MYSON MTU419B Datasheet

MTU419B

(Preliminary)

MYSON

TECHNOLOGY

1/18 MTU419B Revision 3.0 28/Oct/1999

FEATURES

• Low power and low voltage operation.

• Powerful instruction set (135 instructions).

• Memory capacity.

- Instruction ROM capacity 2048 x 16 bits.

- Index ROM capacity 256 x 8 bits.

- Internal RAM capacity 128 x 4 bits.

• Input/output ports.

- Port IOC 4 pins.

- Buzzer output.

- INT.

• 8-level subroutine nesting.

• Built-in LCD/LED driver, 4 x 33 = 132 segments.

• Built-in EL driver, frequency or melody generator

• Built-in Resistance-to-Frequency Converter.

• Built-in key strobe function.

• Built-in voltage doubler, halver, tripler charge

pump circuit.

• Two 6-bit programmable timers with programmable clock source.

• Watchdog timer.

• 3 external & 5 internal interrupt resources.

• Dual clock operation.

• HALT and STOP function.

GENERAL DESCRIPTION

The MTU419B is an embedded high-performance

4-bit microcomputer with LCD driver. It contains all

the necessary functions in a single chip: 4-bit parallel

processing ALU, ROM, RAM, I/O ports, timer, clock

generator, dual clock, RFC, alarm, EL-light, LCD

driver, look-up table and watchdog timer. The

instruction set consists of 135 instructions which

include nibble operation, manipulation various conditional branch instructions and LCD data transfer

instructions which are powerful and easy to follow.

The halt function stops any internal operations

other than the oscillator, divider and LCD driver in

order to minimize the power dissipation.

The stop function stops all the clocks in the chip.

