Myron L ULTRAMETER III 9PTKB, POOLPRO PS9TKB Operation Manual

ULTRAMETER

Operation

Manual

MODEL 9PTKB

III

™

®

24 July 2019

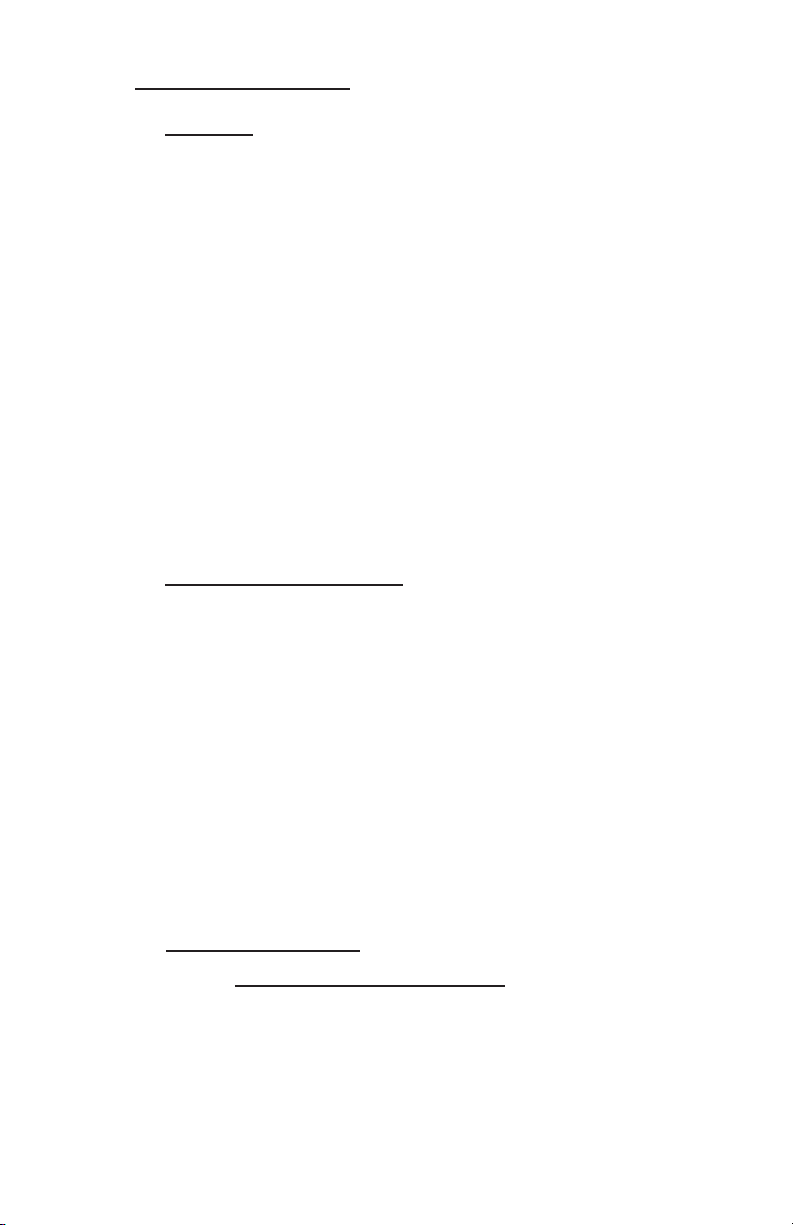

THE 9P TITRATION KIT (WITH BLUDOCKTM OPTION)

COMES WITH EVERYTHING YOU SEE HERE

3

4

10 11

9

8

7

6

1

18

17

16

15

14

13

12

5

2

19

PLEASE CHECK THE CONTENTS OF YOUR KIT!

