Page 1

INSTALLATION INSTRUCTIONS FOR CALMOUNT

®

and MULTICAL

®

BRAND CAPACITORS

GENERAL

Congratulations! You have purchased the finest power capacitor available. All Myron Zucker, Inc. Calmount® brand

capacitors are made with state-of-the-art metallized cells designed for low electrical loss and long life. All wiring,

connectors and other components are top quality. Each capacitor is housed in a powder coat painted steel enclosure

fitted with a gasketed cover designed to provide both protection and easy installation. To ensure that you obtain

satisfactory service from your Calmount

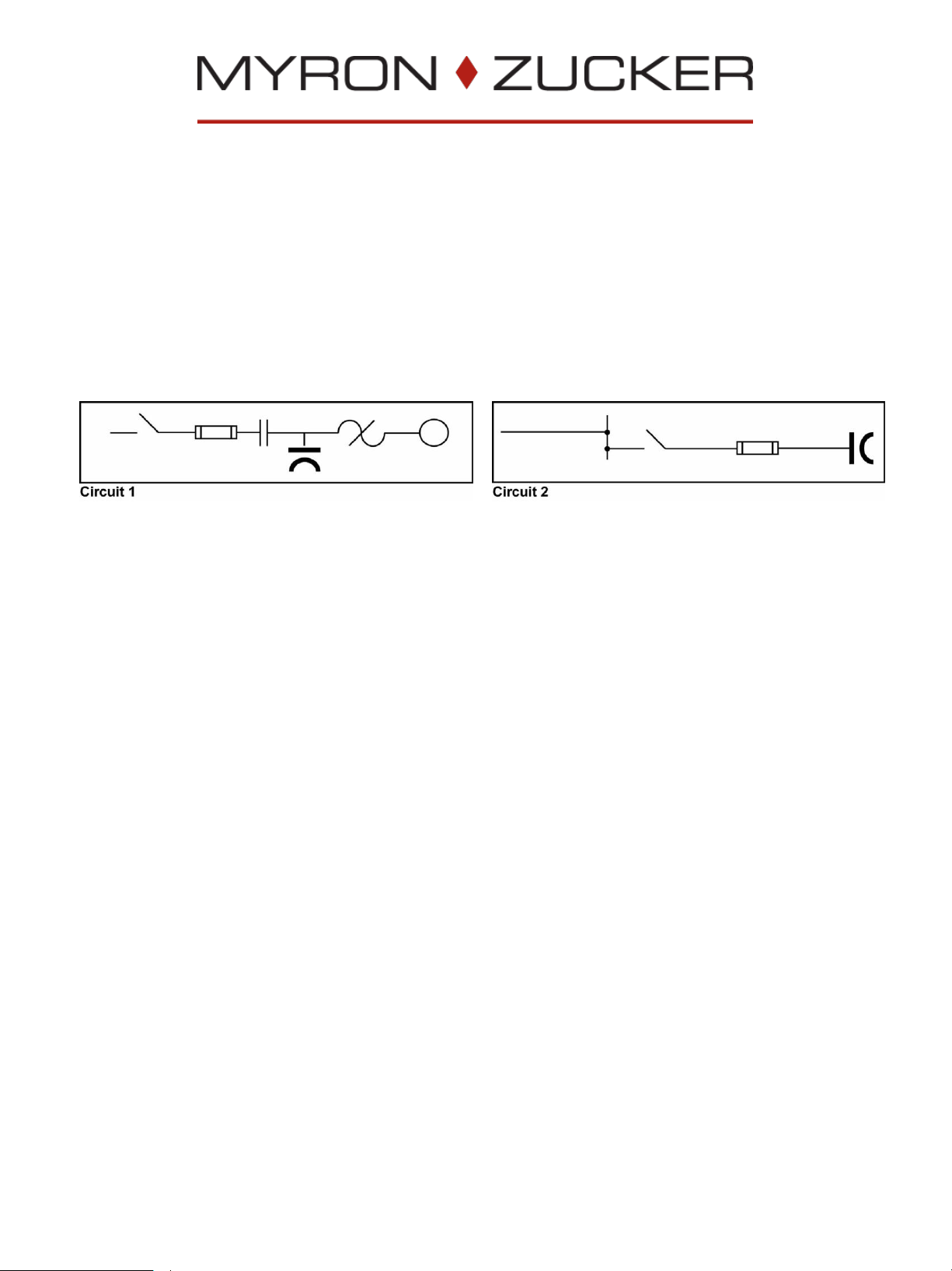

Calmount® brand capacitors can be connected either at the load (Circuit 1) or on the line (Circuit 2). In Circuit 2, the

capacitor must be connected through a disconnect device. Both circuits must have overcurrent protection. (For sizing, see

chart on back of these Installation Instructions.)

