Page 1

Installation, Operating, Maintenance

and After Sales Manual.

SLIM-LINE RC

heatingthroughinnovation.

Product Serial Number:

Please leave this manual with the end user.

Part Number: 1370064

Issue 2

Page 2

Contents

1.0 General Information 03

2.0 Heating System Design 03

3.0 Unit Selection/Sizing 03

4.0 Location 03

5.0 Preparation 04

6.0 Fixing 04

7.0 Water Connections 05

8.0 Electrical Connection 06

9.0 Commissioning Procedure 07

10.0 Technical Data 08

11.0 Operating Instructions 09

12.0 Troubleshooting 10

13.0 Maintenance 11

Page 3

1.0 General Information

SLIM-LINE RC

03

G This MYSON SLIM-LINE RC fan convector is designed for wall

mounted installation with a minimum installation height of

150mm to the underside of the unit.

G The SLIM-LINE RC should only be used on closed

circulation, two pipe, pump assisted central heating systems.

G The SLIM-LINE RC can be used on heat pump systems.

G The minimum side clearance is 100mm.

G The maximum ceiling height is 3m.

G Before proceeding with the installation, the heating system

design must be considered and the unit correctly sized to

meet the heat loss requirements of the room at normal fan

speed.

G This unit is supplied with an infra red remote control system

and can be operated in either automatic or manual mode.

In automatic mode the desired room temperature is

programmed into the unit and the fan speed is automatically

adjusted until the desired room temperature is achieved. In

manual mode any of the 3 available fan speeds can be

selected without automatic room temperature control. This

feature can be used to circulate ambient air in summer,

for example, or to provide manual control of heating

performance.

G The appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities,

or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the

appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play

with the appliance.

This unit MUST NOT be installed in a bathroom or other similar high humidity area.

2.0 Heating System Design

This fan convector must be fitted on a two pipe, pumped

circulation heating system.

For optimum fan convector heating performance the system

must be capable of providing sufficient hot water through the

heat exchanger. This means that:

1. The minimum pipe size from boiler to fan convector must be

15mm.

2. This unit is not suitable for use on microbore pipe-work.

3. Where the unit is fitted on to a system with other emitters a

separate circuit for the fan convector should be considered

to provide adequate water flow.

4. The system water must be above 43°C for heating mode.

5. For heat pump applications - see Commissioning Procedure

6. This unit is NOT suitable for one-pipe systems.

7. Optimum performance will require effective balancing of

the whole system.

8. This unit must not be used to replace a radiator in an

existing system unless an adequate flow of water through

the unit can be guaranteed.

1.0

2.0

3.04.0

3.0 Unit Selection/Sizing

Heat output performance is given in the Technical Data section

of this manual. Outputs are shown for the three fan speeds,

however, it is important to size the unit to match the calculated

heat loss requirements of the room with the unit operating on

the low fan speed. The higher fan speeds are used in automatic

mode when the room temperature is significantly lower than the

preset temperature.

4.0 Location

G This SLIM-LINE RC unit may be fitted to any convenient wall

at a height from floor level that suits the application,

providing an unimpeded flow of warm air into the area to be

heated.

G The minimum distance from the underside of the unit to floor

level is 150mm.

When establishing the temperature difference, ie mean water to

room temperature, allowance should be made for temperature

drop in the system. It is the water temperature of the unit which

dictates the output.

G The unit should be mounted on a flat wall, and stud or

partition walls should be avoided to minimise the possibility

of noise transmission.

Page 4

04

SLIM-LINE RC

5.0 Preparation

Before proceeding with the installation, unpack the carton

contents and check against the checklist below:

1. SLIM-LINE RC unit.

2. 15mm isolating valves (1 pair).

