Page 1

User Manual

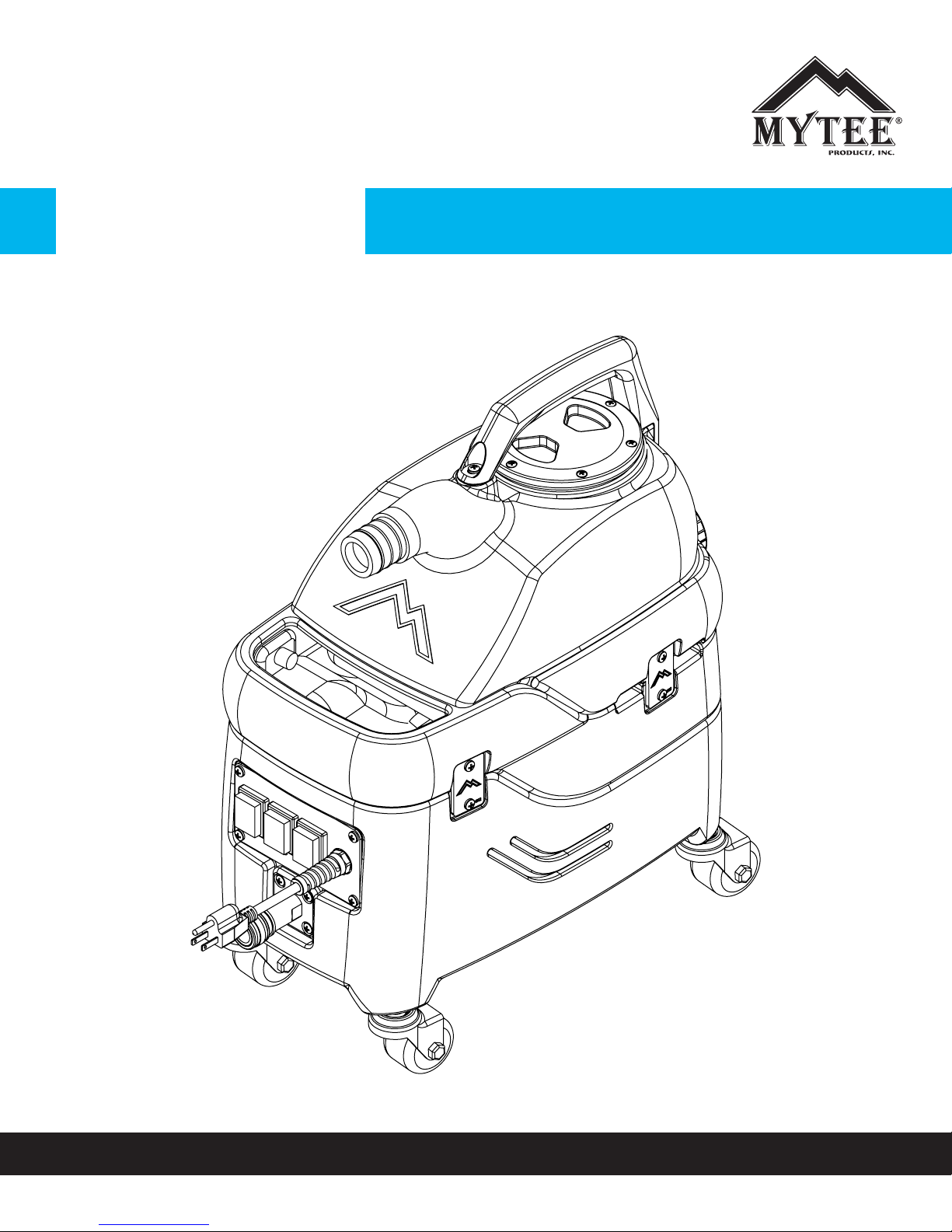

Tempo

™

Models: S-300, S-300H

Upholstery Spotter

REV. 5/2/19

13655 Stowe Dr. Poway, CA 92064 • P: (858) 679-1191 • F: (858) 726-6005

Page 2

Introduction

Dear Customer:

Congratulations on the purchase of your new Tempo™ Upholstery Spotter. As

technology continues to develop you can work condently knowing that both

Mytee Products and its employees are equally dedicated to developing with

the industry and its advances.

