Mytee Mytee-Lite II 8020, Mytee-Lite II 8070, Mytee-Lite II A8020, Mytee-Lite II A8070 Parts Manual

Page 1

MYTEE-LITE II

Extractor

Model Numbers:

8020 cold water

A8020 w/ upholstery tool

8070 w/ Heater

A8070 w/ Heater & upholstery tool

User and Parts Manual

www.mytee.com

Page 2

MYTEE-LITE II

2

This manual is furnished with each new model. It

provides necessary operation and maintenance

instructions and an illustrated parts list.

Read this manual completely and understand the

machine before operating or servicing it.

Use the illustrated Parts List to order parts. Before

ordering parts or supplies, be sure to have your

machine model number and serial number handy.

Parts and supplies may be ordered by phone or mail

from any authorized parts and service center,

distributor or from any of the manufacturer’s

subsidiaries.

• The machine is operated with reasonable

care.

• The machine is maintained regularly – per

the maintenance instructions provided.

• The machine is maintained with

manufacturer supplied or equivalent parts.

MACHINE DATA

Please fill out at time of installation for future

reference.

Model No. – _____________________________

Install Date – ____________________________

Serial No. – _____________________________

TABLE OF CONTENTS:

SAFETY PRECAUTIONS 3

SAFETY LABELS 4

MACHINE COMPONENTS 5

MACHINE SET UP 5

MACHINE OPERATION 7

PRE-OPERATION 7

WHILE OPERATING 7

DRAINING RECOVERY TANK 8

MACHINE MAINTENANCE 8

DAILY MAINTENANCE 8

WEEKLY MAINTENANCE 8

STORING MACHINE 9

TROUBLESHOOTING 10

SPECIFICATIONS 12

MACHINE DIMENSIONS 12

ELECTRICAL DIAGRAMS DWG 1 of 1

ASSEMBLY PARTS LIST DWG 5 of 5

GROUNDING INSTRUCTIONS 3

www.mytee.com

Page 3

MYTEE-LITE II

designed to clean carpet and upholstery in an indoor

All operators must read, understand and practice the

en read

Do not pull cord around sharp edges or

electrocution can result. Always unplug machine

cause an explosion or fire. Do not use flammable

malfunction or breakdown, grounding provides a

3

SAFETY PRECAUTIONS

This machine is intended for commercial use. It is

environment and is not constructed for any other

use. Use only recommended cleaning solutions and

accessory tools.

following safety precautions.

The following safety alerts symbols are used

throughout this manual as indicated in their

description:

WARNING: To warn of hazards or unsafe

practices which could result in severe personal

injury or death.

FOR SAFETY: To identify actions which must be

followed for safe operation of equipment.

The following information signal potentially

dangerous conditions to the operator or equipment:

FOR SAFETY:

1. Do not operate machine:

-Unless trained and authorized.

-Unless operator manual has be

and understood.

-In flammable or explosive areas.

-Unless cord is properly grounded.

-With damaged cord or plug.

-If not in proper operating condition.

-In outdoor areas.

-In standing water.

-With the use of an extension cord.

2. Before operating machine:

-Make sure all safety devices are in

place and operate properly.

3. When using machine:

-Do not run machine over cord.

-Do not pull machine by plug or cord.

corners

-Do not unplug by pulling on cord.

-Do not stretch cord.

-Do not handle plug with wet hands.

-Keep cord away from heated surfaces.

-Report machine damage or faulty

operation immediately to your

distributor.

-Follow mixing and handling

instructions on chemical containers.

4. Before leaving or servicing machine:

-Turn off machine.

-Unplug cord from wall outlet.

5. When servicing machine:

-Unplug cord from wall outlet.

-Avoid moving parts.

-Do not wear loose jackets, shirts, or

sleeves.

-Use manufacturer supplied or

approved replacement parts.

WARNING: Hazardous Voltage. Shock or

before servicing.

WARNING: Flammable materials can

materials in tank(s).

WARNING: Flammable materials or

reactive metals can cause an explosion or fire.

Do not pick up.

GROUNDING INSTRUCTIONS

Machine must be grounded. If it should

path of least resistance for electrical shock. This

machine is equipped with a cord having an

equipment-grounding conductor and grounding

plug. The plug must be plugged into an

appropriate outlet that is properly installed in

accordance with all local code and ordinances.

