Page 1

Operating Instructions

Controller

B130/B150/B180/C280/P300/P310/P330

-> 02.2009

ENGLISCH

Nabertherm GmbH

Bahnhofstrasse 20

28865 Lilienthal/Germany

Phone: +49 (4298) 922-0

Fax: +49 (4298) 922-129

contact@nabertherm.com

www.nabertherm.com

Made

in

Germany

Page 2

Copyright

© Copyright by

Nabertherm GmbH

Bahnhofstrasse 20

28865 Lilienthal

Federal Republic of Germany

Reg: M03.0001 ENGLISCH

Rev: 2009-02

No responsibility is accepted for the correctness of this information. We

reserve the right to make technical alterations.

Headquarters: 2/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 3

1 Introduction ...........................................................................................................................................................6

1.1 Warranty and Liability .....................................................................................................................................7

1.2 General.............................................................................................................................................................8

1.3 Safety ...............................................................................................................................................................8

2 Operation................................................................................................................................................................9

2.1 Power Switch/Control Current Switch.............................................................................................................9

2.2 Turning on the Controller/Furnace...................................................................................................................9

2.3 Turning off the Controller/Furnace..................................................................................................................9

3 Control Fields and Display..................................................................................................................................10

3.1 Displays .........................................................................................................................................................12

3.2 Keyboard Blocks............................................................................................................................................12

4 Features of the Controller...................................................................................................................................15

4.1 Functions........................................................................................................................................................15

5 New Functions of the Nabertherm Controller...................................................................................................16

5.1 Program Entry with/without Gradient as of Version 3.xx..............................................................................16

5.2 Program Starting Behavior for warm Furnaces as of Controller Version 3.xx ..............................................16

5.3 Power Failure Behavior .................................................................................................................................16

6 Controller B 130/C 280........................................................................................................................................17

6.1 Brief Instructions ...........................................................................................................................................17

6.2 Setting or changing Program/Waiting Time ..................................................................................................18

6.3 Setting or Changing the Waiting Time ..........................................................................................................19

6.4 Programming Extra Functions .......................................................................................................................20

6.5 Programming Extra Functions in "T3" (C 280 only) .....................................................................................21

6.6 Turning Extra Functions in Program Execution on and off by Hand.............................................................21

6.7 Saving Programs ............................................................................................................................................21

6.8 Preconfigured Programs for the B 130/C 280................................................................................................22

6.9 Calling Programs ...........................................................................................................................................22

6.10 Program Start .................................................................................................................................................23

6.11 Program Change During Execution ...............................................................................................................23

6.12 Terminating a Program ..................................................................................................................................24

6.13 Key Locking ..................................................................................................................................................24

6.14 Info Menu ......................................................................................................................................................24

7 Controller B 150...................................................................................................................................................25

7.1 Brief Instructions ...........................................................................................................................................25

8 Controller B 180/P 300/P 310/P 330...................................................................................................................26

8.1 Brief Instructions ...........................................................................................................................................26

8.2 Setting and Displaying the Date/Time on the P 330 ......................................................................................27

Headquarters: 3/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 4

8.3 Setting or Changing Programs ...................................................................................................................... 27

8.4 Setting or Changing the Waiting Time.......................................................................................................... 30

8.5 Setting or changing the Start Time................................................................................................................ 30

8.6 Programming Extra Functions....................................................................................................................... 31

8.7 Turning Extra Functions in Program Execution on and off by Hand............................................................ 32

8.8 Saving Programs ........................................................................................................................................... 32

8.9 Calling Programs........................................................................................................................................... 33

8.10 Program Start ................................................................................................................................................ 33

8.11 Program Change During Execution .............................................................................................................. 33

8.12 Brief Program Interruption on the P 330....................................................................................................... 34

8.13 Terminating a Program.................................................................................................................................. 34

8.14 Segment Skip Key (P 300/P 310/P 330 only) ............................................................................................... 34

8.15 Heating Circuits Key (P 310 only)................................................................................................................ 35

8.16 Info Menu...................................................................................................................................................... 36

9 Power Failure Behavior for Version 3.xx Controllers and higher...................................................................37

10 Power Failure Behavior for Controller Versions 1-2.xx, built through the beginning of 2007.....................37

10.1 Power Failure Behavior in the different Segments of B 130, C 280 ............................................................. 37

10.2 Power Failure Behavior in the Different Segments of B 180, P 330............................................................. 37

10.3 Power Failure Behavior for the B 150........................................................................................................... 37

10.4 Power Failure Behavior of P 300/P 310........................................................................................................ 38

11 Eurotherm 2132i Over-Temperature Limit Controller for Installing in Controllers B 180 and P 330

(optional)...............................................................................................................................................................38

11.1 Eurotherm 2132i Over-Temperature Limit Controller.................................................................................. 38

12 Configuration/Customer-Specific Settings ........................................................................................................38

12.1 Configuration ................................................................................................................................................ 38

12.2 Opening the Configuration on the B 130/B 150............................................................................................ 38

12.3 Opening the Configuration for B 180/P 300/P 310/P 330............................................................................. 39

12.4 Configuration Options in Configuration Level 1 (Password = "0") .............................................................. 39

12.4.1 Converting °C/°F...................................................................................................................................... 39

12.4.2 Settings for kW/h Counter........................................................................................................................ 39

12.4.3 Setting the Interface Address.................................................................................................................... 40

12.4.4 Program Entry with/without Gradient (as of Version 3.xx) ..................................................................... 40

12.4.5 Setting/Control of Power Failure Behavior (Version 3.xx or later).......................................................... 40

12.5 Configuration Options in Configuration Level 2 (Password = "2") .............................................................. 41

12.6 Auto Tune...................................................................................................................................................... 41

13 Data Interface.......................................................................................................................................................41

13.1 RS-422 Data Interface (optional) .................................................................................................................. 42

Headquarters: 4/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 5

14 Faults.....................................................................................................................................................................43

14.1 Fault Messages...............................................................................................................................................43

15 Fault Diagnosis.....................................................................................................................................................43

15.1 Controller Check List.....................................................................................................................................44

16 Replacement Parts...............................................................................................................................................46

16.1 Replacing a Built-in Controller......................................................................................................................46

17 Technical Data .....................................................................................................................................................47

18 Electrical Connections (Wiring Diagram).........................................................................................................48

18.1 Furnaces up to 3.6 kW – B 130, B 150, B 180, C 280, P 330 through 12/2008.............................................48

18.2 Furnaces up to 3.6 kW – B 130, B 150, B 180, C 280, P 330 as of 01/2009 .................................................48

18.3 Furnaces > 3.6 kW with Semiconductor Relay – B 130, B 150, C 280, P 300..............................................49

18.4 Furnaces > 3.6 kW with Heat Fuse – B 130, B 150, C 280, P 300 ................................................................49

18.5 Furnaces > 3.6 kW with 2 Heating Circuits – P 310......................................................................................50

18.6 Replacement Controller for Models C/S 3; C/S 5; C/S 7; C/S 8; C/S 19; C/S 30..........................................51

18.6.1 Replacement for S 3 – S 30 Controllers through 12/2008.........................................................................51

18.6.2 Replacement for S 3 – S 30 Controllers as of 01/2009 .............................................................................51

18.6.3 Replacement for C 3 – C 30 Controller.....................................................................................................52

19 Nabertherm Service............................................................................................................. ................................53

20 For Your Notes.....................................................................................................................................................54

Headquarters: 5/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 6

Pos: 1 /TD/Einleitung/Überschrift - Einleitung @ 0\ mod_1167823212238_51.doc @ 5139 @ 1

1 Introduction

Pos: 2 /TD/Einleitung/Controller B150/B130/B170/ C280/C290/C295/P320 @ 0\mod_1168855773334_51.doc @ 6113 @

Dear Customer,

Thank you for choosing a quality product from Nabertherm GmbH.

With this system, you have selected a product which is tailored specifically to your

manufacturing and production conditions and of which you can be justifiably proud.

This product is characterized by

− Easy operation

− LCD display

− Rugged construction

− For use near machinery

− Optional RS-422 data interface

Your Nabertherm Team

Note

These documents are only intended for the purchasers of our products and must not be

duplicated or imparted to or made accessible to third parties without written approval.

(Copyright and related industrial property rights, German Copyright Act dated 09.09.1965)

Industrial property rights

All rights to drawings and other documents plus all rights of disposal are held by

Nabertherm GmbH, including in the event of industrial property right applications.

Pos: 3 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @

Headquarters: 6/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 7

Pos: 4 /TD/Einleitung/Gewährleistung_Haftun g/ Überschrift - Gewährleistung und Haftung @ 0\mod_1167822979492_51.doc @ 5130 @ 2

1.1 Warranty and Liability

Pos: 5 /TD/Einleitung/Gewährleistung_Haftung/ Öfen und Schaltanlagen - Gewährleistung und Haftung @ 0\mod_1157536440972_ 51.doc @ 1569 @

The Nabertherm warranty conditions or warranty services regulated in the individual

contracts apply with regard to the warranty and liability. However, the following also

additionally applies:

§

Warranty and liability claims in the event of personal injury and material damage are out of

the question if these are attributable to one or more of the following causes:

− Each person involved in operating, installing, maintaining or repairing the system

must have read and understood the operating instructions. No liability is accepted

for damage and malfunctions arising from nonadherence to the operating

instructions.

− Improper use of the system.

− Improper installation, commissioning, operation and maintenance of the system.

− Operation of the system with defective safety systems or improperly installed or

nonfunctional safety and protective devices.

− Nonadherence to the notes contained in the operating instructions regarding the

transport, storage, installation, commissioning, operation, maintenance and setup

of the system.

− Unauthorized system design changes.

− Unauthorized operating parameter changes.

− Unauthorized parameterization, setting and program changes.

− Original parts and accessories have been designed especially for Nabertherm

furnace systems. Only use original Nabertherm replacement parts. Otherwise, the

warranty will be void. Nabertherm assumes no liability for damages resulting from

use of nonoriginal parts.

− Catastrophes due to the effects of foreign bodies and force majeure.

Pos: 6 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @

Headquarters: 7/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 8

Pos: 7 /TD/Einleitung/Allgemeines/Controller / Überschrift - Allgemeines @ 0\mod_1168857771977_51.doc @ 6176 @ 2

1.2 General

Pos: 8 /TD/Einleitung/Allgemeines/Controller / Allgemeines @ 0\mod_1168875225840_51.doc @ 6381 @

Before working on electrical systems, switch the power switch to "0" and disconnect the

power cord!

Even with the power switch off, some parts in the furnace may carry voltage!

Work on the electrical system may only be done by a trained person!

The furnace and switching system have been preset by the Nabertherm company. If

required, a process-dependent optimization must be carried out in order to achieve the best

possible control behavior.

The temperature curve must be modified by the user so that the load, furnace or

surrounding are not damaged. Nabertherm GmbH assumes no guarantee for the process.

Note

Before working on the program-controlled grounding receptacle (optional series L, HTC,

N, HL) or the device connected to it, always turn off the furnace and disconnect the power

cord.

Pos: 9 /TD/Betrieb_Bedienung/Controller/B150/B1 30/B170/C280/C290/C295/P320/Sicherheit @ 0\mod_1169023764018 _51.doc @ 6885 @ 2

1.3 Safety

Pos: 10 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @

Carefully read the operating manual of the controller in order to avoid operation mistakes

or malfunction of the controller/furnace during operation.

The controller has a series of electronic safety systems. If a fault occurs, the furnace

automatically shuts off and a fault message appears in the LCD display.

Note

For more information, please see Chapter "Faults - fault messages"

Warning! General Hazards!

The Operating Instructions must be followed prior to switching on the furnace.

Headquarters: 8/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 9

Pos: 11 /TD/Betrieb_Bedienung/Überschrif t - Betrieb @ 0\mod_1168951185590_51.doc @ 6552 @ 1

Operation

2 Operation

Pos: 12 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Überschrift - Netzschalter / Steuerstromschalter @ 0\mod_1168874843173_51.doc @ 6372 @ 2

2.1 Power Switch/Control Current Switch

Pos: 13 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Netzschalter/Steuerstr omschalter am Controller und Ofengehäuse @ 0\mod_1168874626267_51.doc @ 6363 @

27x12,7

Pos: 14 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Überschrift - Controller/Ofe n einschalten @ 0\mod_1168947051396_51.doc @ 6530 @ 2

The power switch/control current switch is located below or next to the keyboard block.

Stop running heating programs before turning off the furnace with the power switch.