®

brand capacitor, please follow these Installation Instructions.

Capacitor lifetime is greatly reduced at high temperatures. Calmount® brand capacitors should be installed in cool

locations with good ventilation. Mechanical requirements of mounting the capacitor must also be considered. In general,

when selecting a mounting location:

• Avoid obvious “hot spots”, such as furnaces, transformers, heating ducts and direct sunlight.

• Avoid locations with harmonic voltages or currents.

• Allow at least three inches (3”) around the capacitor for air circulation.

• Allow mechanical clearances for:

- ducts and conduits (including future needs)

- construction

- machinery

- opening doors

- removal of the capacitor cover

• Position the capacitor for covenient nippling to cabinet or conduit and for visibility of indicator lights.

• Protect the capacitor from excessive dirt, dripping fluids and human interface.

LOCATION AMBIENT TEMPERATURE

Location ambient temperature is the temperature of the location before capacitors are installed, or with the capacitors

installed but not operating (not energized). This is the temperature of the surrounding air in the room, vault, substation or

enclosure where the capacitor will be operating. Maximum location ambient temperature should not exceed 46°C (115°F).

Page 2

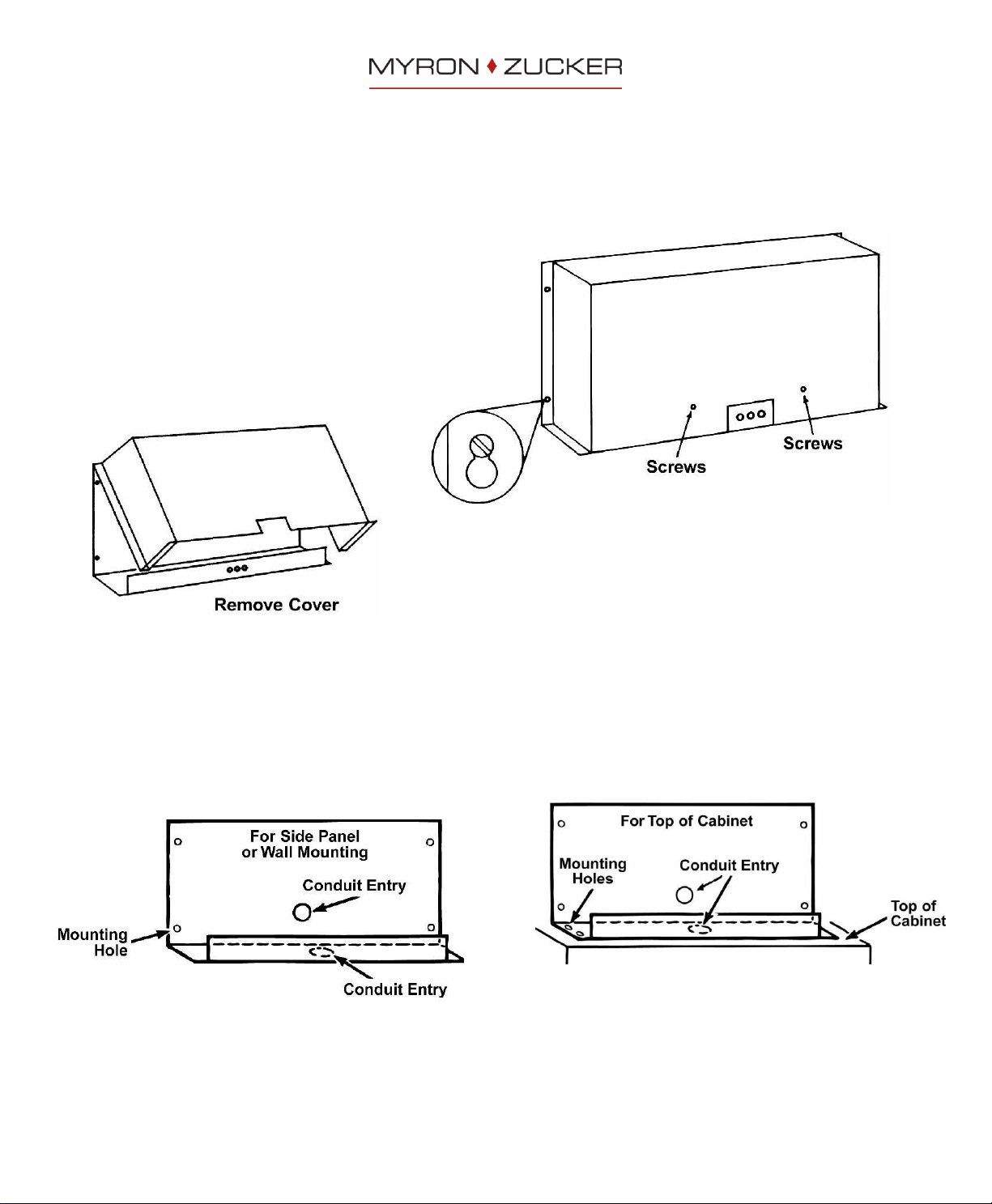

REMOVE COVER

The cover on all Calmount® brand capacitors is held on by four (4) side screws, and on larger units, two (2) or more front

panel screws.

To remove cover:

1. Take out front panel screws (if present).

2. Loosen side screws.

3. Lift cover off slightly.

4. Swing cover free from screws.

5. Lift cover off.

MOUNTING CALMOUNT® BRAND CAPACITORS

Place Calmount® brand capacitor on cabinet or wall, and mark mounting holes. (Mounting holes are prepunched on all