1. Ultrameter III™ Model 9P-BD

2. Cell Extender Model TKCE

3. Foam-lined hard carry case

4. M’PET 100µL xed volume pipette Model FVMP-100

5. 12 disposable pipette tips

6. 2oz. bottle of Alkalinity Standard Solution Model ALK-1002OZ

7. 2oz. bottle of Hardness Standard Solution Model HARD-2002OZ

8. 2oz. bottle of pH 4 buffer Model PH42OZ

9. 2oz. bottle of pH 7 buffer Model PH72OZ

10. 2oz. bottle of pH 10 buffer Model PH102OZ

11. 2oz. bottle of pH/ORP Sensor Storage Solution Model SS2OZ

12. 2oz. bottle of Alkalinity Reagent A1 Model H2SO4-12OZ

13. 2oz. bottle of Hardness Reagent HB, Model HBUFF2OZ

14. 2oz. bottle of Hardness Reagent H4, Model EDTA-B-LC2OZ

15. 2oz. bottle of Hardness Reagent H5, Model EDTA-B-HC2OZ

16. 1oz. bottle of ORP ISA Sensor Conditioner Model ORPCOND1OZ

17. 2oz. bottle of KCl-7000 Model KCL-70002OZ

18. 2oz. bottle of 442-3000 Model 442-30002OZ

19. Titration T-plunger Model TPLUNGER

i

ii

I. INTRODUCTION

Thank you for selecting the feature-packed Ultrameter III™, one of the

Myron L® Company’s latest in an increasing line of instruments utilizing

advanced microprocessor-based circuitry and SMT manufacturing

processes. This circuitry makes the instrument extremely accurate,

reliable and very easy to use.

The Ultrameter III has been designed to include titration measurements

for Alkalinity, Hardness and an LSI Calculator for water balance analysis.

The Ultrameter III also features Myron L® Company's exclusive Free

Chlorine Equivalent (FC

TM

E

) function for making ORP-based free chlorine

measurements, as well as optional Bluetooth® wireless data transfer.

Other features include a clock with time and date, memory of up to 100

locations with time and date stamp, the ability of the user to adjust the

timeout “Auto OFF”, and enhanced performance. See Features and

Specications on pages 2-3.

The most exciting feature is data logging with the ability to wirelessly

download the memory or stored test data with its corresponding time, date

and unit name (requires -BD option or bluDockTM accessory). This feature

allows the user to create spreadsheets and graphs with ease, and quickly

and accurately manipulate data more effectively. The bluDock's Guardian

TM

2 TM

application will operate on Windows® 7 or later/macOS® 10.13 or later with

Bluetooth® capability. The data may be exported to spreadsheet formats

such as Microsoft Excel® (.xls and .xlsx) or universal formatting (.csv). The

user can also save data in a secure, encrypted format (.mlcx).

Please Note: Although the Myron L® Company has performed extensive

testing, we cannot guarantee compatibility of all applications and

formats. We suggest testing your application and format for compatibility

before relying on it.

For your convenience, a brief set of instructions is provided on the

bottom side of your Ultrameter III. A Quick Start Guide with abbreviated

instructions is also included with the instrument as a quick reference.

Special note ... Conductivity, resistivity, and TDS require mathematical

correction to 25°C values (ref. Temperature Compensation, pg. 56). On

the left of the Ultrameter III’s liquid crystal display is shown an indicator of

the salt solution characteristic used to model temperature compensation

of conductivity and its TDS conversion. The indicator may be KCl,

NaCl, 442™ or User. Selection affects the temperature correction of

conductivity and the calculation of TDS from compensated conductivity

(ref. Conductivity Conversion to Total Dissolved Solids (TDS), pg. 59).

The selection can affect the reported conductivity of hot or cold solutions

and will change the reported TDS of a solution. Using KCl for conductivity,

NaCl for resistivity, and 442™ (Natural Water characteristic) for TDS is

consistent with present industry practice for standardization. This is how

your instrument, as shipped from the factory, is set to operate. For use in

seawater desalination for example, both the conductivity and TDS may

easily be changed to NaCl.

