Page 1

Instructions for

D

C

B

7

6

5

4

3

2

1

E

F

REVISIONS

REV.

DESCRIPTION

DATE

APPROVED

OD

ORIGINAL DRAFT

JFL

D

C

B

6

5

4

3

2

1

E

F

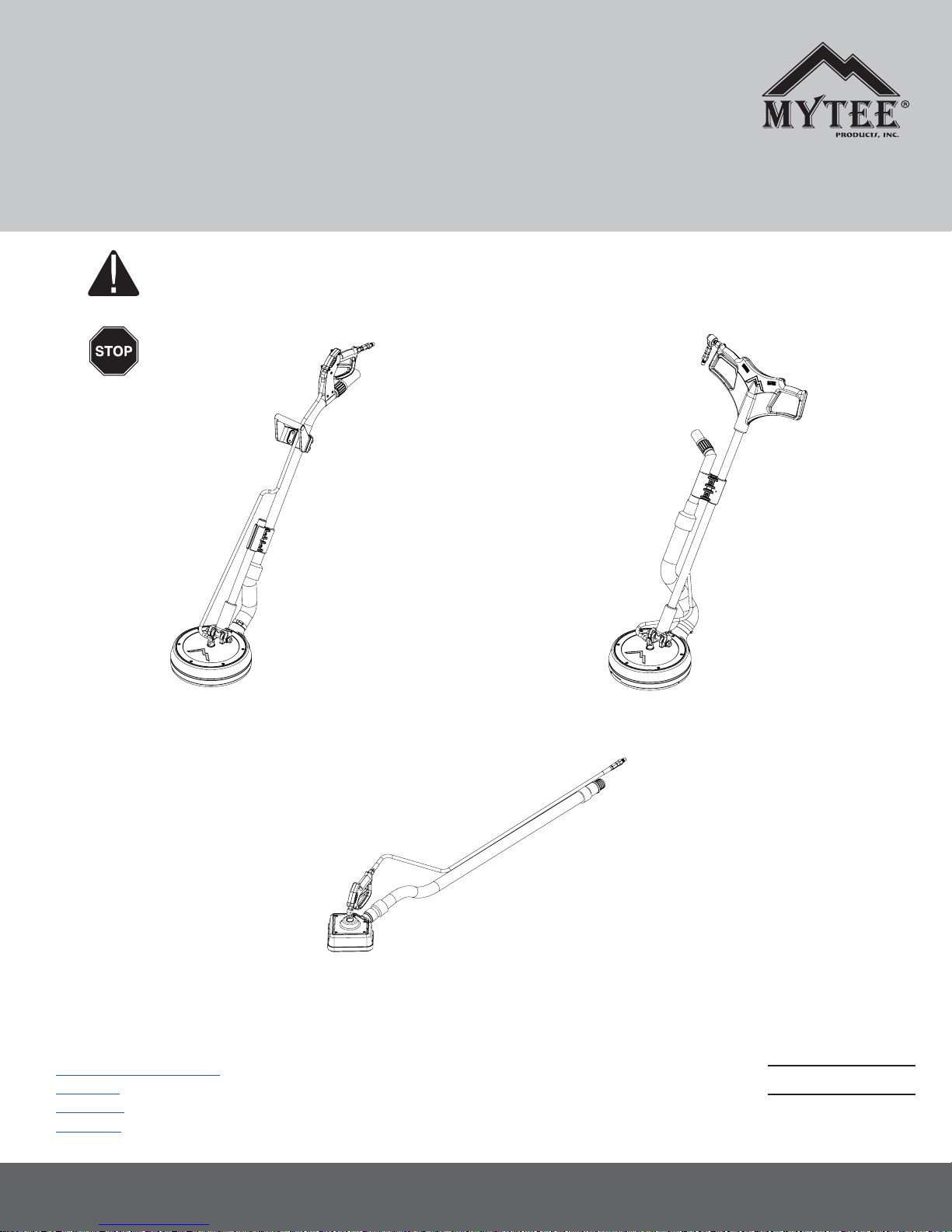

spinner, 12"

2/5/10

UNLESS OTHERWISE SPECIFIED:

TITLE:

NAME

DATE

COMMENTS:

CHECKED

DRAWN

DIMENSIONS ARE IN INCHES

TOLERANCES:

ANGULAR: MACH

.5

ONE PLACE DECIMAL

.03

TWO PLACE DECIMAL

.05

THREE PLACE DECIMAL

.003

A

858-679-1191

mytee

PRODUCTS, INC.

