Page 1

1

INTRODUCTION

Thank you for selecting the Myron L® Company Ultrapen™ PT6 Nitrate Pen. This instrument is designed to be accurate, fast,

and simple to use in diverse water quality applications. Advanced features include:

• Selectable Units for Displaying Nitrate Concentration in ppm as Nitrogen (NO

3

-

-N), or Nitrate (NO

3

-

), or in millivolt (mV)

• 1 or 2 point Calibration Options with Choice of 4 Standard Solutions

• Proprietary ISE Sensor Design

• Built in Double Junction Reference Electrode, No Need for External Reference

• Compatible with EPA Approved Standard Method 4500-NO

3

-

D

• Live or Hold Mode – User Selectable

• Auto-Off feature – User Adjustable

• Rugged Design with Aircraft Aluminum Body

• Durable, Epoxy Encapsulated Electronics

• Waterproof

CONTENTS INCLUDE:

1. Ultrapen™ Pocket Tester Model PT6

2. User Replaceable Nitrate Sensor – Installed

3. 100 ppm NO

3

-

-N Standard Solution, 2 oz.

4. Ionic Strength Adjuster (ISA), 2 oz.

5. Graduated Cylinder with Cap, 2 ea.

6. 100 µL Pipette with Tip

7. Protective Cap

8. Pocket Clip

9. Lanyard

10. One N Type Battery – Installed

QUICK REFERENCE INSTRUCTIONS

1. Press and release the push button to turn the PT6 ON.

2. While the LED flashes rapidly: Dip the pen in prepared sample solution so the sensor is totally submerged.

3. Swirl the pen to remove any bubbles that may be trapped in the sensor.

4. While the LED flashes slowly: Hold the pen steady in the sample solution, keeping the sensor submerged.

5. In HOLD mode – Real time readings are displayed until the LED turns solid ON. The display holds the final

reading briefly then the PT6 turns OFF.

6. In LIVE Mode – The PT6 will display constant, real-time measurements for up to 5 minutes then turn OFF.

ULTRAPEN FEATURES

1. PUSH BUTTON– Turns the PT6 ON, selects

instrument settings, and initiates calibration.

2. BATTERY CAP– Unscrew to access battery for

replacement.

3. BATTERY INDICATOR – Shows battery charge

level.

4. DISPLAY– Displays measurements, menu options,

battery indicator, and firmware revision (during powerup).

5. LED INDICATOR LIGHT– Indicates when to dip

the PT6 in solution, when the measurement is in

progress, and when to remove the PT6 once the

measurement is complete.

6. NITRATE SENSOR– Contains the double junction

reference electrode, and nitrate ion selective electrode.

7. ISE ELECTRODE – Contains the Nitrate ISE membrane.

8. THERMISTOR – Measures temperature of sample solution.

9. PROTECTIVE CAP – Protects sensor and holds solution for conditioning sensor. To remove, wiggle the cap side to side

while pulling it off.

• Use caution not to spill conditioning solution. Verify the sensor remains fully inserted into the PT6. If not, reinstall per

Nitrate Sensor Replacement Instructions (see MAINTENANCE).

• To replace, wiggle the cap side to side while pushing it on.

10. CAP STOP – Shows how far to push the protective cap when putting it on the PT6.

• DO NOT push the protective cap beyond the cap stop as sensor damage may occur.

8 9 7

8

10

Myron L® Company

– ULTRAPEN™ PT6 –

Operation Manual

Nitrate Concentration and Temperature Pen

Page 2

2

MENU OPTIONS

The PT6 Menu allows the user to navigate through the available function/setting options. See detailed instructions below for

complete instructions on each function/setting option.

To get to the menu, simply press and release the push button to turn the PT6 ON, then push and hold the push button. The PT6

display will alternate between the following options:

• CAL – Calibration Menu

• FAC CAL – Factory Calibration Menu

• ºCºF TEMP – Temperature Unit Selection Menu

• ModE SEL – Mode Selection Menu

• PAr SEL – Nitrate Parameter Selection Menu

• SEnSor √ – Sensor Check Menu

• ESC – Escapes/Exits the Menu and immediately powers the PT6 OFF

Release the push button while the desired option is displayed. See detailed instructions below.

