Page 1

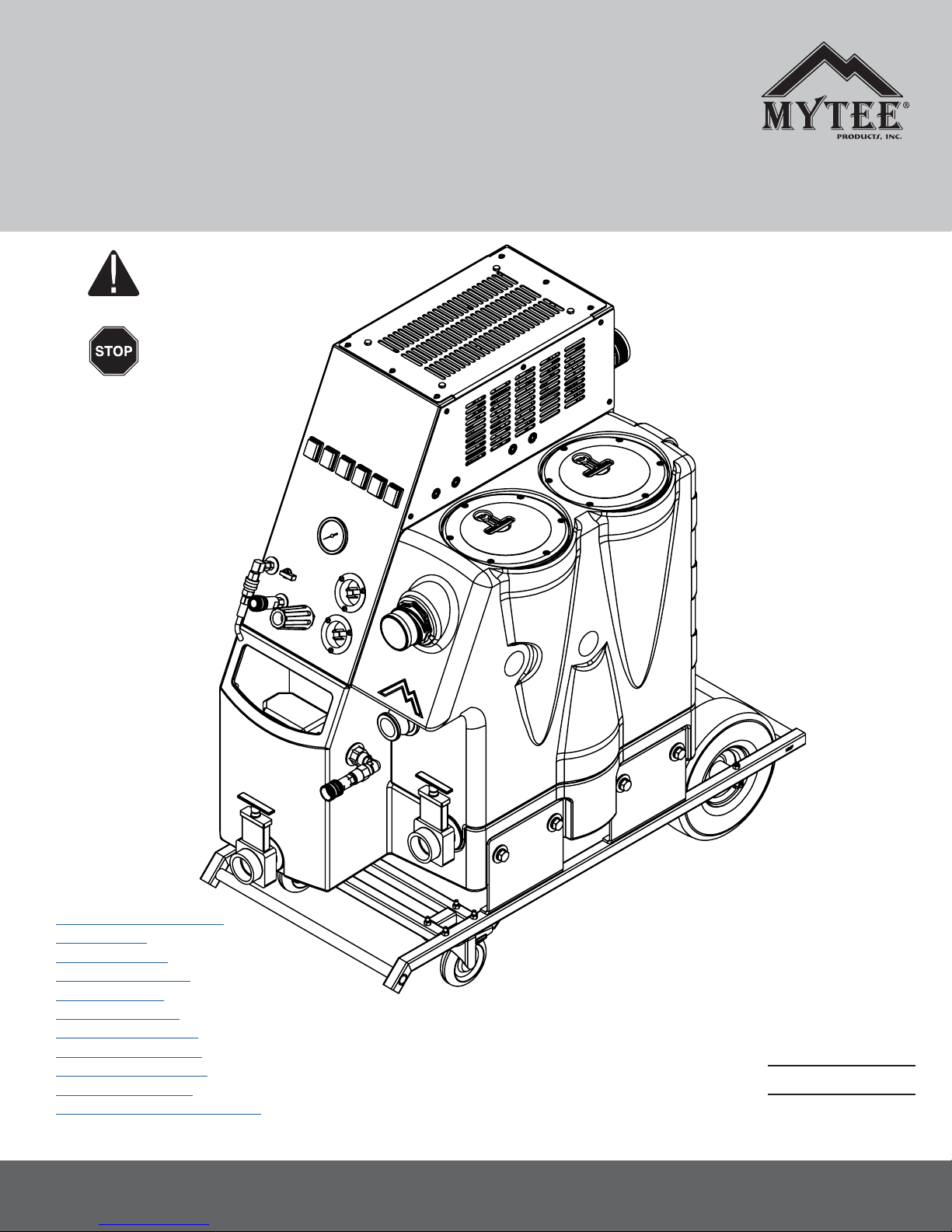

Instructions for

ESCAPE

Please read before use.

Register your product

at http://www.mytee.

com/support/register

™

ETM

General Information p. 2

Features p. 7

Switchplate p. 8

Power Options p. 9

Operation p. 10

Accessories p. 12

Parts & Pricing p. 14

Wiring Diagram p. 17

Vacuum System p. 19

Pump System p. 20

Auto Pump-Out System p. 21

Model #

Serial #

Form # ADP-ETM

9-17

13655 Stowe Dr., Poway, CA 92064

1

Page 2

GENERAL INFORMATION

Dear Customer:

Congratulations on the purchase of your new Escape™ ETM. As

technology continues to develop you can work condently knowing that

both Mytee Products Inc. and its employees are equally dedicated to

developing with the industry and its advances.

Like any other piece of machinery or technology, the ETM also requires

the proper maintenance and care to keep the product working over

extended use. Neglecting your machine, abusing it or not operating it

properly can void its warranty and prevent the machine from performing to

the quality and standard you’d expect out of the Mytee Products Inc. line.

If you have any warranty concerns or questions, please review this manual

thoroughly or do not hesitate to contact your distributor. If there are questions regarding maintenance, replacement or ordering parts please contact

an authorized Mytee Products Inc. Service Center. To see an updated list

please visit our website at http://www.mytee.com/support/service-centers/

Before using your Mytee Product, please read this manually thoroughly.

Sincerely,

Mytee Customer Care Dept.

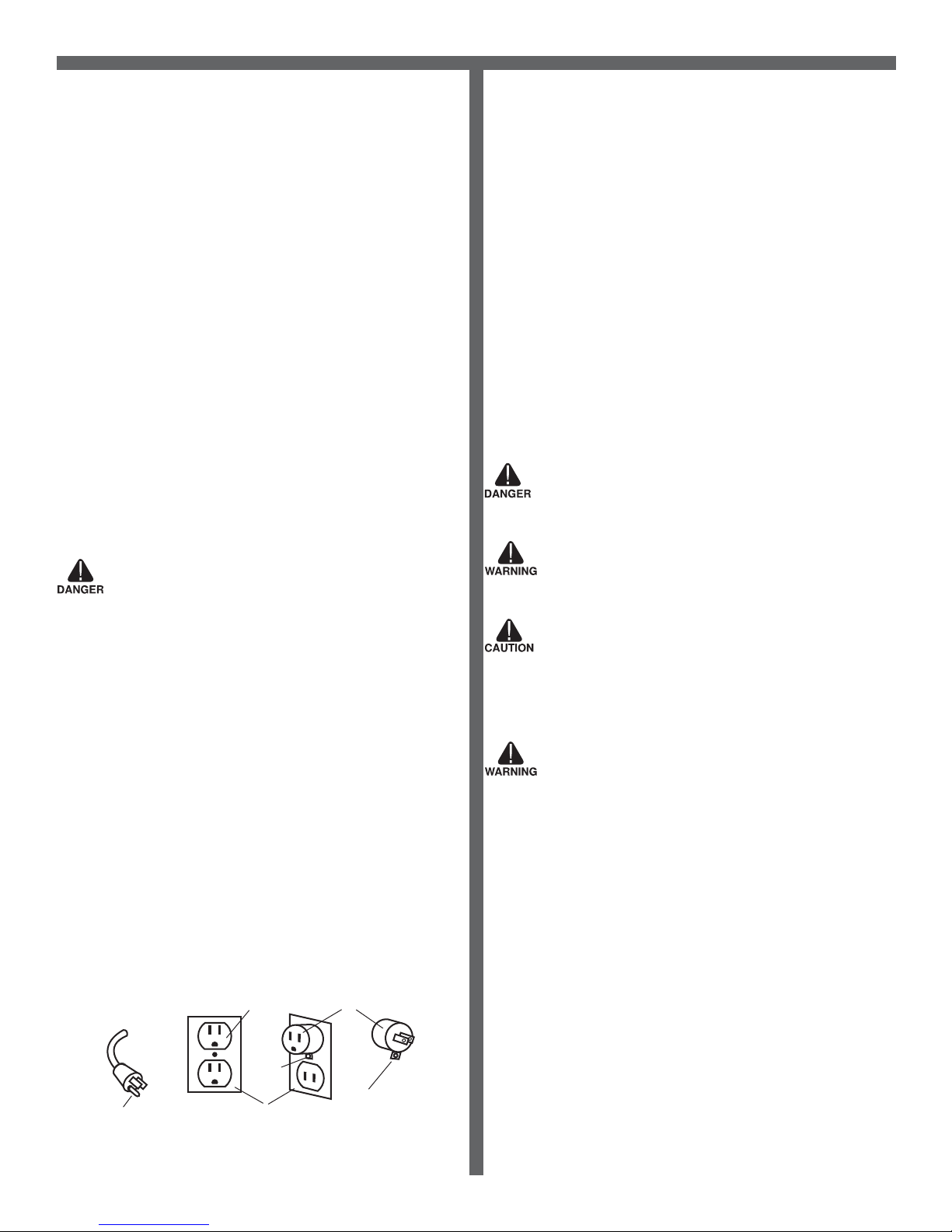

Grounding Instructions

This machine must be grounded. If it should malfunction or breakdown,

grounding provides a path of least resistance for electrical shock. This machine is equipped with a cord having an equipment-grounding conductor

and grounding plug. The plug must be plugged into an appropriate outlet

that is properly installed in accordance with all local code and ordinances.

