Page 1

Operating Instructions

Laboratory Furnaces (Muffle Furnaces)

L / LE / LT / LV / LVT -SKM -SW -HA

-> 10.2005

Original instructions

www.nabertherm.com

Made

in

Germany

Page 2

Copyright

Copyright by

Nabertherm GmbH

Bahnhofstrasse 20

28865 Lilienthal

Federal Republic of Germany

Reg: M01.0032 ENGLISCH

Rev: 2011-01

No responsibility is accepted for the correctness of this information. We

reserve the right to make technical alterations.

2

Page 3

1 Introduction ........................................................................................................................................................... 5

1.1 Product Description ........................................................................................................................................... 6

1.2 Overview of the Complete Oven ....................................................................................................................... 7

1.3 Key to the Model Names ................................................................................................................................... 9

1.4 Scope of Delivery ............................................................................................................................................ 10

2 Specifications ....................................................................................................................................................... 11

2.1 Warranty and Liability .................................................................................................................................... 16

3 Safety .................................................................................................................................................................... 17

3.1 Intended Use.................................................................................................................................................... 17

3.2 Requirements for the Oven Operator .............................................................................................................. 18

3.3 Requirements for the Operating Personnel ...................................................................................................... 19

3.4 Protective Clothing .......................................................................................................................................... 19

3.5 Basic Measures During Normal Operation ..................................................................................................... 20

3.6 Basic Measures in Case of Emergency ........................................................................................................... 20

3.6.1 What to do in an Emergency ....................................................................................................................... 20

3.7 Basic Measures for Servicing and Maintenance.............................................................................................. 21

3.8 Environmental Regulations ............................................................................................................................. 22

3.9 Explanation of the Symbols and Warnings ..................................................................................................... 23

3.10 General Risks with the Oven ........................................................................................................................... 26

4 Transportation, Installation, and Commissioning ............................................................................................ 27

4.1 Delivery ........................................................................................................................................................... 27

4.2 Unpacking ....................................................................................................................................................... 30

4.3 Transportation Securing Equipment/Packaging .............................................................................................. 31

4.4 Constructional and Connection Requirements ................................................................................................ 32

4.4.1 Installation (Oven Location) ....................................................................................................................... 32

4.5 Assembly, Installation, and Connection .......................................................................................................... 33

4.6 Assembly of a Vent ......................................................................................................................................... 33

4.6.1 Waste Gas System ...................................................................................................................................... 35

4.6.2 Connecting the Oven to the Power Supply ................................................................................................. 36

4.6.3 Insertion of the Base Plate .......................................................................................................................... 39

4.7 Commissioning ............................................................................................................................................... 41

4.8 Recommendations for Heating the Oven for the First Time ........................................................................... 41

4.9 Loading/charging ............................................................................................................................................ 42

5 Operation ............................................................................................................................................................. 44

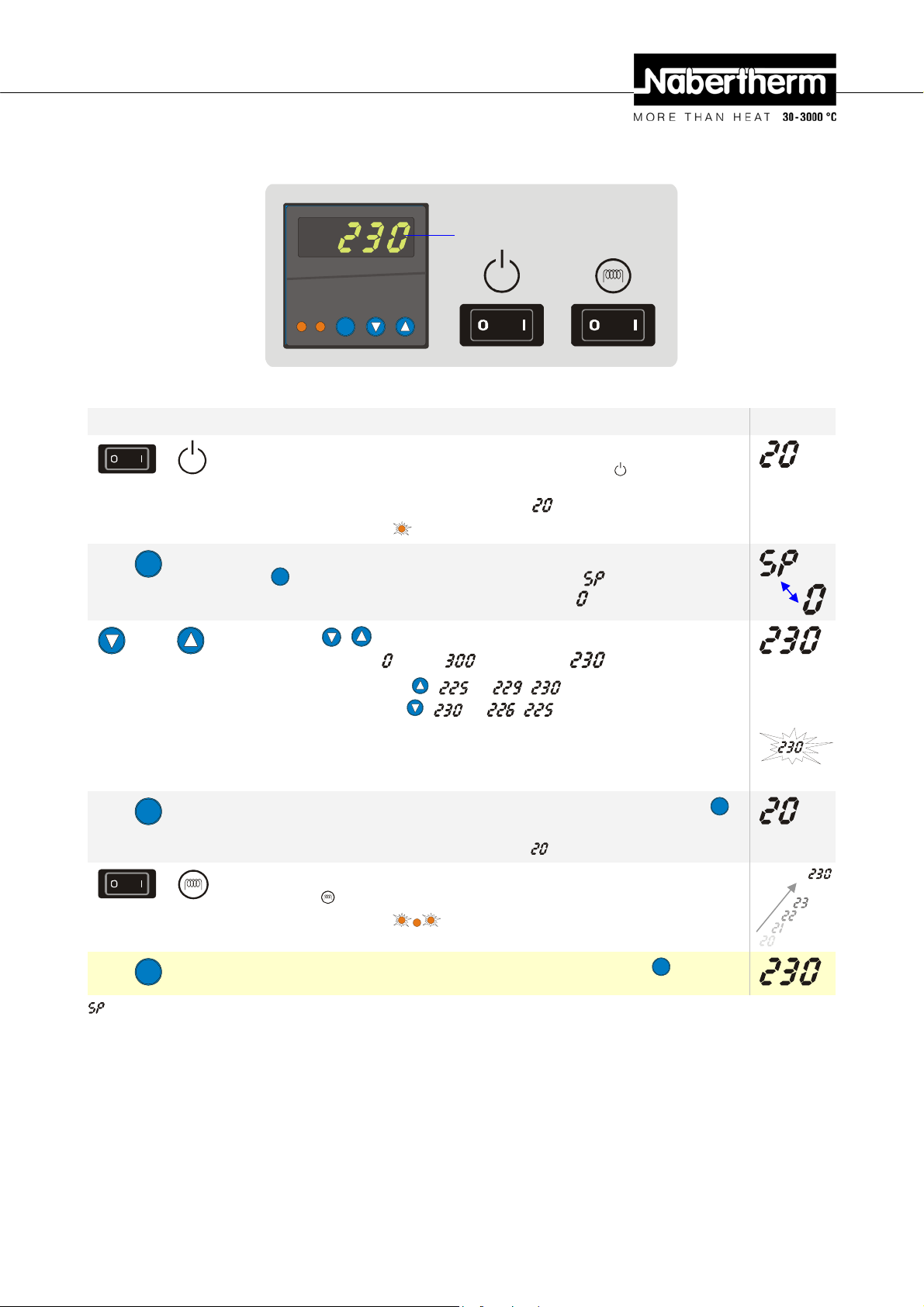

5.1 Operating Controller B 180/P 330 ................................................................................................................... 44

5.2 Operating Controller R 6 ................................................................................................................................. 45

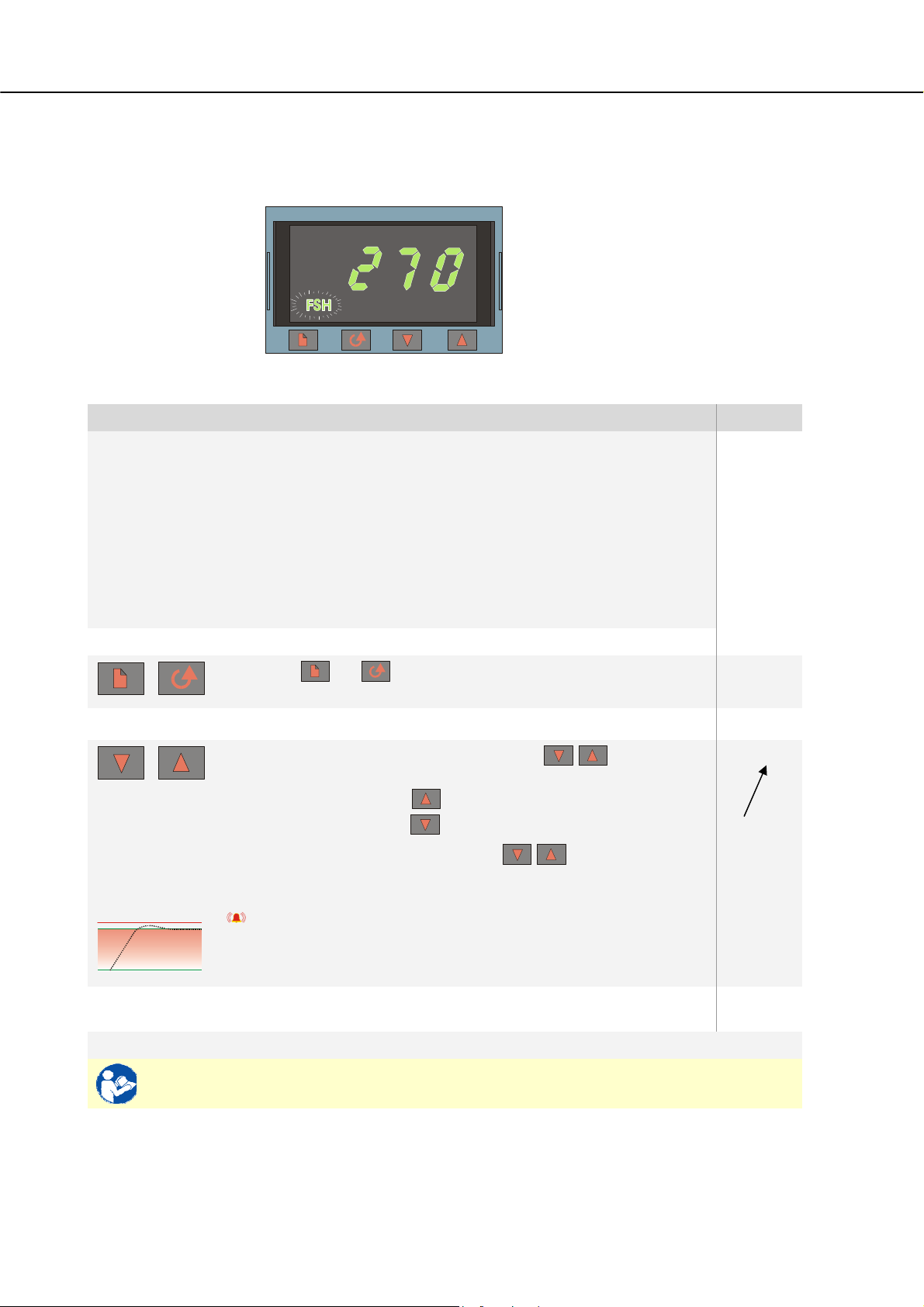

5.3 Over-Temperature Limit Controller with Manual Reset and Adjustable Cut-Off Temperature ..................... 46

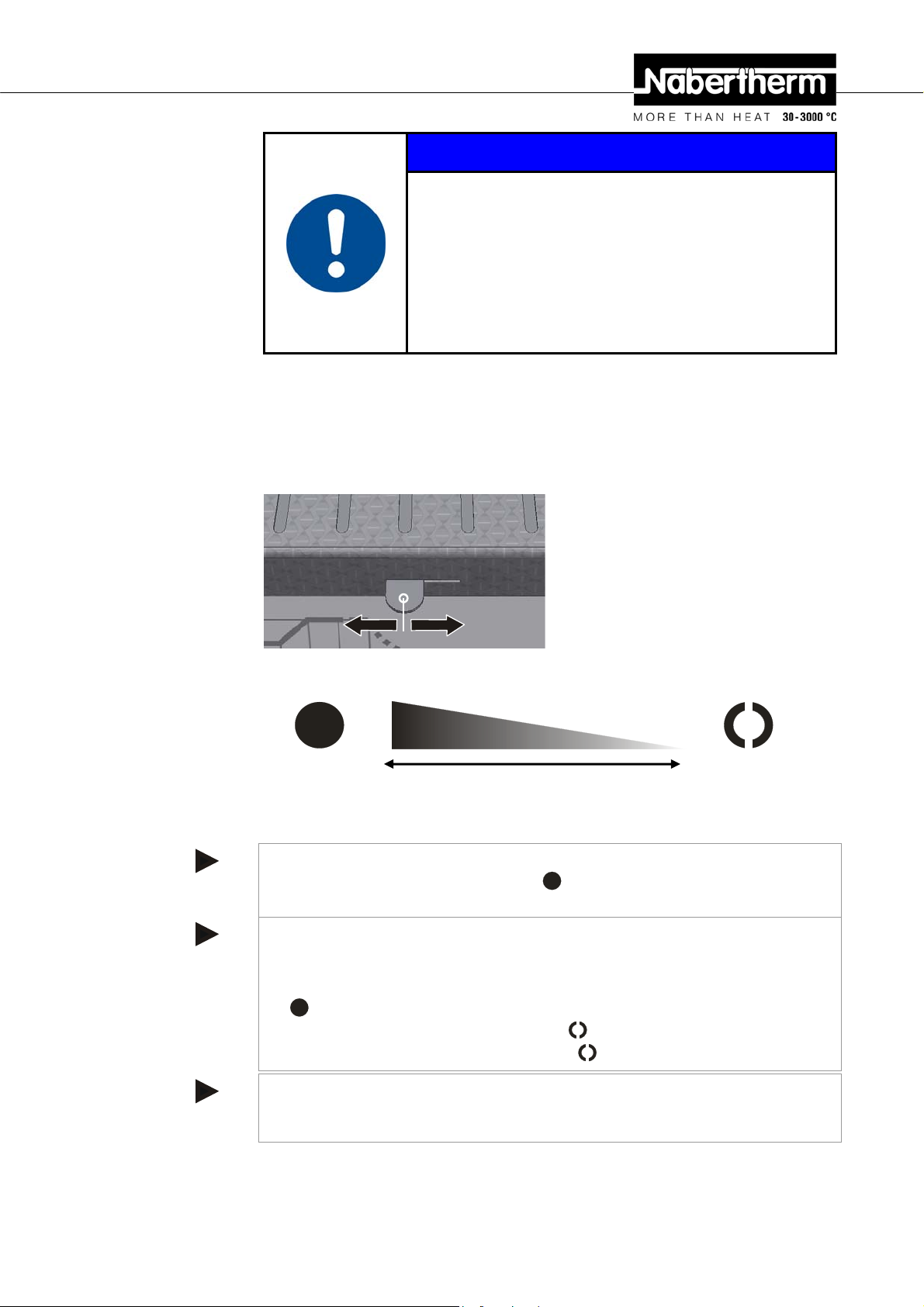

5.4 Air Inflow Lever ............................................................................................................................................. 47

6 Servicing, Cleaning, and Maintenance .............................................................................................................. 48

6.1 Shutting the system down for maintenance ..................................................................................................... 49

6.2 Regular Maintenance of the Oven ................................................................................................................... 50

6.3 Operating and Auxiliary Materials .................................................................................................................. 50

6.4 Cleaning Products ........................................................................................................................................... 50

7 Faults .................................................................................................................................................................... 52

3

Page 4

7.1 Replacing a Fuse ............................................................................................................................................. 53

7.2 Separate the Snap-In Coupling (Plug) from the Furnace Housing .................................................................. 54

8 Spare Parts/Wearing Parts ................................................................................................................................. 55

9 Nabertherm Service ............................................................................................................................................ 56

10 Electrical Connections (Circuit Diagram) ......................................................................................................... 56

11 Shut-Down, Dismantling, and Storage............................................................................................................... 57

11.1 Environmental Regulations ............................................................................................................................. 57

11.2 Transportation/Return Transportation ............................................................................................................. 58

12 Declaration of Conformity .................................................................................................................................. 59

4

Page 5

Pos: 1 /TD/Einleitung/Überschrift - Einleitung 1 @ 0\ mod_1167823212238_51.doc @ 5139 @ 1 @ 1

1 Introduction

Pos: 2 /TD/Einleitung/Öfen @ 0\mod_1158157227533_51. d oc @ 2084 @ @ 1

Dear Customer,

Thank you for choosing a quality product from Nabertherm GmbH.

You can be proud that you have chosen an oven which has been especially tailored to suit

your manufacturing and production conditions.

This product is characterized by

professional workmanship

high performance due to its high efficiency

high-quality insulation

low power consumption

low noise level

simple installation

easy to maintain

high availability of spare parts

Your Nabertherm Team

Pos: 3 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @ @ 1

Note

These documents are intended only for buyers of our products and may not be copied or

disclosed to third parties without our written consent.

