Page 1

Instructions for

ECO-15 & ECO-17 Orbital Floor Machines

Please read before use.

Register your product

at http://www.mytee.

com/support/register

General Information p. 2

Unboxing & Assembly p. 4

Set Up & Operation p. 5

Flywheel Bearing Replacement p. 9

ECO-15 Parts & Pricing p. 11

ECO-17 Parts & Pricing p. 13

Orbital Machine Wiring Diagram p. 15

Notes p. 16

Model #

Serial #

Form # ADM-ECO17

2-17

13655 Stowe Dr. Poway, CA 92064

1

Page 2

GENERAL INFORMATION

Dear Customer:

Congratulations on the purchase of your new Orbital Floor Machine. As you are

already aware, the sc ene of the equipment world is becoming more high tech, and

we at Mytee Products Inc. strive to keep you on the cutting edge with superior quality and technology.

Keep in mind that the ECO-15 & ECO-17 are machines, so neglect or abuse will

cause unnecessary damage and void the warrant y. However with simple maintenance theOrbital Floor Machines will give quality performance for many years to

come.

If warranty questions arise, please consult your user manual or get in touch with

your distributor. If you have questions about maintenance, replacing par ts or

ordering parts, please call an authorized Mytee Products Inc. Service Center.

To see an updated list, visit our website at www.mytee.com.

Before you begin using your new machine, please read your manual thoroughly.

Sincerely,

Mytee Customer Care Dept.

Grounding Instructions

This machine must be grounded. If it should malfunction or breakdown, grounding

provides a path of least resistance for electrical shock. This machine is equipped

with a cord having an equipment-grounding conductor and grounding plug. The

plug must be plugged into an appropriate outlet that is properly installed in accordance with all local code and ordinances. Do not remove ground pin; if missing,

replace plug before use.

Improper connection of the equipment-grounding conductor can result in a risk

of electric shock. Check with a qualied electrician or ser vice person if you are

in doubt as to whether the outlet is properly grounded. Do not modify the plug

provided with the machine. If it will not t the outlet, have a proper outlet installed

by a qualied electrician.

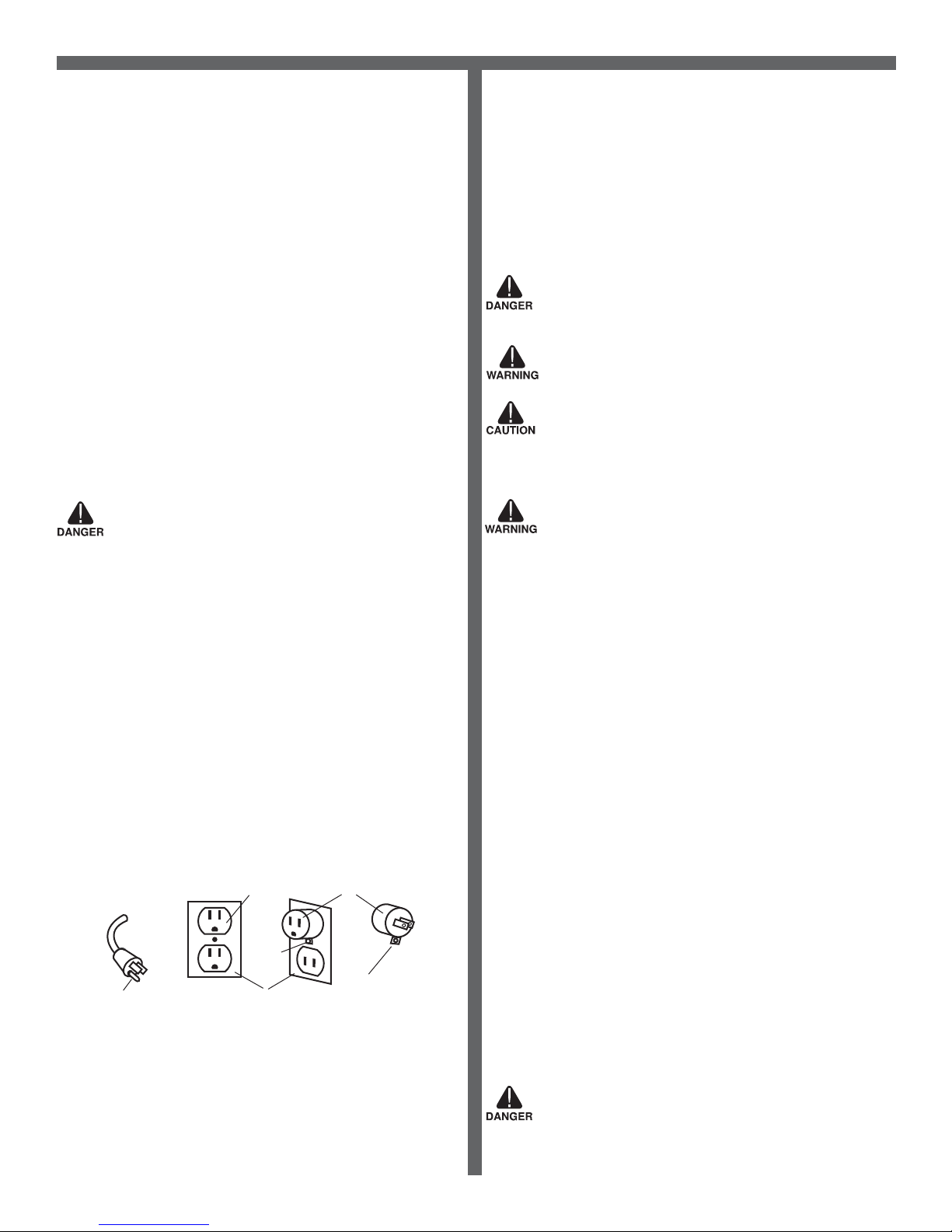

This appliance is for use on a nominal 120-volt circuit, and has a grounding plug

that looks like the plug illustrated in Figure 1 below. A temporary adapter illustrated

in Figures 2 and 3 may be used~to connect this plug to a 2-pole receptacle as

shown in Figure 2 if a properly grounded outlet is not available. The temporary

adapter should be used only until a properly grounded outlet (Figure 1) can be

installed by a qualied electrician. The green colored rigid ear, tab or the like

extending from the adapter must be c onnected to a permanent ground such as a

properly grounded outlet box cover. Whenever the adapter is used, it must be held

in place by a metal screw. Grounding adapters are not approved for use in Canada.

Replace the plug if the grounding pin is damaged or broken.