Do not remove ground pin; if missing, replace plug before use.

Improper installation of the equipment-grounding conductor can result

in a risk of electric shock. Be sure to check with a qualied electrician

or service person if you are in doubt as to whether the outlet is properly

grounded. If the plug will not t in the outlet do not modify either the plug

nor the machine’s cord, instead have a proper outlet installed by a qualied technician.

This machine is for use on a nominal 120-volt circuit and with a grounding

plug similar to the one in Figure 1 below. If a proper outlet is not available,

follow the illustrations of Figure 2 & 3 to install a temporary-grounding

plug. This temporary work-around should be used only until a proper outlet

(Figure 1) can be installed by a qualied electrician. When and if this type

of adapter is employed, screw the adapter’s extended tab into place with

a metal screw. However, grounding adapters are not approved for use in

Canada.

Again, be sure to check the grounding pin for damages and replace if

necessary.

The Green, or Green-Yellow, wire in the cord is the grounding wire. When

replacing a plug, this wire must be attached to only the grounding pin.

DO NOT use extension cords.

Please Note for America use only

Grounding Pin

Figure 1

Grounded Outlet

Metal

Screw

Grounded Outlet Box

Figure 2 Figure 3

Adapter

Tab for Grounding

Screw

Parts and Service

Please contact a Mytee service personnel or Mytee authorized Service

Center using Mytee original replacement parts and accessories for repairs

are needing to be performed. When and if calling Mytee for support,

please have your Model and Serial Number available for faster assistance.

Name Plate

The Model and Serial Number are located on the lower half of the back

of the machine near the power plugs and will be required for ordering

replacement parts. You can use the space provided on the front of this

manual to note down both for future referencing.

Unpacking the Machine

When your new machine is delivered, please carefully inspect both the

shipping carton and the machine for damages. If damage is evident, save

both the shipping carton and machine so that the delivering carrier can

inspect it. Contact the carrier immediately to le a freight claim if there has

been any damage.

Caution and Warnings

Symbols

Mytee uses the symbols below to signal potentially dangerous conditions.

Always read this information carefully and take the necessary steps to

protect personnel and property.

Is used to warn of immediate hazards that will cause severe personal

injury or death.

Is used to call attention to a situation that could cause severe personal

injury.

Is used to call attention to a situation that could cause minor personal

injury or damage to the machine or other property. When using an electrical appliance, basic precautions should always be followed, including the

following: Read all instructions before using this machine. This product is

intended for commercial use only.

To reduce the risk of re, electrical shock, or injury:

1. Read all instructions before using equipment.

2. Use only as described in this manual. Use only manufacturer’s recommended attachments.

3. Always unplug power cord from electrical outlet before attempting any

adjustments or repairs.

4. Do not unplug by pulling on cord. To unplug, grasp the plug, not the

cord.

5. Do not pull or carry by cord. Do not close a door on cord or pull cord

around sharp edges or corners.

6. Do not run appliance over cord. Keep cord away from heated surfaces.

7. Do not use with damaged cord or plug. If cord is damaged, repair

immediately.

8. Do not use outdoors or on wet surfaces and or standing water.

9. Always unplug or disconnect the appliance from power supply when

not in use.

10. Do not allow to be used as a toy. Close attention is necessary when

used by or near children.

11. Do not use in areas where ammable or combustible material may

be present.

12. Do not leave the unit exposed to harsh weather elements. Temperatures below freezing may damage components and void warranty.

13. Use only the appropriate handles to move and lift unit. Do not use any

other parts of this machine for this purpose.

14. Keep hair, loose clothing, ngers, and all parts of the body away from

2

Page 3

GENERAL INFORMATION

all openings and moving parts.

15. Use extra care when using on stairs.

16. To reduce the risk of re or electric shock, do not use this machine with

a solid-state speed control device.

17. The voltage and frequency indicated on the name plate must correspond to the wall receptacle supply voltage.

18. When cleaning and servicing the machine, local or national regulations

may apply to the safe disposal of liquids which may contain: chemicals,

grease, oil, acid, alkalines, or other dangerous liquids.

19. Do not leave operating unattended.

Escape Electronic Truckmount

Unpacking the Machine

When your new machine is delivered, please carefully inspect both the

shipping carton and the machine for damages. If damage is evident, save

both the shipping carton and machine so that the delivering carrier can

inspect it. Contact the carrier immediately to le a freight claim if there has

been any damage.

Installation:

Due to the variety of mounting conditions, Mytee Products Inc. does not

supply the necessary hardware to mount the ETM to the operating vehicle.

1. Do no attempt to move the ETM neither to nor from a vehicle with the

tanks full.

2. Please refer to a qualied technician for safe and proper installation into

your operating vehicle

Grounding Instructions

This machine MUST be grounded. If the machine should malfunction or

break down, grounding provides a path of least resistance for the electrical

current to safely dissipate. This machine is also manufactured with an

equipment-grounding conductor and grounding-plug. The plug must be

used on an appropriate outlet that is properly installed in accordance with

all local code and ordinances. Do not remove the ground pin. If it is missing, replace the plug prior to use. Improper installation of the equipmentgrounding conductor can result in a risk of electric shock. Be sure to check

with a qualied electrician or service person if you are in doubt as to

whether the outlet is properly grounded. If the plug will not t in the outlet

do not modify either the plug or the machine’s cord, instead have a proper

outlet installed by a qualied technician. This machine is for use on a

nominal 120-volt circuit and with a grounding plug. If a proper outlet is not

available, install a temporary-grounding plug. This temporary workaround

should be used only until a qualied electrician can install a proper outlet.

When and if this type of adapter is employed, screw the adapter’s ex-

tended tab into placewith a metal screw. However, grounding adapters are

not approved for use in Canada. Again, be sure to check the grounding pin

for damages and replace if necessary. The Green, or Green-Yellow, wire in

the cord is the grounding wire. When replacing a plug, this wire must be

attached to only the grounding pin. DO NOT use extension cords other

than provided.