Like any other piece of machinery or technology, the Tempo™ also requires the

proper maintenance and care to keep the product working over extended use.

Neglecting your machine, abusing it or not operating it properly can void its

warranty and prevent the machine from performing to the quality and standard

you’d expect out of the Mytee Products line.

If you have any warranty concerns or questions, please review this manual

thoroughly or do not hesitate to contact your distributor. If there are questions

regarding maintenance, replacement, or ordering parts please contact an

authorized Mytee Products Service Center. To see an updated list please visit

our website at http://www.mytee.com/support/service-centers.

Before using your Mytee product, please read this manual thoroughly.

Sincerely,

Mytee Customer Care Dept.

2

Page 3

Table of Contents

Important Safety Information

1

2

At a Glance 6

1.1 - Technical Specications 6

1.2 - Included with the Tempo™ 6

1.3 - Tempo™ Front View 7

1.4 - Tempo™ Rear View 8

1.5 - Switch Plate 9

Machine Operation 10

2.1 - Powering the Tempo™ 10

2.2 - Connecting Hoses & Cleaning Tools 10

2.3 - Filling the Solution Tank 10

2.4 - Switching on the Tempo™ 10

2.5 - Cleaning with the Tempo™ 10

2.5 - Emptying the Recovery Tank 10

4

3

4

5

Machine Maintenance 11

3.1 - Filter Maintenance 11

3.2 - System Maintainer 11

Related Products 12

Troubleshooting 13

3

Page 4

Important Safety Information

Grounding Instructions

This machine must be grounded. If it should malfunction

or breakdown, grounding provides a path of least resis-

tance for electrical shock. This machine is equipped with

a cord having an equipment-grounding conductor and

grounding plug. The plug must be plugged into an appro-

priate outlet that is properly installed in accordance with

all local code and ordinances. Do not remove ground pin;

if missing, replace plug before use.

Improper installation of the equipment-grounding con-

ductor can result in a risk of electric shock. Be sure to

check with a qualied electrician or service person if you

are in doubt as to whether the outlet is properly grounded. If the plug will not t in the outlet do not modify either

the plug nor the machine’s cord, instead have a proper

outlet installed by a qualied technician.

This machine is for use on a nominal 120-volt circuit and

with a grounding plug similar to the one in Figure 1 below.

If a proper outlet is not available, follow the illustrations

of Figure 2 & 3 to install a temporary-grounding plug.

This temporary work-around should be used only until

a proper outlet (Figure 1) can be installed by a qualied

electrician. When and if this type of adapter is employed,

screw the adapter’s extended tab into place with a metal

screw. However, grounding adapters are not approved for

use in Canada.

Again, be sure to check the grounding pin for damages

and replace if necessary.

Parts and Service

Please contact a Mytee service personnel or Mytee

authorized Service Center using Mytee original replace-

ment parts and accessories for repairs are needing to be

performed. When and if calling Mytee for support, please

have your Model and Serial Number available for faster

assistance.

Name Plate

The Model and Serial Number are located on the lower

half of the back of the machine near the power plugs and

will be required for ordering replacement parts. You can

use the space provided on the front of this manual to note

down both for future referencing.

Unpacking the Machine

When your new machine is delivered, please carefully

inspect both the shipping carton and the machine for

damages. If damage is evident, save both the shipping

carton and machine so that the delivering carrier can

inspect it. Contact the carrier immediately to le a freight

claim if there has been any damage.

Caution and Warnings

Symbols

Mytee uses the symbols below to signal potentially dan-

gerous conditions. Always read this information carefully

and take the necessary steps to protect personnel and

pr ope r ty.

