Page 1

Instructions for

New & Reconditioned Equipment & Parts - www.southeasternequipment.net

7000SX Flood Hog

Please read before use.

Register your product

at: www.mytee.com/

support/register

™

General Information p. 2

Set Up p. 4

Parts & Pricing p. 8

Wiring Diagram p. 10

Notes p.11

13655 Stowe Dr., Poway, CA 92064

1

Model #

Serial #

Form # ADM-7000SX

10-17

Page 2

GENERAL INFORMATION

New & Reconditioned Equipment & Parts - www.southeasternequipment.net

Dear Customer:

Congratulations on the purchase of your new 7000SX Flood Hog™. As you

are already aware, the scene of the equipment world is becoming more high tech,

and we at Mytee Products Inc. strive to keep you on the cutting edge with superior

quality and technology.

Keep in mind that the 7000SX Flood Hog™ is a machine, so neglect or abuse will

cause unnecessary damage and void the warranty. However with simple maintenance the Flood Hog™ will give quality performance for many years to come.

If warranty questions arise, please consult your user manual or get in touch with

your distributor. If you have questions about maintenance, replacing parts or

ordering parts, please call an authorized Mytee Products Inc. Service Center.

To see an updated list, visit our website at www.mytee.com

Before you begin cleaning, please read your manual thoroughly.

Sincerely,

Mytee Customer Care Dept.

Grounding Instructions

This machine must be grounded. If it should malfunction or break down, grounding

provides a path of least resistance for electrical shock. This machine is equipped

with a cord having an equipment-grounding conductor and grounding plug. The plug

must be plugged into an appropriate outlet that is properly installed in accordance

with all local code and ordinances. Do not remove ground pin; if missing, replace

plug before use.

Improper connection of the equipment-grounding conductor can result in a risk of

electric shock. Check with a qualied electrician or service person if you are in doubt

as to whether the outlet is properly grounded. Do not modify the plug provided with

the machine. If it will not t the outlet, have a proper outlet installed by a qualied

electrician.

This appliance is for use on a nominal 120 volt circuit, and has a grounding plug

that looks like the plug illustrated in Figure 1 below. A temporary adapter illustrated

in Figures 2 and 3 may be used~to connect this plug to a 2-pole receptacle as

shown in Figure 2 if a properly grounded outlet is not available. The temporary

adapter should be used only until a properly grounded outlet (Figure 1) can be

installed by a qualied electrician. The green colored rigid ear, tab or the like

extending from the adapter must be connected to a permanent ground such as a

properly grounded outlet box cover. Whenever the adapter is used, it must be held

in place by a metal screw. Grounding adapters are not approved for use in Canada.

Replace the plug if the grounding pin is damaged or broken.

The green (or green-yellow) wire in the cord is the grounding wire. When replacing

a plug, this wire must be attached to the grounding pin only.

DO NOT use extension cords.

Please Note for America use only

Grounding Pin

Figure 1

Grounded Outlet

Metal

Screw

Grounded Outlet Box

Figure 2 Figure 3

Adapter

Tab for Grounding

Screw

Parts and Service

Repairs, when required, should be performed by Mytee service personnel or Mytee

authorized Service Center using Mytee original replacement parts and accessories.

Call Mytee for repair parts or service. Please specify the Model and Serial Number

when discussing your machine.

Name Plate

The Model and Serial Number of your machine are shown on the Nameplate on the

back panel of the machine. This information is needed when ordering repair parts

for the machine. Use the space provided on the front cover to note the Model and

Serial Number of your machine for future reference.

Unpacking the Machine

When the machine is delivered, carefully inspect the shipping carton and the

machine for damage. If damage is evident, save the shipping carton so that it can

be inspected by the carrier that delivered it. Contact the carrier immediately to le a

freight damage claim.

Caution and Warnings

Symbols

Mytee uses the symbols below to signal potentially dangerous conditions. Always

read this information carefully and take the necessary steps to protect personnel

and property.

Is used to warn of immediate hazards that will cause severe personal injury or death.

Is used to call attention to a situation that could cause severe personal injury.