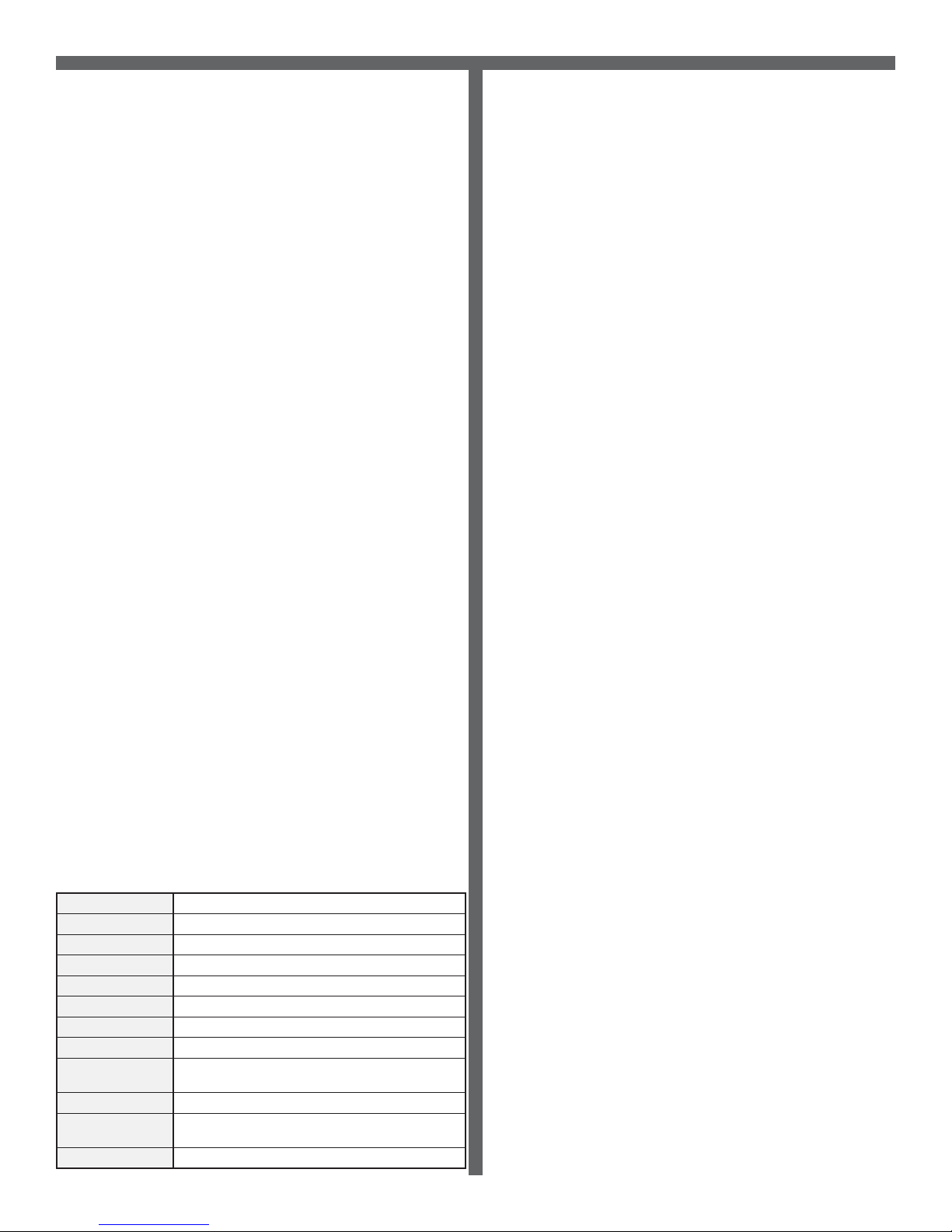

Machine Specications

Solution Tank 12 gallons

Recovery Tank 12 gallons

Vacuum Quad 3-stage

CFM 325

Water Lift 230” or 16.5” Hg

Pump PSI 1,2 00

Pump GPM 2.4

Pump- Out GPM 35

Power

Consumption

Machine Weight 200 lbs.

Machine

Dimensions

Power Cord Dual twist-lock 50’ 12/3

Cord one: 20 amps @ 230V 60Hz/50Hz

Cord two: 10 amps @ 230V 60Hz /50Hz

Without cart: 32 ” x 21.25” x 36”

With cart: 43” x 21.25” x 44.25”

Operating Instructions:

POWER CORDS

There are four basic ways to power your ETM:

1. Plug converter box into 3 prong dryer outlet (230V), then plug both

power leads from the machine into the converter box.

2. Plug converter box into 4 prong dryer/range outlet (230V), then plug

both power leads from the machine into the converter box.

3. Plug one of the ETM cords into the 115V hunter box (sold separately),

which then plugs into two 115V outlets. This will allow you to use your

pump and two of your vacuums for cleaning.

4. Locate 4 115V outlets, and plug in both hunter boxes (sold separately).

This will allow you to run the entire unit. See the back of the converter

boxes for more details.

TO OPERATE

1. Attach the end of a garden hose to the auto-ll male QD and other end

to a water faucet.

2. Turn on the water until the automatic Shut-Off disengages water ow.

3. Using the hose attached to the primer, rest it inside the 2 ½” Vacuum

Port and turn both vacuums on.

4. Locate the Pump Prime and run valve and set to the prime position and

turn pump on.

5. Once water ows through prime hose switch the Prime Valve to run.

6. Regulate the PSI at ≤ 1000.

7. Attach the vacuum hose to the 2 ½” Cuff-Lynx hose port.

8. Connect a wand or other device to the front panel QD.

9. You may now begin cleaning.

10. When the vacuum shuts off you may need to drain the Recovery Tank

using one of the three methods:

a. Release the drain valve.

b. Activate the 35 GPM pump out.

11. When nished, be sure to drain any remaining uids from the hoses

and wands.

12. Shut off all the switches.

After Use

1. Before storing the machine, drain, rinse and dry both the tanks and

vacuum hoses of any residual water or solution.

2. Store standing upright in a dry, enclosed location.

3. Leave the recovery tank lid open for better air circulation.

If storing in freezing temperatures, take extra precautions to make sure the

machine and solution systems are completely drained and dry.

Filter Maintenance

All ETM models have three lters that need to be checked and cleaned

after each week of use. Regular cleaning and changing of lters is a

simple way to extend the life of your machines.

Vacuum Stack Filters

Located inside of the black vacuum tank are two pvc vacuum stacks.

Each stack has one foam lter to help prevent waste material from getting

into the vacuums and causing damage. To maintain these lters:

1. Remove 7” clear vacuum tank.

2. Reach in and pull out the two black lters located in the top ports of the

vacuum stacks.

3. Clean lters of any debris and check for damage. If lters are not

damaged, place them back into the stacks. If lters are damaged and

falling apart, replace them.

Pump Filter

The pump lter is a half-circle shaped screed located on the inside bottom

of the blue solution tank. To maintain lter:

1. Open black solution tank lid.

2. Reach into solution tank and rotate the dome shaped lter from its brass

nipple by rotating it counter clockwise.

3. Check lter for any debris or damage to screen. Rinse lter of any

debris or replace if damaged.

4. Place new or cleaned lter back onto brass nipple by rotating it

clockwise.

3

Page 4

GENERAL INFORMATION

ETM Float Switch Maintenance

Each ETM machine contains three water level oat switches. These oat

switches control certain functions of the machine. The rst oat switch will

control the auto-ll feature. The second oat switch controls power to the

vacuums. The third oat switch controls when the large sump pump

comes on and helps to prevent cavitation in the pump. Having these

prevents water from getting into the vacuum stacks and from spilling out

of the solution tank.

Vacuum Float Switch Maintenance and Replacement

Cleaning and maintaining oat switches will help to extend the life your

machine. Regular cleaning is required for proper functionality. To clean the

vacuum level switch:

1. Remove 7” clear vacuum tank lid located on top of the vacuum tank.

2. Use a ashlight to locate the position of the oat switch. The vacuum

tank oat switch will be located on the inside wall of the tank just below the

vacuum ports.

3. Once located, reach in and hold the oat switch nger all the way to one

side by pushing on the opposite side.

4. Using your other hand, or nger, roll the clip off of its tabs by pulling on

the bottom of the opposite tab from which you are pushing. It should not

take a lot of pressure to remove the switch, so be careful not to break it.

5. Check oat nger and where it attaches for debris or any other damage.

If dirty, clean. If damaged, or one of the male tabs where the oat hooks is

damaged, refer to the oat switch replacement section.

6. Once cleaned, replace oat nger, at side down, onto the male position

tabs located on the oat switch body in the vacuum tank. First, hook one

side of the nger to one tab. Then roll and pull the tab with index nger

until other clip snaps into place.

7. Check to insure oat still works by turning on both vacuums with the

vacuum tank lid off. Reach inside and lift the oat nger. If vacuums turn

off, the oat works. If the vacuums stay on, oat body may need replacement, or oat nger is installed upside down.

Vacuum Float Switch Replacement

Required:

-Colored tape

-New oat switch, rubber washer, and plastic nut

-Silicone

-Medium/deep depth 13/16” socket and ratchet

-Medium crescent wrench

-Philips screwdriver or drill

1. Using Philips head screw driver, remove ETM side panel by taking out

the ten Philips head screws holding panel onto machine.

2. Locate vacuum oat switch wires coming out of the black vacuum tank

directly under the vacuums. Disconnect the two oat switch wires that are

plugged into the system.

