Page 1

DL Cable Assembly

Using Canare MR202-16AT

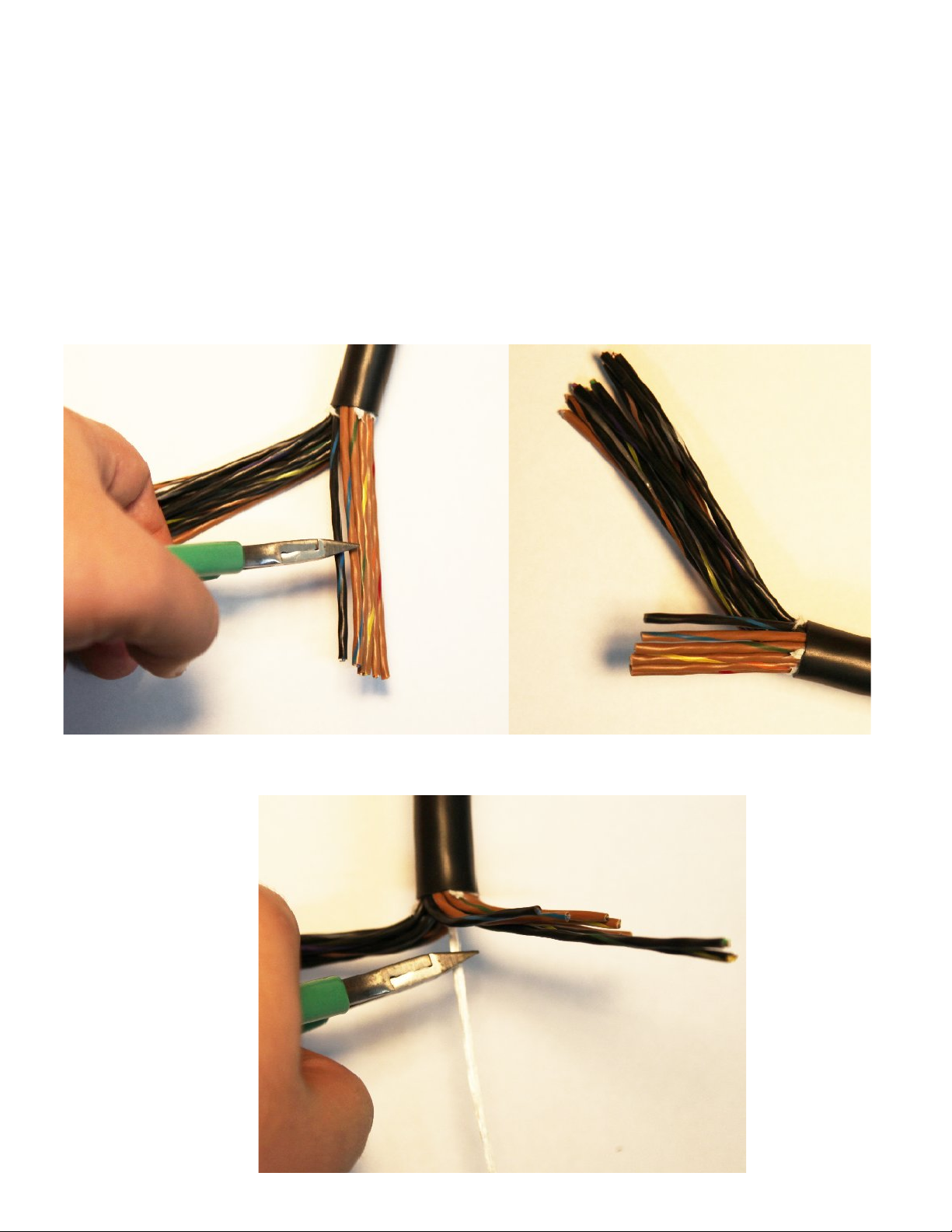

1. Cut a 4 inch piece of ¾ inch diameter black heatshrink and slip it on

to the cable.

2. Remove ~3 inches of the outer jacket by bending the cable and

cutting at the bend with a sharp blade.