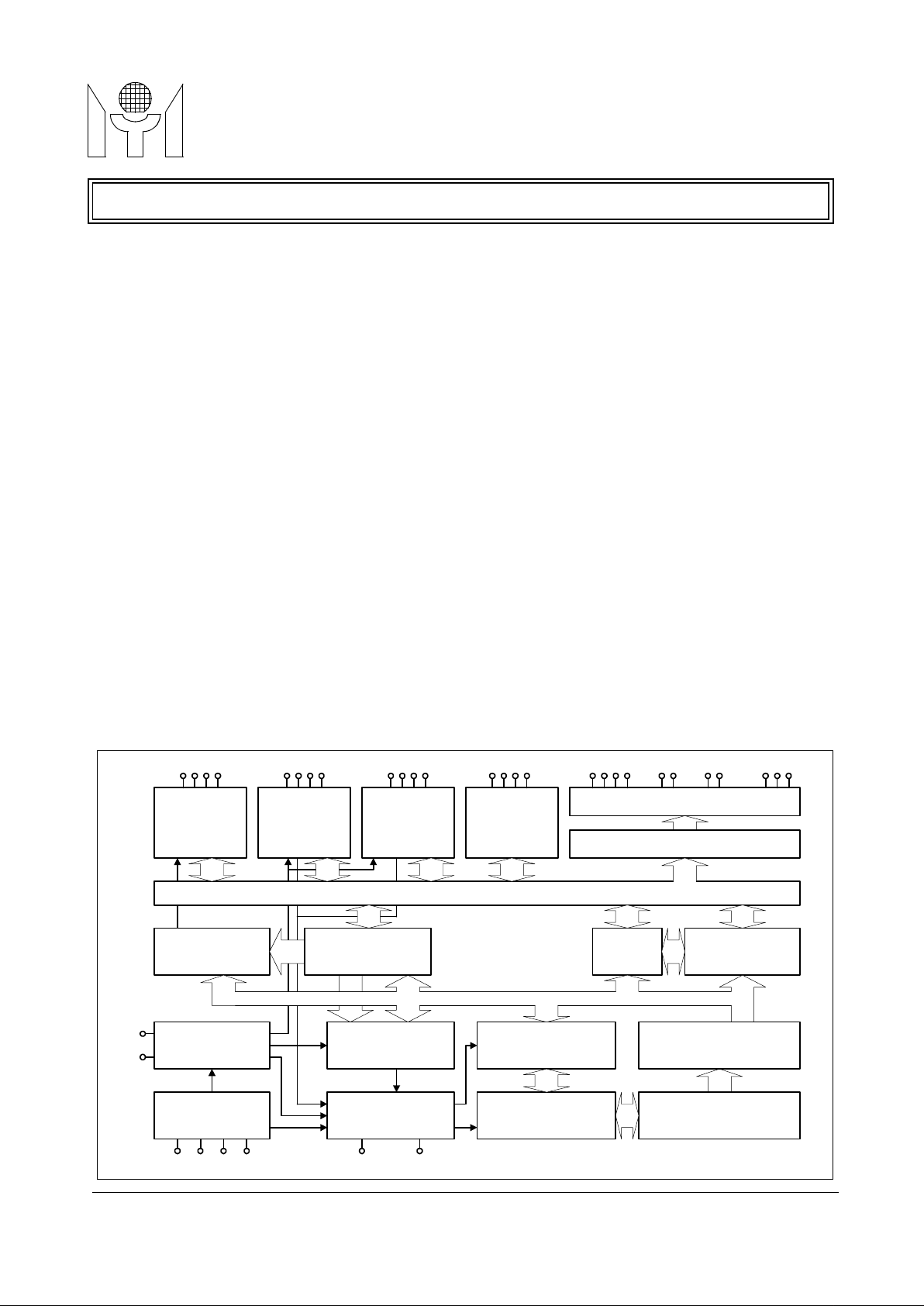

4-bit Microcontroller with LCD Driver

IOC 1~4

KEY SCAN

INPUT

SEG 31~33

RFC

SEG 29~30

EL-LIGHT

SEG 1~12

KEY SCAN

OUTPUT

LCD DRIVER

SEGMENT PLA

4 BITS DATA BUS

FREQUENCY

GENERATOR

ALU

DATA SRAM

(INDEX (L))

128 X 4 BITS

PREDIVIDER

6-BITS PRESET

TIMERX 2

8 LEVELS STACK

WATCHDOG

TIMER

OSCILLATOR

CONTROL

CIRCUIT

11-BIT PROGRAM

COUNTER

MASK ROM

2048 X 16 BITS

INSTRUCTION

DECODER

INDEX MASK

ROM

256 X 8 BITS

COM1~4 VDD1~3SEG1~33

........

INTPRESETCFOUT

CFIN

XTOUT

XTIN

CUP2

CUP1

This datasheet contains new product information. Myson Technology reserves the rights to modify the product specification without

notice. No liability is assumed as a result of the use of this procuts. No rights under any patent accompany the sales of the product.

BLOCK DIAGRAM

MTU419B

(Preliminary)