Is used to call attention to a situation that could cause minor personal injury or

damage to the machine or other property. When using an electrical appliance, basic

precautions should always be followed, including the following: Read all instructions

before using this machine. This product is intended for commercial use only.

To reduce the risk of re, electrical shock, or injury:

1. Read all instructions before using equipment.

2. Use only as described in this manual. Use only manufacturer’s recommended

attachments.

3. Always unplug power cord from electrical outlet before attempting any adjustments

or repairs.

4. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

5. Do not pull by cord. Do not close a door on cord or pull cord around sharp edges

or corners.

6. Do not run appliance over cord. Keep cord away from heated surfaces.

7. Do not use with damaged cord or plug. If cord is damaged, repair immediately.

8. Always unplug or disconnect the appliance from power supply when not in use.

9. Do not allow to be used as a toy. Close attention is necessary when used by or

near children.

10. Do not use in areas where ammable or combustible material may be present.

11. Do not leave the unit exposed to harsh weather elements. Temperatures below

freezing may damage components and void warranty.

12. Use only the appropriate handles to move and lift unit. Do not use any other parts

of this machine for this purpose.

13. Keep hair, loose clothing, ngers, and all parts of the body away from all

openings and moving parts.

14. Use extra care when cleaning on stairs.

15. To reduce the risk of re or electric shock, do not use this machine with a solid-

state speed control device.

16. The voltage and frequency indicated on the name plate must correspond to the

wall receptacle supply voltage.

17. When cleaning and servicing the machine, local or national regulations may apply

to the safe disposal of liquids which may contain: chemicals, grease, oil, acid,

alkalines, or other dangerous liquids.

18. Do not leave operating unattended.

2

Page 3

GENERAL INFORMATION

New & Reconditioned Equipment & Parts - www.southeasternequipment.net

Pre-Operation

1. Remove furniture and other items from the area you are going to treat.

2. Make sure debris lter is clear and electrical cord is in good repair.

3. Make sure a 20A grounded wall outlet is available for cord. Do not use

extension cord.

Operation

1. Attach one end of the vacuum hose to the front of the machine. Then, attach a

scalloped or squeegee vacuum head to the other end of the vacuum hose.

2. If using the Auto Pump-Out feature: On the rear of the machine, attach the pump-

out hose. Secure the hose to the tting using the cam lock. Push the hose cuff onto

the tting, making sure the silver ears and rings are extended forward. Pull the ears

down using the rings until connection is tight. Place the end of the hose in a location

where dirty water can drain.

3. Plug in the power cord(s). Two power cords are located in the back of the machine. To power Vacuum 1 and Pump, plug in the top cord. To power the Vacuum

2, plug in the bottom cord. Plug each of the two power cords into two separate, 20A

grounded wall outlets. Do not use extension cords.

4. Turn on the machine. Three switches are located on the lower left side of the

machine. To use Vacuum 1, turn on the Vacuum 1 switch. To use Vacuum 2, turn on

the Vacuum 2 switch. To use the pump, turn on the Pump switch.

5. Place wand over ooded area and begin extracting.

6. If pump must be accessed during extraction, use the recovery tank lid on top of

the machine. Pull the lever up and turn counter clockwise until it faces the side of the

machine. Pull up and take the lid off. Use reverse procedure to replace.

7. When ood extraction is nished, turn off the machine.

After Use

1. Unplug power cords and remove hose.

2. Inspect hoses and replace if damaged.

3. Inspect lter and clean.

4. The debris lter inside the machine protects the vacuum motor from damaging

debris. Keep it clean by removing vacuum hose and turning the top latch counterclockwise and opening the lid. Remove stainless steel basket and gently rinse with

water. Dry with a soft cloth. Replace basket, lid and hose.

5. Flush out recovery tank and pump-out to prevent silt buildup around the

pump-out intake.

6. Open recovery tank to promote air circulation.

7. Make sure machine and hoses are completely drained and dry.

8. Store the machine in a clean, dry place.

Maintenance Schedule

Maintenance item Daily

Clean and inspect Tanks

Clean and inspect Hoses

Flush out recovery tank and pump-out to prevent sift

buildup around the pump-out intake.