V. LaBarbera

REVISIONS

REV.

DESCRIPTION

DATE

APPROVED

OD

ORIGINAL DRAFT

JFL

D

C

B

6

5

4

3

2

1

E

F

8903, 8904, and 8908 Spinner

Please read before use.

Register your product

at: http://www.mytee.

com/support/register/

®

General Information p.2

8903 p. 4

8904 p. 6

8908 p. 8

8908 - Counter Spinner®

13655 Stowe Dr., Poway, CA 92064

1

8904 - T-Handle8903 - Wand Handle

Model #

Serial #

Form # ADP-SPIN

3-17

Page 2

GENERAL INFORMATION

Dear Customer:

Congratulations on the purchase of your new Spinner®. As you are already

aware, the scene of the equipment world is becoming more high tech, and we

at Mytee Products Inc. strive to keep you on the cutting edge with superior quality

and technology.

Keep in mind that the Spinner

unnecessary damage and void the warranty. However with simple maintenance

the Spinner

If warranty questions arise, please consult your user manual or get in touch with

your distributor. If you have questions about maintenance, replacing parts or

ordering parts, please call an authorized Mytee Products Inc. Service Center.

To see an updated list, visit our website at www.mytee.com

Before you begin cleaning, please read your manual thoroughly.

Sincerely,

Mytee Customer Care Dept.

®

will give quality performance for many years to come.

®

is a machine, so neglect or abuse will cause

Parts and Service

Repairs, when required, should be performed by Mytee service personnel or Mytee

authorized Service Center using Mytee original replacement parts and accessories.

Call Mytee for repair parts or service. Please specify the Model and Serial Number

when discussing your machine.

Name Plate

The Model and Serial Number of your machine are shown on the Nameplate on the

back panel of the machine. This information is needed when ordering repair parts

for the machine. Use the space provided on the front cover to note the Model and

Serial Number of your machine for future reference.

Unpacking the Machine

When the machine is delivered, carefully inspect the shipping carton and the

machine for damage. If damage is evident, save the shipping carton so that it can

be inspected by the carrier that delivered it. Contact the carrier immediately to le a

freight damage claim.

Caution and Warnings

Symbols

Mytee uses the symbols below to signal potentially dangerous conditions. Always

read this information carefully and take the necessary steps to protect personnel

and property.

Is used to warn of immediate hazards that will cause severe personal injury or death.

Is used to call attention to a situation that could cause severe personal injury.

Is used to call attention to a situation that could cause minor personal injury or

damage to the machine or other property. When using an electrical appliance, basic

precautions should always be followed, including the following: Read all instructions

before using this machine. This product is intended for commercial use only.

To reduce the risk of re, electrical shock, or injury:

1. Read all instructions before using equipment.

2. Use only as described in this manual. Use only manufacturer’s recommended

attachments.

3. Always unplug or disconnect the appliance from power supply when not in use.

4. Do not allow to be used as a toy. Close attention is necessary when used by or

near children.

5. Do not use in areas where ammable or combustible material may be present.

6. Do not leave the unit exposed to harsh weather elements. Temperatures below

freezing may damage components and void warranty.

7. Use only the appropriate handles to move and lift unit. Do not use any other parts

of this machine for this purpose.

8. Keep hair, loose clothing, ngers, and all parts of the body away from all

openings and moving parts.