3. Instruction manual.

4. Warranty card.

5. Fixing kit (rubber mounts and cable gland).

6. Remote control handset.

6.0 Fixing

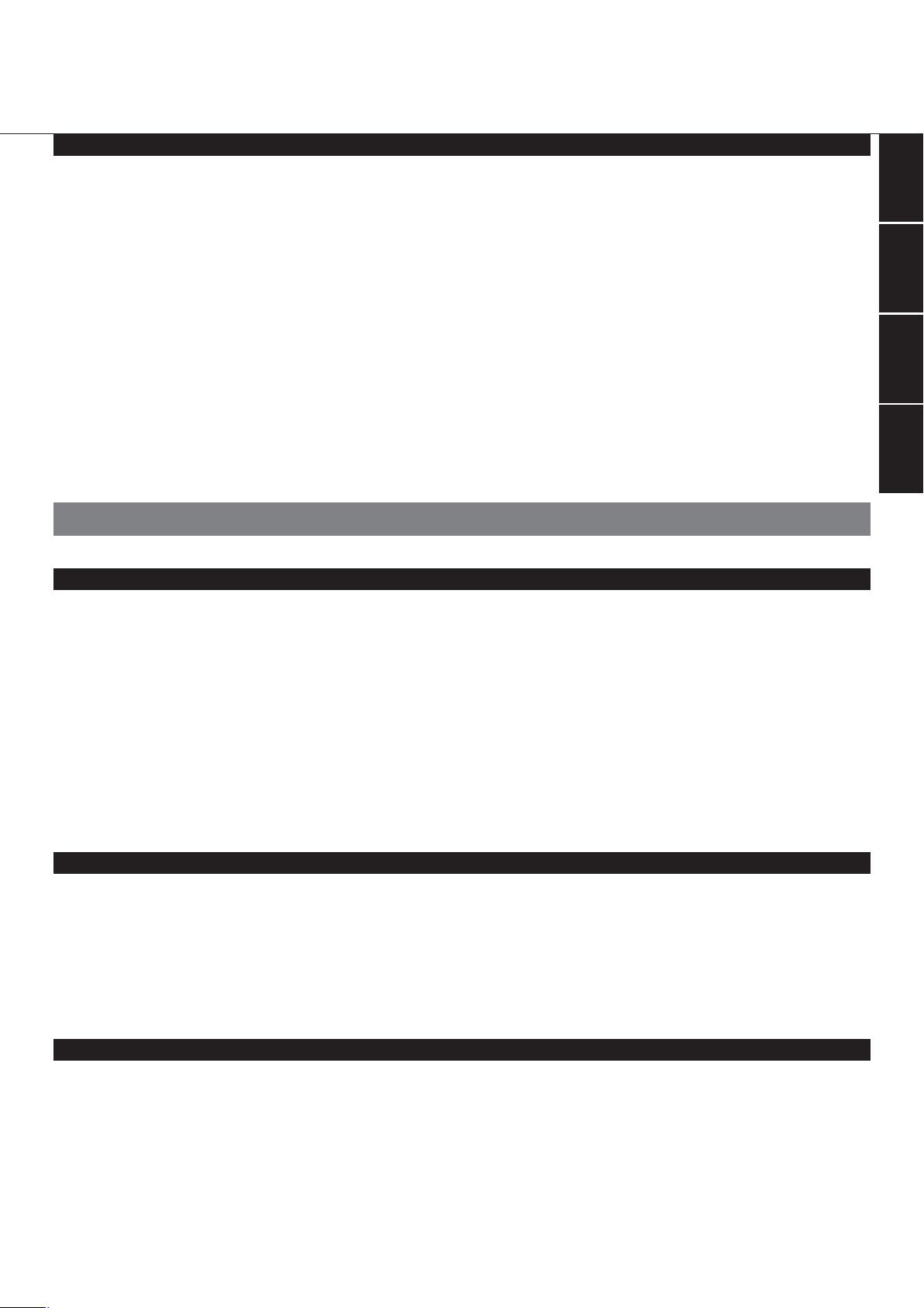

G Using the fixing dimensions (see fig. 1), mark the fixing hole

positions on the wall.

G Drill and plug the wall for No. 8 x 40mm round head wood

screws ensuring that the wall plugs are suitable for the wall

type.

G Remove the backing from the self-adhesive washers and place

on screws with adhesive side towards the point.

G Tighten the screws into the wall leaving about 9mm

projecting.

G Press adhesive washers to the wall.

G Remove outer case fixing screw at the bottom of the unit

(see fig. 2).

G Lift off outer case.

G Fit chassis on to retaining screws and tighten.

Fig. 1

Page 5

7.0 Water Connections

150

SLIM-LINE RC

05

G Connect unit to system flow and return pipes using the two

15mm isolating valves (see fig. 2).

Note: To ensure effective venting of the heat exchanger the flow

pipe should be connected to the bottom connection of the heat

exchanger.

Note: For SLIM-LINE RC installations pipe-work must not be

routed directly underneath the unit as this will adversely affect

the operation of the integral room thermostat. If this cannot be

avoided, the pipe-work must be boxed to prevent heat rise.

G Ensure system is flushed in accordance with recognised best

practice and a suitable inhibitor is added to the system as

necessary.

G Open valves fully, check pipe connections for leaks and vent

the heat exchanger - see Commissioning Procedure.

5.06.07.0

Fig. 2

Page 6

06

LN

Motor

Power Board

Control Board

Air Sensor

Water Sensor

O O

br

bl

y w bl br

SLIM-LINE RC

8.0 Electrical Connection

WARNING: This appliance must be earthed. The electrical installation must comply with local or national

wiring regulations.

G This unit is supplied with factory fitted test leads. Remove

these and discard.

