Nabco Multi-Module

Multifunction Module

for the Control of

Swing, Slide, and Fold Doors

S82 W18717 Gemini Drive

Muskego, WI 53150

Phone: (877) 622-2694

Fax: (888) 679-3319

www.nabcoentrances.com

WARNING

Do not install or service this product unless you have read and understood the Safety Practices,

Warnings, Installation and Operating Instructions contained in this manual.

Failure to do so may result in property damage or bodily injury.

P/N 15-12241

REV 5-7-10

Nabco Multi-Module

Interactive Parts Diagrams,

Installation Manuals,

Service Bulletins,

AutoCAD Drawings,

Specifications,

Sales Literature,

Unit Pricing,

Online Ordering,

News Releases,

Promotional Materials,

and much more.

Just log in with your distributor account number

and password to access all of the above or call 1-877-622-2694 for

more information.

Page 2 www.NabcoEntrances.com 5-7-10

Nabco Multi-Module

Topic Page Number

Introduction ................................................................................................................................................. 4

To The Installer ................................................................................................................. 4

Overview .................................................................................................................................. 4

Modes of Operation ................................................................................................................. 4

Specifications ................................................................................................................................................. 5

Programming instructions ................................................................................................................................ 6

Mode 1 - Electric Strike Sequence Diagram - Magnum 4 Control .................................................................. 7

Mode 1 - Electric Strike Sequence Diagram - Analog Control ........................................................................ 8

Mode 1 - Bi-directional Door Sequencer Diagram - Magnum 4 Control.......................................................... 9

Mode 1 - Bi-directional Door Sequencer Diagram - Analog Control ............................................................. 10

Mode 2 - Apartment or Access Control Diagram - Magnum 4 Control .......................................................... 11

Mode 2 - Apartment or Access Control Diagram - Analog Control ............................................................... 12

Mode 3 - Ratchet or Latching Operation Diagram - Analog Control ............................................................. 13

Mode 4 - Smoke Evacuation Diagram - Magnum 4 Control .......................................................................... 14

Mode 4 - Smoke Evacuation Diagram - Analog Control ................................................................................ 15

Mode 5 - Acugard Lock-out Relay Diagram - Magnum 4 Control ................................................................. 16

Mode 5 - Acugard Lock-out Relay Diagram - Analog Control ....................................................................... 17

Mode 6 - Washroom Control Relay Diagram - Magnum 4 Control ............................................................... 18

Mode 6 - Washroom Control Relay Diagram - Analog Control ..................................................................... 19

NABCO ENTRANCES Return Policy ............................................................................................................ 14

Page 3 www.NabcoEntrances.com 5-7-10

Nabco Multi-Module

To The Installer

The purpose of this manual is to familiarize the installer with the proper installation and operation of this module.

It is essential that this equipment be properly installed and operational before the door is used by the public. It is

the installer’s responsibility to inspect the operation of the entrance system to be sure it complies with any applicable standards. In the United States, ANSI Standard 156.10 may be applicable for this type of door. Other local

standards or codes may apply.

Overview .

The Multi-Module is a programmable relay module that can be used for many applications. Very user friendly, the

module provides a single mode select push button to select the different modes of operation. (No dip switches)

Modes of Operation

Mode 1 - Electric Strike Sequencer

Typical momentary timed operation. Used for interfacing electric locks with automatic door operators. Refer to

diagram labeled “Mode 1 - Electric Strike Sequence Diagram” on page 7 & 8.

In this mode, the Multi-Module can also be used as a fully functional bi-directional door sequencer, no need to

use a second relay. Refer to diagram labeled “Mode 1 - Bi-directional Door Sequencer Diagram” on page 9 & 10.

Mode 2 - Apartment or access control

Used to interface automatic door operators directly to apartment interphone panels. Isolates interphone panel

voltages from automatic door operator. Also can be used to interface with access control systems that have timed

lock functions Refer to diagram labeled: “Mode 2 - Apartment or Access Control Diagram” on page 11 & 12.

Mode 3 - Ratchet or latching operation

Push button activates strike relay for the timed period then latches operator relay 2 indefinitely, until switch is activated a second time. Refer to diagram labeled: “Mode 3 - Ratchet or Latching Operation Diagram” on page 13.

Mode 4 - Smoke Evacuation

For wiring a door operator to a fire alarm panel for smoke evacuation purposes. In this mode the strike relay will

energize momentarily, the operator relay will stay energized for as long as the input is maintained. Refer to diagram labeled: “Mode 4 - Smoke Evacuation Diagram” on page 14 & 15.

Mode 5 - Acugard Lock-out relay

Sensor inhibit, inhibiting of a door mounted sensor preventing sensor from acting like a motion sensor.

Sensor only active once push button has been activated Refer to diagram labeled: “Mode 5 - Acugard

Lock-out Relay Diagram” on page 16 & 17.

Mode 6 - Washroom control relay

Single occupant barrier free washroom control. Allows the door to be electronically locked from the inside while

removing the exterior button from the circuit. Door position switch or interior push button resets system. Installer

should recommend that a “store room” function passage set be used. Handle always locked from the exterior,

and free on the interior. Refer to diagram labeled: “Mode 6 - Washroom Control Relay Diagram” on page 18 & 19.

Page 4 www.NabcoEntrances.com 5-7-10

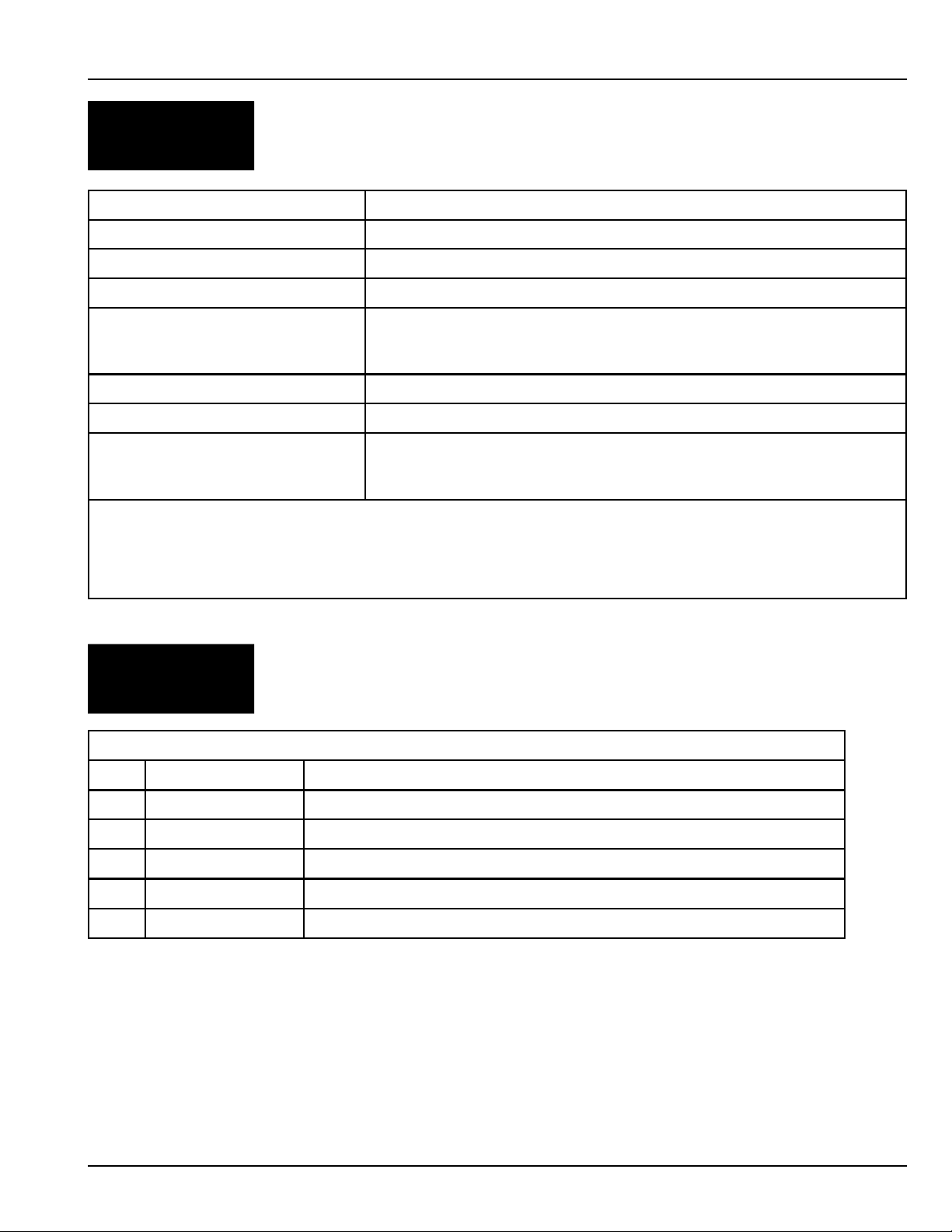

Size 3 1/4" x 2 1/4" x 3/4"

Mounting Double sided foam tape

Operating voltage 12/24 volts Ac or Dc

Current Draw 18 mA Standby, 40 mA Max.