The Green, or Green-Yellow, wire in the cord is the

grounding wire. When replacing a plug, this wire must be

attached to only the grounding pin.

DO NOT use extension cords.

Please Note for America use only.

Grounded Outlet

Metal

Screw

Grounding Pin

Figure 1

Grounded Outlet Box

Figure 2 Figure 3

Adapter

Tab for Grounding

Screw

Is used to warn of immediate hazards that will cause

severe personal injury or death.

Is used to call attention to a situation that could cause

severe personal injury.

Is used to call attention to a situation that could cause

minor personal injury or damage to the machine or other

property. When using an electrical appliance, basic precautions should always be followed, including the following: Read all instructions before using this machine. This

product is intended for commercial use only.

4

Page 5

Important Safety Information

To reduce the risk of re, electrical shock, or injury:

1. Read all instructions before using equipment.

2. Use only as described in this manual. Use only manu-

facturer’s recommended attachments.

3. Always unplug power cord from electrical outlet before

attempting any adjustments or repairs.

4. Do not unplug by pulling on cord. To unplug, grasp the

plug, not the cord.

5. Do not pull or carry by cord. Do not close a door on

cord or pull cord around sharp edges or corners.

6. Do not run appliance over cord. Keep cord away from

heated surfaces.

7. Do not use with damaged cord or plug. If cord is damaged, repair immediately.

8. Do not use outdoors or on wet surfaces and or standin g wa ter.

9. Always unplug or disconnect the appliance from power

supply when not in use.

plate must correspond to the wall receptacle supply

voltage.

19. When cleaning and servicing the machine, local or

national regulations may apply to the safe disposal of

liquids which may contain: chemicals, grease, oil, acid,

alkalines, or other dangerous liquids.

20. Do not leave operating unattended.

10. Do not allow to be used as a toy. Close attention is

necessary when used by or near children.

11. Do not use in areas where ammable or combustible

material may be present.

12. Do not leave the unit exposed to harsh weather ele-

ments. Temperatures below freezing may damage com-

ponents and void warranty.

13. Use only the appropriate handles to move and lift

unit. Do not use any other parts of this machine for this

purpose.

14. Do not pull on hoses in order to move the unit. Only

use the appropriate handles.

15. Keep hair, loose clothing, ngers, and all parts of the

body away from all openings and moving parts.

16. Use extra care when using on stairs.

17. To reduce the risk of re or electric shock, do not use

this machine with a solid-state speed control device.

18. The voltage and frequency indicated on the name

5

Page 6

1 - At a Glance

1.1 - Technical Specications

S-300 Tempo™

Solution Tank

Recovery Tank

Vacuum

CFM

Water Lift

Pump PSI

Pump GPM

Power

Consumption

Machine

Weight

Machine

Dimensions

Power Cord

1 Gallon

1 Gallon

Single 2-Stage

97

85”

55

0.37

7 amps @ 115V 60Hz

30 lbs.

20” x 10” x 16 1/2”

Single 25’ 16/3

1.2 - Included with the Tempo™

S-300H Tempo™ w/ Heat

Solution Tank

Recovery Tank

Vacuum

CFM

Water Lift

Pump PSI

Pump GPM

Heater

Power

Consumption

Machine

Weight

Machine

Dimensions

Power Cord

1 Gallon

1 Gallon

Single 2-Stage

97

85”

55

0.37

600W

12 amps @ 115V 60Hz

30 lbs.

20” x 10” x 16 1/2”

Single 25’ 16/3

8400P-8 Air Lite™ Upholstery Tool

and 8’ Vacuum and Solution Hose

Combo

E631 25’ 12/3 Power CordG079 Heatguard™ Hose Wrap

6

Page 7

1 - At a Glance

1.3 - Tempo™ Front View

8

1

2

3

4

5

1. Barbed vacuum hose connection

2. Recovery tank

3. Solution tank ll opening

4. Switch plate

7

6

5. Power cord pigtail

6. Quick connect tting

7. Solution tank

8. Recovery tank lid

7

Page 8

1 - At a Glance

1

1.4 - Tempo™ Rear View

2

1. Carrying handle 2. Recovery tank drain cap 3. 3” swivel casters

3

8

Page 9

1.5 - Switch Plate

1 - At a Glance

1. Vacuum Switch

Activates the vacuum motor.