Inspect lters

Check electrical cord

Clean machine with all purpose cleaner and cloth

Inspect vacuum hoses for holes and loose cuffs

Lubricate wheels with water-resistant oil

Inspect machine for water leaks and loose hardware

x

x

x

x

x

x

Once a week

x

x

x

Troubleshooting

There is no power.

1. Plug machine in proper outlet.

2. Check circuit breaker; reset circuit breaker, other items should not run on the

same circuit as machine. Outlet must be a 20 amp circuit. For 7000SX models, two

separate 20 amp circuits are required.

Pump-out does not work properly.

1. Check pump-out wire. May need to reconnect wire.

2. Switch plate switch may need to be replaced.

3. If pump motor brushes are worn, replace pump.

4. Float switch obstructed. Clean.

5. Pump-out intake is obstructed. Flush out recovery tank and pump-out to clear

pump-out intake.

Vacuum motor does not work properly.

1. Check that hose is tightly connected.

2. Close drain hose valve completely.

3. Secure the vacuum tank tightly.

4. If water is coming out of vacuum motor, use a low foaming detergent.

Machine Specications

Recovery Tank 12 gallons

Vacuum Dual 3-stage high performance, in series

CFM 113

Water Lift 249”

Pump-Out 66 GPM

Filter Stainless steel strainer basket

Power

Consumption

Machine Weight 124 l bs .

Machine

Dimensions

Power Cord Dual 50’ 12/3

Cord 1: 18 amps @ 115V 60Hz

Cord 2: 13 amps @ 115V 60Hz

29” x 17.5” x 35”

230V Conguration Information

Model Number 7000SX-230

Power

Consumption

Cord 1: 10 amps @ 230V 60Hz/50Hz

Cord 2: 7 amps @ 230V 60Hz /50Hz

FAQs

Q: What comes standard with the 7000SX?

A: The 7000SX comes with a 2” x 1.5” Cuff Lynx™ (H141), a 50’ lay-at pump-out

hose (AH121), and pack of lters (G008).

Q: Where do I plug the machine in?

A: Plug each power cord into a separate, 20A grounded wall outlet. Outlets must

be on two separate breakers. When the amber light on the switch plate illuminates,

the machine is on separate circuits (not necessarily 20A circuits). You can identify the

primary cord by the yellow tag.

Q: Is there anything I can do to increase the expected life of my machine?

A: Running the vacuum motors with the tank empty and lid off will allow excess

moisture in the vacuums to dry off.

