Page 1

TECHNICAL SUPPORT

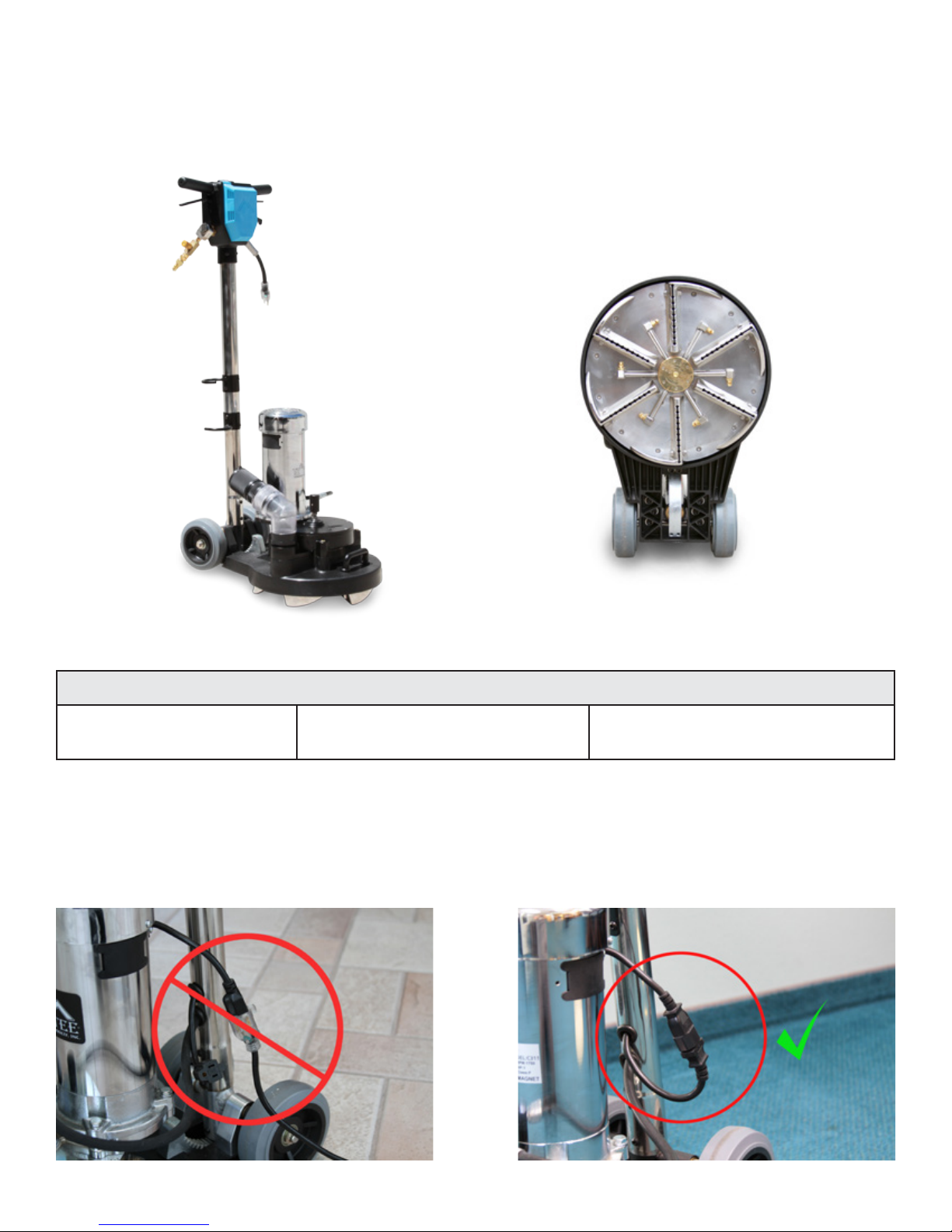

T-REX™ TOTAL ROTARY EXTRACTOR

General Troubleshooting

Problem: Possible Causes: Solutions:

Motor fan is spinning but cleaning

head is not.