3. At this point, use the colored tape to mark the wires that the oat switch

was unplugged from. The back end of the vacuum oat switch should be

visible. Remove the 7” clear vacuum tank lid located on top of the vacuum

tank.

4. Use a ashlight to locate the position of the oat switch inside of the

tank. The vacuum oat switch will be located on the inside wall of the tank

below the vacuums.

5. Once located, reach in and hold the oat switch nger all the way to one

side by pushing on the opposite side.

1. Using your other hand, or nger, roll the clip off of its tabs by pulling on

the bottom of the opposite tab from which you are pushing. It should not

take a lot of pressure to remove the switch, so be careful not to break it.

2. Place the medium crescent wrench on the back nut of the oat switch

and the 13/16” socket on the inside nut of the oat switch. Loosen the oat

by rotating the ratchet counter clockwise until completely loose.

Make sure not to lose any nuts or rubber washers in case they are needed

in the future.

3. On the new oat switch, hold the oat switch nger all the way to one

side by pushing on the opposite side.

4. Using your other hand, or nger, roll the clip off of its tabs by pulling on

the bottom of the opposite tab from which you are pushing. It should not

take a lot of pressure to remove the switch, so be careful not to break it

5. Place the rubber washer over the threads of the new switch and all the

way down to the 13/16” nut side.

6. Place a thin layer of silicone on the rubber washer.

7. Thread oat switch (with actuating nger off) wires back through

vacuum tank hole and thread in using the 13/16” socket.

8. Using your hand, thread the plastic nut onto the back side of the oat

switch. Place medium crescent wrench on the nut to hold in place

9. Tighten the 13/16” oat until snug. Make sure at side of oat body is

facing towards the top of the vacuum tank.

10. Replace oat nger, at side down, onto the male position tabs located

on the oat switch body in the vacuum tank. First, hook one side of the

nger to one tab. Then roll and pull the tab with index nger until other clip

snaps into place.

11. Check to insure new oat switch works by turning on both vacuums

with the vacuum tank lid off. Reach inside and lift the oat nger. If vacuums turn off, the oat works. If the vacuums stay on or will not turn on,

the oat nger may be installed upside down or wires were not connected

completely.

Auto-ll Float Switch Maintenance and Replacement

Cleaning and maintaining oat switches will help

to extend the life your machine. Regular cleaning is

required for proper functionality. To clean the auto-ll

level switch:

1. Remove silver cover on the front of the blue solution tank by removing

the four Philips head screws.

2. Use a ashlight to locate the position of the oat switch. The auto-ll

oat switch will be located on the inside wall of the tank just below the

water inlet.

3. Once located, reach in and hold the oat switch nger all the way to one

side by pushing on the opposite side.

4. Using your other hand, or nger, roll the clip off of its tabs by pulling on

the bottom of the opposite tab from which you are pushing. It should not

take a lot of pressure to remove the switch, so be careful not to break it.

5. Check oat nger and where it attaches for debris or any other damage.

If dirty, clean. If damaged, or one of the male tabs where the oat hooks is

damaged, refer to the oat switch replacement section.

6. Once cleaned, replace oat nger, at side down, onto the male position

tabs located on the oat switch body in the vacuum tank. First, hook one

side of the nger to one tab. Then roll and pull the tab with index nger

until other clip snaps into place.

7. Check to insure oat still works by turning on both vacuums with the

vacuum tank lid off. Reach inside and lift the oat nger. If vacuums turn

off, the oat works. If the vacuums stay on, oat body may need replacement, or oat nger is installed upside down.

Auto-ll Float Switch Replacement

Required:

-Colored tape

-New oat switch, rubber washer, and plastic nut

-Silicone

-Medium/deep depth 13/16” socket and ratchet

-Medium crescent wrench

-Philips screwdriver or drill

1. Using Philips head screw driver, remove ETM side panel by taking out

the ten Philips head screws holding panel onto machine.

2. Locate vacuum oat switch wires coming out of the

blue solution tank directly behind the main pump. Disconnect the two oat

switch wires that are plugged into the system. At this point, use the

colored tape to mark the wires that the oat switch was unplugged from.

3. The back end of the vacuum oat switch should be visible.

4. Use a ashlight to locate the position of the oat switch inside of the

tank. The vacuum oat switch will be located on the inside wall of the tank

below the vacuums.

5. Once located, reach in and hold the oat switch nger all the way to one

side by pushing on the opposite side.

6. Using your other hand, or nger, roll the clip off of its tabs by pulling on

the bottom of the opposite tab from which you are pushing. It should not

take a lot of pressure to remove the switch, so be careful not to break it.

7. Place the medium crescent wrench on the back nut of the oat switch

4

Page 5

GENERAL INFORMATION

and the 13/16” socket on the inside nut of the oat switch. Loosen the oat

by rotating the ratchet counter clockwise until completely loose. Make sure

not to lose any nuts or rubber washers in case they are needed in the

future.

8. On the new oat switch, hold the oat switch nger all the way to one

side by pushing on the opposite side.

9. Using your other hand, or nger, roll the clip off of its tabs by pulling on

the bottom of the opposite tab from which you are pushing. It should not

take a lot of pressure to remove the switch, so be careful not to break it

10. Place the rubber washer over the threads of the new switch and all the

way down to the 13/16” nut side.

11. Place a thin layer of silicone on the rubber washer.

12. Thread oat switch (with actuating nger off) wires back through

vacuum tank hole and thread in using the 13/16” socket.

13. Using your hand, thread the plastic nut onto the back side of the oat

switch. Place medium crescent wrench on the nut to hold in place

14. Tighten the 13/16” oat until snug. Make sure at side of oat body is

facing towards the top of the vacuum tank.

15. Replace oat nger, at side down, onto the male position tabs located

on the oat switch body in the vacuum tank. First, hook one side of the

nger to one tab. Then roll and pull the tab with index nger until other clip

snaps into place.

16. Check to insure new oat switch works by turning on water for auto-ll

with the solution tank lid off. Reach inside and lift the oat nger. If water

stops, the oat works. If the water keeps running, the oat nger may be

installed upside down or wires were not connected completely.

Sump Pump Switch Maintenance and Replacement

Cleaning and maintaining oat switches will help to

extend the life your machine. Regular cleaning is

required for proper functionality. To clean the sump

level switch:

1. Remove 7” clear vacuum tank lid located on top of the vacuum tank.

2. Use a ashlight to locate the position of the oat switch. The sump

pump oat switch will be located on the inside wall of the tank almost at

the bottom.

3. Once located, reach in and hold the oat switch nger all the way to one

side by pushing on the opposite side.

4. Using your other hand, or nger, roll the clip off of its tabs by pulling on

the bottom of the opposite tab from which you are pushing. It should not

take a lot of pressure to remove the switch, so be careful not to break it.

5. Check oat nger and where it attaches for debris or any other damage.

If dirty, clean. If damaged, or one of the male tabs where the oat hooks is

damaged, refer to the oat switch replacement section.

6. Once cleaned, replace oat nger, at side up, onto the male position

tabs located on the oat switch body in the vacuum tank. First, hook one

side of the nger to one tab. Then roll and pull the tab with index nger

until other clip snaps into place.

7. Check to insure oat still works by turning on both vacuums with the

vacuum tank lid off. Reach inside and lift the oat nger. If vacuums turn

off, the oat works. If the vacuums stay on, oat body may need replacement, or oat nger is installed upside down.

Sump Pump Switch Replacement

Required:

-Colored tape

-New oat switch, rubber washer, and plastic nut

-Silicone

-Medium/deep depth 13/16” socket and ratchet

-Medium crescent wrench

-Philips screwdriver or drill

1. Using Philips head screw driver, remove ETM side panel by taking out

the ten Philips head screws holding panel onto machine.

2. Locate sump pump oat switch wires coming out of the black vacuum

tank directly under the behind the main pump. Disconnect the two oat

switch wires that are plugged into the system. At this point, use the colored

tape to mark the wires that the oat switch was unplugged from.

3. The back end of the vacuum oat switch should be visible. Remove the

7” clear vacuum tank lid located on top of the vacuum tank.

4. Use a ashlight to locate the position of the oat switch inside of the

tank. The sump pump switch will be located on the inside wall of the tank

near the bottom front.