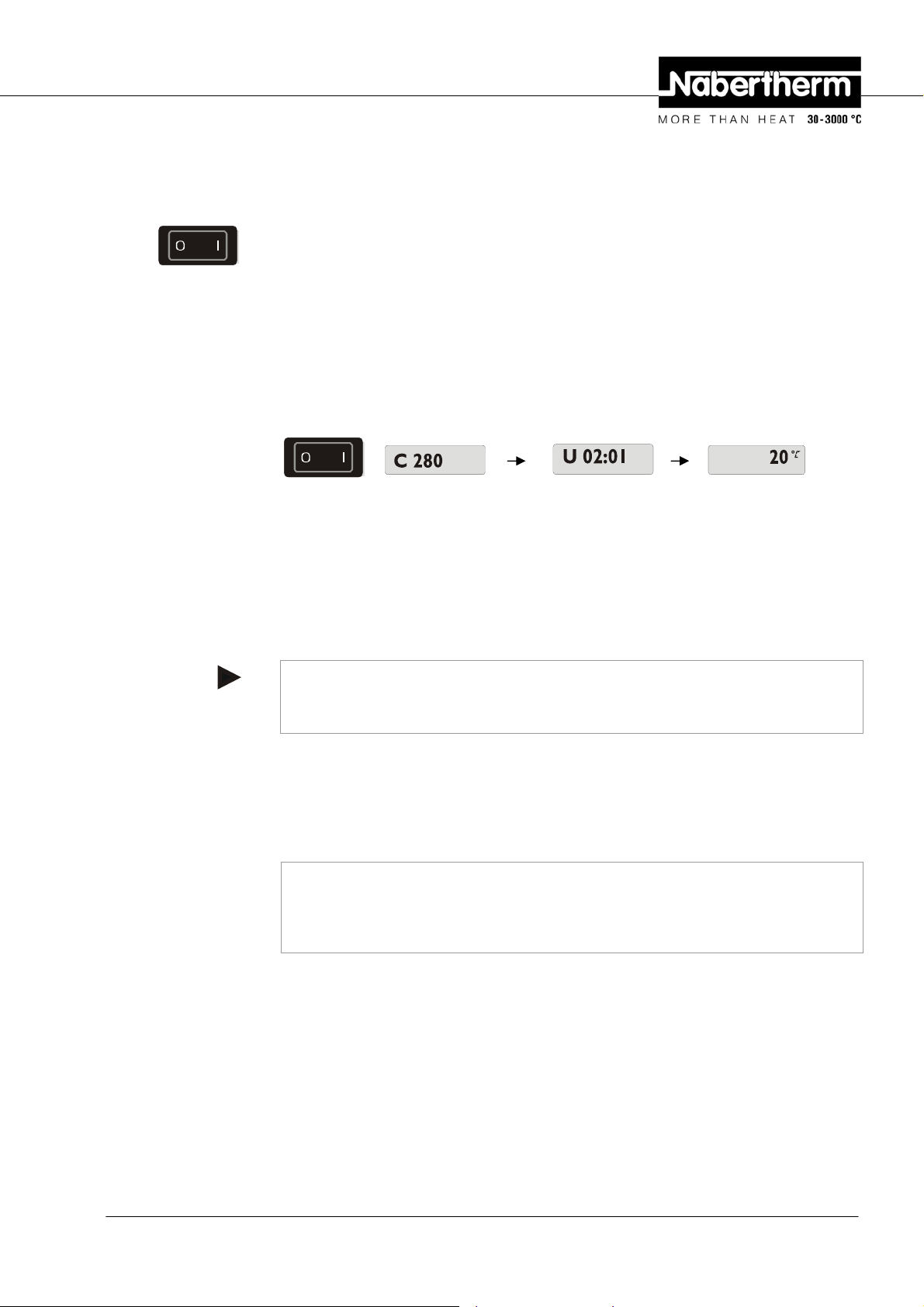

2.2 Turning on the Controller/Furnace

Pos: 15 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Controller einschalten (all e Controller) @ 0\mod_1168947103177_51.doc @ 6539 @

Switch power switch to "I" position. The controller first displays the controller type and

version number and then the temperature display. If the temperature is displayed, the

controller is ready to operate.

Turning on the

controller

27x12,7

Display Version number Temperature display

All necessary settings for proper function have already been done at the factory.

For the B 130 and C 280, heating programs for baking and glazing (see chapter

"Preconfigured programs for the B 130/C 280") are configured. For the other controllers,

the heating programs must be configured on a process- or user-specific basis.

Note

Some new functions depend on the version number. Turn the controller off and on again

briefly to be able to read the version number.

Pos: 16 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Überschrift - Controller aussc halten @ 0\mod_1169109234337_51.doc @ 7191 @ 2

2.3 Turning off the Controller/Furnace

Pos: 17 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Controller ausschalten (al le Con troller) @ 0\mod_1169108582644_51.doc @ 7182 @

Turn off main switch at position "O".

Pos: 18 /TD/Allgemeine Hinweise (für alle Anleitungen) /Hinweis - Beenden Sie laufende Heizprogramme, bevor Sie den Ofen am Netzschalter ausschalten ... @ 1\mod_1176291125332_51.doc @ 12843 @

Note

Stop running heating programs before turning the furnace off at the main switch, since the

controller will otherwise generate a fault message when it is turned back on.

See Faults/fault messages

Pos: 19 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @

Headquarters: 9/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 10

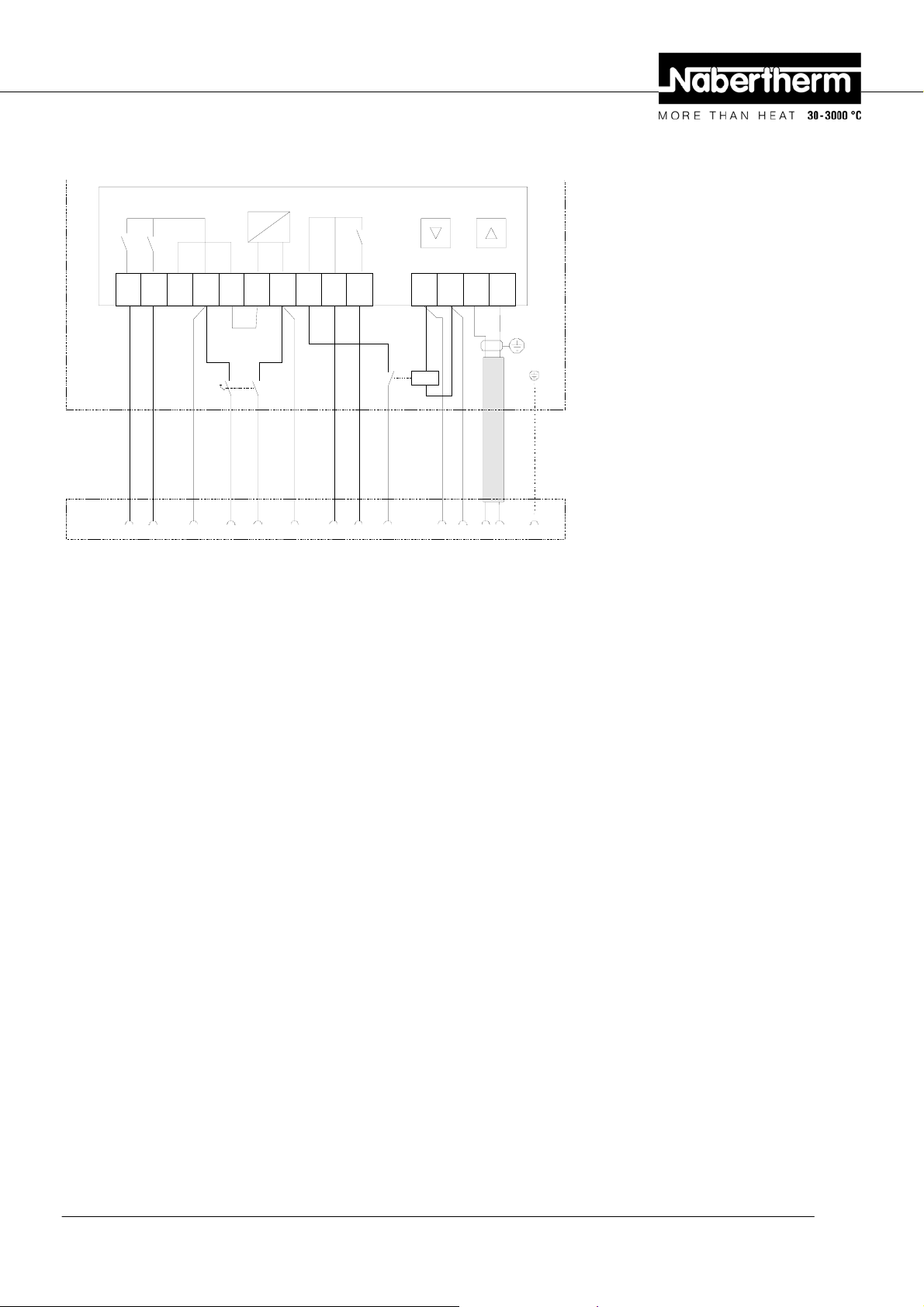

Pos: 20 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Bedienfelder/Überschri ft - Bedienfelder und Anzeige @ 0\mod_1168871157672_51.doc @ 6338 @ 1

3 Control Fields and Display

Pos: 21 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Bedienfelder/B180 @ 5\mod_12094 57499159_51.doc @ 36117 @

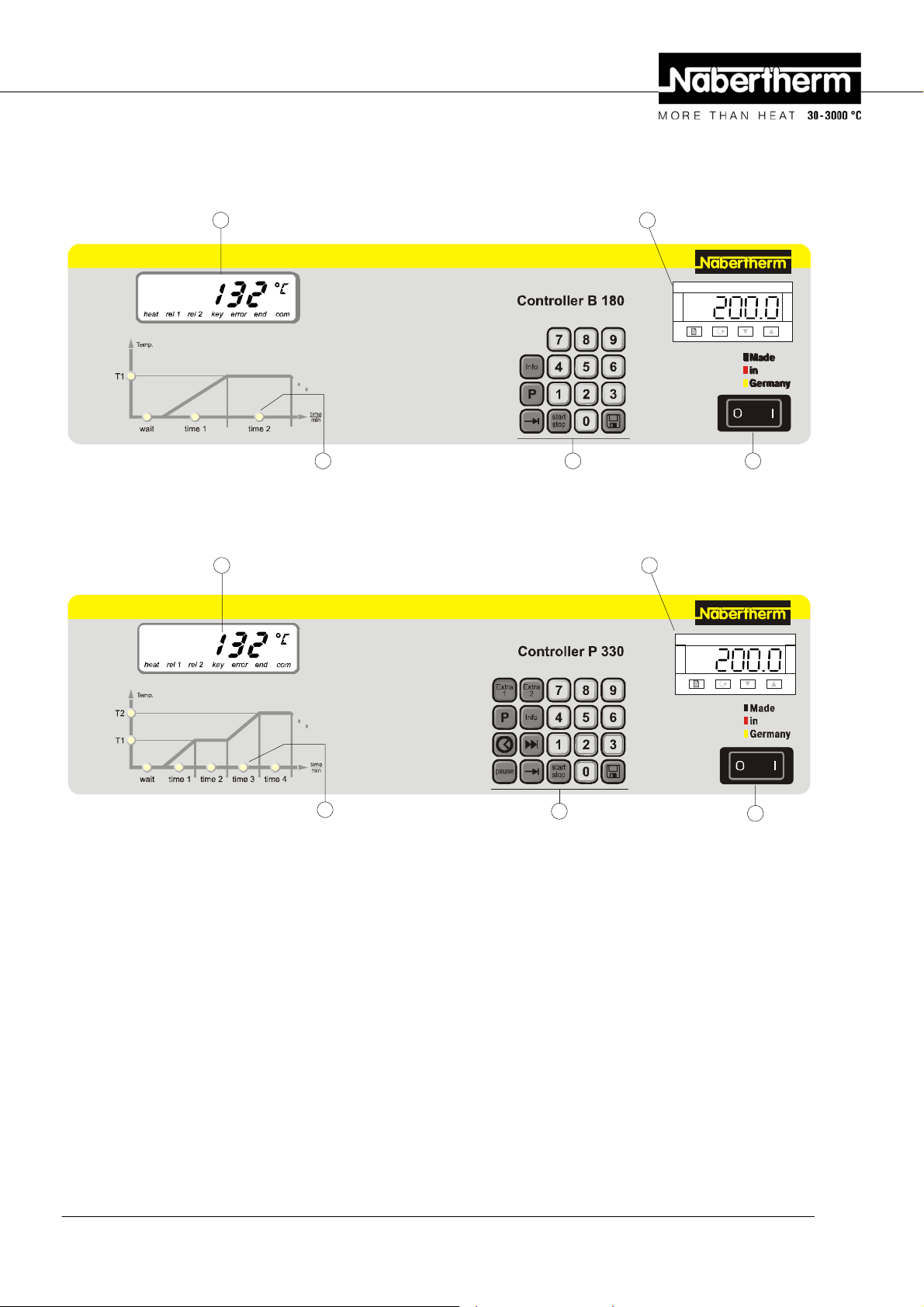

B 180

56

Fig. 1: B 180 control panel

Pos: 22 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Bedienfelder/P330 @ 5\mod_12094 56948677_51.doc @ 36101 @