1 2 3

2. Pump Switch

Activates the solution pump.

3. Heater Switch

Activates the heater.

9

Page 10

2 - Machine Operation

2.1 - Powering the Tempo™

To power the Tempo™, plug the female end of the included extension cord into the pigtail and the male end into a

20 amp wall outlet. ♦

2.2 - Connecting Hoses & Cleaning Tools

IMPORTANT: Do not pull on hoses in

order to move the unit. Only use the

appropriate handles.

The Tempo™ features a 1 1/4” barbed vacuum hose connection as well as a standard 1/4” quick disconnect tting

for solution hoses. ♦

2.3 - Filling the Solution Tank

2.4 - Switching on the Tempo™

S-300 Tempo™

After a cleaning tool is connected and the solution tank is

lled, switch on the vacuum and the pump in any order.

S-300H Tempo™ w/ Heat

13 2

In order to avoid vapor locking the unit, the Tempo’s™

components should be switched on by following the procedure below:

1. Turn pump switch on.

2. Pull the lever on the cleaning tool to release air in the

line. Hold lever until a steady ow of water comes out of

the wand.

3. Once pump is primed and there is pressure in the solution line, turn on heater switch and wait a few minutes for

water to heat up.

4. Once water is heated, turn on vacuum and begin

cleaning.

Note: When cleaning upholstery, always check manufacturer’s cleaning instructions. ♦

The Tempo™ solution tank can be lled up from a pitcher

or other water container via the opening. ♦

2.5 - Cleaning with the Tempo™

For best results when extracting, do one wet pass

followed by two dry passes. This ensures you’re not

over-soaking the material and also gives the heater

time to catch up. ♦

2.6 - Emptying the Recovery Tank

The recovery tank drain is

located on the back of the

machine at the bottom of

the recovery tank. ♦

10

Page 11

3 - Machine Maintenance

In order to keep the Tempo™ running smoothly and reduce the risk of damage to the machine and subsequent

downtime, Mytee recommends following the maintenance

schedule below:

Maintenance Item Daily Weekly

Clean and inspect tanks.

Clean and inspect hoses.

Check and clean internal lters.

Check power supply cable.

Clean machine with all-purpose

cleaner and cloth.

Check spray nozzles.

Flush solution system with Mytee

System Maintainer.

Inspect vacuum hoses for holes and

loose cus.

Inspect spray pattern for clogging.

If clogged, remove spray tips and

soak them in a recommended liquid

neutralizer for up to six hours. To re-

move spray tip, twist spray tip body

counter-clockwise.

X

X

X

X

X

X

X

X

X

solution tank.

3. Turn the pump on FIRST, and run solution through

your cleaning tool. NOTE: The jet should be removed

from the cleaning tool in order to prevent clogging due to

loosening of deposits in line.

4. Next, turn on the heater. If the heater is turned on rst,

it will result in a vapor lock, which will aect the ma-

chine’s operation.

5. Next, with both the pump and heater on, begin running

the solution through the machine. This allows the solution

to break down any build up in the lines.

6. After running all of the solution through the machine,

ll the tank with clean, warm water. Run the water through

the machine to clear the solution completely out of the

tank & lines. ♦

Lubricate wheels with water resis-

tant oil.

Inspect machine for water leaks and

loose hardware.

X

X

3.1 - Filter Maintenance

The Tempo™ has a small lter on the top of the vacuum

stack in the recovery tank. This lter should be checked

and cleaned after each use. ♦

3.2 - System Maintainer

Weekly ushing of the solution system with Mytee®

System Maintainer helps keep lines clean and prevents

chemical build-up, improving pump life, performance and

pressure.