The Green (or GreenYellow) wire in the cord is the grounding wire. When replacing

a plug, this wire must be attached to the grounding pin only.

DO NOT use extension cords.

Please Note for America use only

Grounding Pin

Figure 1

Grounded Outlet

Metal

Screw

Grounded Outlet Box

Figure 2 Figure 3

Adapter

Tab for Grounding

Screw

Parts and Service

Repairs, when required, should be performed by Mytee service personnel or Mytee

authorized Service Center using Mytee original replacement parts and accessories. Call Mytee for repair par ts or service. Please specify the Model and Serial

Number when discussing your machine.

Name Plate

The Model and Serial Number of your machine are shown on the Nameplate on the

handle of the machine. This information is needed when ordering repair parts

for the machine. Use the space provided on the front cover to note the Model and

Serial Number of your machine for future reference.

Unpacking the Machine

When the machine is delivered, carefully inspect the shipping cartons and the

machine for damage. If damage is evident, save the shipping car tons so that it can

be inspected by the carrier that delivered it. Contact the carrier immediately to le a

freight damage claim. NOTE: This machine ships in two boxes.

Caution and Warnings

Symbols

Mytee uses the symbols below to signal potentially dangerous conditions. Always

read this information carefully and take the necessary steps to protect personnel

and property.

Is used to warn of immediate hazards that will cause severe personal injury or

death.

Is used to call attention to a situation that could cause severe personal injur y.

Is used to call attention to a situation that could cause minor personal injury or

damage to the machine or other property. When using an electrical appliance, basic precautions should always be followed, including the following: Read all instructions before using this machine. This product is intended for commercial use only.

To reduce the risk of re, electrical shock, or injury:

1. Read all instructions before using equipment.

2. Use only as described in this manual. Use only manufacturer’s recommended

attachments.

3. Always unplug power cord from electrical outlet before attempting any adjustments or repairs.

4. Use care to keep the electrical supply cord from c ontac ting the rotating brush

or drive block.

5. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

6. Do not pull or carr y by cord. Do not close a door on cord or pull cord around

sharp edges or corners.

7. Connect to properly grounded (3 -wire) outlet only. Refer to grounding instructions.

8. Do not run appliance over cord. Keep c ord away from heated surfaces.

9. Do not use with damaged cord or plug. If cord is damaged, repair immediately.

10. Turn off all controls before unplugging.

11. Always unplug or disconnect the appliance from power supply when not in use.

12. Do not handle the plug or oor machine with wet hands.

13. Do not allow to be used as a toy. Close attention is necessar y when used by or

near children.

14. Wind the c ord no tighter than is necessary to retain it during storage.

15. Do not use in areas where ammable or combustible material may be present.

16. Do not leave the unit exposed to harsh weather elements. Temperatures below

freezing may damage components and void warranty.

17. Use only the appropriate handles to move and lift unit. Do not use any other

parts of this machine for this purpose.

18. Keep hair, loose clothing, ngers, and all parts of the body away from all

openings and moving parts.

19. Use extra care when working near stairs.

20. To reduce the risk of re or electric shock, do not use this machine with a

solid-state speed control device.

21. The voltage and frequency indicated on the name plate must correspond to the

wall receptacle supply voltage.

22. When cleaning and servicing the machine, local or national regulations may

apply to the safe disposal of liquids which may contain: chemicals, grease, oil,

acid, alkalines, or other dangerous liquids.

23. Store your oor machine indoors in a cool, dr y area.

24. Keep your work area well lit.

25. Do not leave operating unattended.

Use of ammable chemicals could cause explosion, re, and death.

2

Page 3

GENERAL INFORMATION

Pre-Operation

1. Vacuum carpet and upholstery and remove other debris.

2. Inspect power c ord for damage.

Operation

1. Squeeze the Adjustment Height lever.

2. Pivot handle to desired position (best is at waist height).

3. Release lever to lock handle in place.

4. Place both hands rmly on the handle grips.

5. Flip the power switch to the “on” position.

6. To spray solution, squeeze either spray lever.

7. To stop the machine, simply ip the power switch to the “off” position.

Pad Driver Removal / Installation

1. Disconnect the power cord from the electrical outlet and empty any liquid in

the solution tank before installing a brush or pad driver.

2. Leave the handle in the upright position and tip the machine backwards so it

rests on its wheels and upper handle section.

3. Use an 11mm wrench to loosen and remove the four bolts from the bot tom to

the pad driver.

4. To install the pad driver, place the pad driver into position and bolt into place

with the original four 11mm bolts.

5. Raise the machine back into upright position.

6. To install a cleaning pad, tip the machine back and lower it, with the pad driver

installed, onto the cleaning pad. Keep the pad as centered as possible.

7. When the machine is not in use, store it with the pad attached. This will protect

the pad driver from damage.

1. Work away from outlet and power cord to prevent cord damage.

2. To clean heavily soiled areas, repeat cleaning path from different direction.

Guidelines

1. For ease of operation, always keep the brush or pad surface level, balanced,

and at on the oor at all times.

2. Always adjust the operating handle to a comfortable height at which the brush

or pad surface is balanced before starting the machine.

3. Your oor machine will operate differently on various surfaces. There will be

more resistance when the machine is used with a brush on carpet than when it

is used with a pad on a smooth surface.

4. To move the machine for ward or backward, push or pull in the desired direc -

tion, keeping the pad or brush level on the oor at all times.

After Use

1. Unplug the extension cord from wall and the machine’s power cord pigtail and

loosely wind it up.

2. After each use, wipe your oor machine with a clean, soft, damp cloth.

3. Store in a clean, dr y place with a pad attached to protect the pad driver.

4. Do not expose to rain. Store indoors.

Maintenance Schedule

Maintenance item Daily Once a week

Clean and inspect motor

Check power supply cable

Clean machine with all purpose cleaner and cloth

Inspect machine for water leaks and loose hardware

x

x

x

x

Troubleshooting

There is no power.

1. Plug machine in proper outlet.

2. Ensure that switch is not damaged or defective.

Plug on the power cord doe sn’t light up when plugged in.

1. Replace the power cord.

Plug lights up when plugged in but machine does not turn on.

1. Open the faceplate on the handle and check for loose or disconnected wires.

2. Power switch may be bad. Replace the power switch.

ECO-15 Machine Specications

Motor 1 horsepower

Cleaning Path 15”

Pump Diaphragm spray pump

Pump PSI 100

Pump GPM 1.3

Solution Tank 4 gallons

Levers Stainless steel

Deck Plate Stainless steel

Power

Consumption

Machine Weight 130 l bs.