Page 2

3. Separate wires 6, 12, 13, 14, 15, and 16. Cut them in half. Use the

resistor color code to number wires. (Ex. Black-Brown stripe = 01,

Black-Red stripe = 02, Black-Blue = 06, Brown-Red = 12, BrownOrange = 13, Brown-Yellow = 14, Brown-Green = 15, Brown-Blue

= 16.)

4. Cut the nylon core.

Page 3

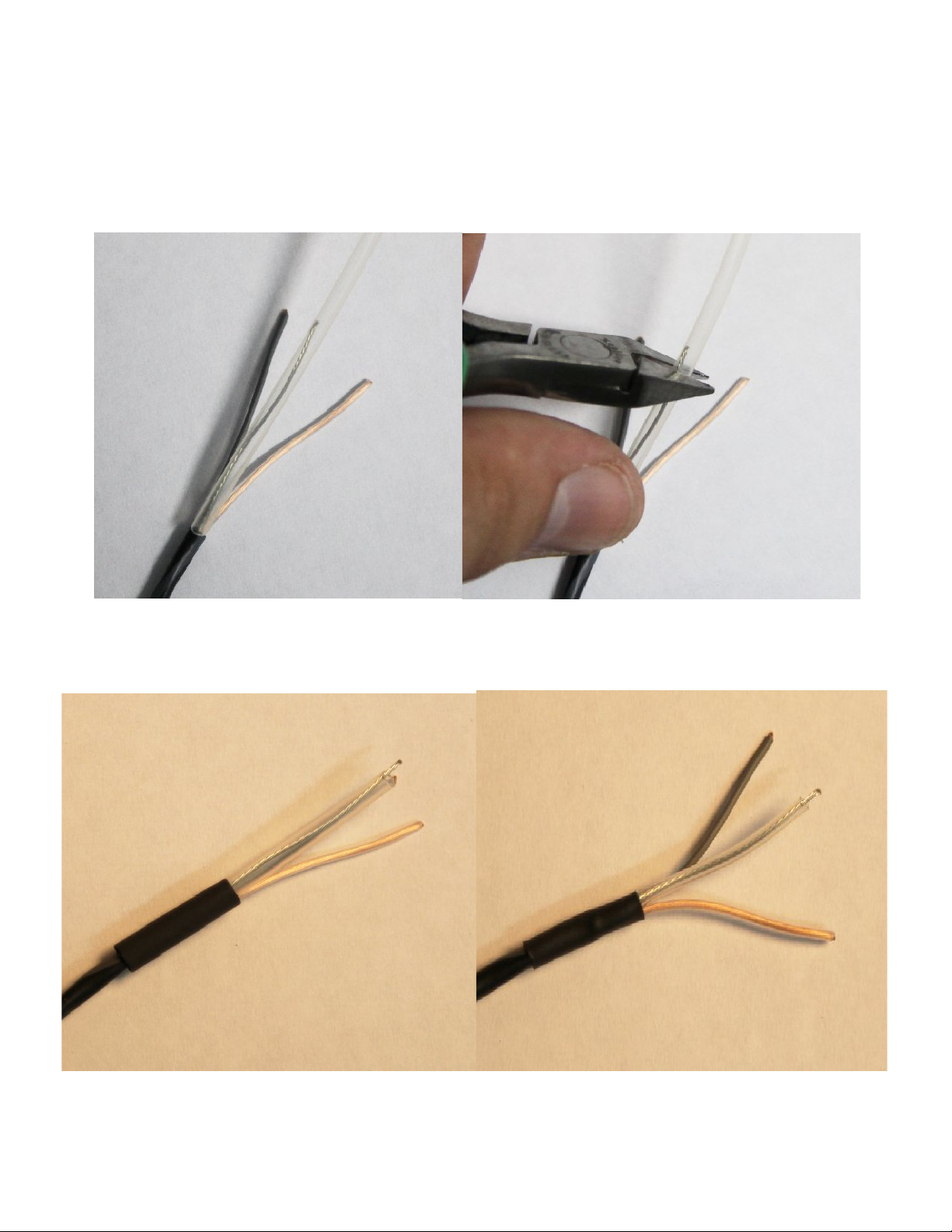

5. Cut 12 ½-inch pieces of 3/32 inch diameter black heatshrink and

place it on wires 1-12.

