Page 1

Installation, Operating, Maintenance

and After Sales Manual.

LO-LINE RC & LO-LINE RC Heater/Cooler

Models: 6-4, 9-6, 14-10, 19-15

heatingthroughinnovation.

Product Serial Number:

Installation Date:

Please leave this manual with the end user.

Part Number: 1371053

01.01.2012 ISSUE 2

Issue 2

Tested to UL & CSA Standards

Page 2

Contents

1.0 General Information 03

2.0 Heating System Design 03

3.0 Unit Selection/Sizing 03

4.0 Location 03

5.0 Preparation 04

6.0 Fixing 04

7.0 Water Connections 05

8.0 Electrical Connection 06

9.0 Commissioning Procedure 07

10.0 Technical Data 08

11.0 Operating Instructions 09

12.0 Troubleshooting 10

13.0 Maintenance 11

Page 3

1.0 General Information

LO-LINE RC & LO-LINE RC Heater/Cooler

03

l This MYSON LO-LINE fan convector is designed for wall

mounted installation with a minimum installation height of

6 inches to the underside of the unit.

l The LO-LINE should only be used on closed circulation, two

pipe, pump assisted central heating systems (LO-LINE), on

heating and cooling systems (LO-LINE Heater/Cooler), or as a

stand alone zone.

l The LO-LINE Heater and Heater/Cooler can be used on low

water temperature systems.

l The minimum side clearance is 4 inches.

l In rooms with ceiling heights above 10ft a ceiling fan or other

means of heating stratification should be considered.

l Before proceeding with the installation, the heating system

design must be considered and the unit correctly sized

to meet the heat loss requirements of the room at normal

fan speed.

2.0 Heating System Design

This fan convector can be fitted on a series loop with mono-flo

or venturi Tees, on a two pipe system, or on a stand alone zone.

For optimum fan convector heating performance the system

must be capable of providing sufficient hot water through the

heat exchanger. This means that:

1. Care must be taken in sizing both the pump and the piping.

2. The minimum pipe size from boiler to fan convector must be

1

/2inch copper tube.

3. Where the unit is fitted on to a system with other emitters a

separate circuit for the fan convector should be considered

to provide adequate water flow.

l This unit is supplied with an infra red remote control system

and has 3 operating modes:

Automatic – the desired room temperature is programmed in

to the unit and the fan speed is automatically adjusted until

the desired room temperature is achieved.

Fan only – allows user selection of any of the 3 available

fan speeds irrespective of room temperature or water

temperature in the coil.

Fan only with water temperature control – allows the user to

select any of the available fan speeds, which will operate only

if the water temperature in the coil is above 90°F. This enables

control of the unit via an externally mounted room thermostat

if desired.

4. The system water must be above 90°F for heating mode.

5. Optimum performance of this unit will require effective

balancing of the whole system.

6. This unit must not be used to replace a radiator in an

existing system unless an adequate flow of water through

the unit can be guaranteed.

7. The loop must be pumped. LO-LINE fan convectors are not

suitable for gravity circulation systems.

1.02.03.04.0

3.0 Unit Selection/Sizing

Heat output performance is given in the Technical Data section

of this manual. Outputs are shown for the three fan speeds,

however, it is important to size the unit to match the calculated

heat loss requirements of the room with the unit operating on

the normal fan speed. The higher fan speeds are used in

automatic mode when the room temperature is significantly

lower than the preset temperature.

4.0 Location

l This LO-LINE unit may be fitted to any convenient wall at a

height from floor level that suits the application, providing an

unimpeded flow of warm air into the area to be heated.

l The minimum distance from the underside of the unit to floor

level is 6 inches.

When establishing the temperature difference, i.e. entering

water to room temperature, allowance should be made for

temperature drop in the system. It is the water temperature at

the unit that dictates the output.

l Prior to installation the wall should be checked to make sure

it is straight and flat, to avoid twisting the unit.

l For cooling applications, the need for disposal of condensate

may influence the position of the unit.