9. Use extra care when cleaning on stairs.

10. When cleaning and servicing the machine, local or national regulations may apply

to the safe disposal of liquids which may contain: chemicals, grease, oil, acid, alkalines, or other dangerous liquids.

11. Do not leave operating unattended.

Use only non-ammable liquid in this machine.

Preparation

1. Remove furniture from cleaning area, and sweep or vacuum.

2. Protect cabinets, carpets, walls and painted surfaces from spray with drop cloths

or plastic.

3. Identication – Identify the type of oor you are going to clean. This step is vital,

since each ooring type may call for different chemicals, brushes and equipment.

Basic ooring types are: resilient (vinyl, VCT, linoleum), which is generally softer;

stone (terrazzo, quarry, ceramic, brick, concrete) made of natural materials; and

stone substitute (marble, slate and granite), which mimics stone.

4. Application – Once the ooring is identied, apply the appropriate type of cleaning

(or in the case of resilient ooring, stripping) chemical. On tile surfaces, spray chemi-

cal evenly over tile and grout lines, allowing it to pool in the lines.

5. Emulsication – Chemicals typically require dwell time to remove the dirt and

grime driven into the surface. The dirtier the oor, the longer the chemicals may need

to dwell. Without proper dwell time, chemicals will not be effective.

6. Agitation and Elimination – Agitate the chemical into the oor to facilitate cleaning

using a Spinner® oor machine connected to an extractor. The Spinner® lays down

high-pressure spray to agitate and rinse, and vacuums up the solution simultaneously, eliminating it from the surface.

Spinner® Operation

1. Attach the Vacuum and Solution Hoses to the extractor.

2. Attach the Solution Hose to the Male Quick Disconnect and the Vacuum Hose to

the Wand Tube.

3. Turn on the extractor to engage the vacuum, while making sure the bottom of the

Spinner™ is ush with the cleaning surface to ensure proper suction.

4. Squeeze the Spinner’s™ high-pressure trigger gun to dispense solution on to

the surface.

5. Hold the machine at waist level and use a back-and-forth motion.

After Use

1. Unplug.

2. Inspect hoses and replaced if damaged.

3. After each use, wipe oor machine with a clean, soft, damp cloth.

4. Do not expose to rain.

5. Store indoors. In a clean, dry place.

6. Do not store sitting on brush.

Maintenance Schedule

Maintenance item Daily

Clean and inspect hoses

Check for loose hardware

Clean machine with clean, soft damp cloth

Inspect spray jets once a week.

Use Mytee

hours. Circulate through the hose and tool.

®

System Maintainer 3601 every 100

x

x

x

Once a week

x

x

Product Specications

Spinner® Style

Tube Construction Stainless steel

Cleaning Path 12” 7.5”

PSI Requirements 500 - 3,000 PSI

Spray Jets Dual 1502

Product Weight 18 lb s. 16 lb s. 7 lbs.

Product

Dimensions

8903

1.5” Wand Style

12” x 14” x 52” 16” x 19” x 49” 11” x 9” x 9”

8904

1.5”

T-H and le

8908

Counter Spinner

1.5” Vacuum

Hose

2

Page 3

GENERAL INFORMATION

FAQs

Q – How much PSI do I need to operate the Spinner®?

A – Spinners

Troubleshooting

The Spinner® is not spinning.

1. Inspect the jets to make sure they are not clogged.

2. Check the machine for a normal ow of solution by disconnecting the Solution

Hose from the Spinner

3. If the solution’s ow is disrupted, use Mytee

4. Try to spin the unit by hand. If it does not move, replace the swivel. If it moves, the

seal may need rebuilding. Take the Spinner

Guidelines

1. For ease of use, keep the brush and manifold balanced and at.

2. Adjust the handle at a comfortable height for the operator; making sure the brush

remains balanced before starting the extractor.

3. The Spinner

more resistance than surfaces such as tile and grout. If you experience resistance of

movement, adjust the vacuum release slot to release air from the Vacuum Hose.