Machine

Dimensions

Power Cord 50’ 12/3 extension c ord

13 amps @ 115V 60Hz

27” x 15.5” x 49”

ECO-15 230V Conguration Information

Model Number ECO15- 230

Power

Consumption

6.5 amps @ 230V 60Hz

ECO-17 Machine Specications

Motor 1 horsepower

Cleaning Path 17”

Pump Diaphragm spray pump

Pump PSI 100

Pump GPM 1.3

Solution Tank 4 gallons

Levers Stainless steel

Deck Plate Stainless steel

Power

Consumption

Machine Weight 130 l bs.

Machine

Dimensions

Power Cord 50’ 12/3 extension c ord

13 amps @ 115V 60Hz

27” x 17.5” x 49”

ECO-17 230V Conguration Information

Model Number EC O17-2 3 0

Power

Consumption

6.5 amps @ 230V 60Hz

FAQs

Q: What comes standard with the Orbital Floor Machines?

A: The Orbital Floor Machines come with:

• Pad driver (pre-installed)

• 2x microber cleaning pads

• 50’ extension cord (12/3)

Q: Where do I plug the machine in?

A: The Orbital Floor Machines require a grounded circuit. Please note: GFI outlets

may trip before the breaker set ting.

Q: Is there anything I can do to increase the expecte d life of my machine?

A: Check all parts for wear regularly. Keep machine clean.

Motor is drawing too many amps and blowing breakers.

1. Power cord is defective or damaged - replace power cord.

2. Check the power switch for shorts or loose connections. Replace the switch if

nece ss ary.

3. Check if the power c ord from the switch is defective or damaged. Replac e if

nece ss ary.

3

Page 4

ECO-15/ECO-17 UNPACKING & ASSEMBLY

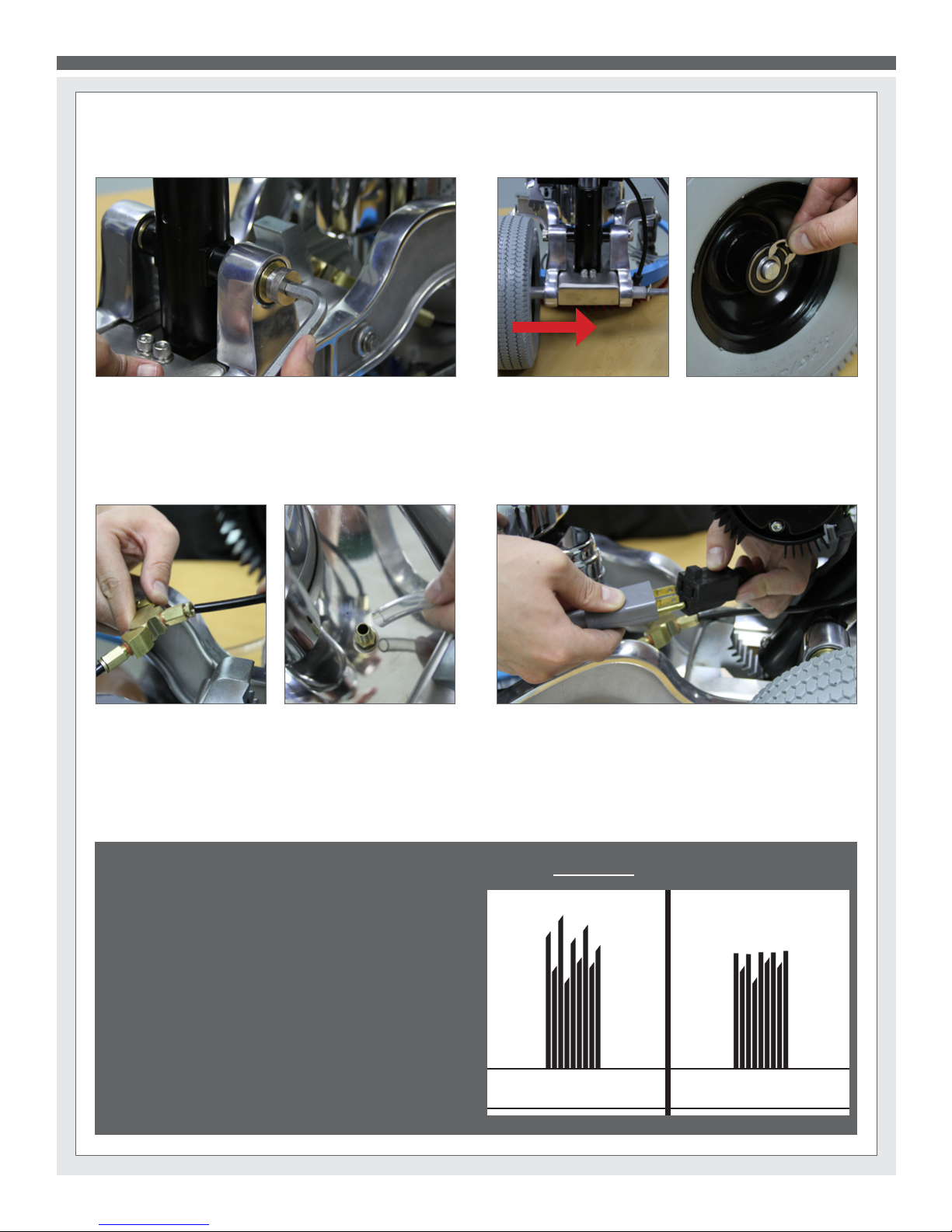

The ECO-15 & ECO-17 ship in two boxes and will

need to be assembled before use. Follow these

directions to assemble the two pieces.

1. Set the handle assembly in place and bolt it in using

the two included bolts. Thread the bolts in by hand as

far as you can in order to prevent stripping of the

threads in the handle. Tighten with 5/16” allen key.

Tools Needed:

• 5/16” allen hex key

• Needle nose pliers

2. Remove both C-clips from the axle using needle nose

pliers. Slide the wheels onto the axle. Use needle nose

pliers to secure wheels with the C-clips.

3. Connect the hoses for solution spray and gravity feed

as shown above.

5. Make sure all bolts are tightened. Your Orbital Floor

Machine is now ready to operate.

IMPORTANT: BEFORE FIRST USE

The new (red bristle) pad-driver may require some

surface preparation before it will uniformly hold to

thin pads.