Page 4

04

Cover Fixing Screws

B

C

2 inches

A

2 7/

16

2 1/

4

min each

side

9

3

/

4

15

3

/

16

2

3

/

16

4 1/

4

6 inches

LO-LINE RC & LO-LINE RC Heater/Cooler

5.0 Preparation

Before proceeding with the installation, unpack the carton

contents and check against the checklist below:

1. LO-LINE or LO-LINE Heater/Cooler unit.

1

2.

/2inch isolating valves (1 pair).

3. Instruction manual.

4. Fixing kit (rubber mounts and cable gland).

5. Remote control handset.

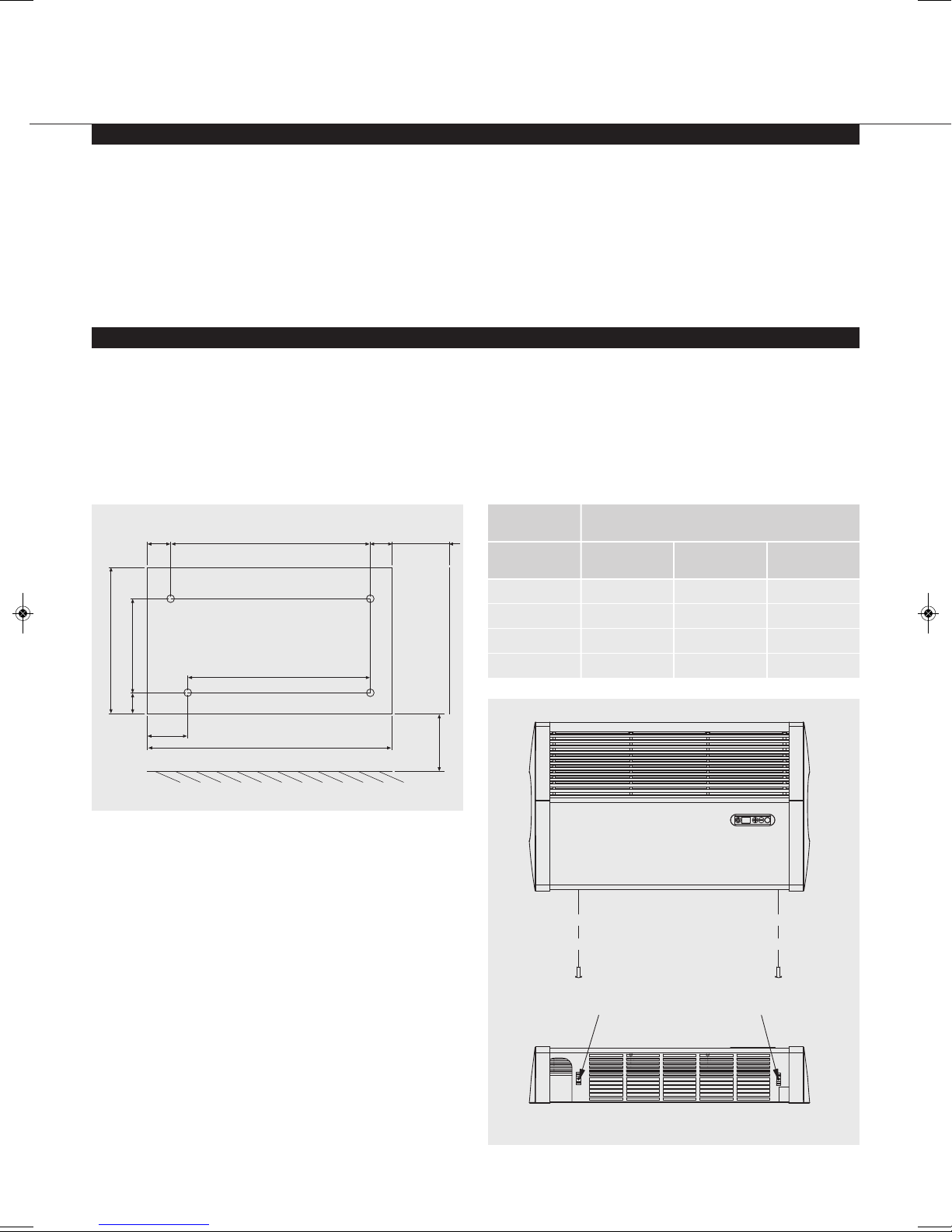

6.0 Fixing

l Using the fixing dimensions (see fig. 1), mark the fixing hole

positions on the wall.

l Plastic or metal anchors suitable for No.8 wood screws should

be used for mounting the convector to the wall.

l Remove the backing from the self-adhesive washers and place

on screws with adhesive side towards the point.

Fig. 1

l Tighten the screws into the wall leaving about

projecting.

l Press adhesive washers to the wall.

Dimensions (inches)

Unit A B C

19-15 4413/

14-10 335/

9-6 253/

6-4 205/

16

8

8

8

401/

297/

2011/

1515/

16

8

16

16

383/

2613/

1815/

141/

3

/8inch

8

16

16

8

Remove the outer casing as follows:

l Remove the 2 screws from the underside of the unit (see fig. 2).

l Lift off the outer case.

l Fit chassis on to mounting screws and tighten.

Fig. 2 Case fixing screw positions

Page 5

7.0 Water Connections

5

1

/

8

7

1

/

2

2

11

/

16

2

3

/

8

3

29

/

32

2

27

/

32

3

29

/

32

2

3

/

8

LO-LINE RC & LO-LINE RC Heater/Cooler

05

l Connect unit to system flow and return pipes using the two

1

/2inch isolating valves (see fig. 3).

Note: To ensure effective venting of the heat exchanger the

supply pipe should be connected to the bottom connection of

the heat exchanger.

Note: For LO-LINE installations pipe-work must not be routed

directly underneath the unit as this will adversely affect the