MYSON

TECHNOLOGY

2/18 MTU419B Revision 3.0 28/Oct/1999

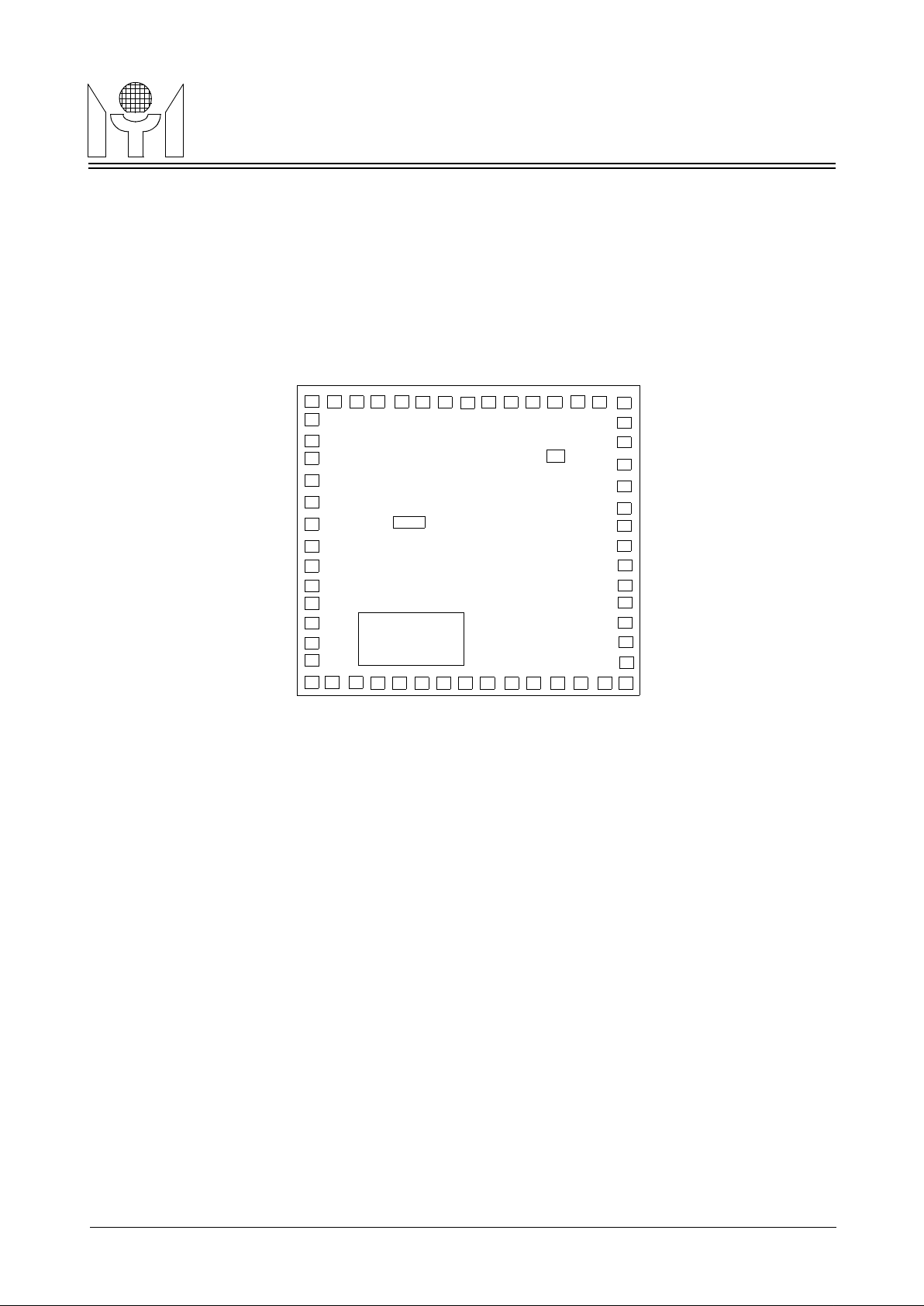

1.0 PAD DIAGRAM

Chip size : 1875 x 1875 µm

Pad size : 100 x 100 µm

Pad window : 90 x 90 µm

Pad pitch : min. 120 µm

IOC3 / KI3

IOC1 / KI1

XTOUT

XTIN

CFOUT

CFIN

BAK

VDD3

CUP1

CUP2

COM1

COM2

COM3

COM4

KO2 / SEG2

KO3 / SEG3

KO4 / SEG4

KO5 / SEG5

KO7 / SEG7

KO9 / SEG9

KO10 / SEG10

KO11 / SEG11

KO12 / SEG12

SEG13

SEG14

SEG15

SEG16

SEG17

SEG18

SEG19

SEG20

SEG21

SEG22

SEG23

SEG25

SEG26

SEG27

SEG28

SEG29 / ELC

SEG30 / ELP

SEG31 / RH

SEG32 / RT

SEG33 / RR

INT / CX

BZ

GND

KO6 / SEG6

KO8 / SEG8

SEG24

VDD1

IOC4 / KI4

IOC2 / KI2

RESET

TESTA

VDD2

ROM

LOGO

Code No.

KO1 / SEG1

Note: The substrate of die must connect to GND.

1

10

20

30 40

50

56

MTU419B

(Preliminary)