Calmount® brand capacitors.)

The following illustration shows the locations for conduit entry:

Page 3

Calmount® brand capacitors

Multical® brand capacitors

Electrical connections to these capacitors are made either to fuse

block, fuse lugs, or to a distribution block. Connect a single-phase

wire to each terminal. Be sure to attach grounding wire to

ground lug for safety.

On these units, each capacitor is wired to a

separate fuse block.

ATTACHING WIRES TO CALMOUNT

Select proper wire size from chart on back of these Installation Instructions.

CALMOUNT® BRAND CAPACITOR WITH CONTACTOR OPTION (CIRCUIT 3)

A two position terminal strip is provided for the remote operation of the contactor. Ensure that the voltage being supplied

to the contactor terminals is the same as the contactor coil.

INDICATING LIGHTS

Calmount® brand capacitor - KIM Series

On the KIM series capacitors, there are two (2) red lights and one (1) amber light. The two red lights are for indicating

blown fuses. The amber light serves two (2) indicating purposes:

blown fuse – middle phase (L2)

loss of capacitance in a capacitor cell detected by CelTel® brand indicator

Calmount® brand capacitor - KNM Series

On the KNM series capacitors, there are three (3) red indicating lights for indicating blown fuses. If a fuse blows, the fuse

light will illuminate. Each fuse light is wired in parallel to its fuse.

®

BRAND CAPACITORS

Page 4

KVAR

Current*

(Amps)

Wire Size

90° C-Type

THHN

XHHW* or

Equiv.†

Fuse

(Amps)

C.B. or

Switch

(Amps)

Current*

(Amps)

Wire Size

90° C-Type

THHN

XHHW* or

Equiv.†

Fuse

(Amps)

C.B. or

Switch

(Amps)

Current*

(Amps)

Wire Size

90° C-Type

THHN

XHHW* or

Equiv.†

Fuse

(Amps)

C.B. or

Switch

(Amps)