operation of the integral room thermostat. If this cannot be

avoided, the pipe-work must be boxed to prevent heat rise.

l Ensure system is flushed in accordance with recognised best

practice and a suitable inhibitor is added to the system as

necessary.

l Open valves fully, check pipe connections for leaks and vent

the heat exchanger - see Commissioning Procedure.

LO-LINE Heater/Cooler installations with chilled water will

require provision for condensate disposal in accordance with any

local regulations.

A drain tray is fitted for condensate collection within the unit.

This should be connected to a 15mm drain pipe.

Note: External pipe-work carrying chilled water must be

insulated. Use a suitable sealant as necessary to ensure that

condensate does not spill or leak. Once connection to the

system supply and return pipes is made, any exposed internal

1

/2inch pipework and isolating valves must be insulated.

5.0

6.07.0

Fig. 3

Page 6

06

O O

LN

Motor

Power Board

Control Board

Air Sensor

Water Sensor

O O

Brown

Blue

White

Yellow

G

LO-LINE RC & LO-LINE RC Heater/Cooler

8.0 Electrical Connection

WARNING: This appliance must be grounded. The electrical installation must comply with state or local codes.

l This unit is supplied with a factory fitted 3 core cord, 6ft in

length with moulded plug.

Fig. 4 Wiring diagram

Page 7

9.0 Commissioning Procedure

Dipswitches

LO-LINE RC & LO-LINE RC Heater/Cooler

07

l Fill and vent the system.

l Open both valves fully and vent air from the heat exchanger

by unscrewing the air bleed valve situated above the valves in

the angled top of the chassis.

l Check for leaks at pipe connections.

l Refit the outer case and secure using the 2 fixing screws.

l Check the operation of the unit by following the operating

instructions.

l When installation and commissioning are complete, hand over

instruction manual to end-user.