1

II. FEATURES and SPECIFICATIONS

A. Features

• ORP-based FCE Free Chlorine measurement; displays as ppm

concentration

• Alkalinity and Hardness Conductometric Titrations

• Langelier Saturation Index (LSI) Calculator

• Superior resolution 4 digit LCD displays full 9999 µS/ppm

• Cond/TDS Accuracy of ±1% of READING / ±0.1% at calibration point

• All electrodes are internal for maximum protection

• Improved 4-electrode sensor technology

• Waterproof to 1 meter/3 feet

• Autoranging conductivity/TDS/resistivity

• Prompts for easy pH calibration

• Factory calibrations stored in microprocessor

• 3 conductivity/TDS solution conversions preprogrammed into

microprocessor

• User mode feature allows:

Programming your own Cond/TDS conversion factor

Programming your own temperature compensation factor

Disabling temperature compensation

• Real Time Clock with Time and Date

• Data Logging with TIME and DATE in memory

• Memory stores 100 readings

• User adjustable timeout “Auto OFF”

• Bluetooth® wireless download capability with optional bluDock™

accessory package

B. General Specications

Display 4 Digit LCD

Dimensions (LxWxH) 196 x 68 x 64 mm/

7.7 x 2.7 x 2.5 in.

Weight 352 g/12.4 oz.

Case Material VALOX*

Cond/Res/TDS Cell Material VALOX*

Cond/TDS Electrodes (4) 316 Stainless Steel

Cond/Res/TDS Cell Capacity 5 ml/0.17 oz.

pH/ORP Sensor Well Capacity 1,2 ml/0.04 oz.

Power 9V Alkaline Battery

Battery Life >100 Hours/5000 Readings

Operating/Storage Temperature 0-55°C/32-131°F

Protection Ratings IP67/NEMA 6 (waterproof to

1 meter/3 feet)

EMI/EMC Ratings EN61326-1: 2006 + Annex A: 2008

(hand-held devices)

(Conformité Européenne)

IEC 61000-4-2: 2001 and,

IEC 61000-4-3: 2002

* ™ SABIC Innovative Plastics IP BV

Additional information is available on our website:

CISPR 11: 2003

www.myronl.com

MADE IN USA

2

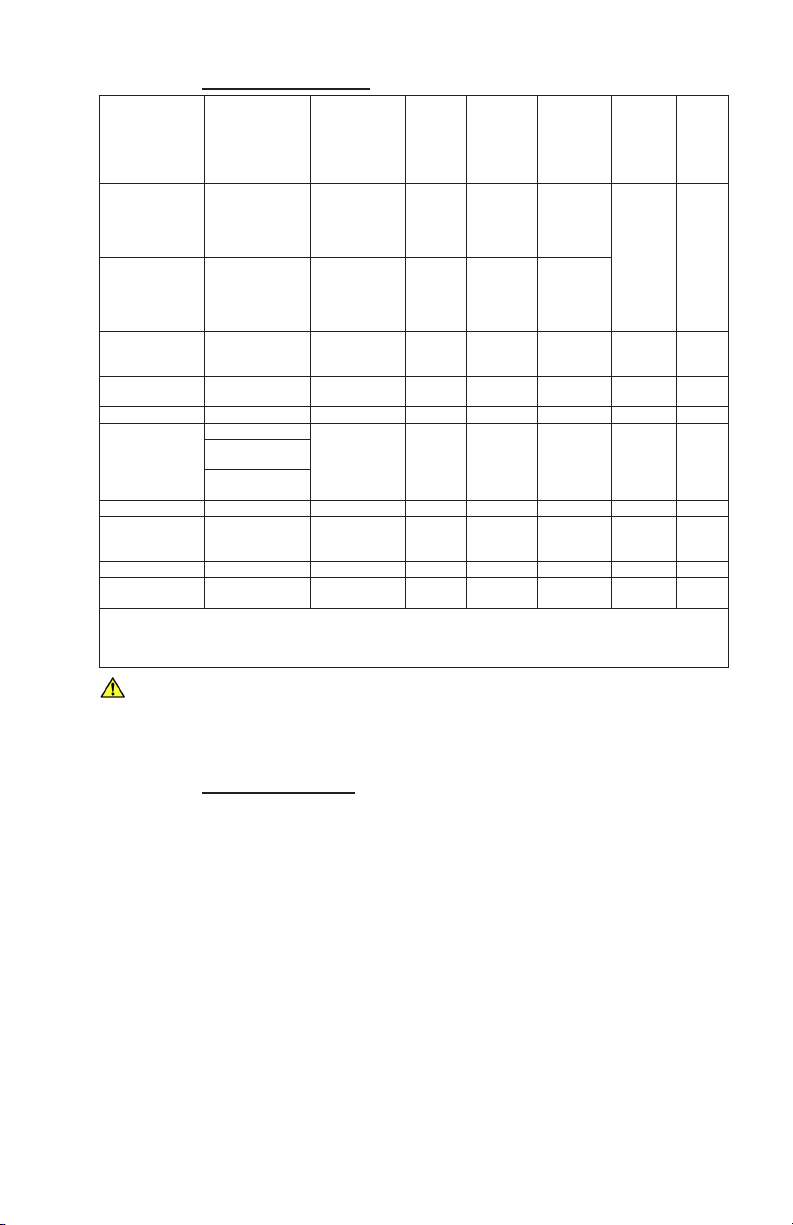

C. Specication Chart

*

*

*

Auto

Temperature Compensation

0-71ºC

32-160ºF

0-71ºC

32-160ºF

0-71ºC

32-160ºF

0-71ºC

32-160ºF

0-71ºC

32-160ºF

Parameters Ranges Resolution

0.01(<100µS)

0.1(<1000µS)

1(<10mS)

0.01(<100mS)

0.1(<200mS)

0.01(<100ppm)

0.1(<1000ppm)

1(<10ppt)

0.01(<100ppt)

0.1(<200ppt)

0.01(<100KΩ)

0.1(<1000KΩ)

0.1(>1MΩ)

0.01ppm

0.1(<1000 ppm)

1(<1710 ppm)

0.1(<100 grains)

0.1ºC/ºF ±0.1ºC

350≤ORPmV<725

)

725≤ORPmV<825

0-9999µS/cm

10-200mS/cm

in 5 autoranges

0-9999ppm

10-200ppt

in 5 autoranges

0.00-9.99ppm**

and 0.0≤pH<9.9

and 0.0≤pH<8.9

0-1710ppm

(0-100 grains)

0-71ºC

32-160ºF

Conductivity

TDS

Resistivity 10KΩ-30MΩ

pH 0-14pH 0.01pH ±0.01pH

ORP ±999mV 1mV ±1mV

Free Chlorine

Equivalent

TM

E

(FC

Alkalinity Titration 10-800ppm 0.1ppm

Hardness Titration

LSI Calculator -10 to +10 0.01

Temperature

*EM Susceptibility: When Measuring 10.0 pH Reference Solution

±0.2 pH in the presence of RF elds ≥ 3 V/m.

±0.37 pH in the presence of RF elds at 300 MHz (±30MHz)

**If either ORP or pH is outside the specied limits, the instrument will display "-Or-".

Accu-

racy

±1% of

reading

±1% of

reading

±1% of

reading

±0.3ppm

<1.00ppm*

±0.2ppm

≥1.00ppm

Adjustable

Temperature Compensation

0-9.99%/ºC

0-9.99%/ºC

0-9.99%/ºC

Cond/TDS

Ratios

Prepro-

grammed

KCl, NaCl,

442™

Adjust-

able

Cond/

TDS

Ratio

Factor

0.20-

7.99

WARNING: These products can expose you to chemicals including

Di(2-ethylhexyl)phthalate (DEHP), which is known to the State of

California to cause cancer and birth defects or other reproductive harm.

For more information go to www.P65Warnings.ca.gov

D. Warranty/Service

The Myron L® Ultrameter III, excluding the pH/ORP sensor, has a Two

(2) Year Limited Warranty. The pH/ORP sensor has a Six (6) Month

Limited Warranty for materials and workmanship. If an instrument fails

to operate properly, see Troubleshooting Chart, pgs. 52-53. The battery,

pH/ORP sensor and cell extender are user-replaceable. For other

service, return the instrument prepaid to the Myron L® Company.