Replacement Parts

8903, and 8904

Brush & Glide Kit – No. A109

Glide – No. P500

Brush – No. G098

Swivel – No. H926

Rebuild Kit – No. H927

®

require between 500 and 3,000 PSI.

®

and letting the liquid run freely.

®

operates differently according to the surface. Smooth surfaces offer

®

System Maintainer 3601.

®

to your local service center.

8908

Glide – No. P593

Brush – No. G111

Swivel – No. H926

Rebuild Kit – No. H927

3

Page 4

8903 WAND HANDLE, 1.5” TUBE SPINNER®

REVISIONS

REV.

DESCRIPTION

DATE

APPROVED

OD

ORIGINAL DRAFT

JFL

D

C

B

7

6

5

4

3

2

1

E

F

REVISIONS

REV.

DESCRIPTION

DATE

APPROVED

OD

ORIGINAL DRAFT

JFL

D

C

B

6

5

4

3

2

1

E

F

2/5/10

UNLESS OTHERWISE SPECIFIED:

TITLE:

NAME

DATE

COMMENTS:

CHECKED

DRAWN

DIMENSIONS ARE IN INCHES

TOLERANCES:

ANGULAR: MACH

.5

ONE PLACE DECIMAL

.03

TWO PLACE DECIMAL

.05

A

858-679-1191

mytee

PRODUCTS, INC.

V. LaBarbera

8901 FRONT

5

6

1. Quick disconnect

2. High-pressure gun

3. Vacuum hose connection

4. Vac relief

3

4

7

8

5. Wand grip handle

6. Hi-pressure solution hose

7. 12” Spinner® head

8. Nylon glide with removeable brush

1

VACUUM HOSE AND SOLUTION HOSE ATTACHMENT

Attach solution line

2

After the Vacuum Hose and Solution Hose are attached to the

extractor, connect the Solution Hose to the Male Quick Discon-

nect, and the Vacuum Hose to wand tube. Use the included

adapter if you are using a 2” vacuum hose. You can permanently

attach the adapter using silicone or similar adhesive.

here.

Adapter for use with 2”

vacuum hoses.

Attach vacuum hose

here.

JETS

After the extractor is turned on and vacuum is engaged,

squeeze the High-Pressure Trigger Gun. Liquid ows through

the Solution Hose and activates the Spinner Bar.

Hold the machine at waist level and use a back-and-forth motion.

USE

4

Page 5

8903 WAND HANDLE, 1.5” TUBE SPINNER®

2

1

3

6

7

11

18

25

12

16

17

16

21

20

26

15

8

14

32

8

28

5

37

35

10

9

26

29

19

33

34

36

22

31

30

4

13

23

24

33

33

27

ITEMS NOT SHOWN

ITEM

NO.

PART NO.

DESCRIPTION

QTY.

MSRP

1

H505A

jet, s/s, 1/8", 1502

2 $9.99 ea

2

H441

bar, t, straight, 42 deg, 10"

1 $129.99 ea

3

G098

brush, spinner ring

1 $24.99 ea

4

P500

spinner ring, nylon

1 $25.99 ea

5

P689A

manifold, 12" spinner, low profile

1 $51.99 ea

6

H230

screw, 10-32 x 1/2" phil pan head, s/s 3 $0.99 ea

7

H926

swivel, spinner

1 $208.99 ea

8

H289

Washer #10 flat, s/s

6 $0.99 ea

9

H465A

mounting plate, 12" spinner

1 $84.99 ea

10

H882

screw, 8 x 3/4 phil pan head, type a, s/s

6 $0.99 ea

11

B136

elbow, brass, 90 deg, 1/4" mpt x 1/4" mpt

1 $4.99 ea

12

H008

set; bolt, 2 lock nuts, 4 washers

1 $2.99 ea

13

H102

yoke, spinner

1 $11.99 ea

14

AH206

sol hose, 1/4" x 48", 1/4 fsw x 1/4 mpt

1 $21.99 ea

15

H197

handle, lower, wand style spinner

1 $17.99 ea

16

H210

washer, 1/4" flat, s/s

4 $0.99 ea

17

H203

bolt, 1/4-20 x 1-1/4"