ULTRAPEN SETTINGS

NOTE: In all menus, selecting “ESC” immediately powers the PT6 OFF without saving changes to the settings.

I. NITRATE PARAMETER SELECTION

The PT6 allows you to select how you wish to display the nitrate concentration readings: Nitrate as Nitrogen (NO

3

-

-N) displayed

as ppm N, Nitrate (NO

3

-

) displayed as ppm NO3, or millivolt displayed as mV.

To select a parameter for display:

1. Press and release the push button to turn the PT6 ON.

2. Push and hold the push button to enter menu mode.

3. Release the push button while “PAr SEL” is displayed.

4. The display will alternate between “PUSHnHLD” and “PAr SEL”.

5. Push and hold the push button. The display will alternate between the following:

• “N” (displays Nitrate as Nitrogen and Temperature)

• “NO3” (displays Nitrate and Temperature)

• “mV” (displays millivolts and Temperature)

• “ESC”

6. Release the push button when desired parameter type is displayed.

• “SAVEd” will display, then the PT6 will power OFF.

II. TEMPERATURE UNIT SELECTION

The PT6 allows you to select the type of units used for displaying temperature; ˚C (Celsius) or ˚F (Fahrenheit).

To select the Temperature Units:

1. Press and release the push button to turn the PT6 ON.

2. Push and hold the push button to enter menu mode.

3. Release the push button while “˚C˚F TEMP” is displayed.

4. The display will alternate between “PUSHnHLD” and “˚C˚F TEMP”.

• Push and hold the push button. The display will alternate between “˚C” (Celsius), “˚F” (Fahrenheit), and “ESC”.

5. Release the push button when desired unit is displayed.

6. “SAVEd ˚C” or “SAVEd ˚F” will display, then the PT6 will power OFF.

III. MODE SELECTION

The PT6 allows you to select between two measurement modes; Live mode or Hold mode.

HOLD mode (Default) – Real-time readings are displayed until the LED turns solid ON. The display holds the final reading

briefly then the PT6 turns OFF.

LIVE mode – Real-time readings are displayed continuously for up to 5 minutes. A press and release of the push button will turn

your PT6 OFF immediately. User may select auto-off timeout period from 140 to 300 seconds.

To select the mode:

1. Press and release the push button to turn the PT6 ON.

2. Push and hold the push button to enter menu mode.

3. Release the push button while “ModE SEL” is displayed.

4. The display will alternate between “ModE SEL” and “PUSHnHLD”.

5. Push and hold the push button. The display will alternate between “Hold”, “LIVE” and “ESC”.

6. Release the push button when the desired mode is displayed.

• If Hold mode is selected: “SAVEd” will display, then the PT6 will power OFF.

Page 3

3

• If LIVE mode is selected you will be prompted to set the auto-off time: The display will alternate between “PUSH CONT”

and “[value] SEC”. Press and release repeatedly or push and hold to adjust the time out period. The display will scroll from

140 to 300 seconds, then repeat. When you have selected the desired timeout period, let the PT6 time out.

SENSOR CONDITIONING

If the sensor is new and/or has been stored dry, the sensor needs to be conditioned before calibration or measurement.

1. Remove the protective cap. Rinse the sensor with clean water (preferably DI, RO, or distilled) and pat it dry with a clean soft

lint-free cloth.

2. Fill the protective cap half-full with PREPARED calibration solution (with Nitrate ISA added, See PREPARING

CALIBRATION SOLUTION, below), carefully put the cap back on the sensor for conditioning (using caution as excess

solution may squirt out). It may take up to an hour for sensor to restore stable readings after dry storage.

NOTE: For best results, you should always condition your sensor using a PREPARED calibration solution with a value

close to the lower end of the concentration values you will be measuring.

CALIBRATION

The Myron L® Company recommends calibrating the PT6 before each series of tests, depending on usage. The PT6 offers 1-point

or 2-Point calibration and is calibrated in Nitrate as Nitrogen (NO

3

-

-N) using 1, 10, 100, or 1000 ppm Standard Solutions. For

greatest accuracy complete a 2-point calibration, selecting the closest Standard Solutions above and below your expected test

solution range (example: If you are measuring test solutions in the range of 200 to 400 ppm NO

3

-

-N, then you would want to

calibrate using 100 ppm and 1000 ppm Standard Solutions). Calibration solutions must be prepared prior to use.

