Page 1

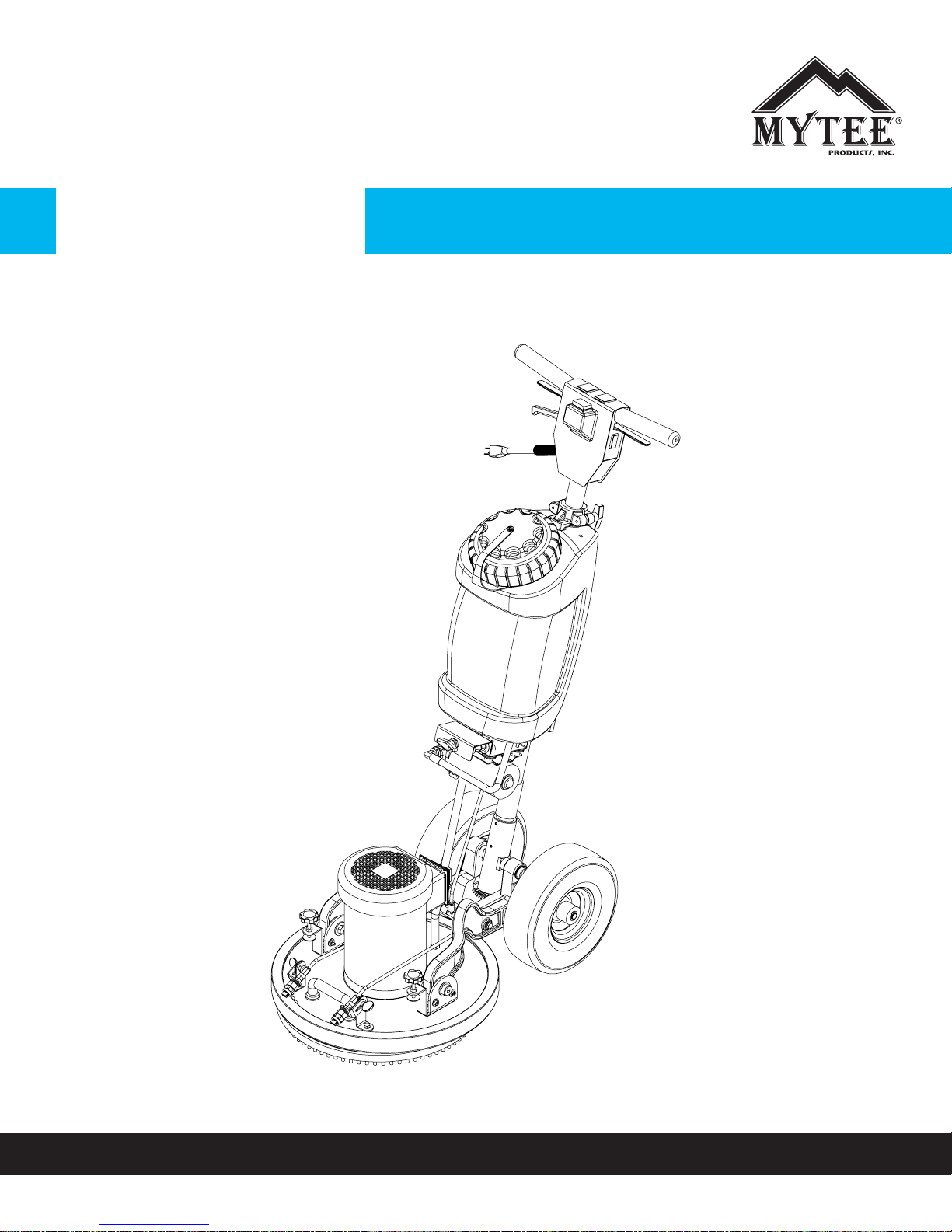

User Manual

ORBITAL

Model: ECO-13, ECO-17

Orbital All-Surface Floor Machine

REV. 3/5/18

13655 Stowe Dr. Poway, CA 92064 • P: (858) 679-1191 • F: (858) 726-6005

Page 2

INTRODUCTION

Dear Customer:

Congratulations on the purchase of your new Orbital All-Surface Floor

Machine.