P 330

5

2132iEurotherm

27x12,7

123

6

3

Fig. 2: P 330 control panel

Pos: 23 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Bedienfelder/Legende B 180 und P 330 @ 7\ mo d_12 33845191857_51.doc @ 49523 @

Pos: 24 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @

1 = Power switch

2 = Keyboard block

3 = Program LED

4 = - - -

5 = Display

6 = Over-temperature limit controller (optional)

2132iEurotherm

27x12,7

2

1

Headquarters: 10/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 11

Pos: 25 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Bedienfelder/ P 300 und P 310 @ 7\mod_12338 45695184_51.doc @ 49539 @

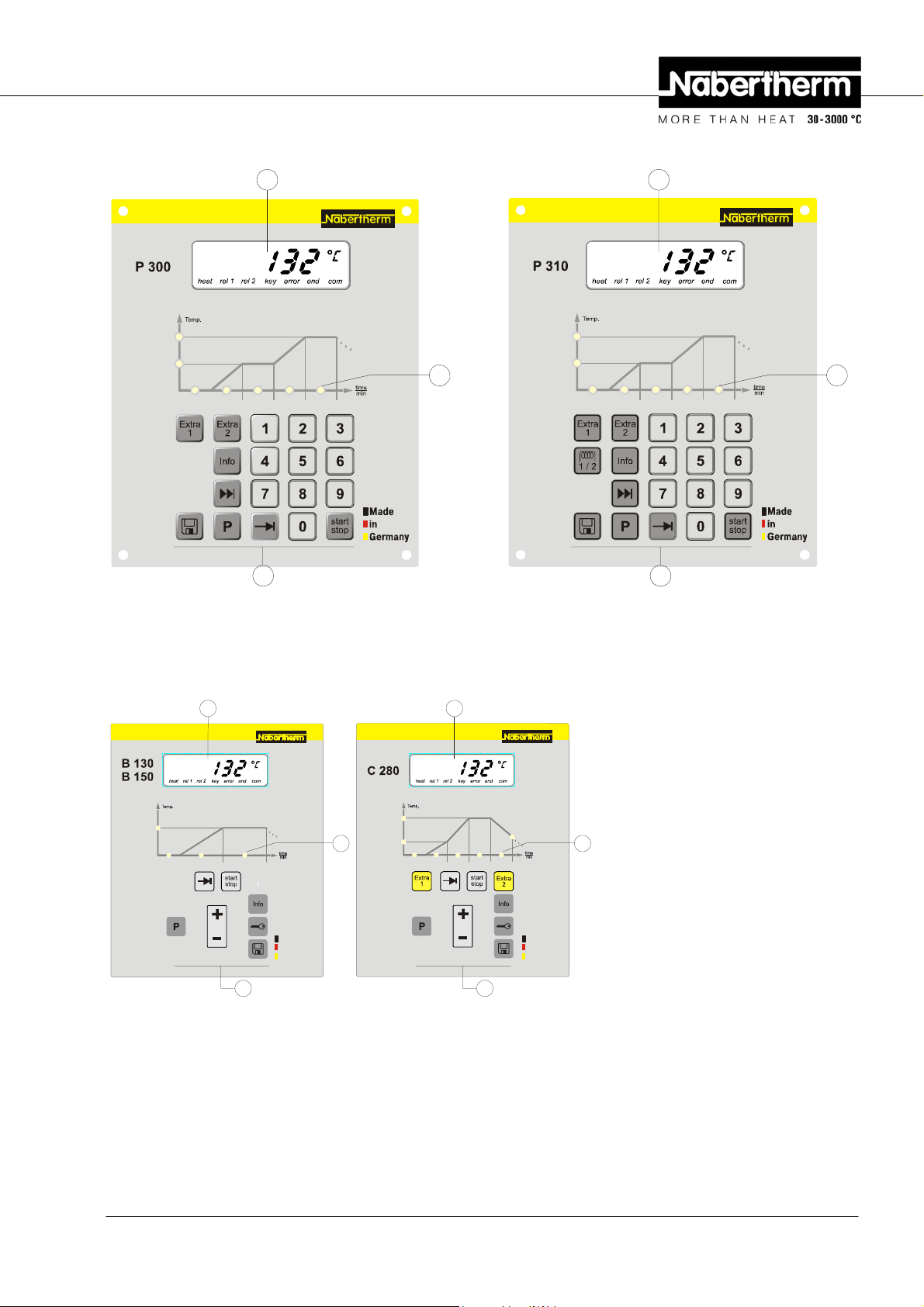

P 300/P 310

5 5

T2

T1

wait time 3 time 4time 2time 1

2 2

Fig. 3: P 300/P 310 control panel

Pos: 26 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Bedienfelder/B130/B150C2 80 @ 7\ mod_1233837787769_51.doc @ 49443 @

B 130/B 150/C 280

5 5

T2

T1

3

wait time 3 time 4time 2time 1

3

1 = - - -

2 = Keyboard block

3 = Program LED

T1

wait time 2time 1

Made

in

Germany

3 3

T2

T1

wait time 3 time 4time 2time 1

T3

Made

in

Germany

22

Fig. 4: B 130/B 150/C 280 control panel

Pos: 27 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @

Headquarters: 11/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

4 = - - -

5 = Display

6 = - - -

Page 12

Pos: 28 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Displays/Überschrift - Displays @ 0\mod_1168867379777_51.doc @ 6302 @ 2

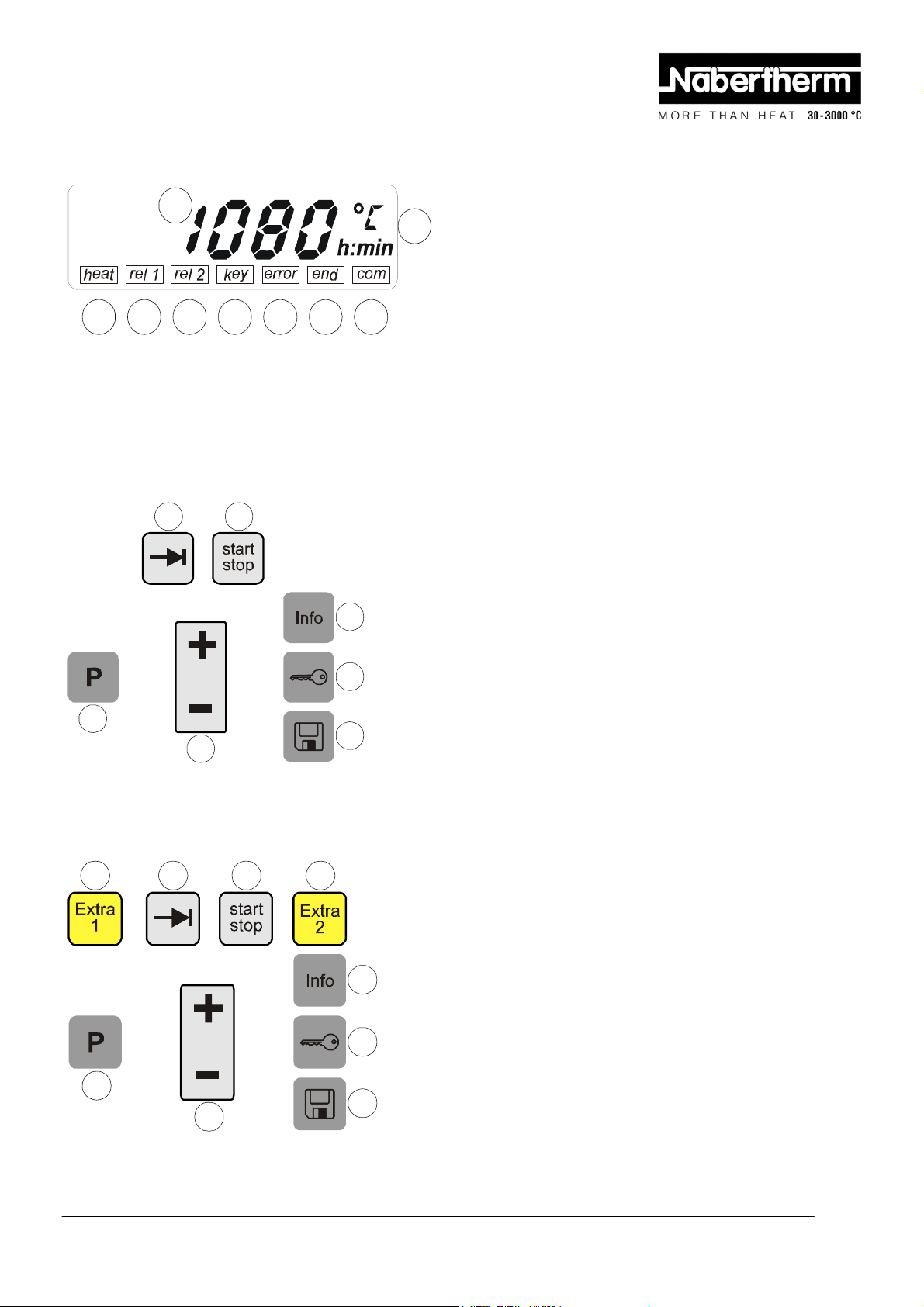

3.1 Displays

Pos: 29 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Displays/B130/B150/B170/ B180/ C280/C290/C295/P300/P310/P330 @ 0\mod_1168868366031_51.doc @ 6320 @

1

1 = Furnace temperature

2 = Temperature unit °C/°F

3 = Heating on

4 = Extra relay 1 ON

5 = Extra relay 2 ON (or ventilation motor ON

32456789

Fig. 5: Display

Pos: 30 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Tastaturblöcke/Übersc hr ift - Tastaturblöcke @ 0\mod_1168858756210_51.doc @ 6221 @ 2

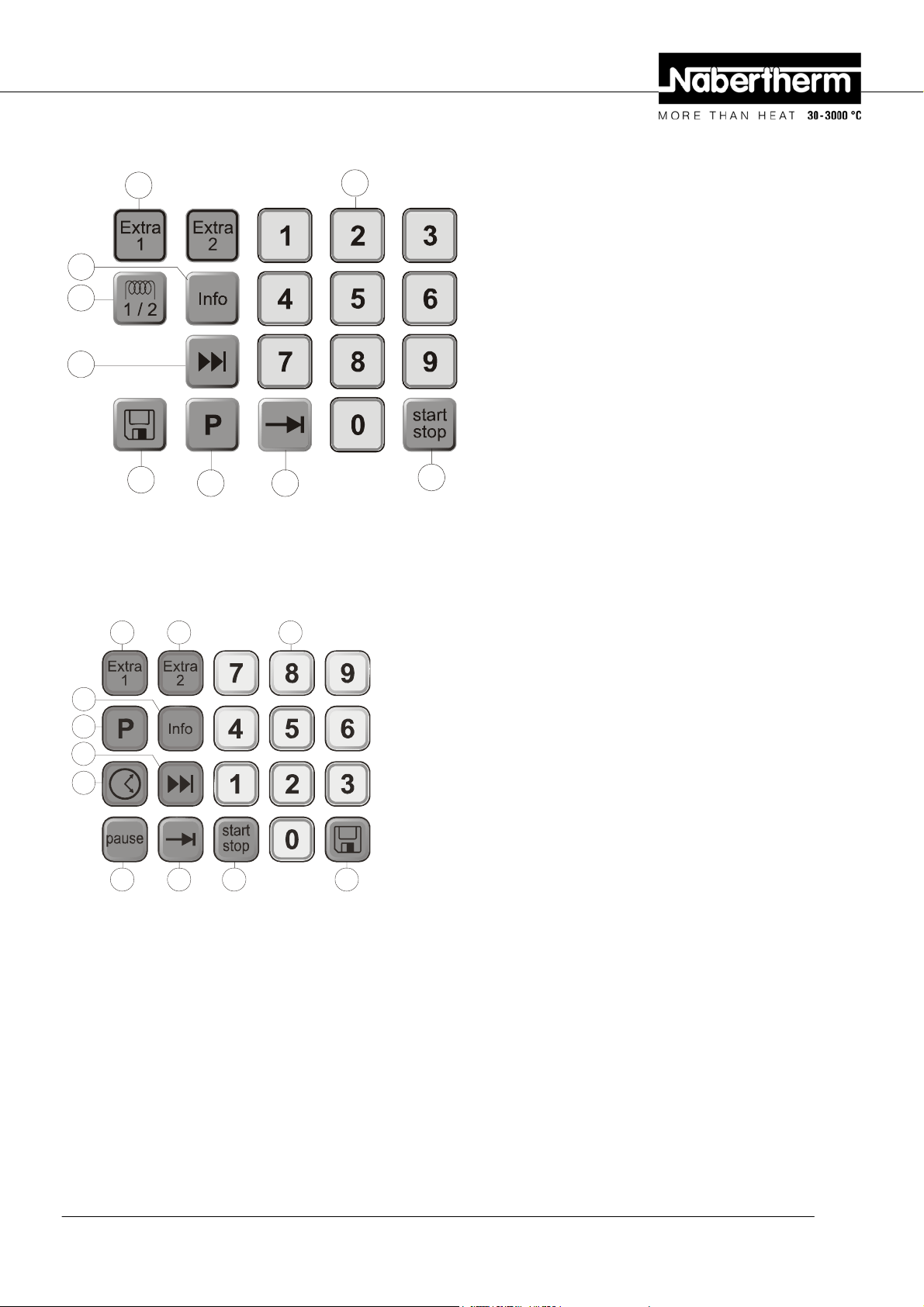

3.2 Keyboard Blocks

Pos: 31 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Tastaturblöcke/B130/B150 und Le gende @ 7\mod_1233838025910_51.doc @ 49459 @