If necessary, run the bare pad-driver on smooth

concrete for several minutes, checking periodically

that the tallest bristles are then worn down a bit

(~1/8”). This procedure will also atten the tips of

the longest third of the bristles to better grip the

pad tufts (see illustration to the right).

This procedure does not apply to the black

“Mytee-Lok” pad driver.

4. Connect the power cord from the base of the handle to

th e moto r.

BEFORE AFTER

4

Page 5

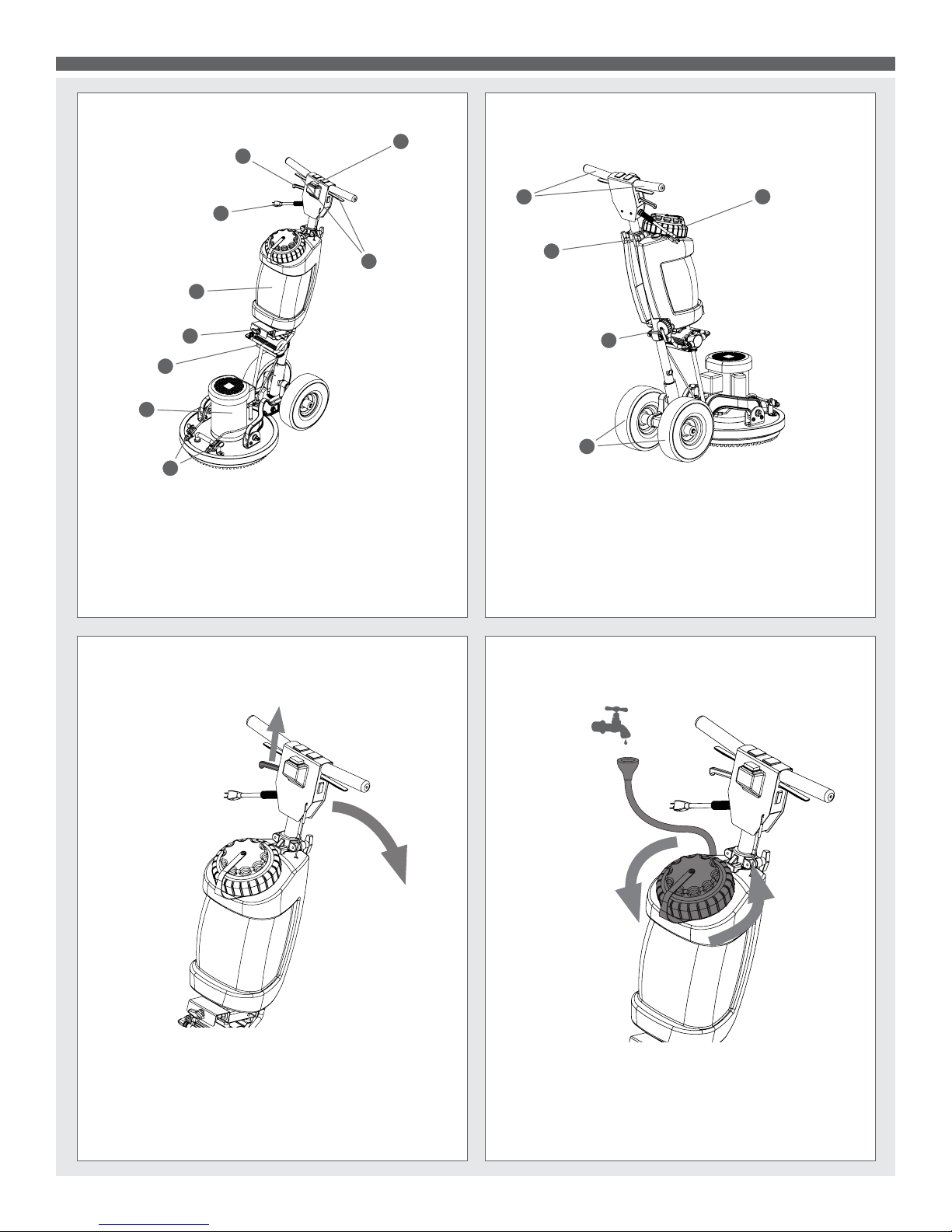

ECO-15/ECO-17 SETUP & OPERATION

3

4

5

6

7

8

1. Power Switch

2. Handle Height

Adjustment Lever

3. Power Cord Pigtail

4. Solution Tank

5. Bi-Directional Valve

FRONT

2

6. Pump

7. Motor

8. Spray Jets

9. Solution Spray Levers

BACK

1

10

9

11

12

13

14

10. Handlebars

11. Faucet Fill Hose

12. Solution Tank Drain Cap

13. Wheels

14. Solution Tank Lid

The handle can be adjusted to any desired working position by simply squeezing the adjustment lever. Move the

handle to the desired position, then release the adjustment lever, locking the handle in place.

SHAMPOO TANK HEIGHT ADJUSTMENT LEVER

To ll the shampoo tank, twist off the large cap and ll

with water from a bucket or ll using the faucet ll hose.

Add desired shampoo or chemical. To drain, lower the

handle a bit, place a bucket under the drain cap, and

unscrew the cap.

5

Page 6

ECO-15/ECO-17 SETUP & OPERATION

PAD DRIVER AND PAD INSTALLATION

Note: Disconnect the power cord from electrical outlet

and empty any solution from the tank before removing or

installing the pad driver. The pad driver is attached with

four bolts (highlighted above). To use a pad, simply lay

the pad on the oor and lower the machine with the pad

driver onto the pad. Try to center the pad as much as

possible.

BI-DIRECTIONAL VALVE

The ECO-15 & ECO-17 feature a valve that allows you to

switch between using the pump to spray solution or using

the gravity-feed hose. Point the valve knob to the left for

gravity feed and to the right to use the spray jets.

POWER SWITCH

To turn the machine on, lower the handle to the desired

position and then ip the power switch to the “on” position.

SOLUTION SPRAY LEVER

Squeeze the left or right solution spray levers to activate

the pump and spray solution.

6

Page 7

ECO-15/ECO-17 SETUP & OPERATION

ECO-15 & ECO-17 CLEANING PATTERN

To effectively clean oors, move the Orbital Floor Machine forwards and backwards, similar to using a

household vacuum cleaner. Wet the oor by spraying solution as you roll the unit forwards.

7

Page 8

ECO-15/ECO-17 SETUP & OPERATION

USING THE ECO-15 & ECO-17 ON VARIOUS SURFACES

IMPORTANT: Ensure that you are using the appropriate pad type

CARPET

depending on the surface you are cleaning.