MYSON

TECHNOLOGY

3/18 MTU419B Revision 3.0 28/Oct/1999

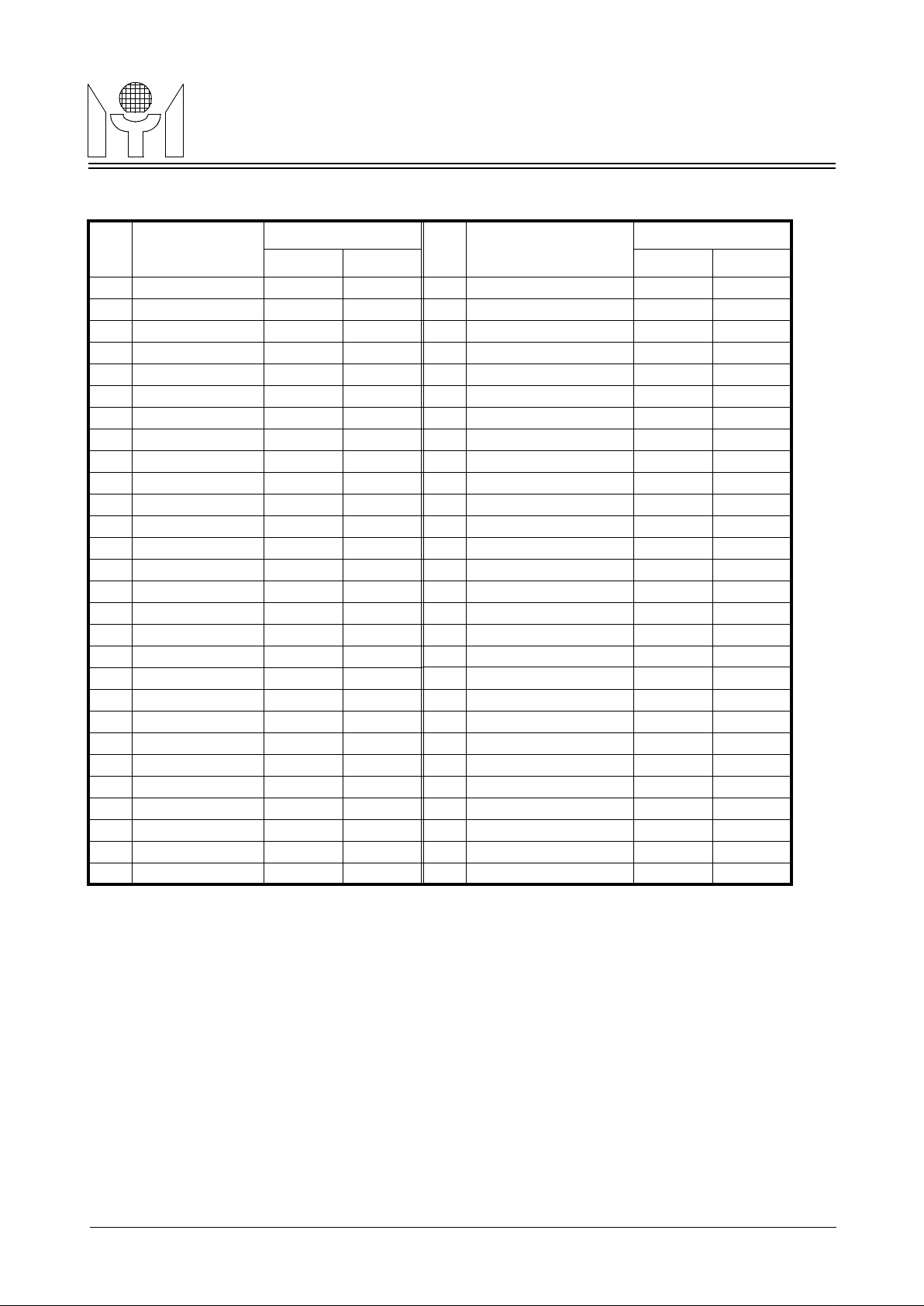

2.0 PAD ASSIGNMENT

Pad

No.

Pad Name

Coordinate

Pad

No.

Pad Name

Coordinate

X Y X Y

1 BAK 1657.5 1797.5 29 SEG9/KO9 217.5 77.5

2 CFIN 1537.5 1797.5 30 SEG10/KO10 337.5 77.5

3 CFOUT 1417.5 1797.5 31 SEG11/KO11 457.5 77.5

4 XTIN 1297.5 17975 32 SEG12/KO12 577.5 77.5

5 XTOUT 1177.5 1797.5 33 SEG13 697.5 77.5

6 TESTA 1057.5 1797.5 34 SEG14 817.5 77.5

7 RESET 937.5 1797.5 35 SEG15 937.5 77.5

8 IOC1/KI1 817.5 1797.5 36 SEG16 1057.5 77.5

9 IOC2/KI2 697.5 1797.5 37 SEG17 1177.5 77.5

10 IOC3/KI3 577.5 1797.5 38 SEG18 1297.5 77.5

11 IOC4/KI4 457.5 1797.5 39 SEG19 1417.5 77.5

12 VDD1 337.5 1797.5 40 SEG20 1537.5 77.5

13 VDD2 217.5 1797.5 41 SEG21 1657.5 77.5

14 VDD3 77.5 1797.5 42 SEG22 1797.5 77.5

15 CUP1 77.5 1657.5 43 SEG23 1797.5 217..5

16 CUP2 77.5 1537.5 44 SEG24 1797.5 337.5

17 COM1 77.5 1417.5 45 SEG25 1797.5 457.5

18 COM2 77.5 1297.5 46 SEG26 1797.5 577.5

19 COM3 77.5 1177.5 47 SEG27 1797.5 697.5

20 COM4 77.5 1057.5 48 SEG28 1797.5 817.5

21 SEG1/KO1 77.5 937.5 49 SEG29/ELC 1797.5 937.5

22 SEG2/KO2 77.5 817.5 50 SEG30/ELP 1797.5 1057.5

23 SEG3/KO3 77.5 697.5 51 SEG31/RH 1797.5 1177.5

24 SEG4/KO4 77.5 577.5 52 SEG32/RT 1797.5 1297.5

25 SEG5/KO5 77.5 457.5 53 SEG33/RR 1797.5 1417.5

26 SEG6/KO6 77.5 337.5 54 INT/CX 1797.5 1537.5

27 SEG7/KO7 77.5 217.5 55 BZ 1797.5 1657.5

28 SEG8/KO8 77.5 77.5 56 GND 1797.5 1797.5

MTU419B

(Preliminary)