(Law governing copyright and associated protective rights, German Copyright Law from

Sept. 9, 1965)

Protective Rights

Nabertherm GmbH owns all rights to drawings, other documents and authorizations, also in

case of applications for protective rights.

Note

All the figures in the instructions have a descriptive character; in other words, they do not

represent the exact details of the oven.

5

Page 6

Pos: 4 /TD/Einleitung/Produktbeschreibung/Öfen/ Überschrift - Produktbeschreibung 1.1 @ 0\mod_116 7821943807_51.doc @ 5103 @ 2 @ 1

1.1 Product Description

Pos: 5 /TD/Einleitung/Produktbeschreibung/Öfen/ Laborofen L-LE-L(T)-LV(T)-SKM-SW-HA - Pr oduktbeschreibung @ 14\mod_1299596880427_51.doc @ 113276 @ @ 1

These laboratory furnaces are a high-quality product which will give you many

years of reliable service if they are properly cared for and maintained. One basic

prerequisite is that the furnace is used the way it was designed to be used.

During development and production a high priority was placed on safety,

functionality and economy.

Laboratory Furnaces are attractive thanks to their many advantages. These

furnaces are all-rounders for research and laboratory applications. They are made

from expertly finished, high-quality materials and are easy to operate. These

furnaces are optimally designed for incinerating and heat treatment. The very best

insulation materials permit energy-saving operation and fast heating times thanks

to low heat storage and thermal conductivity. Laboratory furnaces attain furnace

chamber temperatures of max. 1100 °C (2012 °F), 1200 °C (2192 °F) or 1300 °C

(2372 °F).

Other characteristics of this product are:

All the models have a high-quality, multi-layered and energy-saving thermal

Double-wall housing means low outer temperatures and solid stability. All

Good temperature uniformity provided by special air supply and exhaust system

There are furnaces with drop-down doors or lift doors

Ceramic heating plates with integrated heating wire, protected against splattering

Model L/LT …/…/SW with scale and software (Controltherm MV) for annealing

All the models are equipped with a controller which provides considerable safety

Additional Equipment

Vent, vent with fan or catalytic converter.

Over-temperature limit controller with adjustable shut-down temperature for

Manual or automatic protective gas system Protective gas connection on the back

Digital interface RS 422, for example, for process control and documentation

Base plates and catch basins to protect of the furnace and to enable easy charging

Rectangular container, stackable for charging on several levels

Pos: 6 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @ @ 1

insulation

furnaces have housings made of textured stainless steel sheet.

for models LV/LVT .../… and LT …/…HA. For models LV/LVT .../… the system

delivers more than 6 air changes a minute. The incoming air is pre-heated, so that

a good temperature uniformity is ensured.

and exhaust-air for models L/LT …/… and LV/LVT .../…

loss specifications

against operator mistakes. The furnace chamber temperature is measured and

regulated by a long-life thermocouple (NiCr-Ni Tmax < 1100 °C or PtRh-Pt Tmax

> 1100 °C).

thermal protective class 2 as specified in EN 60519-2 to protect the furnace and

the ware against overheating.

side of the furnace

provided by Controltherm MV software package.

6

Page 7

Pos: 7 /TD/Einleitung/Lieferumfang/Öfen/Übersc hrift - Gesamtübersicht der Anlage @ 1\mod_11743026 3699 2_51.doc @ 11332 @ 2 @ 1

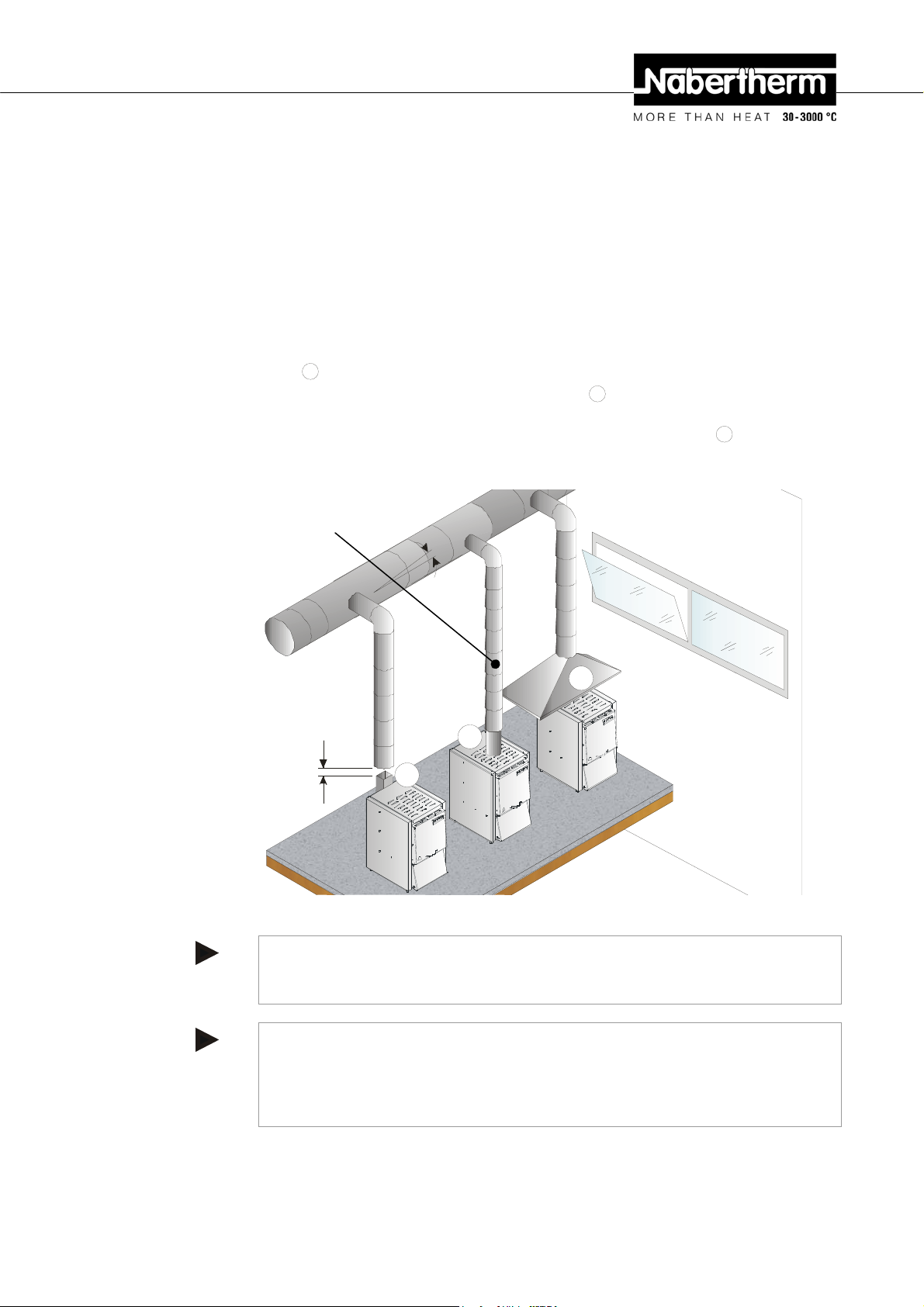

1.2 Overview of the Complete Oven

Pos: 8 /TD/Einleitung/Lieferumfang/Öfen/Gesa mtübersicht Laborofen L-LE-L(T)-LV(T)-SKM-SW -HA @ 14\mod_1295003962965_51.doc @ 111859 @ @ 1

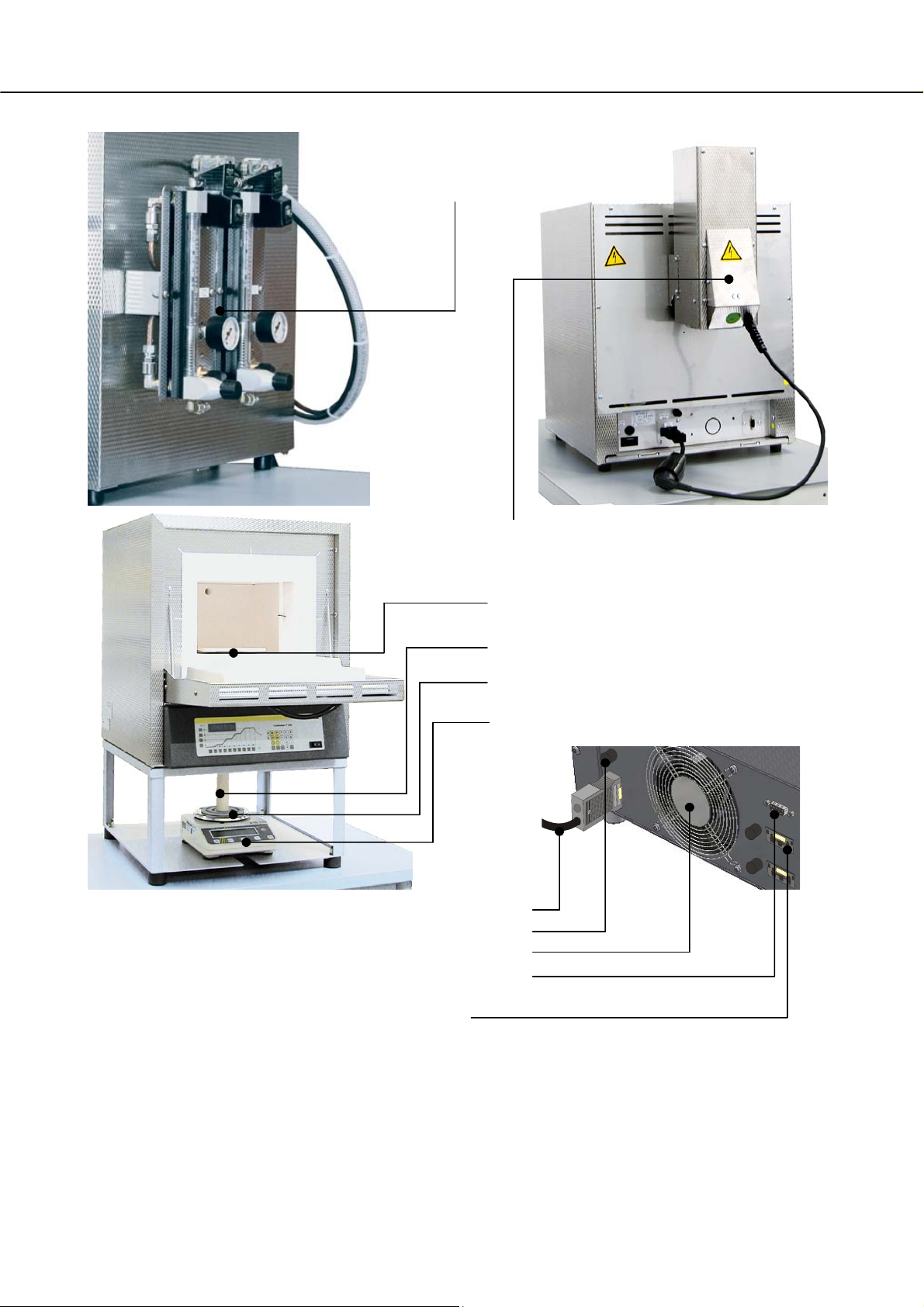

Furnace door

Handle

Air for the regulation of fresh air

Furnace chamber

Display

Exhaust-air system

Display

Controller

Power switch (ON/OFF)

Controller

Power switch (ON/OFF)

Heating (ON/OFF)

7

Page 8

Gas supply system

(additional

equipment)

Vent, vent with fan or catalytic converter

(accessories)

Support plate in the furnace

chamber

Ceramic die

Support die

Scale

Backup power connection

(lock for backup power connection)

for example, for vent with fan or gas supply system (additional equipment)

Fig. 1: Example: Complete overview of various laboratory furnaces

Pos: 9 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @ @ 1

Digital interface RS 422 (option)

Power line

Lock

Switchgear fan

8

Page 9

Pos: 10 /TD/Einleitung/Produktbeschreibung/ Öfen/Überschrift - Entschlüsselung der Modellbez ei chnung @ 2\mod_1184245078907_51.doc @ 19775 @ 2 @ 1

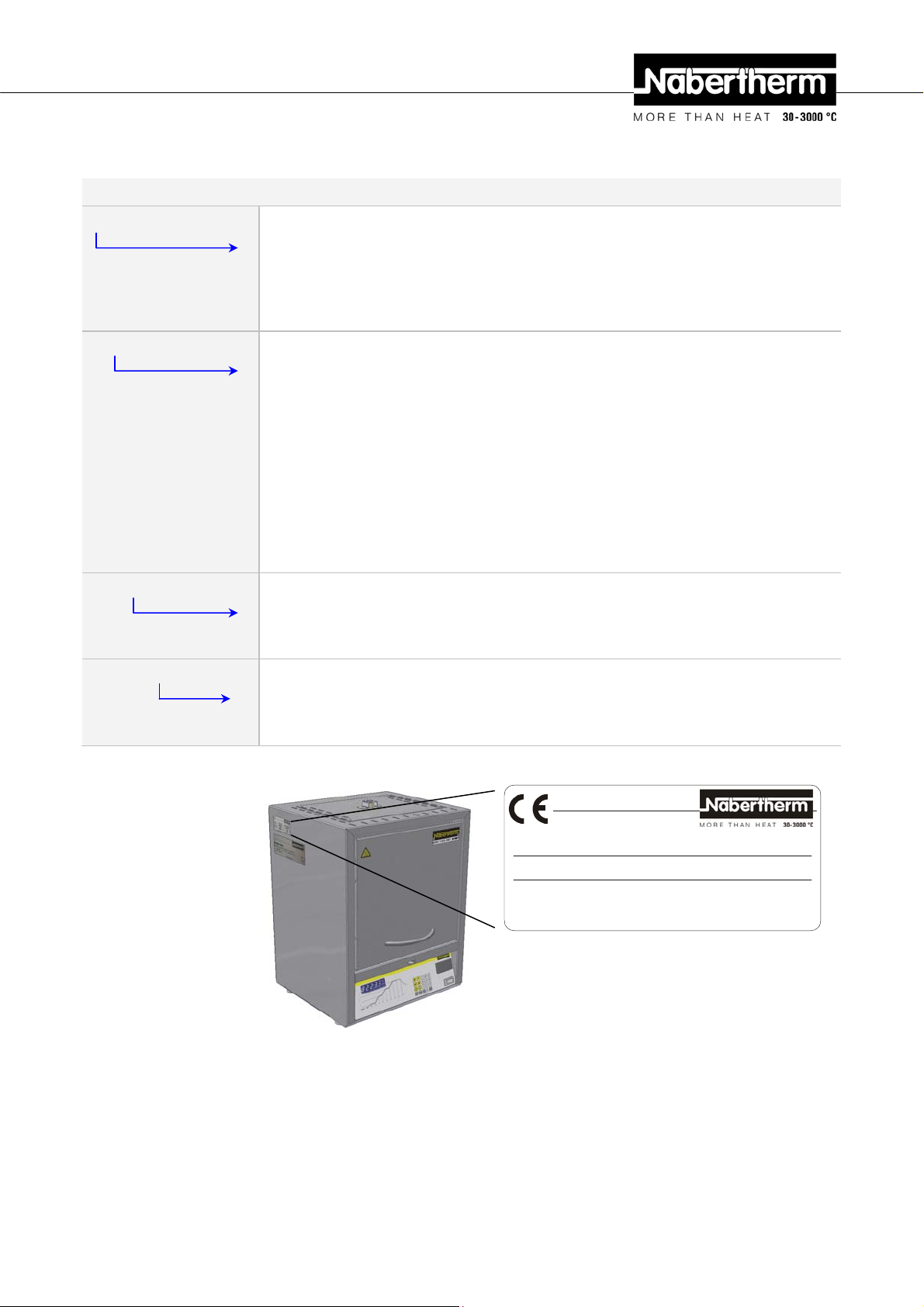

1.3 Key to the Model Names

Pos: 11 /TD/Einleitung/Produktbeschreibung/ Öfen/Entschlüssellung der Modellbezeichnung Labor ofen L-LE-L(T)-LV(T)-SKM-SW-HA @ 14\mod_1299593606 987_51.doc @ 113253 @ @ 1