STONE

TILE & GROUT

EPOXY

VINYL

WOOD

CONCRETE

& MORE

8

Page 9

ECO-15/ECO-17 FLYWHEEL BEARING REPLACEMENT

The ywheel bearing is a wear part, similar to rotors on

a car. Over time, the bearing will require replacing.

1. Remove the pad driver assembly by removing the 4 hex

bolts with a 7/16” wrench or socket.

Tools Needed:

• 7/16” open-end wrench

• 15/16” open-end wrench

• Soft-face dead-blow mallet

• Medium-large athead

screwdriver

• 3/16” Allen wrench

• Blue Loctite

®

2. Hold the jam nut, located between the ywheel and mo-

tor, in place with a 15/16” open-end wrench. Using a mallet,

tap the ywheel counter-clockwise to loosen. Hand-turn

the ywheel the rest of the way off.

3. Remove the black plastic plug from the motor fan hous-

ing, using ngers and a screwdriver. Take care not to damage the housing, or the plug.

5. Install the new bearing assembly using the Allen bolts

removed in Step 4. Orient the bearing against the ywheel

plate such that the raised side of the bearing assembly is

against the side of the ywheel plate that has the counterweight.

4. Unscrew the two Allen bolts from the back of the y-

wheel plate, and remove the bearing assembly. Clean the

Allen bolts and coat the rst 4 threads with Blue Loctite

®

.

6. Thread the jam nut all the way down the motor shaft and

hold it with a 15/16” wrench. It may help to use a screwdriver to hold the motor shaft stationary, while threading

the jam nut.

9

Page 10

ECO-15/ECO-17 FLYWHEEL BEARING REPLACEMENT

7. Install the ywheel assembly by hand, threading it onto

the shaft clockwise until it stops at the jam nut. Use the

mallet to strike the ywheel counterweight to tighten the

ywheel against the jam nut.

9. By hand, turn the bearing to assure it rotates smoothly

and freely.

8. By hand, turn the ywheel to assure the ywheel coun-

terweight clears the motor bolt heads.

10. Install the pad driver using the bolts removed in

Step 1. Clean, then apply Blue Loctite

®

to the rst 4 threads

of each bolt. Fasten each bolt by hand. Then use the 7/16”

wrench to gradually tighten each bolt in turns using a crisscross pattern until each bolt is securely tightened.

11. Replace the black plastic plug removed in Step 3,

using ngers only.

10

Page 11

ECO-15 PARTS & PRICING

ITEMS NOT SHOWN

PART NO.

DESCRIPTION

QTY

MSRP

E530

power cord, ext, 50', 12/3

1 $74.99 ea

G127-17

bonnet, micro fiber, 17", ECO-15, 2pack

1 $21.99 ea

P568A

cord lock, s-type

1 $8.99 ea

H689

wrench, allen, 5/16"

1 $1.99 ea

ITEM

NO.

PART NO.

DESCRIPTION

QTY.

MSRP

1

H151

bolt, 5/16-18 x 3/4" Long SHCS

4 $0.99 ea

2

H421

washer, 5/16" lock, s/s

6 $0.99 ea

3

H843

locking arc, handle adj, floor machine

1 $51.99 ea

4

H555

plate, yoke, ECO-17

1 $33.99 ea

5

H216

nut, lock, 1/4-20, nylon insert, s/s

4 $0.99 ea

6

H210

washer, 1/4" flat, s/s

19 $0.99 ea

7

H316

bolt, 1/4-20 x 1-1/2" hex head, s/s

6 $0.99 ea

8

H065

bushing, sleeve, 5/8 i.d. x 1.25" long

2 $9.99 ea

9

H066

bolt, shoulder 5/8" x 1.25", 1/2-13 thrds 2 $14.99

10

H427

washer, wave

2 $1.49 ea

11

H212

flat washer, 9/16"ID x 1 1/16"OD, AN960-C916

9 $0.99 ea

12

H109

wheel, 10", foam filled

2 $79.99 ea

13

H042

c-clip, 12mm, external

2 $0.99 ea

14

H228

axle, 13.10" x .50" dia

1 $9.99 ea

15

H553

arm, left

1 $98.99 ea

16

P607

bushing, flange, .63" i.d. x .38" long

4 $0.99 ea

17

H554

bracket, arm, ECO

2 $28.99 ea

18

P606

bushing, flange, .63" i.d. x .25" long

4 $0.99 ea

19

H242

bolt, shoulder, 5/8" x 1.5", 1/2-13 threads 2 $19.99 ea

20

H252

bolt, shoulder, 1/4" x 1.5", 10-24 threads

4 $3.99 ea

21

H351 screw, 1/4-20 x 3/4", socket head, s/s

4 $0.99 ea

22

H213

washer, 1/4" lock, s/s

11 $0.99 ea

23

C326B

motor, ECO

1 $548.99 ea

24

B140

connector, 1/4" push-in x 1/8" mpt

6 $7.49 ea

25

H559B

plate, ECO-15

1 $308.99 ea

26

G123B

BUMPER, ECO-15

1 $34.99 ea

27

H327

washer, 3/8" lock, s/s

4 $0.99 ea

28

H293

bolt, 3/8-16 x 1", hex head

4 $0.99 ea

29

H558

weight, counter, #3 offset, threaded, ECO

1 $43.99 ea

30

H556

bearing, offset, ECO

1 $30.99 ea

31

H342

bolt, 1/4-20 x 1" hex head, s/s 3 $0.99 ea

32

P608 adapter, pad driver, encap machine

1 $23.99 ea

33

G113B

PAD DRIVER, ECO-15

1 $91.99 ea

34

H202

bolt, 1/4-20 x 3/4" hex head, s/s

8 $0.99 ea

35

H398

nut, hex, 5/8-18

1 $1.99 ea

36

H485

handle, aluminim grip, black

1 $6.99 ea

37

B645A

filter, cap, ECO

2 $4.99 ea

38

B645C

jet, ECO

2 $9.99 ea

39

B645D

filter, strainer, ECO

2 $8.99 ea

40

B645B

filter, body, ECO

2 $5.99 ea

41

H384

washer, 3/8 flat, s/s

6 $0.99 ea

42

H560

L bracket, ECO

2 $3.99 ea

43

H561

jet bracket, ECO

2 $3.99 ea

44

H922

screw, thumb, 1/4-20 x 1/2"