6. Strip ~1 inch of the jacket off cables 1-12 and remove the foil.

Page 4

7. Separate the 3 wires and place clear 1/32 inch diameter clear

heatshrink on the bare ground wire. To cut the proper length slide

the clear heatshrink all the way on to the wire, then place the

cutters so that it leaves ~1/8 inch of wire at the end. Hold the

cutters place, lift the clear tube free from the wire, then cut.

8. Slide the piece of black heatshrink over the 3 wires and the clear

heatshrink and shrink it with a heatgun.

Page 5

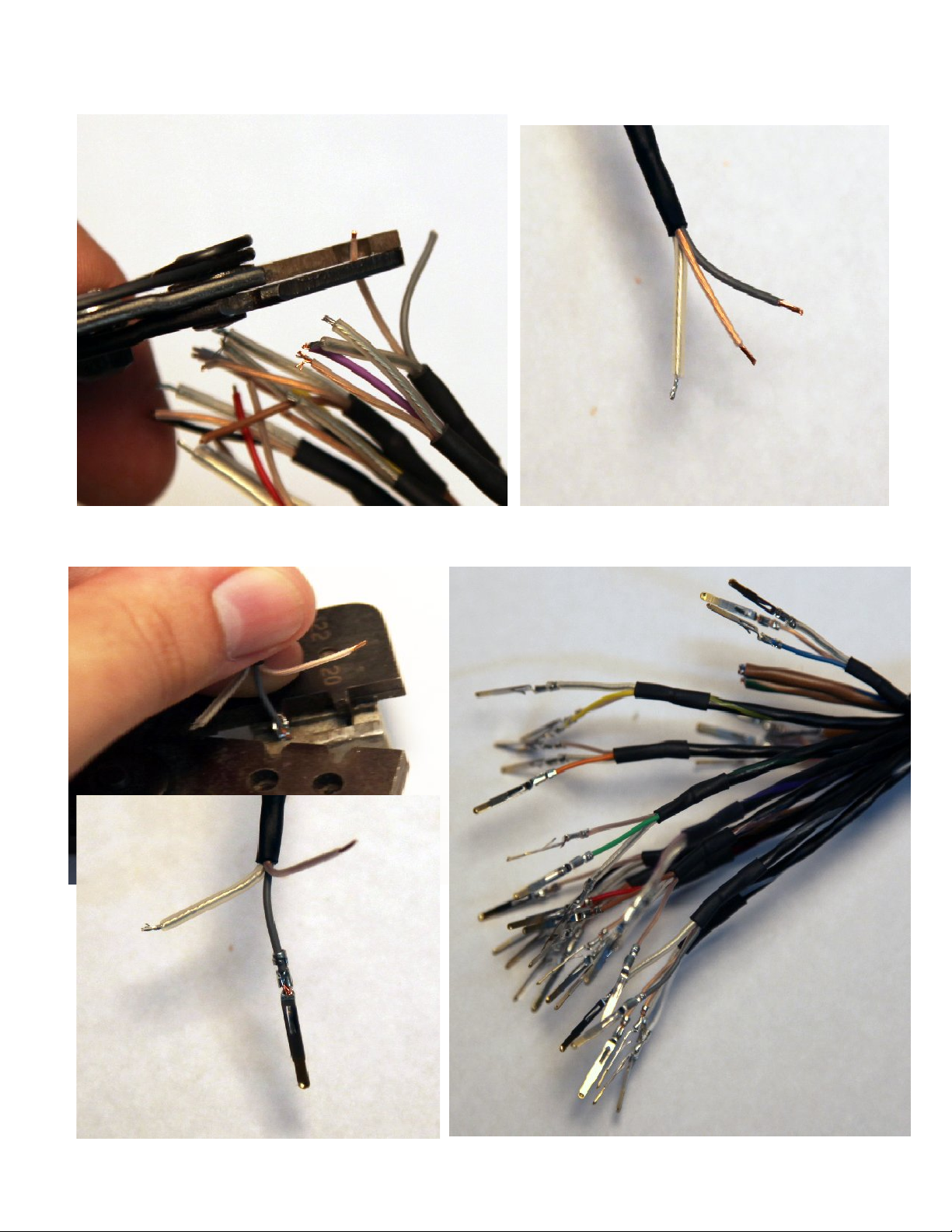

9. Strip ~1/8 inch off the end of the other wires.

10. Proceed to crimp the pins on to cables 1-12. Be sure to use

the smaller gauge crimp.