B 130/B 150

4 5

6

7

1

8

2

Fig. 6: B 130/B 150 keyboard block

6 = Key lock (B 130/C 280 only)

7 = Error message

8 = Program end

9 = PC communication (optional)

1 = Program selection

2 = +/-

3 = - - -

4 = Page

5 = Program start/stop

6 = Info menu

7 = Key lock

8 = Save

Pos: 32 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Tastaturblöcke/C280 und Legen de @ 7\ mod_1233843516307_51.doc @ 49483 @

C 280

1 = Program selection

3 4 5 3

2 = +/-

3 = Extra functions

4 = Page

6

5 = Program start/stop

6 = Info menu

7 = Key lock

7

8 = Save

1

8

2

Fig. 7: C 280 keyboard block

Pos: 33 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @

Headquarters: 12/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 13

Pos: 34 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Tastaturblöcke/B180 und Lege nde @ 7\ mod_1233850588652_51.doc @ 49609 @

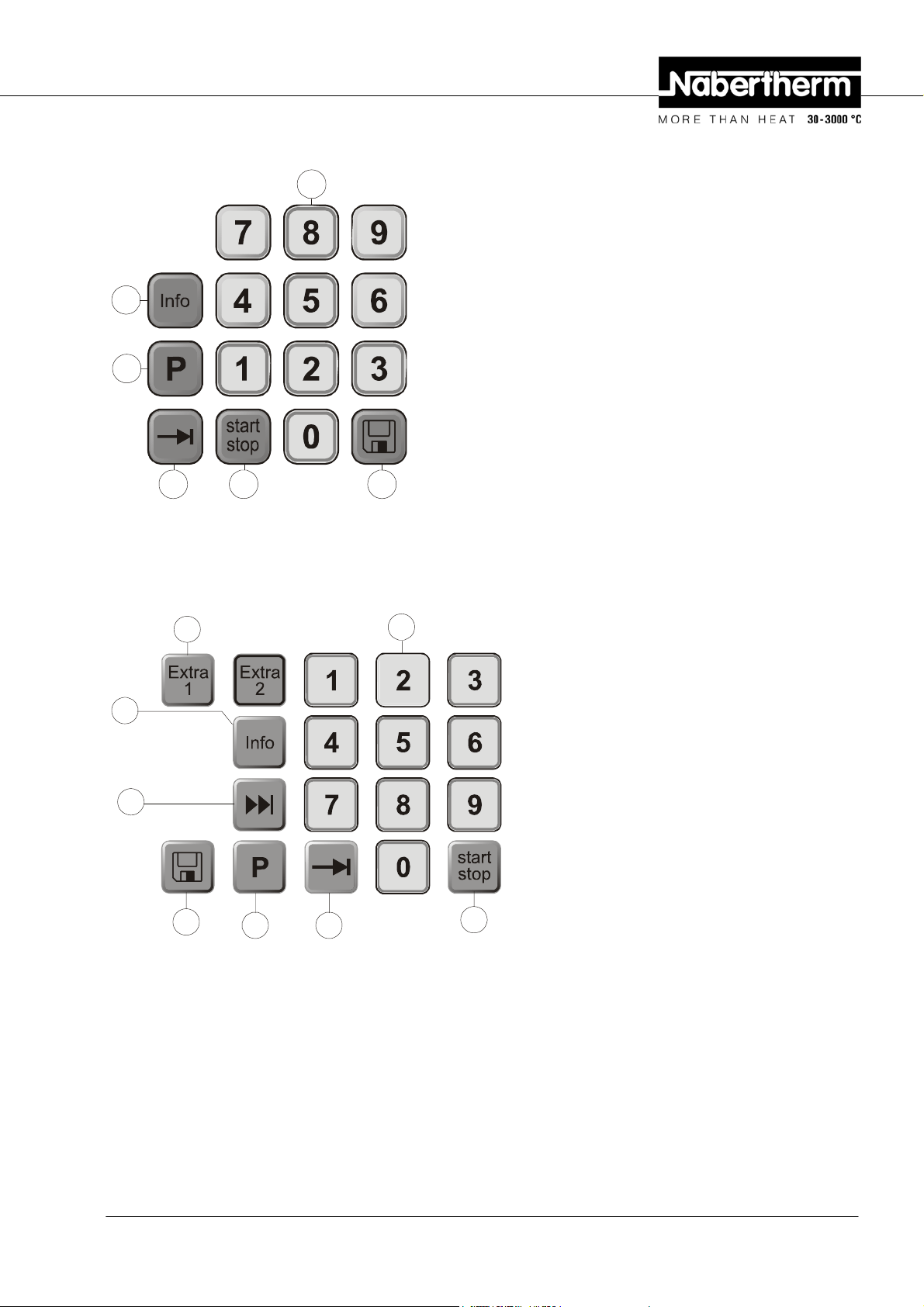

B 180

6

1

45 8

Fig. 8: B 180 keyboard block

Pos: 35 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Tastaturblöcke/P300 und Lege nde @ 7\ mod_1233846166420_51.doc @ 49555 @

P 300

3

2

1 = Program selection

2 = Numerical block

3 = - - -

4 = Page

5 = Program start/stop

6 = Info menu

7 = - - -

8 = Save

2

6

7

8

Fig. 9: P 300 keyboard block

Pos: 36 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @

1

1 = Program selection

2 = Numerical block

3 = Extra functions

4 = Page

5 = Program start/stop

6 = Info menu

7 = Segment skip

8 = Save

4

5

Headquarters: 13/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 14

Pos: 37 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Tastaturblöcke/P310 und Lege nde @ 7\ mod_1233846249883_51.doc @ 49571 @

P 310

3

6

9

7

8

Fig. 10: P 310 keyboard block

Pos: 38 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Tastaturblöcke/P330 und Lege nde @ 7\ mod_1233850309077_51.doc @ 49593 @

P 330

3

1

3

2

1 = Program selection

2 = Numerical block

3 = Extra functions

4 = Page

5 = Program start/stop

6 = Info menu

7 = Segment skip

8 = Save

9 = Heating circuit

4

2

5

1 = Program selection

6

1

7

10

9

Fig. 11: P 330 keyboard block

Pos: 39 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @

45 8

2 = Numerical block

3 = Extra functions

4 = Page

5 = Program start/stop

6 = Info menu

7 = Segment skip

8 = Save

9 = Pause

10 = Time

Headquarters: 14/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 15

Pos: 40 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Überschrift - Eigenschaften der Kon troller @ 0\mod_1168946054727_51.doc @ 6512 @ 1

4 Features of the Controller

Pos: 41 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Eigenschaften der Kontroller ( alle Controller) @ 7\mod_1233915567692_51.doc @ 49663 @ 2

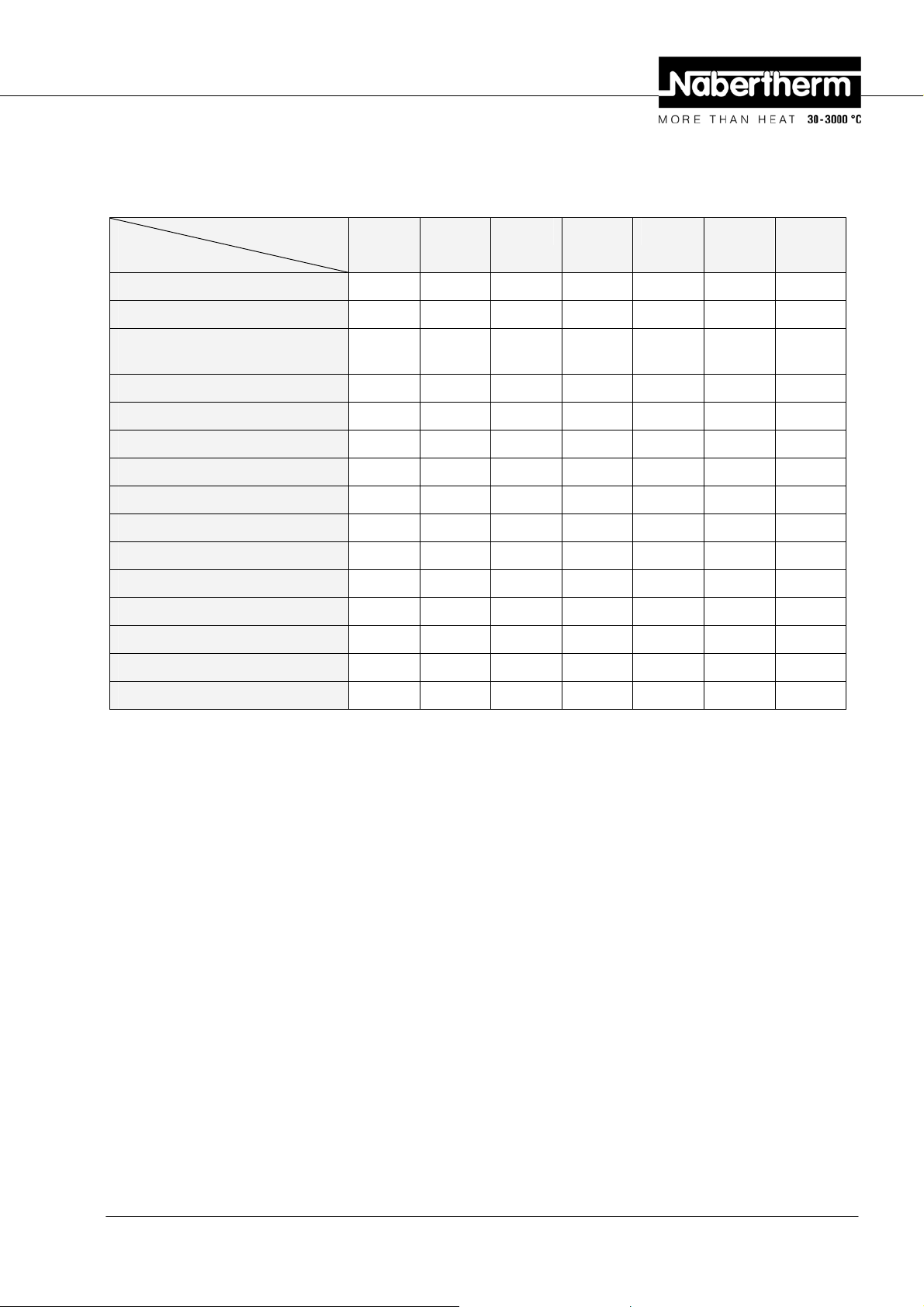

4.1 Functions

Controller

Function

Over-temperature protection 1)

Extra relay function

Manual configuration of the

heating circuits

Air circulation motor control 2)

Waiting time

Number of programs

Number of segments

Auto tune

kW/hr counter 3)

Operating hours counter

Real-time clock

Acoustic signal

RS-422 data interface

Constant heat output

B 130 B 150 B180 C 280 P 300 P 310 P 330

√ √ √ √ √ √ √

- - - 2 2

4)

2

4)

2

4)

- - - - - √ -

√ √ √ √ √ √

√ √ √ √ √ √ √

2 1 1 9 9 9 9

4 2 2 4 40 40 40

√ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √

- - - - - - √

- - - - - - √

Optional Optional Optional Optional Optional Optional Optional

- - - - - √ Optional

10-key keyboard

Pos: 42 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/1) Mit Programmstart wird die höchs te im Programm eingestellte Temperatur ermittelt ... @ 1\mod_1176292760467_51.doc @ 12854 @

- - √ - √ √ √

1) When the program starts, the highest temperature in the program is calculated. If the furnace is 30°C warmer than the

highest program temperature for 3 minutes during the program sequence, the controller turns off the heating and the

safety relay, and a fault message appears.