2 $4.99 ea

45

G052

washer, buna 1-1/8" od x 3/16" id

10 $1.99 ea

46

B153

coupling, 1/8" npt, light pattern

2 $5.49 ea

47

PH657-13

tubing, 1/4", nylon, blk

2

$1.99 ft

48

H403

nut, lock, 10-24, nylon insert

4 $0.99 ea

49

H322

nut, hex, 1/2-13, s/s

2 $0.99 ea

50

H552

arm, right

1 $98.99 ea

51

B110

adapter, brass, 1/4" sw barb x 1/4" fpt, w/gasket

1 $3.99 ea

52

B103

elbow, brass, 90 deg, 1/4"mpt x 1/4" fpt

1 $4.49 ea

53

B107 nipple, brass, 1/4"m, hex

1 $3.19 ea

54

B119

filter, strainer, 1/4"

1 $3.99 ea

55

PH634-8 sol hose, 1/4", silicone braided, clear

1

$6.49 ft

56

B170

ferrule, 1/4" brass

4 $0.99 ea

57

B136

elbow, brass, 90 deg, 1/4" mpt x 1/4" mpt

1 $4.99 ea

58

B147

tee, 1/8" fpt x 1/8" fpt x 1/8" fpt

1 $6.49 ea

59

B657

elbow, 45 deg street, 1/8" mpt x 1/8" fpt

2 $4.99 ea

60

B129

nipple, hex, 1/8" mpt x 1/8" mpt

2 $1.99 ea

61

B656C

valve, ball, 1/8" fpt x 1/8" fpt, s/s

1 $10.99 ea

62

PH657-17

tubing, 1/4", nylon, blk

1

$1.99 ft

ITEM

NO.

PART NO.

DESCRIPTION

QTY.

MSRP

63

PH634-12 sol hose, 1/4", silicone braided, clear

1

$6.49 ft

64

B152

elbow, brass, 90 deg, 1/4" barb x 1/4" mpt

1 $5.49 ea

65

B241

adapter, brass, 3/8" barb x 1/4"mpt

2 $1.99 ea

66

PH715-22 sol hose, 3/8", silicone braided, clear

1

$7.99 ft

67

B217

check valve, 1/8" mpt x 1/8" fpt, 5 PSI

1 $8.99 ea

68

B261

valve assy 3 way

1 $54.99 ea

69

B143

street elbow, 90 degrees, 1/8"

2 $2.99 ea

70

B195

barb, 3/8" barb x 1/8" mpt

1 $2.49 ea

71

H164

grommet, 5/8" ID

4 $1.99 ea

72

B131

fitting, 1/4" barb x 1/8" FPT

1 $2.99 ea

73

B105

bushing, brass, 3/8"mpt x 1/4" 2 $3.19 ea

74

C305A

pump, 100 PSI, no pressure switch

1 $136.99 ea

75

H397

bracket, pump mount, ECO

1 $25.99 ea

76

H007

screw, 10-32 x 2", phil pan head, s/s

4 $0.99 ea

77

H915

clamp, shampoo tank

2 $4.99 ea

78

P559

tank, ST-4

1 $39.99 ea

79

PH612-60

clear tubing, 1/2" OD x 3/8" ID, faucet fill

1

$1.99/ft

80

G031

gasket, 3.25" i.d. x 5.88" o.d.

1 $6.99 ea

81

P560

cap, 6", threaded

1 $23.99 ea

82

G055

tether, cap, 6 1/2"

1 $12.99 ea

83

H612

Washer, #8, flat regular

2 $0.99 ea

84

H230

screw, 10-32 x 1/2" phil pan head, s/s 4 $0.99 ea

85

H178

faucet fill

1 $10.99 ea

86

H357

thumb screw, 1/4" - 20, shampoo tank

2 $1.99 ea

87

G036

cap, 2.5" threaded, tethered

1 $3.49 ea

88

H148

washer, 5/16", narrow

3 $0.99 ea

89

H341

handle pivot, floor machine

1 $74.99 ea

90

H705

bolt, giude, locking piston

1 $0.99 ea

91

H847

bushing, locking piston

1 $17.99 ea

92

H152

ring, retaining, internal 1 1/2"

1 $5.99 ea

93

H157

spring, handle adjustment

1 $5.99 ea

94

H844

locking piston, handle adj.

1 $19.99 ea

95

H273

nut, kep, #10-32 zinc

2 $0.99 ea

96

H916

clip, cord, 5/16", nylon- BLACK

1 $0.99 ea

97

P529

spacer, lever, handle adj.

1 $1.99 ea

98

H159

cable, handle adj, floor machine

1 $6.99 ea

99

H149

bolt, 5/16" shldr x 5/8" w/ 1/4-20 thrd

1 $0.99 ea

100

H839

lever, handle adj., floor machine

1 $19.99 ea

101

H216

nut, lock, 1/4-20, nylon insert, s/s

1 $0.99 ea

102

E384

power cord, end, 15.5", 14/3

1 $11.99 ea

103

H144

strain relief, power cord, metal

1 $12.99 ea

104

H167

switch, floor machine

1 $13.99 ea

105

H640

washer, internal star, 3/8" zinc

1 $0.99 ea

106

H166

insulation, switch, floor machine

1 $3.99 ea

107

H855

lever, switch, floor machine

1 $6.99 ea

108

H160

spring, switch/lever

2 $0.99 ea

109

E515

switch, rocker, 2 position

1 $13.99 ea

110

H255

switch cover, EC, floor machine

1 $30.99 ea

111

P967A

plug, switch

2 $1.99 ea

112

G040

grip, handle, floor machine

2 $1.99 ea

113

P524

plug, plastic, floor machine handle

1 $0.99 ea

114

H231

screw, 10-32 x 1" phil pan head, s/s

1 $0.99 ea

115

H215

nut, hex, 1/4-20 s/s

1 $0.99 ea

116

H849

handle, floor machine

1 $89.99 ea

D

C

B

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

E

F

E

F

ECO-15

SHEET 1 OF 3

Encap

3/2015

OD

SCALE: 1:24

REV

DWG. NO.

C

SIZE

TITLE:

NAME

DATE

COMMENTS:

CHECKED

DRAWN

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

MYTEE PRODUCTS, INC. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

MYTEE PRODUCTS, INC. IS

PROHIBITED.

A

DO NOT

SCALE DRAWING

858-679-1191

mytee

PRODUCTS, INC.