MYSON

TECHNOLOGY

4/18 MTU419B Revision 3.0 28/Oct/1999

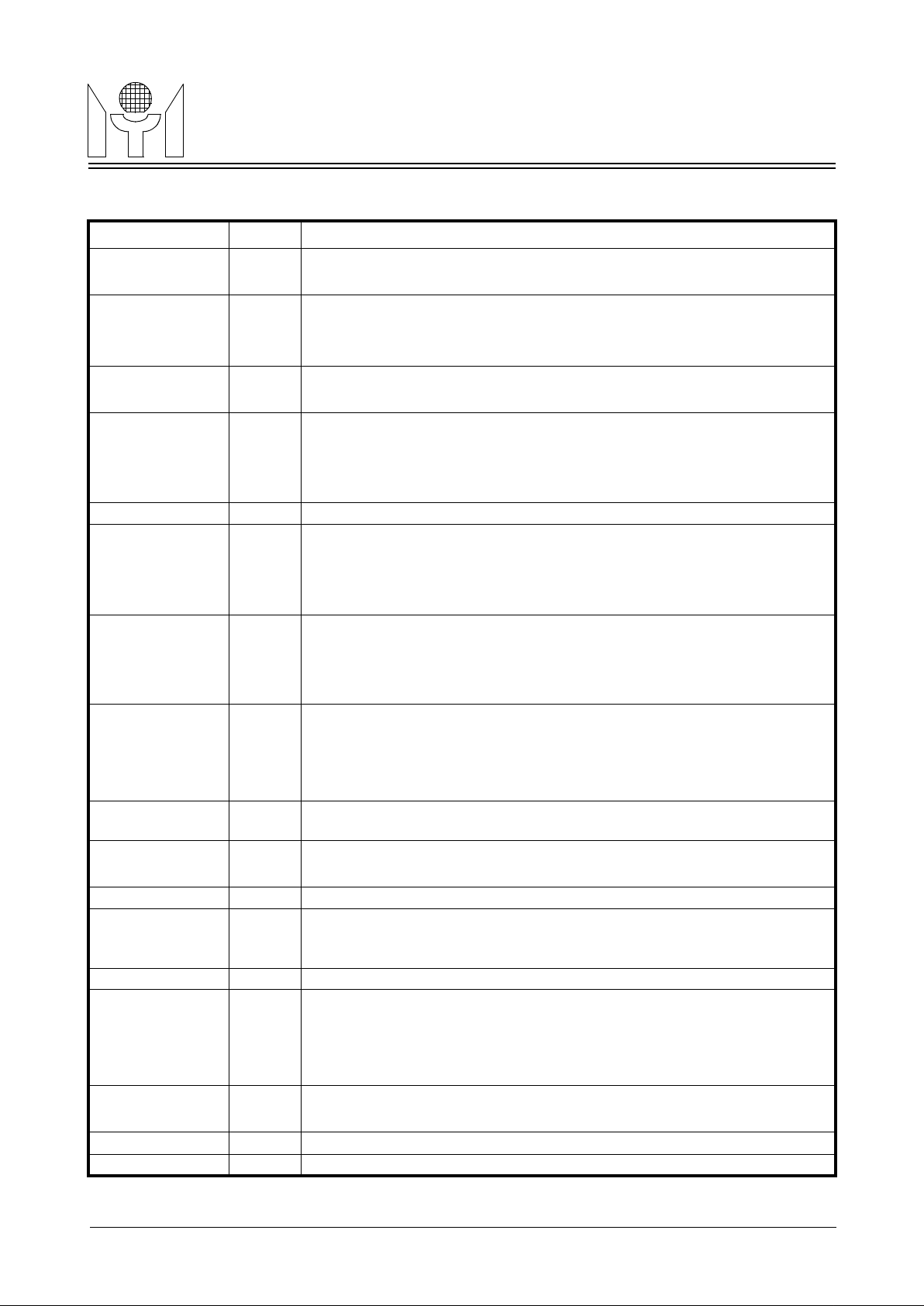

3.0 PAD DESCRIPTIONS

Name I/O Descriptions

BAK

Positive back-up voltage.

At Li mode, connects a 0.1u capacitance to GND.

VDD1,2,3

LCD drives voltage and positive supply voltage.

While Ag mode, connects +1.5V to VDD1.

While Li/ExtV mode, connects +3.0V to VDD2.

RESET I

Input pin from LSI reset request signal.

Internal pull-down resistor.

INT I

Input pin for external INT request signal.

Falling or rising edge triggered by mask option.