Pos: 43 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/2) Voreingestellte Funktion bei Umluftöfen: Sobald ein Programm am ... @ 1\mod_1176292979087_51.doc @ 12864 @

2) Preconfigured function for circulation furnaces: Once a program has been started on the controller, the air circulation

motor starts. It remains in operation until the program terminates or is interrupted, and the furnace temperature falls

back below 80°C. Extra function 2 is no longer available with this function.

Pos: 44 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/3) Der kW/h Zähler berechnet über die Ei nschaltzeit der Heizung, den theoretisch ... @ 1\mod_1176293183301_51.doc @ 12875 @

3) The kW/hr counter calculates the power theoretically consumed over the time the heater is turned on for a heating

program at nominal voltage. However, there may actually be deviations: If the voltage is low, the power consumption

displayed will be too high, and for a higher voltage the power consumption displayed will be too low.

Pos: 45 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/4) Bei Öfen mit einem Luftumwälzmotor s teht in der Regel nur eine Extra-Funktion zur Verfügung .. @ 4\mod_120056305943 5_51.doc @ 30603 @

4) In furnaces with an air circulation motor, only one extra function is usually available (see furnace operating

instructions).

Pos: 46 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @

Headquarters: 15/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 16

Pos: 47 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Überschrift - Neue Funktionen der Nabertherm Controller @ 1\mod_1173192128446_51.doc @ 10423 @ 1

5 New Functions of the Nabertherm Controller

Pos: 48 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programmeingabe mit/ohne Gradi ent ab Controller Version 3.xx @ 5\mod_1210665723438_51.doc @ 36633 @ 2

5.1 Program Entry with/without Gradient as of Version 3.xx

As of controller version 3.xx you can enter ramps either as gradients (e.g. 120°C/h) or using

the "time and target temperature" combination.

Turn the controller off and on again briefly to be able to read the version number.

The input mode can be changed on a user-specific basis in the configuration in support of

the process specification. To change the input mode, see "Configuration"

The mode configured can be seen during program input in a segment, e.g. "time 1", as

follows:

For "time and set temperature" input, only °C/°F or the time h is displayed as the input

unit. For gradient input, °C/°F and h appear together in the display as the unit. The

maximum gradient is 6000°C (fast heating)

Pos: 49 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Die Zeiteinheit für die Gradient eneingabe ist fest auf Stunde (h) eingestellt ... @ 5\mod_1210666214044_51.doc @ 36655 @

Pos: 50 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programmstartverhalten bei warmen Ofen ab Controller Version 3.xx @ 1\mod_1173192896751_51.doc @ 10442 @ 2

Note

The unit of time for the gradient input is preset to hours (h) and cannot be changed to

minutes.

Example: 100°C/h

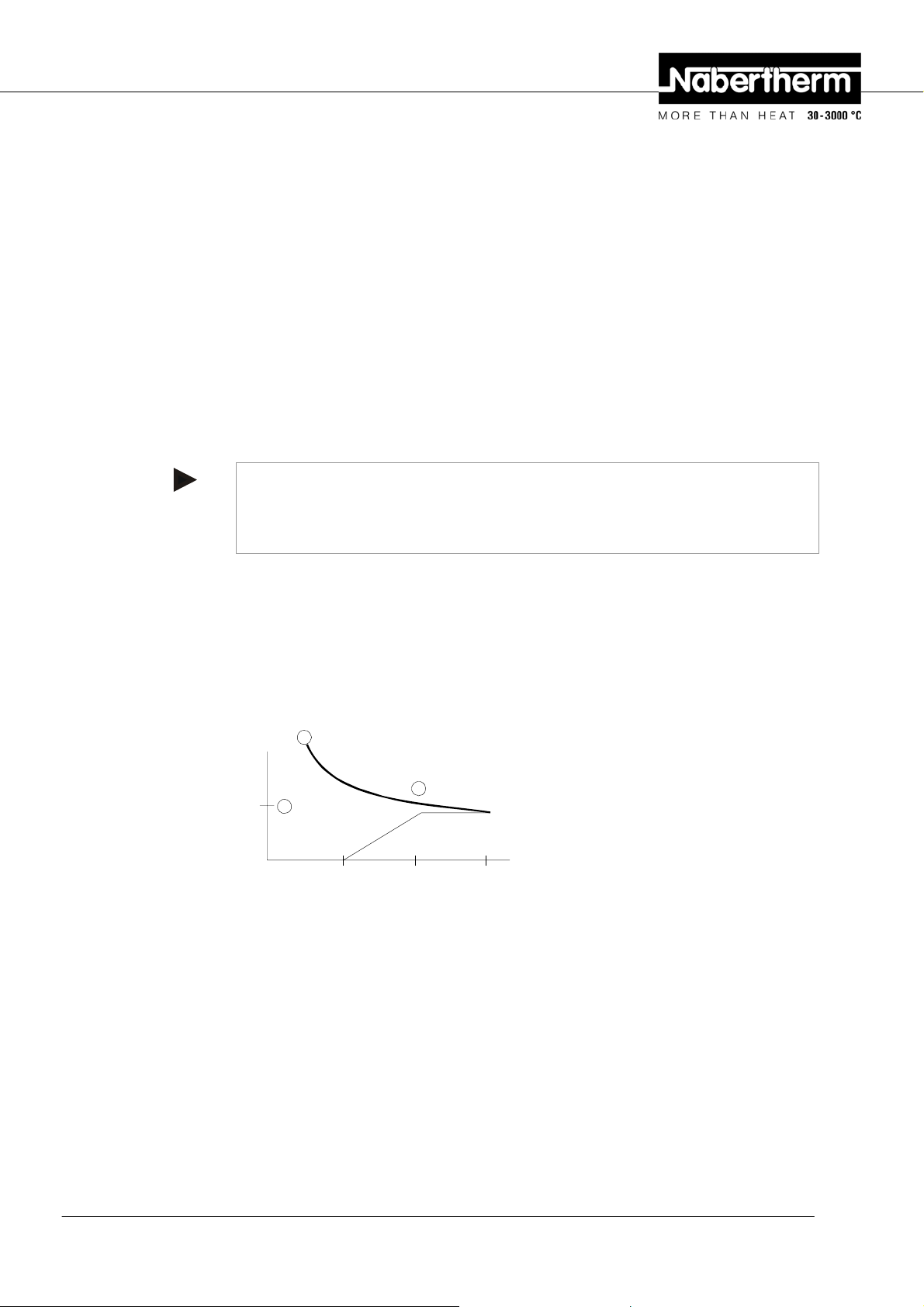

5.2 Program Starting Behavior for warm Furnaces as of Controller Version 3.xx

If the furnace temperature c at program start is higher than the set temperature d of the

first segment "T 1", the program start is delayed until the furnace chamber temperature

cools to a value of T1 + 10 °C e. That is, segment "Time 1" is skipped and the program

start occurs in the following segment "Time 2".

1

3

T 1

2

Time 1 Time 2

Fig. 12: Program start behavior

This program start behavior is permanently programmed into all controllers as of version

number 3.xx and cannot be changed. Turn the controller off and on again briefly to be able

to read the version number.

Pos: 51 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Spanungsausfallverhalten @ 1\ mod_1173193408926_51.doc @ 10451 @ 2

5.3 Power Failure Behavior

As of controller version 3.xx the power failure behavior can be configured.

Turn the controller off and on again briefly to be able to read the version number. To

change the power failure behavior, see chapter "Configuration/customer-specific

settings".

Pos: 52 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Überschrift - Controller B130/C2 80 @ 7\mod_1233921605957_51.doc @ 49679 @ 1

Headquarters: 16/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 17

6 Controller B 130/C 280

Pos: 53 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Kurzanleitung/Überschri ft - Kurzanleitung @ 0\mod_1169544239740_51.doc @ 7618 @ 2

6.1 Brief Instructions

Pos: 54 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Kurzanleitung/Controller ei nschalten B130/C280 @ 7\mod_1233925936587_51.doc @ 49705 @

Turning on the

controller

27x12,7

Display Version number Temperature display

Example: controller type

Pos: 55 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Kurzanleitung/Program m aufr ufen B130/B150/C280/C290/C295 @ 1\mod_1173193921396_51.doc @ 10460 @

Call program

Confirm program selection with

Pos: 56 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Kurzanleitung/Program m eingeb en/kontrollieren B130/B150/C280 @ 7\mod_1234361168010_51.doc @ 50225 @

Enter / control

program

Pos: 57 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Kurzanleitung/Program m star ten B130/B150/B170/B180/C280/C290/C295/P230/P330 @ 1\mod_117319 4624787_51.doc @ 10478 @

Start program

Display

. . .

time 1

Enter time

segment 1

T 1

Enter

temperature 1

time 2

Enter time

segment 2

Display

Pos: 58 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @

Headquarters: 17/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 18

Pos: 59 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Überschrift - Programme/W artezeit einstellen oder verändern @ 1\mod_1174634424831_51.doc @ 12333 @ 2

6.2 Setting or changing Program/Waiting Time

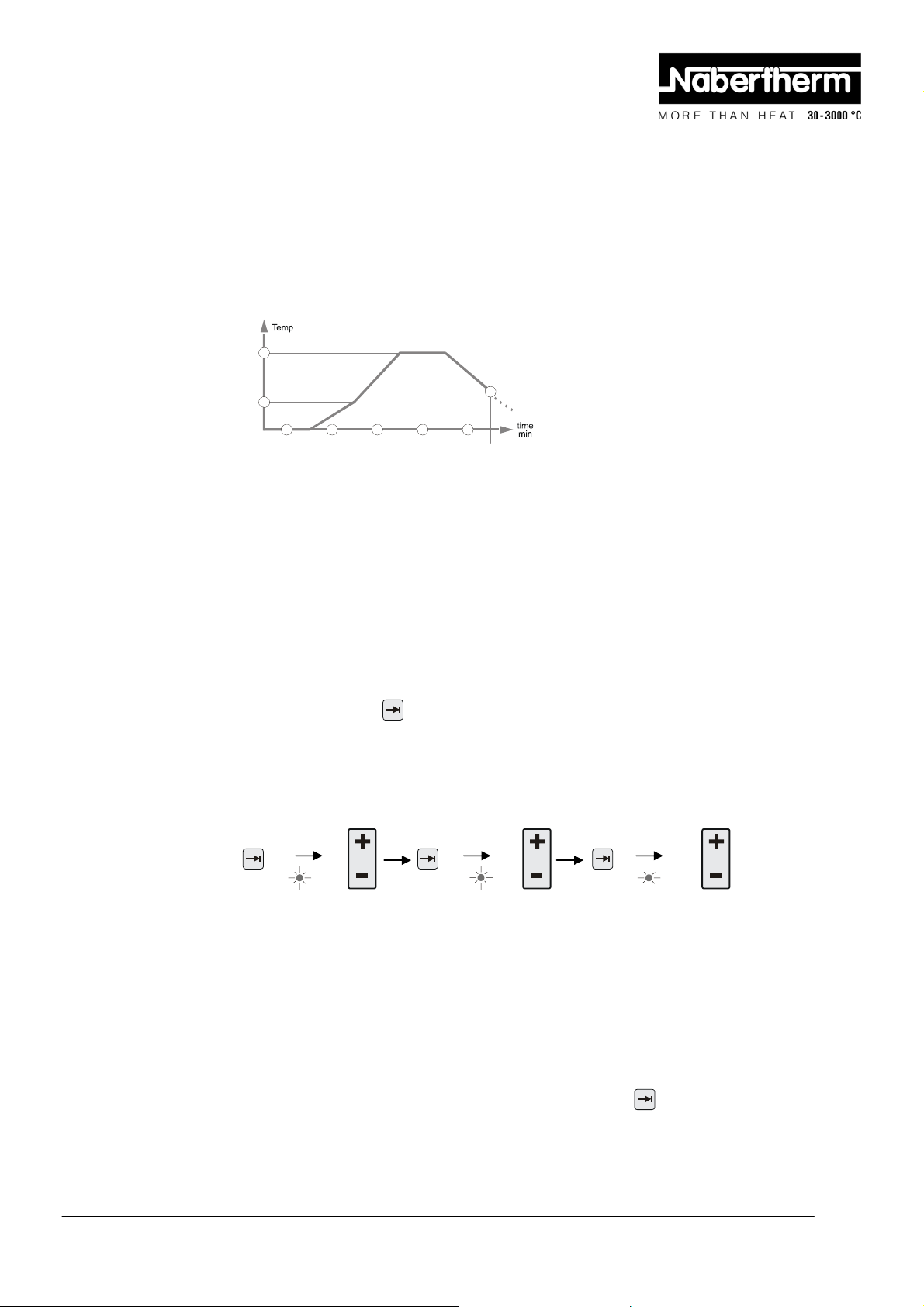

Pos: 60 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programme/Wartezeit einste l len oder verändern B130/C280 - 1 @ 0\mod_1169026202596_51.doc @ 6930 @

For the automatic operation of the furnace, before starting the controller a temperature

characteristic must be configured which describes the desired temperature behavior. This

configured temperature behavior is also called a heating program.