Calibration is always done in Nitrate as Nitrogen (NO

3

-

-N) even if your PT6 is set to measure in Nitrate (NO

3

-

). To select the

optimal Standard Solutions and to verify calibration, see the CONVERSION TABLE below.

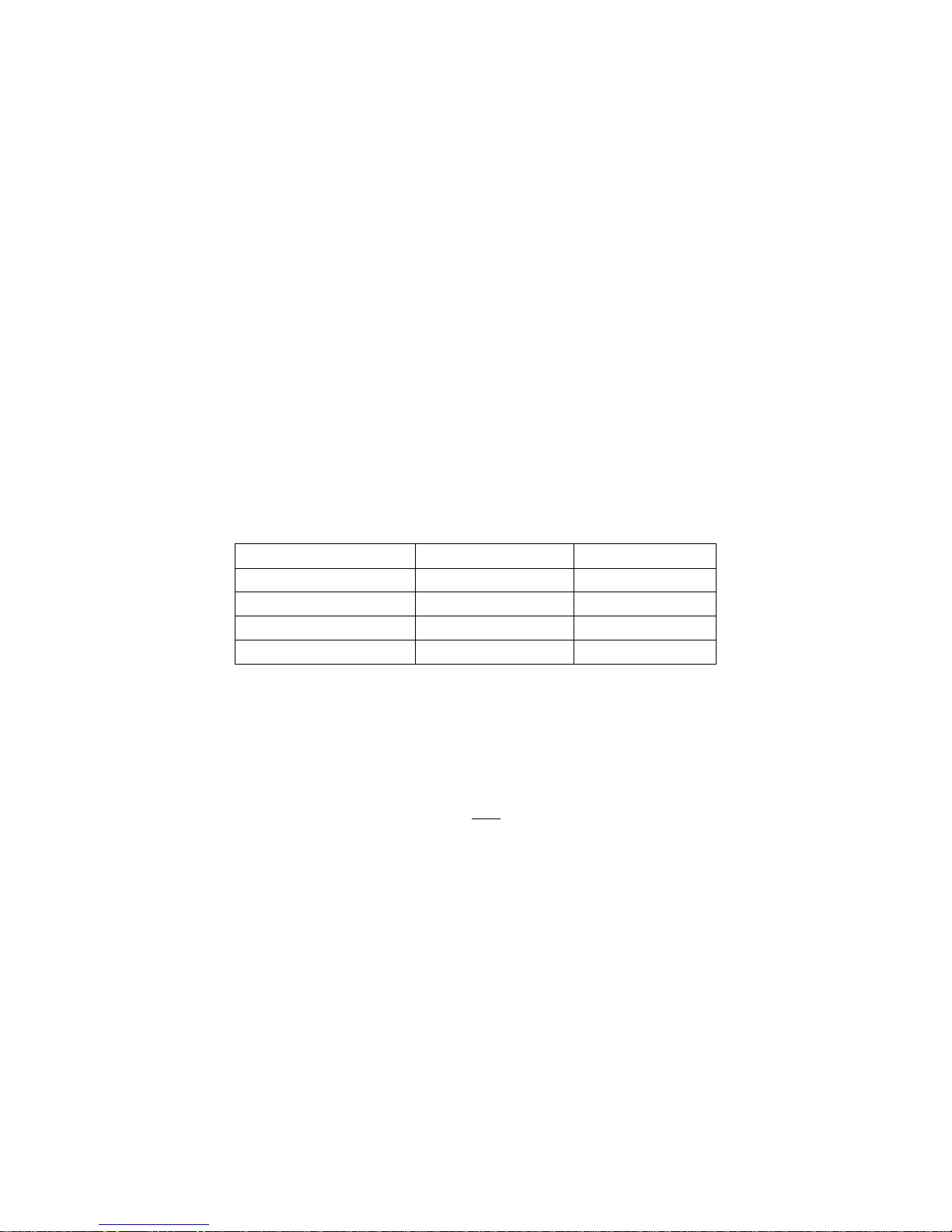

CONVERSION TABLE

Standard Solution

Value in NO

3

-

-N

Value in NO

3

-

N1SOL

1 ppm

4.4 ppm

N10SOL

10 ppm

44 ppm

N100SOL

100 ppm

440 ppm

N1000SOL

1000 ppm

4400 ppm

NOTES

• Always start with the lower calibration point first.