3

Page 4

7000SX FLOOD HOG™

New & Reconditioned Equipment & Parts - www.southeasternequipment.net

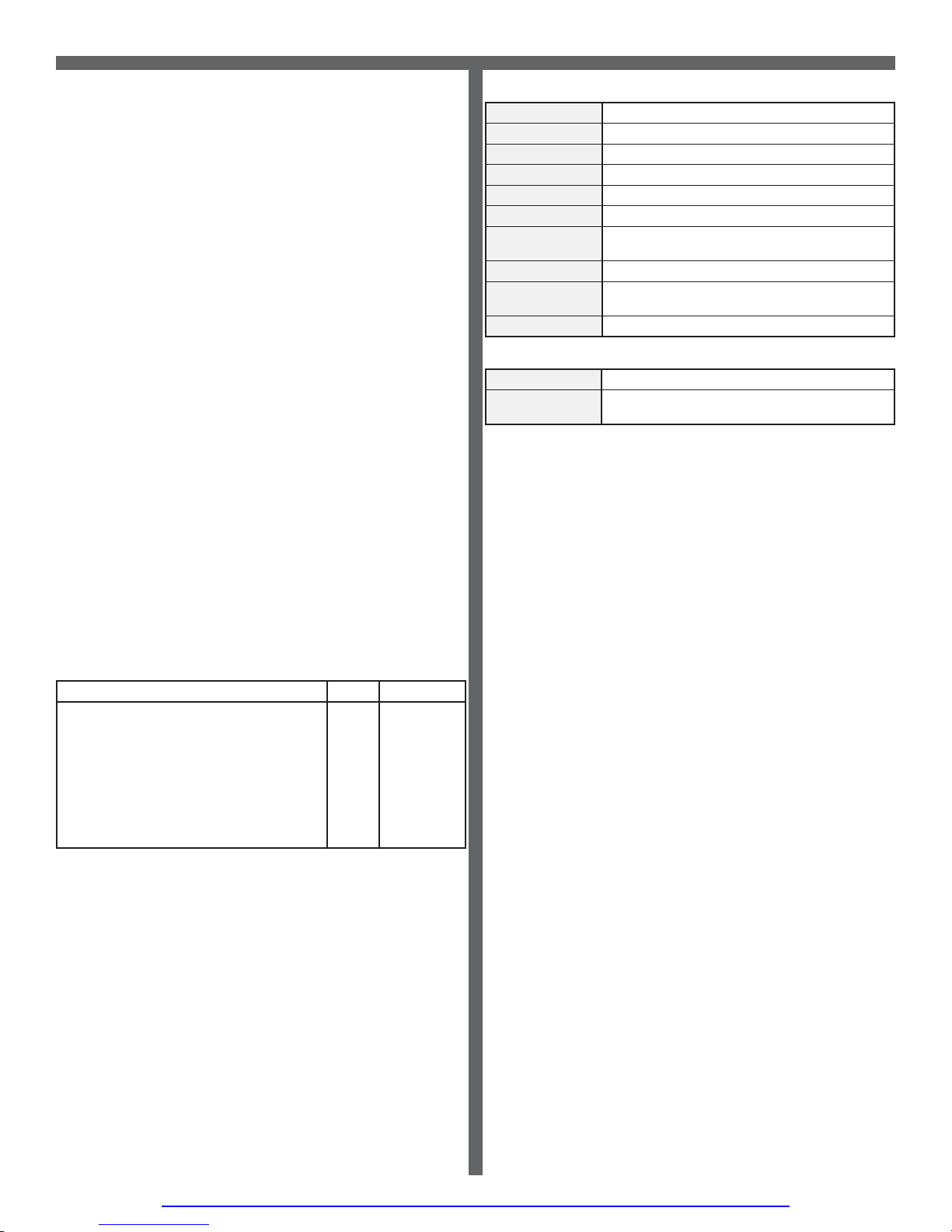

7000SX FEATURES

1

1. Switch plate

2. 4” locking casters

3. Service latches

4. Recovery tank drain valve

5. Recovery tank

6. Front handle

8

7

6

11

5

4

13

9

10

12

14

3

2

7. Front recovery tank lid latches

8. 2” Cuff-Lynx™ Vacuum hose connection

9. Recovery tank lid

10. Rear recovery tank lid latch

11. Rear upper wheels

12. Rear handle

15

13. Pump-out hose connection

14. Power cord pigtails

15. Rear 10” foam-lled wheels

7000SX SWITCHES

Dual circuit indicator

light.

Three switches are located on the lower left side of the machine. To use either vacuum, turn on the Vacuum switch 1 or 2. To use the pump,

turn on the Pump switch.

4

Page 5

7000SX FLOOD HOG™

8

7

6

5

4

3

2

1

E

F

New & Reconditioned Equipment & Parts - www.southeasternequipment.net

7000SX INCLUDED ACCESSORIES A138 OPTIONAL ACCESSORY PACKAGE

(SOLD SEPARATELY)

AH121 - 2.5” x 50’ Lay-Flat

Pump-Out Hose

H226 - Drain Elbow

H141 - 2” x 1.5”

Cuff-Lynx™ Reducer

FILTERS

G008 - Pack Of Filters

7000SX DUAL CORDS

Top cord: Powers Vac 1 & Pump.

Bottom cord: Powers Vac 2.

H908 - 2 Piece

Aluminum Wand Tube

H294 - 1.5” x 25’ Vacuum Hose

Yellow tag

indicates primary

cord.