Each heating program for the B 130 and C 280 has two ramps, one holding time, and one

cooling ramp.

T2

T1

wait time 3 time 4time 2time 1

T3

Fig. 13: Program graphic, B 130/C 280

− In the ramps, a segment temperature "T" and a segment time, "time 1" and "time

2" define a linear temperature increase (slow heating).

− In the holding time, "time 3"determines how long the temperature value

configured in "T 2" should be held.

− In the cooling time, the natural cooling can be slowed using the rate set in "T 3"

and "time 4". If there is no specification in "T 3" and "time 4", the

program is already terminated after "time 3" has elapsed.

Program Entry

Using the paging key

you can enter input mode. Every push selects the following

segment or time value. The selected value is displayed with the blinking LED for either "T"

or "time".

Pos: 61 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Kurzanleitung/Program m eingeb en/kontrollieren B130/B150/C280 @ 7\mod_1234361168010_51.doc @ 50225 @

Enter / control

program

. . .

time 1

Enter time

segment 1

T 1

Enter

temperature 1

time 2

Enter time

segment 2

Pos: 62 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programme/Wartezeit einste l len oder verändern B130/C280/ - 2 @ 1\mod_1174639619097_51.doc @ 12354 @

In the display, the temperature value "T" or time value "time" corresponding to the flashing

LED is shown.

Pos: 63 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programme/Wartezeit einste l len oder verändern B130/B150/C280 @ 7\mod_1234362060765_51.doc @ 50257 @

If the value displayed should not be changed, use the page key to page to the next

temperature or time value.

The display also shows the unit of the value expected:

Headquarters: 18/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 19

- set temperature values with °C/°F

- set time specifications with hr:min

- set gradient specifications with °C/hr:min or °F/hr:min

If a value should be changed, you can set it with the

Each time you press the

If you hold the

key down, the value first changes in steps of 10,

and if you hold the

key, the value changes by 1 °C or by one minute.

key down for a longer time, the value changes in steps of 100.

key.

Times are entered in hours and minutes, e.g. 6 hr and 30 min as 06:30.

For holding times, an entry of 99:59 means program execution will continue forever.

When input is complete, the program can be started (see Starting the program).

If ramps contain the time entry 00:00, the controller attempts to reach the temperature value

stored in "T" as quickly as possible

If no key is pressed for 60 seconds, the display automatically returns to the display of

temperature. Changed settings are initially only buffered. If a changed or new program

should be permanently stored in the controller for more frequent use, see "Saving

Programs".

Note

Not all segments have to be programmed. For segments which are not needed, the

temperature and time values must be set to "0". The controller then automatically ends the

program after the last segment programmed

Pos: 64 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Wartezeit einstellen oder veränd ern B150/B180/P300/P310 @ 7\mod_1233926255573_51.doc @ 49731 @ 2

6.3 Setting or Changing the Waiting Time

B 150/B 180/P 300/P 310 waiting time

To start a heating program automatically at a later point in time, e.g. after a drying time, a

waiting time ("wait") can be programmed.

To select the waiting time, press the

Times are entered in hours and minutes, e.g. 6 hrs and 30 min as 06:30, i.e., when a heating

program is started, first the wait time elapses and only then does the program start with

segment 1 and heating.

Pos: 65 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @

key repeatedly until the

wait

LED flashes.

Headquarters: 19/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 20

Pos: 66 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programmierung der Extrafunk ti onen B 130/B150/C280/C290/C295 @ 1\mod_1173260029266_51.doc @ 10552 @ 2

6.4 Programming Extra Functions

With controllers of types "C" and "P", up to two optional extra functions "Extra 1" and

"Extra 2" can be turned on or off in the segments depending on the program

Extra functions are, for instance, exhaust air flaps, fans, solenoids, or optical and acoustic

signals, which have been included in the furnace (if applicable, see additional operating

instructions for extra functions)

These extra functions can be specified during program entry in all segments, e.g. "time 1",

by selecting the "Extra 1" or "Extra 2" key.

That is, when the controller processes the programmed segment, the extra functions are

automatically turned on and then turned back of in the next segment, for instance.

Programming of extra functions is done during program entry.

The desired segment must be selected as described in "Entering programs/wait time", so

that the corresponding LED, e.g. "time 1", is flashing.

If the "Extra 1" or "Extra 2" key is now pressed, the extra function is specified for this

segment, and in the display the status field "REL 1" lights up for "Extra 1" and/or "REL

2" for "Extra 2". During program execution, the programmed extra function is

automatically turned on during this segment.

To turn off the specification of an extra function, press the corresponding "Extra" key

again – in the display, the status field "REL 1" or "REL 2" disappears – the extra function

is now no longer turned on. Both extra functions can also be activated at the same time.

time 1 T1

Fig. 14: Selection of "Extra 1 funktion" in segment "time 1"; LED "time 1" flashes

wait time 1

Fig. 15: In the display, "REL 1" lights up for the selected "Extra 1 funktion"

When paging through the program with

, programmed extra functions are indicated in

each segment ("time" LED flashing) with the status fields "REL 1" or "REL 2" in the

display – if the status fields do not light up, the extra functions are not specified.

Note

The programming of extra functions is saved along with storage of heating programs!

Pos: 67 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programmierung der Extrafunk ti onen i n „T3“ (nur C 280) @ 1\mod_1174385526182_51.doc @ 11383 @ 2

Headquarters: 20/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 21

6.5 Programming Extra Functions in "T3" (C 280 only)

When programming extra functions in the program value "T3" (C 280 only), the extra

function stays turned on after conclusion of the program, for instance in order to continue

cooling the furnace with a cooling fan.

Extra functions which are automatically turned on during program execution by "T3" must

be turned off by hand if necessary.

Pos: 68 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Extrafunktionen im Programmab lauf manuell Ein- und Ausschalten B 130/150/C 280/C290/295 @ 1\mod_117438586561 7_51.doc @ 11393 @ 2

6.6 Turning Extra Functions in Program Execution on and off by Hand

Extra functions can be turned on or off during a started program, for the active segment or

after termination of the program, by pressing the corresponding "Extra" key.

If an extra function is turned on during a running program, it remains on until the programspecific segment transition to the following segment occurs.

Pos: 69 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programme speichern B130/B150/C 280 @ 7\ mod_1234362375876_51.doc @ 50273 @ 2

6.7 Saving Programs

Changed settings are initially only buffered. That is, buffered programs are overwritten

once a different program is started. If a changed or new program should be permanently

saved in the controller for more frequent use, it can be saved to a permanent program slot as

follows:

Press the save key

The number can be changed to the desired program number using

Pressing the save key

– a program number appears in the display.

again finally saves to the selected program slot.

+

-

.

Pos: 70 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programme speichern B130/B150/C 280/ C290/C295/P320 - 2 @ 1\mod_1174405559639_51.doc @ 12203 @

Pos: 71 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Voreingestellte Programme B 130/C 280 @ 1\ mod_1174386532079_51.doc @ 11413 @ 2

++

Fig. 16: Saving a program to program slot no. 9

The program can now be called up from this storage slot at any time (see Program start)

Note

Existing heating programs already saved in a storage slot will be overwritten with no

message or warning. Saved heating programs are still retained after the controller is turned

off. Configured waiting times are not saved. They must be reentered before each process!

The controller automatically returns to the display of the furnace temperature after about 10

seconds when you save without pressing the save key

buffered in this case.

again. The program is only

Headquarters: 21/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 22

6.8 Preconfigured Programs for the B 130/C 280

The following programs are preconfigured and can be started directly.

"Baking" refers to the baking of clay, while "glazing" refers to the baking of glazes.

Note

In any case, note the specifications and instructions of the raw material manufacturers,

which may make it necessary to change or adapt the preconfigured programs. It cannot be

guaranteed that optimum results can be obtained with the preconfigured programs. The

configured factory programs can be overwritten for your own purposes (see Setting

programs/wait time).

B 130

Î

T1 Time1 T2 Time2 Time3 Time4 T3

P1 650 6:00 900 0:00 0:20 0:00 0 Baking

P2 500 3:00 1050 0:00 0:20 0:00 0 Glazing

C 280

Î

T1 Time1 T2 Time2 Time3 Time4 T3

P1 650 3:00 900 0:00 0:20 0:00 0 Baking 1

P2 650 6:00 900 0:00 0:20 0:00 0 Baking 2

P3 650 5:00 1100 0:00 0:30 0:00 0 Baking 3

P4 320 2:00 1050 0:00 0:20 0:00 0 Glazing 1

P5 500 3:00 1050 0:00 0:20 0:00 0 Glazing 2

P6 500 3:00 1200 0:00 0:20 0:00 0 Glazing 3

P7 Unused

P8 Unused

P9 Unused

Note

For furnace models with lower maximum temperatures, the programs listed above are

adapted at the factory to the maximum temperature of the furnace.

Pos: 72 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Überschrift - Programme aufruf en @ 1\mod_1174648969015_51.doc @ 12376 @ 2

6.9 Calling Programs

Pos: 73 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programme aufrufen B130/B150/C 280 @ 7\ mod_1234362533901_51.doc @ 50289 @

Start saved programs with the P key. Use the

number and monitor the program using the

++

Fig. 17: Starting heating program no. 9

Pos: 74 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programme aufrufen (Hinweis) B130/ B150/B170/C280/C290/C295/P320 - 2 @ 1\mod_1174407235343_51.doc @ 12236 @

Headquarters: 22/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

+

-

key to select the desired program

key.

Page 23

Note

Check the heating program called up before starting it, to be sure that it is the right heating

program.

As of version 3, heating programs are reloaded after program termination.That is, the

heating program can be started after a process without having to reenter it. Turn the

controller off and on again briefly to be able to read the version number .

Pos: 75 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programmstart B130/B150/C280/ C290/C295 @ 0\mod_1169026395783_51.doc @ 6939 @ 2

6.10 Program Start

After a heating program is entered or called up, it can be started with the

As of version 3: if the furnace temperature at the starting time is higher than the

temperature specified in "T 1", the controller first waits until the temperature of the warm

furnace has fallen to the first segment temperature T1, and only then does it start the rest of

the program's execution. (See also Chapter "New functions of the Nabertherm controller").

For a cold furnace, the heating program is started immediately.

If the heating program has been started, during program execution the LED of the active

segment "time 1 – time 4" lights up. The controller regulates the configured temperature

profile completely automatically and the status field "heat" lights up in the heating cycle.

If the waiting time is set, the LED "wait" first lights up and the display counts down the

remaining waiting time. The status field "heat" only lights up after program start in

segment "time 1" if the heater is turned on. After conclusion of the last segment, the heater

is turned off and the program terminates. In the display, the end of the program is indicated

with the message "end".

Pos: 76 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programmänderung im Programmabl auf B130/B150/C 280 @ 7\mod_1234362637073_51.doc @ 50305 @ 2

6.11 Program Change During Execution

During program execution, program changes can be made as follows:

Use the paging key

or time value. The selected value is displayed with the flashing LED for either "T" or

"time".

In the display, the temperature value "T" or time value "time" corresponding to the flashing

LED is shown. Holding times can be changed in steps of 5 minutes and temperatures by +/1 °C/°F. If the value displayed should not be changed, use the page key

next segment or time value. All temperature and time values, as well as the extra functions,

can be changed; the only exception is the segment time of the ramp currently being

processed.