• For greatest accuracy, keep the temperature of prepared calibration solution(s) the same as the test solution. The

temperature difference should be within ±2oC.

• Nitrate sensor should be conditioned prior to performing a calibration (see Sensor Conditioning, above).

I. PREPARING CALIBRATION SOLUTION

Calibration solution(s) must be prepared prior to calibration. For each standard solution selected:

1. Fill a Graduated Cylinder to the 10 mL line with the Standard Solution.

2. Add 200 µL of the Nitrate ISA solution to the Graduated Cylinder (using the supplied 100 µL pipette).

NOTE: When using the pipette to draw, depress pipette to 1st stop, then place tip in ISA solution and release slowly. To

dispense, depress pipette completely to the 2nd stop.

NOTE: Do not contaminate the pipette tip by touching it with your fingers or setting it in a dirty toolbox. Do not dip the

pipette tip in the calibration solution as this will cause cross-contamination between solutions.

3. Replace the cap on the Graduated Cylinder and shake well to mix the prepared calibration solution.

II. 2-POINT CALIBRATION

To perform a 2-Point calibration you will need two prepared calibration solutions, clean water (preferably DI, RO, or distilled),

and a clean, dry, lint-free cloth.

1. Remove the protective cap. Rinse the sensor for about 5 seconds with clean water (preferably DI, RO, or distilled) and pat it

dry with a clean soft lint-free cloth.

2. Press and release the push button to turn the PT6 ON.

3. Push and hold the push button to enter menu mode.

4. Release the button while “CAL” is displayed. The display will alternate between “PUSHnHLD” and “CAL”.

5. Push and hold the push button. The display will alternate between “1ppm”, “10ppm”, “100ppm”, “1000ppm”, and “ESC”.

Page 4

4

6. Release the push button while the desired calibration solution value is displayed. (Remember to calibrate the lower value

first). The LED will begin to flash rapidly.

7. While the LED flashes rapidly, dip the pen in the prepared calibration solution so that the sensor is completely submerged and

swirl it around to remove any bubbles that may have been caught in the sensor.

8. While the LED flashes slowly, the display will show “[value] ppm”. Hold the sensor steady during calibration.

9. If the first calibration point is successful, the display will indicate “SAVEd”, then “PUSHnHLD” will be displayed.

10. Rinse the sensor in clean water (preferably DI, RO, or distilled) and pat it dry with a clean soft lint-free cloth (you will have

up to 25 seconds for this step).

11. Push and HOLD the push button to continue. The display will alternate between the remaining options for calibration values.

NOTE: If you press and release the button at this point, or let the pen timeout, a 1-point calibration will be stored. You would

need to start over for a 2-point calibration.

12. Release the push button while the 2nd calibration point value is displayed. The LED will begin flashing rapidly.

13. While the LED is flashing rapidly, dip the pen in the 2nd prepared calibration solution so that the sensor is completely

submerged and swirl it around to remove any bubbles that may have been caught in the sensor.

14. While the LED flashes slowly, the display will alternate between “CAL” and “[value]”. Hold the sensor steady during

calibration.

15. If the second calibration point is successful, the display will indicate “SAVEd 2PT” and the PT6 will power OFF.

16. Verify calibration by retesting the prepared calibration solutions. The values should be within ±10% of the stated value of the

standard solutions.

17. Remove the sensor from the solution and rinse it with clean water (preferably DI, RO, or distilled) and pat it dry with a clean

soft lint-free cloth. Use caution not to touch the ISE membrane.

18. Fill the protective cap half-full with lower valued prepared calibration solution. Carefully put the cap back on the sensor for

conditioning (using caution as excess solution may squirt out).

NOTE: Individual calibration points can be verified by retesting the prepared calibration solutions. The PT6 will also check the

gain/slope of the calibration during a 2-point calibration. If, after the second calibration point the PT6 detects an error in the

gain/slope, it will display “Error”. If this happens, clean and condition the sensor, then verify you are using approved and properly

prepared calibration solutions, and recalibrate.

NOTE: If at any point during calibration you do not submerge the sensor in solution before the flashing slows, allow the pen to

power OFF and start over.