5. Once located, reach in and hold the oat switch nger all the way to one

side by pushing on the opposite side.

6. Using your other hand, or nger, roll the clip off of its tabs by pulling on

the bottom of the opposite tab from which you are pushing. It should not

take a lot of pressure to remove the switch, so be careful not to break it.

7. Place the medium crescent wrench on the back nut of the oat switch

and the 13/16” socket on the inside nut of the oat switch. Loosen the

oat by rotating the ratchet counter clockwise until completely loose. Make

sure not to lose any nuts or rubber washers in case they are needed in the

future.

8. On the new oat switch, hold the oat switch nger all the way to one

side by pushing on the opposite side.

9. Using your other hand, or nger, roll the clip off of its tabs by pulling on

the bottom of the opposite tab from which you are pushing. It should not

take a lot of pressure to remove the switch, so be careful not to break it

10. Place the rubber washer over the threads of the new switch and all the

way down to the 13/16” nut side.

11. Place a thin layer of silicone on the rubber washer.

12. Thread oat switch (with actuating nger off) wires back through

vacuum tank hole and thread in using the 13/16” socket.

13. Using your hand, thread the plastic nut onto the back side of the oat

switch. Place medium crescent wrench on the nut to hold in place

14. Tighten the 13/16” oat until snug. Make sure at side of oat body is

facing towards the BOTTOM of the vacuum tank. This is the ONLY switch

that will be positioned this way.

15. Replace oat nger, at side up, onto the male position tabs located

on the oat switch body in the vacuum tank. First, hook one side of the

nger to one tab. Then roll and pull the tab with index nger until other clip

snaps into place.

16. Check to insure new oat switch works by turning on the sump pump

on with the vac tank lid off. Reach inside and lift the oat nger. If sump

turns on. The oat works. If the sump will not turn on, or will not turn off,

the oat nger may be installed upside down or wires were not connected

completely.

Maintenance item Daily Once a week

Clean and inspect tanks.

Clean and inspect hoses.

Check and clean internal lters by twisting

off, rinsing with clean water and replacing.

Check power supply cable.

Clean machine with all-purpose cleaner

and cloth.

Check spray nozzles.

Flush solution system with Mytee® System

Maintainer.

Remove and oat shut-off screen from

tank and clean. Simply pull off.

Inspect vacuum hoses for holes and loose

cuffs.

Inspect spray pattern for clogging. If

clogged, remove spray tips and soak them

in a recommended liquid neutralizer for

up to six hours. To remove spray tip, twist

spray tip body counter-clockwise.

Lubricate wheels with water resistant oil.

Inspect machine for water leaks and loose

hardware.

x

x

x

x

x

x

x

x

x

x

x

x

Generators for use with Escape® Electric Truck Mount

Mytee Products recommends the use of a 10,000- ‐watt generator with

this unit. This will supply ample power for the ETM.

However, the Escape can be run on some 8,000- ‐watt generators, depending on the manufacturer. Generators are rated differently, so if

using 8,000- ‐watt generator the rating must represent continuous running

5

Page 6

GENERAL INFORMATION

watts, not peak watts.

In any case, check with the Generator manufacturer to ensure the unit

can provide 30 amps at 230 volts continuously.

6

Page 7

REVISIONS

REV.

DESCRIPTION

DATE

APPROVED

OD

ORIGINAL DRAFT

JFL

D

C

B

8

7

6

5

4

3

2

1

E

F

12/2013

UNLESS OTHERWISE SPECIFIED:

TITLE:

NAME

DATE

CHECKED

DRAWN

DIMENSIONS ARE IN INCHES

TOLERANCES:

ANGULAR: MACH

.5

858-679-1191

mytee

PRODUCTS, INC.

V. LaBarbera

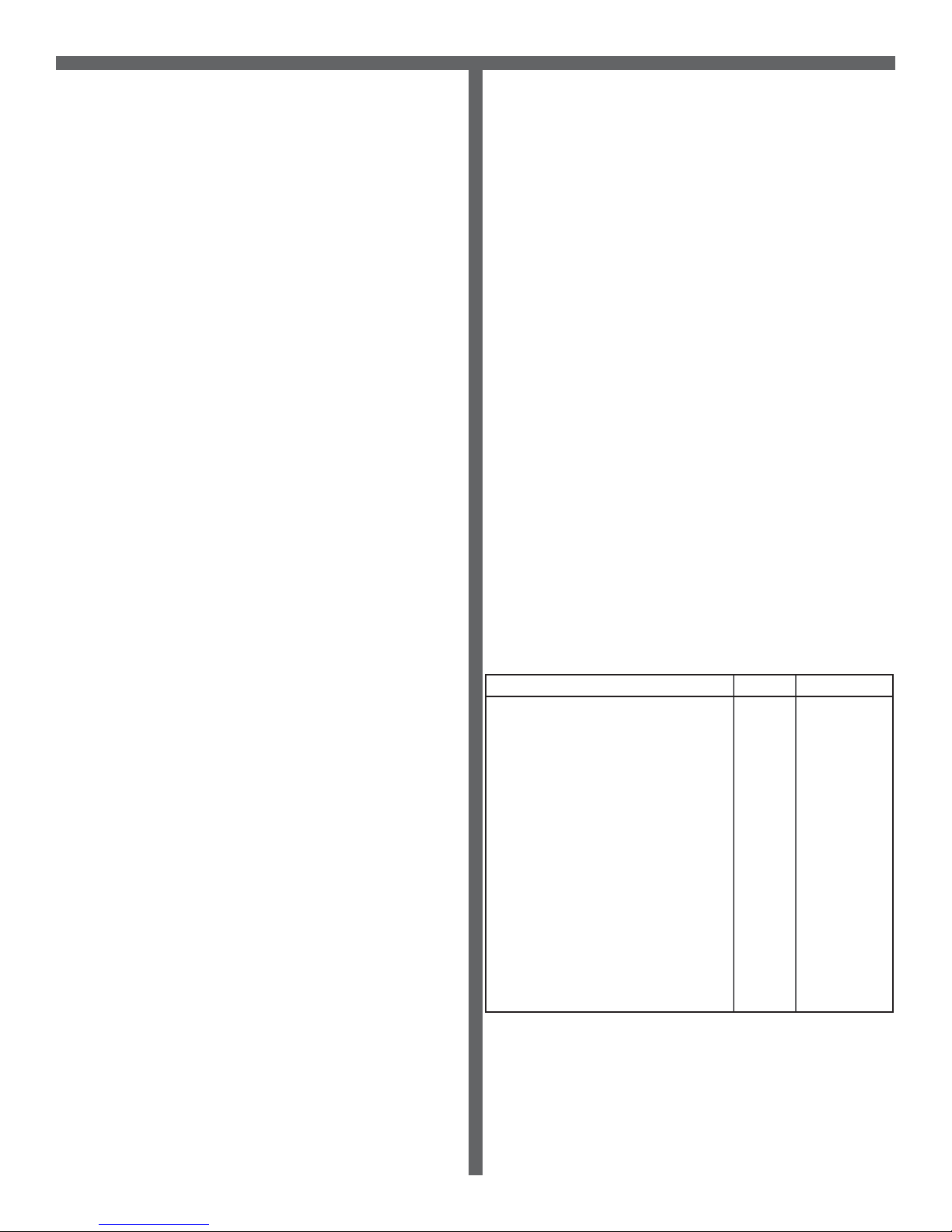

ESCAPE™ ETM

ESCAPE™ ETM BACKESCAPE™ ETM FRONT

12

1

2

3

4

5

6

7

1. Switch Plate

2. Prime Valve

3. Female Quick Disconnect

(QD)