Example Explanation

LT 9/11SKM

LT 9/11SKM

LT 9/11SKM

LT 9/11SKM

L = Laboratory furnace with drop-down door

LE = Laboratory furnace economy series

LT = Laboratory furnace with lift door

LV = Laboratory incinerator with drop-down door

LVT = Laboratory incinerator with lift door

1 = 1-liter furnace chamber (volume in L)

2 = 2-liter furnace chamber (volume in L)

3 = 3-liter furnace chamber (volume in L)

4 = 4-liter furnace chamber (volume in L)

5 = 5-liter furnace chamber (volume in L)

6 = 6-liter furnace chamber (volume in L)

9 = 9-liter furnace chamber (volume in L)

14 = 14-liter furnace chamber (volume in L)

15 = 15-liter furnace chamber (volume in L)

24 = 24-liter furnace chamber (volume in L)

40 = 40-liter furnace chamber (volume in L)

11 = Tmax 1100 °C (2012 °F)

12 = Tmax 1200 °C (2192 °F)

13 = Tmax 1300 °C (2372 °F)

HA = Laboratory furnace with recirculating air fan in the back wall

SKM = Furnace chamber made of ceramic muffle

SW = Scale furnace with support frame and scale

Pos: 12 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @ @ 1

LT 9/11SKM

LC011H6SN 1100 °C 2011

230 V 1/N/PE~ 15.2 A 50/60 Hz 3.5 kW

www.nabertherm.de Made in Germany

Fig. 2: Example: Model designation (type plate)

SN xxxxxx

9

Page 10

Pos: 13 /TD/Einleitung/Lieferumfang/Öfen/Über schrift - Lieferumfang @ 0\mod_1167822508130_51. doc @ 5112 @ 2 @ 1

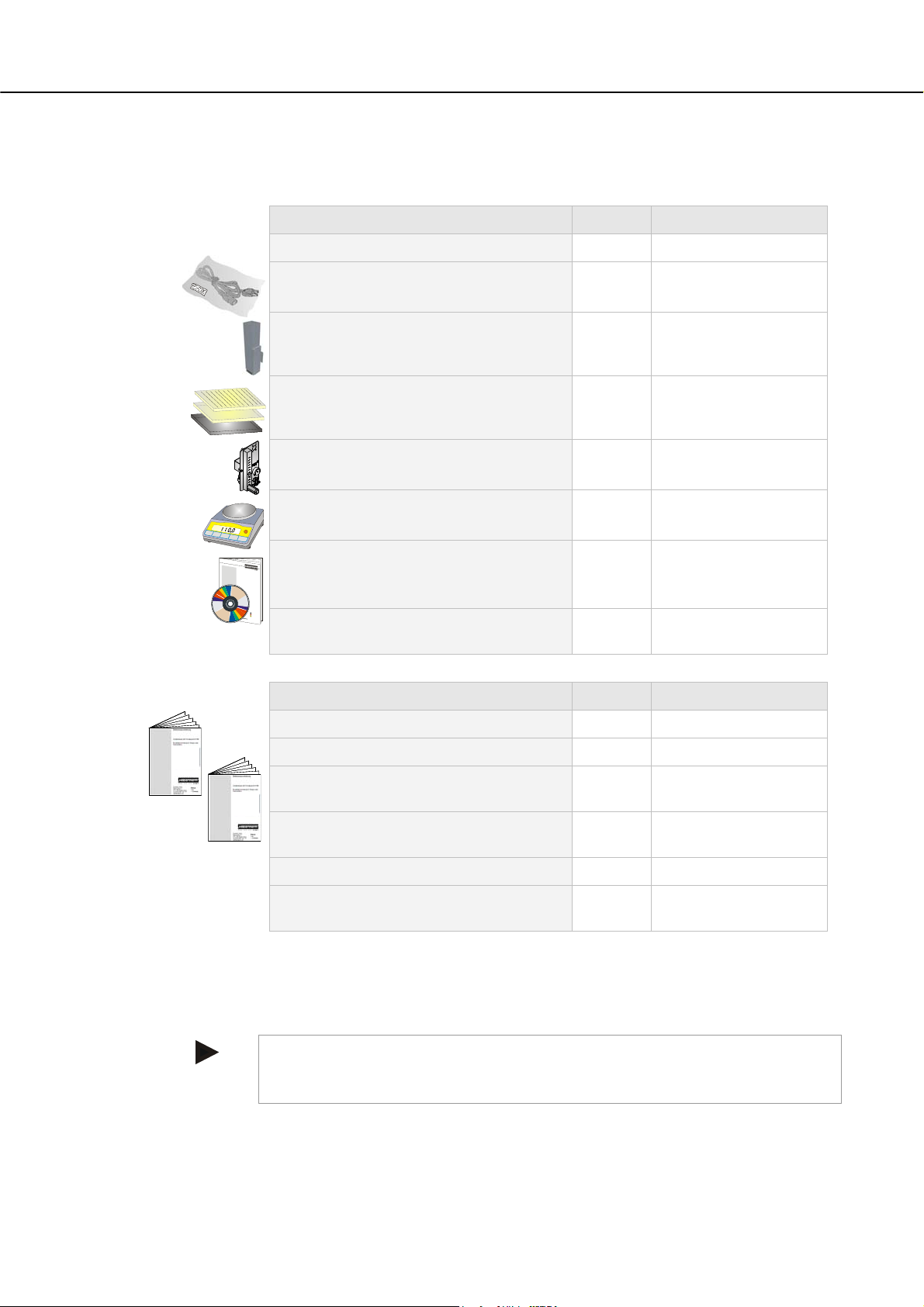

1.4 Scope of Delivery

Pos: 14 /TD/Einleitung/Lieferumfang/Öfen/Labor ofen L-LE-L(T)-LV(T)-SKM-SW-HA - Liefer umfang @ 14\mod_1299662508331_51.doc @ 113310 @ @ 1

The scope of delivery includes:

Furnace components Quantity Comment

Laboratory furnace 1) 1 x Nabertherm GmbH

Power cable 1)

1 x Nabertherm GmbH

Vent ) 2)

1 x

Vent with fan 1) 2)

Catalytic converter 1) 2)

Ceramic ribbed plate

4)

Ceramic ceramic catch basin

Steel catch basin

Gas supply system 2)

1 x Nabertherm GmbH

Scale 2)

1 x Nabertherm GmbH

Process documentation

B

e

t

r

e

i

b

s

a

n

l

e

i

t

u

n

g

Controltherm MV software package 1) 2)

P

r

o

z

e

s

s

d

o

k

u

m

e

n

t

a

t

o

i

n

C

o

n

t

o

r

h

t

l

e

r

m

M

V

1 x Nabertherm GmbH

M

a

d

e

i

n

G

e

r

m

a

n

y

Other components, variable depending

on the particular furnace

- - - Consult the shipping

papers

Pos: 15 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @ @ 1

Document type Quantity Comment

Instruction Manual Laboratory Furnace 1) 1 x Nabertherm GmbH

Operating Instructions for Controller 1) 1 x Nabertherm GmbH

Operating Instructions

1 x Nabertherm GmbH

gas supply system 1)

Operating Instructions

1 x Nabertherm GmbH

Controltherm MV software package 1)

Other documents, variable depending on

- - -

the particular furnace

1) = in scope of delivery depends on design/furnace model

2) = in scope of delivery depend on need, see shipping papers

3) = quantity depends on furnace model

4) = quantity depends on on need, see shipping papers

Caution

Make sure that all documents are carefully stored. All the functions of this furnace

were tested during manufacturing and prior to shipping.

10

Page 11

Pos: 16 /TD/Einleitung/Technische Daten/Öfen/ Üb er schrift - Technische Daten - mit Hinweis @ 0\mod_1167822840 737_51.doc @ 5121 @ 1 @ 1

2 Specifications

Pos: 17 /TD/Einleitung/Technische Daten/Öfen/ Mo de ll Muffelofen Klapptür -Tabelle für L 3/11 - L 40/11 bis L 1/ 12 - L 40/12 @ 14\mod_1294910652628_51.doc @ 111513 @ @ 1

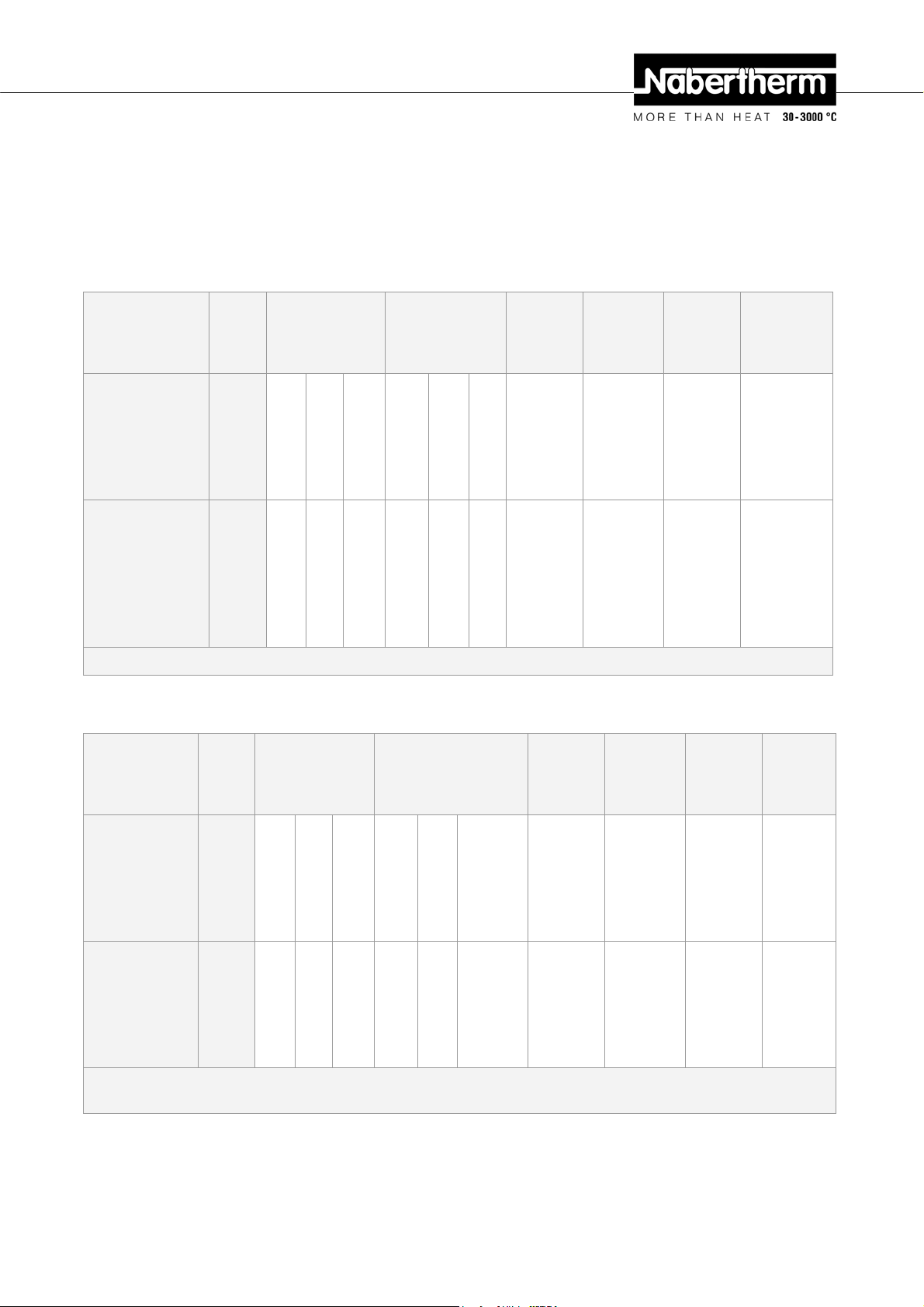

Muffle Furnace

Electrical specifications are on the type plate located on the side of the oven.

Model

Drop-Down Door

Tmax

°C

Dimensions

Interior in mm

w d h

Dimensions

Outer in mm

W D

Volume

in l

Capacity

kW max.

Weight

kg

Minutes

to

Tmax 1)

H

L 3/11 1100 160 140 100 380 370 420 3 1.2 20 60

L 5/11 1100 200 170 130 440 470 520 5 2.4 35 60

L 9/11 1100 230 240 170 480 550 570 9 3.0 45 75

L 15/11 1100 230 340 170 480 650 570 15 3.6 55 90

L 24/11 1100 280 340 250 560 660 650 24 4.5 75 95

L 40/11 1100 320 490 250 600 790 650 40 6.0 95 95

L 1/12 1200 90 115 110 250 265 340 1 1.5 10 25

L 3/12 1200 160 140 100 380 370 420 3 1.2 20 75

L 5/12 1200 200 170 130 440 470 520 5 2.4 35 75

L 9/12 1200 230 240 170 480 550 570 9 3.0 45 90

L 15/12 1200 230 340 170 480 650 570 15 3.6 55 105

L 24/12 1200 280 340 250 560 660 650 24 4.5 75 110

L 40/12 1200 320 490 250 600 790 650 40 6.0 95 110

1) = for connection to 230 V 1/N/PE or 400 V 3/N/PE

Pos: 18 /TD/Einleitung/Technische Daten/Öfen/ Mo de ll Muffelofen Hubtür -Tabelle für LT 3/11 - LT 40/11 bis LT 3/12 - LT 40/ 12 @ 14\mod_1294933924209_51.doc @ 111553 @ @ 1

Muffle Furnace

Model

Lift Door

Tmax

°C

Dimensions

Interior in mm

w d

Dimensions

Outer in mm

W D H

Volume

in l

Capacity

kW max.

Weight

kg

Minutes

to

Tmax 1)

h

LT 3/11 1100 160 140 100 380 370 420+165 3 1.2 20 60

LT 5/11 1100 200 170 130 440 470 520+220 5 2.4 35 60

LT 9/11 1100 230 240 170 480 550 570+290 9 3.0 45 75

LT 15/11 1100 230 340 170 480 650 570+290 15 3.6 55 90

LT 24/11 1100 280 340 250 560 660 650+335 24 4.5 75 95

LT 40/11 1100 320 490 250 600 790 650+335 40 6.0 95 95

LT 3/12 1200 160 140 100 380 370 420+165 3 1.2 20 75

LT 5/12 1200 200 170 130 440 470 520+220 5 2.4 35 75

LT 9/12 1200 230 240 170 480 550 570+290 9 3.0 45 90

LT 15/12 1200 230 340 170 480 650 570+290 15 3.6 55 105

LT 24/12 1200 280 340 250 560 660 650+335 24 4.5 75 110

LT 40/12 1200 320 490 250 600 790 650+335 40 6.0 95 110

1) = for connection to 230 V 1/N/PE or 400 V 3/N/PE

2) = incl. opened lift door

Pos: 19 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @ @ 1

11

Page 12

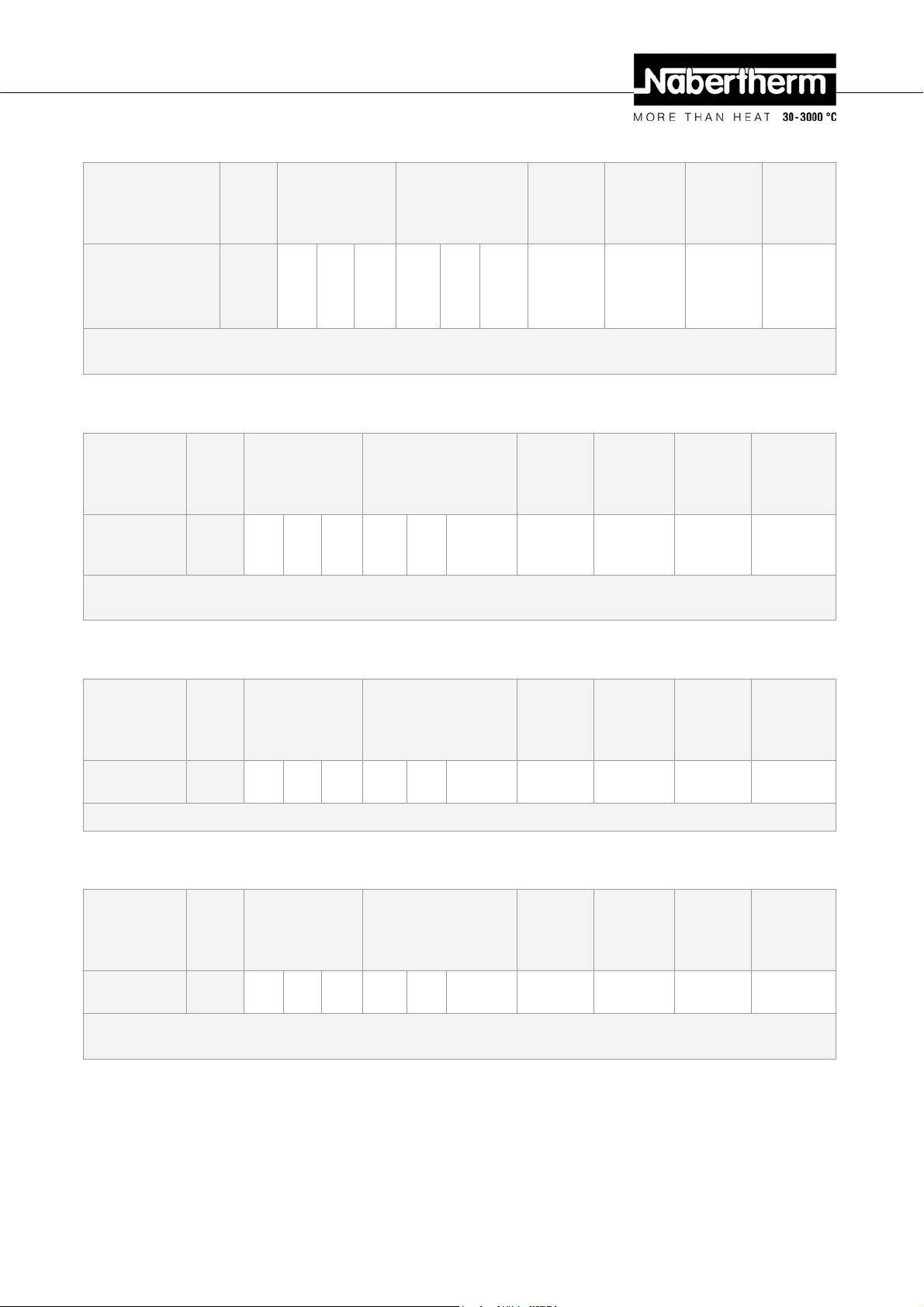

Pos: 20 /TD/Einleitung/Technische Daten/Öfen/ Mo de ll Muffelofen Klapptür -Tabelle für L 5/13 - L 15/13 @ 14\ mod_12 9499 1083275_51.doc @ 111629 @ @ 1