Note

to enter input mode. Each key press selects the following segment

start

stop

key.

to page to the

Changes to individual values during program execution must be confirmed with

Otherwise, the change will not be accepted. If you only want to change the active

time segment, this can be done without selecting using the paging key

+

-

can use the

key directly to increase or decrease the holding time in steps of five

. To do this, you

.

holding

minutes.

Extra functions can be turned on or off during a started program, for the active segment or

after termination of the program, by pressing the corresponding "Extra" key.

Pos: 77 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programmabbruch B130/B150/C 280/C 2 90/C295 @ 1\mod_1174388539571_51.doc @ 11443 @ 2

Headquarters: 23/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 24

6.12 Terminating a Program

To terminate a program, press the

field "end" lights up. Program termination can be performed at any time.

Note

It is not possible to interrupt a program temporarily!

start

stop

key again. The heater is turned off and the status

Pos: 78 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Tastenverriegelung B130/B150/ C280 @ 0\mod_1169039668540_51.doc @ 7092 @ 2

6.13 Key Locking

Pos: 79 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Infomenü B130/B150/C280/C290/ C295 - 1 @ 0\mod_1169470892509_51.doc @ 7465 @ 2

6.14 Info Menu

Pos: 80 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Infomenü B130/B150/C280/C290/ C295/P320 - 2 @ 1\mod_1174894342983_51.doc @ 12426 @

For protection against unintended or unallowed changes to the program execution, the

keyboard can be locked after program start using the "key lock". Key locking can only be

released by turning the controller off and on again. If the furnace is turned off while a

program is running, see the power failure behavior.

From the info menu, the current program status, program-relevant information, and fault

messages can be read out.

You can reach the info menu by pressing the "Info" key.

Use the "Info" key to page through the entire info menu until the furnace temperature is

displayed again.

Pr Selected program

SP Set temperature value

Pt Program run time of the active/last program, in minutes

E Power consumption of the active/last program, in kW/hr

tt Total operating hours

OP Heating output power in %

F1 Fault buffer of last fault

F2 Fault buffer of next to last fault

Ht Highest program temperature of the active/last program

tA Maximum furnace temperature

Note

The info menu is not automatically switched back to the temperature display, so that you

can observe it for longer periods of time.

Use the "Info" key to page through the entire info menu until the furnace temperature is

displayed again.

Some values are reset after a heating program is started.

Pos: 81 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @

Headquarters: 24/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

The operating hour counter cannot be reset

Page 25

Pos: 82 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Überschrift - Controller B150 @ 7\m od_1 234162838898_51.doc @ 49753 @ 1

7 Controller B 150

Pos: 83 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Kurzanleitung/Überschri ft - Kurzanleitung @ 0\mod_1169544239740_51.doc @ 7618 @ 2

7.1 Brief Instructions

Pos: 84 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Kurzanleitung/Controller ei nschalten B150/C290/C295 @ 0\mod_1169566365267_51.doc @ 7643 @

Turning on the

controller

27x12,7

Display Version number Temperature display

Example: controller type

Pos: 85 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Kurzanleitung/Program m aufr ufen B130/B150/C280/C290/C295 @ 1\mod_1173193921396_51.doc @ 10460 @

Call program

Confirm program selection with

Pos: 86 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Kurzanleitung/Program m eingeb en/kontrollieren B130/B150/C280 @ 7\mod_1234361168010_51.doc @ 50225 @

Enter / control

program

Pos: 87 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Kurzanleitung/Program m star ten B130/B150/B170/B180/C280/C290/C295/P230/P330 @ 1\mod_117319 4624787_51.doc @ 10478 @

Start program

Display

. . .

time 1

Enter time

segment 1

T 1

Enter

temperature 1

time 2

Enter time

segment 2

Display

Pos: 88 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @

Headquarters: 25/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 26

Pos: 89 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Überschrift - Controller B180/P3 00/P310/P330 @ 7\mod_1234162979838_51.doc @ 49769 @ 1

8 Controller B 180/P 300/P 310/P 330

Pos: 90 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Kurzanleitung/Überschri ft - Kurzanleitung @ 0\mod_1169544239740_51.doc @ 7618 @ 2

8.1 Brief Instructions

Pos: 91 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Kurzanleitung/Controller ei nschalten B180/P300/P310/P330 @ 5\mod_1209461914143_51.doc @ 36213 @

Turning on the

controller

27x12,7

Display Version number Temperature display

Pos: 92 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Kurzanleitung/Program m eingeb en-Startzeit eingeben-start- B180/P330 @ 5\mod_1209462365500_5 1.doc @ 36229 @

Enter waiting time

wait

Enter waiting time

Display

Enter program

Enter time

segment 1

Confirm input with

Confirm input with

Enter

temperature 1

.

Enter time

segment 2

.

Pos: 93 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Kurzanleitung/Program m star ten B130/B150/B170/B180/C280/C290/C295/P230/P330 @ 1\mod_117319 4624787_51.doc @ 10478 @

Start program

Display

Pos: 94 /=== Seitenumbruch === @ 0\mod_1158819844943_0.doc @ 2983 @

Headquarters: 26/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 27

Pos: 95 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Tag/Uhrzeit einstellen und anz ei gen P330 @ 5\mod_1209471331954_51.doc @ 36293 @ 2

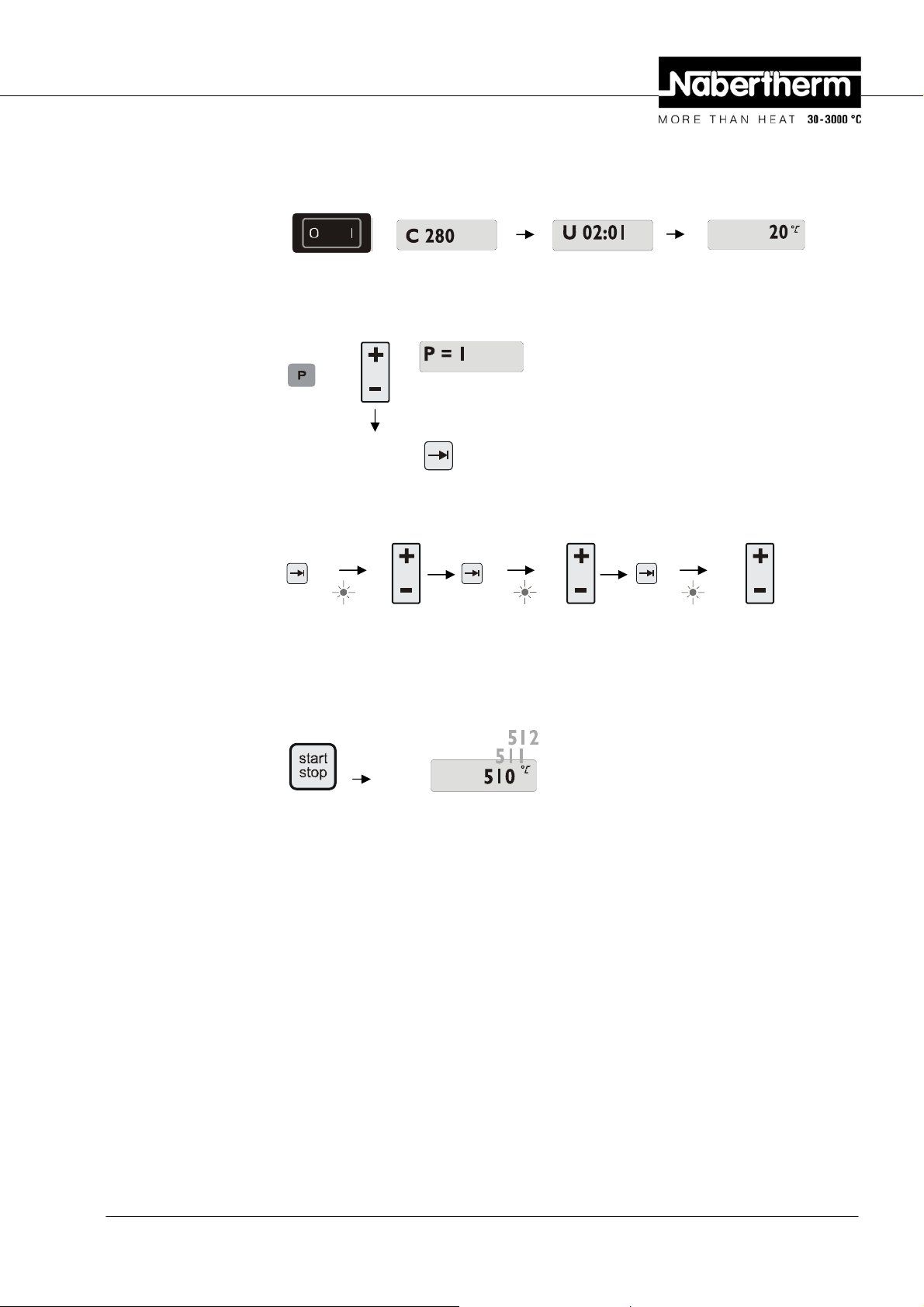

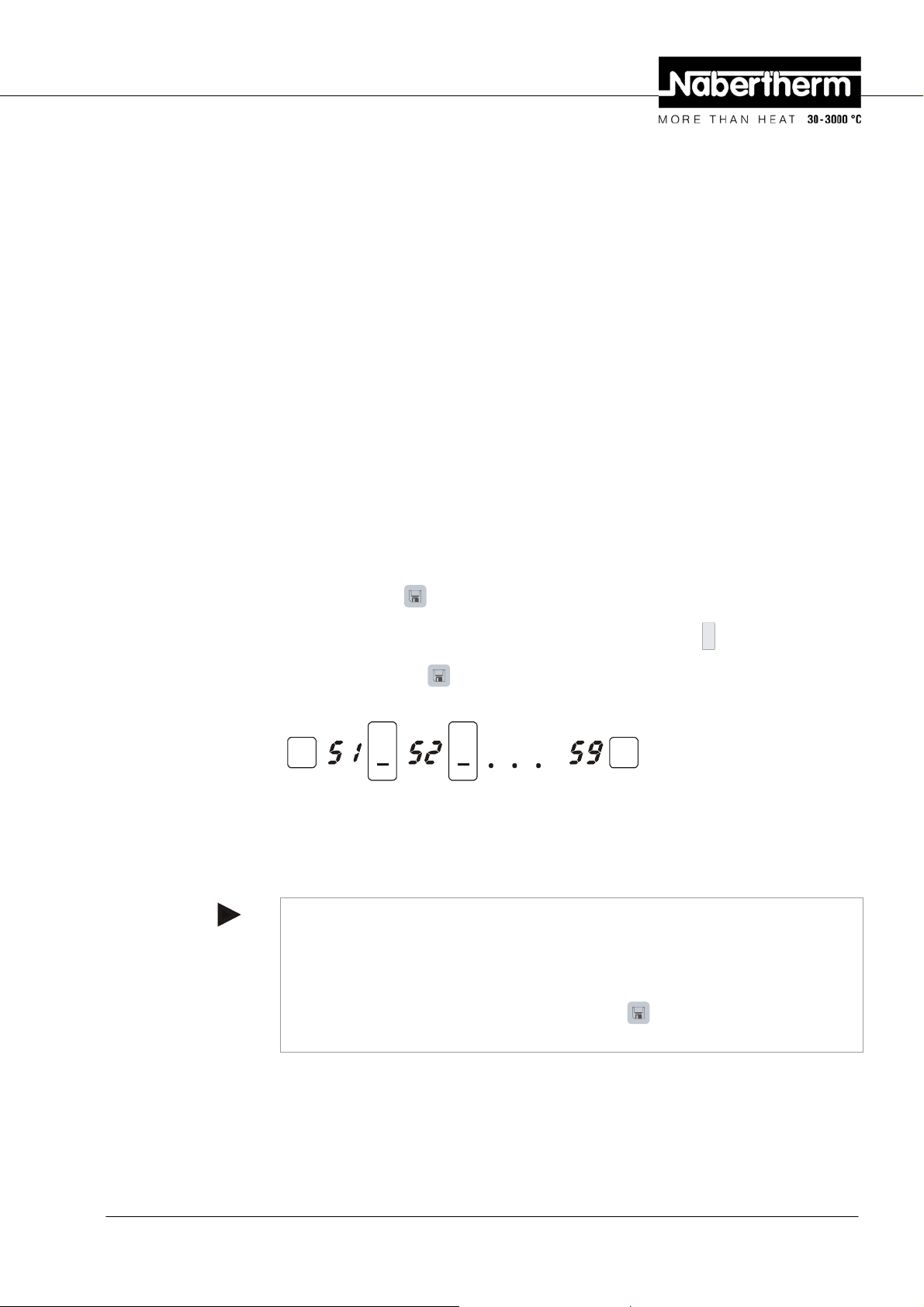

8.2 Setting and Displaying the Date/Time on the P 330

The P 330 has a real time clock that is set at the factory. The time of day can be displayed

by pressing the

follows: The clock is set using a numerical combination of the day of the week and the

time. The setting of the day of the week corresponds to the first digit of the numerical

combination. Each day of the week has its own number.