As technology continues to develop you can work condently knowing that

both Mytee Products and its employees are equally dedicated to developing

with the industry and its advances.

Like any other piece of machinery or technology, the Orbital Floor Machines

also require proper maintenance and care to keep the product working over

extended use. Neglecting your machine, abusing it or not operating it properly

can void its warranty and prevent the machine from performing to the quality

and standard you’d expect out of the Mytee Products line.

If you have any warranty concerns or questions, please review this manual

thoroughly or do not hesitate to contact your distributor. If there are questions

regarding maintenance, replacement, or ordering parts please contact an

authorized Mytee Products Service Center. To see an updated list please visit

our website at http://www.mytee.com/support/service-centers.

Before using your Mytee product, please read this manual thoroughly.

Sincerely,

Mytee Customer Care Dept.

2

Page 3

TABLE OF CONTENTS

IMPORTANT SAFETY INFORMATION

1

2

3

AT A GLANCE 6

1.1 - Technical Specications 6

1.2 - Included with the Orbital Floor Machines 6

1.3 - Orbital Floor Machine Front View 7

1.4 - Orbital Floor Machine Rear View 8

1.5 - Gravity Feed/Spray Jets Selector Valve 9

MACHINE OPERATION 10

2.1 - Powering the Orbital Floor Machines 10

2.2 - Pad Drivers, Pads, and Brushes 10

2.3 - Filling the Shampoo Tank 10

2.4 - Operating the Orbital Floor Machine 11

2.5 - Emptying the Shampoo Tank 11

MACHINE MAINTENANCE 12

4

3.1 - Flywheel Bearing Replacement 12

3.2 - Flywheel Replacement 13

4

TROUBLESHOOTING 14

3

Page 4

IMPORTANT SAFETY INFORMATION

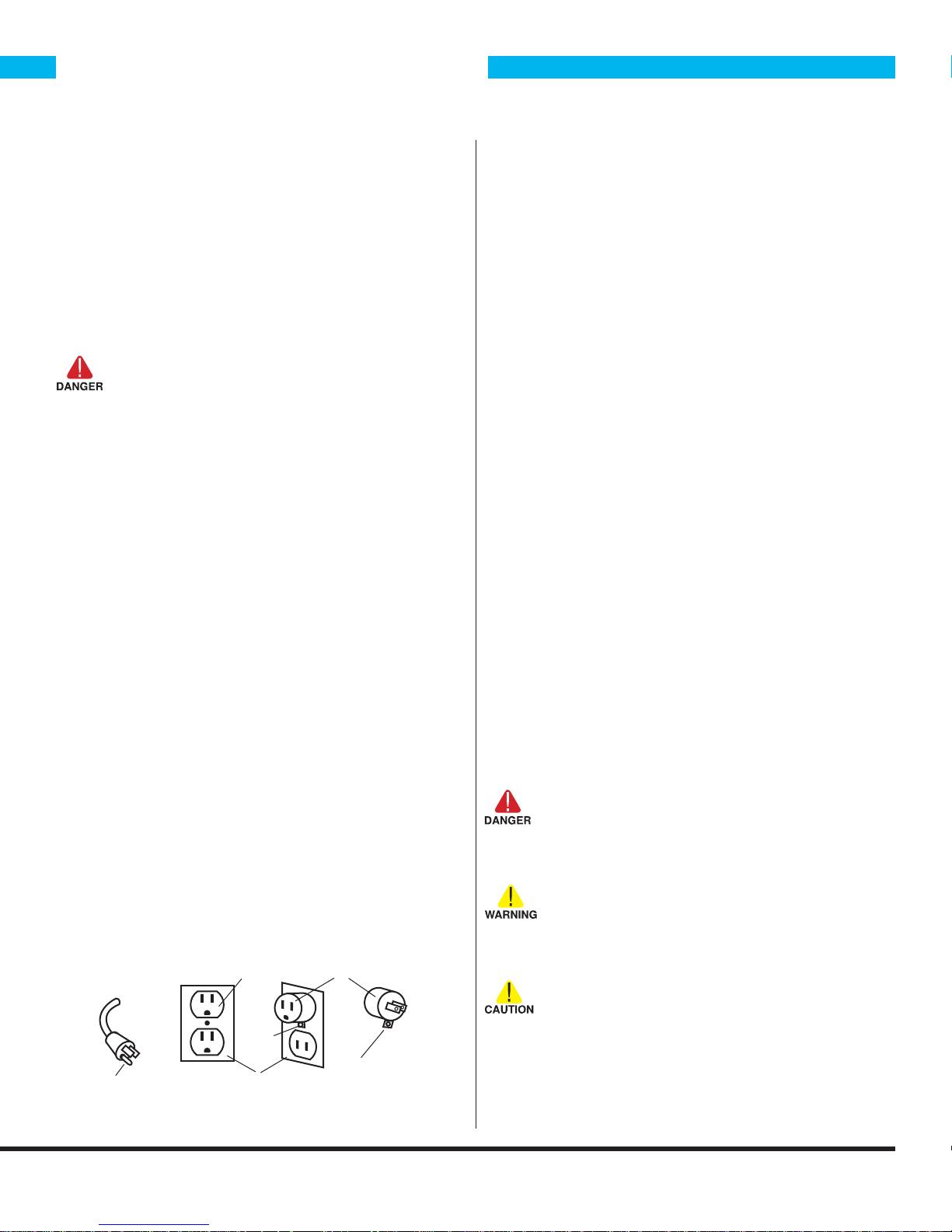

Grounding Instructions

This machine must be grounded. If it should malfunction

or breakdown, grounding provides a path of least resistance for electrical shock. This machine is equipped with

a cord having an equipment-grounding conductor and

grounding plug. The plug must be plugged into an appropriate outlet that is properly installed in accordance with

all local code and ordinances. Do not remove ground pin;

if missing, replace plug before use.

Improper installation of the equipment-grounding conduc-

tor can result in a risk of electric shock. Be sure to check

with a qualied electrician or service person if you are in

doubt as to whether the outlet is properly grounded. If

