furnace in case of an emergency.

Therefore, the power plug must be accessible at all times when the furnace is operating so

that it can be pulled out quickly in case of an emergency.

Pos: 57 /TD/Sicherheit/Grundlegende Maßnahmen im Notfa ll - Netzstecker ziehen (alle Anleitungen) - Grafik @ 36\ mod_1360079722854_51.docx @ 208920 @ @ 1

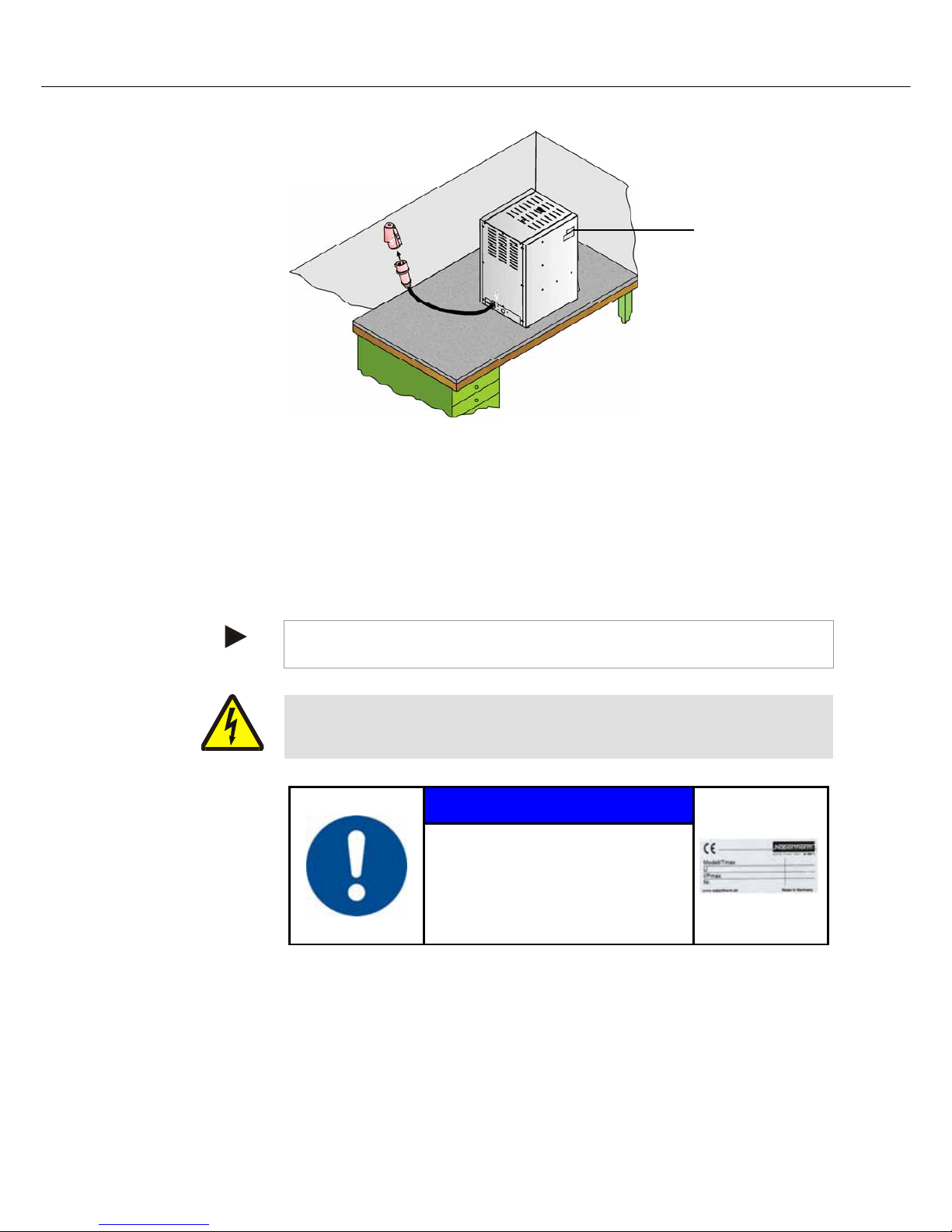

Fig. 5: Pull the power plug (similar to picture)

Pos: 58 /TD/Allgemeine Hinweise (für alle Anleitungen)/ Warnung - Bei unerwarteten Vorgängen im Ofen (z.B. starke Rauc hent wicklung oder Geruchsbelästigung) @ 4\mod_120530657973 7_51.docx @ 34218 @ @ 1

Risks during Normal Operation!