Internal pull-down or pull-up resistor or neither is selected by mask option

and shared with CX.

TESTA I Test signal input pin.

CUP1,2 O

Switching pins for supplying the LCD driving voltage to the VDD1, 2, 3 pins.

Connects the CUP1 and CUP2 pins with nonpolarized electrolytic capacitor if

1/2 or 1/3 bias mode has been selected.

In the static mode, these pins should be open.

XIN

XOUT

I

O

Time base counter frequency (clock specified, LCD alternating frequency,

alarm signal frequency) or system clock oscillation.

32KHz crystal oscillator.

Oscillation stops at the execution of stop instruction.

CFIN

CFOUT

I

O

System clock oscillation.

Connected with ceramic resonator.

Connected with RC oscillation circuit.

Oscillation stops at the execution of stop or slow instruction.

COM1,2,3,4 O

Output pins for supplying voltage to drive the common pins of the LCD or

LED panel.

SEG1-12 /

KO1~12

O

Output pins for LCD or LED panel segment.

Key strobe function, share pins as key scan output.

SEG13-33 O Output pins for LCD or LED panel segment.

IOC1-4 I/O

Input / Output port C, can use software to define internal pull-low / low-level

hold resistor and chattering clock to reduce input bounce and generate inter-

rupt.

KI1~4 I Key scan input, this port shares pins with IOC1~4 and is set by mask option.

RFC

CX

RR

RT

RH

I

O

O

O

1 input pin and 3 output pins for RFC application.

This port shares pins with SEG31~33 and INT, and is set by mask option.

EL

ELC

ELP

O

O

Output port for EL-light.

This port shares pins with SEG29,30, and is set by mask option.

ALM BZ O Output port for alarm, frequency or melody generator.

GND Negative supply voltage.

MTU419B

(Preliminary)

MYSON

TECHNOLOGY

5/18 MTU419B Revision 3.0 28/Oct/1999

4.0 FUNCTIONAL DESCRIPTION

4.1 SRAM

The 128 X 4 bits SRAM is addressing by direct addressing or index addressing mode.

4.2 Index ROM

The 256 X 8 bits index ROM can be used in the 4-bit or 8-bit mode.

4.3 I/O Ports

The IOC port can be selected by software separately as input or output, and with/without internal pull-low and

different chattering clocks for halt release / interrupt trigger in order to reduce the input bounce for key scan:

PH6: 512Hz PH8: 128Hz PH10: 32Hz

The initial state of all IOC ports is input mode with pull-low.

Before setting the I/O ports from input to output, execute the output function first to ensure the output state.