Heat Pump and Low Water Temperature Systems

In heating mode, the control system brings the fan on when the

water in the coil reaches 90°F. For low water temperature

systems, e.g. heat pump systems, it is possible to switch off the

boost speed option in automatic mode so that the unit runs in

medium or normal fan speeds depending on demand. This

means low outlet air temperatures from the unit are avoided

when the room temperature is low in relation to the set

temperature.

This facility can be switched on or off by following the instruction

below:

l Isolate electrical supply.

l Remove outer cover.

l Change switch 1 position according to requirements

(see fig. 4).

l Refit outer cover.

l Switch on electrical supply.

Fan Pulse

Fan pulse mode causes room air to be drawn over the air

temperature sensor periodically to maintain room temperatures

more effectively. In certain circumstances, for example when

units are over-sized in relation to the heat loss of the room, it

may be necessary to turn off this function. Use dipswitch 3

according to requirements.

Displayed Temperature Calibration

Depending on the location of the unit there may be a difference

between the temperature at the unit and the temperature in the

middle of the room being heated.

The displayed temperature calibration function enables

calibration in heating mode of the displayed temperature to the

actual room temperature using the following procedure:

l Run the fan convector until room conditions stabilise.

l Press the ʻOn/Offʼ key and ʻ+ʼ key for 5 seconds (the display

will flash, alternating between ʻroʼ and the calibration

temperature.

l Calibrate the displayed room temperature by using the

ʻ+ʼ and ʻ-ʼ keys with the fan running.

l Press the ʻOn/Offʼ key to finish.

Fig. 5

Switch Switch Down Switch Up

1 Auto Fan Speed Selection 2 Speed 3 Speed

2 Heating / Cooling Heating Heating & Cooling

3 Fan Pulse Off On

4 Temperature Display °F °C

8.09.0

Page 8

08

LO-LINE RC & LO-LINE RC Heater/Cooler

10.0 Technical Data

Heating Performance Data

Model Fan Setting

Flowrate

(GPM)

Entering Water Temperature (°F), entering air temperature 65°F

110 120 130 140 150 160 170 180 190 200

Boost

19-15

14 -10

9-6

6-4

Note: Performance figures for heating and cooling based on a flow rate of 3 GPM. For a flow rate of 1 GPM multiply by 0.87.

Medium

Normal

Boost

Medium

Normal

Boost

Medium

Normal

Boost

Medium

Normal

3

3

3

3

7997 9691 11372 13042 14702 16354 17999 19637 21269 22895

7224 8753 10270 11777 13275 14766 16250 17728 19200 20667

6374 7722 9060 10389 11710 13024 14333 15636 16933 18227

6137 7435 8723 10002 11274 12539 13798 15052 16301 17546

5247 6356 7457 8550 9636 10717 11793 12864 13931 14994

4316 5227 6132 7030 7922 8810 9694 10574 11450 12324

4081 4942 5797 6645 7489 8328 9163 9994 10822 11647

3274 3964 4649 5329 6005 6678 7347 8013 8676 9337

2525 3058 3586 4111 4633 5151 5668 6182 6694 7204

2668 3231 3790 4344 4895 5443 5988 6531 7072 7611

1954 2366 2775 3181 3584 3985 4385 4782 5178 5572

1724 2087 2447 2804 3159 3512 3863 4213 4561 4908

Heat Output (Btu/h)

Test Pressure: 290psi

Max working pressure: 145psi

Water connections:

Electrical Supply: 110V 60Hz

1

/2" compression

Cooling Performance Data (figures @ 50% RH)

Approximate Hydraulic Resistance through Fan Convectors

GPM

3

1

Cooling Performance (Btu/h)

Model Fan Setting

Flowrate

(GPM)

25° 35° 45°

Air-Mean Water Temperature Difference (°F)

Tot. Sens. Tot. Sens. Tot. Sens.