Muffle Furnace

Model

Drop-Down

Door

Tmax

°C

Dimensions

Interior in mm

w d

h

Dimensions

Outer in mm

W D

H

Volume

in l

Capacity

kW max.

Weight

kg

Minutes

to

Tmax 1)

L 5/13 1300 200 170 130 440 470 520 5 2.4 45 45

L 9/13 1300 230 240 170 480 550 570 9 3.0 50 50

L 15/13 1300 230 340 170 480 650 570 15 3.6 60 60

1) = for connection to 230 V 1/N/PE or 400 V 3/N/PE

Pos: 21 /TD/Einleitung/Technische Daten/Öfen/ Mo de ll Muffelofen Hubtür -Tabelle für LT 5/13 - LT 15/13 @ 14\mod_12949 91040209_51.doc @ 111583 @ @ 1

Muffle Furnace

Model

Lift Door

Tmax

°C

Dimensions

Interior in mm

w d

Dimensions

Outer in mm

W D H

Volume

in l

Capacity

kW max.

Weight

kg

Minutes

to

Tmax 1)

h

LT 5/13 1300 200 170 130 440 470 520+220 5 2.4 42 45

LT 9/13 1300 230 240 170 480 550 570+290 9 3.0 60 50

LT 15/13 1300 230 340 170 480 650 570+290 15 3.6 70 60

1) = for connection to 230 V 1/N/PE or 400 V 3/N/PE

2) = incl. opened lift door

Pos: 22 /TD/Einleitung/Technische Daten/Öfen/ Mo de ll Kompakt-Muffelofen Klapptür -Tabelle für LE 1/ 11 - LE 14/11 @ 14\mod_1294992044264_51.doc @ 111652 @ @ 1

Compact Muffle Furnace

Model

Drop-Down

Door

Tmax

°C

Dimensions

Interior in mm

w d

h

Dimensions

Outer in mm

W D

H

Volume

in l

Capacity

kW max.

Weight

kg

Minutes

to

Tmax 1)

LE 1/11 1100 90 115 110 250 265 340 1 1.5 10 10

LE 2/11 1100 110 180 110 275 380 350 2 1.8 10 25

LE 4/11 1100 170 200 170 335 400 410 4 1.8 15 35

LE 6/11 1100 170 200 170 510 400 320 6 1.8 18 35

LE 14/11 1100 220 300 220 555 500 370 14 2.9 25 40

1) = for connection to 230 V 1/N/PE or 400 V 3/N/PE

Pos: 23 /TD/Einleitung/Technische Daten/Öfen/ Mo de ll Veraschungsofen Klapptür -Tabelle für LV 3/11 - LV 15/ 11 @ 14\mod_1294992766140_51.doc @ 111675 @ @ 1

Incinerator

Model

Drop-Down

Door

Tmax

°C

Dimensions

Interior in mm

w d

h

Dimensions

Outer in mm

W D

Hb+2)

Volume

in l

Capacity

kW max.

Weight

kg

Minutes

to

Tmax 1)

LV 3/11 1100 160 140 100 380 370 750 3 1.2 20 120

LV 5/11 1100 200 170 130 440 470 850 5 2.4 35 120

LV 9/11 1100 230 240 170 480 550 900 9 3.0 45 120

LV 15/11 1100 230 340 170 480 650 900 15 3.6 55 120

1) = for connection to 230 V 1/N/PE or 400 V 3/N/PE

2) = incl. exhaust air pipe (Ø 80 mm)

Pos: 24 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @ @ 1

12

Page 13

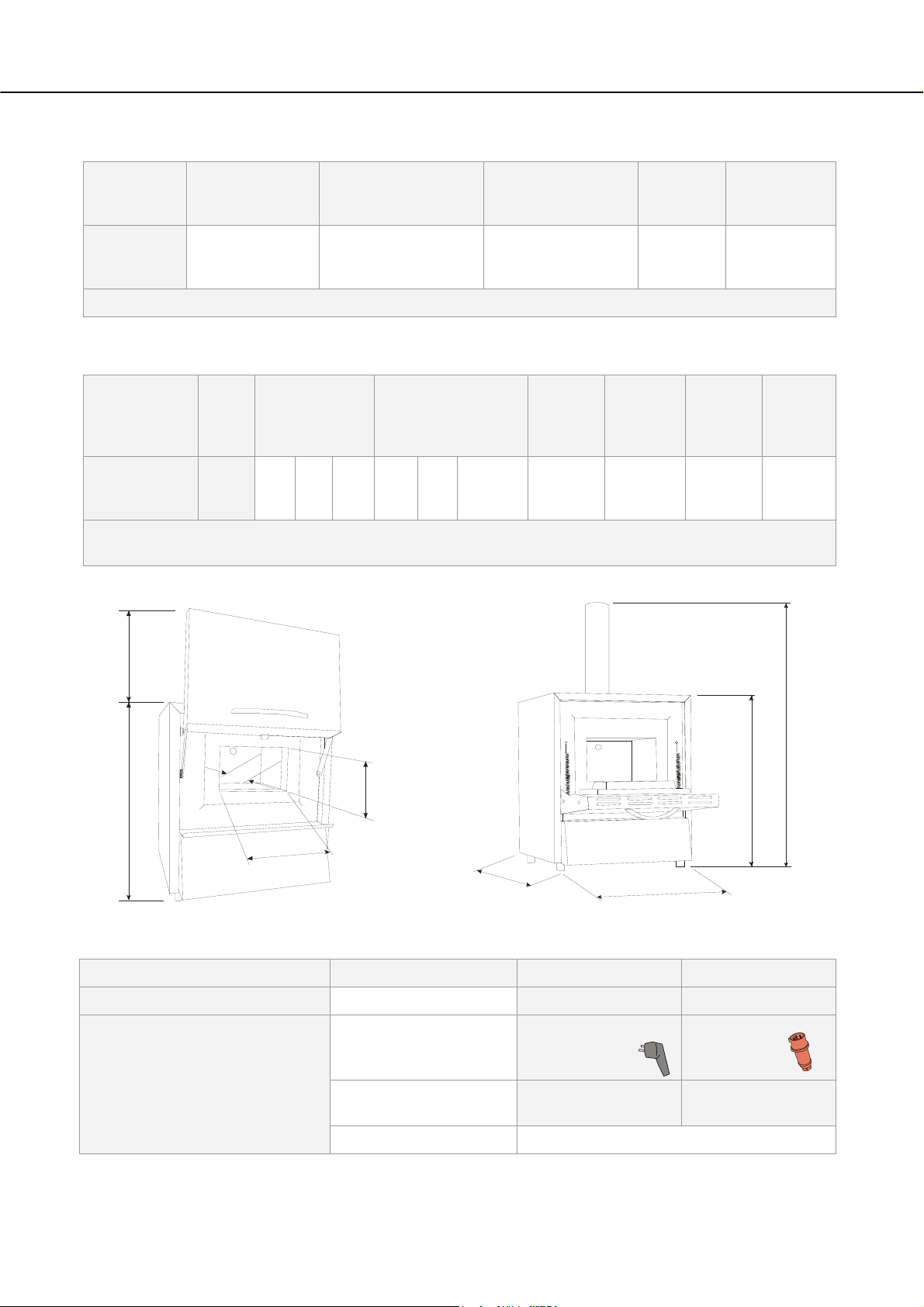

Pos: 25 /TD/Einleitung/Technische Daten/Öfen/ Mo de ll Veraschungsofen Hubtür -Tabelle für LVT 3/11 - LVT 15/11 @ 14\ mod_1294992895007_51.doc @ 111698 @ @ 1

Incinerator

Model

Lift Door

Tmax

°C

Dimensions

Interior in mm

w d

Dimensions

Outer in mm

W D Hb+2)

Volume

in l

Capacity

kW max.

Weight

kg

Minutes

to

Tmax 1)

h

LVT 3/11 1100 160 140 100 380 370 750 3 1.2 20 120

LVT 5/11 1100 200 170 130 440 470 850 5 2.4 35 120

LVT 9/11 1100 230 240 170 480 550 900 9 3.0 45 120

LVT 15/11 1100 230 340 170 480 650 900 15 3.6 55 120

1) = for connection to 230 V 1/N/PE or 400 V 3/N/PE

2) = incl. exhaust air pipe (Ø 80 mm)

Pos: 26 /TD/Einleitung/Technische Daten/Öfen/ Mo de ll Muffelofen mit Keramikmuffel Klapptür/Hubtür -Tabelle für L 9/11/SKM - LT 9/11/SKM @ 14\mod_1294994910658 _51. doc @ 111721 @ @ 1

Muffle Furnace

Model

Drop-Down

Door/

Lift Door

Tmax

°C

Dimensions

Interior in mm

w d

h

Dimensions

Outer in mm

W D

H+Ha 2)

Volume

in l

Capacity

kW max.

Weight

kg

Minutes

to

Tmax 1)

L 9/11/SKM 1100 230 240 170 480 550 570 9 3.0 50 90

LT

1100 230 240 170 480 550 570+290 9 3.0 50 90

9/11/SKM

1) = for connection to 230 V 1/N/PE or 400 V 3/N/PE

2) = incl. opened lift door

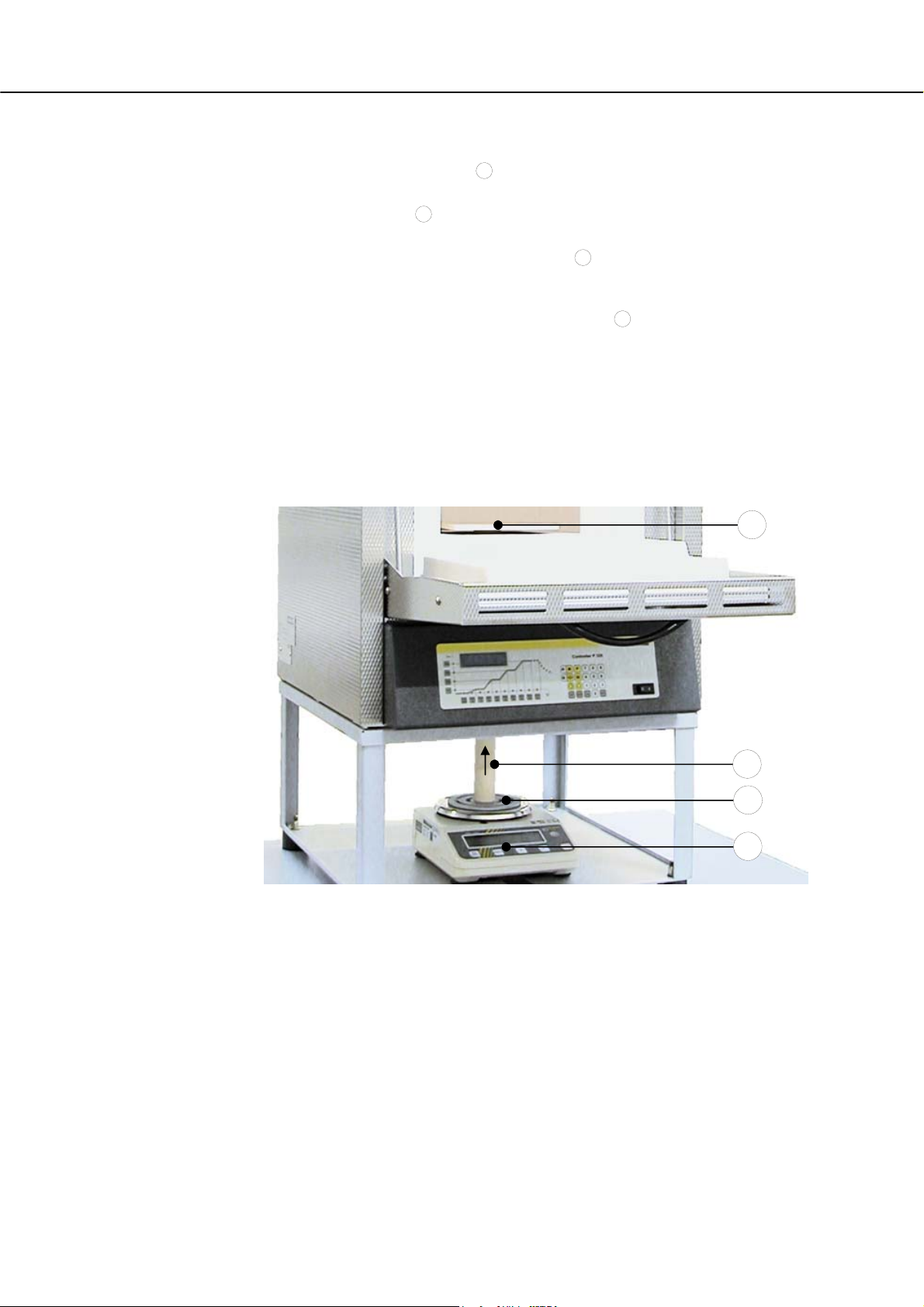

Pos: 27 /TD/Einleitung/Technische Daten/Öfen/ Mo de ll Muffelofen mit Klapptür und Waage -Tabelle für L 9/11/ SW - L 9/12/SW @ 14\mod_1294995752712_51.doc @ 111744 @ @ 1

Muffle Furnace

Model

Drop-Down

Door

Tmax

°C

Dimensions

Interior in mm

w d

Dimensions

Outer in mm

W D H

Volume

in l

Capacity

kW max.

Weight

kg

Minutes

to

Tmax 1)

h

L 9/11/SW 1100 230 240 170 480 550 800 9 3.0 55 75

L 9/12/SW 1200 230 240 170 480 550 800 9 3.0 55 90

1) = for connection to 230 V 1/N/PE or 400 V 3/N/PE

Pos: 28 /TD/Einleitung/Technische Daten/Öfen/ Mo de ll Muffelofen mit Hubtür und Waage -Tabelle für LT 9/11/SW - LT 9/12/SW @ 14\mod_1294996314888_51.doc @ 111767 @ @ 1

Muffle Furnace

Model

Drop-Down

Door

Tmax

°C

Dimensions

Interior in mm

w d

Dimensions

Outer in mm

W D H

Volume

in l

Capacity

kW max.