2 $0.99 ea

18

H785

grip, 1.5" dia, wand

1 $15.99 ea

19

B130

45 deg, street elbow, brass, 1/4" male

1 $5.49 ea

20

H458

nut, lock, 10-32, thin pattern

6 $0.99 ea

21

H540

gun, high pressure

1 $41.99 ea

22

B105

bushing, brass, 3/8"mpt x 1/4" 1 $3.19 ea

23

B107

nipple, brass, 1/4"m, hex

1 $3.19 ea

24

B247

filter, in-line, 100 mesh, 1/4" MPT x FPT

1 $13.99 ea

25

B101

qd, brass, 1/4" m

1 $8.49 ea

26

H457 screw, 10-32 x 1-1/2", p-pan

6 $0.99 ea

27

P719

inlet, 2"

1 $10.99 ea

28

G082

cap, vacuum relief slot (spin)

1 $3.25 ea

29

H614A

gun style valve clamp, 1.5"

1 $16.99 ea

30

H342

bolt, 1/4-20 x 1" hex head, s/s 4 $0.99 ea

31

H148

washer, 5/16", narrow

4 $0.99 ea

32

H616

tube, 1.5" spinner, wand style

1 $81.99 ea

33

H613A

clamp, spinner handle , 1.5" x 1.25"

2 $11.99 ea

34

H216

nut, lock, 1/4-20, nylon insert, s/s

2 $0.99 ea

35

H142

cuff, 2" thread x 1-1/2" slip

1 $14.99 ea

36

PH628-24

hose, vac wire reinforced 2"

1

$8.99/ft

37

H217

clamp, hose, 2-1/4 dia

1 $1.49 ea

PART NO.

DESCRIPTION

QTY.

MSRP

G102

gasket, cork, 3/4" X 3", 1/8“ thick

3 $1.99 ea

D

C

B

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

E

F

E

F

8903

SHEET 1 OF 2

Spinner,

Wand Style, 1.5"

8/22/11

E

SCALE: 1:6

REV

DWG. NO.

C

SIZE

TITLE:

NAME

DATE

CHECKED

DRAWN

PROPRIETARY AND CONFIDENTIAL

A

DO NOT

SCALE DRAWING

858-679-1191

mytee

PRODUCTS, INC.

M. LaBarbera

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

MYTEE PRODUCTS, INC. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

MYTEE PRODUCTS, INC. IS

PROHIBITED.

5

Part prices are subject to change.

Page 6

REVISIONS

REV.

DESCRIPTION

DATE

APPROVED

OD

ORIGINAL DRAFT

JFL

D

C

B

6

5

4

3

2

1

E

F

8904 “T” HANDLE, 1.5” TUBE SPINNER®

REVISIONS

REV.

DESCRIPTION

DATE

APPROVED

OD

ORIGINAL DRAFT

JFL

D

C

B

6

5

4

3

2

1

E

F

2/5/10

UNLESS OTHERWISE SPECIFIED:

NAME

DATE

DIMENSIONS ARE IN INCHES

mytee

PRODUCTS, INC.

V. LaBarbera

8904 FRONT

1

3

4

5

6

1. Quick disconnect

2. High-pressure gun

3. Vacuum hose connection

4. Vac relief

2

7

5. Hi-pressure solution hose

6. 12” Spinner® head

7. Nylon glide with removeable brush

VACUUM HOSE AND SOLUTION HOSE ATTACHMENT

Attach solution line

here.

Adapter for use with 2”

vacuum hoses.

Attach vacuum hose

here.

After the Vacuum Hose and Solution Hose are attached to the

extractor, connect the Solution Hose to the Male Quick Discon-

nect, and the Vacuum Hose to wand tube. Use the included

adapter if you are using a 2” vacuum hose. You can permanently

attach the adapter using silicone or similar adhesive.