MYRON L® COMPANY

2450 Impala Drive

Carlsbad, CA 92010-7226 USA

+1-760-438-2021

E-Mail: info@myronl.com

techquestions@myronl.com

www.myronl.com

If, in the opinion of the factory, failure was due to materials or

workmanship, repair or replacement will be made without charge. A

reasonable service charge will be made for diagnosis or repairs due to

normal wear, abuse or tampering. This warranty is limited to the repair or

replacement of the Ultrameter III only. The Myron L® Company assumes

no other responsibility or liability.

3

E. Ultrameter

Model

III

Ultrameter III Model 9P

PARAMETERS

Conductivity/Resistivity/TDS/Alkalinity/Hardness/LSI/ORPmV/

Free Chlorine Equivalent (FCE) ppm/pH/Temperature

PLEASE NOTE:

Because of our commitment to product improvement, the substance and

style of this manual may change. When changes are made, the updated

manual is posted for download in PDF format from the Myron L® Website:

www.myronl.com

4

TABLE OF CONTENTS

9PTK Contents ............................................i

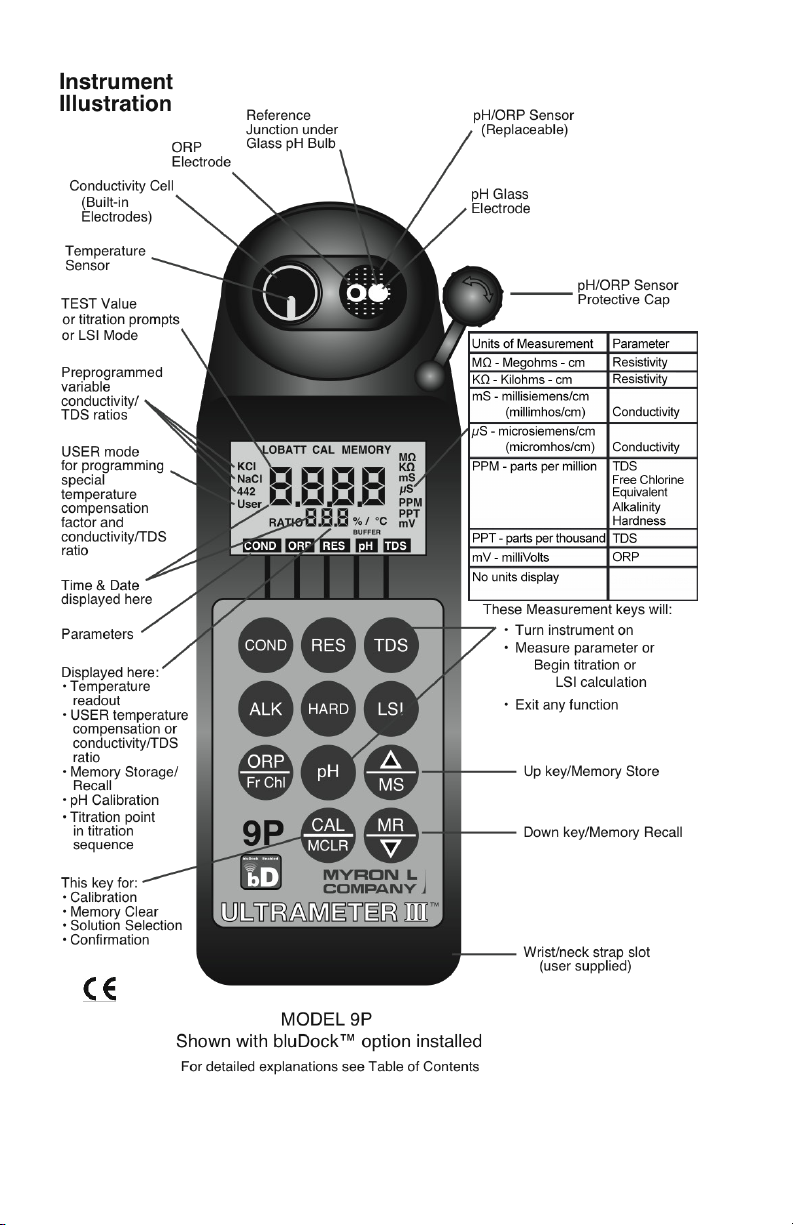

Instrument Illustration ...................................... ii

I. INTRODUCTION ................................... 1

II. FEATURES and SPECIFICATIONS ....................2

A. Features ................................2

B. General Specications .....................2

C. Specication Chart ........................3

D. Warranty/Service..........................3

E. Ultrameter III Model .......................3

III. RULES of OPERATION..............................8

A. Operation ...............................8

B. Characteristics of the Keys ..................8

C. Operation of the Keys ......................8

1. Measurement Keys in General......... 8

2. COND, RES and TDS Keys ........... 9

3. Alkalinity, Hardness and LSI Keys . . . . . . 9

4. pH and ORP/FCE Keys ...............10

5. CAL/MCLR Key ...................10

6. UP or DOWN Keys................. 10

IV. AFTER USING THE ULTRAMETER III................. 11

A. Maintenance of the Conductivity Cell ......... 11

B. Maintenance of the pH/ORP Sensor.......... 11

V. SPECIFIC RECOMMENDED MEASURING

PROCEDURES ...................... 11

A. Parameter Methods....................... 11

B. Titration Methods......................... 11

1. Pipette Instructions................. 12

2. T-plunger Instructions...............13

3. Mixing Solution in Cell ..............13

C. Measuring Conductivity &

Total Dissolved Solids (TDS) ............ 14

D. Measuring Resistivity .....................14

E. Measuring Alkalinity ......................14

F. Measuring Hardness......................16

1. Hardness Unit Selection............. 16

2. Select EDTA Reagent...............16