How to use System Maintainer:

1. Mix 1-quart 3601 System Maintainer with 1-quart of

warm water.

2. After thoroughly mixing, pour this solution into the

11

Page 12

4 - Related Products

1500 Focus™ Vapor Steamer 8070 Mytee Lite™ Heated Carpet Extractor

8700 Crevice Tool 8400DX Mytee Dry™ Upholstery Tool

12

Page 13

5 - Troubleshooting

5.1 - Vacuum Troubleshooting

Vacuum is not turning on.

Possible Cause Solution

Vacuum may not be get-

ting power.

Vacuum is not producing suction.

Possible Causes Solutions

Recovery tank is full. Empty the recovery tank.

If the vacuum exhausts but

there is no suction, then

the hose from the recovery

tank to the vacuum motor

is disconnected.

Vacuum hose blockage

(if there is no suction or

exhaust).

Clogged lter in vacuum

tank.

Check the electrical connections and the switch.

Look for loose or damaged

wires.

To check the switch:

Unbolt the switch plate.

Take a picture of the layout

of the wires or tagging the

wires for future reference.

Switch the wires from the

vacuum switch with the

wires from either the pump

or heater switch. Turn on

the pump or heater switch

(whichever one you exchanged wires with). If the

vacuum turns on, then you

know the vacuum switch

is bad.

Open the machine and

nd the hose running from

the recovery tank to the

vacuum motor. Check if

it is disconnected. If so, reconnect it. If it has a leak,

replace the hose (Part #

PH627 if 1.5”, PH628 if

2”).

Check for blockage in the

hose, starting from the

cleaning tool to the machine.

Clean out lter regularly.

Vacuum blows water out the exhaust.

Possible Causes Solutions

Foam building up in the

recovery tank.

There is a loud grinding noise coming from the

Possible Cause Solution

Debris has been sucked

into the vacuum motor

chamber. Usually results

from dry vacuuming.

Use a defoaming solution

in the recovery tank.

vacuum.

Replace the vacuum motor. To avoid repeat prob-

lem, DO NOT dry vacuum

with your extractor.

5.2 - Pump Troubleshooting

Pump doesn’t turn on.

Possible Causes Solutions

Bad switch at control

panel.

Loose or disconnected

wire.

Unbolt the switch plate.

We recommend taking

a picture of the layout of

the wires or tagging the

wires for future reference.

Switch the wires from the

pump switch with the wires

from either the vacuum or

heater switch. Turn on the

vacuum or heater switch

(whichever one you exchanged wires with). If the

pump turns on, the pump

switch is bad.

Disconnect the power cord

from the electrical outlet.

Open up the machine

and look for any loose or

disconnected wires. Re-at-

tach or replace wires.

Drain valve/cap is loose

and is causing air leakage.

Hose cus are loose and

causing air leakage.

Lid on tank is loose and is

causing air leakage.

Tighten the drain valve/

cap.

Tighten all hose cus reg-

ularly as may loosen over

time. Use a glue to prevent

cus from coming loose

(optional).

Make sure the lid is tight.

Pump runs but there is no spray.

Possible Causes Solutions

Blockage or kink somewhere in the line.

13

See chart on page 4 of this

document to diagnose the

location of the blockage.

Page 14

5 - Troubleshooting

Air is in the pump. Prime the pump.

Remove QD o the ma-

chine and solution hose.

Make sure that the three-

prong clip on the inside of

the threaded end is evenly

aligned below the thread

of the QD.

Pump runs but there is no spray.

Possible Causes Solutions

On a new unit, the check

valve between the pump

and heater may hang up,

causing the ow of water

to be impeded or stop

entirely.

Remove the check valve

temporarily and check to

see if the pump will ow

water out of the pump outlet hose when the pump is

turned on for a brief instant

in order to verify cause.

The remedy is to install a

new check valve. Observe

the proper orientation (ow

direction) of the check

valve.