JETS

After the extractor is turned on and vacuum is engaged,

Hold the machine at waist level and use side to side.

USE

squeeze the High-Pressure Trigger Gun. Liquid ows through

the Solution Hose and activates the Spinner Bar.

6

Page 7

8904 “T” HANDLE, 1.5” TUBE SPINNER®

2

1

3

4

5

6

7

8

9

10

11

14

16

15

18

19

20

19

19

21

22

23

28

24

25

26

27

30

31

32

33

34

35

29

13

12

17

ITEMS NOT SHOWN

ITEM

NO.

PART NO.

DESCRIPTION

QTY.

MSRP

1

H505A

jet, s/s, 1/8", 1502

2

$9.99 ea

2

H441

bar, t, straight, 42 deg, 10"

1

$129.99 ea

3

G098

brush, spinner ring

1

$24.99 ea

4

P500

spinner ring, nylon

1

$25.99 ea

5

P689A

manifold, 12" spinner, low profile

1

$51.99 ea

6

H230

screw, 10-32 x 1/2" phil pan head, s/s 3

$0.99 ea

7

H926

swivel, spinner

1

$208.99 ea

8

H289

washer #10 flat, s/s

9

$0.99 ea

9

H465A

mounting plate, 12" spinner

1

$84.99 ea

10

H882

screw, 8 x 3/4 phil pan head, type a, s/s

6

$0.99 ea

11

B136

elbow, brass, 90 deg, 1/4" mpt x 1/4" mpt

1

$4.99 ea

12

H008

set; bolt, 2 lock nuts, 4 washers

1

$2.99 ea

13

H102

yoke, spinner

1

$11.99 ea

14

H613A

clamp, spinner handle , 1.5" x 1.25"

2

$11.99 ea

15

H094

tube, vac, elbow, 1.5" dia, spinner

1

$48.99 ea

16

AH206

sol hose, black 48" (OAL), fsw 1/4" x m 1/4"

1

$21.99 ea

17

P719

inlet, 2"

1

$10.99 ea

18

G082

cap, vacuum relief slot (spin)

1

$3.25 ea

19

B101

qd, brass, 1/4" m

1

$8.49 ea

20

B247

filter, in-line, 100 mesh, 1/4" mpt x fpt

1

$13.99 ea

21

B107

nipple, brass, 1/4"m, hex

1

$3.19 ea

22

B100A

swivel, high pressure, stainless steel

1

$45.99 ea

23

B105

bushing, brass, 3/8"mpt x 1/4"

1

$3.19 ea

24

P591

trigger, spinner

1

$19.99 ea

25

B540

valve, high pressure, spinner

1

$39.99 ea

26

P579

handle, back half, spinner

1

$19.99 ea

27

H155

screw, 8 x 5/8", phil pan, s/s

14

$0.99 ea

28

P578

handle, front half, spinner

1

$25.99 ea

29

H092

handle, "T", spinner

1

$139.99 ea

30

H204

bolt, 1/4-20 x 1 3/4" hex head, s/s

2

$0.99 ea

31

H210

washer, 1/4" flat, s/s

4

$0.99 ea

32

H216

nut, lock, 1/4-20, nylon insert, s/s

2

$0.99 ea

33

H142

cuff, 2" thread x 1-1/2" slip

1

$14.99 ea

34

PH628-24

vac hose, 2", wire reinforced

1

$8.99/ft

35

H217

clamp, hose, 2-1/4 dia

1

$1.49 ea

PART NO.

DESCRIPTION

QTY.

MSRP

G102

gasket, cork, 3/4" X 3", 1/8“ thick

3

$1.99 ea

D

C

B

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

E

F

E

F

8904

SHEET 1 OF 2

Spinner,

"T" Style, 1.5"

8/2013

C

SCALE: 1:6

REV

DWG. NO.