2 - dry contacts

Inputs

3 - wet inputs

12-24 VAC or DC, optically isolated, non-polarity sensitive

Outputs 2 - form C (SPDT)

Nabco Multi-Module

Relay contact rating

4 amps @ 30VDC

Relay 1 on time - 0.5-30 sec.

Time delays

Delay on operate Relay 2 - 1-30 sec

Relay 2 on time - 0.5-30 sec.

To protect the Multi-Module from voltage spikes, please use

the provided transient voltage suppressor

QTY PART NO. DESCRIPTION

1 14-12240 Multi-Module & Voltage Suppressor

1 15-12241 Multi-Module Installation Manual

1 14-11313 Magnetic Switch Assembly

P/N 11-12242 Multi-Module Assembly

1 14-6284-03 Plastic Bag

1 14-2243 Label

Page 5 www.NabcoEntrances.com 5-7-10

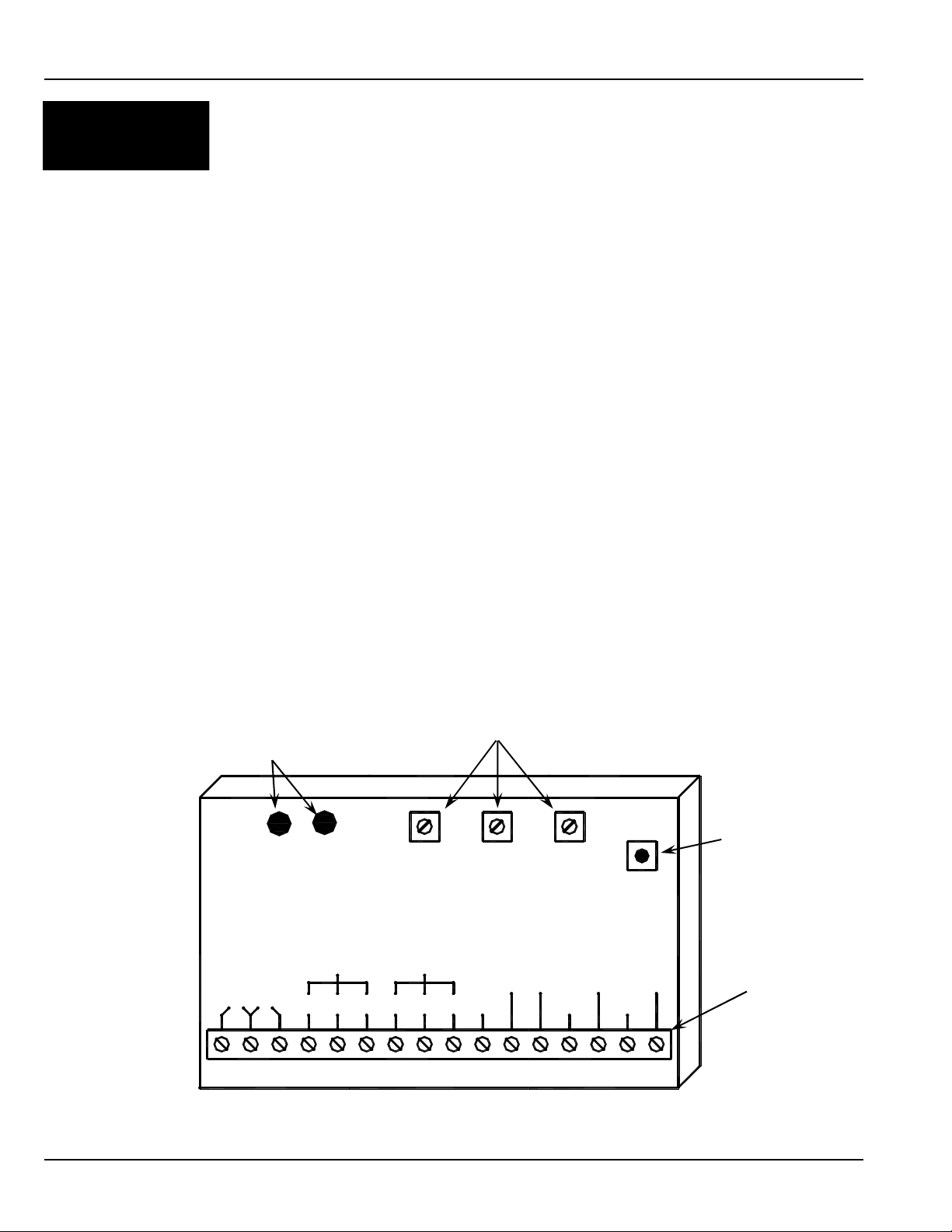

Nabco Multi-Module

Refer to the Figure 1 below:

To enter the program mode, push and hold SW1 Mode Switch for 2 seconds. The mode that is presently

selected will be “flashed”.

Example: if the Multi-Module is in mode 3, the relays will click and the Indicator LEDs will flash 3 times. The user

now has 3 seconds to press the mode select button again to select the next mode. Pressing the button again

within 3 seconds will advance programming to the next mode. This newly selected mode will be flashed by the

relays and LEDs.

Example: the board is in mode 3 and the button is pressed for more than 2 seconds. The LEDs will flash 3 times.

To advance to the next mode the switch is again pressed within 3 seconds. The relays and LEDs flash 4 times

and mode 4 is now selected. Repeat this action until the desired mode is reached. When the desired mode is

reached and the mode select button remains off for 3 seconds the last mode that was “flashed” will be the mode

that is now selected. Power outages will not delete the selected mode.

The installer must ensure that all codes and standards are adhered to. Instruct the owner on door system operation and how to test it. Doors should be checked on a daily basis to ensure safe operation. Strongly

recommend that system be inspected on a yearly basis by an AAADAM certified technician.

Indicator LEDs

Figure 1 - Multi-Module

Potentiometers

SW1 Mode Switch

RL1 RL2

iti-200S

LEDLED

RELAY 1

ON TIME

DOO

(DELAY

ON

OPERATE)