4. Pressure Regulator

5. Electrical Power Ports

6. Solution Tank Drain Valve

7. Auto Fill

11

10

9

8

8. Recovery Tank Drain Valve

9. Pump-Out

10. 2” Male Cuff-Lynx™ Inlet

11. PSI Gauge

13

14

15

12. Recovery Lids

13. Recovery Tank

14. 4” Locking Casters

15. Cart

16. 10” foam lled wheels

17. Rear Cooling Fans

18. Top, Rear & Side Vents

19. Rear Vacuum Exhaust

19

18

17

16

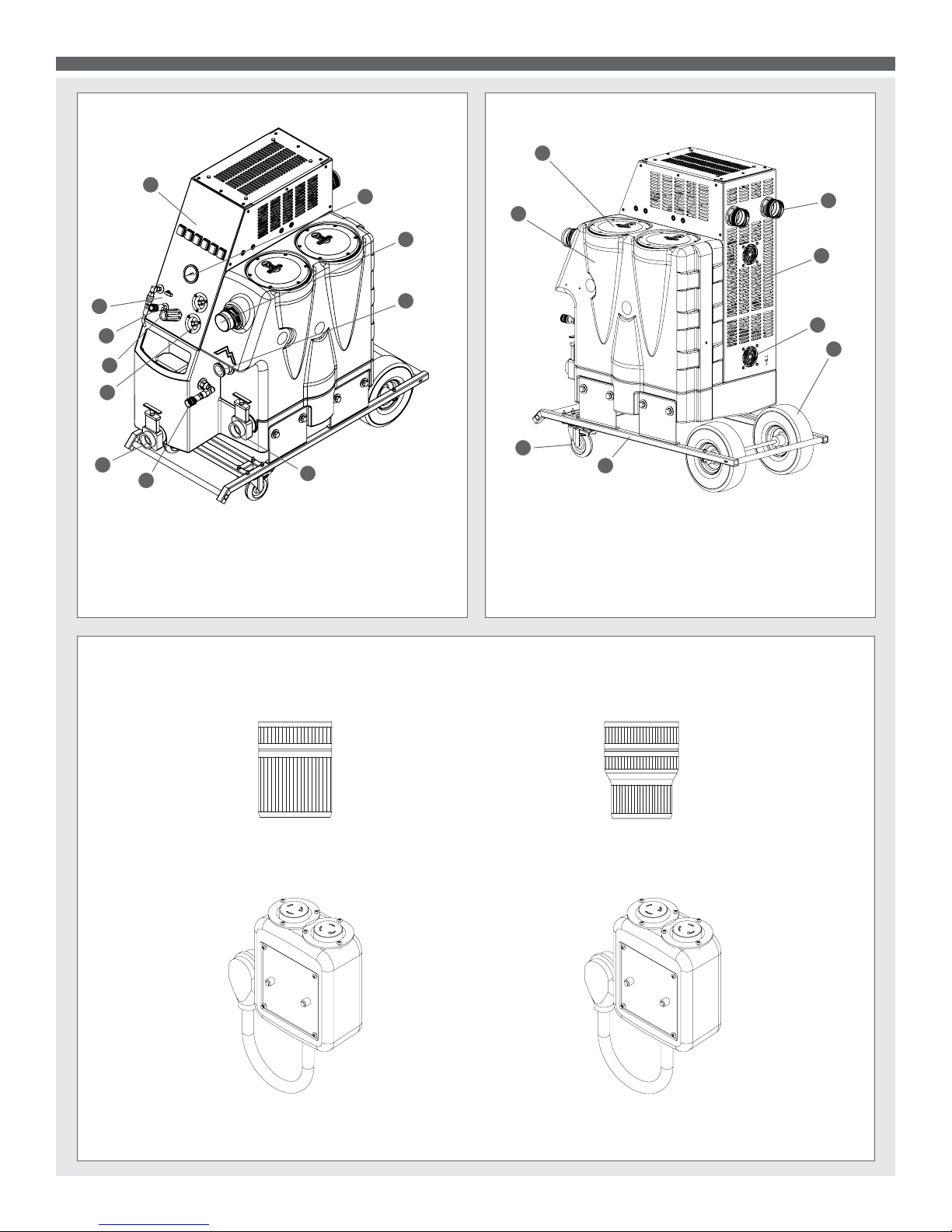

ESCAPE™ ETM ACCESSORY ITEMS INCLUDED

H107 Cuff-Lynx™

2.5” x 2.5” Hose Adapter

5005

3-prong Electrical Converter

H106 Cuff-Lynx™

2.5” x 2” Hose Reducer

5006

4-prong Electrical Converter

7

Page 8

ESCAPE™ ETM

ESCAPE™ ETM SWITCH PLATE AND POWER SOCKETS

Top Socket: Powers Vac 1, Vac 2 Pump, & Pump-out.

Bottom Socket: Powers Vac 3 and Vac 4.

Top power socket

Bottom power socket

Plug in to top socket to use vacuum 1 or 2, pump or pump-out. To use vacuum 3 or 4 plug in bottom socket.

8

Page 9

*sold separately

ESCAPE™ ETM

ESCAPE™ ETM POWER OPTIONS 1 & 2

Plug each 50’ power cord into the 3 or 4 prong electrical adaptor. Once connected, plug electrical adaptor into dryer outlet.

ESCAPE™ ETM POWER OPTION 3 USING HUNTER BOXES (SOLD SEPARATELY)

*

*

Plug each 50’ power cord in the hunter boxes (sold separately - part # 5007). Once connected to the hunter boxes, plug each cord in to four

separate 115 volt electrical legs.

9

Page 10

ESCAPE™ ETM

ESCAPE™ ETM PSI GAUGE & REGULATOR

The gauge allows you to monitor PSI levels. Turning the Pressure

Regulator to its left will decrease water pressure and turning to the

right will increase water pressure. *Please refer to the Pressure

Gauge to monitor your water pressure.

ESCAPE™ ETM PUMP PRIME / WASH OUT HOSE

The wash out hose is available for rinsing out recovery tank.

ESCAPE™ ETM SOLUTION HOSE AND VACUUM HOOK UP

Attach female end of a solution hose to a wand or tool then attach male end of QD to ETM. Attach hose along with a 2.5” Cuff-Lynx™ hose

adapter to the ETM’s hose port. Then connect a vacuum hose or tool to other end of hose.

10

Page 11

ESCAPE™ ETM

ESCAPE™ ETM AUTO FILL & SOLUTION TANK DUMP VALVE

For a convienent way to ll up the ETM’s solution tank, connect a water hose to the auto-ll. This will help speed up the work ow. Once the

water level reaches a certain point the water stops, then rells again. Empty the solution tank by pulling the solution tank dump valve.

ESCAPE™ ETM PUMP OUT HOOK UP &

ESCAPE™ ETM CLEAR T - LIDS

RECOVERY TANK DUMP VALVE

Attach hose bearing cam lock to the Pump-out tting. Secure the

hose to the tting using the cam lock. Push the hose cuff onto

the tting, making sure the silver ears and rings are extended

forward. Pull the ears down using the rings until connection is

tight. Place the end of the hose in a location where dirty water

can drain. Using the recovery tank drain valve is also available.

Recovery tank lids for easy entry.

11

Page 12

ESCAPE™ ETM ACCESSORIES

D

C

B

2

1

E

F

D

C

B

2

1

E

F

T-80R - Recovery Tank T-80S - Solution Tank

A500 - Stackable Van

T-REX™ - Total

Rotary Extraction

Shelving System Set

T-REX™ Jr. - Total

Rotary Extraction

12

Page 13

ESCAPE™ ETM ACCESSORIES

REVISIONS

REV.

DESCRIPTION

DATE

APPROVED

OD

ORIGINAL DRAFT

JFL

D

C

B

6

5

4

3

2

1

E

F

2/5/10

UNLESS OTHERWISE SPECIFIED:

TITLE:

NAME

DATE

COMMENTS:

CHECKED

DRAWN

DIMENSIONS ARE IN INCHES

TOLERANCES:

ANGULAR: MACH

.5

ONE PLACE DECIMAL

.03

A

858-679-1191

mytee

PRODUCTS, INC.

V. LaBarbera

8901 - Wand Style

2” Spinner®

8902 - “T” Style

2” Spinner®

8908 - Counter Spinner®

13

Page 14

ESCAPE™ ETM PARTS & PRICING

ITEMS NOT SHOWN

ITEM

NO.

PART NO.

DESCRIPTION

QTY.

