Myron Zucker CALMOUNT, MULTICAL Operation Manual

OPERATION AND MAINTENANCE MANUAL FOR CALMOUNT® AND MULTICAL® BRAND CAPACITORS

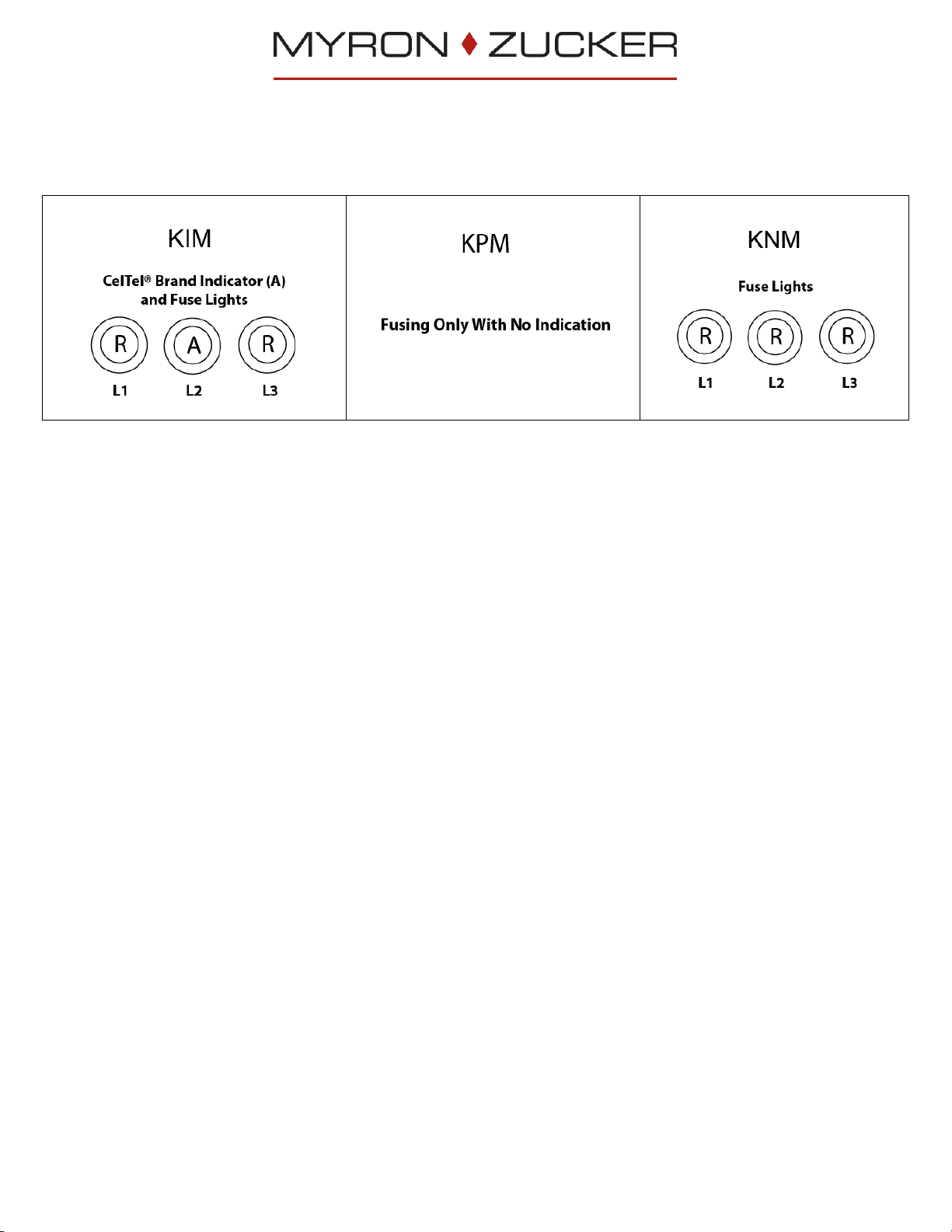

Calmount® and Multical® Brand Capacitor Series Indication Lights

AMBER LIGHT (A)

The amber light on the KIM series will illuminate in either of the following circumstances:

Blown fuse – middle phase (L2)

Loss of capacitance in a capacitor cell detected by CelTel® brand indicator

RED LIGHTS (R)

A red light will illuminate when a fuse blows. Each red fuse light is wired in parallel to its fuse. The left-most light (L1) will illuminate if

the left fuse blows and the right-most light (L3) will illuminate if the right fuse blows.