RELAY 2

RELAY 2

ON TIME

SW 1

MODE

SWITCH

RELAY1 RELAY2

24V 12V

Page 6 www.NabcoEntrances.com 5-7-10

N.O. COM N.C. N.C.COMN.O. WET1

WET

DRY

COM COM

WET2 WET3

DRY1 DRY2

Terminal Strip

DN 0302

Page 7 www.NabcoEntrances.com 5-7-10

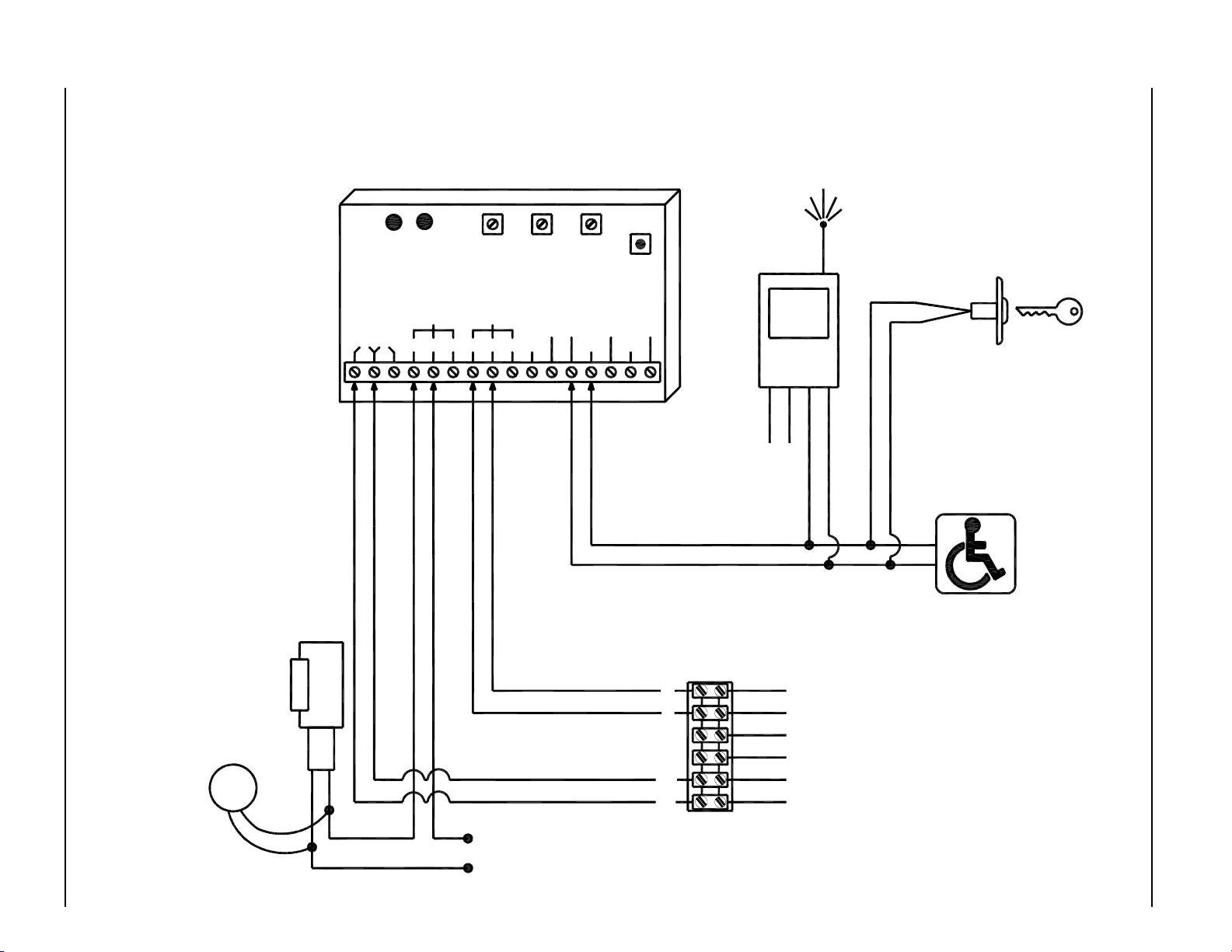

MODE 1 - ELECTRIC STRIKE SEQUENCER DIAGRAM - MAGNUM 4 CONTROL

Note:

1. A black circle indicates

a wire connection.

2. Power supply inputs not

polarity sensitive.

3. Multi-Module must be

set to Mode 1

If magnetic

lock or fail safe

strike used,

connect lock

ELECTRIC

STRIKE

wires to COM

and N.C.

terminals of

Multi-Module

TVS

Connect Transient

Voltage Suppressor

(supplied)

directly to strike.

Not polarity sensitive.

iti-200S

24V 12V

MULTI MODULE

RL1 RL2

LEDLED

RELAY1 RELAY2

N.O. C OM N.C. N.C.COMN.O. WET1

RELAY 1

ON TIME

PN 14-12240

RELAY 2

DOO

ON

WET

COM COM

ON TIME

DRY

DRY1 DRY2

(DELAY

OPERATE)

RELAY 2

STRIKE POWER

(To match strike

voltage)

SW 1

MODE

SWITCH

WET2 WET3

(IF USED)

RADIO

RECEIVER

4-TERM

N.O.

Power

6

5

4

3

2

1

BLACK

RED

WHITE

VIOLET

ORANGE

BROWN

COM

Power

Terminal Strip on Magnum Control

EXTERIOR KEY SWITCH

Normally Open - Dry Contacts

INTERIOR PUSH SWITCH

Normally Open - Dry Contacts

Nabco Multi-Module

DN 0302

Page 8 www.NabcoEntrances.com 5-7-10

Nabco Multi-Module

MODE 1 - ELECTRIC STRIKE SEQUENCER DIAGRAM - ANALOG CONTROL

Note:

1. A black circle indicates

a wire connection.

2. Power supply inputs not

polarity sensitive.

24 VAC120 VAC

Transformer

P/N 14-2101

24 VAC

If magnetic

lock or fail safe

strike used,

connect lock

ELECTRIC

STRIKE

wires to COM

and N.C.

terminals of

Multi-Module

iti-200S

LED LED

12V24V

RL2RL1

RELAY 1

ON TIME

RELAY2RELAY1

DOO

(DELAY

ON

OPERATE)

RELAY 2

WET

WET1N.O. C OM N.C.N.C.COMN.O.

RELAY 2

ON TIME

DRY

COMCOM

SW 1

MODE

SWITCH

WET3WET2

DRY2DRY1

(IF USED)

RADIO

RECEIVER

4-TERM

Power

Power

N.O.

COM

EXTERIOR KEY SWITCH

Normally Open - Dry Contacts

INTERIOR PUSH SWITCH

Normally Open - Dry Contacts

BLACK

RED

Activation Connector on Analog Control

TVS

Connect Transient

Voltage Suppressor

(supplied)

directly to strike.

Not polarity sensitive.

STRIKE POWER

(To match strike

voltage)

DN 0302

Page 9 www.NabcoEntrances.com 5-7-10

MODE 1 - BI-DIRECTIONAL DOOR SEQUENCER DIAGRAM - MAGNUM 4 CONTROL

RL1 RL2

LEDLED

iti-200S

RELAY1 RELAY2

24V 12 V

N.O. COM N.C. N .C.COMN.O. WET1

RELAY 1

ON TIME

DOO

(DELAY

ON

OPERATE)

RELAY 2

WET

COM COM

RELAY 2

ON TIME

DRY

DRY1 DRY2

SW 1

MODE

SWITCH

WET2 WE T3

INTERIOR PUSH SWITCH

Normally Open - Dry Contacts

EXTERIOR PUSH SWITCH

Normally Open - Dry Contacts

BLACK

RED

WHITE

VIOLET

ORANGE

BROWN

Terminal Strip on

Exterior Magnum

Control

OPTIONAL VESTIBULE PUSH SWITCH

Normally Open - Dry Contacts

6

5

4

3

2

1

BLACK

VIOLET

ORANGE

BROWN

Terminal Strip on

Interior Magnum

Control

RED

WHITE

NOTE:

1. When the module is triggered

by push switch (DRY1)

Relay # 1 will activate

first, then after an adjustable

delay, Relay # 2 will activate.

When the module is triggered

by the push switch (DRY2)

Relay # 2 will activate

first, then after an adjustable

delay, Relay # 1 will activate.

2. A black circle indicates a

wire connection.

3. Power supply inputs not

polarity sensitive.

DN 0302

Nabco Multi-Module

Page 10 www.NabcoEntrances.com 5-7-10

Nabco Multi-Module

MODE 1 - BI-DIRECTIONAL DOOR SEQUENCER DIAGRAM - ANALOG CONTROL

RL2RL1

LED LED

iti-200S

12V24V

24 VAC120 VAC

Transformer

P/N 14-2101

24 VAC

BLACK

RED

Activation Connector

on Exterior Analog

Control

RELAY 1

ON TIME

RELAY2RELAY1

DOO

ON

WET

RELAY 2

ON TIME

DRY

COMCOM

BLACK

RED

(DELAY

OPERATE)

RELAY 2

WET1N.O. COM N.C.N.C.COMN.O.