1=Mon, 2=Tue, 3=Wed, 4=Thu, 5=Fri, 6=Sat, 7=Sun.

Entry of the time of day must then be carried out with the last four digits of the combination

using a 24-hour clock:

E.g. 0735 for 7:35 AM, 1700 for 5:00 PM, etc.

key. If the time of day is displayed incorrectly, the clock can be set as

Example: Setting the time "Wednesday (day 3), 7:35 AM"

Fig. 18: Example of setting the clock

The day and time are saved by pressing the

the symbol key

.

This clock is a real-time clock, that is, even when the controller is turned off, the time is

retained using a built-in battery. The lifetime of the battery is about 3 years. When the

battery is replaced, the saved data (set time) is lost. For the battery type, see the chapter

"Technical data".

The time can only be entered and displayed in 24-hour mode, that is, a display of 12:00

AM/PM is not possible. After the time is set, the controller is fully ready for operation.

Pos: 96 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programme einstellen oder veränder n B150/P300/P310 - 1 @ 7\mod_1234163504356_51.doc @ 49785 @ 2

8.3 Setting or Changing Programs

For the automatic operation of the furnace, before starting the controller a temperature

characteristic must be configured which describes the desired temperature behavior. This

configured temperature behavior is also called a heating program.

key. They can be queried at any time with

P 300/P 310

Each of the 9 heating programs for the P 300/P 310 has 20 ramps and 20 hold times (40

segments in all) which are connected together with the segment blocks A – I.

Headquarters: 27/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 28

T2

T1

T2

T1

T2

T1

wait time 3 time 3 time 3time 4 time 4 time 4time 2 time 2 time 2time 1 time 1 time 1

Fig. 19: P 300/P 310 program graph

B 150

The heating program for the B 150 has one ramp and one holding time.

Pos: 97 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Kurzanleitung/Program m eingeb en/kontrollieren B130/B150/C280 @ 7\mod_1234361168010_51.doc @ 50225 @

T1

wait time 2time 1

Fig. 20: Program graph, B 150

− In a ramp, a segment temperature "T" and a segment time, e.g. "time 1", define a

linear temperature increase (slow heating).

− In a holding time, e.g. "time 2", it is configured how long the temperature value

configured in "T 1" should be held.

Program input

Using the paging key

you can enter input mode. Each key press selects the following

segment or time value. The selected value is displayed with the flashing LED for either "T"

or "time".

Enter / control

program

. . .

time 1

Enter time

segment 1

T 1

Enter

temperature 1

time 2

Enter time

segment 2

Pos: 98 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programme/Wartezeit einste l len oder verändern B130/B150/C280/C290/C295 - 2 @ 1\mod_1174639305804_51. doc @ 12343 @

In the display, the corresponding segment block A-I and the temperature value "T" or time

value "time" corresponding to the flashing LED are also shown.

Pos: 99 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programme/Wartezeit einste l len oder verändern B130/B150/C280 @ 7\mod_1234362060765_51.doc @ 50257 @

If the value displayed should not be changed, use the page key to page to the next

temperature or time value.

Headquarters: 28/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 29

The display also shows the unit of the value expected:

- set temperature values with °C/°F

- set time specifications with hr:min

- set gradient specifications with °C/hr:min or °F/hr:min

If a value should be changed, you can set it with the

Each time you press the

If you hold the

key down, the value first changes in steps of 10,

and if you hold the

key, the value changes by 1 °C or by one minute.

key down for a longer time, the value changes in steps of 100.

key.

Times are entered in hours and minutes, e.g. 6 hr and 30 min as 06:30.

For holding times, an entry of 99:59 means program execution will continue forever.

When input is complete, the program can be started (see Starting the program).

If ramps contain the time entry 00:00, the controller attempts to reach the temperature value

stored in "T" as quickly as possible

If no key is pressed for 60 seconds, the display automatically returns to the display of

temperature. Changed settings are initially only buffered. If a changed or new program

should be permanently stored in the controller for more frequent use, see "Saving

Programs".

Note

Not all segments have to be programmed. For segments which are not needed, the

temperature and time values must be set to "0". The controller then automatically ends the

program after the last segment programmed

Pos: 100 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Kurzanleitung/Program m einge ben/kontrollieren P300/P310 @ 7\mod_1234164091088_51.doc @ 49801 @

Enter / control

program

Pos: 101 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programme/Wartezeit einst el len oder verändern B130/B150/C280/C290/C295 - 2 @ 1\mod_1174639305804_51. doc @ 12343 @

Pos: 102 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programme/Wartezeit einst el len oder verändern B180/P300/P310/P330 - 3 @ 7\mod_1234165962141_51.doc @ 49817 @

. . .

time 1

Enter time

segment 1

T 1

Enter temperature

1

time 2

Enter time

segment 2

In the display, the corresponding segment block A-I and the temperature value "T" or time

value "time" corresponding to the flashing LED are also shown.

If the value displayed should not be changed, use the page key to page to the next

temperature or time value.

The display also shows the unit of the value expected:

- set temperature values with °C/°F

- set time specifications with hr:min

- set gradient specifications with °C/hr:min or °F/hr:min

Headquarters: 29/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 30

If a value should be changed, you can set it with the numerical block .

Times are entered in hours and minutes, e.g. 6 hr and 30 min as 06:30.

For holding times, an entry of 99:59 means program execution will continue forever.

When input is complete, the program can be started (see Starting the program).

If ramps contain the time entry 00:00, the controller attempts to reach the temperature value

stored in "T" as quickly as possible

If no key is pressed for 60 seconds, the display automatically returns to the display of

temperature. Changed settings are initially only buffered. If a changed or new program

should be permanently stored in the controller for more frequent use, see "Saving

Programs".

Note

Not all segments have to be programmed. For segments which are not needed, the

temperature and time values must be set to "0". The controller then automatically ends the

program after the last segment programmed

Pos: 103 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Wartezeit einstellen oder verän dern B150/B180/P300/P310 @ 7\mod_1233926255573_51.doc @ 49731 @ 2

8.4 Setting or Changing the Waiting Time

B 150/B 180/P 300/P 310 waiting time

To start a heating program automatically at a later point in time, e.g. after a drying time, a

waiting time ("wait") can be programmed.

To select the waiting time, press the

Times are entered in hours and minutes, e.g. 6 hrs and 30 min as 06:30, i.e., when a heating

program is started, first the wait time elapses and only then does the program start with

segment 1 and heating.

Pos: 104 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Startzeit einstellen oder verändern P 330 @ 5\mod_1209473804268_51.doc @ 36356 @ 2

8.5 Setting or changing the Start Time

P 330 start time

To start a heating program automatically at a later point in time, e.g. after a drying time, a

waiting time can be programmed via the 7-day timer.

To select the waiting time, press the

wait

The "

" LED flashes.

key repeatedly until the

key.

wait

LED flashes.

The timer is set using a numerical combination consisting of the day of the week and the

time. The setting of the day of the week corresponds to the first digit of the numerical

combination. Each day of the week has its own number.

1=Mon, 2=Tue, 3=Wed, 4=Thu, 5=Fri, 6=Sat, 7=Sun.

Entry of the time of day must then be carried out with the last four digits of the combination

using a 24-hour clock:

e.g. 0800 for 8:00 a.m., 1800 for 6:00 p.m., etc.

Also see "Setting and displaying the date/time"

Example: Program start on Thursday at 08:00.

Headquarters: 30/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 31

wait

Fig. 21: Waiting time input Display

Note

Incorrect input:

Exit Wait function by pressing the

time.

Pos: 105 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programmierung der Extrafunk ti one n B130/B150/C280/C290/C295 @ 1\mod_1173260029266_51.doc @ 10552 @ 2

8.6 Programming Extra Functions

With controllers of types "C" and "P", up to two optional extra functions "Extra 1" and

"Extra 2" can be turned on or off in the segments depending on the program

Extra functions are, for instance, exhaust air flaps, fans, solenoids, or optical and acoustic

signals, which have been included in the furnace (if applicable, see additional operating

instructions for extra functions)

These extra functions can be specified during program entry in all segments, e.g. "time 1",

by selecting the "Extra 1" or "Extra 2" key.

That is, when the controller processes the programmed segment, the extra functions are

automatically turned on and then turned back of in the next segment, for instance.

Programming of extra functions is done during program entry.

d = day

key. Press again to select or correct the wait

The desired segment must be selected as described in "Entering programs/wait time", so

that the corresponding LED, e.g. "time 1", is flashing.

If the "Extra 1" or "Extra 2" key is now pressed, the extra function is specified for this

segment, and in the display the status field "REL 1" lights up for "Extra 1" and/or "REL

2" for "Extra 2". During program execution, the programmed extra function is

automatically turned on during this segment.

To turn off the specification of an extra function, press the corresponding "Extra" key

again – in the display, the status field "REL 1" or "REL 2" disappears – the extra function

is now no longer turned on. Both extra functions can also be activated at the same time.

time 1 T1

Fig. 22: Selection of "Extra 1 funktion" in segment "time 1"; LED "time 1" flashes

wait time 1

Fig. 23: In the display, "REL 1" lights up for the selected "Extra 1 funktion"

When paging through the program with

, programmed extra functions are indicated in

each segment ("time" LED flashing) with the status fields "REL 1" or "REL 2" in the

display – if the status fields do not light up, the extra functions are not specified.

Headquarters: 31/56

Nabertherm GmbH . Bahnhofstr. 20 .28865 Lilienthal/Bremen, Germany . Tel +49 (4298) 922-0, Fax -129 . contact@nabertherm.de . www.nabertherm.com

Page 32

Note

The programming of extra functions is saved along with storage of heating programs!

Pos: 106 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programmierung der Extrafunk ti one n (Taste Extra 1) P 330 @ 5\mod_1216735363604_51.doc @ 40165 @

Note

The P 330 has an acoustic alarm coupled to Extra Relay 1. This means that when the Extra

1 function is activated the acoustic alarm sounds and when the Extra 1 function is

Pos: 107 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Extrafunktionen im Programmab la uf manuell Ein- und Ausschalten B 130/150/C 280/C290/295 @ 1\mod_117438586 5617_51.doc @ 11393 @ 2

deactivated the alarm turns off.

8.7 Turning Extra Functions in Program Execution on and off by Hand

Extra functions can be turned on or off during a started program, for the active segment or

after termination of the program, by pressing the corresponding "Extra" key.

If an extra function is turned on during a running program, it remains on until the programspecific segment transition to the following segment occurs.

Pos: 108 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programme speichern B180/P300/ P310/P330- 1 @ 7\mod_1234167125891_51.doc @ 49833 @ 2

8.8 Saving Programs

Changed settings are initially only buffered. That is, buffered programs are overwritten

once a different program is started. If a changed or new program should be permanently

saved in the controller for more frequent use, it can be saved to a permanent program slot as

follows:

Press the save key

The number can be changed to the desired program number using the numerical block

– a program number appears in the display.

.

Pos: 109 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programme speichern B150 - 2 @ 0\mod_11 6902 5134357_51.doc @ 6912 @

Pos: 110 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Programme speichern B130/B150/ C 280/C290/C295/P320 - 2 @ 1\mod_1174405559639_51.doc @ 12203 @

Pressing the save key

again finally saves to the selected program slot.

Fig. 24: Saving a program to program slot no. 9

Fig. 25: B 150 example programs

The program can now be called up from this storage slot at any time (see Program start)

Note

Existing heating programs already saved in a storage slot will be overwritten with no

message or warning. Saved heating programs are still retained after the controller is turned

off. Configured waiting times are not saved. They must be reentered before each process!

The controller automatically returns to the display of the furnace temperature after about 10

seconds when you save without pressing the save key

Pos: 111 /TD/Betrieb_Bedienung/Controller/B 150/ B130/B170/C280/C290/C295/P320/Überschrift - Programme aufruf en @ 1\mod_1174648969015_51.doc @ 12376 @ 2

Headquarters: 32/56