III. 1-POINT CALIBRATION

1. Remove the protective cap. Rinse the sensor for about 5 seconds with clean water (preferably DI, RO, or distilled) and pat it

dry with a clean soft lint-free cloth.

2. Press and release the push button to turn the PT6 ON.

3. Push and hold the push button to enter menu mode.

4. Release the button while “CAL” is displayed. The display will alternate between “PUSHnHLD” and “CAL”.

5. Push and hold the push button. The display will alternate between “1 ppm”, “10 ppm”, “100 ppm”, “1000 ppm”, and “ESC”.

6. Release the push button while the desired calibration solution value is displayed. The LED will begin to flash rapidly.

7. While the LED flashes rapidly, dip the pen in the calibration solution so that the sensor is completely submerged and swirl it

around to remove any bubbles that may have been caught in the sensor.

8. While the LED flashes slowly, the display will show “[value] ppm”. Hold the sensor steady during calibration.

9. If the calibration is successful, the display will indicate “SAVEd”, then “PUSHnHLD” will be displayed.

10. Press and release the button to exit or allow the PT6 to time out WITHOUT pushing the button.

11. Verify calibration by retesting the prepared calibration solution. The value should be within ±10% of the stated value of the

standard solution.

12. Fill the protective cap half full with prepared calibration solution. Carefully put the cap back on the sensor for conditioning

(using caution as excess solution may squirt out).

NOTE: If at any point during calibration you do not submerge the sensor in solution before the flashing slows, allow the pen to

power OFF and start over.

IV. FACTORY CALIBRATION

The PT6 can be returned to factory default calibration using the FAC CAL function. This will erase any stored wet calibration.

NOTE: Default factory calibration resets the electronics only and does NOT take the condition of the sensor into consideration.

To return your unit to factory calibration:

1. Press and release the push button to turn the PT6 ON.

2. Push and hold the push button to enter menu mode.

3. Release the button when “FAC CAL” displays. The display will alternate between “PUSHnHLD” and “FAC CAL”.

4. Push and hold the push button. “SAVEd FAC” will be displayed indicating the pen has been reset to its factory calibration.

Page 5

5

NITRATE MEASUREMENT

I. MEASUREMENT PREPARATION

The following steps should be taken prior to performing a measurement with your PT6:

1. Perform a calibration check with calibration solution, and if the reading is off more than 10%, calibrate the PT6. (See

CALIBRATION).

2. Prepare test solution:

a. Fill the Graduated Cylinder to the 10 mL line with solution to be tested.

b. Add 200 µL of the Nitrate ISA Solution to the Graduated Cylinder (using the supplied 100 µL pipette).

NOTE: When using the pipette to draw, depress pipette to 1st stop, then place tip in solution and slowly release. To

dispense, depress pipette completely to the 2nd stop.

NOTE: Do not contaminate the pipette tip by touching it with your fingers or setting it in a dirty toolbox. Do not dip the

pipette tip in the calibration solution as this will cause cross-contamination between solutions.

c. Replace the cap on the Graduated Cylinder and shake well to mix the prepared test solution.

II. NITRATE MEASUREMENT

For highest accuracy, the temperature of the calibration solution(s) should be the same as the temperature of the test

solution(s). The temperature difference should be no more than ±2oC/±3.6oF.

1. Remove the protective cap. Rinse the sensor for about 5 seconds with clean water (preferably DI, RO, or distilled) and pat it

dry with a clean soft lint-free cloth.

2. Press and release the push button to turn the PT6 ON.

3. Dip the PT6 sensor in the prepared test solution and swirl it around to remove any air bubbles.

4. Hold the PT6 sensor steady in the solution while the measurement is taking place.

The following table explains what the LED Indicator Light signals indicate and gives the duration of each signal:

LED SIGNAL

ACTION

DURATION

Rapid Flashing

Dip sensor in solution and swirl to remove bubbles.

6 sec

Slow Flashing

Measurement in process; hold the sensor steady during measurement.

In HOLD mode real-time readings are displayed until the LED is ON solid.

In LIVE mode real-time readings are displayed until the PT6 turns OFF.

90 sec in HOLD mode

Up to 300 sec in LIVE mode

Solid Light (HOLD mode only)

Measurement is complete. Values are displayed until the PT6 turns OFF.

