Installation, Operating, Maintenance

and After Sales Manual.

®

WHISPA III

5000, 9000 & 12000 RCU

heatingthroughinnovation.

Product Serial Number:

Installation Date:

Part Number: 1371056

01.06.2009 ISSUE 1

Issue 1

Tested to UL & CSA Standards

Contents

1.0 General Information 03

2.0 Heating System Design 03

3.0 Selection and Sizing for Heating 03

4.0 Location 03

5.0 Preparation 04

6.0 Electrical Connection 05

7.0 Water Connection 06

8.0 Technical Data 08

9.0 Operating Instructions 09

10.0 Troubleshooting 10

11.0 Maintenance 11

1.0 General Information

WHISPA III

®

5000, 9000 & 12000 RCU

03

G This MYSON WHISPA III®recessed commercial unit (RCU) is

designed for recessed wall applications where the use of

surface mounted units would not be appropriate. All units

have a one piece low profile front cover.

G WHISPA III

®

RCU fan convectors are designed to be used with

mono-flo Tees from a series loop, on a two pipe system, or as

a stand alone zone.

G WHISPA III

®

RCU fan convectors are available in three sizes,

and before proceeding with the installation the heating

system design must be considered and the unit correctly

selected to meet the heat loss requirement of the room.

G WHISPA III

®

RCU fan convectors are supplied with a fan speed

selector switch mounted on the front of the unit.

G WHISPA III

®

RCU fan convectors are supplied with built in

½" compression shut off valves for both the supply and

return.

G WHISPA III

®

RCU fan convectors are supplied with high

volume purge valve - air vents.

2.0 Heating System Design

The WHISPA III

mono-flo or venturi Tees, on a two pipe system or as a stand

alone zone.

For optimum fan convector performance the system must be

capable of providing sufficient hot water through the heat

exchanger. This means that:

1. Care must be taken in sizing both the pump and piping.

The minimum pipe size from the boiler to the fan convector

must be 1/2" copper tube.

2. Where the WHISPA III

emitters, mono-flo Tees or diverter Tees should be used to

provide adequate water flow.

®

RCU can be fitted on a series loop with

®

RCU is fitted on to a system with other

G WHISPA III

®

RCU fan convectors are supplied with an integral

combi - zone control and flow control valve, with a factory

fitted insert set to give 1 GPM. The flow rate through the unit

will not exceed this value, however, other inserts of 2 GPM or

3 GPM can be fitted by the installer to give higher flow rates.

G A low limit thermostat prevents the fan from operating if the

water temperature in the unit is below 110°F

G WHISPA III

®

RCU fan convectors are not designed for use with

steam.

G A 24V room thermostat, On – Off or set back type, can be

wired to this unit to give room temperature control.

G A time control can be wired to WHISPA III RCU fan convectors

to provide occasional coil purging flow through the coil if

considered necessary.

G All waterways are of copper. No lead brazing materials are

used to assemble this unit.

3. The system water must be above 110°F for fan to switch on,

and best results the mean water temperature should not be

below 140°F.

4. Optimum performance will require effective balancing of the

whole system.

5. The WHISPA III

®

RCU should not be used to replace a

radiator in an existing system unless an adequate flow of

water can be guaranteed through the unit.

6. The loop must be pumped. WHISPA III®RCU fan convectors

are not suitable for gravity circulation systems.

1.0

2.0

3.04.0

3.0 Selection and Sizing for Heating

G Heat output performance figures for the three sizes of

WHISPA III

Data section of this manual.

G Since WHISPA III

speed control, it is important to size the unit to match the

calculated heat loss requirements of the room with the unit

operating at the low fan speed (I).

®

RCU fan convectors are given in the Technical

®

RCU fan convectors are supplied with fan

4.0 Location

G The WHISPA III®RCU fan convector is designed for recessed

wall applications.

G WHISPA III

2" x 4" stud wall framing, with 5/16" thick cover

extending beyond the wall surface once installed.

®

RCU fan convectors are designed for normal

G The higher fan speed can then be used for more rapid

heating from cold in extreme conditions.

G When establishing the temperature difference, i.e. entering

water to room temperature, allowance should be made for

temperature drop in the system. It is the water temperature

at the fan convector that dictates the output.

G The size of the opening required to be cut for installation is

shown in Fig 1.

04

WHISPA III

®

5000, 9000 & 12000 RCU

5.0 Preparation

Before proceeding with the installation, unpack the carton

contents and check against the checklist below:

1. WHISPA III

2. Instruction manual.

3. Front cover.

4. Screw fixing kit.

G The WHISPA III

piping and wiring connections are made within the cabinet of

the unit itself. The installer should inspect the unit and note

that the ½" piping should enter on the lower right corner of

the unit and the 110V AC wiring for the unit enters on the

lower left hand corner of the unit, see Fig 2.