the plug will not t in the outlet do not modify either the

plug nor the machine’s cord, instead have a proper outlet

installed by a qualied technician.

This machine is for use on a nominal 120-volt circuit and

with a grounding plug similar to the one in Figure 1 below.

If a proper outlet is not available, follow the illustrations of

Figure 2 & 3 to install a temporary-grounding plug. This

temporary work-around should be used only until a proper

outlet (Figure 1) can be installed by a qualied electrician.

When and if this type of adapter is employed, screw the

adapter’s extended tab into place with a metal screw.

However, grounding adapters are not approved for use in

Canada.

Again, be sure to check the grounding pin for damages

and replace if necessary.

The Green, or Green-Yellow, wire in the cord is the

grounding wire. When replacing a plug, this wire must be

attached to only the grounding pin.

Parts and Service

Please contact a Mytee service personnel or Mytee

authorized Service Center using Mytee original replacement parts and accessories for repairs are needing to be

performed. When and if calling Mytee for support, please

have your Model and Serial Number available for faster

assistance.

Name Plate

The Model and Serial Number are located on the lower

half of the back of the machine near the power plugs and

will be required for ordering replacement parts. You can

use the space provided on the front of this manual to note

down both for future referencing.

Unpacking the Machine

When your new machine is delivered, please carefully inspect both the shipping carton and the machine for damages. If damage is evident, save both the shipping carton

and machine so that the delivering carrier can inspect it.

Contact the carrier immediately to le a freight claim if

there has been any damage.

Caution and Warnings

Symbols

Mytee uses the symbols below to signal potentially dangerous conditions. Always read this information carefully

and take the necessary steps to protect personnel and

pr oper t y.

Is used to warn of immediate hazards that will cause severe personal injury or death.

DO NOT use extension cords.

Please Note for America use only.

Grounded Outlet

Metal

Screw

Grounding Pin

Figure 1

Grounded Outlet Box

Figure 2 Figure 3

Adapter

Tab for Grounding

Screw

Is used to call attention to a situation that could cause

severe personal injury.