Pinion gear has broken.

IMPORTANT: Do not plug the motor into power directly. Serious damage to the motor

will result. The machine should only be powered through the lighted pigtail coming o

the handle.

Replace the pinion gear.

(Part # H129. See next page.)

TS-TREX-09/02/15 • PAGE # 1

Page 2

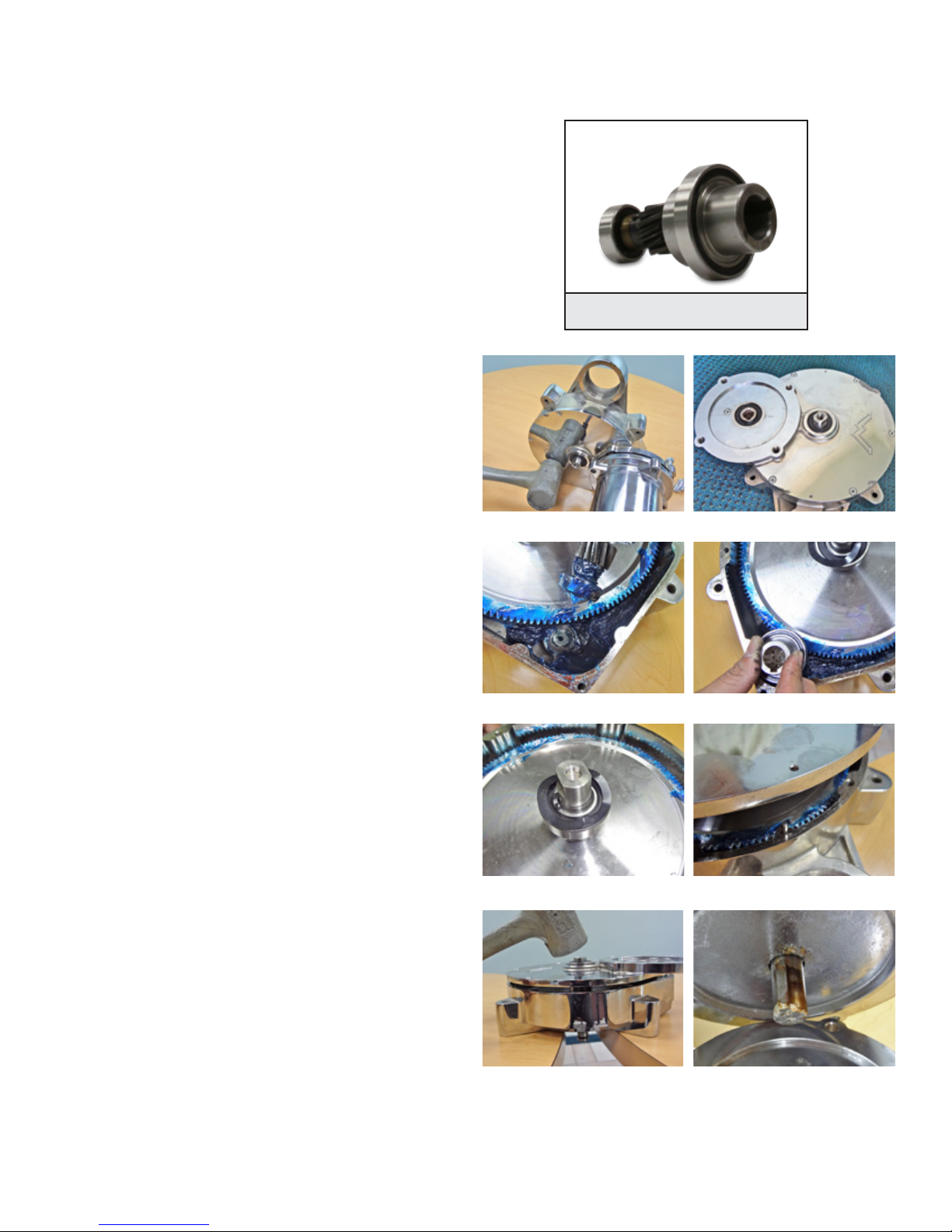

How to Replace Pinion Gear for T-REX™ with 1/2 HP Motor

Does not apply to T-REX™ Jr.