Weight

kg

Minutes

to

Tmax 1)

h

LT 9/11/SW 1100 230 240 170 480 550 800+290 9 3.0 55 75

LT 9/12/SW 1200 230 240 170 480 550 800+290 9 3.0 55 90

1) = for connection to 230 V 1/N/PE or 400 V 3/N/PE

2) = incl. opened lift door

13

Page 14

Pos: 29 /TD/Einleitung/Technische Daten/Öfen/ Mo de ll Waage für Muffelofen L/LT 9/11-12/SW -Tabelle für EW -1500/3000/6000 @ 14\mod_1294996701851_51.doc @ 111790 @ @ 1

Scale

Type Readability

in g

Weight Range

in g

Stamp Weight

in g

Calibratio

n Value

in g

Minimum

Load

in g

EW-1500 0.01 1500 incl. stamp 850 0.1 0.5

EW-3000 0.01 1500 incl. stamp 850 0.1 0.5

EW-6000 0.10 1500 incl. stamp 850 1.0 5.0

Pos: 30 /TD/Einleitung/Technische Daten/Öfen/ Mo de ll Muffelofen Hubtür -Tabelle für LT 5/11HA - LT 15/11HA @ 14\ mod_ 1294 997879629_51.doc @ 111813 @ @ 1

Muffle Furnace

Model

Lift Door

Tmax

°C

Dimensions

Interior in mm

w d

Dimensions

Outer in mm

W D H

Volume

in l

Capacity

kW max.

Weight

kg

Minutes

to

Tmax 1)

h

LT 5/11HA 1100 200 160 130 440 470 520+220 5 2.4 36 60

LT 9/11HA 1100 230 230 170 480 550 570+290 9 3.0 46 60

LT 15/11HA 1100 230 330 170 480 650 570+290 15 3.6 56 75

1) = for connection to 230 V 1/N/PE or 400 V 3/N/PE

2) = incl. opened lift door

Pos: 31 /TD/Einleitung/Technische Daten/Öfen/ Mo de ll-Tabelle für Laboröfen L-LE-L(T)-LV(T)-SKM- SW -HA - Grafik - 1 @ 14\mod_1300087573327_51.doc @ 113363 @ @ 1

Ha

H

d

h

Hb

H

w

D

W

Fig. 3: Dimensions

Pos: 32 /TD/Einleitung/Technische Daten/Öfen/ Tabe lle für Laboröfen L/LT/LE/LV/LVT/ - Öfen - 1 @ 14\mod_1295001 050844_51.doc @ 111836 @ @ 1

Electrical connection

Model:

Power plug

1-phase: (1 N/PE) 3-phase: (3 N/PE)

to 3.6 kW from 4.5 kW

Protective contact plug

(with snap-in socket)

CEE plug

Voltage:

110 V – 240 V

380 V – 480 V

220 V – 240 V

14

Frequency: 50 or 60 Hz

Page 15

Thermal protection class

Protective type

Ambient conditions for electrical

equipment

Pos: 33 /TD/Einleitung/Technische Daten/Öfen/ Tabe lle Dauerschalldruckpegel < 80 dB(A) - 2 @ 1\mod_1170750985 488_51.doc @ 8913 @ @ 1

Emissions

Pos: 34 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @ @ 1

Heating output in kW: see section "Specifications" or type plate on the

furnace

Furnaces:

as specified in DIN EN 60519-2

without safety controller Class 0

Furnaces: IP20

Temperature: Humidity: +5 °C to + 40 °C max. 80 % not

condensing

Continuous sound pressure

< 80 dB(A)

level:

15

Page 16

Pos: 35 /TD/Einleitung/Gewährleistung_Haftu ng/ Überschrift - Gewährleistung und Haftung 1.1 @ 0\mod_11 67822979492_51.doc @ 5130 @ 2 @ 1

2.1 Warranty and Liability

Pos: 36 /TD/Einleitung/Gewährleistung_Haftung/ Öfen und Schaltanlagen - Gewährleistung und Haftung @ 0\m od_1 157536440972_51.doc @ 1569 @ @ 1

As regards warranty and liability, the normal Nabertherm warranty terms apply,

unless individual terms and conditions have been agreed. However, the following

conditions also apply:

Warranty and liability claims for personal injury or damage to property shall be excluded if

they are attributable to one or more of the following causes:

Everyone involved in operation, installation, maintenance, or repair of the oven

must have read and understood the operating instructions. No liability will be

accepted for damage or disruptions to operation resulting from non-compliance

with the operating instructions.

Not using the oven as intended,

Improper installation, start-up, operation, or maintenance of the oven,

Operation of the oven with defective safety equipment or improperly installed or

non-functioning safety and protective equipment,

Not observing the references in the operating instructions to transportation,

storage, installation, start-up, operation, maintenance, or equipping the oven,

Making unauthorized changes to the oven,

Making unauthorized changes to the operating parameters,

Making unauthorized changes to the parameterization, the settings, or the program,

Original parts and accessories are designed especially for Nabertherm ovens.

Replace parts only with original Nabertherm parts. Otherwise the warranty will be

void. Nabertherm accepts absolutely no liability for damage caused by using parts

that are not original Nabertherm parts.

Catastrophes due to third-party causes and force majeure.

Pos: 37 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @ @ 1

§

16

Page 17

Pos: 38 /TD/Sicherheit/Überschrift - Sicher heit @ 0\mod_1158843961540_51.doc @ 3103 @ 1 @ 1

3 Safety

Pos: 39 /TD/Sicherheit/Überschrift - Bestimmung sge mäße Verwendung @ 0\mod_1167823503921_51.doc @ 5148 @ 2 @ 1

3.1 Intended Use

Pos: 40 /TD/Sicherheit/Bestimmungsgemäße Verwendun g LHT-Hochtemperaturöfen (Tischmodell) @ 2\mod_118 234 7443948_51.doc @ 18724 @ @ 1

Safety

This Nabertherm system was designed and manufactured after careful selection of the

harmonized standards to be observed as well as other technical specifications. It therefore

corresponds to the state of the art, ensuring the highest possible degree of safety.

Only materials with known characteristics and melting temperatures may be used. Check

the material safety data sheets if necessary.

Use of the furnace for any other purpose whatsoever such as processing

products other than those intended or handling hazardous substances or

substances posing a health hazard constitutes improper use and must be

agreed upon with Nabertherm in writing.

Whether or not the materials used in the furnace can potentially corrode or destroy

the insulation or heating elements must be ascertained.

For furnaces with over-temperature limit controllers, the cutoff temperature must be set to

prevent overheating of the material.

Modifications to system equipment must be agreed upon with

Nabertherm in writing. It is not permitted to remove, bypass, or shut down safety devices.

The installation instructions and safety guidelines must be observed. Otherwise, the furnace

will not be considered as being used as designated, and all claims against Nabertherm

GmbH will be void.

Opening the furnace when hot (temperature greater than 200/392 °C/°F) can lead to

accelerated wear of the following components: insulation, heating elements, and furnace

housing.

Operating with power sources, products, operating equipment, additives,

etc. that are subject to the Ordinance on Hazardous Substances or cause

risks to the health of operating personnel in any way is not permitted.

Pos: 41 /TD/Allgemeine Hinweise (für alle Anleitungen) /Hinweis - Dieser Ofen verfügt über keine Sicherheit stechnik für Prozesse, in denen zündfähige Gem @ 8\mod_123 5038699771_51.doc @ 51483 @ @ 1

Pos: 42 /TD/Allgemeine Hinweise (für alle Anleitungen) /Hinweis - Dieses Produkt entspricht nicht der ATEX- Richtlinie und darf nicht ... @ 2\mod_1184228756893_5 1. doc @ 19686 @ @ 1

- This furnace is designed for commercial use. The furnace must not be used

for heating food, animals, wood, grain, etc.

- The furnace must not be used as a workplace heater.

- Do not use the furnace to melt ice or similar materials.

- Do not use the furnace as a clothes dryer.

Note

See safety instructions in the individual sections.

Note

The oven must not be operated with explosive gases or mixtures and it must be ensured that

explosive gases or mixtures do not form during the process.

This oven has no safety technology for processes in which ignitable mixtures could form,

e.g. debinding.

If the oven is to be used for such processes, the concentration of organic gases must never

exceed 3% of the lower explosive limit (LEL) in the oven. This requirement not only

applies to normal operation, but also especially to exceptions, such as process faults (e.g.

due to the failure of a unit, etc.).

Nabertherm offers a wide range of ovens and furnaces that were especially developed for

processes with ignitable gases.

17

Page 18

Note

This product does not

comply with the ATEX Directive and may not be used in ignitable

atmospheres. It must not be operated with explosive gases or mixtures or during processes

where explosive gases or mixtures are produced.

Pos: 44 /TD/Sicherheit/Überschrift - Anfor derungen an den Betreiber der Anlage @ 0\mod_1167823775531_51.doc @ 5157 @ 2 @ 1

3.2 Requirements for the Oven Operator

Pos: 45 /TD/Sicherheit/Anforderungen an den Betreiber der Anlage - RHTH, RHTC, LHT, Rohröfen @ 2\mod_1184570280797_ 51. doc @ 19913 @ @ 1

The set-up instructions and safety regulations must be followed, otherwise the oven will be

deemed to have been used improperly, effectively cancelling any claims against

Nabertherm GmbH.

This level of safety when operating the oven can be achieved only if all the necessary

measures have been taken. It depends on the oven operator's diligence in planning these

measures and controlling how they are carried out.

The operator must ensure that

all harmful gases are removed from the workplace, for example by an extraction

system,

the extraction system is switched on,

the workplace is properly ventilated,

the oven is operated only in a perfect operating condition and, in particular, that

the functions of the safety components are checked regularly.

the required personal protective equipment is available for and used by the

operating, maintenance, and repair personnel.

these operating instructions, including the supplier documentation, are kept near

the oven. These instructions must be available at all times for anyone working with

or on the oven;

all the safety and operating instruction signs on the oven can be read properly.

Damaged or unreadable signs must be replaced immediately,

oven personnel are informed regularly about all issues involving occupational

safety and environmental protection and are familiar with all the operating

instructions, especially those involving safety,

a risk assessment is carried out (in Germany, covered by Section 5 of the

Occupational Safety Act) to determine any other hazards that may result from the

working conditions particular to the oven's location,

all other instructions and safety guidelines that have been determined in a risk

assessment for the workplace are compiled in an operation manual (in Germany,

covered by Section 6 of the Ordinance Regulating the Use of Operating

Equipment).

operating personnel still in training initially perform their work at the oven under

the supervision of an experienced person. Successful completion of the training

period must be confirmed in writing.

Pos: 46 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @ @ 1

18

Note

In Germany, the VBG and BGZ accident prevention regulations must be followed. The

accident prevention regulations applicable in the country where the oven is installed must

be followed.

Page 19

Pos: 47 /TD/Sicherheit/Überschrift - Anfor derungen an das Bedienpersonal @ 0\mod_1167825643423_51.doc @ 5166 @ 2 @ 1

3.3 Requirements for the Operating Personnel

Pos: 48 /TD/Sicherheit/Anforderungen an das Bedienper s onal @ 0\mod_1158218663482_51.doc @ 2155 @ @ 1

The oven may be operated only by persons who are trained, instructed, and authorized to do

so. These persons must know the operating instructions and act accordingly. The

authorizations of the operating personnel must be clearly defined.

Only adequately qualified and authorized persons may operate, maintain, or repair the oven.

Operating personnel are instructed regularly in all aspects of occupational safety and

environmental protection and are familiar with all the operating instructions, in particular,

safety instructions.

Only trained personnel may operate the control and safety equipment.

The operator should complete these details:

Operator____________________________________________________

The oven may only be transported by _____________________________

The oven may only be installed by _____________________________

The oven may only be commissioned by___________________________

Initial instructions may only be given by____________________________

Faults may only be rectified by _____________________________

The oven may only be maintained by _____________________________

The oven may only be cleaned by _____________________________

The oven may only be serviced by _____________________________

The oven may only be repaired by _____________________________

The oven may only be shut down by _____________________________

Pos: 49 /TD/Sicherheit/Überschrift - Schutzklei du ng @ 0\mod_1167825795750_51.doc @ 5175 @ 2 @ 1

3.4 Protective Clothing

Pos: 50 /TD/Sicherheit/Schutzkleidung - Schutzklei d ung tragen @ 5\mod_1220274995030_51.doc @ 42108 @ @ 1

Wear protective clothing

Pos: 51 /TD/Sicherheit/Schutzkleidung - Hitzebes tändige Handschuhe tragen @ 9\mod_1246542013306_51.doc @ 62473 @ @ 1

Wear heat-resistant gloves to protect your hands.

Pos: 52 /TD/Sicherheit/Schutzkleidung - Schutzbri lle tragen @ 5\mod_1220273954830_51.doc @ 42086 @ @ 1

Wear protective goggles.

Pos: 53 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @ @ 1

19

Page 20

Pos: 54 /TD/Sicherheit/Überschrift - Grundlegende Maßnahmen bei Normalbetrieb @ 0\mod_1167825919827_51. doc @ 5184 @ 2 @ 1

3.5 Basic Measures During Normal Operation

Pos: 55 /TD/Sicherheit/Grundlegende Maßnahmen bei Norm al betrieb (LHT ../..-Tischmodell) @ 3\mod_1195478872113_51.doc @ 27827 @ @ 1

Risks during Normal Operation!

Before switching the oven on, check and ensure that only authorized persons are in the

working area of the oven and that no one can be injured as a result of operating the oven.

Before starting production each time, check and ensure that all the safety equipment works

properly.

Before starting production each time, check the oven for obvious damage and ensure that it

is operated only in a perfect condition. Report any defects to a supervisor immediately.

Before starting production each time, remove all materials and objects that are not needed

for production from the working area.