Is used to call attention to a situation that could cause

minor personal injury or damage to the machine or other

property. When using an electrical appliance, basic precautions should always be followed, including the follow-

ing: Read all instructions before using this machine. This

4

Page 5

IMPORTANT SAFETY INFORMATION

product is intended for commercial use only.

To reduce the risk of re, electrical shock, or injury:

1. Read all instructions before using equipment.

2. Use only as described in this manual. Use only manu-

facturer’s recommended attachments.

3. Always unplug power cord from electrical outlet before

attempting any adjustments or repairs.

4. Do not unplug by pulling on cord. To unplug, grasp the

plug, not the cord.

5. Do not pull or carry by cord. Do not close a door on

cord or pull cord around sharp edges or corners.

6. Do not run appliance over cord. Keep cord away from

heated surfaces.

7. Do not use with damaged cord or plug. If cord is damaged, repair immediately.

8. Do not use outdoors or on wet surfaces and or standin g water.

9. Always unplug or disconnect the appliance from power

supply when not in use.

tional regulations may apply to the safe disposal of liquids

which may contain: chemicals, grease, oil, acid, alkalines,

or other dangerous liquids.

19. Do not leave operating unattended.

10. Do not allow to be used as a toy. Close attention is

necessary when used by or near children.

11. Do not use in areas where ammable or combustible

material may be present.

12. Do not leave the unit exposed to harsh weather elements. Temperatures below freezing may damage components and void warranty.

13. Use only the appropriate handles to move and lift unit.

Do not use any other parts of this machine for this purpose.

14. Keep hair, loose clothing, ngers, and all parts of the

body away from all openings and moving parts.

15. Use extra care when using on stairs.

16. To reduce the risk of re or electric shock, do not use

this machine with a solid-state speed control device.

17. The voltage and frequency indicated on the name

plate must correspond to the wall receptacle supply voltage.

18. When cleaning and servicing the machine, local or na-

5

Page 6

1 - AT A GLANCE

1.1 - Technical Specications

EC O -13

Cleaning Path

Solution Tank

Motor

Pump PSI

Pump GPM

Power Consumption

Machine Weight

Machine Dimensions

Power Cord

Cleaning Path

Solution Tank

Motor

Pump PSI

Pump GPM

Power Consumption

13”

4 Gallons

1 Horsepower

100

1.3

20 amps @ 115V 60Hz

100 lbs.

26” x 13.5” x 48.5”

Single 50’ 12/3

EC O -17

17”

4 Gallons

1 Horsepower

100

1.3

20 amps @ 115V 60Hz

Machine Weight

Machine Dimensions

Power Cord

Pad Driver Two Cleaning Pads

130 lbs.

28” x 17.5” x 48.5”

Single 50’ 12/3

1.2 - Included with the Orbital Floor Machines

6

Page 7

1.3 - Orbital Floor Machine Front View

1 - AT A GLANCE

1

11

2

3

4

5

10

6

7

1. Handle Height Adjustment

Lever

2. Power Cord Pigtail

3. Solution Tank Lid

4. 4 Gallon Solution Tank

5. Gravity Feed/Spray Jets

Selector Valve

6. 1 Horsepower Motor

7. Lifting Handle

8. Forward-Facing Spray Jets

7

9

8

9. Head Rotation Direction

Selector Switch

10. 100 PSI Diaphragm Pump

11. Power Switch

Page 8

1 - AT A GLANCE

1

1.4 - Orbital Floor Machine Rear View

4

2

3

1. Solution Spray Levers

2. Solution Tank Drain Cap

3. 10” Foam-Filled Wheels

4. Faucet Fill Hose

8

Page 9

1.5 - Gravity Feed/Spray Jets Selector Valve

1 - AT A GLANCE

Gravity Feed

Water or shampoo solution is pumped down

to the cleaning head, wetting the oor directly

under the pad or brush.

Arrow points in the direction

of the selected feature.

Spray Jets

Water or shampoo solution is pumped out of the

spray jets on the front on the machine, wetting

the oor directly in front of the unit.