SITUATIONS WHEN FUSE MAY BLOW

In general, overcurrent is the cause for any fuse failure. The amount and duration of the overcurrent may determine which of the

following is the actual cause:

Shorted Cell

Capacitor cells normally fail open; however, it may be possible for a cell to short. Use capacitance meter to check.

Starter or contactor bad contact pickup

If a set of contacts bounces, the capacitor starts to charge, allowing it to receive a new voltage before it is completely

discharged. This may cause a spike that can overload the fast-acting fuse.

Jogging motors

The capacitor could be charged to peak of the sine wave and then receive a new charge. This may cause a spike and overload

the fuse. In this case, the fuse should be removed from the capacitor when checking a machine or checking motor rotation.

Adjustable Speed drive (ASD) in system

Any ASD, whether VFD or DC drive, will generate harmonic currents that the capacitor will attract in addition to the normal 60

Hz current. This additional current can then overload the fuse to the point of failure.

Other capacitors

Adding new capacitors to a system that already has capacitors or adding a large unit to a system might put the system

resonance point at or near a harmonic frequency. In this case, even a small harmonic current can excite very high circulating

currents that can overload either the capacitor or switchgear fuse.

Welding

Excessive welding in a facility may cause many voltage spikes and ringing transients that are at many different frequencies

above 60 Hz. The spikes typically are short-lived but can accumulate with multiple welders. These higher-frequency currents

and spikes are attracted by the capacitor and cause the fuse to overload.

120V

190V

208V

230V

240V

380V

415V

435V

480V

575V

600V

3

PHASE

60 Hz

4.81

3.04

2.78

2.51

2.41

1.52

1.39

1.33

1.20

1.00

0.96

50 Hz

4.01

2.53

2.31

2.09

2.00

1.27

1.16

1.11

1.00

0.84

0.80

1

PHASE

60 Hz

8.33

5.26

4.81

4.35

4.17

2.63

2.41

2.30

2.08

1.74

1.67

50 Hz

6.94

4.39

4.01

3.62

3.47

2.19

2.01

1.92

1.74

1.45

1.39

Induction heating and other nonlinear loads

Harmonics are generated with induction heating and by rectifiers in a plating process or large UPS systems. Here again, the

additional harmonic currents are attracted by the capacitor and may overload the fuse.

Fuse lights come on when energized

Consult factory.

MAINTENANCE ON CAPACITORS MUST BE DONE BY QUALIFIED PERSONNEL

Field evaluation of capacitors is called for on a routine maintenance basis. There are no moving parts to wear out; however, on rare

occasions failures do occur. If the application is severe due to high voltages, harmonics, switching surges or vibration, a more frequent

check is warranted. This is to ensure that the capacitor equipment is operating properly. Capacitor cells are of low losses; they operate

barely warm. If the capacitor cell case is cold, check for blown fuses, open switches, or other losses of power. Bulging cases or puffed-up

covers are a good indication of capacitor cell failure. Before simply replacing a fuse on the capacitor, check for bulging c ases or puffed-

up covers. These are often signs of failed capacitor cells.

If the top is not distorted, test each capacitor cell from terminal to terminal with a capacitance meter. If the capacitor c ell’s pressure-

actuating device has opened, no microfarad reading will be present. This means that the capacitor cell is opened and should be

replaced. If a capacitance meter is not available, use a clamp-on amp meter. Re-fuse where necessary and then energize the capacitor.