Activation Connector

on Interior Analog

SW 1

MODE

SWITCH

WET3WET2

DRY2DRY1

Control

INTERIOR PUSH SWITCH

Normally Open - Dry Contacts

EXTERIOR PUSH SWITCH

Normally Open - Dry Contacts

NOTE:

1. When the module is triggered

by push switch (DRY1)

Relay # 1 will activate

first, then after an adjustable

delay, Relay # 2 will activate.

When the module is triggered

by the push switch (DRY2)

Relay # 2 will activate

first, then after an adjustable

delay, Relay # 1 will activate.

2. A black circle indicates a

wire connection.

3. Power supply inputs not

polarity sensitive.

OPTIONAL VESTIBULE PUSH SWITCH

Normally Open - Dry Contacts

DN 0302

Page 11 www.NabcoEntrances.com 5-7-10

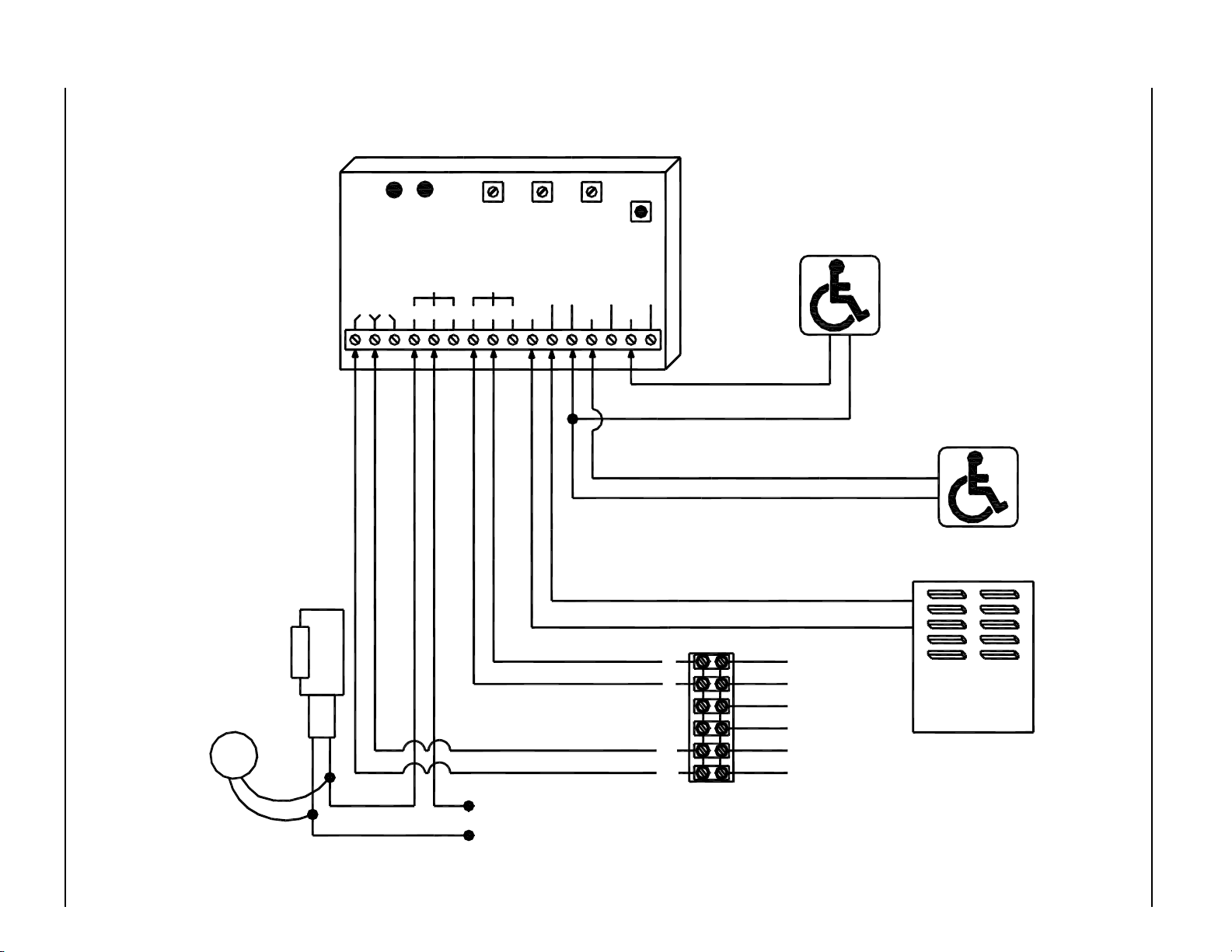

MODE 2 - APARTMENT OR ACCESS CONTROL DIAGRAM - MAGNUM 4 CONTROL

RL2RL1

LED LED

iti-200S

12V24V

RELAY 1

ON TIME

RELAY2RELAY1

DOO

(DELAY

ON

OPERATE)

RELAY 2

WET

WET1N.O. COM N.C.N.C.COMN.O.

RELAY 2

ON TIME

DRY

COMCOM

SW 1

MODE

SWITCH

WET3WET2

DRY2DRY1

Exterior Switch

(Only active when someone "buzzes

down") Switch opens door.

Normally Open - Dry Contacts

Interior Switch

Unlocks and opens door

Normally Open - Dry Contacts

If magnetic

lock or fail safe

strike used,

connect lock

wires to COM

and N.C.

terminals of

Multi-Module

Connect Transient

Voltage Suppressor

(supplied)

directly to strike.

Not polarity sensitive.

ELECTRIC

STRIKE

TVS

STRIKE POWER

(To match strike

voltage)

EXISTING LOCK POWER

6

5

4

3

2

1

BLACK

RED

WHITE

VIOLET

ORANGE

BROWN

Terminal Strip on

Magnum Control

Apartment

Interphone Panel

(Powered

Signal)

Unlocks door

only

Nabco Multi-Module

DN 0302

Page 12 www.NabcoEntrances.com 5-7-10

Nabco Multi-Module

MODE 2 - APARTMENT OR ACCESS CONTROL DIAGRAM - ANALOG CONTROL

RL1 RL2

Transformer

P/N 14-2101

24 VAC

If magnetic

lock or fail safe

strike used,

connect lock

wires to COM

and N.C.

terminals of

Multi-Module

Connect Transient

Voltage Suppressor

(supplied)

directly to strike.

Not polarity sensitive.

24 VAC120 VAC

ELECTRIC

STRIKE

TVS

iti-200S

24V 12V

LEDLED

RELAY1 RELAY2

N.O. COM N.C. N.C.COMN.O. WET1

RELAY 1

ON TIME

(DELAY

OPERATE)

RELAY 2

STRIKE POWER

(To match strike

voltage)

DOO

ON

WET

DRY

COM COM

RELAY 2

ON TIME

DRY1 DRY2

SW 1

MODE

SWITCH

WET2 WET3

EXISTING LOCK POWER

BLACK

RED

Activation Connector on Analog Control

Exterior Switch

(Only active when someone "buzzes

down") Switch opens door.

Normally Open - Dry Contacts

Interior Switch

Unlocks and opens door

Normally Open - Dry Contacts

Apartment

Interphone Panel

(Powered

Signal)

Unlocks door

only

DN 0302

Page 13 www.NabcoEntrances.com 5-7-10

MODE 3 - RATCHET OR LATCHING OPERATION DIAGRAM - ANALOG CONTROL

Mode 3 not required with Magnum control - Magnum control includes this feature

NOTES:

1. Pushing either switch once

unlocks and opens door.

2. Door will remain open until

switch is pushed again.

3. This mode only used with

Analog control. Magnum and

U series controls have this

feature built in.

4. A black circle indicates a

wire connection.

5. Power supply inputs not

polarity sensitive.

24 VAC120 VAC

Transformer

P/N 14-2101

24 VAC

If magnetic

lock or fail safe

strike used,

connect lock

wires to COM

and N.C.

ELECTRIC

STRIKE

terminals of

Multi-Module

iti-200S

LED LED

12V24V

This potentiometer has no effect

RL2RL1

RELAY 1

ON TIME

RELAY2RELAY1

DOO

(DELAY

ON

OPERATE)

RELAY 2

WET

WET1N.O. COM N.C.N.C.COMN.O.