C

SIZE

TITLE:

NAME

DATE

CHECKED

DRAWN

PROPRIETARY AND CONFIDENTIAL

A

DO NOT

SCALE DRAWING

858-679-1191

mytee

PRODUCTS, INC.

M.LaBarbera

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

MYTEE PRODUCTS, INC. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

MYTEE PRODUCTS, INC. IS

PROHIBITED.

7

Part prices are subject to change.

Page 8

D

4

3

2

1

E

F

D

C

B

7

6

5

4

3

2

1

E

F

7

6

5

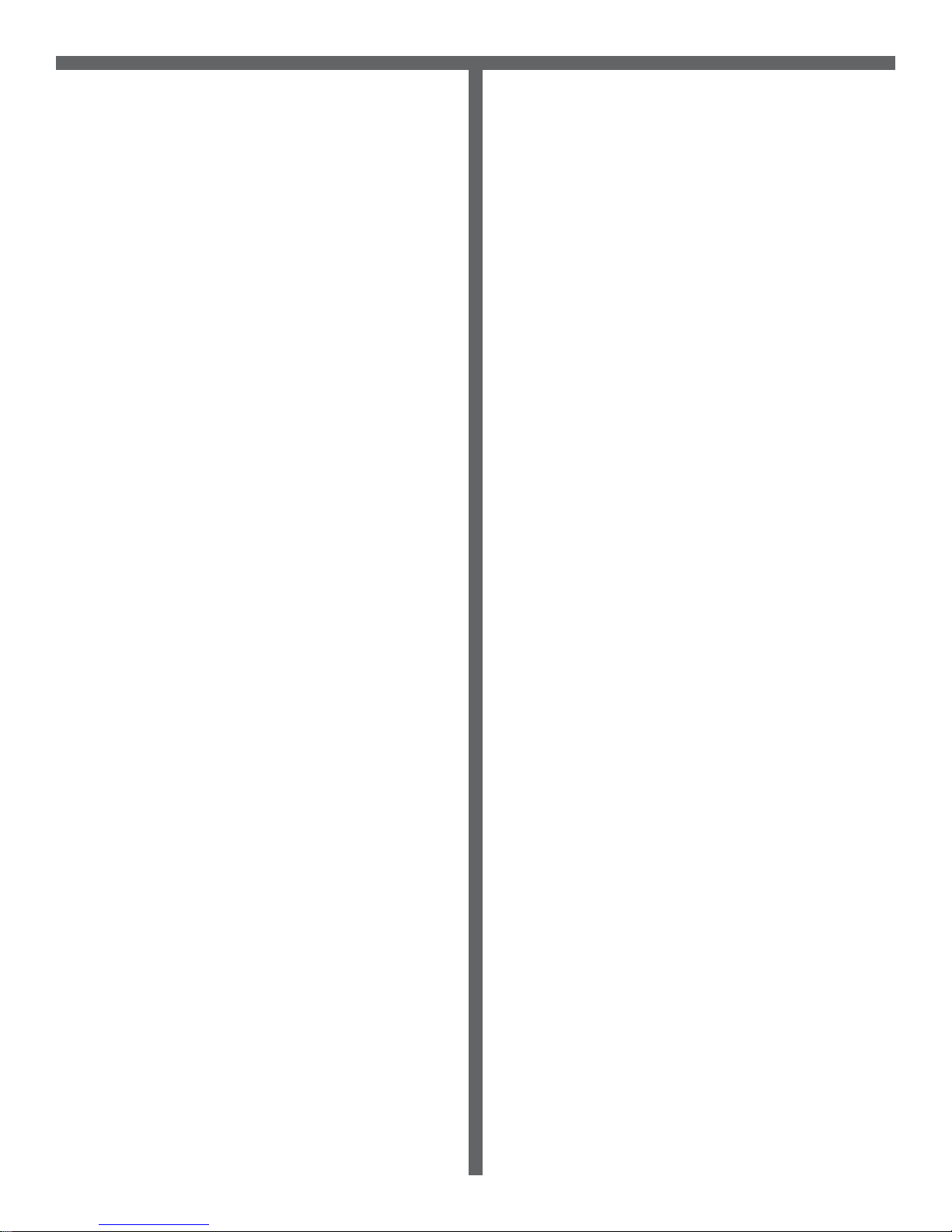

8908 COUNTER SPINNER®

8908 FRONT

2

3

5

4

1. Male quick disconnect

2. Solution hose

3. High-pressure trigger gun

4. Nylon glide

1

6

5. 6” Spinner® head

6. Vacuum hose

7. Vacuum hose connection

port

VACUUM HOSE AND SOLUTION HOSE ATTACHMENT

Connect solution

hose here.

7

Connect vacuum

hose here.

After the Vacuum Hose and Solution Hose are attached to the

extractor, connect the Solution Hose to the Male Quick Discon-

nect, and the Vacuum Hose to wand tube.

JETS

After the extractor is turned on and vacuum is engaged,

squeeze the High-Pressure Trigger Gun. Liquid ows through

the Solution Hose and activates the Spinner Bar.

USE

Use unit on counter top or other hard surface.

8

Page 9

8908 COUNTER SPINNER®

1

2

4

5

6

9

10

11

12

14

16

17

18

19

7

8

8

8

6

13

15

14

14

3

ITEMS NOT SHOWN

ITEM

NO.

PART NO.

DESCRIPTION

QTY.

MSRP

1

H505A

jet, s/s, 1/8", 1502

2

$9.99 ea

2

H425

spray bar, 4"

1

$117.99 ea

3

G111

brush, corner spinner

1

$29.99 ea

4

P593

glide, nylon, corner spinner

1

$19.99 ea

5

P701