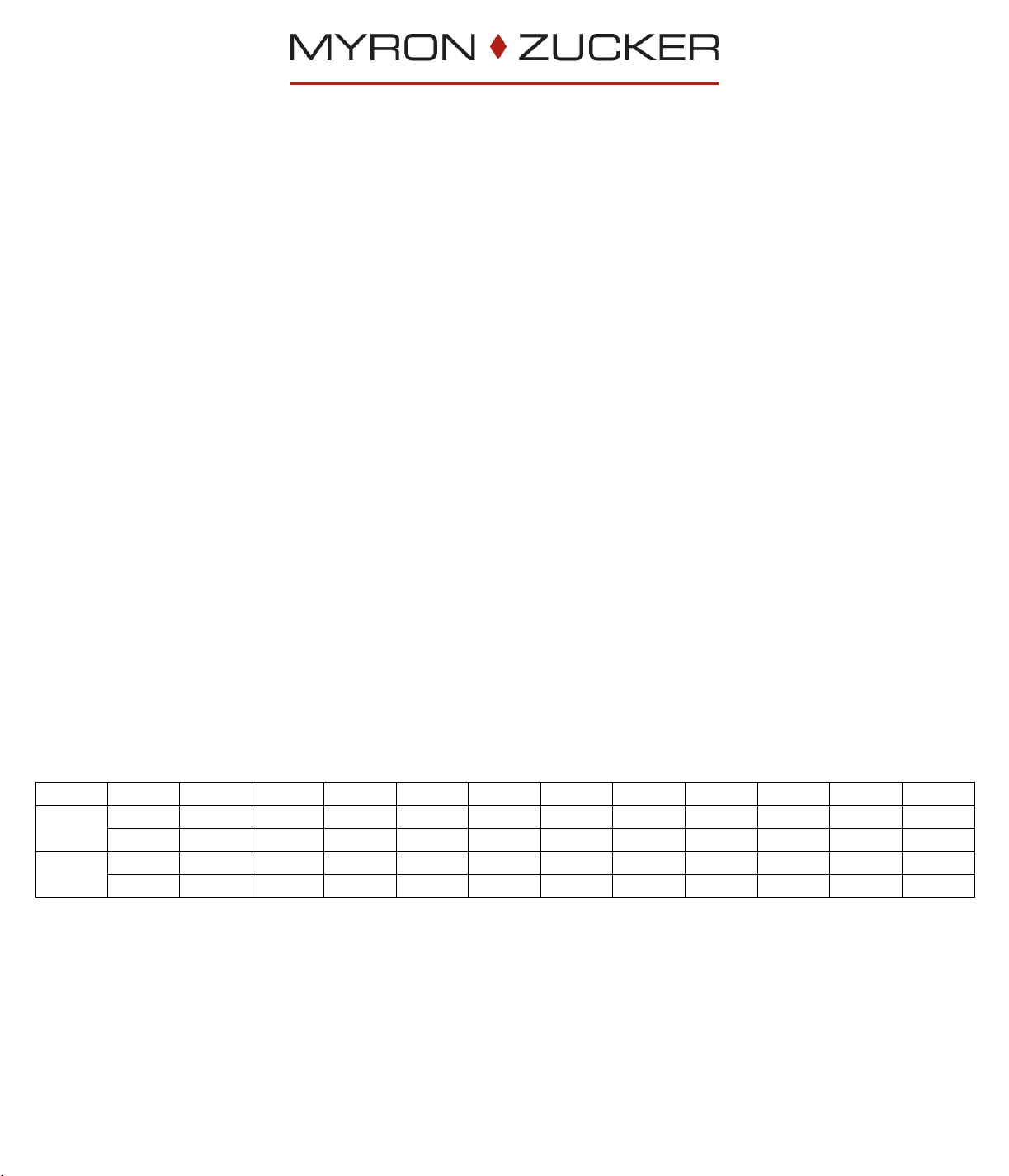

A clamp-on meter will indicate if the capacitor cell’s currents are balanced in each phase and drawing the correct amperage per phase. If

this is not the case, then the capacitor cell might have to be replaced. To determine how much amperage is correct for your capacitor

cell, see the ratings below.

Standard Ratings

240 VAC, 3 Phase, 60 Hertz = 2.41 amps per kVAr per phase

480 VAC, 3 Phase, 60 Hertz = 1.20 amps per kVAr per phase

600 VAC, 3 Phase, 60 Hertz = 0.96 amps per kVAr per phase

All Available Ratings

Example: 10 kVAr at 480V, 3 Phase, 60 Hertz

10 kVAr x 1.2 = 12 amps per phase

Loading...

Loading...