M.LaBarbera

11

Page 12

ECO-15 PARTS & PRICING

1

2

3

4

5

7

8

9

10

11

12

13

14

15

16

17

18

19

6

20

21

22

24

23

25

26

27

28

29

30

32

33

34

22

36

22

39

38

40

41

42

43

47

6

48

49

18

16

50

1

2

86

77

78

87

7

88

77

54

24

58

63

74

76

79

65

85

80

81

82

83

84

98

99

88

100

101

97

102

103

104

105

41

41

106

107

108

109

110

84

112

114

115

116

89

90

91

92

93

94

71

95

96

95

84

6

11

37

59

60

61

11

34

6

6

22

31

35

113

111

34

46

24

45

44

53

11

52

51

55

56

75

56

64

66

68

69

70

71

73

62

24

72

60

65

57

45

45

67

D

C

B

A

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

E

F

E

F

ECO-15

SHEET 2 OF 3

Encap

SCALE: 1:24

REV

DWG. NO.

D

SIZE

TITLE:

NAME

DATE

CHECKED

DRAWN

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

MYTEE PRODUCTS, INC. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

MYTEE PRODUCTS, INC. IS PROHIBITED.

mytee

PRODUCTS, INC.

858-679-1191

M. LaBarbera

3/2015

OD

DO NOT SCALE

DRAWING

12

Page 13

ECO-17 PARTS & PRICING

ITEMS NOT SHOWN

ITEM

NO.

PART NO.

DESCRIPTION

QTY.

MSRP

1

H151

bolt, 5/16-18 x 3/4" Long SHCS

4 $0.99 ea

2

H421

washer, 5/16" lock, s/s

6 $0.99 ea

3

H843

locking arc, handle adj, floor machine

1 $51.99 ea

4

H555

plate, yoke, ECO-17

1 $33.99 ea

5

H216

nut, lock, 1/4-20, nylon insert, s/s

4 $0.99 ea

6

H210

washer, 1/4" flat, s/s

19 $0.99 ea

7

H316

bolt, 1/4-20 x 1-1/2" hex head, s/s

6 $0.99 ea

8

H065

bushing, sleeve, 5/8 i.d. x 1.25" long

2 $9.99 ea

9

H066

bolt, shoulder 5/8" x 1.25", 1/2-13 thrds 2 $14.99 ea

10

H427

washer, wave

2 $1.49 ea

11

H212

flat washer, 9/16"ID x 1 1/16"OD, AN960-C916

6 $0.99 ea

12

H109

wheel, 10", foam filled

2 $79.99 ea

13

H042

c-clip, 12mm, external

2 $0.99 ea

14

H228

axle, 13.10" x .50" dia

1 $9.99 ea

15

H553

arm, left

1 $98.99 ea

16

P607

bushing, flange, .63" i.d. x .38" long

4 $0.99 ea

17

H554

bracket, arm, ECO

2 $28.99 ea

18

P606

bushing, flange, .63" i.d. x .25" long

4 $0.99 ea

19

H242

bolt, shoulder, 5/8" x 1.5", 1/2-13 threads 2 $19.99 ea

20

H252

bolt, shoulder, 1/4" x 1.5", 10-24 threads

4 $3.99 ea

21

H351 screw, 1/4-20 x 3/4", socket head, s/s

4 $0.99 ea

22

H213

washer, 1/4" lock, s/s

11 $0.99 ea

23

C326B

motor, ECO

1 $548.99 ea

24

B140

connector, 1/4" push-in x 1/8" mpt

6 $7.49 ea

25

H559

plate, ECO-17

1 $329.99 ea

26

G123

BUMPER, ECO-17

1 $29.99 ea

27

H327

washer, 3/8" lock, s/s

4 $0.99 ea

28

H293

bolt, 3/8-16 x 1", hex head

4 $0.99 ea

29

H558

weight, counter, #3 offset, threaded, ECO

1 $43.99 ea

30

H556

bearing, offset, ECO

1 $30.99 ea

31

H342

bolt, 1/4-20 x 1" hex head, s/s 3 $0.99 ea

32

P608 adapter, pad driver, encap machine

1 $23.99 ea

33

G113A

PAD DRIVER, ECO-17

1 $98.99 ea

34

H202

bolt, 1/4-20 x 3/4" hex head, s/s

8 $0.99 ea

35

H398

nut, hex, 5/8-18

1 $1.99 ea

36

H485

handle, aluminim grip, black

1 $6.99 ea

37

B645A

filter, cap, ECO

2 $4.99 ea

38

B645C

jet, ECO

2 $9.99 ea

39

B645D

filter, strainer, ECO

2 $8.99 ea

40

B645B

filter, body, ECO

2 $5.99 ea

41

H384

washer, 3/8 flat, s/s

6 $0.99 ea

42

H560

L bracket, ECO

2 $3.99 ea

43

H561

jet bracket, ECO

2 $3.99 ea

44

H922

screw, thumb, 1/4-20 x 1/2"

2 $4.99 ea

45

G052

washer, buna 1-1/8" od x 3/16" id

2 $1.99 ea

46

B153

coupling, 1/8" npt, light pattern

2 $5.49 ea

47

PH657-11

tubing, 1/4", nylon, blk

2

$1.99 ft

48

H403

nut, lock, 10-24, nylon insert

4 $0.99 ea

49

H322

nut, hex, 1/2-13, s/s

2 $0.99 ea

50

H552

arm, right

1 $98.99 ea

51

H007

screw, 10-32 x 2", phil pan head, s/s

4 $0.99 ea

52

B110

adapter, brass, 1/4" sw barb x 1/4" fpt, w/gasket

1 $3.99 ea

53

B103

elbow, brass, 90 deg, 1/4"mpt x 1/4" fpt

1 $4.49 ea

54

B107 nipple, brass, 1/4"m, hex

1 $3.19 ea

55

B119

filter, strainer, 1/4"

1 $3.99 ea

56

PH634-8 sol hose, 1/4", silicone braided, clear

1

$6.49 ft

57

H349

heat sink, demand pump

1 $24.99 ea

58

B147

tee, 1/8" fpt x 1/8" fpt x 1/8" fpt

1 $6.49 ea

59

B657

elbow, 45 deg street, 1/8" mpt x 1/8" fpt

2 $4.99 ea

60

B129

nipple, hex, 1/8" mpt x 1/8" mpt

2 $1.99 ea

61

B656C

valve, ball, 1/8" fpt x 1/8" fpt, s/s

1 $10.99 ea

62

PH657-15

tubing, 1/4", nylon, blk

1

$1.99 ft

ITEM

NO.

PART NO.

DESCRIPTION

QTY.