G A fused electrical spur with a maximum 3A fuse and a switch

having 3mm separation on all poles must be provided in an

easily accessible position adjacent to the unit.

G Electrical cable entry to the unit should be made through the

underside of the unit using the cable gland provided, or

through the hole provided at the upper right hand corner of

the chassis.

Wiring diagram

G Connect live and neutral wires to the power board terminal

connections, and the earth wire to the chassis earth terminal.

y = Yellow

w = White

bl = Blue

br = Brown

Page 7

9.0 Commissioning Procedure

SLIM-LINE RC

07

G Fill and vent the system.

G Open both valves fully and vent air from the heat exchanger

by unscrewing the air bleed valve situated above the valves in

the angled top of the chassis.

G Check for leaks at pipe connections.

G Refit the outer case and secure using the 2 fixing screws.

G Switch on electrical supply.

G Check the operation of the unit in automatic and manual

modes by following the operating instructions.

G When installation and commissioning are complete, hand over

instruction manual to end-user.

Heat Pump Applications - Low Water Set Point

Adjustment Heating Mode

The low limit water set point is factory set to 43°C, but for

systems such as those with heat pumps, a lower water set point

may be required. The set point can be adjusted using the set

point dip switch located on the control board.

G Isolate electrical supply.

G Remove outer cover.

G Change switch position (see fig. 3).

G Refit cover.

G Switch on electrical supply.

Displayed Temperature Calibration

Depending on the location of the unit there may be a difference

between the temperature at the unit and the temperature in the

middle of the room being heated.

The displayed temperature calibration function enables

calibration in heating mode of the displayed temperature to the

actual room temperature using the following procedure:

G Press the ‘On/Off’ key and ‘+’ key for 5 seconds (the display

will flash, alternating between ‘ro’ and the calibration

temperature.

G Calibrate the displayed room temperature by using the

‘+’ and ‘-’ keys with the fan running.

G Press the ‘On/Off’ key to finish

Switch Switch Down Switch Up

1 Water Stat Set Point 32°C 43°C

2 Heating Heating Do not use

3 Not Used

4 Temperature Display °F °C

8.09.0

Fig. 3

Page 8

08

SLIM-LINE RC

10.0 Technical Data

Heating Performance Data

Power

Consumption

(watts)

125

Tested in accordance with BS 4856 Part 1.

Flow rate 340 ltr/h (75 gal/h).

Flow Rate Correction Factors:

455 ltr/h (100 gal/h) multiply by 1.03

227 ltr/h (50 gal/h) multiply by 0.96

113 ltr/h (25 gal/h) multiply by 0.85

Electrical supply 230V 50Hz

Test pressure 20bar (1MPa)

Max working pressure 10bar (1MPa)

Water connections 15mm compression

Unit weight dry 14.3kg

Water capacity 0.51 litres

Fan Speed

Normal

Medium

Boost

20° 30° 40° 50° 60° 20° 30° 40° 50° 60°

860 1340 1820 2290 2770

1130 1710 2280 2870 3460

1470 2220 2960 3720 4460

Temperature Difference (°C)

Heat Output (watts) Heat Output (Btu/h)

2934 4572 6210 7813 9451

3856 5835 7779 9792 11806

5013 7575 10100 12693 15218

Approximate Hydraulic Resistance through

Fan Convectors

Litres/h

455

340

227

113

mm wg

1771

1161

561

201

Noise levels in accordance with EN 23741

Fan

Setting

Normal

Medium

Boost

Sound Pressure at 2.5m (dBA)

21.9

30.6

39.7

kPa

17.4

11.4

5.5

2.0

Page 9

11.0 Operating Instructions

SLIM-LINE RC

09

Description

This SLIM-LINE RC unit is fitted with a control system that

provides either automatic or manual control of the unit. In

automatic mode the desired temperature set point is selected

and the unit will adjust the fan speed according to the difference

between the actual room temperature and the set point. When

the room temperature reaches the set point the fan will switch

off and thereafter will continue to cycle on and off to maintain

the room temperature. The temperature set point range is 15 - 35°C.

In manual mode the automatic temperature control is

overridden and any of the three fan speeds can be operated

inrespective of the water temperature in the unit. This means

that air circulation can be provided in summer for example, or

that heating performance can be controlled manually.

The unit can be controlled using the infra red remote control

handset supplied with the unit (see fig. 4) and also using

the control panel on the unit (see fig. 5). If necessary, however,

the control panel can be locked electronically to prevent

tampering once the controls have been set (see over).

Fig. 4 Fig. 5

The remote control hand set takes 2 AAA batteries (not supplied).