P570 - Scalloped Vacuum Head

G200 - Squeegee Vacuum Head

Plug each power cord into a separate, 20A grounded wall outlet. Outlets must be on two separate breakers. When the amber light on the

switch plate illuminates, the machine is on separate circuits (not necessarily 20A circuits). You can identify the primary cord by the yellow

tag.

5

Page 6

7000SX FLOOD HOG™

New & Reconditioned Equipment & Parts - www.southeasternequipment.net

7000SX FRONT VACUUM HOSE HOOK UP

Attach the hose (not included) with the 1.5” Cuff-Lynx™ reducer to

the machine. Attach other end of same hose to wand tube.

7000SX AUTO PUMP-OUT HOSE HOOK UP

Attach the second hose bearing cam lock to the Auto Pump-out

tting. Secure the hose to the tting using the cam lock. Push the

hose cuff onto the tting, making sure the silver ears and rings are

extended forward. Pull the ears down using the rings until connection is tight. Place the end of the hose in a location where dirty

water can drain.

7000SX WATER LEVEL CONTROL SWITCHES

Vacuum stack lter

Vacuum water level

control switch

Pump-out water

level control switch

As the water level reaches the pump-out water level control

switch, the pump is activated. Once the water level reaches the

vacuum water level control switch, the vaccum shuts off prevent-

ing the water from going into the vacuum stack, damaging the

vacuum motors. At the top of the vaccum stack, there is a lter.

Clean it weekly.

7000SX DRAIN VALVE AND SPOUT

When not using the Auto Pump-out, empty the tank by using the

drain valve on the front of the machine with the included drain

elbow (part # H226).

6

Page 7

7000SX FLOOD HOG™

New & Reconditioned Equipment & Parts - www.southeasternequipment.net

7000SX LATCHES AND LIFT HANDLE7000SX STRAINER BASKET

The lter protects the vacuum motor from damaging debris. Keep

it clean by removing the vacuum hose and opening the recovery

tank lid via the latch on the front of the machine. Remove stainless steel basket and gently rinse with water. Dry with a soft cloth.

Replace basket, lid and hose.

7000SX FLOOD HOG™ IN USE

DRAIN

The Flood Hog™ features a series of latches to remove the

recovery tank lid for access to the strainer basket. There are also

two latches on the front of the unit allowing access to the internal

components. When opening the machine, lift the recovery tank

section using the lift handle on the front of the unit.

FLOODED AREA

Flood Hog™ pumps up to 66 GPM.