Step 1: Remove the four bolts holding the

transmission and motor together.

Step 2: Pull the motor o the transmission. You

can use a rubber mallet to loosen the seal if

necessary (Figure A).

Step 3: Use a Phillips head screwdriver to

unscrew the 6 screws on the transmission cap

(Figure B). Remove the transmission cap.

Step 4: Remove the broken pinion gear.

Step 5: Install the new pinion gear (Part # H129)

by inserting the gear side into the space beside

the large transmission gear. Use the existing

grease inside the transmission to lube the

pinion gear (Figure C). Twist the pinion gear to

make sure the gears are aligned. You should

see the large gear spin a little (Figure D).

Step 6: Make sure the wave washer is centered

on the bearing for the large gear (Figure E). Line

up the pins on the transmission casing with the

holes on the transmission cap and tap the cap

into place (Figure F). The transmission should

be on a surface that allows the threaded shaft

on the bottom to hang free so that it doesn’t

push back up against the cap as you’re trying

to tap the cap back on (Figure G).

A

C

E

H129

Pinion Gear

B

D

F

Step 7: Replace the screws with a Phillips

screwdriver. The longer screw goes in the hole

in the motor cavity.

Step 8: Twist the pinion gear by hand to make

sure it is aligned properly. You will see the

bearing for the main gear spin slightly.

Step 9: Match the locking key on the motor

shaft to the key slot on the transmission and

slide the motor back in place (Figure H). Line

up the bolt holes and make sure the power

cord is coming out the back.

G

H

TS-TREX-09/02/15 • PAGE # 2

Page 3

T-REX™ JR. TOTAL ROTARY EXTRACTOR

General Troubleshooting

Problem: Possible Causes: Solutions:

Gear box is making loud grinding

noise while running. (When gears

are properly working, the motor

will run quietly.

Oset gear is damaged.

Replace the gear.

(Part # H237. See next page.)

TS-TREX-09/02/15 • PAGE # 3

Page 4

How to Replace the Gears on T-REX™ Jr. Gearbox

Does not apply to T-REX™.

Step 1: Remove the screws holding the

bottom transmission plate and gearbox

together (Figure A).

Step 2: Remove the plate o the transmission.

If it binds up on the shaft, gently rock the plate

as you pull it o (Figure B).

Step 3: Remove rubber gasket from gearbox -

set aside for reassembly (Figure C).

Step 4: Remove the oset gear (smaller gear) -

it should lift straight out (Figure D).

Step 5: Before installing the new oset gear,

fully coat the new oset gear with blue lube

from the motorbox (Figure E).

Step 6: Install the new gear by pressing back

into place by hand. To ensure that gears are

straight and engage with one another, twist the

gear by hand to make sure teeth are aligned

properly. (Figure F).

A

C

H237

Oset Gear w/ bearing

B

D

Step 7: Replace rubber gasket. Make sure

holes are aligned (Figure G).

Step 8: Re-install plate. You can tap down with

a mallet if needed. Replace the screws with a

Phillips head screwdriver (Figure H).

E

G

F

H

TS-TREX-09/02/15 • PAGE # 4

Page 5

Switching the T-REX™to New Style Power Cord Between Motor

and Handle

If you are switching your T-REX™ to the new style motor with the black transmission, you will need

to replace the power cord running through the handle since the new motor has a dierent style plug.

Does not apply to the T-REX™ Jr.

Step 1: Remove back cover by unscrewing the 4 screws.

I

Step 2: Remove front cover by unscrewing the 3 screws.

Step 3: Clip o the black and white wires that are

connected to the blue and red wires on the front board

(Figure I).

Step 4: Clip the green ground wire on the back of the

handle (Figure J).

Step 5: Pull the the old power cord out through the hole

at the bottom of the handle.