RELAY 2

ON TIME

DRY

COMCOM

SW 1

MODE

SWITCH

WET3WET2

DRY2DRY1

Interior Switch

Normally Open - Dry Contacts

Exterior Switch

Normally Open - Dry Contacts

BLACK

RED

Nabco Multi-Module

Connect Transient

Voltage Suppressor

(supplied)

directly to strike.

Not polarity sensitive.

TVS

Activation Connector on Analog Control

STRIKE POWER

(To match

strike voltage)

DN 0302

Page 14 www.NabcoEntrances.com 5-7-10

DN 0302

MODE 4 - ELECTRIC STRIKE DIAGRAM WITH HOLD OPEN SWITCH - MAGNUM 4 CONTROL

Note:

1. A black circle indicates

a wire connection.

2. Power supply inputs not

polarity sensitive.

3. Multi-Module must be set

to Mode 4.

If magnetic

lock or fail safe

strike used,

connect lock

ELECTRIC

STRIKE

wires to COM

and N.C.

terminals of

Multi-Module

TVS

Connect Transient

Voltage Suppressor

(supplied)

directly to strike.

MULTI MODULE

RL1 RL2

LEDLED

iti-200S

RELAY1 RELAY2

24V 12V

N.O. COM N.C. N.C.COMN.O. WET1

PN 14-12240

RELAY 1

ON TIME

DOO

(DELAY

ON

OPERATE)

RELAY 2

WET

COM COM

STRIKE POWER

(To match strike

voltage)

RELAY 2

ON TIME

DRY

DRY1 DRY2

SW 1

MODE

SWITCH

WET2 WET3

On/Off/Hold Open

Rocker Switch

WHITE

6

5

4

3

2

1

RED

BLACK

BLACK

RED

WHITE

VIOLET

ORANGE

BROWN

Terminal Strip on Magnum Control

EXTERIOR KEY SWITCH

(IF USED)

RADIO

RECEIVER

4-TERM

Power

Power

N.O.

Normally Open - Dry Contacts

COM

INTERIOR PUSH SWITCH

Normally Open - Dry Contacts

Nabco Multi-Module

Page 15 www.NabcoEntrances.com 5-7-10

Nabco Multi-Module

MODE 4 - SMOKE EVACUATION DIAGRAM - MAGNUM 4 CONTROL

NOTES:

1. In smoke evacuation or

maintained operator mode the

module can be triggered by a

wet input or a dry contact like a

sensor or any other relay

contact.

2. A black circle indicates a

wire connection.

3. Common and N.O. on

Acusensor 1B are Yellow wires.

4. Power supply inputs not

polarity sensitive.

iti-200S

LED LED

12V24V

RL2RL1

RELAY 1

ON TIME

RELAY2RELAY1

DOO

(DELAY

ON

OPERATE)

RELAY 2

WET

WET1N.O. COM N.C.N.C.COMN.O.

RELAY 2

ON TIME

DRY

COMCOM

SW 1

MODE

SWITCH

WET3WET2

DRY2DRY1

This potentiometer has no effect

FIRE

Fire Alarm Panel

Shown with maintained

and powered signal (WET)

12-24V AC/DC

If magnetic

lock or fail safe

strike used,

connect lock

wires to COM

and N.C.

terminals of

Multi-Module

Connect Transient

Voltage Suppressor

(supplied)

directly to strike.

Not polarity sensitive.

ELECTRIC

STRIKE

TVS

STRIKE POWER

(To match

strike voltage)

6

5

4

3

2

1

VIOLET

ORANGE

Terminal Strip on

Magnum Control

PUSH SWITCH

Normally Open - Dry Contacts

BLACK

RED

WHITE

BROWN

DN 0302

Page 16 www.NabcoEntrances.com 5-7-10

MODE 4 - SMOKE EVACUATION DIAGRAM - ANALOG CONTROL

NOTES:

1. In smoke evacuation or

maintained operator mode the

module can be triggered by a

wet input or a dry contact like a

sensor or any other relay

contact.

2. A black circle indicates a

wire connection.

3. Common and N.O. on

Acusensor 1B are Yellow wires.

4. Power supply inputs not

polarity sensitive.

120 VAC 24 VAC

iti-200S

24V 12V

RL1 RL 2

LEDLED

RELAY1 RELAY2

N.O. COM N.C. N.C.COMN.O. WET1

RELAY 1

ON TIME

DOO

(DELAY

ON

OPERATE)

RELAY 2

WET

COM COM

RELAY 2

ON TIME

DRY

DRY1 DRY2

SW 1

MODE

SWITCH

WET2 WET3

This potentiometer has no effect

FIRE

Fire Alarm Panel

Shown with maintained

and powered signal (WET)

12-24V AC/DC

Transformer

P/N 14-2101

24 VAC

If magnetic

lock or fail safe

strike used,

connect lock

wires to COM

and N.C.

terminals of

Multi-Module

Connect Transient

Voltage Suppressor

(supplied)

directly to strike.

Not polarity sensitive.

ELECTRIC

STRIKE

TVS

Activation Connector on Analog Control

STRIKE POWER

(To match

strike voltage)