Switch the furnace off immediately in case of unexpected occurrences in the furnace (e.g. a

lot of smoke or unusual smells). Wait until the furnace has cooled naturally to room

temperature.

Pos: 59 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Warnsymbol_Gefahr - Elektri sc her Schlag - Piktogramm elektr. Schlag - Hauptschalter @ 9\ mod_1247472185096_51.docx @ 63063 @ @ 1

DANGER

• Danger of electric shock.

• Risk of fatal injury.

• Work on electrical

equipment may be carried out only by

qualified electricians

or by trained personnel authorized by

Nabertherm.

• Before starting work, pull out the

power plug

22

Pos: 60 /TD/Sicherheit/Überschrift - Grundlegende Maß nah men bei Wartung und Instandhaltung @ 0\mod_116782

3.7 Bas

Pos: 61 /TD/Sicherheit/Grundlegende Maßnahmen bei War tung und Instandhaltung @ 0\mod_1158222458436_51

.

Pos: 62 /TD/Sicherheit/Überschrift - Umweltschutzvor schriften @ 0\mod_1167826189237_51.docx @ 5202 @ 2 @

3.8 Env

Pos: 63 /TD/Sicherheit/Umweltschutzvorschri ften Schmierfette-Hydrauliköl-Kühlmittel @ 0\mod_11 58223424304_5

1

Pos: 64 /TD/Sicherheit/Umweltschutzvorschri ften Elektronische Bauteile-Isolierung-Altmetal l @ 4\mod_120514331

4

2

6060620_51.docx @ 5193 @ 2 @ 1

ic Measu

r

.docx @ 2188 @ @ 1

1

ironment

a

1.docx @ 2199 @ @ 1

4

853_51.docx @ 32563 @ @ 1

es for Se

r

Maintenan

c

instruction

s

and repair

w

may cause

i

Switch off

t

main switc

h

Clear an a

d

Suspended

risk of fata

l

Relieve th

e

work (if ap

p

When clea

n

them with

w

When mai

n

ensure the

f

Chec

k

Reins

t

Remo

work

f

Remo

Chec

k

Power

l Regula

t

All statuto

r

observed

w

Problem m

a

p

laced in n

o

During ins

t

such as

lubric

hydra

u

refrig

e

solve

n

sewa

g

These subs

t

containers.

Note

The operat

o

When it is

d

classificati

o

furnace ins

u

environme

n

vicing a

n

e work must

and the acci

d

ork be carri

e

i

njuries, deat

h

t

he furnace a

n

and secure i

equate area a

r

loads are dan

g

injury.

pressure on

h

p

licable).

ing furnaces,

ater.

tenance or re

p

ollowing:

that loosene

d

all protectiv

e

ve all materi

a

rom the wor

k

ve any liquid

s

that all safet

y

cables may b

e

ions

y duties rega

r

hen work is

c

terials that a

r

rmal waste

d

allation, repa

i

a

ting grease

a

lic oils

rants

-based clea

n

e system.

ances must b

r must ensur

e

elivered, thi

s

n necessary.

lation durin

g

t.

d Mainte

n

be performe

d

ent preventi

o

d out by the

s

, or consider

a

d make sure

i

t with a padl

o

ound the fur

n

gerous. Wor

k

ydraulic equ

i

control cabi

n

p

air work has

screw conn

e

equipment,

s

l, tools, and

o

ing area of t

h

that have le

a

y

functions (

e

e replaced on

l

ding waste a

v

arried out on

e no longer

n

isposal syste

m

r, and maint

e

nd oils

ing fluids m

u

e stored, tran

s

that nationa

l

furnace con

t

However, res

operation. T

h

ance

by authorize

d

n regulations

ervice team

o

ble damage

t

i

t cannot be s

w

ck), or pull o

u

ace to facilit

a

ing beneath

a

pment befor

e

ets, or electri

been comple

t

ctions have

b

creens, and f

i

ther equipme

e furnace,

ked,

.g. emergenc

y

l

y with simil

a

oidance, pro

p

and with the

f

eeded, such

a

s or allowe

d

nance work,

s

st not be allo

w

ported, colle

c

environmen

t

ains no subst

a

idues of proc

e

h

ese may be

h

persons foll

o

. We recom

m

f Naberther

m

o property.

itched on a

g

t the power

p

te the repair

w

suspended l

o

carrying out

c

al equipmen

t

ed, before re

c

een re-tighte

n

lters,

n

t used for th

e

stop button)

r, approved c

a

er recycling,

urnace.