6 sec

5. Remove the sensor from the solution and rinse with clean water (preferably DI, RO, or distilled) and pat it dry with a clean

soft lint-free cloth. Use caution not to touch the ISE membrane.

6. Fill the protective cap half full with prepared calibration solution. Carefully put the cap back on the sensor for conditioning

(using caution as excess solution may squirt out).

NOTE: You can turn OFF the unit at any time during LIVE measurement with a simple press and release of the push button.

• For best results when measuring solution at the extremes of the specified temperature or nitrate range allow the PT6 to

equilibrate by submerging the sensor in the sample solution for 1 minute prior to taking a measurement.

• ALWAYS make sure the nitrate sensor is completely submerged in the solution being tested.

• For multiple samples, regularly perform a calibration check with calibration solution between sample measurements.

III. INTERFERENCE

Other anions in solution may interfere with nitrate measurement, depending on the species and their relative levels to nitrate. The

impact of interference ions on measurements can be expressed by the Nikolsky equation.

𝐸 = 𝐶𝑜𝑛𝑠𝑡𝑎𝑛𝑡 +

!.!"!!"

!!!

log (𝑎 + 𝐾

!

𝑎

!

!!

!

!

)

Where 𝐸- the voltage sensor measures

𝑎 - the activity of nitrate

𝑎!- the activity of interference ion

𝑧!- the charge of the interference ion with sign

𝐾

!

–the Selectivity coefficient of the interference ion for nitrate measurement

Generally, interference ions may cause positive errors for the measurement. The higher selectivity coefficient the interference ion

has, the higher error it may cause at a given concentration. The approximate selectivity coefficients of PT6 for some anions are

SO

4

2-

Cl-

CH3COO-

K(NO

3

-

/x)

0.00016

0.007

0.0007

Page 6

6

listed above. For example, if the activity of Cl- is ten times higher than nitrate in the sample, Cl- may cause 7% error for the nitrate

measurement, while CH3COO- and SO

4

2-

in the same ratio may only cause 0.7% and 0.05% error, respectively.

When testing samples with high interference levels, such as wastewater, chlorinated water, and soil water, the interference ions

will be counted as nitrate with the coefficient factor and cause measurement errors. Some commonly existing interference ions,

such as Cl-, Br-, I-, S2-, HCO

3

-

and NO

2

-

can be reduced by using Nitrate Interference Suppression Buffer (NISB). Add NISB at 1:1

volume ratio to all sample/standard solutions (e.g. add 5 mL NISB to 5 mL solution) in place of ISA throughout the sensor

conditioning, calibration and measurement.

NOTE: Nitrate Interference Suppression Buffer (NISB) is purchased separately, see ACCESSORIES.

NOTE: When using NISB, do NOT add ISA. White precipitate may form in sample solution after mixing with NISB, it will not

affect the measurement.

NOTE: Strong interference ions such as ClO

4

-

and SCN- require their concentrations to be up to 2000x lower than nitrate in the

sample to avoid high errors.

IV. MEASUREMENT VALIDATION METHODS:

1. Calibration Check:

a. Choose one standard solution within the testing range, and prepare the solution according to the measurement procedure.

b. Test readings in the standard solution and the value should be within 10% of the expected value. If not, the measurement

result may not be reliable. The source of error should be identified and the measurement should be redone after

correction.

2. Known Addition Recovery Check:

This validation method works well for validating low concentration measurement (1-60 ppm-N) by using concentrated

standard solutions to increase the nitrate concentration in the sample by a known value, optimally double the measured value,

and then compare the value with the increase in Pen readings. For about 10 mL sample, one spike of standard solution with

the 100 µL pipette will increase the sample nitrate concentration by roughly 1% of the standard solution concentration,

example ~1 ppm increase by one spike of 100 ppm standard solution, ~10 ppm increase by one spike of 1000 ppm standard

solution.

Spike reference for different sample concentration for 10 mL sample volume (V/mL)

Measured Sample Concentration (ppm NO

3

-

-N)

×100 µL pipette

Standard Solution (ppm NO

3

-

-N)

1-3 1 100

3-9 3 100

9-20

1

1000

20-60

3

1000

a. Add n spikes (volume increase: 𝑽

𝒂𝒅𝒅

=0.1×n/mL) of standard solution (Cs/ppm) to the sample solution after measurement

(C1/ppm) and swirl for mixing.

b. Take the 2nd measurement (C2/ppm) and calculate the recovery using the following equation.