7

Page 8

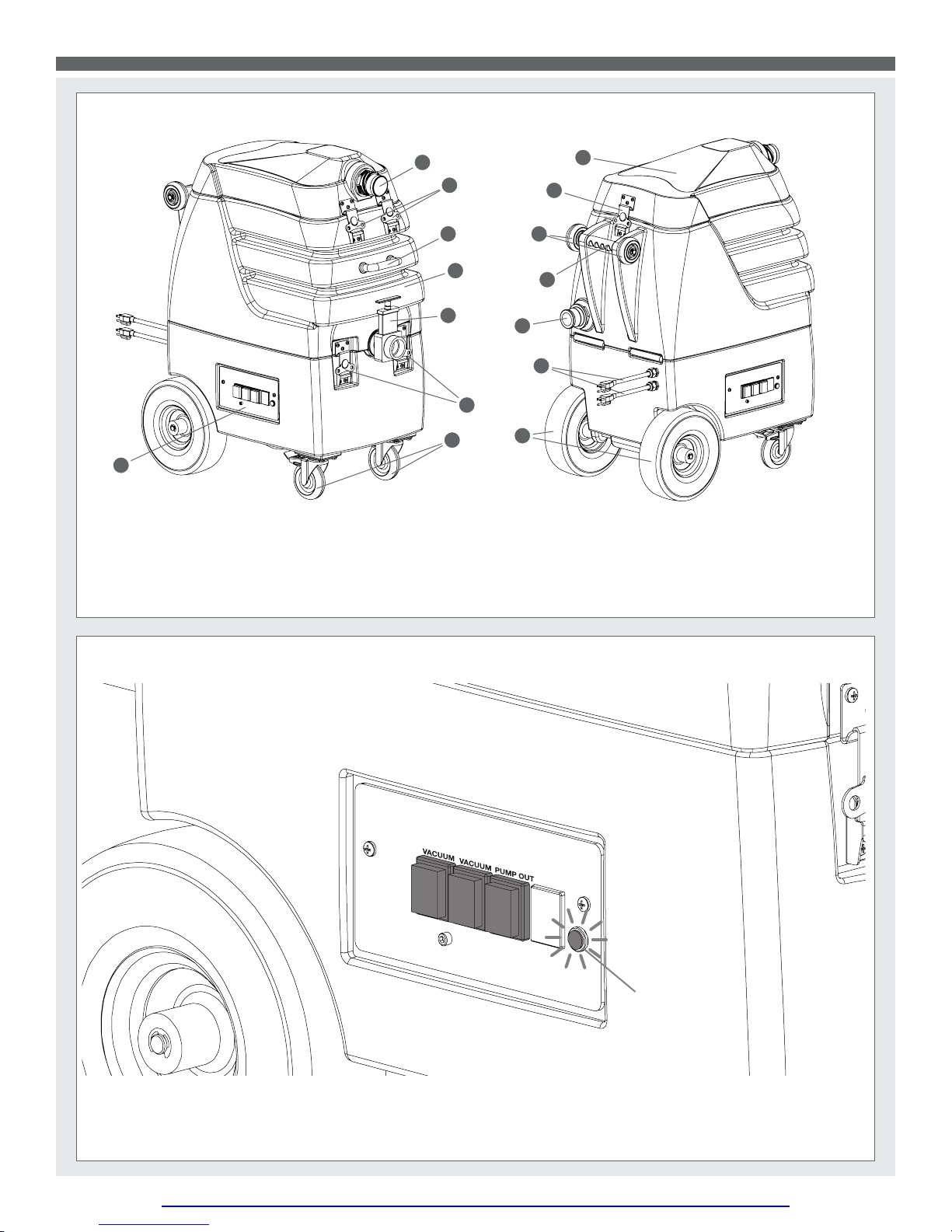

7000SX FLOOD HOG™ PARTS & PRICING

ITEMS NOT SHOWN

ITEM

NO.

PART NO.

DESCRIPTION

QTY.

MSRP

1

H135

Cuff-Lynx, 2" m cuff x 2" mpt

1

$3.99 ea

2

H230

screw, 10-32 x 1/2" phil pan head, s/s

59

$0.99 ea

3

H486

latch, front

5

$13.99 ea

4

P746

lid, 7000SX 1

$89.99 ea

5

G092

gasket, lid, 7000SX

1

$39.99 ea

6

H253

plate, dual manifold, 9" x 13"

1

$14.99 ea

7

H302

cuff, hose, 2" x 2.5", swivel, grey

1

$12.99 ea

8

PH627-15

vac hose, 1-1/2", black, wire reinforced

1

$4.99 ft

9

P735

manifold, single vac, no gasket

2

$14.99 ea

10

G004

gasket, vacuum motor

2

$8.99 ea

11

H202

bolt, 1/4-20 x 3/4" hex head, s/s

6

$0.99 ea

12

H501

vac support, 3 stage, 4-1/16"

6

$4.99 ea

13

H770

bolt, 1/4-20 x 1/2" serrated hex flange, zinc

6

$0.99 ea

14

C302A

vac motor, 3-stage hp, 120V, 145"