MSRP

1

P505

ETM Sol Tank / Chassis

1

$224.99 ea

2

H541A

valve, float, autofill

1

$108.99 ea

3

H097

washer, 1"ID x 1.5"OD, flat, s/s

2

$0.99 ea

4

B182

adapter, 3/4" fgh x 1/2" fpt

1

$12.99 ea

5

B273

elbow, 90 deg street, 3/8"fpt x 1/2" mpt

1

$8.99 ea

6

H541C

chemical injector

1

$39.99 ea

7

B204

qd, 3/4" female x female garden hose

1

$9.99 ea

8

B205B

QD, 1/2" npt x 3/4" mgh, pump-out

1

$3.99 ea

9

B272

adapter, 1/2" fpt x 3/8 mpt

1

$16.99 ea

10

PH634-33 sol hose, 1/4", silicone braided, clear

1

$6.49 ft

11

B170

ferrule, 1/4" brass

6

$0.99 ea

12

B109

adapter, brass, 1/4" barb x 1/4" mpt

4

$1.99 ea

13

H484

plate, mounting, QD

1

$4.99 ea

14

B656B

valve, ball, 1/4" fpt x 1/4" fpt, s/s

2

$13.49 ea

15

B127

plug, brass, 1/4"mpt, hex

2

$0.99 ea

16

H230

screw, 10-32 x 1/2" phil pan head, s/s 38

$0.99 ea

17

H225

valve, drain, 1-1/2"

2

$20.99 ea

18

H203

bolt, 1/4-20 x 1-1/4" hex head, s/s

2

$0.99 ea

19

H213

washer, 1/4" lock, s/s

10

$0.99 ea

20

H210

washer, 1/4" flat, s/s

10

$0.99 ea

21

H196

support, pump, truckmount

1

$18.99 ea

22

H201

bolt, 1/4-20 x 1/2" hex head, zinc

2

$0.99 ea

23

PH615-35 sol hose, 1/2", silicone braided clear

1

$8.99 ft

24

B173

ferrule, 1/2", brass

3

$0.99 ea

25

B644

adapter, brass, 1/2" barb x 1/4" mpt

1

$2.49 ea

26

B119

filter, strainer, 1/4"

1

$3.99 ea

27

H012

instrument panel, truck mount

1

$185.99 ea

28

E628A

controller, water level, single, 230V

1

$114.99 ea

29

H273

nut, kep, #10-32 zinc

7

$0.99 ea

30

E360

flanged male inlet recaptacle, 230V, 20A

2

$28.99 ea

31

PH634-20 sol hose, 1/4", silicone braided, clear

1

$6.49 ft

32

H046

screw, 10-32 x 3/8", phil pan, zinc

2

$0.99 ea

33

H289

washer, 10 flat, s/s

2

$0.99 ea

34

AH184

hose, pulse, 3/8" x 14.5", 1/4 FSW x 1/4 FPT

2

$27.99 ea

35

PH634-24 sol hose, 1/4", silicone braided, clear

1

$6.49 ft

36

B652

elbow, brass, 90 deg, 3/8"mpt x 1/4"mpt

2

$8.49 ea

37

H306C

unloader, 1200 psi

1

$125.99 ea

38

B103

elbow, brass, 90 deg, 1/4"mpt x 1/4" fpt

8

$4.49 ea

39

H876

washer, 1/2" flat, s/s

5

$0.99 ea

40

B111

adapter, brass, extender, 1/4" mpt x 1/4" fpt, hex

2

$3.49 ea

41

B102

qd, brass, 1/4" f x 1/4" fpt

1

$17.99 ea

42

B142A

coupling, brass, 1/4" fpt x 1/4" fpt

4

$4.49 ea

43

B135

tee, brass, 1/4" mpt

1

$5.49 ea

44

PH634-36 sol hose, 1/4", silicone braided, clear

1

$6.49 ft

45

B110

adapter, brass, 1/4" sw barb x 1/4" fpt, w/gasket

1

$3.99 ea

46

B259

qd, brass, 1/4" fqd x mpt

1

$11.99 ea

47

B260

qd, brass, 1/4" mqd x fpt

1

$10.49 ea

48

B107

nipple, brass, 1/4"m, hex

4

$3.19 ea

49

B136

elbow, brass, 90 deg, 1/4" mpt x 1/4" mpt

3

$4.99 ea

50

H325

flow meter, electric truckmount

1

$189.99 ea

51

G069

gasket, flow meter

1

$0.99 ea

52

B129

nipple, hex, 1/8" mpt x 1/8" mpt

2

$1.99 ea

53

B131

fitting, 1/4" barb x 1/8" FPT

2

$2.99 ea

54

H308D

gauge, pressure, 2000psi

1

$38.99 ea

55

B130

45 deg, street elbow, brass, 1/4" male

1

$5.49 ea

56

E369

hour meter, panel mount, analog

1

$35.99 ea

57

E515

switch, rocker, 2 position

6

$13.99 ea

58

H009

side panel, truckmount

1

$189.99 ea

59

P535

bottle, 5 quart, w/ caps

1

$16.99 ea

60

G036

cap, 2.5" threaded, tethered

1

$3.49 ea

61

H547

hanger, wire for injection sprayer

1

$7.49 ea

62

H456B

cap (only) w/ hole

1

$3.99 ea

63

PH634-35 sol hose, 1/4", silicone braided, clear

1

$6.49 ft

64

B117

strainer, with check, chemical injector

1

$18.99 ea

65

C332

pump head, general, 2.1 GPM

1

$569.99 ea

66

B186

elbow, brass, 90 deg, 3/8"mpt x 3/8" fmpt

1

$8.99 ea

67

B172

elbow, brass, 90 deg, 1/2" barb x 3/8"mpt

1

$9.49 ea

68

B105

bushing, brass, 3/8"mpt x 1/4"

1

$3.19 ea

PART NO.

DESCRIPTION

QTY.

MSRP

A959

harness, electrical

1

$74.99 ea

E351

power cord, ext, 50', 12/3, twist lock

2

$78.99 ea

H106

Cuff-Lynx, 2" hose x 2.5" female

1

$4.99 ea

H107

Cuff-Lynx 2.5" hose x 2.5" f swivel

1

$4.99 ea

H294

vac hose, 1-1/2" x 25' SW 1

$74.99 ea

H205

cam & groove fitting 1-1/2", female w/ lock

1

$32.99 ea

5005

electrical adaptor ETM - 3 prong

1

$169.99 ea

5006

electrical adaptor ETM - 4 prong

1

$159.99 ea

ADM-ETM

ETM manual

1

ITEM

NO.

PART NO.

DESCRIPTION

QTY.

MSRP

69

C329

motor, for pump, 1 HP, 1725 RPM

1

$359.99 ea

70

AH203

hose, pulse, 3/8" x 34", (OAL)

2

$47.99 ea

71

B113

tee, brass, 1/4" fpt

1

$6.99 ea

72

B643 adapter, brass, 3/8" fnpt x 1/4" mnpt

2

$4.99 ea

73

C304

motor, 3-stage, 115 cfm,14.5 amps

4

$199.99 ea

74

H217

clamp, hose, 2-1/4 dia

9

$1.49 ea

75

PH628-16

vac hose, 2", black, wire reinforced

2

$8.99 ft

76

H768

bolt, 1/4-20 x 3/4" serrated hex flange, zinc

6

$0.99 ea

77

H501

vac support, 3 stage, 4-1/16"

6

$4.99 ea

78

G004

gasket, vacuum motor

4

$8.99 ea

79

P735

manifold, single vac, no gasket

2

$14.99 ea

80

PH628-2.5

vac hose, 2", black, wire reinforced

1

$8.99 ft

81

PH628-17

vac hose, 2", black, wire reinforced

1

$8.99 ft

82

E370A

controller, 230v, water level switch, dual vac

2

$133.99 ea

83

H343

screw, 10 x 5/8" hex head, zinc

4

$0.99 ea

84

C318

fan, cooling, 230V

1

$21.49 ea

85

H001

side panel, small, truckmount

1

$99.99 ea

86

H011

back panel, truckmount

1

$185.99 ea

87

H124

Cuff-Lynx, 2" mpt x 2" female cuff

2

$3.99 ea

88

H304

screw, #8 x 5/8 phil oval, s/s

15

$0.99 ea

89

G090 lid, vac tank, clear, 7"