Tip: the check valve may

be able to be temporarily returned to service by

un-sticking the check valve

poppet with manipulation

of the poppet ball with a

thin tool, like a straightened paperclip. Replace

the check valve in unit

assembly.

NEVER OPERATE A UNIT

WITHOUT A CHECK

VALVE IN PLACE.

Pump doesn’t stop running.

Possible Causes Solutions

Leak somewhere in the

line.

Cracks or vacuum leaks on

inlet side of pump.

Seals have been degraded

by chemical.

Debris blocking inlet lter

or pump head.

Pump trips circuit breaker when turned on.

Possible Causes Solutions

Short in power switch. Test by swapping vacuum

Disconnect the solution

hose from the machine.

If this causes the pump

to stop running then the

problem is outside the ma-

chine, either in the solution

hose or tool. If it continues

running on, open the machine and check for leaks.

Repair the leak. If there are

no leaks, run Mytee’s Sys-

tem Maintainer™ (Part #

3601) through the machine

to clear blockages.

Make sure hoses are

secured tightly. If the

inlet side of the pump

is cracked or damaged,

replace the pump.

Install seal repair kit.

Clean lter and/or pump

head.

and pump switch. If problem resolves, but vacuum

begins tripping breaker, replace switch (Part #E515).

Pump runs for a second then shuts down.

Possible Causes Solutions

QD is pressure locked. Relieve pressure from be-

hind the QD by pressing in

the button inside the QD.

Low PSI.

Possible Causes Solutions

The jet nozzle could be too

large.

Replace the jet with one

that has a smaller opening.

Short in electrical harness.

Short in pump motor. If switch and harness

14

Risk of electric shock.

Do this at your own risk.

Remove pump from circuit

by attaching power leads

together. If breaker still

pops when switch is toggled, then there is a short

to the ground in the circuit.

Replace wires as needed.

check is OK, the short

may be in the pump motor.

Replace pump.

Page 15

5 - Troubleshooting

5.3 - Heater Troubleshooting

Heater is not heating water.

Possible Causes Solutions

Loose electrical connection.

Automatic sensor has

failed, causing manual

sensor to trip.

Heater element has failed. Check for continuity

Bad power switch. If the element, sensors,

Check all electrical connections, including power

cord and harness.

Reset the manual sensor

button by pressing the

small white and yellow

button in the center of the

sensor. If this works, but

heater continues to trip the

manual sensor, replace

the automatic sensor (Part

#E573) on the heater.

through the element by

reading the amperage. If

amps are low, only part of

the element may be heat-

ing up – in this case, the

element is damaged and

needs to be replaced.

and wiring all check out

okay, there may be a bad

switch on the switch-plate.

Heater has hard water

buildup inside, leading to

lost eciency.

Unit has vapor locked and there is no water pump-

ing out of the unit.

Possible Cause Solution

Turning on the heater be-

fore turning on the pump

and priming the unit.

Run Mytee System Main-

tainer™ (Part # 3601)

through the machine regularly in order to clear hard

water or chemical residue

that can block water ow

and reduce heating ability.

See product label for in-

structions.

Turn o the heater and

allow the unit to cool

completely. When machine

has cooled, turn on the

pump rst. Prime the unit

by spraying solution out

of the cleaning tool. Then,

turn on the heater.

Running out of hot water too fast.

Possible Causes Solutions

Too much water owing

through the heater.

Jets being used are too

large.

Water in tank is very cold. If possible, ll your solu-

Remember, when using

your machine, it is recommended you do one

wet pass followed by two

dry passes. This way you

are not spraying as much

and the hot water will last

longer.

If your machine has a

1,000W or 1,200W heating

system, make sure your

cleaning tool has 0.02 jets.

tion tank with warm water

in order to shorten the

amount of time it takes for

the water to heat up. The

pumps are usually rated

for 140°F water.

15

Page 16

Notes

Mytee Products, Inc.

13655 Stowe Dr.

Poway, CA 92064

www.mytee.com

© 2019 Mytee Products, Inc.

Printed in the USA

Loading...

Loading...