Controls Display

Power button Switches unit on & off

‘+/-’ button Adjust temperature set point from

15 - 35°C

Scrolls into F1, F2 or F3 manual mode

Heating

The unit will only operate in heating mode when the central

heating boiler is on, the pump is running and the system water

temperature is greater than 43°C. Ensure the boiler is on, and

set timer, boiler controls and room thermostats as

necessary.

10.011.0

Page 10

10

SLIM-LINE RC

11.0 Operating Instructions (continued...)

Operation Display

Power off No Display

Switch on supply to unit for 30 seconds

(unit off)

Supply on / unit off

Switch on unit Set point flashes for

approx 5 secs, then

Ambient temperature

displayed

Use ‘+/-’ to adjust Set point flashes for

set point approx 5 secs, then

Ambient temperature

The ambient temperature is always displayed unless the water

temperature falls below 43°C*, or if the set point is being

adjusted.

Water temp <43°C Shows both power

& unit on

Manual

Manual mode can be used for air circulation without heat or for

manual control of the heating function.

Use ‘+’ to scroll Selected fan speed

beyond 35°C displayed

Or use ‘-’ to scroll

below 15°C

Scrolling back out of manual using the ‘+’ or ‘–’ button will revert

the unit back to last temperature set point.

Locking Unit Controls

The control panel on the main unit can be locked electronically

to prevent interference once the controls have been set. After

setting the unit to the desired temperature setting and with the

unit in running mode, press the On/Off button on the main unit

for about 6 seconds until the two middle horizontal bars appear

on the display. The horizontal bars will disappear after about 6

seconds and the unit is in key lock mode.

If any of the unit controls are pressed the horizontal bars will

reappear to show the key lock mode is activated, however,

during this mode the handset controls remain functional.

To unlock the system press the On/Off button for about 6

seconds until the horizontal bars disappear.

*43°C in normal heating system, 32°C for heat pumps and above 20°C in cooling.

12.0 Troubleshooting

Once installed this fan convector becomes part of a complete

heating system that will generally include a boiler, pump, other

emitters such as radiators and fan convectors, and a number of

heating controls, dependent on system complexity. An apparent

problem with this unit may be the result of system controls being

incorrectly set and can be solved easily without calling out your

installer or MYSON Service. Before calling your installer or

MYSON Service, please carry out the checks listed opposite.

Note: If you call out MYSON Service to a fault detailed opposite,

or to repair a fault caused by incorrect use, a call out charge will

be made.

Page 11

12.0 Troubleshooting (continued...)

SLIM-LINE RC

11

Problem Remedy

Possible Causes

Unit switched off

Increase temperature set point

Switch on at spur

Heating Mode -

No Fan

Temperature set point reached

Unit not switched on at fused spur

Fuse blown at fused spur

Unit isolating valves shut

Water temperature reaching fan

convector below 43°C

Programmer ON

(Heater model only)

Boiler ON and set to high with central

heating pump running

Heating Mode

(Heater model only)

poor heating

performance and/or

unit cycles on

water sensor

Note: Operation of fan convector can be checked by

Low water temperature to unit Turn up boiler thermostat

Poor water flow Vent air from heating system

Note: Operation of fan convector can be checked by

switching to manual fan setting

switching to manual fan setting

Turn on

Replace fuse

Open valves

Check boiler -

If the fan convector is still faulty after checking the above, call your installer or MYSON Service.

Common Installation Faults

For optimum performance, this unit must be correctly sized to

match the heat loss requirements of the space it is required to

Problem

Poor heating performance

(Heater model only)

Unit incorrectly sized for heat loss of room

heat, and the heating system must be correctly designed to

provide adequate flow of hot water to the unit (refer to section

2). If the recommendations in section 2 are not followed,

problems may arise as detailed below.

Possible Causes

Boiler thermostat set too low

Heating Mode

(Heater model only)

poor heating

Lack of flow to fan convector -

Pump set on low setting

performance and/or

unit cycles on

Isolating valves not fully open

water sensor

System incorrectly balanced with unit starved of hot water flow

Pipe sizing to unit too small

13.0 Maintenance

11.012.013.0

Before undertaking any maintenance activity isolate the

electrical supply.

Maintenance should be restricted to occasional removal of dust

and lint around the unit. The outer surface may be wiped over

with warm water and mild detergent taking care to avoid water

entering the grille areas.

Page 12

MYSON Eastern Avenue, Team Valley, Gateshead, Tyne & Wear NE11 0PG, UK

T: 0845 402 3434, F: 0191 491 7568, sales@myson.co.uk, www.myson.co.uk

After Sales Service:

MYSON Service, Somerden Road, Hull, East Yorkshire HU9 5PE

T: 01482 713927, F: 01482 789056, service.convectors@myson.co.uk

Spare parts and technical help on all Convector products are available from MYSON Service.

heatingthroughinnovation.

01.07.2009 ISSUE 2

Loading...

Loading...