s lubricants o

r

to enter the

s

ubstances th

a

ed to conta

m

ted, and disp

o

al regulation

s

nces that ma

k

ss materials

m

azardous to

h

owing the m

a

end that the

m

GmbH. No

n

ain inadverte

n

lug.

w

ork.

ad is prohibi

t

maintenance

t housings, n

e

ommencing

p

ed,

e maintenanc

e

work proper

l

a

bles.

and disposal

r batteries, m

u

ewage syste

m

t are hazardo

u

inate the soi

l

osed of in sui

t

are observe

d

e a hazardo

u

ay accumul

a

ealth and/or

t

intenance

aintenance

-compliance

n

tly (lock the

ed. There is

a

o

r repair

ver spray

oduction

or repair

y,

must be

st not be

.

u

s to water,

or enter the

t

able

.

s waste

te in the

he

23

Dismantle the electronic components and dispose of them as electric scrap.

Remove the insulation and dispose of it as hazardous waste (See Servicing, Cleaning,

and Maintenance with Ceramic Fiber Material)

Dispose of the housing as scrap metal.

Pos: 65 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Erläuterung ANSI Z535.6 @ 8\mod_124 3323558881_51.docx @ 57444 @ 2 @ 1

3.9 Explanation of the Symbols and Warnings

Note

In the following operating instructions, specific warnings are given to draw attention to

residual risks that cannot be avoided when the furnace is operating. These residual risks

include dangers for humans/products/ the furnace, and the environment.

The symbols used in the operating instructions are especially intended to draw attention to

safety information.

The symbols used cannot replace the text of the safety information. Therefore, always read

the entire text.

Graphic symbols correspond to ISO 3864. In accordance with the American National

Standard Institute (ANSI) Z535.6 the following warning information and words are used in

this document:

The general hazard symbol, in combination with the words CAUTION, WARNING and

DANGER warns about the risk of serious injury. Observe the following information to

prevent injury or death.

NOTICE

Refers to a hazard that could damage or destroy the equipment.

CAUTION

Refers to a hazard with a minor or medium risk of injury.

WARNING

Refers to a hazard that could cause death, serious or irreversible injury.

DANGER

Refers to a hazard that could directly cause death, serious or irreversible injury.

Structure of the Warning: All Warnings are Structured as Follows

WARNING

• Type and source of the danger

• Consequences of non-compliance

• Action to prevent danger

Hazard symbol

Indicates the risk of injury

Signal word

Classifies the danger

Graphical symbols (optional)

according to ISO 3864:

Consequences, measures, and

prohibitions

Reference texts:

• Type and source of the danger

• Possible consequences of noncompliance

• Measures/Prohibitions

24

Pos: 66 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Überschrift - Hinweissymbole i n der Anleitung

Pos: 67 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Hinweis - Unter diesem Symbol erha lten Sie

A

Pos: 68 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitung - Gebo t - Geb ot s

z

Pos: 69 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitung - Gebo t - W ichtig

Pos: 70 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitung - Gebo t - W ichtig

Pos: 71 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitung - Gebo t - Ne tzs te

@ 9\mod_1247053429626_51.docx @ 62751 @ @ 1

A

nweisungshinweise und ... @ 9\mod_1247053932311_51.doc x @ 62785 @ @ 1

zeichen - Wichtige Gebote sind zu befolgen @ 9\mod_124705617 5982_51.docx @ 62853 @ @ 1

g

e Information für den Bediener @ 9\mod_1247053200729_51.doc x @ 627 17 @ @ 1

g

e Information für das Wartungspersonal @ 9\mod_12470532060 42_51.docx @ 62734 @ @ 1

e

cker ziehen @ 9\mod_1247055471526_51.docx @ 62836 @ @ 1

or

Informati

o

Note

Below this

s

Rule - Rul

e

This symbo

l

p

eople agai

n

Rule - Imp

This symbo

l

instructions

Rule - Imp

This symbo

l

maintenanc

e

Rule - Pull

This symbo

l

Graphic

a

accordi

n

Consequ

e

p

rohibiti

o

Hazard s

y

Indicates

t

•

•

•

n Symbol

s

ymbol you w

Sign

draws attent

i

st injury and

ortant Infor

m

draws the o

p

that must be

f

ortant Infor

m

draws the m

a

instructions

Out the Po

w

tells the ope

r

l symbols (o

g

to ISO 386

4

nces, measu

r

ns

mbol

he risk of inj

u

Type and s

o

Consequen

c

Action to pr

e

in the Inst

r

ill find instru

c

on to import

a

show what is

mation for

O

erator's atten

t

ollowed.