Boost

19-15

14 -10

9-6

6-4

Cooling performance tested in accordance with BS 4856 Part 2. Flow rate 340 ltr/h. Relative humidity 50%.

Medium

Normal

Boost

Medium

Normal

Boost

Medium

Normal

Boost

Medium

Normal

3

3

3

3

5128 4366 8203 5929 11650 6425

4896 4024 7832 5412 11124 6077

4482 3693 7169 4816 10181 5407

4108 3519 6570 4823 9330 5315

3451 2937 5522 3986 7843 4317

2934 2523 4691 3469 6660 3851

2376 1943 3799 2757 5394 3564

2007 1696 3208 2288 4555 2439

1669 1414 2669 1916 3790 2059

1659 1328 2653 1884 3769 2435

1308 1121 2093 1535 2973 1691

1074 927 1718 1277 2440 1427

6-4

6.7

0.6

9-6

6.4

0.8

ft wg

14 - 10

9.4

1.0

19 - 15

13.1

1.4

Noise Levels

Model

19-15 27.2 31.8 38.6

14-10 23.1 28.5 40.1

9-6 21.6 29.6 38

6-4 23.7 31.7 40.7

Noise levels tested in accordance with EN 23741.

Sound Pressures at 2.5m (dBA)

Normal Medium Boost

Weight, Water Content and Motor Power

Model

19-15 80 1.6 34.6

14-10 62 1.2 28

9-6 35 0.7 20

6-4 35 0.6 17

Test Pressure: 20bar (2 MPa)

Water connections: 15mm

Motor

Power (W)

Maximum working pressure: 10bar (1MPa)

Electrical supply: 230V - 50Hz

Water

Content (pints)

Unpacked

Weight (lbs)

Page 9

11.0 Operating Instructions

LO-LINE RC & LO-LINE RC Heater/Cooler

09

Description

This LO-LINE unit is fitted with a control system that provides

either automatic or manual control of the unit. In automatic

mode the desired temperature set point is selected and the unit

will adjust the fan speed according to the difference between

the actual room temperature and the set point. When the room

temperature reaches the set point the fan will switch off and

thereafter will continue to cycle on and off to maintain the room

temperature. The temperature set point range is 59 - 95°F.

In manual mode the automatic temperature control is over

ridden and any of the three fan speeds can be operated

inrespective of the water temperature in the unit. This means

that air circulation can be provided in summer for example, or

that heating performance can be controlled manually.

In manual mode, with water temperature control, any of the 3

fan speeds can be selected and the fan will operate when the

water temperature in the coil is greater than 90°F. This means

that heating performance can be controlled manually, and the

unit could be controlled via an external room thermostat.

The unit can be controlled using the infra red remote control

handset supplied with the unit (see fig. 6) and also using the

control panel on the unit (see fig. 7). If necessary, however, the

control panel can be locked electronically to prevent tampering

once the controls have been set (see over).

Fig. 6 Fig. 7

The remote control hand set takes 2 AAA batteries (not supplied).

Controls Display

Power button Switches unit on & off

‘+/-’ button Adjust temperature set point from

59 - 95°F

Scrolls into F1, F2, F3, A1, A2 or A3

manual mode.

Heating

Heating will only be provided when the central heating boiler is

on, the pump is running and the system water temperature is

greater than 90°F. Ensure the boiler is on, and set timer, boiler

controls and room thermostats as necessary.

10.0

11.0

Page 10

10

LO-LINE RC & LO-LINE RC Heater/Cooler

11.0 Operating Instructions (continued...)

Operation Display

Power off No Display

Switch on supply to unit for 30 seconds

(unit off)

Supply on / unit off

Switch on unit Set point flashes for

approx 5 secs, then

Ambient temperature

displayed

Use ‘+/-’ to adjust Set point flashes for

set point approx 5 secs, then

Ambient temperature

The ambient temperature is always displayed unless the water

temperature falls below 110°F*, or if the set point is being

adjusted.