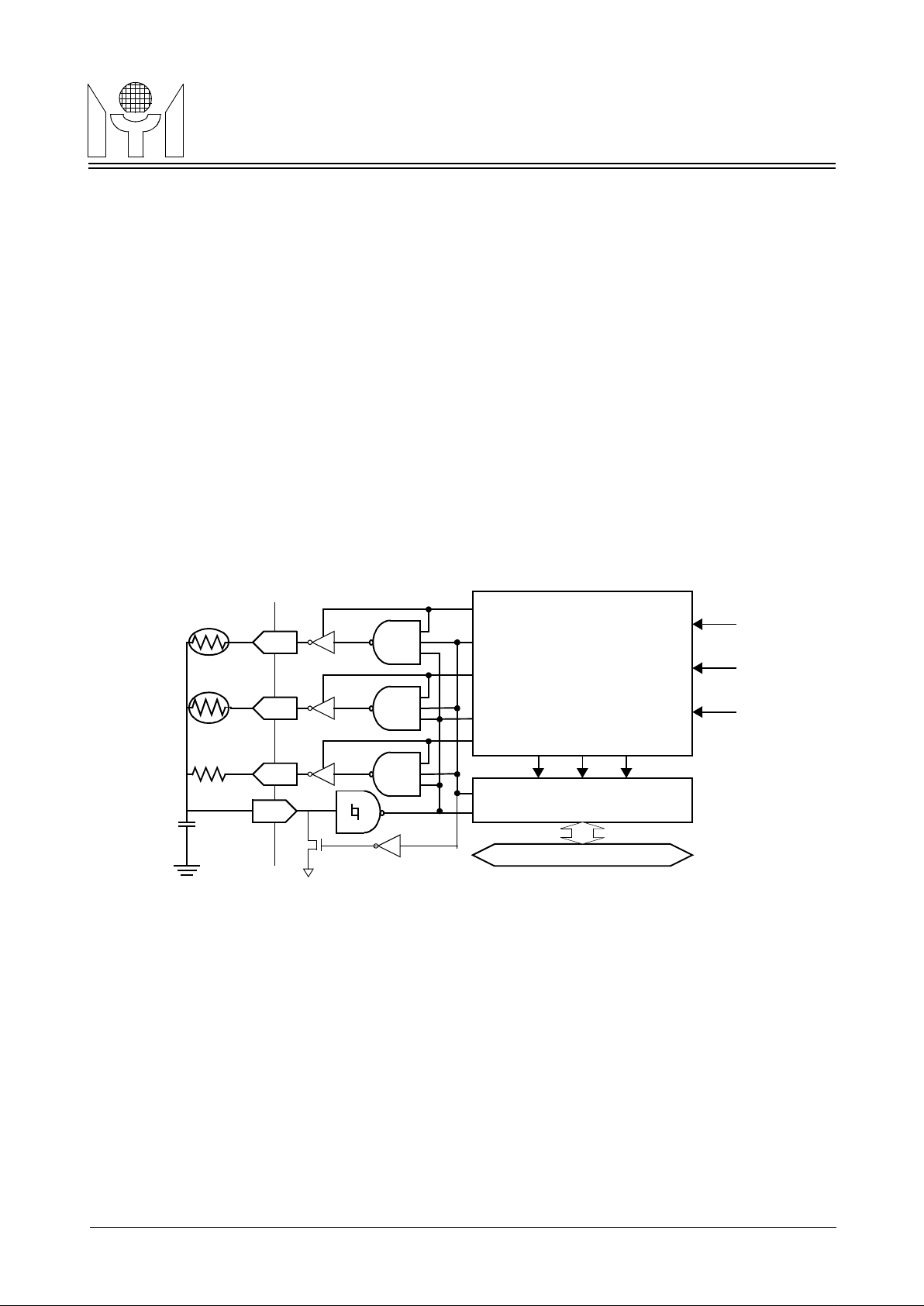

4.4 Resistor to Frequency Converter

We use an RC oscillation circuit and a 16-bit counter to calculate the relative resistance of temperature and

humidity sensor. The diagram is shown below:

There are two kinds of methodology for measuring the input frequency: first, set FIN (i.e. CX) as the clock

input, using timer 2 or the software directly as interval control; second, if the FIN (CX) frequency is too low

(either because of a poor resolution for a fixed interval or a longer interval for better resolution but a longer

read-out rate [for example, 10 seconds per read-out]), you can switch the measure mode to set FIN (CX) as

interval control (it will enable the counter from the first FIN rising edge to the next rising edge, then will generate an interrupt) or use FREQ (internal frequency generator output) as clock input, hence you can count the

interval of CX.

To measure the resistor value of temperature and humidity sensor, first we measure the frequency of Rref,

then the frequency of Sensor:

Fref = K / Rref CX and

Fsensor = K / Rsensor CX, hence

Rsensor = Rref * Freq / Fsensor.

.

ELP

ENX

EHM

FIN

ERR

Timer

&

R/F Controller

16-Bit Counter

Freq

FreqCLCLLDLD

ENX

FIN

4-Bit Data Bus

RT

RH

RR

CX

RTP

RHM

Rref

CX

TMS

PH9

MRF

Where K is a coefficient for RC-oscillation and

will be a constant in a short time period.

MTU419B

(Preliminary)

MYSON

TECHNOLOGY

6/18 MTU419B Revision 3.0 28/Oct/1999

4.5 Key_board Scanning Function

SEG1~12 shares the key_board scanning output, the output of the key_board scanning is a P open-drain to

VDDO (positive power supply) and all other SEGs and COMs are in Hi-z state during this period. This will minimize the effect of the LCD output.

The segment 1-12 also could be used as keyscan output and LCD still could be displayed with only slightly

affected.

SPK 00b5 b4 b3 b2 b1 b0.

b5: 1 will disable key-scan output.

b4: 1 will set all keyscan output as high, if b5=0.

b3~b0: will set the corresponding segment output as 1, if b5=0 and b4=0.

During power on, LCD off, STOP condition. All the common & segment output will be the chips supply power.