PUSH SWITCH

Normally Open - Dry Contacts

BLACK

RED

Nabco Multi-Module

DN 0302

Page 17 www.NabcoEntrances.com 5-7-10

Nabco Multi-Module

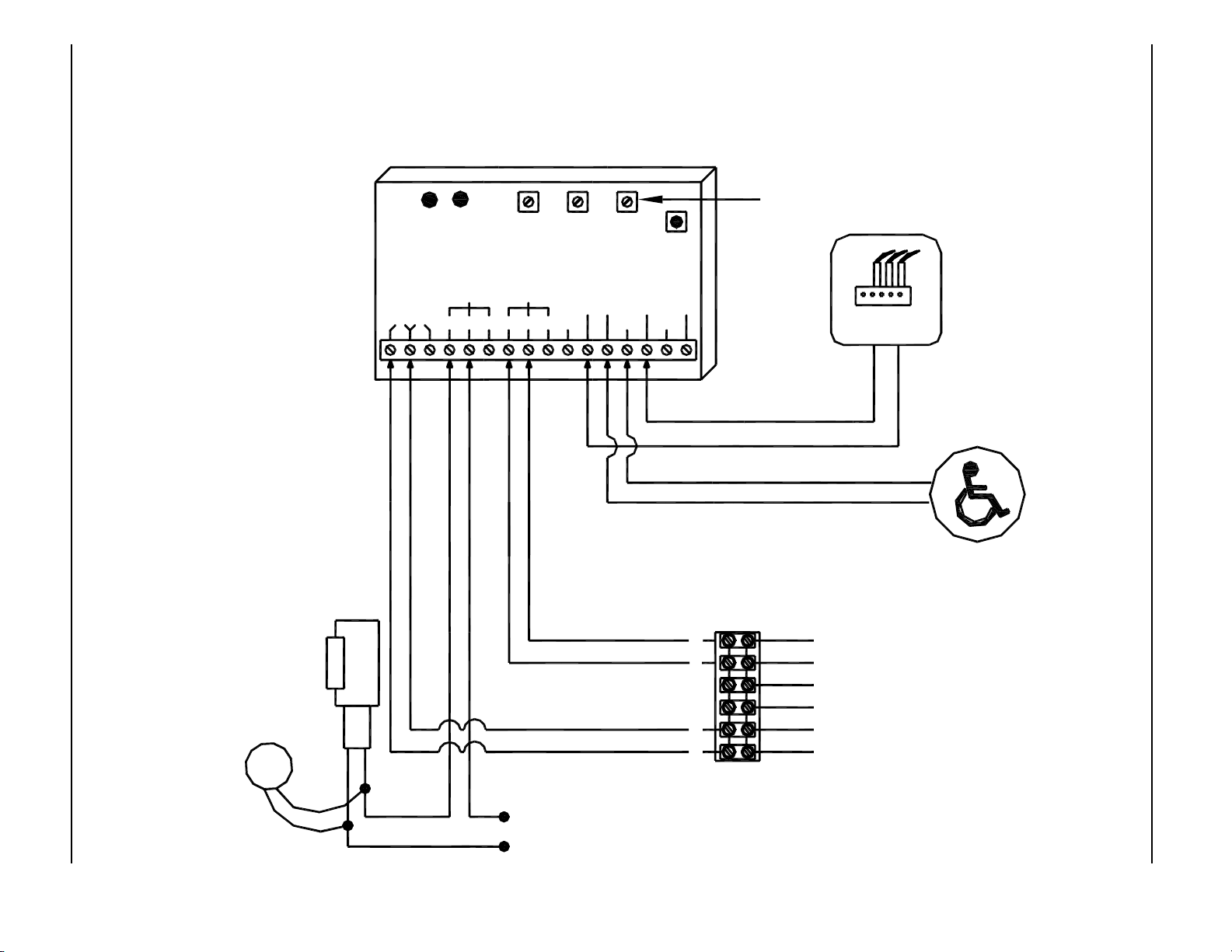

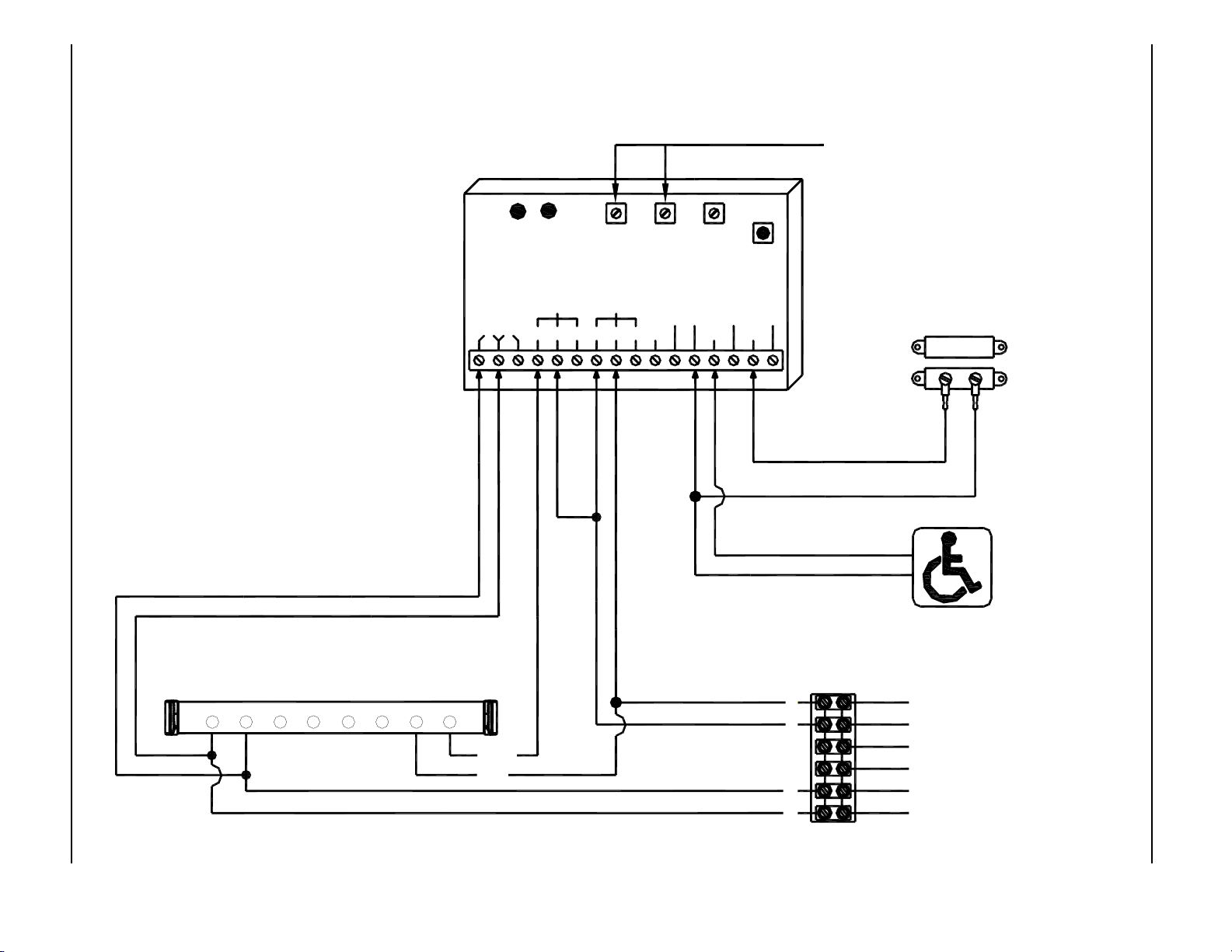

MODE 5 - ACUGARD LOCK OUT RELAY DIAGRAM - MAGNUM 4 CONTROL

These Potentiometers have no effect

DN 0302

NOTES:

1. Sensor only active after push

plate is actuated. It will stay

active until the door shuts and

door position switch closes.

Multi-Module will reset after 2

minutes if the door does not

open for any reason.

2. A black circle indicates a

wire connection.

3. Power supply inputs not

polarity sensitive.

Acugard 3 LE on Non-swing side of door

P/N 21-10158-35

RL1 RL2

iti-200S

24V 12V

LEDLED

RELAY1 RELAY2

N.O. COM N.C. N.C.COMN.O. WET1

RELAY 1

ON TIME

DOO

(DELAY

ON

OPERATE)

RELAY 2

WET

COM COM

RELAY 2

ON TIME

DRY

DRY1 DRY2

SW 1

MODE

SWITCH

WET2 WET3

Magnetic Door Position Switch

P/N 14-11313

Contacts should close when door is

closed - Connect to COM and N.O.

terminals on switch.