Dimensions of opening to be cut in wall

®

RCU.

®

RCU fan convector is designed so that the

141/2"

241/2"

G Prepare the opening in the wall to accept the unit as shown

in Fig. 1. Depending on the wall framing layout, the 9,000 and

12,000 models may require re-framing of the opening to

ensure proper support.

G Do not fit the unit at this stage.

195/16"

241/2"

5000 RCU

241/2"

Fig. 1

Note: All models require a depth of at least 3½".

9000 RCU

313/4"

12000 RCU

6.0 Electrical Connection

Line

(Supply) Ground

Neutral

T1 T2

Ground

Actu

Tr Ac T

WARNING: This appliance must be grounded.

WHISPA III

®

5000, 9000 & 12000 RCU

05

G The electrical installation must comply with local or national

wiring regulations.

G A hole is provided at the lower left hand corner of the unit

for a BX or Romex connector.

G Make electrical connection to the terminal block:

Black Lead – Hot 110V 60Hz

White lead – Neutral

Green – Ground

Do not energize the electrical supply until the remaining stages of the installation have been completed.

5.0

Fig. 2

6.0

06

C

B

A

WHISPA III

®

5000, 9000 & 12000 RCU

7.0 Water Connection

G This unit is supplied with ½" compression isolating valves.

Bring ½ " copper tubing to the unit and make the

compression joints. Connect the supply to the left hand

isolating valve. This is necessary to allow proper venting and

purging of the fan convector.

G The WHISPA III

regulator set at 1 GPM maximum. If another pre-set

maximum flowrate is required then the insert can be changed

at this stage. Unscrew the insert cap on the flow control valve.

Remove the insert and replace with the alternative. Replace

cap and tighten.

G Many installers are now beginning to use flexible heat tubing

to make these connections. Ensure prior to use that the

tubing selected is appropriate for the water temperature to

be supplied.

®

RCU fan convector is fitted with a flow

G Once the connections to the heating loop are complete, the

unit must be vented using the air purge valve. Fit a length of

hose to the purge valve so that any water from the heating

circuit escaping during the venting process can be directed

to waste, see Fig 3. Open the air purge valve by loosening

the screw.

G Open the left hand valve at the bottom of the unit and purge

the unit for 1-2 minutes. Close the LH valve and then open

the RH valve. Switch on the supply to the unit and energise

the flow control valve by switching on the room thermostat.

Purge the air from the unit, then close the RH valve and switch

off the room thermostat. Close the purge valve, disconnect

the hose and open both valves.

G When the operation of the unit has been tested, align and

secure the front cover (eight screws), see Fig 4.