9

Page 10

2 - MACHINE OPERATION

2.1 - Powering the Orbital Floor Machines

The Orbital Floor Machines require a 20 amp, 115V power

outlet to operate.

Included 50’

extension cord

Plug the female end of the 50’ lighted extension cord into

the Orbital Floor Machine’s pigtail power cord and plug the

male end of the extension cord into a wall outlet. ♦

2.2 - Pad Drivers, Pads, and Brushes

Pad Driver

The pad driver comes pre-installed on Mytee’s Orbital

Floor Machines. To remove the pad driver, undo the four

screws on the bottom of the pad driver.

Applying Cleaning Pad

To apply a cleaning pad, just lower the machine with pad

driver onto a 16” cleaning pad for the ECO-13 or a 19”

pad for the ECO-17. Make sure the pad is as centered as

possible on the pad driver with no driver bristles exposed

to carpet.

Tile & Grout Brush

To apply the optional Tile & Grout Brush, remove the

pre-installed pad driver via the four screws holding it in

place. Screw the Tile & Grout Brush directly into the bear-

ing just like the pad driver was.

Using the Optional Star Lok™ Driver Hub

Quickly switch between the Pad Driver and Tile & Grout

Brush with the A145 Star Lok™ Driver Hub (sold separately). The Star Lok™ Driver Hub bolts onto the Orbital Floor

Machine’s bearing, eliminating the need for tools when

swapping cleaning heads. Just slide one head o of the

star-shaped Driver Hub and slide another on. ♦

IMPORTANT:

When lling with

a bucket, tilt the

handle back in

order to avoid

spilling water on

the motor.

10

2.3 - Filling the Shampoo Tank

Page 11

Faucet Fill

The shampoo tank can be lled from a standard faucet.

Simply lift the Faucet Fill hose out of the tank and press it

against the faucet. Turn on the faucet to allow water to ow

down into the tank.

Bucket Fill

To ll using a bucket, twist o the shampoo tank cap

counter-clockwise and pour in water. IMPORTANT: Tilt

back the handle before lling with a bucket in order

to avoid spilling water on the motor causing damage.

Add shampoo or chemical if desired. ♦

2.4 - Operating the Orbital Floor Machine

2 - MACHINE OPERATION

Switching On the Orbital Floor Machines

After plugging in the machine, lower the handle to a comfortable height and press the power switch on the handle

to turn on the machine.

Running the Orbital Floor Machine

To eectively clean oors, move the Orbital Floor Machine

forwards and backwards, similar to using a household

vacuum cleaner. Wet the oor by spraying solution as you

roll the unit forwards. ♦

2.5 - Emptying the Shampoo Tank

The shampoo tank can be easily emptied into a bucket

by unscrewing the drain cap on the bottom of the tank.

IMPORTANT: Tilt the handle back in order to avoid

spilling water on the motor while emptying. ♦

11

Page 12

3 - MACHINE MAINTENANCE

In order to keep the Orbital Floor Machine running

smoothly and reduce the risk of damage to the machine

and subsequent downtime, Mytee recommends following

the maintenance schedule shown to the right:

3.1 - Flywheel Bearing Replacement

The ywheel bearing is a wear part, similar to rotors on a

car. Over time, the bearing will require replacing.

Maintenance Item Daily Weekly

Clean and inspect motor.

Check power supply cable.

Clean machine with all purpose

cleaner and cloth.

Inspect machine for water leaks and

loose hardware.

Tools Needed:

• 7/16” open-ended wrench or socket

• 3/16” Allen wrench

• Blue Loctite

®

X

X

X

X

1. Remove the pad driver assembly

by removing the four bolts with a 7/16”

wrench or socket.

4. Insert the Allen bolts into the new

bearing and line up the bolts with the

holes on the ywheel.

2. Using a 3/16” Allen wrench, undo

the two Allen bolts holding the bearing

onto the ywheel.

5. Using the 3/16” Allen wrench, bolt

the new bearing onto the ywheel.

12

3. Remove the Allen bolts from the

bearing and apply Blue Loctite

6. Apply Blue Loctite® to the pad

driver bolts and bolt it back onto the

machine. ♦

®

.