Water temp <110°F Shows both power

& unit on

*110°F in normal heating system, 90°F for heat pumps and above 68°F in cooling.

Manual

Manual mode can be used for air circulation without heat or for

manual control of the heating function.

Use ‘+’ to scroll beyond 95°F

Or use ‘-’ to scroll below 59°F

Selected fan speed displayed

Continuous

fan only

Fan & water

temperture

(water inlet >90°F)

Scrolling back out of manual using the ‘+’ or ‘–’ button will revert

the unit back to last temperature set point.

Cooling Mode

l Close the heating system and isolate any other heat emitters.

l Open the cooling water system.

l Ensure cooling is on, and set cooling unit timer and controls

as necessary.

Cooling operation works in exactly the same way as heating.

Follow the procedure above to set the unit controls.

Locking Unit Controls

The control panel on the main unit can be locked electronically

to prevent interference once the controls have been set. After

setting the unit to the desired temperature setting and with the

unit in running mode, press the On/Off button on the main unit

for about 6 seconds until the two middle horizontal bars appear

on the display. The horizontal bars will disappear after about 6

seconds and the unit is in key lock mode.

If any of the unit controls are pressed the horizontal bars will

reappear to show the key lock mode is activated, however,

during this mode the handset controls remain functional.

To unlock the system press the On/Off button for about 6

seconds until the horizontal bars disappear.

12.0 Troubleshooting

Once installed this fan convector becomes part of a complete

heating system that will generally include a boiler, pump, other

emitters such as radiators and fan convectors, and a number of

heating controls, dependent on system complexity. An apparent

problem with this unit may be the result of system controls being

incorrectly set and can be solved easily without calling out your

installer or MYSON. Before calling your installer or MYSON,

please carry out the checks listed opposite.

Page 11

12.0 Troubleshooting (continued...)

LO-LINE RC & LO-LINE RC Heater/Cooler

11

Problem Remedy

Possible Causes

Unit switched off

Temperature set point reached

Unit not switched on at breaker panel

Heating Mode -

No Fan

Breaker tripped at panel

Unit isolating valves shut

Water temperature reaching fan

convector below 110°F

(Heater model only)

Boiler ON and set to high with central

Note: Operation of fan convector can be checked by

Heating Mode

(Heater model only)

poor heating

performance and/or

Low water temperature to unit Turn up boiler thermostat

Poor water flow Vent air from heating system

unit cycles on

water sensor

If the fan convector is still faulty after checking the above, call your installer or MYSON.

Turn on

Increase temperature set point

Switch on breaker

Check all wiring and reset breaker

Open valves

Check boiler -

Programmer ON

heating pump running

switching to manual fan setting

Common Installation Faults

For optimum performance, this unit must be correctly sized to

match the heat loss requirements of the space it is required to

Problem

Poor heating performance

(Heater model only)

Heating Mode

(Heater model only)

poor heating

performance and/or

unit cycles on

water sensor

System incorrectly balanced with unit starved of hot water flow

Unit incorrectly sized for heat loss of room

13.0 Maintenance

Before undertaking any maintenance activity isolate the

electrical supply.

Maintenance should be restricted to occasional removal of dust

and lint around the unit. The outer surface may be wiped over

heat, and the heating system must be correctly designed to

provide adequate flow of hot water to the unit (refer to section

2). If the recommendations in section 2 are not followed,

problems may arise as detailed below.

Possible Causes

Boiler thermostat set too low

Lack of flow to fan convector -

Pump set on low setting

Isolating valves not fully open

Pipe sizing to unit too small

11.0

with warm water and mild detergent taking care to avoid water

entering the grille areas.

12.013.0

Page 12

MYSON INC 49 Hercules Drive, Suite 4904, Colchester VT0446

T: 802 654 7500, F: 802 654 7022, info@mysoninc.com, www.mysoninc.com

heatingthroughinnovation.

01.01.2012 ISSUE 2

Loading...

Loading...