Do not remove ground pin; if missing, replace

plug before use.

www.mytee.com

Page 4

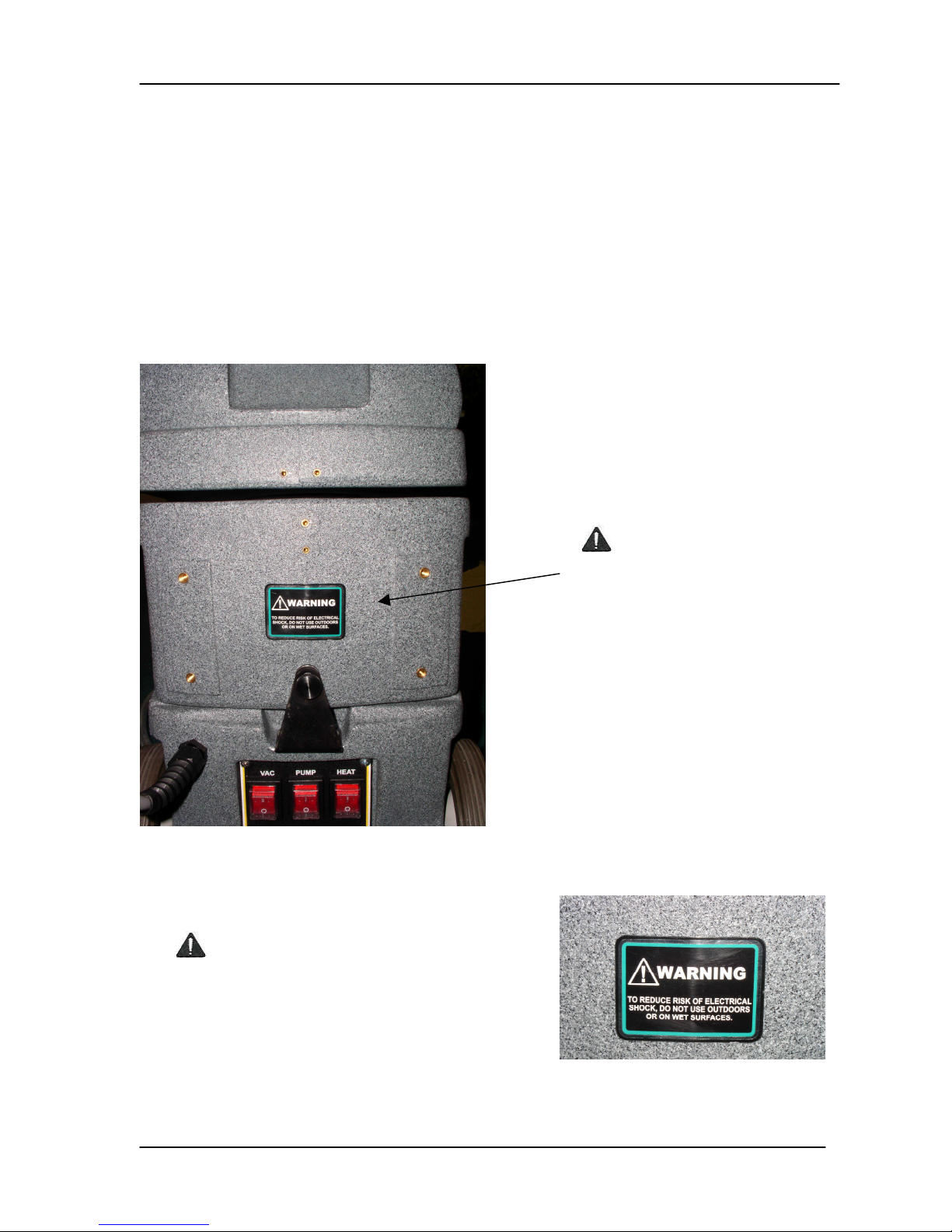

SAFETY LABELS

4

explosion or fire. Do not pick up.

The safety labels appear on the machine in

the locations indicated. Replace labels if

they become damaged or cannot be read.

WARNING: Flammable materials can

cause an explosion or fire. Do not use

flammable materials in tank(s). Flammable

materials or reactive metals can cause

MYTEE-LITE II

WARNING LABEL- Located on back.

Label warns operator of safe practices of

equipment – English text.

www.mytee.com

Page 5

MACHINE COMPONENTS MACHINE SET UP

5

1

1. Carefully check carton for signs of damage.

Report damage at once to freight carrier. The

machine is shipped fully assembled and is

ready for use.

2. Unlock latch connecting recovery tank and

solution tank.