2

$36.99 ea

90

G091

gasket, 7", vac lid

2

$11.99 ea

91

P508

deflector, LX \ ETM

1

$21.99 ea

92

G022

filter, foam, 2-3/8" x 1"

2

$2.99 ea

93

H045

screen, 4" diameter, 1/4" mesh

2

$6.99 ea

94

G004-A gasket, vacuum motor

2

$6.99 ea

95

H096

bolt, hex, 1/4-20 x 4", zinc Finish

6

$0.99 ea

96

H064-A U, ETM vac

2

$9.99 ea

97

H503

vac support, 3 stage, 3.25", no thrds

6

$3.99 ea

98

H073

coupler, 2.5" dia x 9.5", ss

1

$23.99 ea

99

E373

level switch, vacuum shut-off, rear threads

3

$13.99 ea

100

H132

Cuff-Lynx, 2.5" m cuff x 2.5" mpt

1

$4.99 ea

101

H207

cam & grovve fitting 1-1/2", male

1

$21.99 ea

102

P506

ETM Vac Tank

1

$219.99 ea

103

C384A

pump out, 35 gpm, 230v, stainless

1

$598 .99 ea

104

H396

barb, 1-1/2" x 1-1/2" fpt, pump out 1

$19.99 ea

105

H300

cuff, hose, 1-1/2 x 1-1/2, wire

1

$5.99 ea

106

PH627-20

vac hose, 1-1/2", black, wire reinforced

1

$6.99 ft

107

P686 swing check valve, pump out

1

$24.49 ea

108

H185

screw, 10-32 x 1 1/4", phil flat full thread

1

$0.99 ea

109

H059

bracket, ETM, pump-out

1

$9.99 ea

110

H010

top panel, truckmount

1

$99.99 ea

111

H062

vac mounting plate, ETM

1

$39.99 ea

112

H202

bolt, 1/4-20 x 3/4" hex head, s/s

10

$0.99 ea

113

H216

nut, lock, 1/4-20, nylon insert, s/s

14

$0.99 ea

114

H174

bolt, 1/2-13 x 3/4, c/s, hex head

8

$0.99 ea

115

H173

washer, lock, 1/2 med split, steel zinc

8

$0.99 ea

116

H254

washer, axle, cut 1/2" id

8

$0.99 ea

117

H057

cart, ETM

1

$399.99 ea

118

H668

caster, 4", black hub & gray tread

2

$19.49 ea

119

H204

bolt, 1/4-20 x 1-3/4" hex head, s/s

10

$0.99 ea

120

H109

wheel, 10", foam filled

2

$79.99 ea

121

H058

axle, ETM cart

1

$18.99 ea

D

C

B

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

E

F

E

F

ETM_230v

SHEET 1 OF 5

ETM

12/2013

E

SCALE: 1:8

REV

DWG. NO.

C

SIZE

TITLE:

NAME

DATE

COMMENTS:

CHECKED

DRAWN

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

MYTEE PRODUCTS, INC. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

MYTEE PRODUCTS, INC. IS

PROHIBITED.

A

DO NOT

SCALE DRAWING

858-679-1191

mytee

PRODUCTS, INC.

M.LaBarbera

14

Part prices are subject to change.

Page 15

ESCAPE™ ETM PARTS & PRICING

59

60

62

63

61

16

58

16

21

22

31

25

26

38

41

52

100

89

103

107

106

85

16

73

79

78

77

76

75

74

17

105

104

101

49

14

1

116

115

114

10

12

13

16

14

15

17

2

4

16

86

88

16

72

38

71

49

66

67

23

69

65

53

72

81

80

87

70

18

19

20

28

29

30

16

27

57

56

55

54

51

50

32

33

37

36

90

91

73

78

93

92

97

19

20

95

5

6

9

8

7

19

20

68

12

38

39

48

40

38

47

46

45

44

35

15

12

39

40

43

42

64

96

99

38

42

48

39

109

102

24

88

3

3

29

108

82

16

to sol tank

to sol tank

to PH634-11

10

to pressure

gauge

thru B130

55

to unloader

thru B136

36

to flow meter

thru B131

53

to 7qt

bottle thru

PH634-32

63

24

11

11

98

35

11

38

34

94

D

C

B

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

E

F

E

F

ETM_230v

SHEET 2 OF 5

ETM

12/2013

E

SCALE: 1:8

REV

DWG. NO.

C

SIZE

TITLE:

NAME

DATE

COMMENTS:

CHECKED

DRAWN

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

MYTEE PRODUCTS, INC. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

MYTEE PRODUCTS, INC. IS

PROHIBITED.

A

DO NOT

SCALE DRAWING

858-679-1191

mytee

PRODUCTS, INC.

M.LaBarbera

15

Page 16

ESCAPE™ ETM PARTS & PRICING

16

112

111

112

113

114

115

116

117

113

119

118

120

121

113

119

D

C

B

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

E

F

E

F

ETM_230v

SHEET 3 OF 5

ETM

12/2013

E

SCALE: 1:8

REV

DWG. NO.

C

SIZE

TITLE:

NAME

DATE

COMMENTS:

CHECKED

DRAWN

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

MYTEE PRODUCTS, INC. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

MYTEE PRODUCTS, INC. IS

PROHIBITED.

A

DO NOT

SCALE DRAWING

858-679-1191

mytee

PRODUCTS, INC.

V. LaBarbera

16

Page 17

ESCAPE™ ETM LOWER WIRING DIAGRAM

Electric Truck Mount - 230 Volt

Hour Meter

VAC

1

VAC

2

Pump

VAC 1

L2L1

G

VAC 2

L2L1

G

Pump

L2L1

G

Pump

Out

Pump

Out

L2L1

G

230

Volts

G

X

Y

Cooling

Fan

N/O

Switch

Twist lock Flanged

Receptacle

C-304

C-304

C-384A

C-332

E-369

C-318

E-360

To Metal

Plate

To Metal

Plate

To Metal

Plate

To Metal

Plate

230V

Relays

Float

Switch

L1

Float

Switch

Relay

230V

L1

E-628

N/O

Switch

3/12/2013

E-370

Red wires are 12 gauge

17

Page 18

ESCAPE™ ETM UPPER WIRING DIAGRAM

VAC 3

L2L1

G

VAC 4

L2L1

G

VAC 4

Twist Lock Flanged

Receptacle

230

volts

Ground Wire

to metal

faceplate

C-304

C-304

E-360

N/O

E-373

L1

L2

G

Cooling

Fan

C-318

VAC 3

230V

Relays

Float

Switch

L1

Electric Truck Mount - 230 Volt

3/12/2013

E-370

Red wires are 12 gauge

18

Page 19

ESCAPE™ ETM VACUUM SYSTEM

Vacuum System

Cabinet

Tank

Vac 3Vac 4

Vac 2

Vac 1

Vac Motors

w/ gasket

Foam Filter-

clean regularly

for maximum CFM

Mesh Screen

Air Flow

Air Flow

Air Flow

Vac Control Boxes-

Each box controls 1

level switch. Boxes

should always be

set to 230V.

Vacs 3 & 4

Cord #2. Mounted

to cabinet top

Vacs 1 & 2

Cord #1. Mounted

to the tank wall.

2 vac shuto

switches in tank-

Each controls 1 set

of vacs (1&2 or 3&4).

Should be cleaned

regularly.

Cu Lynx

Miliamp Current

Miliamp Current

19

Page 20

ESCAPE™ ETM HIGH PRESSURE PUMP SYSTEM

High Pressure Pump System

Inlet Hose

Pressure

Gauge

Pressure

Regulator

Solution

Quick Disconnect

Filter

In Tank.

Clean Regularly.

Bypass Hose To Tank

= High Pressure

= Low Pressure

20

Page 21

ESCAPE™ ETM AUTO PUMP-OUT SYSTEM

Male Cam

Fitting

Auto Pump-Out Pump

Vacuum HoseCheck Valve-

keeps vacuum

from leaking

through pump

Auto Pump-Out System

Level Switch-

Controls pumps

On/O

. Clean

regularly.

21

Page 22

NOTES

Mytee Products Inc.

13655 Stowe Dr.

Poway, CA 92064

www.mytee.com

FX 858.679.7814

© 2017 Mytee Products Inc.

Printed in the U.S.A.

22

Loading...

Loading...