Activation Push Plate

Normally Open - Dry Contacts

6

87654321

COM

N.O

5

4

3

2

1

BLACK

RED

WHITE

VIOLET

ORANGE

BROWN

Terminal Strip on Magnum Control

Page 18 www.NabcoEntrances.com 5-7-10

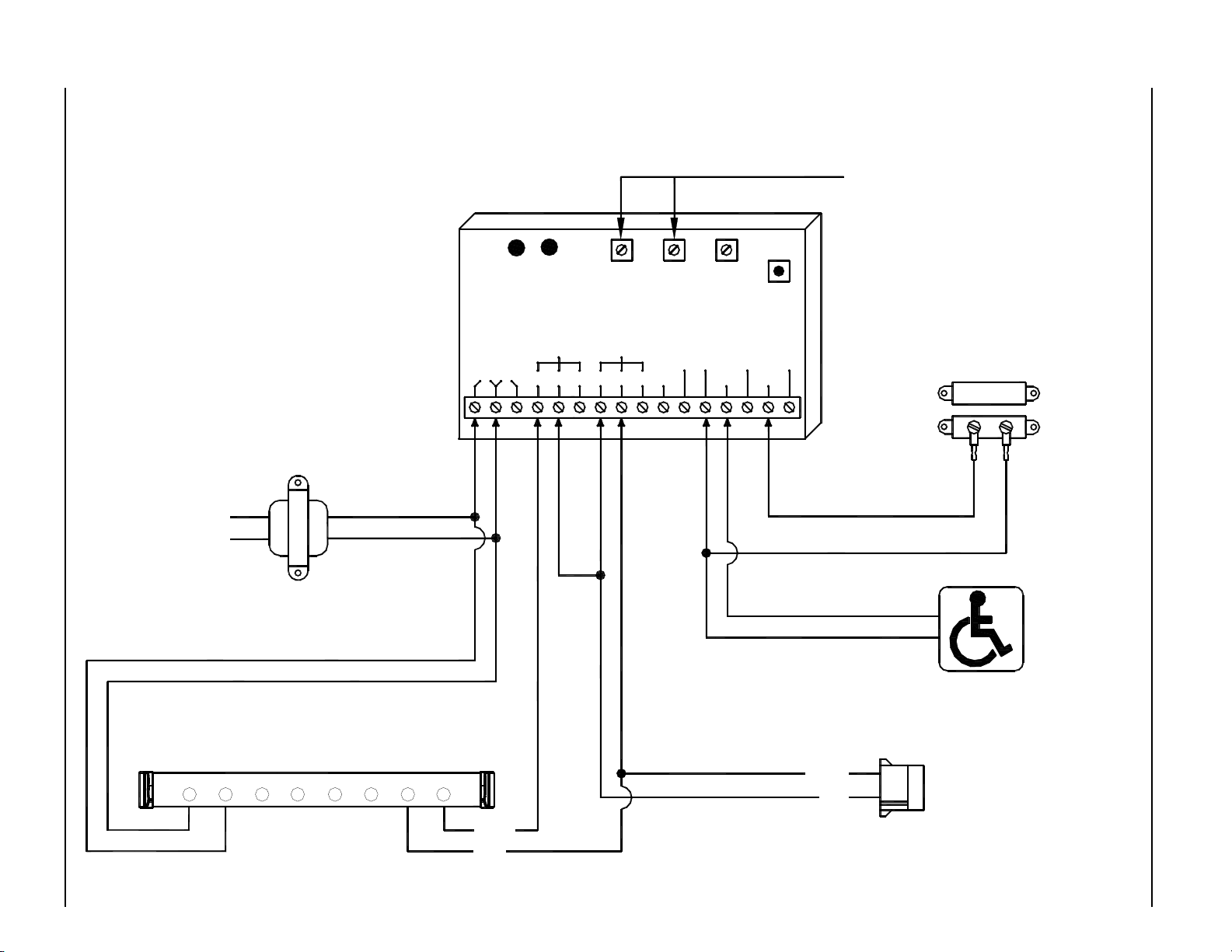

MODE 5 - ACUGARD LOCK OUT RELAY DIAGRAM - ANALOG CONTROL

These Potentiometers have no effect

NOTES:

1. Sensor only active after push

plate is actuated. It will stay

active until the door shuts and

door position switch closes.

Multi-Module will reset after 2

minutes if the door does not

open for any reason.

2. A black circle indicates a

wire connection.

3. Power supply inputs not

polarity sensitive.

120 VAC 24 VAC

iti-200S

LED LED

12V24V

RL2RL1

RELAY 1

ON TIME

RELAY2RELAY1

DOO

(DELAY

ON

OPERATE)

RELAY 2

WET

WET1N.O. COM N.C.N.C.COMN.O.

RELAY 2

ON TIME

DRY

COMCOM

SW 1

MODE

SWITCH

WET3WET2

DRY2DRY1

Magnetic Door Position Switch

P/N 14-11313

Contacts should close when door is

closed - Connect to COM and N.O.

terminals on switch.