Step 6: Snake the new power cord up the handle to the

swtich box.

J

Step 7: Wire the new power cord to the same terminals

as the old power cord (black to blue, white to red, green

to green).

If O-Ring on the Bottom of the Transmission Shaft Goes Bad

Mytee carries a replacement O-Ring (Part # G107).

It is available at

www.mytee.com.

G107

O-Ring

Lubricating Felt Seal

Make sure to keep your felt seal (Part # G014) lubricated. To do this, saturate the felt seal thoroughly

with included Super Lube® (Part # PH648).

TS-TREX-09/02/15 • PAGE # 5

Page 6

Adjusting the Board to Factory Settings on T-REX™and

T-REX™ Jr.

Follow these troubleshooting instructions to ensure your T-REX™ is running optimally.

Step 1: Remove back cover by unscrewing the 4 screws.

Step 2: Remove front cover by unscrewing the 3 screws.

Step 3: The board should look like the one in Figure K. The notches on the knobs should be set to

the following positions:

• Knob 1: 3 o’clock

• Knob 2: 2 o’clock

• Knob 3: 8 o’clock

• Knob 4: 9 o’clock

• Knob 5: 9 o’clock

If your board does not match this, use a Philips screwdriver to adjust the knobs to these settings.

Step 4: Put the front and back covers back on.

K

TS-TREX-09/02/15 • PAGE # 6

Page 7

T-REX Wire Schematic

AC Power

Rev. 10-29-2014

T-REX with Dart Controls

Upgrading Speed Control Board on T-REX

™

If your old style speed control board is broken and irrepairable, it must be replaced with the new

style control board. Follow these diagrams to rewire your speed control from old style to new style.

Does not apply to T-REX™ Jr.

Old Style Control Board

L1

L2

LED specs

E-

B+

G

Dart 125D

Motor speed

control

safety switch

Must Have Permanent

Connection

top view

2

1

+

L

E-

Slide Potentiometer

Note: X indicates non use

3

B+

+

6.8k resistor

G

DC

Motor

-+

Speedpot LO

Speedpot High

Speedpot Wiper

- Armature

+ Field

AC Input N

AC Input L

+ Armature

New Style Control Board

L1

G

L2

+

+

Note: X indicates non use

Momentary Switch

Must Have Permanent

Connection

Top View

2

1

L

E-

Slide Potentiometer

3

B+

to Board

L2

L1

A+

A-

P2 P1

DC Power

to Motor

P3

G

DC

Motor

-

+

TS-TREX-09/02/15 • PAGE # 7

Page 8

Jet Information

T-REX

Jet part number

Jet size 1/8K-1.0 1/8K-1.0 11002

Flow 0.2 GPM 0.2 GPM 0.2 GPM

Installing Optional 7th Jet on T-REX

™

B183 B183 B114A

T-REX™ Jr. Flexstar

™

Optional 7th jet can be added on to the T-REX™ only.

To install, simply unscrew the hex screw in the center of the brass spray manifold and screw in the

jet.

B114A

Jet part number

Jet size 11002

Flow 0.2 GPM

7th Jet

Info

B114A

Motor Carbon Brushes

The DC motors on the T-REX™, and T-REX™ Jr. models have carbon brushes. These carbon brushes

will wear with time and usage. It is important that the brushes be replaced at the rst signs of wear.

If the brushes wear out and let the commutator and armature come in contact, it can cause costly

damage to the speed control board used in the machine.

Signs of Brush Wear

• On-and-o cycling. If motor begins to cycle, as if turning on-and-o rapidly, the brushes are likely

worn.

• Shaking, banging, or slapping sound from motor.

• Sparks and/or smoke from motor.

• Marked decrease in power of motor.

In any of these cases, replace the brushes immediately.

Replacement Carbon Brushes

• T-REX™: Part # C311-BMK

• T-REX™ Jr.: Part # C311B-BMK

TS-TREX-09/02/15 • PAGE # 8

Loading...

Loading...