Page 13

3 - MACHINE MAINTENANCE

3.2 - Flywheel Replacement

These instructions cover how to remove and replace the

ywheel assembly on ECO-17 and ECO-13 models.

1. Remove the pad driver assembly

by removing the four bolts with a 7/16”

wrench or socket.

2. Hold the jam nut, located between

the ywheel and motor, in place with a

15/16” open-end wrench. Using a mallet, tap the ywheel counter-clockwise

to loosen.

Tools Needed:

• 7/16” open-end wrench or

socket

• 15/16”open-end wrench

• Soft-face dead blow

mallet

3. Remove the plastic plug from the

top of the motor and hold the motor

shaft in place by inserting a athead

screw- driver into the top of the shaft

on top of the motor. Loosen the ywheel the rest of the way o with the

other hand.

• Anti-Sieze

• Flathead screwdriver

• Blue Loctite

®

4. Apply Anti-Sieze to the motor shaft.

To install the new ywheel, hold the

motor shaft in place with the athead

screwdriver just like before and thread

the new ywheel on with the other

hand until it stops at the jam nut.

5. Use the 15/16” wrench to hold the

jam nut in place and use a mallet to

strike the ywheel counterweight to

tighten the ywheel against the jam

nut.

13

6. Apply Blue Loctite

driver bolts and bolt it back onto the

machine. ♦

®

to the pad

Page 14

4 - TROUBLESHOOTING

4.1 - Machine Troubleshooting

Plug on the power cord doesn’t light up when

plugged in.

Possible Causes Solutions

Problem with the power

cord.

Burnt out light. No action needed or

Plug lights up when plugged in but machine does not

Possible Causes Solutions

Wires connecting to the

switch may be loose or

disconnected.

Replace power cord.

38” Pigtail: Part # E575

replace power cord.

38” Pigtail: Part # E575

turn on.

Open up the faceplate on

the handle and check the

switch for loose or discon-

nected wires. Re-connect

any loose wires.

Motor is drawing too many amps and blowing

breakers.

Possible Causes Solutions

Power cord is defective or

damaged.

Power switch has shorts or

loose connections.

Power cord from the switch

is defective or damaged.

Machine is making a loud grinding noise.

Possible Causes Solutions

Bearing failure. Replace bearing (click for

Replace power cord. 38”

Pigtail: Part # E575

Replace power switch. Part

# E515

Replace power cord. 38”

Pigtail: Part # E575

instructions). Install Part

# A140 Kit if using gravity

feed (click for instructions).

4.2 - Pump Troubleshooting

Bad power switch. Replace switch. Part #

E515

(120 volt units only) Motor

circuit breaker may have

tripped.

Figure A

Make sure motor is rst

cooled down, then reset

breaker by pressing button

located on bottom of motor

conduit box (see Figure

A). Make sure that only the

proper Mytee power cord

extension is being used,

and that it is good condition. If the problem persists

or reoccurs, contact a

Mytee Service Center.

No water ow.

Possible Causes Solutions

Tank is empty. Fill tank.

Filter is clogged. Clean the lter.

Pump valves are clogged

or damaged.

Low pressure.

Possible Causes Solutions

Work nozzle. Replace nozzle with a new

Leak in high pressure hose

or connections.

Filter is clogged. Clean the lter.

Pump valves are clogged

or damaged.

Examine the valves and

clean or replace.

one of the same size.

Check the hose and connections.

Examine the valves and

clean or replace.

14

Page 15

Pump pulsates when spraying.

Possible Causes Solutions

Filter is clogged. Clean the lter.

4 - TROUBLESHOOTING

Pump valves are clogged

or damaged.

Leaks seen under pump.

Possible Causes Solutions

Worn pump seals. Replace with new plunger

Abrasives in solution have

damaged pump seals.

Examine the valves and

clean or replace.

and seals.

Mix chemical thoroughly

and make sure lter is not

damaged.

15

Page 16

NOTES

Mytee Products, Inc.

13655 Stowe Dr.

Poway, CA 92064

www.mytee.com

© 2018 Mytee Products, Inc.

Printed in the USA

Loading...

Loading...