𝑅𝑒𝑐𝑜𝑣𝑒𝑟𝑦 % =

𝐶!×100

𝑉×𝐶!+𝑉

!""×𝐶!

×(1/(1 − 𝐷!))

(𝑉

!""

+ 𝑉)

Where Df is the dilution factor when spiking unprepared standard solutions, 1/51 for using ISA and ½ for using NISB. If

adding prepared standard solutions, Df is 0.

The recovery should be within 10% of the expected value. If not, the measurement result may not be reliable. The source of

error should be identified and the measurement should be redone after correction.

MAINTENANCE

I. ROUTINE MAINTENANCE

1. After each use ALWAYS rinse the Nitrate sensor with clean water (preferably DI, RO, or distilled) and then carefully pat the

sensor with a clean, soft, lint-free cloth to remove any water drops.

2. ALWAYS replace the protective cap on the Nitrate sensor after each use.

3. Do not touch the ISE membrane as oil from your finger may contaminate the sensor.

4. Do not drop, throw, or otherwise strike the PT6 as this may void the warranty.

5. Do not store the PT6 in a location where the ambient temperatures exceed its operating/storage temperature limits.

Page 7

7

6. The Nitrate sensor needs to be conditioned after dry storage, see SENSOR CONDITIONING.

II. STORAGE

After each use ALWAYS rinse the Nitrate sensor with clean water (preferably DI, RO, or distilled) and then carefully pat the

sensor with a clean soft lint-free cloth to remove any water drops.

1. Short term storage (<=3 days):

Keep the sensor in the protective cap filled half-full with prepared 100 ppm standard solution (DO NOT use standard solution

prepared with NISB for storage). Store the PT6 in a cool place.

2. Long term storage (>3 days):

a. Rinse the Nitrate sensor with clean water (preferably DI, RO, or distilled) and then carefully pat the sensor with a clean

soft lint-free cloth to remove any water drops.

b. Rinse the protective cap with clean water (preferably DI, RO, or distilled), pat with a clean soft lint-free cloth to remove

any water drops.

c. Put the protective cap on the sensor and store the PT6 in a cool place.

III. BATTERY REPLACEMENT

The PT6 display has an indicator that depicts the PT6’s battery charge

level. When the charge level indicator only shows one bar,

immediately replace the battery with a new N type battery.

1. In a CLEAN and DRY place unscrew the battery cap in a counter-

clockwise motion.

2. Slide the cap and battery housing out of the PT6.

3. Remove the depleted battery from its housing.

4. Insert a new battery into the battery housing oriented with the

negative end touching the spring.

5. Align the groove along the battery housing with the guide bump

inside the PT6 case and slide the battery housing back in.

6. Screw the battery cap back on in a clockwise direction. Do not over tighten.

IV. REPLACING OR REINSTALLING THE NITRATE SENSOR

• Follow the instructions that come with your replacement sensor.

• Only remove/replace the Nitrate sensor in a CLEAN and DRY environment.

To remove the Nitrate sensor:

1. Remove the protective cap by wiggling it side to side while you pull it off the PT6.

2. Make sure the PT6 (including the sensor) is clean and dry.

3. Loosen the battery tray (to allow pressure equalization).

4. Firmly grasp the sensor body and slowly pull the sensor out. DO NOT allow any dust or moisture into the body of the PT6.

To install a new Nitrate sensor:

1. Line up the alignment tabs on the sensor with the alignment slots on the PT6 unit.

2. Gently push the sensor into position.

3. Tighten the battery cap.

NOTE: The PT6 MUST be recalibrated any time the Nitrate sensor is replaced.

V. TROUBLESHOOTING

1. SENSOR CHECK

Sensor Check verifies the slope of the recent calibration. If readings are not as expected, or measurements of calibration solutions

after calibration are not within ±10% of the printed value, checking the slope of current calibration can be a starting point for

troubleshooting. To do a Sensor Check:

1. Press and release the push button to turn the PT6 ON.

2. Push and hold the push button to enter menu mode.

3. Release the button while “SEnSor √” is displayed. The display will flash “SEnSor √” and then indicate the mV value of the

slope for current calibration.