1 2.4 14 5 30 1.2 14 3 30 1.0 14 3 30

1.5 3.6 14 6 30 1.8 14 3 30 1.4 14 3 30

2 4.8 14 10 30 2.4 14 5 30 1.9 14 3 30

2.5 6.0 14 10 30 3.0 14 6 30 2.4 14 5 30

3 7.2 14 15 30 3.6 14 6 30 2.9 14 5 30

4 9.6 12 20 30 4.8 14 10 30 3.8 14 6 30

5 12 12 20 30 6.0 14 10 30 4.8 14 10 30

6 14 10 25 30 7.2 14 15 30 5.8 14 10 30

7.5 18 10 30 30 9.0 14 15 30 7.2 14 15 30

10 24 8 40 60 12 12 20 30 9.6 12 20 30

12.5 30 8 50 60 15 10 25 30 12 12 20 30

15 36 6 60 60 18 10 30 30 14 10 25 30

17.5 42 6 70 100 21 8 35 60 16 10 30 30

20 48 4 80 100 24 8 40 60 19 8 35 60

22.5 54 4 90 100 27 8 50 60 22 8 35 60

25 60 2 100 100 30 8 50 60 24 8 40 60

27.5 66 2 125 200 33 6 60 60 26 8 45 60

30 72 2 125 200 36 6 60 60 29 8 50 60

32.5 78 1/0 150 200 39 6 65 100 31 8 50 60

35 84 1/0 150 200 42 6 70 100 34 6 60 60

37.5 90 1/0 150 200 45 6 75 100 36 6 60 60

40 96 2/0 175 200 48 4 80 100 38 6 65 100

42.5 102 2/0 175 200 51 4 90 100 41 6 70 100

45 108 3/0 200 200 54 4 90 100 43 6 75 100

50 120 3/0 200 200 60 2 100 100 48 4 80 100

52.5 126 3/0 200 200 63 2 110 200 50 4 80 100

55 132 4/0 250 400 66 2 125 200 53 4 90 100

60 144 4/0 250 400 72 2 125 200 58 2 100 100

65 156 4/0 250 400 78 1/0 150 200 62 2 110 200

70 168 300MCM 300 400 84 1/0 150 200 67 2 125 200

75 180 300MCM 300 400 90 1/0 150 200 72 2 125 200

80 192 350MCM 350 400 96 2/0 175 200 77 1/0 150 200

90 216 500MCM 400 400 108 3/0 200 200 86 1/0 150 200

100 240 500MCM 400 400 120 3/0 200 200 96 2/0 175 200

125 300 (2)4/0 500 600 150 4/0 250 400 120 3/0 200 200

150 360 (2)300MCM 600 600 180 300MCM 300 400 144 4/0 250 400

175 420 (2)350MCM 700 800 210 500MCM 400 400 168 300MCM 300 400

200 480 (2)500MCM 800 800 240 500MCM 400 400 192 350MCM 350 400

225 540 (3)300MCM 900 1200 270 (2)4/0 500 600 216 500MCM 400 400

250 600 (3)350MCM 1000 1200 300 (2)4/0 500 600 240 500MCM 400 400

275 660 (3)500MCM 1100 1200 330 (2)300MCM 600 600 264 (2)4/0 500 600

300 720 (3)500MCM 1200 1200 360 (2)300MCM 600 600 288 (2)4/0 500 600

350 420 (2)350MCM 700 800 336 (2)300MCM 600 600

400 480 (2)500MCM 800 800 384 (2)350MCM 700 800

450 540 (3)300MCM 900 1200 432 (2)400MCM 750 800

500 600 (3)350MCM 1000 1200 480 (2)500MCM 800 800

550 660 (3)500MCM 1100 1200 528 (3)300MCM 900 1200

600 720 (3)500MCM 1200 1200 576 (3)350MCM 1000 1200

* Rated current based on operation at rated voltage, frequency, and KVAR

† Cons ul t National Electrical Code for other wire types . Above size base d on 35°C Ambient Operation. (Refer to NEC table 310-16.)

Note: Fuses furnished within Capacitor Assembly may be rated at higher value than shown in this table. The table is correct for field installations and

reflects the manufacturer's suggested rating for overcurrent protection and disconnect means in compliance with the National Electrical Code.

RECOMMENDED WIRE SIZES, SWITCHES, AND FUSES FOR 3-PHASE, 60Hz CAPACITORS

(These wire sizes are based on 135% of rated current in accordance with the National Electrical Code, Article 460.)

240 VOLTS

480 VOLTS

600 VOLTS

USE COPPER CONDUCTORS ONLY. UNIT TERMINALS ARE NOT DESIGNED TO ACCEPT OTHER TYPE

WIRING. THE USE OF ALUMINUM WIRING MAY CAUSE GALVANIC CORROSION AND/OR OVERHEATING AT

CAUTION:

Loading...

Loading...