Page 6

11. Now prepare the power and ground wires (13,14 = GND, 15

= +29V, 16 = -29V) by stripping off ~1/4 inch and also

completely stripping the 3 inner wires and shorting them together.

Wires 13 and 14 have all 6 wires twisted together.

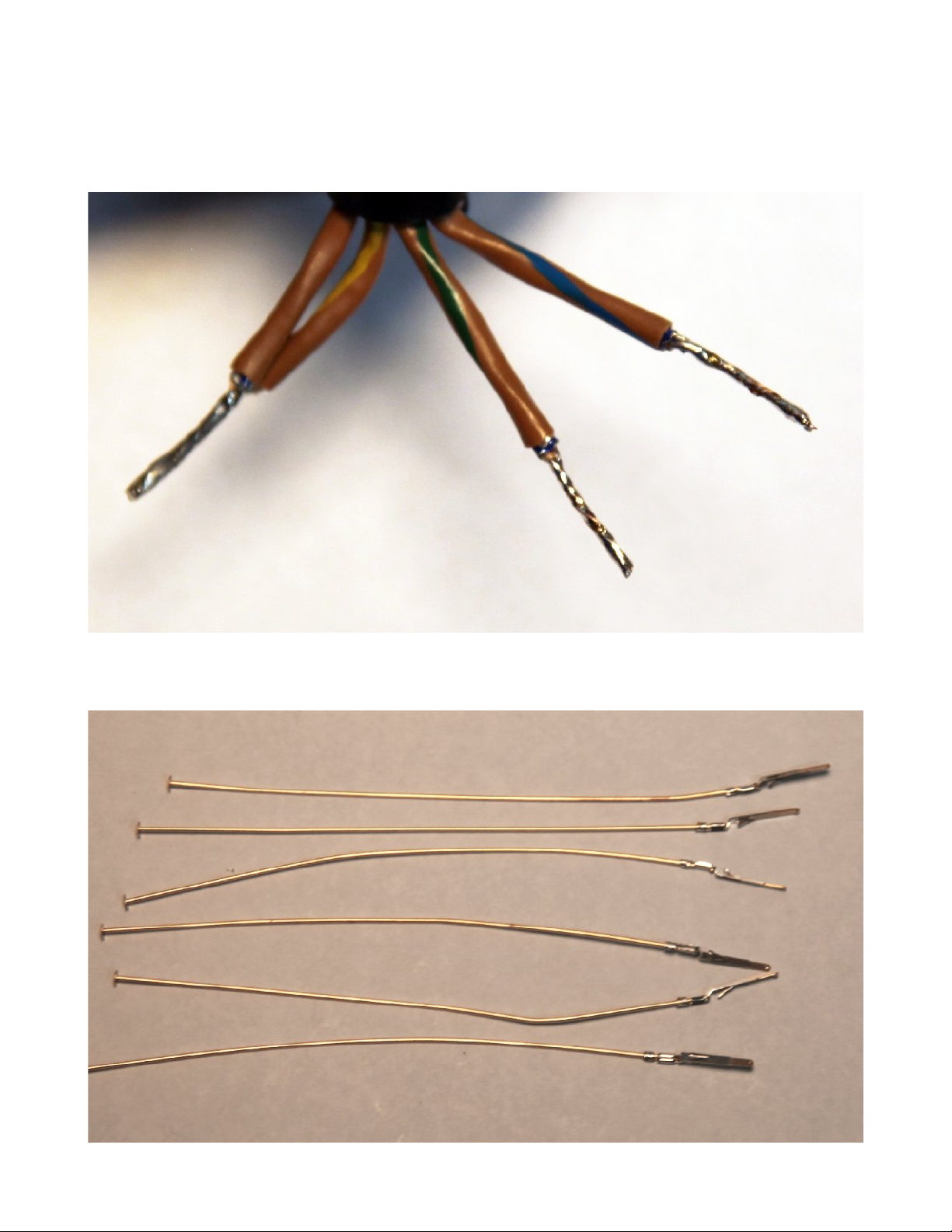

12. Next is to prepare the male DL connector. For the GND,

+29V, and -29V rows you will have to crimp 18 pins with a stiff,

solid wire. We use a gold plated jewelery wire.