4. A gain ranging between -50 to -62 mV indicates a normal calibration in the linear range. Values beyond that may indicate a

calibration out of the linear range, an insufficiently conditioned sensor, or a worn membrane. Most of the time the issue can

be resolved by conditioning the sensor for at least one hour and re-doing a 2-point calibration. If the problem persists, the

sensor should be replaced.

NOTE: The gain range of -50 to -62 mV is based on a calibration temperature of 25˚C.

Page 8

8

2. UNSTABLE READINGS / SLOW RESPONSE

A soiled membrane or dry reference junction can cause unstable/slow response of sensors. Rinse the sensor with plenty of water

and recondition the sensor in 100 ppm standard solution for at least one hour.

Temperature changes, pH variation of solutions, or ambient electrical noise may also contribute to the issue. The source should be

identified and corrected.

SPECIFICATIONS

Nitrate as Nitrogen NO

3

-

-N

Nitrate NO

3

-

Temperature

Ranges

1-1400 ppm

4.4-6200 ppm

0-71˚C / 32-160˚F

Accuracy1

±10% of the reading

±10% of the reading

± 0.1°C

Resolution

0.1 ppm

0.1 ppm

0.1°C/F

pH Range: 3 to 11 pH

Time to Reading Stabilization: 10 - 180 seconds

Power Consumption: Active Mode: 33 - 140 mA

Physical Dimensions: 17.15 cm L x 1.59 cm D or 6.75 in. L x .625 in. D

Weight: 54 g or 1.94 oz.

Case Material: Anodized Aircraft Aluminum with Protective Coating

Battery Type: One N type, Alkaline 1.5 V

Calibration Standard Solutions: 1, 10, 100, or 1000 ppm NO

3

-

-N

Operating / Storage Temperature: 0-40ºC / 32-104ºF 2

Enclosure Ratings: IP67 and NEMA 6

EN61236-1: 2006 - Annex A: 2008: Electrostatic discharge to the PT6 may cause it to spontaneously power ON.

In this case, the PT6 will power OFF after several seconds.

WARNING! These products can expose you to chemicals including Di(2-ethylhexyl)phthalate (DEHP), which is known to the

State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov

1

Accuracy of measuring calibration solutions after Temperature Controlled 2-Point Calibration with one order of concentration difference.

2

For extended life of the sensor, store the PT6 in a cool location (5-25˚C). DO NOT FREEZE!

EPA Approved Standard Method 4500-NO

3

-

D*

This method using the nitrate ion selective electrode is one of EPA approved methods for measuring nitrate in drinking water and

wastewater, listed in USA Code of Federal Regulations Title 40 Part 136 and Part 141. The PT6 is compatible to follow this

method. Consult with your regulator for reporting purposes.

* Standard Methods for the Examination of Water and Wastewater 20th Edition, published by American Public Health Association,

Washington, D.C., 20005. USA. www.standardmethods.org.

ACCESSORIES

STANDARD SOLUTIONS FOR CALIBRATION:

The ULTRAPEN™ PT6 can be calibrated with 1, 10, 100, or 1000 ppm NO

3

-

-N Standard Solution.

Order Models:

• N1SOL - 1 ppm NO

3

-

-N (Nitrate as Nitrogen) Standard Solution

• N10SOL - 10 ppm NO

3

-

-N (Nitrate as Nitrogen) Standard Solution

• N100SOL - 100 ppm NO

3

-

-N (Nitrate as Nitrogen) Standard Solution

• N1000SOL - 1000 ppm NO

3

-

-N (Nitrate as Nitrogen) Standard Solution

IONIC STRENGTH ADJUSTER:

Order Model: NISASOL

NITRATE INTERFERENCE SUPPRESSION BUFFER:

Order Model: NISBSOL

REPLACEMENT NITRATE SENSOR:

Order Model: RPT6

WARRANTY

The PT6, excluding the sensor and battery, has a one (1) year limited warranty.

The Nitrate sensor has a six (6) month limited warranty.

MYRON L® COMPANY

2450 Impala Drive u Carlsbad, CA 92010-7226 u Phone: +1-760-438-2021

E-Mail: Customer Service – info@myronl.com u Technical Support – techquestions@myronl.com

Website: www.myronl.com

PT6OM 09/18

Loading...

Loading...