2

3

3. Remove recovery tank from solution tank.

1. Recovery Tank

2. Solution Tank

3. Motor housing/ Base

MYTEE-LITE II

www.mytee.com

Page 6

hine unless

the use of an extension cord.

6

cause an explosion or fire. Do not use flammable

4. Carefully fill up solution tank. (Do not

spill fluid in to vacuum chamber)

6. Lock latch.

Vacuum

chamber

7. Plug machine’s cord into a

grounded wall outlet.

ATTENTION: Do not use recovery tank to fill

solution tank. Residual dirt or debris will cause

damage to solution pump.

WARNING: Flammable materials can

materials in tank(s).

FOR SAFETY: When using machine, follow

mixing and handling instructions on chemical

containers.

ATTENTION: If using powdered cleaning

chemicals, mix prior to adding.

FOR SAFETY: Do not operate mac

cord is properly grounded.

FOR SAFETY: Do not operate machine with

8. Connect solution hose and make sure it is

firmly secured.

5. Replace recovery tank onto solution tank.

MYTEE-LITE II

www.mytee.com

Page 7

4. Begin cleaning

7

9. Connect vacuum hose to recovery tank.

3. Inspect power cord for damage.

Always turn pump on and prime

FOR SAFETY: Do not operate machine unless

operator manual is read and understood.

PRE-OPERATION

1. Vacuum carpet and remove other debris.

2. Perform MACHINE SETUP procedures.

MACHINE OPERATION

1. Turn pump switch on.

NOTE: When cleaning upholstery, always check

cleaning instructions sewn in furniture by

manufacturer.

2. Hold down upholstery trigger lever to

clear air out of line. Do this until there is

a consistent flow of water. This will

prime the pump

NOTE:

pump first before turning on heater.

3. Turn on heater. Wait a few minutes

for water to heat up.

WARNING: Flammable materials or

reactive metals can cause an explosion or fire.

Do not pick up.

1. Work away from outlet and power cord to

prevent cord damage.

2. Use a recommended foam control solution to

prevent vacuum motor damage. Periodically

check for excessive foam buildup in solution

tank.

3. To clean heavily soiled areas, repeat cleaning

path from different direction.

MYTEE-LITE II

D. Turn on vacuum power

WHILE OPERATING

www.mytee.com

Page 8

8

: When servicing machine, unplug

Remove vacuum hose.

2. Wipe off power cord and check for damage, replace if

2. Unlock latch connecting recovery tank and

4. When ball float shuts off vacuum, it is time to

empty the dirty water from the recovery tank, and

refill solution tank.

3. Remove recovery tank from solution tank.

5. After cleaning, relieve water pressure from tool

before disconnecting hose. Squeeze trigger for five

seconds after turning main power switch off.

4. Empty recovery tank.

DRAINING RECOVERY TANK

FOR SAFETY

cord from wall outlet.

1. Turn machine off and unplug power cord.

MACHINE MAINTENENCE

To keep machine in good working condition,

simply follow machine’s daily and weekly

maintenance procedures.

FOR SAFETY: When servicing machine,

unplug cord from wall outlet.

solution tank.

DAILY MAINTENANCE

1. Empty and rinse out solution tank thoroughly.

necessary. Coil cord neatly after use.

3. Clean machine with an all purpose cleaner and damp

cloth.

MYTEE-LITE II

www.mytee.com

Page 9

and

9

WEEKLY MAINTENANCE

follow mixing and handling instructions on

(EVERY 20 HOURS OF OPERATION)

1. Flush solution system with Mytee system

maintainer to dissolve normal chemical buildup.

a. Pour 7.5L (2 gal) of hot water 60°C (140°F)

into solution tank. Add Mytee system

maintainer according to mixing instructions

on bottle

FOR SAFETY: When using machine,

chemical containers.

b. Operate machine for one minute.

c. Shut off machine and allow

remaining solution to break down

chemical buildup overnight.

d. Next day, spray out remaining

solution and flush system with

11L (3gal) of clean water.

2. Inspect vacuum hoses for holes and loose cuffs.

3. Inspect spray pattern for clogging. If clogged,

remove spray tips and soak them in a

recommended liquid neutralizer for up to six

hours. To remove spray tip, twist spray tip body

counter-clockwise. Do not use pointed objects to

unplug tips, damage will occur.

4. Lubricate wheels with water resistant oil.

5. Inspect machine for water leaks and loose

hardware.

6. Remove float shut-off screen from recovery

tank and clean.

NOTE: The float shut off screen is not glued on.

Simply pull it off.

MYTEE-LITE II

STORING MACHINE

1. Before storing machine, be certain to completely drain

rinse tanks of all water and solution.