MSRP

63

PH634-12 sol hose, 1/4", silicone braided, clear

1

$6.49 ft

64

B170

ferrule, 1/4" brass

4 $0.99 ea

65

B136

elbow, brass, 90 deg, 1/4" mpt x 1/4" mpt

2 $4.99 ea

66

B105

bushing, brass, 3/8"mpt x 1/4" 2 $3.19 ea

67

C305A

pump, 100 PSI, no pressure switch

1 $136.99 ea

68

H397

bracket, pump mount, ECO

1 $25.99 ea

69

B131

fitting, 1/4" barb x 1/8" FPT

1 $2.99 ea

70

H164

grommet, 5/8" ID

4 $1.99 ea

71

B195

barb, 3/8" barb x 1/8" mpt

1 $2.49 ea

72

B143

street elbow, 90 degrees, 1/8"

2 $2.99 ea

73

B261

valve assy 3 way

1 $54.99 ea

74

PH715-25 sol hose, 3/8", silicone braided, clear

1

$7.99 ft

75

B241

adapter, brass, 3/8" barb x 1/4"mpt

2 $1.99 ea

76

H915

clamp, shampoo tank

2 $4.99 ea

77

P559

tank, ST-4

1 $39.99 ea

78

PH612-60

clear tubing, 1/2" OD x 3/8" ID, faucet fill

1

$1.99/ft

79

G031

gasket, 3.25" i.d. x 5.88" o.d.

1 $6.99 ea

80

P560

cap, 6", threaded

1 $23.99 ea

81

G055

tether, cap, 6 1/2"

1 $12.99 ea

82

H612

Washer, #8, flat regular

2 $0.99 ea

83

H230

screw, 10-32 x 1/2" phil pan head, s/s 4 $0.99 ea

84

H178

faucet fill

1 $10.99 ea

85

H357

thumb screw, 1/4" - 20, shampoo tank

2 $1.99 ea

86

G036

cap, 2.5" threaded, tethered

1 $3.49 ea

87

H148

washer, 5/16", narrow

3 $0.99 ea

88

H341

handle pivot, floor machine

1 $74.99 ea

89

H705

bolt, giude, locking piston

1 $0.99 ea

90

H847

bushing, locking piston

1 $17.99 ea

91

H152

ring, retaining, internal 1 1/2"

1 $0.99 ea

92

H157

spring, handle adjustment

1 $5.99 ea

93

H844

locking piston, handle adj.

1 $19.99 ea

94

H273

nut, kep, #10-32 zinc

2 $0.99 ea

95

H916

clip, cord, 5/16", nylon- BLACK

1 $0.99 ea

96

P529

spacer, lever, handle adj.

1 $1.99 ea

97

H159

cable, handle adj, floor machine

1 $6.99 ea

98

H149

bolt, 5/16" shldr x 5/8" w/ 1/4-20 thrd

1 $0.99 ea

99

H839

lever, handle adj., floor machine

1 $19.99 ea

100

H216

nut, lock, 1/4-20, nylon insert, s/s

1 $0.99 ea

101

E384

power cord, end, 15.5", 14/3

1 $11.99 ea

102

H144

strain relief, power cord, metal

1 $12.99 ea

103

H167

switch, floor machine

1 $13.99 ea

104

H640

washer, internal star, 3/8" zinc

1 $0.99 ea

105

H166

insulation, switch, floor machine

1 $3.99 ea

106

H855

lever, switch, floor machine

1 $6.99 ea

107

H160

spring, switch/lever

2 $0.99 ea

108

E515

switch, rocker, 2 position

1 $13.99 ea

109

H255

switch cover, EC, floor machine

1 $30.99 ea

110

P967A

plug, switch

2 $1.99 ea

111

G040

grip, handle, floor machine

2 $1.99 ea

112

P524

plug, plastic, floor machine handle

1 $0.99 ea

113

H231

screw, 10-32 x 1" phil pan head, s/s

1 $0.99 ea

114

H215

nut, hex, 1/4-20 s/s

1 $0.99 ea

115

H849

handle, floor machine

1 $89.99 ea

PART NO.

DESCRIPTION

QTY

MSRP

E530

power cord, ext, blue lit, 50', 12/3

1 $88.99 ea

G127-19

bonnet, micro fiber, 19"

1 $23.99 ea

P568A

cord lock, s-type

1 $8.99 ea

D

C

B

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

E

F

E

F

ECO-17

SHEET 1 OF 3

Encap

3/2015

OD

SCALE: 1:24

REV

DWG. NO.

C

SIZE

TITLE:

NAME

DATE

COMMENTS:

CHECKED

DRAWN

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

MYTEE PRODUCTS, INC. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

MYTEE PRODUCTS, INC. IS

PROHIBITED.

A

DO NOT

SCALE DRAWING

858-679-1191

mytee

PRODUCTS, INC.

M.LaBarbera

13

Page 14

ECO-17 PARTS & PRICING

1

2

3

4

5

7

8

9

10

11

12

13

14

15

16

17

18

19

6

20

21

22

24

23

25

26

27

28

29

30

6

33

34

34

22

36

42

22

34

43

44

45

46

24

47

6

48

49

18

16

50

1

2

85

76

77

86

7

87

75

76

57

62

24

58

67

51

78

75

84

79

80

81

82

83

97

98

87

99

100

96

101

102

103

104

41

41

105

106

107

108

109

83

111

113

114

115

88

89

90

91

92

93

70

94

95

94

83

6

11

59

60

61

31

22

6

11

32

69

68

52

70

7172

73

60

24

74

41

40

38

37

39

24

66

65

64

56

63

35

110

2

112

53

11

11

54

55

D

C

B

A

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

E

F

E

F

ECO-17

SHEET 2 OF 3

Encap

SCALE: 1:24

REV

DWG. NO.

D

SIZE

TITLE:

NAME

DATE

CHECKED

DRAWN

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

MYTEE PRODUCTS, INC. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

MYTEE PRODUCTS, INC. IS PROHIBITED.

mytee

PRODUCTS, INC.

858-679-1191

M. LaBarbera

3/2015

OD

DO NOT SCALE

DRAWING

14

Page 15

ECO-15/ECO-17 WIRING DIAGRAM

Orbital Machine Wire Schematic

L1

L2

G

Rev.10-16-2016

Pump

+

-

G

To Metal

Plate

Motor

G

E-515

-

+

15

Page 16

NOTES

Mytee Products Inc.

13655 Stowe Dr.

Poway, CA 9 206 4

www.mytee.com

© 2017 M y te e P ro d uct s I nc.

Printed in the U.S.A.

16

Loading...

Loading...