2

$148.99 ea

15

G059

exhaust boot, plastisol

1

$4.99 ea

16

PH628-10

vac hose, 2", black, wire reinforced

1

$8.99 ea

17

H217

clamp, hose, 2-1/4 dia

5

$1.49 ea

18

H225

valve, drain, 1-1/2" 1

$20.99 ea

19

H485

handle, aluminim grip, black

1

$6.99 ea

20

G052

washer, buna 1-1/8" od x 3/16" id

6

$1.99 ea

21

H211

washer, 1/4"id x 1"od, flat, s/s

2

$0.99 ea

22

H768

bolt, 1/4-20 x 3/4" serrated hex flange, zinc

2

$0.99 ea

23

P745

vac tank, 7000SX

1

$149.99 ea

24

H023

filter basket, flood hog

1

$64.99 ea

25

C388

pump out, 66 gpm, stainless, 115v

1

$695.99 ea

26

H256

screw, 10-32 x 3/4" phil pan head, zinc

1

$0.99 ea

27

H059

bracket, ETM, pump-out

2

$9.99 ea

28

H273

nut, kep, #10-32 zinc

17

$0.99 ea

29

H216

nut, lock, 1/4-20, nylon insert, s/s

13

$0.99 ea

30

H342

bolt, 1/4-20 x 1" hex head, s/s 9

$0.99 ea

31

P686

swing check valve, pump out

1

$24.49 ea

32

PH627-15

vac hose, 1-1/2", black, wire reinforced

1

$4.99 ft

33

H396

barb, 1-1/2" x 1-1/2" fpt, pump out 1

$19.99 ea

34

H207

cam & grovve fitting 1-1/2", male

1

$21.99 ea

35

H205

cam & groove fitting 1-1/2", female

1

$32.99 ea

36

AH121

hose, layflat, 50', pump-out

1

$49.99 ea

37

PH633-1

pipe, pvc, 1-1/2"

1

$4.99 ft

38

G003 filter, foam, 2" x .50" o.d.

1

$1.99 ea

39

G097

screen, mesh filter, 1-1/2" dia

1

$4.99 ea

40

P502

adapter, 1.5" pvc, fslip x fslip

1

$5.00 ea

41

PH633-12

pipe, pvc, 1-1/2"

1

$4.99/ft

42

H244

adapter, pvc, 1-1/2" fms x fmpt

1

$4.99 ea

43

H229

inlet, pvc, 1-1/2", gray

1

$5.99 ea

44

P609

handle, 7000SX

1

$5.99 ea

45

H089

axle, 9.63" x .50" dia

1

$10.99 ea

46

H358B

wheel, 3"

2

$10.99 ea

47

H042

c-clip, 12mm, external

4

$0.99 ea

48

E373

level switch, vacuum shut-off, rear threads

2

$24.99 ea

49

B103

elbow, brass, 90 deg, 1/4"mpt x 1/4" fpt

3

$4.49 ea

50

B142A

coupling, brass, 1/4" fpt x 1/4" fpt

1

$4.49 ea

51

B303

nipple, 3" x 1/4" npt x 1/4" npt

2

$8.99 ea

52

B113

tee, brass, 1/4" fpt

1

$6.99 ea

53

B199 coupler, 1/2" fpt x 1/4" fpt

1

$8.99 ea

54

H384

washer, 3/8 flat, s/s 3

$0.99 ea

55

B210

bushing, brass, 1/2"mpt x 3/8" fpt, hex

2

$2.49 ea

56

B216

nipple, brass, 3/8" x close

1

$1.99 ea

57

H210

washer, 1/4" flat, s/s

20

$0.99 ea

58

H169

bolt, 1/4-20 x 2", hex head

4

$3.99 ea

59

G040

grip, handle, floor machine

2

$1.99 ea

60

H548

handle, 1" bar, s/s 1

$45.99 ea

61

H641

plate, switch, RL1200, 7000DX

1

$6.99 ea

62

E512B

light, indicator, 125v (amber)

1

$9.99 ea

ITEM

NO.

PART NO.

DESCRIPTION

QTY.