Page 7

13. Insert them in to row H first. It is VERY IMPORTANT that you

look at and take notice of the markings on the connector so that

you do not accidentally pin it up-side down. Cut the wires so that

only 1/8 inch of the wire is sticking up.

14. Bend the wires down with a flat head screwdriver so that

they form a row. Solder them together.

Page 8

15. Do steps 13-14 to rows J and K. Careful not to solder the

rows together.

16. Place a small piece of black heatshrink on the GND,+, and -.

GND will use a slightly larger diameter heatshrink.

Page 9

17. One end of the cable will have the wires arranged so that it

will comfortably connect to the connector. The other end will be

mirrored. In the case of the mirrored side, you should split the short

wires in to two even groups and then bend them around all the

other wires.

18. Solder wire 15 to row H. It should come on from the left side.

Page 10

19. Solder the remaining ground and -29V wire. Ground should

come in from the right side and wire 16 from the left. This is tricky

so be patient and take your time to make sure that you do not

solder the rows together and short them.

20. Insert wires 6 and 12 now. Refer to the DL pinout diagram

which can be found in the PQ manual or at the end of this guide.

The colored wire is +, the clear copper wire is -, and the silver wire

that you put clear heatshrink over is the shield.

Page 11

21. Check for shorts between the power rows with a meter. Once

verified that there are indeed no shorts, hot glue the 3 rows so that

they dont move around.

22. Now insert wires 7-11, starting with 11 first. It is easiest to

insert the shield first, then -, then +.

Page 12

23. Insert 1-5, starting with 5.

24. Now push and bend the wires so that they are flat and close

to the connector. Slide the 4 inch ¾ diameter heatshrink up as far

as you can and shrink it.

Page 13

25. Prepare your DL cover.

26. Secure the half of the DL cover that has the cover tab. You'll

have to maneuver the large cable through the opening to have it fit

easily.

Page 14

27. Snap the other half on. It is easiest if you slide the remaining

half on upright from the side. You will have to bend the locking

tabs on top a little bit with a flathead for the two halves to snap

together. Make sure the cover tab does not get stuck under the

other half. It should sit on top. Also be sure that the cable does not

get pinched between the two halves.

28. Insert the top part of the strain relief by placing the tab in the

hole upright, then push it down on to the cable. You might have to

spread it open a little bit.

Page 15

29. Insert the bottom part in the same fashion. Once in, stick the

large screw through both pieces and then secure it with a nut. Try

not to let the heatshrink get pinched between where the bottom

and top piece meet. After the strain relief is secured you can reheat

the heatshrink to get rid of any scratches or if it was stretched.

30. Screw the handle on and you have completed assembly of the

DL connector.

Page 16

The female connector is similar in construction except that you dont cut

wires 6,12,13,14,15, and 16 in half, and it is mirrored to the male DL.

IMPORTANT!: ALWAYS MAKE SURE TO MATCH THE CORRECT WIRE TO

THE CORRECT ROW AND COLUMN.

Page 17

Reference

Resistor Color Code Wire # (Solid-Stripe)

Black = 0 Black-Brown = 01 Black-White = 09

Brown = 1 Black-Red = 02 Brown-Black = 10

Red = 2 Black-Orange = 03 Brown-Brown = 11

Orange = 3 Black-Yellow = 04 Brown-Red = 12

Yellow = 4 Black-Green = 05 Brown-Orange = 13

Green = 5 Black-Blue = 06 Brown-Yellow = 14

Blue = 6 Black-Purple = 07 Brown-Green = 15

Purple = 7 Black-Grey = 08 Brown-Blue = 16

Grey = 8

White = 9

DL Pinout

Loading...

Loading...