At least once every day (see also Servicing and Maintenance) check the following:

Check the oven for obvious external damage,

Check that all safety equipment is working as intended (e.g. emergency stop

button),

Check all hydraulic or pneumatic hoses, make sure that they are not leaking and

that they are connected properly (if applicable),

Check all gas and oil lines, make sure that they are not leaking and that they are

connected properly (if applicable),

Check that the fan works properly,

Pos: 57 /TD/Sicherheit/Überschrift - Grundlegende Maßnahmen im Notfall @ 1\mod_1170943369267_51.doc @ 9093 @ 2 @ 1

3.6 Basic Measures in Case of Emergency

Pos: 58 /TD/Sicherheit/Überschrift - Verhalten im No tf al l @ 1\mod_1170949904855_51.doc @ 9123 @ 3 @ 1

3.6.1 What to do in an Emergency

Pos: 59 /TD/Allgemeine Hinweise (für alle Anleitungen) /Hinweis - Das Stillsetzen im Notfall ist vorgeseh en dur ch Ziehen des Netzsteckers. @ 6\mod_1222062836860 _51. doc @ 42829 @ @ 1

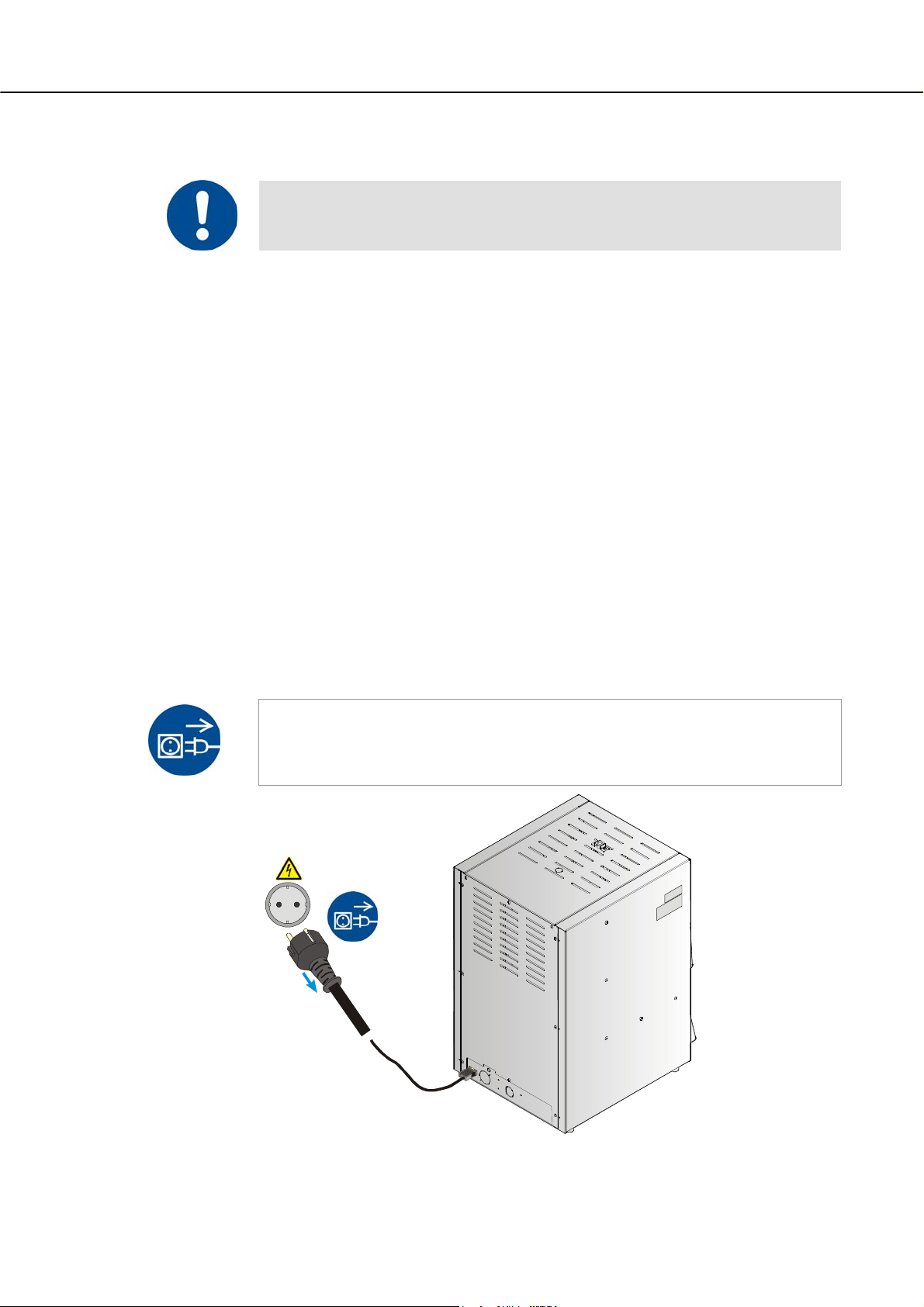

Note

The power plug is to be pulled out to stop the oven in case of an emergency. Therefore,

the power plug must be accessible at all times when the oven is operating so that it can be

Pos: 60 /TD/Sicherheit/Grundlegende Maßnahmen im Notf a ll - Netzstecker ziehen LHT/HTC-Renishaw - Grafi k @ 10\ mod_1253804741998_51.doc @ 66279 @ @ 1

pulled out quickly in case of an emergency.

20

Fig. 4: Pulling the power plug

Page 21

Pos: 61 /TD/Allgemeine Hinweise (für alle Anleitungen) /Warnung - Bei unerwarteten Vorgängen im Ofen (z.B. star ke Rauchentwicklung oder Geruchsbelästigung) @ 4\mod_ 1205 306579737_51.doc @ 34218 @ @ 1

Risks during Normal Operation!

Switch the oven off immediately in case of unexpected occurrences in the oven (e.g. a lot of

smoke or unusual smells). Wait until the oven has cooled naturally to room temperature.

Pos: 62 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Warnsymbol_Gefahr - Elektrischer Schlag - Piktogramm elektr. Schlag - Hauptsc halter @ 9\mod_1247472185096_51.doc @ 63063 @ @ 1

DANGER

• Danger of electric shock.

• Risk of fatal injury.

• Work on electrical

equipment may be carried out only by

qualified electricians

or by trained personnel authorized by

Nabertherm.

• Before starting work, pull out the

power plug

Pos: 63 /TD/Sicherheit/Überschrift - Grundlegende Maßnahmen bei Wartung und Instandhaltung @ 0\mod_11678260 60620_51.doc @ 5193 @ 2 @ 1

3.7 Basic Measures for Servicing and Maintenance

Pos: 64 /TD/Sicherheit/Grundlegende Maßnahmen bei W artung und Instandhaltung @ 0\mod_1158222458436_51.doc @ 2188 @ @ 1

Maintenance work must be performed by authorized persons following the maintenance

instructions and the accident prevention regulations. We recommend that the maintenance

and repair work be carried out by the service team of Nabertherm GmbH. Non-compliance

may cause injuries, death, or considerable damage to property.

Switch off the oven and make sure it cannot be switched on again inadvertently (lock the

main switch and secure it with a padlock), or pull out the power plug.

Clear an adequate area around the oven to facilitate the repair work.

Suspended loads are dangerous. Working beneath a suspended load is prohibited. There is a

risk of fatal injury.

Relieve the pressure on hydraulic equipment before carrying out maintenance or repair

work (if applicable).

When cleaning ovens, control cabinets, or electrical equipment housings, never spray them

with water.

When maintenance or repair work has been completed, before recommencing production

ensure the following:

Check that loosened screw connections have been re-tightened,

Reinstall protective equipment, screens, and filters,

Remove all material, tools, and other equipment used for the maintenance or repair

work from the working area of the oven,

Remove any liquids that have leaked,

Check that all safety functions (e.g. emergency stop button) work properly,

Power cables may be replaced only with similar, approved cables.

Pos: 65 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @ @ 1

21

Page 22

Pos: 66 /TD/Sicherheit/Überschrift - Umweltschutz vorschriften @ 0\mod_1167826189237_51.doc @ 5202 @ 2 @ 1

3.8 Environmental Regulations

Pos: 67 /TD/Sicherheit/Umweltschutzvorschr iften Schmierfette-Hydrauliköl-Kühlmittel @ 0\ mod_1158223424304_51.doc @ 2199 @ @ 1

All statutory duties regarding waste avoidance, proper recycling, and disposal must be

observed when work is carried out on and with the oven.

Problem materials that are no longer needed, such as lubricants or batteries, must not be

placed in normal waste disposal systems or allowed to enter the sewage system.

During installation, repair, and maintenance work, substances that are hazardous to water,

such as

lubricating grease and oils

hydraulic oils

refrigerants

solvent-based cleaning fluids must not be allowed to contaminate the soil or enter

the sewage system.

These substances must be stored, transported, collected, and disposed of in suitable

containers.

Note

The operator must ensure that national environmental regulations are observed.

Pos: 68 /TD/Sicherheit/Umweltschutzvorschr iften Elektronische Bauteile-Isolierung-Al tmetall @ 4\mod_1205143314853_51.doc @ 32563 @ @ 1

Pos: 69 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @ @ 1

When it is delivered, this oven contains no substances that make a hazardous waste

classification necessary. However, residues of process materials may accumulate in the

oven insulation during operation. These may be hazardous to health and/or the

environment.

Dismantle the electronic components and dispose of them as electric scrap.

Remove the insulation and dispose of it as hazardous waste (See Servicing,

Cleaning, and Maintenance with Ceramic Fiber Material)

Dispose of the housing as scrap metal.

22

Page 23

Pos: 70 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Erläuterung ANSI Z535.6 @ 8\ mod_1243323558881_51.doc @ 57444 @ 2 @ 1

3.9 Explanation of the Symbols and Warnings

Note

NOTICE

In the following operating instructions, specific warnings are given to draw attention to

residual risks that cannot be avoided when the oven is operating. These residual risks

include dangers for humans/products/ the oven, and the environment.

The symbols used in the operating instructions are especially intended to draw attention to

safety information.

The symbols used cannot replace the text of the safety information. Therefore, always read

the entire text.

Graphic symbols correspond to ISO 3864. In accordance with the American National

Standard Institute (ANSI) Z535.6 the following warning information and words are used in

this document:

The general hazard symbol, in combination with the words CAUTION, WARNING and

DANGER warns about the risk of serious injury. Observe the following information to

prevent injury or death.

Refers to a hazard that could damage or destroy the equipment.

CAUTION

WARNING

DANGER

Refers to a hazard with a minor or medium risk of injury.

Refers to a hazard that could cause death, serious or irreversible injury.

Refers to a hazard that could directly cause death, serious or irreversible injury.

Structure of the warning: All warnings are structured as follows

Hazard symbol

Indicates the risk of injury

Signal word

Classifies the danger

WARNING

• Type and source of the danger

• Consequences of non-compliance

• Action to prevent danger

Graphical symbols (optional)

according to ISO 3864:

Consequences, measures, and

prohibitions

Reference texts:

• Type and source of the danger

• Possible consequences of noncompliance

• Measures/Prohibitions

23

Page 24

Pos: 71 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Überschrift - Hinweissy mbole in der Anleitung @ 9\mod_1247053429626_51.doc @ 62751 @ @ 1

Pos: 72 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Hinweis - Unter diesem Sy mbo l er halten Sie Anweisungshinweise und ... @ 9\mod_1247053932 311_51.doc @ 62785 @ @ 1

or

Hazard symbol

Indicates the risk of injury

Signal word

Classifies the danger

DANGER

• Type and source of the danger

• Consequences of non-compliance

• Action to prevent danger

Graphical symbols (optional)

according to ISO 3864:

Consequences, measures, and

prohibitions

Graphical symbols

(optional) according to ISO

3864:

Instructions or prohibitions

Reference texts:

• Type and source of the danger

• Possible consequences of noncompliance

• Measures/prohibitions

Information Symbols in the Instructions:

Note

Below this symbol you will find instructions and particularly useful information.

Pos: 73 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitu ng - Gebot - Gebotszeichen - Wichtige Gebote sind zu befolgen @ 9\ mo d_12 47056175982_51.doc @ 62853 @ @ 1

Pos: 74 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitu ng - Gebot - Wichtige Information für den Bediener @ 9\mod_1247053 200729_51.doc @ 62717 @ @ 1

Pos: 75 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitu ng - Gebot - Wichtige Information für das Wartungspersona l @ 9\mod_1247053206042_51.doc @ 62734 @ @ 1

Pos: 76 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitu ng - Gebot - Netzstecker ziehen @ 9\mod_1247055471526_51.doc @ 62836 @ @ 1

Pos: 77 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitu ng - Gebot - Anheben mit mehreren Personen @ 9\mod_1247063058002_5 1.doc @ 62938 @ @ 1

Rule - Rule Sign

This symbol draws attention to important rules that must be followed. Rule signs protect

people against injury and show what is to be done in certain situations.

Rule - Important Information for Operators

This symbol draws the operator's attention to important information and operating

instructions that must be followed.

Rule - Important Information for Maintenance Personnel

This symbol draws the maintenance personnel's attention to important operating and

maintenance instructions (service) that must be followed.

Rule - Pull Out the Power Plug

This symbol tells the operator to pull out the power plug.

24

Page 25

Pos: 78 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitu ng - Warnung - Heiße Oberfläche - Oberfläche nicht berühren @ 9\ mod_1247054774780_51.doc @ 62802 @ @ 1

Pos: 79 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitu ng - Warnung - elektrischer Schlag - zur Vermeidung Anweisung f olgen @ 9\mod_1247055093892_51.doc @ 62819 @ @ 1

Pos: 80 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitu ng - Warnung - Umkippen des Gerätes @ 9\mod_1247059198372_5 1. doc @ 62870 @ @ 1

Pos: 81 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitu ng - Warnung - Schwebende Lasten @ 9\mod_1251450500309_51.doc @ 65454 @ @ 1

Pos: 82 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitu ng - Warnung - Heben schwerer Lasten @ 9\mod_1247059891358_51.doc @ 62887 @ @ 1

Pos: 83 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitu ng - Warnung - Umweltgefährdung @ 9\mod_1247060443419_51.doc @ 62904 @ @ 1

Pos: 84 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitu ng - Warnung - Brandgefahr @ 9\mod_1251445272822_51.doc @ 65437 @ @ 1

Pos: 85 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitu ng - Warnung - Explosionsgefährliche Stoffe @ 9\mod_124706114 8859_51.doc @ 62921 @ @ 1

Rule - Lift only with Several People

This symbol draws the personnel's attention to the fact that this device may only be lifted

and moved to its final destination by several people.

Warning - Hot Surface, Do Not Touch

This symbol warns the operator that the surface is hot and should not be touched.

Warning - Danger of Electric Shock

This symbol warns the operator that there is a risk of an electric shock if the following

warnings are not heeded.

Warning – Risk of Device Toppling Over

This symbol tells the operator that there is a risk of the device toppling over if the following

warnings are not heeded.

Warning – Suspended Load

This symbol warns the operator of potential dangers of suspended loads. Working below a

suspended load is strictly forbidden. Ignoring this can lead to fatal injury.

Warning – Danger if Heavy Loads Are Lifted

This symbol warns the operator of the potential dangers of lifting heavy loads. Ignoring this

can lead to injury.

Warning – Risk to the Environment

This symbol warns the operator of the risk to the environment if the following information

is not heeded. The operator must ensure that national environmental regulations are

observed.

Warning - Fire Danger

This symbol warns operators of the danger of fire if the following information is not

followed.

Warning – Risk of Explosive Substances or

Explosive Atmosphere

These symbols warn the operator of explosive substances or an explosive atmosphere

Pos: 86 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm in der Anleitu ng - Gefahr - nicht mit Wasser überschütten @ 9\mod_1247826410 886_51.doc @ 63819 @ @ 1

Pos: 87 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Überschrift - Warnhi nweis symbole an der Anlage @ 9\mod_1247053700273_51.doc @ 62768 @ @ 1

Pos: 88 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm an der Anlage - W ar nung - Gefahr vor heißer Oberfläche und Verbrennung @ 9\mod_1247 0529 57145_51.doc @ 62700 @ @ 1

Pos: 89 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Piktogramm an der Anlage - W arnung - Gefahren durch elektrischen Strom @ 9\mod_124705263982 4_51.doc @ 62683 @ @ 1

Pos: 90 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @ @ 1

Prohibited - Important Information for Operators

This symbol warns the operator that water or cleaning products must NOT be poured over

the objects. A high-pressure cleaning device must also not be used.

Warning Signs on the Oven:

Warning - Hot Surface, Danger of Burning – Do Not Touch

You may not always realize that surfaces, such as oven components, oven walls, doors and

materials, and even liquids are hot. Do not touch the surface.

Warning - Danger of Electric Shock!

Warning, dangerous electric voltage

25

Page 26

Pos: 91 /TD/Sicherheit/Überschrift - Allgemeine Gefahren an der Anlage @ 0\mod_1168596796288_51.doc @ 6014 @ 2 @ 1

3.10 General Risks with the Oven

Pos: 92 /TD/Sicherheit/Allgemeine Gefahren (Ver br ennung, Quetschen, Strom) - Laboröfen @ 2\mod_118466602302 2_51.doc @ 19974 @ @ 1

Warning! General hazards!

- Risk of burning on the furnace housing and on the tube

- The door handle/grip can become very hot during operation; wear gloves.

- Risk of crushing on moving parts (door hinge, rotary tube drive,

lifting table, etc.)

- The switchgear cabinet (if present) and the terminal boxes on the system contain

dangerous electrical voltages.

- Do not insert any objects into the openings on the furnace housing, exhaust air holes, or

cooling slots on the

switchgear or furnace (if present). This poses a risk of electric shock.

Pos: 93 /TD/Allgemeine Hinweise (für alle Anleitungen) /Warnung - Es dürfen keine Gegenstände auf den/der Ofen/Sc haltanlage abgelegt/abgestellt werden... @ 4\mod_1203924555465_51.doc @ 31568 @ @ 1

Pos: 94 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @ @ 1

Warning! General hazards!

No objects may be placed or set down on the furnace or switchgear. Doing so creates a fire

or explosion hazard.

26

Page 27

Pos: 95 /TD/Transport_Montage_Inbetriebnahme/E r stinbetriebnahme/Überschrift - Transport, Montage und Erstinbetriebnahme @ 0\mod_1158844227416_51. doc @ 3112 @ 1 @ 1

4 Transportation, Installation, and Commissioning

Pos: 96 /TD/Transport_Montage_Inbetriebnahme/Er stinbetriebnahme/Überschrift - Anliefer ung @ 0\mod_1167826534889_51.doc @ 5220 @ 2 @ 1

4.1 Delivery

Pos: 97 /TD/Transport_Montage_Inbetriebnahme/Er stinbetriebnahme/Anlieferung - (Hinweise a l lgemein) @ 0\mod_1158233508887_51.doc @ 2223 @ @ 1

Check that Everything is Complete

Compare the delivered items with the delivery note and the purchase order documents.