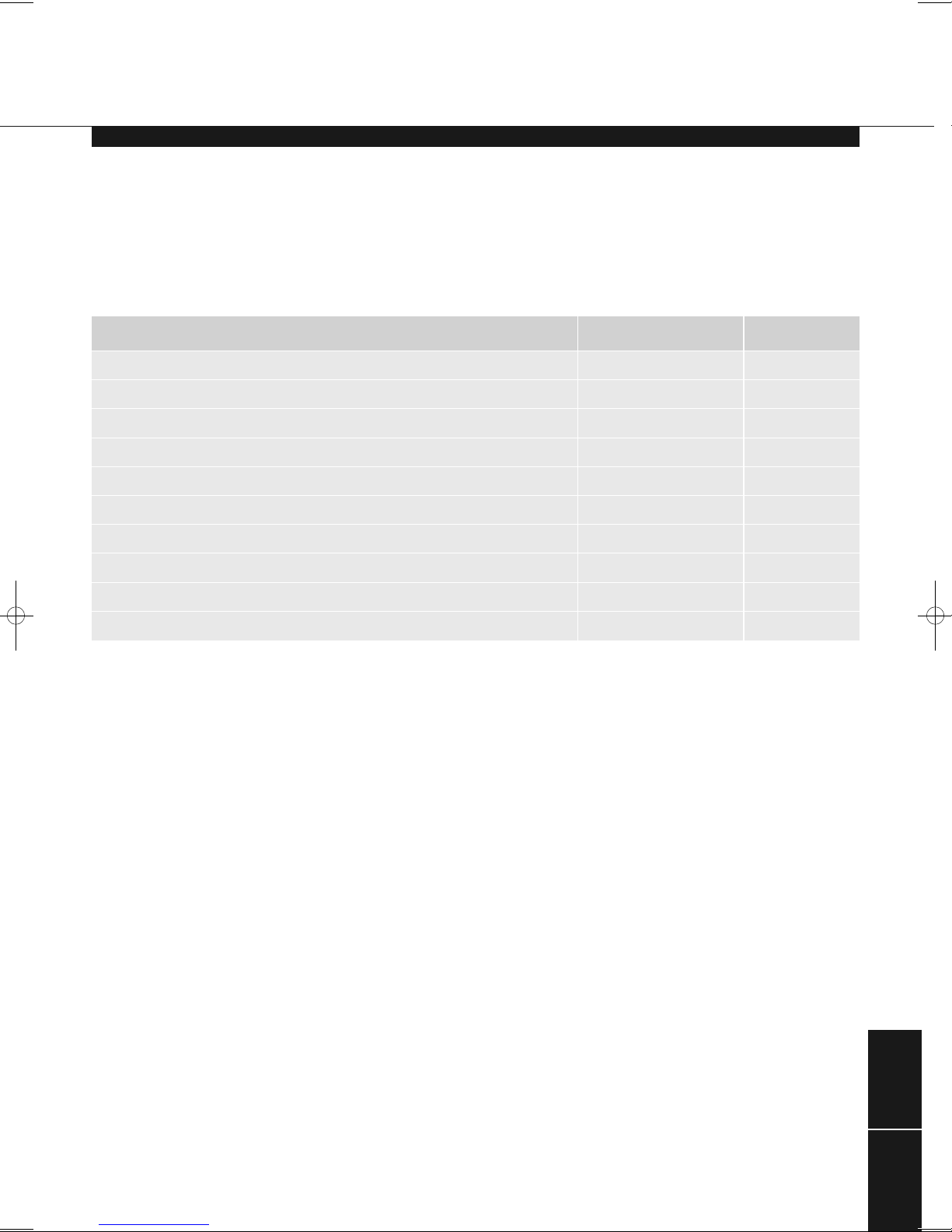

Dimensions (in)

Model A B C

5000 143/16 135/8 103/8

7000 191/8 171/8 151/16

9000 315/8 291/4 271/8

Note: dimensions in inches.

Fig. 3

7.0 Water Connection (continued...)

Front cover

fixing screws

WHISPA III

®

5000, 9000 & 12000 RCU

07

Fig. 4

7.0

08

WHISPA III

®

5000, 9000 & 12000 RCU

8.0 Technical Data

Heating Performance Data

Model

5000 RCU

9000 RCU

12000 RCU

Fan Setting

High (II)

Low (I)

High (II)

Low (I)

High (II)

Low (I)

High (II)

Low (I)

High (II)

Low (I)

High (II)

Low (I)

Flowrate

(gpm)

3

1

3

1

3

1

Heat Output (Btu/h)

Entering Water Temperature (°F), Entering Air Temperature (65°F)

110 120 130 140 150 160 170 180 190 200

2040 2516 2997 3480 3967 4457 4949 5443 5939 6437

1749 2096 2437 2773 3104 3432 3756 4078 4397 4713

1795 2214 2637 3063 3491 3922 4355 4790 5226 5664

1539 1844 2144 2440 2732 3020 3306 3589 3869 4147

3759 4629 5504 6385 7271 8160 9053 9949 10848 11750

3266 3916 4556 5185 5807 6422 7031 7634 8233 8827

3308 4073 4844 5619 6398 7181 7967 8755 9546 10340

2874 3446 4009 4563 5110 5652 6187 6718 7245 7767

4369 5437 6524 7623 8739 9866 11003 12149 13307 14472

3019 3733 4454 5180 5911 6649 7389 8136 8887 9640

3845 4785 5740 6709 7690 8682 9682 10692 11709 12734

2657 3284 3918 4558 5202 5851 6504 7160 7819 8482

Maximum inlet water temperature 200°F

Heat outputs tested in accordance with BS 4856 Part 1

Electrical supply: 110V 60Hz

Max working pressure: 145psi

Water connections:

1

"

Sweat

/

2

Approximate Hydraulic Resistance through Units

g/min

3 4.90 6.89 13.1

1 0.75 1.07 1.4

5000 9000 12000

ft wg

Weight, Water Content and Motor Power

Model

5000 25 5 9.5

9000 40 11.5 14.2

12000 62 18.9 19

Motor

Power (W)

Water

Content (fl oz)

Unit Weight

(lbs)

Fig. 5 Wiring diagram

9.0 Operating Instructions

WHISPA III

®

5000, 9000 & 12000 RCU

09

WHISPA III®RCU fan convectors are controlled by the switch on

the front of the unit.

Ensure the electricity supply is switched on.