MSRP

63

P967A

plug, switch

1

$1.99 ea

64

H389

screw, 10-32 x 1/2" SHCS, alloy 1

$0.99 ea

65

H612

washer, 8 flat, s/s

1

$0.99 ea

66

E515

switch, rocker, 2 position

3

$13.99 ea

67

E564

controller, circuit light

1

$62.99 ea

68

E370

controller, water level, single, 115v

1

$114.99 ea

69

H186

screw, 10-32 x 3/4, phil flat full thread

6

$0.99 ea

70

E628

controller, water level, single, 115V

1

$114.99 ea

71

H221

nut, lock, 1/2" steel

2

$1.99 ea

72

H220

fitting, strain relief, cord

2

$3.19 ea

73

E550

power cord, pigtail, 30", 12/3, black

2

$11.49 ea

74

H487

bracket, hinge

2

$4.49 ea

75

P696

base, 7000SX

1

$114.99 ea

76

H254

washer, axle, cut 1/2" id

2

$0.99 ea

77

H371

axle, 18.03" x .50" dia

1

$9.99 ea

78

H109

wheel, 10", foam filled

2

$79.99 ea

79

H668

caster, 4", black hub & gray tread

2

$19.49 ea

PART NO.

DESCRIPTION

QTY.

MSRP

H141

Cuff-Lynx, 2" x 1.5" reducer

1

$3.99 ea

G109

gasket, strip, vac lid, 7000S

1

$10.99 ea

E530

power cord, ext 50', 12/3

2

$74.99 ea

P568A

cord lock, s-type

2

$8.99 ea

H226

spout, drain, 45 degree

1

$3.99 ea

H294

hose, vac 1-1/2" x 25' sw cuff

1

$74.99 ea

D

C

B

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

E

F

E

F

7000SX

SHEET 1 OF 3

Flood Hog

6/2015

OD

SCALE: 1:32

REV

DWG. NO.

C

SIZE

TITLE:

NAME

DATE

COMMENTS:

CHECKED

DRAWN

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

MYTEE PRODUCTS, INC. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

MYTEE PRODUCTS, INC. IS

PROHIBITED.

A

DO NOT

SCALE DRAWING

858-679-1191

mytee

PRODUCTS, INC.

M.LaBarbera

New & Reconditioned Equipment & Parts - www.southeasternequipment.net

8

Part prices are subject to change.Order parts at: www.mytee.com

Page 9

7000SX FLOOD HOG™ PARTS & PRICING

1

4

40

41

14

18

23

24

25

34

79

71

72

73

2

76

77

47

30

57

57

29

3

2

61

62

63

64 65

28

66

2

67

68

69

70

28

74

78

7

8

6

9

10

11

12

13

15

16

2

43

42

39

38

31

2

3

17

28

48

49

49

50

51

52

51

53

54

55

56

55

75

44

45

46

47

32

33

37

3

2

19

20

21

22

35

36

5

30

29

28

2

27

26

29

20

57

58

59

60

D

C

B

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

E

F

E

F

7000SX

SHEET 2 OF 3

Flood Hog

6/2015

OD

SCALE: 1:32

REV

DWG. NO.

C

SIZE

TITLE:

NAME

DATE

COMMENTS:

CHECKED

DRAWN

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

MYTEE PRODUCTS, INC. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

MYTEE PRODUCTS, INC. IS

PROHIBITED.

A

DO NOT

SCALE DRAWING

858-679-1191

mytee

PRODUCTS, INC.

M.LaBarbera

New & Reconditioned Equipment & Parts - www.southeasternequipment.net

9

Page 10

7000SX FLOOD HOG™ WIRING DIAGRAM

7000SX Wire Schematic

L1

L2

G

L1

L2

G

VAC 1

L1L2

G

VAC 2

L2L1

G

E-515

E-515

E-515

Pump

Out

L2L1

G

E-564

L1a

L1b

L2a

L2b

light

C-302A

C-302A

C-384

E-512

Cord 2

Cord 1

E-628

Ground to

metal plate

3/12/2015

Float

Switch

E-370

Float

Switch

New & Reconditioned Equipment & Parts - www.southeasternequipment.net

10

Page 11

NOTES

New & Reconditioned Equipment & Parts - www.southeasternequipment.net

Mytee Products Inc.

13655 Stowe Dr.

Poway, CA 92064

www.mytee.com

FX 858.679.7814

© 2017 Mytee Products Inc.

Printed in the U.S.A.

11

Loading...

Loading...