Immediately notify the carrier and Nabertherm GmbH of any missing or damaged parts, as

complaints at a later date cannot be acknowledged.

Danger of Injury

When the oven is being lifted, parts of the oven or the oven itself could topple over, slip, or

fall. Before the oven is lifted, make sure no one is in the working area. Wear safety

footwear and a hard hat.

Safety Instructions

Forklifts must be operated only by authorized personnel. The operator bears sole

responsibility for safe operation and the load.

When the oven is being lifted, make sure that the ends of the forks or the load do

not catch on neighboring goods. Use a crane to move tall parts, such as control

cabinets.

Use only lifting equipment with sufficient load-bearing capacity.

Lifting gear must be attached only to positions that have been designated for this

purpose.

Attachments, piping, or cable conduits must never be used to affix lifting gear.

Unpackaged parts should only be lifted with ropes or straps.

Attach transportation equipment only to positions intended for this purpose.

Lifting and securing equipment must conform to the provisions contained in

accident prevention regulations.

Consider the weight of the oven when choosing lifting and securing equipment.

(see Specifications)

Stainless steel parts (including mounting elements) must always be kept separate

from unalloyed steel parts.

Do not remove corrosion protection until immediately prior to assembly.

Risks during Normal Operation!

Suspended loads are dangerous. Working beneath a suspended load is prohibited. There is a

risk of fatal injury.

Pos: 98 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @ @ 1

Note

Safety and accident prevention guidelines applicable for forklift trucks must be followed.

27

Page 28

Pos: 99 /TD/Transport_Montage_Inbetriebnahme/Er stinbetriebnahme/Anlieferung von Öfen mit eine m Hub wagen @ 2\mod_1184672460200_51.doc @ 20000 @ @ 1

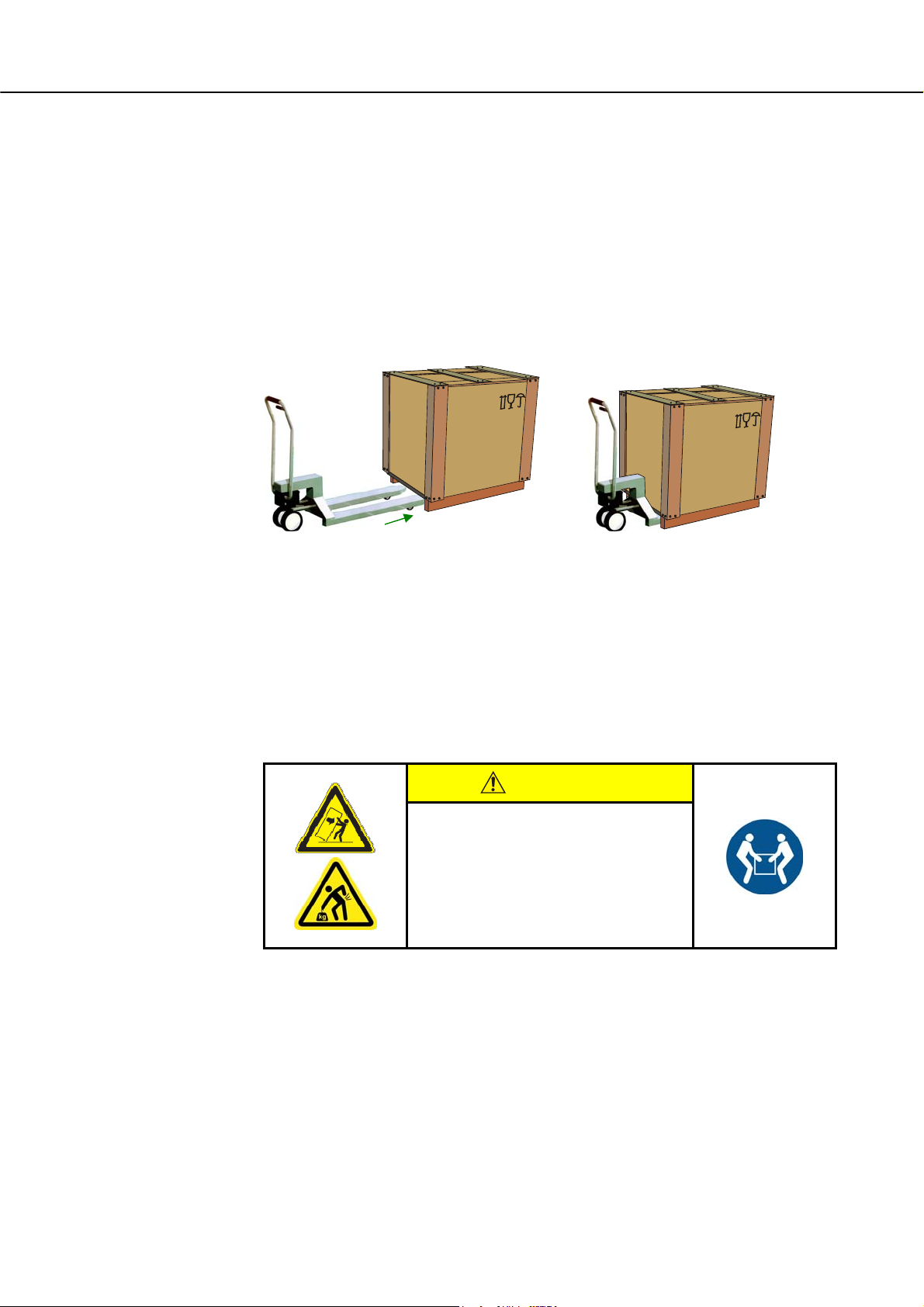

Transportation with a Pallet Truck

Observe the maximum permitted capacity of the pallet truck.

1. Our ovens are delivered ex works on wooden frames to facilitate unloading.

Transport the oven in its original packaging and with suitable equipment to prevent

any damage. Remove the packaging only when the oven is in its final location.

When transporting the oven, make sure it is secured against sliding, toppling over,

and damage. The oven should be transported and installed by at least two persons.

Do not store the oven in damp rooms or outdoors.

2. Push the pallet truck underneath the transportation frame. Make sure that the pallet

truck is completely beneath the frame. Pay attention to neighboring goods.

Pos: 100 /TD/Sicherheit/Sicherheitssymbole/ W arnhinweise-ISO-ANSI/Warnsymbol_Vorsic ht - Rutschen/Kippen des Gerätes - Piktogramm Kippen/He ben/ Anheben @ 9\mod_1247064081950_51.doc @ 62955 @ @ 1

Pos: 101 /=== Seitenumbruch === @ 0\mod_1158819844943_0. doc @ 2983 @ @ 1

Fig. 5: Pallet truck is pushed completely beneath the transportation frame

3. Lift the oven carefully and pay attention to its center of gravity. When the oven is

being lifted, make sure that the ends of the forks or the load do not catch on

neighboring goods.

4. Make sure that the oven is balanced safely; if not, attach securing equipment. Push

the oven carefully, slowly and with the pallet truck at its lowest position. Do not

transport the oven on inclines.

5. Carefully lower the oven at its final position. Pay attention to neighboring goods.

Try not to set it down too abruptly.

CAUTION

• Device may slip or topple over.

• Damage to the device.

• Risk of injury from lifting

heavy loads.

• Transport device only in original

packaging.

• Several people must carry the device.

28

Page 29

Pos: 102 /TD/Transport_Montage_Inbetriebnahme/E r stinbetriebnahme/Legende für Packstücke z.B. zerbrechlich @ 1\mod_1173776713307_51.doc @ 10746 @ @ 1

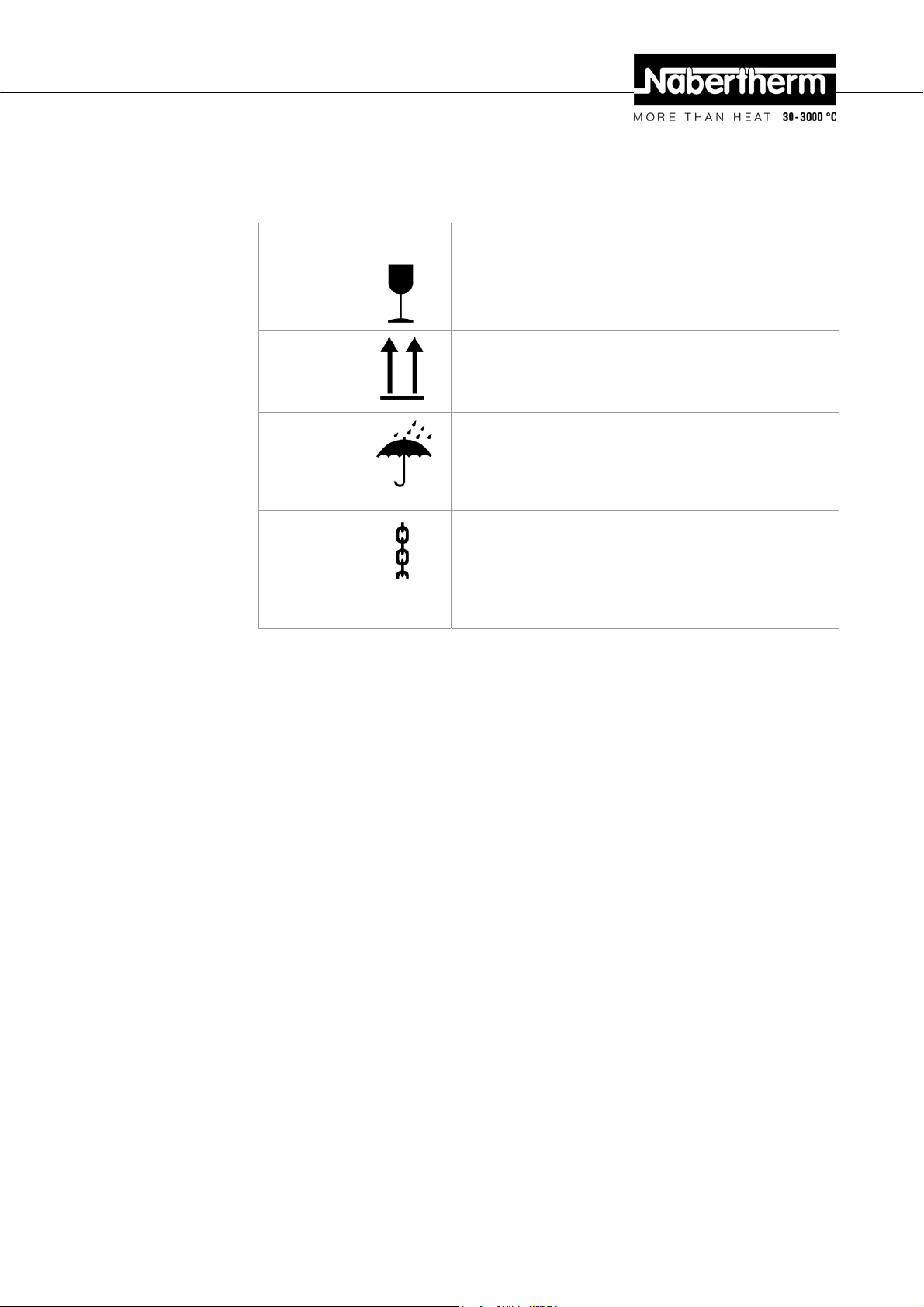

Symbols:

The international standard symbols for handling packaging are defined in ISO R/780

(International Organization for Standardization) and in DIN 55 402 (German Institute for

Standardization).

Description Symbol Explanation

Pos: 103 /=== Seitenumbruch === @ 0\mod_1158819844943_0. doc @ 2983 @ @ 1

Fragile

This side up

Keep dry

Sling here

This symbol is to be attached to fragile goods. Goods

marked like this are to be handled carefully and must not be

thrown or tied up.

The freight must be transported, transshipped, and stored in

such a way that the arrows point upward. The freight must

not be rolled, folded, or stored on edge. However, the

package does not have to be packed on top of other freight.

Products with this symbol must be protected against high air

moisture, hence, they must be stored under cover. If

particularly heavy or bulky packages cannot be stored in

halls or sheds, they must be covered carefully with a

tarpaulin or similar.

The symbol shows only where the sling should be attached,

not the method of slinging. If the symbols are at an equal

distance from the middle or center of gravity of the package,

the package hangs straight if the slings are the same length.

If this is not the case, the sling on one side has to be

shortened.

29

Page 30

Pos: 104 /TD/Transport_Montage_Inbetriebnahme/Er stinbetriebnahme/Überschrift - Auspac ken @ 2\mod_1184739517985_51.doc @ 20013 @ 2 @ 1

4.2 Unpacking

Pos: 105 /TD/Allgemeine Hinweise (für alle Anleitungen) /Hinweis - Allgemeiner Hinweis zur Verpackung (z. B. Laboröfen) @ 3\mod_1192437185846_51.doc @ 23509 @ @ 1

Pos: 106 /TD/Transport_Montage_Inbetriebnahme/E r stinbetriebnahme/Auspacken Laborofen - LHT- Tisc hmodell , R, RT - Teil 1 @ 2\mod_1184739616497_51.doc @ 20026 @ @ 1

Wear protective

gloves

Note

The oven packaging prevents damage during transportation. Make sure that you remove all

packaging material (also inside the oven chamber). Keep the packaging and transportation

securing equipment in case it is needed for future transportation or storage.

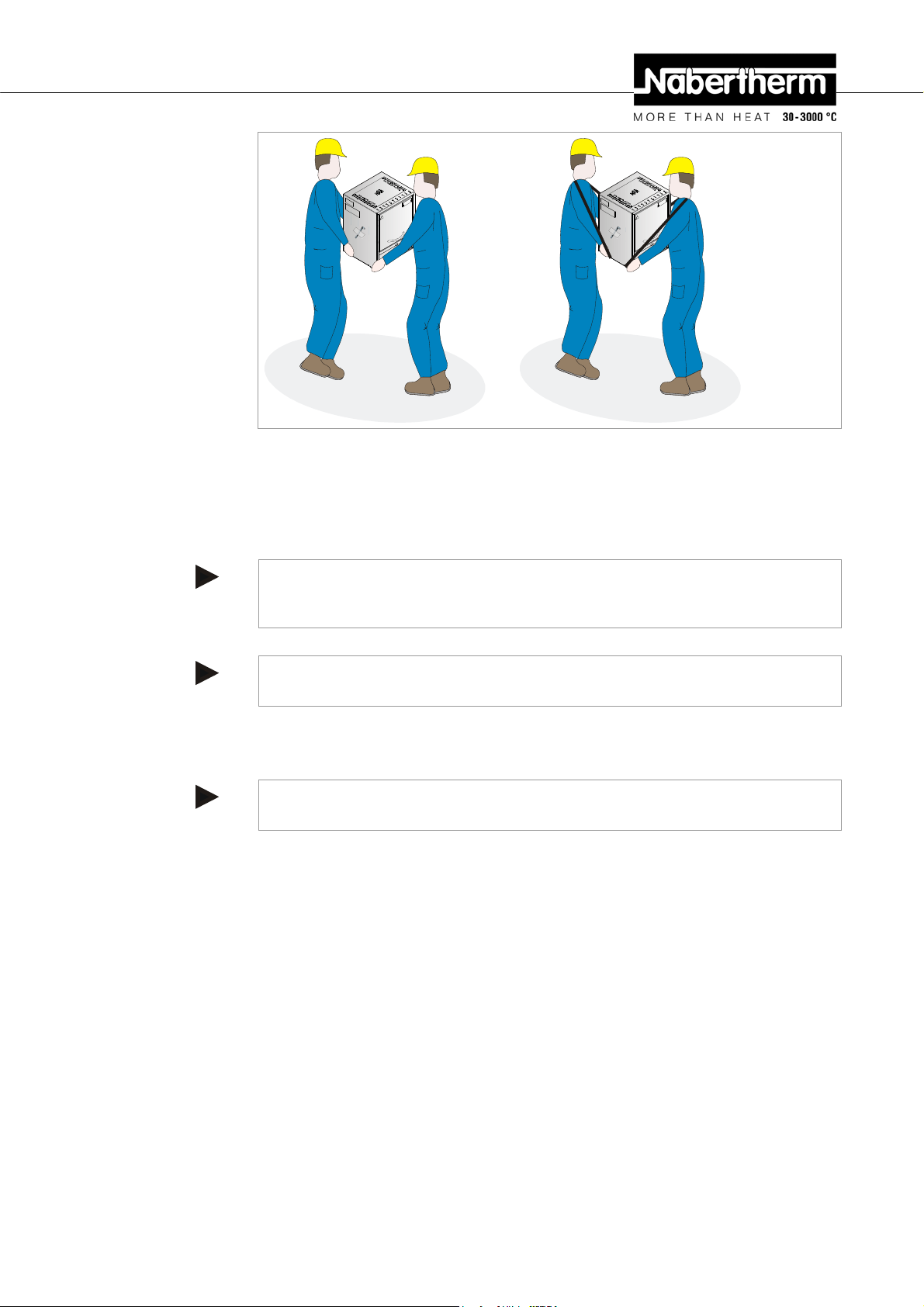

At least two people are needed to carry/transport the oven, more for larger ovens.