mation for

M

intenance pe

(service) that

wer Plug

ator to pull o

u

ptional)

4:

es, and

ry

DANGE

R

urce of the

d

es of non-co

m

vent dange

r

uctions:

tions and pa

r

nt rules that

m

to be done i

n

perators

ion to import

a

aintenanc

e

rsonnel's atte

n

must be follo

u

t the power

p

Refe

r

• Typ

e

• Pos

s

comp

l

• Me

a

anger

pliance

ticularly use

fu

ust be follo

w

certain situa

t

nt informati

o

Personne

l

tion to impo

r

w

ed.

lug.

ence texts:

and source

o

ible consequ

e

iance

sures/prohibi

t

Grap

h

(opti

o

3864:

Instru

S

C

l informatio

n

ed. Rule sig

n

ions.

n and operat

i

tant operatin

g

f the danger

nces of non-

ions

hical symbol

nal) accordi

n

ctions or pro

h

ignal word

lassifies the

d

.

s protect

ng

and

s

to ISO

ibitions

anger

Pos: 72 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitung - Gebo t - Anheb

e

Pos: 73 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitung - W ar nung - Hei

ß

Pos: 74 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitung - W ar nung - elek

t

Pos: 75 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitung - W ar nung - Um

k

Pos: 76 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitung - W ar nung - Sch

w

Pos: 77 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitung - W ar nung - Heb

e

Pos: 78 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitung - W ar nung - Um

w

Pos: 79 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitung - W ar nung - Bra

n

Pos: 80 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitung - W ar nung - Expl

o

Pos: 81 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitung - Gefahr - nicht

m

e

n mit mehreren Personen @ 9\mod_1247063058002_51.docx @ 62938 @ @ 1

ß

e Oberfläche - Oberfläche nicht berühren @ 9\mod_1247054774780 _51.docx @ 62802 @ @ 1

t

rischer Schlag - zur Vermeidung Anweisung folgen @ 9\mod_ 124 7055093892_51.docx @ 62819 @ @ 1

k

ippen des Gerätes @ 9\mod_1247059198372_51.docx @ 62870 @ @ 1

w

ebende Lasten @ 9\mod_1251450500309_51.docx @ 65454 @ @ 1

e

n schwerer Lasten @ 9\mod_1247059891358_51.docx @ 62887 @ @ 1

w

eltgefährdung @ 9\mod_1247060443419_51.doc x @ 62904 @ @ 1

n

dgefahr @ 9\mod_1251445272822_51.docx @ 65437 @ @ 1

l

osionsgefährliche Stoffe @ 9\mod_1247061148859_51.d ocx @ 62921 @ @ 1

m

it Wasser überschütten @ 9\mod_1247826410886_51.doc x @ 63819 @ @ 1

Rule - Lift

This symbo

l

and moved

t

Warning -

This symbo

l

Warning -

This symbo

l

warnings ar

e

Warning –

This symbo

l

warnings ar

e

Warning –

This symbo

l

suspended l

o

Warning –

This symbo

l

can lead to i

Warning –

This symbo

l

is not heede

d

observed.

Warning -

This symbo

l

followed.

Warning –

These symb

o

Prohibite

d

This symbo

l

the objects.

A

only with S

e

draws the p

e

o its final de

s

Hot Surfac

e

warns the o

p

Danger of

E

warns the o

p

not heeded.

Risk of De

v

tells the ope

r

not heeded.

Suspende

d

warns the o

p

ad is strictly

Danger if

H

warns the o

p

n

jury.

Risk to the

warns the o

p

. The operat

o

Fire Dange

r

warns opera

t

Risk of Ex

p

o

ls warn the

o

- Importan

t

warns the o

p

A

high-press

u

everal Peo

p

rsonnel's atte

n

tination by s

e

, Do Not T

o

erator that th

e

lectric Sh

o

erator that th

e

ice Toppli

n

ator that ther

e

Load

erator of pot

e

forbidden. Ig

n

eavy Load

s

erator of the

p

Environm

e

erator of the

r

r must ensur

e

ors of the da

n

losive Sub

perator of ex

p

Informati

o

erator that w

a

re cleaning

d

le

tion to the f

a

veral people.

uch

surface is h

o

ck

re is a risk o

f

g Over

is a risk of t

h

ntial dangers

n

oring this c

a

Are Lifted

otential dan

g

nt

isk to the en

v

e

that nationa

l

ger of fire if

t

s

tances or

E

p