manifold, counter tool

1

$35.99 ea

6

H230

screw, 10-32 x 1/2" phil pan head, s/s

8

$0.99 ea

7

H926

swivel, spinner

1

$198.99 ea

8

H289

washer #10 flat, s/s

9

$0.99 ea

9

H482

casting, counter spinner

1

$27.99 ea

10

B107 nipple, brass, 1/4"m, hex

1

$3.19 ea

11

B130

45 deg, street elbow, brass, 1/4" male

1

$5.49 ea

12

H540

gun, high pressure

1

$41.99 ea

13

B105

bushing, brass, 3/8"mpt x 1/4"

1

$3.19 ea

14

AH195

sol hose, 57" x 1/4", (OAL), m

1

$37.99 ea

15

B247

filter, in-line, 100 mesh, 1/4" MPT x FPT

1

$13.99 ea

16

B101

qd, brass, 1/4" m

1

$8.49 ea

17

H655

coupler, 1-1/2" barb to barb fitting

1

$8.99 ea

18

H300

cuff, hose, 1-1/2 x 1-1/2, wire

2

$5.99 ea

19

H504

vac hose, 4' x 1-1/2", 1sw cu

1

$19.49 ea

PART NO.

DESCRIPTION

QTY.

MSRP

G079 hose wrap, heat guard

1

$2.99 ea

D

C

B

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

E

F

E

F

8908

SHEET 1 OF 1

Spinner, Counter

3/2013

B

SCALE: 1:4

REV

DWG. NO.

C

SIZE

TITLE:

NAME

DATE

CHECKED

DRAWN

PROPRIETARY AND CONFIDENTIAL

A

DO NOT

SCALE DRAWING

858-679-1191

mytee

PRODUCTS, INC.

M.LaBarbera

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

MYTEE PRODUCTS, INC. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

MYTEE PRODUCTS, INC. IS

PROHIBITED.

Part prices are subject to change.

9

Page 10

NOTES

Mytee Products Inc.

13655 Stowe Dr.

Poway, CA 92064

www.mytee.com

FX 858.679.7814

© 2017 Mytee Products Inc.

Printed in the U.S.A.

10

Loading...

Loading...