Heating Mode

The fan will only operate when

The central heating boiler is on

•

The pump is running

•

The system water temperature is greater than 110°F.

•

The room thermostat linked to the unit is switched on.

•

Ensure boiler is on, and set timer, boiler controls and room

thermostats as necessary.

G Set the fan speed switch to the LOW (I) position.

G The unit will now run on low fan speed. For satisfactory

operation the mean water temperature should not be below

140°F.

Operating Sequence

Power On

Timer On

Boiler On

Pump running

Select fan speed

Turn up room

thermostat

Solenoid valve

energises and valve

(1-2 seconds)

Temperature Control

The room thermostat setting should be adjusted to obtain the

desired temperature.

The fan speed can be set to boost by switching the fan speed

switch to II.

A low speed setting is recommended for normal operation with

the higher speeds for boost heating when required.

Low Limit Operation

The low limit thermostat fitted to the WHISPA III®RCU will

ensure that the fan stops after the heating system is switched

off and the water flow stops. If left in an operating position the

unit will automatically restart when the heating system is

reheated.

Off Position

Set the fan speed selector switch to the off position.

opens

Warm water flows

into coil. After 1-2

mins low limit stat

makes as coil

temperature rises

and fan starts.

Unit cycles on room

thermostat through

similar sequence

while heating is on.

8.09.0

10

WHISPA III

®

5000, 9000 & 12000 RCU

10.0 Troubleshooting

Once installed, this fan convector becomes an integral part of

the heating system that will also include boiler, pump, other

emitters such as radiators and fan convectors, and a number of

heating controls depending on system complexity. An apparent

Problem Remedy

Possible Causes

Room thermostat not calling for heat

Unit not switched on at breaker panel

Breaker tripped at panel

Heating Mode -

No Fan

Heating Mode

Water temperature reaching unit

below 110°F

Low water temperature to unit Turn up boiler thermostat

poor heating

performance and/or

unit cycles on

Poor water flow Vent air from heating system

low limit thermostat

problem with this unit may be the result of system controls being

incorrectly set, and can be solved easily without calling out your

installer or MYSON. Before calling out your installer or MYSON,

please carry out the checklist below.

Turn up room thermostat

Switch on breaker

Check all wiring, reset breaker

Check boiler -

Programmer ON

Boiler ON and set to high

Circulating pump running

Note: Operation of fan convector can be checked by

switching to summer setting

If the fan convector is still faulty after checking the above, call your installer or MYSON.

Common Installation Faults

For optimum performance, this unit must be correctly sized to

match the heat loss requirements of the space it is required to

Problem

Poor heating

performance

Unit incorrectly sized for heat loss of room

heat, and the heating system must be correctly designed to

provide adequate flow of hot water to the unit (see section 2). If

the recommendations in section 2 are not followed problems

may arise as detailed below.

Possible Causes

Boiler thermostat set too low

Lack of flow to fan convector Poor heating

performance

(unit may cycle on

low limit thermostat

System incorrectly balanced with unit starved of hot water flow

Pump set on low setting

Isolating valves not fully open

Pipe sizing to unit too small

Other Faults

Problem Remedy

No flow through unit,

and fan not operating

Possible Causes

Solenoid valve not energised

Solenoid valve not opening

Check room thermostat set correctly and

functioning

Check transformer output 24V

Check 24V actuator

11.0 Maintenance

WHISPA III

®

5000, 9000 & 12000 RCU

11

Before undertaking any maintenance activity isolate the

electrical supply.

Maintenance should be restricted to occasional removal of dust

and lint around the front cover plate.

The unit should be serviced periodically by a competent person.

Spares List

Motor / Fan Assembly WHISPA III® 5000 RCU 7100088 1

Motor / Fan Assembly WHISPA III®9000 RCU 7100090 1

Motor / Fan Assembly WHISPA III

Switch, 3 way 1300025 1

Low Limit Thermostat 1260007 1

Cover plate Whispa III 5000 RCU TBA 1

Cover plate Whispa III 9000 RCU TBA 1

Cover plate Whispa III 12000 RCU TBA 1

24V Actuator TBA 1

®

12000 RCU TBA 1

This should involve internal cleaning of the heat exchanger using

a soft brush or vacuum cleaner, taking care not to damage the

fan or heat exchanger.

Part NumberDescription Quantity

Transformer TBA 1

10.0

11.0

MYSON Inc. 948 Hercules Drive, Suite 5, Colchester, Vermont VT05446

T: (802) 654-7500, F: (802) 654 7022, info@mysoninc.com, www.mysoninc.com

heatingthroughinnovation.

01.06.2009 ISSUE 1

Loading...

Loading...