2. Drain and dry the vacuum hose as well, using the drain

hose provided

3. Store machine in a dry area in the upright position.

4. Open recovery tank cover to promote air circulation.

ATTENTION: Do not expose to rain. Store indoors.

ATTENTION: If storing machine in freezing temperatures,

be sure that machine and solution system are completely

drained and dry.

www.mytee.com

Page 10

MYTEE-LITE II

10

TROUBLESHOOTING

SYMPTOM: UNIT WILL NOT TURN ON:

PROBLEM: Not plugged in.

SOLUTION: Plug machine in proper outlet.

PROBLEM: Circuit breaker has popped.

SOLUTION: Reset circuit breaker. Make sure no other items are running on the same circuit as

machine. Outlet must be a 15-amp circuit.

PROBLEM: Wire from power cord has become disconnected from terminal block.

SOLUTION: Reattach wire to terminal block.

SYMPTOM: PUMP IS NOT RUNNING PROPERLY:

PROBLEM: Quick disconnects are not completely locked together.

SOLUTION: Snap quick disconnects firmly together.

PROBLEM: The solution tank is empty.

SOLUTION: Fill the solution tank up with a premixed detergent.

PROBLEM: Jet on upholstery tool is clogged.

SOLUTION: Clean jet with soft wire brush or remove jet and flush clean.

PROBLEM: Filters are clogged.

SOLUTION: Remove filters and rinse clean with water.

PROBLEM: Heater is blocked with hard water deposits.

SOLUTION: Flush out heaters with system maintainers. If they are still blocked, replace heaters.

PROBLEM: Brass check valve is stuck.

SOLUTION: Replace with new check valve.

PROBLEM: Pump wire has become disconnected.

SOLUTION: Reconnect wire.

PROBLEM: Switch on switch plate is bad.

SOLUTION: Replace switch.

PROBLEM: Pump motor brushes are worn out.

SOLUTION: Replace pump.

SYMPTOM: HEATER IS NOT WORKING PROPERLY:

PROBLEM: The back up sensor, mounted on the heater has popped.

SOLUTION: Reset sensor by pushing in button.

PROBLEM: The automatic sensor mounted to the heater has worn out.

SOLUTION: Replace with a new automatic sensor.

www.mytee.com

Page 11

PROBLEM: Heater wire has become disconnected.

11

SOLUTION: Reconnect wire.

PROBLEM: Switch on switch plate is bad.

SOLUTION: Replace switch.

PROBLEM: Heating element is bad.

SOLUTION: Replace element.

SYMPTOM: VACUUM MOTOR IS NOT WORKING PROPERLY:

PROBLEM: Hose not connected tightly to upholstery tool or machine.

SOLUTION: Connect hose tightly.

PROBLEM: Drain valve is not shut completely.

SOLUTION: Close drain valve completely.

PROBLEM: Vacuum tank lid is not on tightly.

SOLUTION: Secure the vacuum tank tightly.

PROBLEM: Ball float is shut off.

SOLUTION: Empty the vacuum tank of all wastewater.

PROBLEM: Water is coming out of vacuum motor.

SOLUTION: Use a low foaming detergent.

PROBLEM: Upholstery tool is clogged with hair, carpet fibers and or debris.

SOLUTION: Clean upholstery tool.

PROBLEM: Ball float is not installed correctly.

SOLUTION: Make sure that ball float is firmly installed on the elbow.

PROBLEM: Switch on switch plate is bad.

SOLUTION: Replace switch.

PROBLEM: Vacuum motor armature is worn out.

SOLUTION: Replace vacuum motor.

MYTEE-LITE II

www.mytee.com

Page 12

MYTEE-LITE II

12

SPECIFICATIONS

Model 8020, A8020, 8070, A8070,

LENGTH

WIDTH

HEIGHT

WEIGHT

SOLUTION TANK CAPACITY

RECOVERY TANK CAPACITY

SOLUTION PUMP

VACUUM MOTOR

SEALED WATER LIFT

TOTAL POWER CONSUMPTION w/ heater

TOTAL POWER CONSUMPTION w/o heater

POWER CORD

DECIBEL RATING AT OPERATOR’S EAR

INDOOR ON CARPET

26 in

12 in

29 in

45 lbs

3 gal

3 gal

55 psi

2 stage

85”

1610 Watts

839 Watts

25’, 14ga x 3

<72 db (A)

MACHINE DIMENSIONS

www.mytee.com

Loading...

Loading...