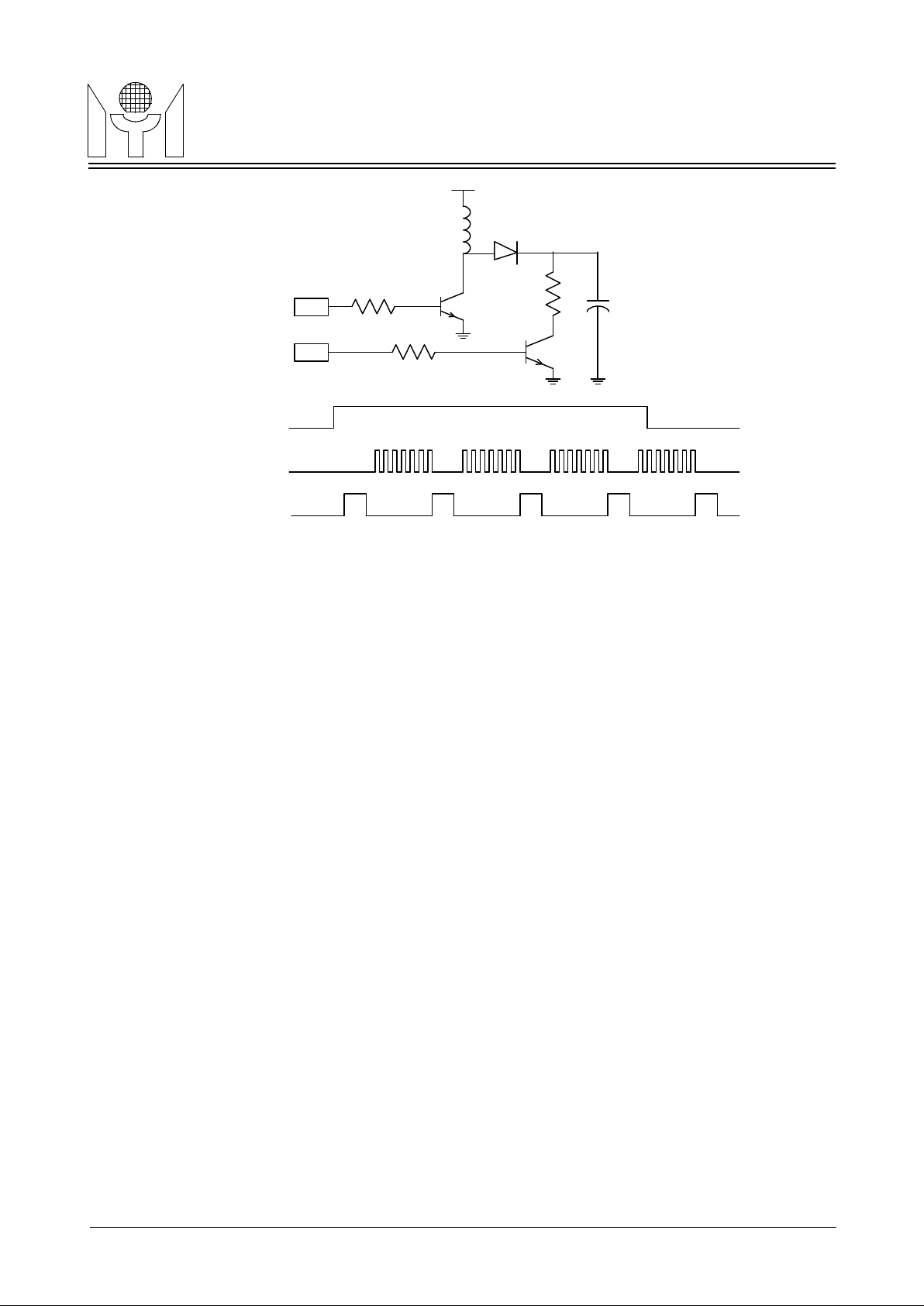

4.6 EL-light

Set ELC and ELP clock and duty cycle using ELC X instruction, then turn on and off ELC and ELP output by

SF X and RF X instruction. With external transistor, diode, inductor and resistor, we can pump the EL panel to

AC 100~250V.

When the EL-light is turned on, the ELC will turn on before ELP, but when the EL-light is off, the ELP and ELC

will turn off after the next falling edge of ELC in order to make sure no voltage is left on the EL plane.

4.7 TIMER

The 6-bit programmable timer can select PH3/PH9/PH15/FREQ (Timer 2 can also select PH5/ PH7/ PH11/

PH13 by TM2X instruction) as clock source. When it underflows, the halt release signals are generated.

4.8 Predivider

The predivider is a 15-sage counter that uses PH0 as clock source. The output of T-FF is changed when the

input signal is changed from H to L. PH11~15 are reset to L when PLC 100H instruction is executed or power

on reset or external reset is used. When PH14 is changed from H to L, the halt release signal is generated.

4.9 Alarm / Frequency / Melody

There is an 8-bit programmable counter and an 8-bit envelope control for alarm, frequency or melody output

from BZ/BZB.

The frequency counter can use software to select 1/2duty, 1/3duty,1/4duty drive modes.

LIT

ELP

ELC

L1

Q1

Q2

R1

R2

ELP

ELC

EL-plane

D1

Loading...

Loading...