Transformer

P/N 14-2101

24 VAC

Acugard 3 LE on Non-swing side of door

P/N 21-10158-35

1 2 3 4 5 6 7 8

COM

N.O

Activation Push Plate

Normally Open - Dry Contacts

BLACK

RED

Activation Connector on Analog Control

Nabco Multi-Module

DN 0302

Page 19 www.NabcoEntrances.com 5-7-10

Nabco Multi-Module

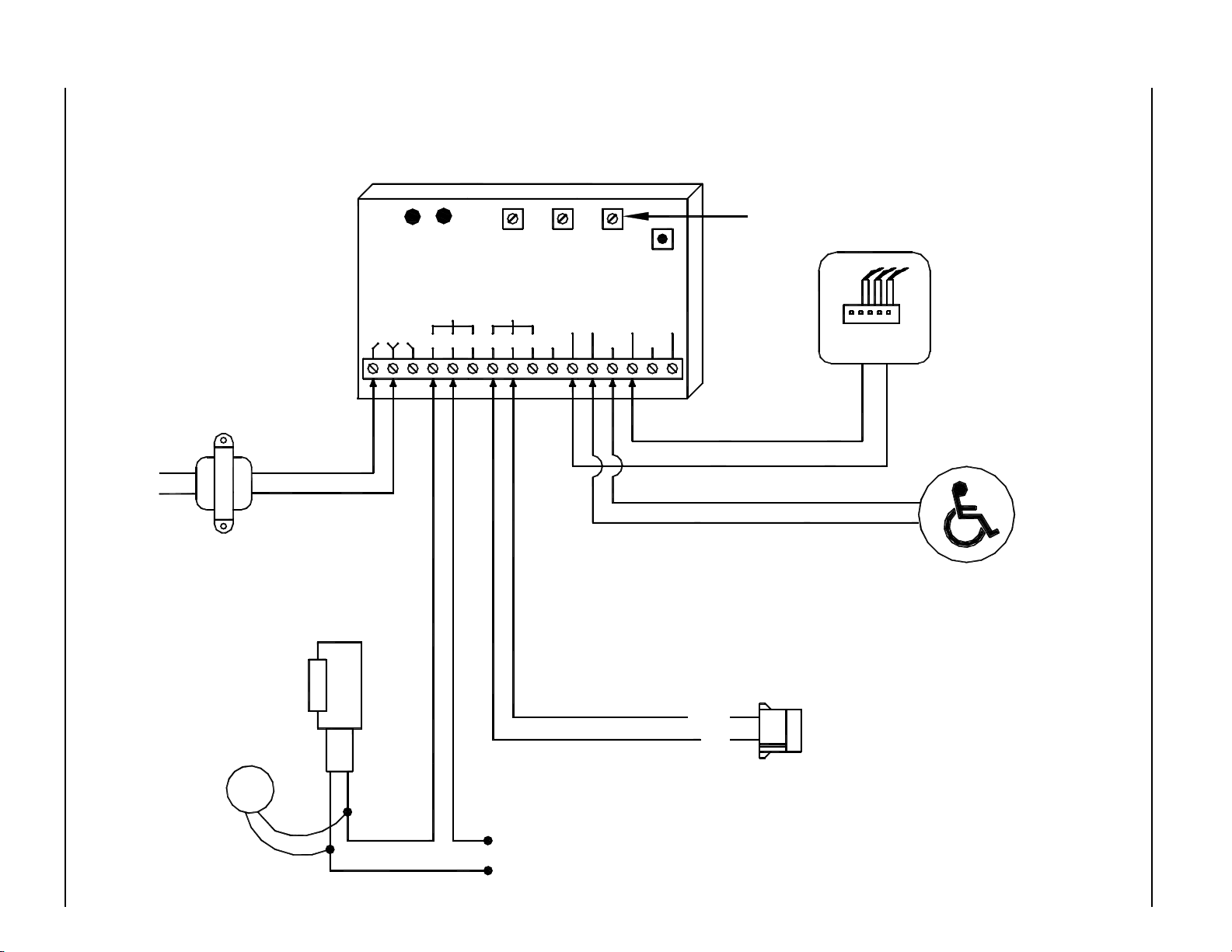

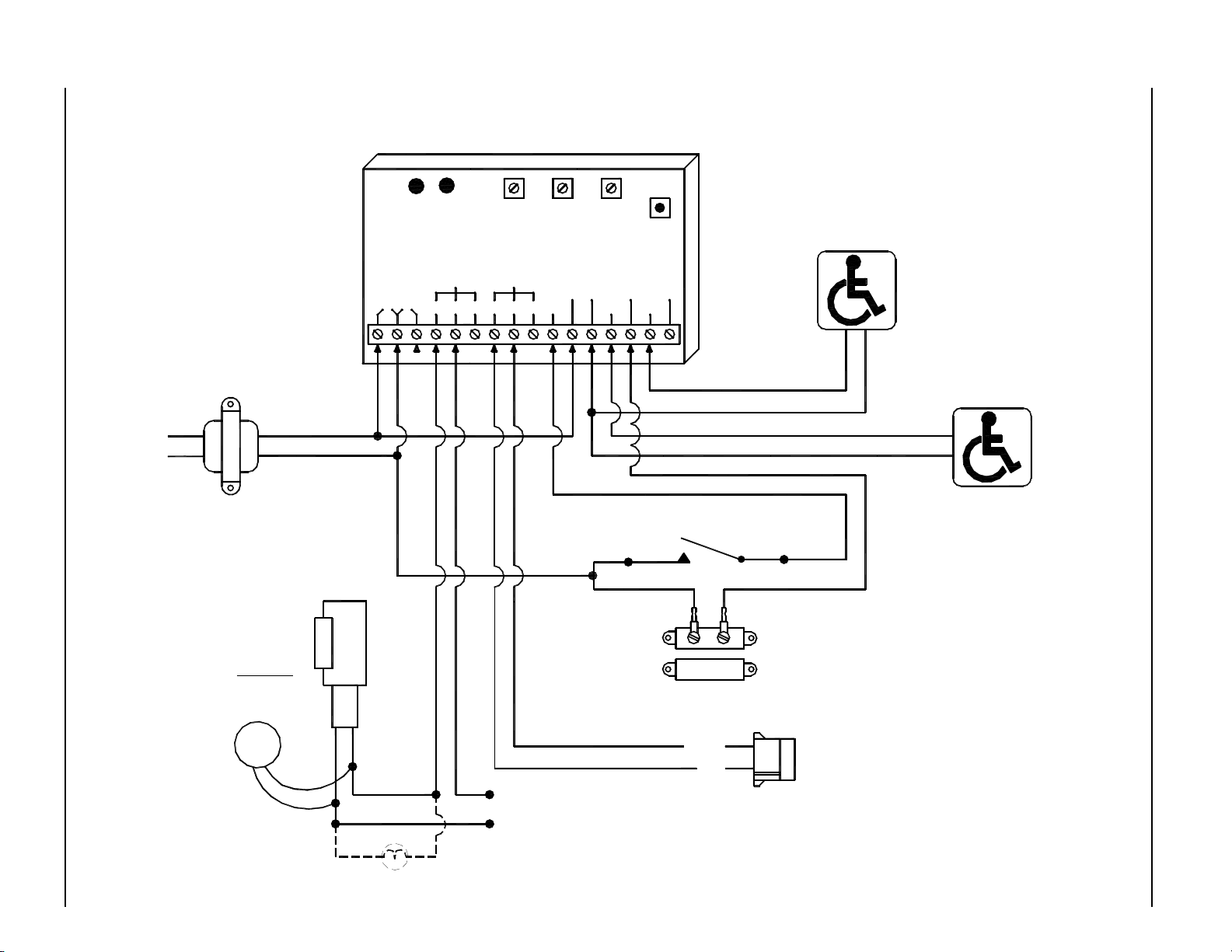

MODE 6 - WASHROOM CONTROL RELAY DIAGRAM - MAGNUM 4 CONTROL

NOTES:

1. Fail Safe Strike Used

2. A black circle indicates a

wire connection.

3. Power supply inputs not

polarity sensitive.

Connect Transient

Voltage Suppressor

(supplied)

directly to strike.

Not polarity sensitive.

DN 0302

ELECTRIC

STRIKE

Fail Safe

TVS

LED LED

iti-200S

12V24V

Optional Occupied Light

RL2RL1

STRIKE POWER

(To match strike

voltage)

RELAY 1

ON TIME

RELAY2RELAY1

DOO

(DELAY

ON

OPERATE)

RELAY 2

WET

WET1N.O. COM N.C.N.C.COMN.O.

RELAY 2

ON TIME

DRY

COMCOM

SW 1

MODE

SWITCH

WET3WET2

DRY2DRY1

Push to Lock Switch

Magnetic Door Position Switch

P/N 14-11313

Interior Push Plate

Normally Open - Dry Contacts

Exterior Push Plate

Normally Open - Dry Contacts

Contacts close when door is closed

Connect to COM and N.O. terminals on switch.

6

5

4

3

2

1

BLACK

RED

WHITE

VIOLET

ORANGE

BROWN

Terminal Strip on Magnum Control

Page 20 www.NabcoEntrances.com 5-7-10

MODE 6 - WASHROOM CONTROL RELAY DIAGRAM - ANALOG CONTROL

NOTES:

1. Fail Safe Strike Used

2. A black circle indicates a

wire connection.

3. Power supply inputs not

polarity sensitive.

Transformer

P/N 14-2101

24 VAC

ELECTRIC

STRIKE

Fail Safe

Connect Transient

Voltage Suppressor

TVS

(supplied)

directly to strike.

Not polarity sensitive.

iti-200S

24V 12V

RL1 RL2

LEDLED

RELAY1 RELAY2

N.O. COM N.C. N.C.COMN.O. WET1

RELAY 1

ON TIME

DOO

(DELAY

ON

OPERATE)

RELAY 2

WET

COM COM

RELAY 2

ON TIME

DRY

DRY1 DRY2

SW 1

MODE

SWITCH

WET2 WET3

Interior Push Plate

Normally Open - Dry Contacts

Exterior Push Plate

Normally Open - Dry Contacts

24 VAC120 VAC

Push to Lock Switch

Contacts close when door is closed

Connect to COM and N.O. terminals on switch.

Magnetic Door Position Switch

P/N 14-11313

BLACK

RED

Activation Connector on Analog Control

Nabco Multi-Module

STRIKE POWER

(To match

strike voltage)

DN 0302

Optional Occupied Light

Nabco Multi-Module

NABCO Entrances Return Policy - Limited Warranty

NABCO ENTRANCES INC. for its Gyro Tech product line, provides to its distributor a limited warranty, on Gyro

Tech products. This warranty is:

NABCO ENTRANCES INC. will exchange or repair, F.O.B. the plant, any component found defective in

workmanship and/or material, subject to Nabco’s inspection, for a period of one (1) year after

installation or 18 months after manufacture, whichever comes first. Warranty does not include field

service labor. The installing contractor/distributor will be responsible for installation and field service.

This is NABCO ENTRANCES Inc.’s sole warranty.

This warranty does not cover loss or damages resulting from causes beyond the manufacturer's control,

misuse, neglect, accidents, windstorms, or other acts of God, or acts of terrorism. Warranty is for normal use

and service. The warranty does not apply to equipment that has been repaired or altered so as to adversely

affect conditions of operation. Warranty will not obligate NABCO for damages resulting from such alterations,

misuse, or acts of God, or acts of terrorism.

Extended Warranties - New Parts and Equipment Only

Two-year warranties on all Gyro Tech entrance systems are available. The two (2) year warranty is the same

as the one (1) year warranty except for a period of two (2) years after installation or 30 months after

manufacture whichever comes first. All orders requesting a multi year warranty must be included on the

purchase order at the time of the original order to establish proper records. Any other extended warranty must

be specifically approved and priced by NABCO Management.

Warranty Seal on Operators

All operators will contain a warranty seal placed over the cover and housing. The warranty will become invalid if

any operator is returned with the seal broken.

Return of Warranty Parts

NABCO must be promptly notified (within 2 weeks of failure) of all warranty claims. All parts for warranty claims

must be returned to NABCO within the following two (2) weeks for US locations and six (6) weeks for all other

locations. All parts must be returned freight prepaid and include a Return Material Authorization Tag/Number

which is available by contacting the Customer Service Department. All items returned are subject to inspection

and testing to determine the cause of failure. If in NABCO's determination:

A. For all items, when the part returned is defective and within the terms of the warranty, it will be repaired or

replaced. Any repaired item would carry the full warranty from original installation date. If the piece has been

replaced, a credit memo will be issued against the replacement invoice. Warranty parts are shipped prepaid via

ground transportation by Nabco. Expedited delivery costs are paid by the distributor.

B. For all items, if it is determined the part returned is not defective and within the terms of the warranty the

part will remain the property of the Distributor at the time of this determination. The disposition of the item will

be agreed upon with the distributor. The only options considered will be:

1. To return the item at the distributor cost.

2. To return it to stock less inspection and testing costs if the piece has not been used

and remains saleable as a new part. A 20% restocking charge will apply and be paid

by the distributor.

3. Discarded by NABCO.

Non-warranty Returns

Applications for the return and credit of any parts item must be made in writing to Nabco Customer Service

within 60 days of the date of our shipment. Only items listed on attached Nabco RMT tags will be considered.

Parts that have been ordered incorrectly can be exchanged for the correct items provided Nabco Customer

Service is notified in writing within 60 days of the date of our shipment and subsequent return authorization has

been given. Credit for parts that have been ordered by the distributor and are no longer needed for repair in the

field will be subject to the discretion of Nabco. A 20% stocking fee will apply.

Page 21 www.NabcoEntrances.com 5-7-10

Loading...

Loading...