Pos: 107 /TD/Transport_Montage_Inbetriebnahme/Er stinbetriebnahme/Auspacken Hochtemperatur ofen - HTCT 01/14-16-Tischmodell - Teil 2 @ 12\mod_1281942490 665_51.doc @ 96845 @ @ 1

Pos: 108 /TD/Transport_Montage_Inbetriebnahme/Er stinbetriebnahme/Auspacken-Tragen Labor ofen - LHT-Tischmodell - Teil 3 @ 3\mod_1192436920381_5 1. doc @ 23483 @ @ 1

1

2

1. Check the transportation packaging for possible damage.

2. Remove tensioning straps from the transportation packaging.

3. Slacken screws and remove wooden casing from the covering box (if available).

4

5

6

4. Carefully lift the cardboard box and remove it from the pallet.

5. Remove the foam insert in the box. The box contains a packaging unit for

accessories (Example: exhaust air tube, insert plate, power cable). Compare the

delivered items with the delivery note and the order documents, see "Delivery".

6. Carefully lift the furnace out of the packaging unit.

3

30

Page 31

7. To carry, grip furnace from below at the sides and make sure you have a firm grip.

8. For furnaces weighing more than 25 kg, transport work must be carried out by at

least 2 people. If transport straps are used, they must be attached crosswise only.

Ensure that they are secure.

Note

In Germany, the general accident protection guidelines of VBG or BGZ must be observed.

The national accident prevention regulations of the country of operation apply.

Note

Save the packaging for possible shipping or for storing the furnace.

Pos: 110 /TD/Transport_Montage_Inbetriebnahme/Er stinbetriebnahme/Überschrift - Transpor tsi c herung/Verpackung @ 0\mod_1167826775847_51.doc @ 5229 @ 2 @ 1

4.3 Transportation Securing Equipment/Packaging

Pos: 111 /TD/Transport_Montage_Inbetriebnahme/E r stinbetriebnahme/Verpackung - Allgemeine Hin weise zur Verpackung - keine spezielle Transportsi c herung @ 1\mod_1171004073117_51.doc @ 9153 @ @ 1

Note

No special transportation securing equipment is available for this oven

The oven packaging prevents damage during transportation. Make sure that you remove all

packaging material (also inside the oven chamber). All packaging material can be recycled.

The packaging was designed so that no special description is necessary.

Pos: 112 /=== Seitenumbruch === @ 0\mod_1158819844943_0. doc @ 2983 @ @ 1

31

Page 32

Pos: 113 /TD/Transport_Montage_Inbetriebnahme/E r stinbetriebnahme/Überschrift - Baulic he- und Anschlussvoraussetzungen @ 0\mod_1167826890943_ 51.doc @ 5238 @ 2 @ 1

4.4 Constructional and Connection Requirements

Pos: 114 /TD/Transport_Montage_Inbetriebnahme/E r stinbetriebnahme/Überschrift - Auf stellung ( Standort des Ofens) @ 2\mod_1184848718972_51.doc @ 20166 @ 3 @ 1

4.4.1 Installation (Oven Location)

Pos: 115 /TD/Transport_Montage_Inbetriebnahme/Er stinbetriebnahme/Standort eines LHT-Ofens @ 2\ mod_1184852454302_51.doc @ 20179 @ @ 1

When setting up the furnace, the following safety instructions must be followed:

The furnace must be installed in a dry room in accordance with the safety

instructions.

The table/supporting surface must be flat to enable the furnace to be installed

straight. The furnace must be placed on a noncombustible base (stone, metal,

etc.).

The carrying capacity of the table must be designed to bear the weight of the

furnace incl. accessories.

The floor covering must be made of nonflammable material so that hot material

falling out of the furnace will not cause the floor covering to ignite.

Despite good insulation, the furnace radiates heat from its external surfaces. If necessary,

this heat must be conducted away (a ventilation engineer must be consulted if required).

In addition, the furnace must be positioned a minimum safety distance (S) of 0.5 m on each

side and 1 m at the top away from combustible materials. In individual cases, more space

must be chosen in order to match the local conditions. The minimum distance away from

noncombustible materials may be reduced to 0.2 m at the sides.

Should gases or vapors escape from the charge, then sufficient air supply and ventilation at

the installation location or an appropriate exhaust gas line must be provided.

A suitable exhaust for the burner exhaust must be provided by the customer.

Pos: 116 /TD/Sicherheit/Sicherheitssymbole/W arnhinweise-ISO-ANSI/Warnsymbol_Gefahr - Brandgefahr - Piktogramm Brandgefahr @ 9\mod_1247148035738_ 51.doc @ 63010 @ @ 1

Pos: 117 /TD/Allgemeine Hinweise (für alle Anleitungen) /Hinweis - Vor Inbetriebnahme des Ofens sollte die ser 24 Stunden am Aufstellungsort akklimatisiert .. @ 3\mod_1195568014336_51.doc @ 27871 @ @ 1

S

S

S

S

Noncombustible base

Fig. 6: Installation (Oven Location)

DANGER

• Fire- danger to health.

• Risk of fatal injury.

• Adequate ventilation must be ensured at the

installation location to conduct waste heat and any

exhaust gases away.

Note

Before starting the oven for the first time, allow it to acclimatize at its installation location

for 24 hours.

32

Page 33

Pos: 119 /TD/Transport_Montage_Inbetriebnahme/E r stinbetriebnahme/Überschrift - Montage, Ins tallation und Anschluss @ 0\mod_1167827976269_51. doc @ 5292 @ 2 @ 1

4.5 Assembly, Installation, and Connection

Pos: 120 /TD/Transport_Montage_Inbetriebnahme/E r stinbetriebnahme/Überschrift - Montage eines A bz ugskamins @ 14\mod_1300115306448_51.doc @ 113409 @ 2 @ 1

4.6 Assembly of a Vent

Pos: 121 /TD/Transport_Montage_Inbetriebnahme/E r stinbetriebnahme/Abzugskamin Laboröfen - all gemeiner Text @ 14\mod_1300115642723_51.doc @ 113432 @ @ 1

Which vents are supplied vary depending on the application/order (doe s not apply

to protective gas connection):

Pos: 122 /TD/Transport_Montage_Inbetriebnahme/ Er stinbetriebnahme/Abzugskamin Laboröfen - A bzugs kamin zum Anschluss an ein Abluftrohr @ 14\mod_13001161 4377 6_51.doc @ 113455 @ @ 1

Vent (not for LV models)

Vent which exhausts the escaping gases and vapors through the exhaust air

connecting piece (back wall) and releases them overhead. Exhaust air cross

section: 40 x 30 mm

Install by slipping the vent onto the connecting piece on the back wall of the

furnace and fasten it with the screws included in the scope of delivery.

Pos: 123 /TD/Transport_Montage_Inbetriebnahme/E r stinbetriebnahme/Abzugskamin Laboröfen - Abzugs kamin mit Ventilator @ 14\mod_1300116418296_51.doc @ 113478 @ @ 1

Pos: 124 /TD/Transport_Montage_Inbetriebnahme/E r stinbetriebnahme/Abzugskamin Laboröfen - K ata lysator @ 14\mod_1300116553629_51.doc @ 113501 @ @ 1

Fig. 7: Vent

Vent with fan (not for LV models)

Supports the venting of gases and vapors from the furnace chamber. Exhaust air

cross section: 85 x 60 mm

Install by slipping the vent onto the connecting piece on the back wall of the

furnace and fasten it with the screws included in the scope of delivery. Plug the

connecting plug into the socket on the back of the switchgear (optional) or in an

external socket.

Fig. 8: Vent with fan

Vent with fan and catalytic converter (not for LV models)

Heats the gases and vapors from the furnace chamber to approx. 600 °C and feeds

it through the catalytic converter honeycomb. The converter incinerates most of

33

Page 34

the organic substances, i.e. breaks them down into carbon dioxide and steam. This

largely eliminates any annoying odors (for example, during dewaxing).

Warning! Inorganic substances such as heavy metals halogens, silicons and

particulates (even in small quantities) will destroy the catalytic converter!

The temperature of the catalytic converter must be checked; from the start of the

program the converter must be operating at approx. 600 °C. A statement cannot be

made regarding residues which may be released into the environment. This is

largely dependent on the individual materials/embedding masses used and their

compositions. Exhaust air cross section: 120 x 120 mm

Installation: Fasten the U-shaped brackets to the back wall of the furnace using the

screws included in the scope of delivery, slide the included section of pipe onto the

connecting piece of the furnace and screw the vent (with CAT) firmly to the

bracket. Plug the power plug into the socket on the back side (optional) of the

switchgear or into an external socket.

Pos: 125 /TD/Transport_Montage_Inbetriebnahme/E r stinbetriebnahme/Abzugskamin Laboröfen - Mon tag e eines Abgasrohres bei LV-Ofenmodelle @ 14\mod_1300118 616710_51.doc @ 113547 @ @ 1

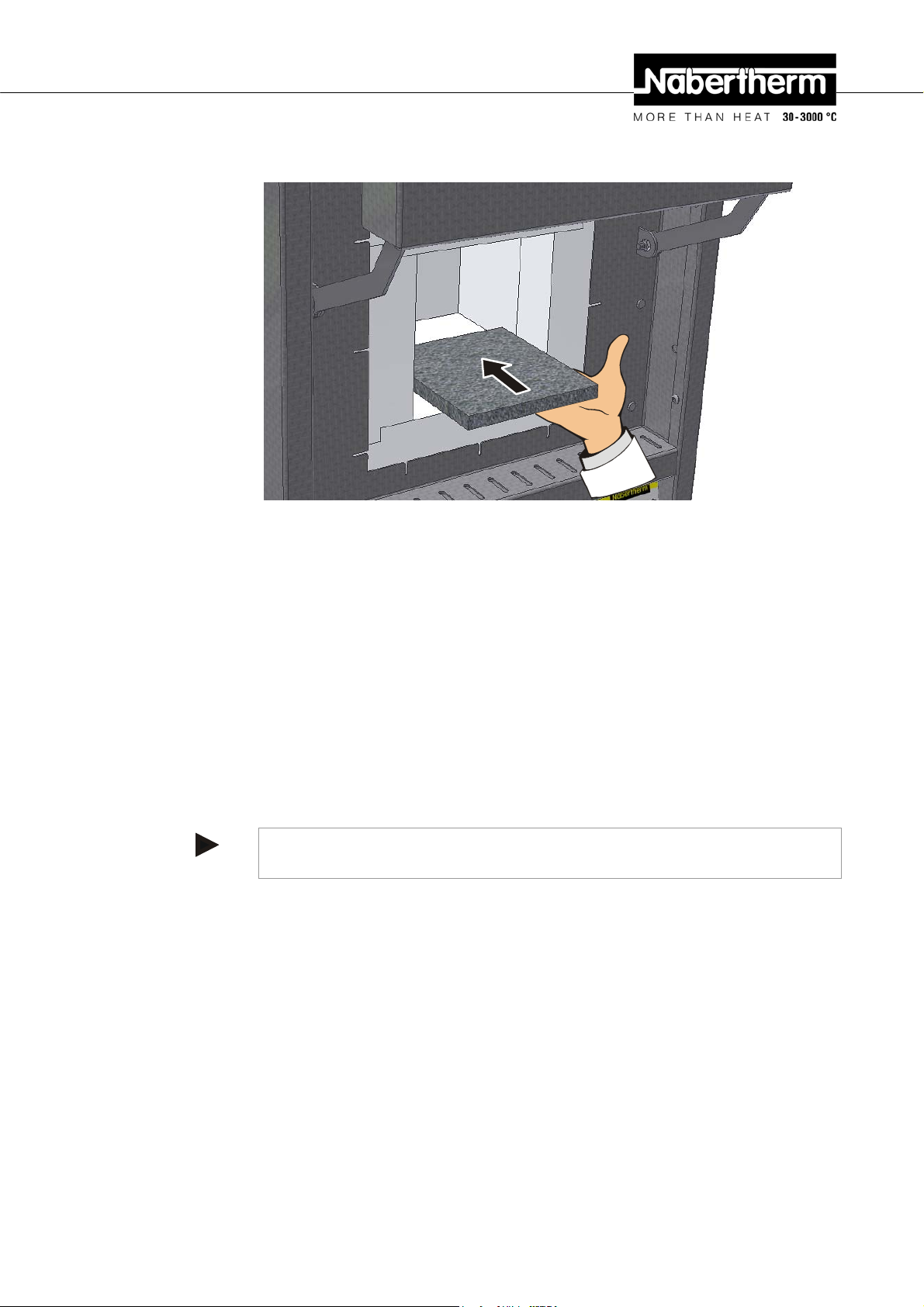

Pos: 126 /=== Seitenumbruch === @ 0\mod_1158819844943_0. doc @ 2983 @ @ 1

Fig. 9: Catalytic converter

Installation of a Exhaust Gas Pipe on LV(T) …/… Models

These models come with a special exhaust gas pipe.

Begin the installation by fastening the rectangular pipe to the inner housing of the

furnace with the screws included in the scope of delivery, then by fastening the

rounds section to the outer housing. The screws included in the scope of delivery

are for this purpose.

Operating the furnace without this pipe results in a reduced air flow which is

insufficient for an incinerating process.

Caution

The installation of a catalytic converter or vent with fan is not possible on these

models.

34

Page 35

A

A

Pos: 127 /TD/Transport_Montage_Inbetriebnahme/Er stinbetriebnahme/Überschrift - Abgasf ührung @ 0\mod_1167828513042_51.doc @ 5310 @ 3 @ 1

4.6.1 Waste Gas System

Pos: 128 /TD/Transport_Montage_Inbetriebnahme/Er stinbetriebnahme/Abgasführung Laborofen L- LE-L(T)-LV(T)-SKM-SW-HA @ 14\mod_1300178990365_5 1. doc @ 113593 @ @ 1

We recommend connecting an exhaust air pipe to the furnace to remove the

exhaust gases.

For this purpose you can use a commercially available, metal exhaust gas pipe

with NW80 to NW120. It must be installed continuously rising and fastened to the

wall or ceiling. Center the pipe over the furnace vent (for models with vent fan or

catalytic converter, NW 120 is necessary.

The exhaust gas pipe must not be installed with a tight fit to the furnace vent pipe

since this would prevent any bypass effect. This is necessary so that not too much

fresh air is sucked in by the furnace. (An exception are the LV furnaces: Here the

exhaust gas pipe NW80 can be slid directly onto the furnace vent pipe.)

Vent

Exhaust air (model LV/LVT) or vent with fan

directly onto the exhaust air pipe or vent.

Furnaces without exhaust air pipe or with catalytic converter

recommend feeding the exhaust air through a flue.

: Position the exhaust air piping approx. 50 mm over the vent.

B

: Exhaust air piping can be slid

C

: We

Exhaust air piping

C

B

50 mm

Fig. 10: Example: Various ways of removing the exhaust air

Caution

The exhaust gases can only be vented if the workspace is ventilated with an

adequate fresh-air opening.

Caution

The customer is responsible for providing the masonry and roofing work necessary

for venting the exhaust. The size and design of the exhaust air system must be

decided by a ventilation expert. The accident prevention regulations applicable in