3. Hardness Titration Procedure ........16

G. LSI Calculator Functions...................18

1. Measuring LSI ....................19

2. Hypothetical LSI Calculations ........19

H. Measuring pH ...........................19

I. Measuring ORP..........................20

1. ORP/FCE Mode Selection ...........20

2. Measuring ORP ...................21

J. Measuring FCE ..........................21

1. Prepare for FCE Measurement ........ 21

2. FCE Flow Method ..................21

3. FCE Immersion Method .............22

4. FCE Best Practices ................. 23

5

VI. SOLUTION SELECTION ............................ 23

A. Why Solution Selection is Available .......... 23

B. The 4 Solution Types ..................... 23

C. Calibration of Each Solution Type ............ 23

D. Procedure to Select a Solution ..............23

E. Application of User Solution Type ............24

1. User Programmable Temperature

Compensation (Tempco) ........24

2. Disabling Temperature Compensation ...25

3. User Programmable Conductivity to

TDS Ratio .................... 25

VII. CALIBRATION....................................26

A. Calibration Intervals ......................26

B. Rules for Calibration of the Ultrameter III ......26

1. Calibration Steps ..................26

2. Calibration Limits ..................28

C. Calibration Procedures ....................28

1. Conductivity or TDS Calibration ....... 28

2. User Calibration Conductivity/TDS..... 28

3. Resistivity Calibration...............29

4. Reloading Factory Calibration

(Cond or TDS) ................29

5. Alkalinity Calibration................29

6. Hardness Calibration ...............31

7. pH Calibration ....................33

8. ORP Calibration ...................35

9. Temperature Calibration.............35

VIII. CALIBRATION INTERVALS .........................35

A. Suggested Intervals ......................35

B. Calibration Tracking Records ...............35

C. Conductivity, RES, TDS Practices............36

D. pH and ORP/FCE Practices.................36

IX. MEMORY........................................36

A. Memory Storage .........................36

B. Memory Recall ..........................37

C. Clearing a Record/Memory Clear ............37

X. TIME and DATE................................... 38

A. Setting TIME ............................38

B. Setting DATE............................39

C. DATE FORMAT “US & International (Int)” ...... 40

XI. TEMPERATURE FORMAT “Centigrade & Fahrenheit” .....41

XII. TOTAL RETURN to FACTORY SETTINGS..............41

XIII. CELL CHECK ....................................42

XIV. AUTO OFF ......................................43

XV. USER MODE CALIBRATION LINC™ FUNCTION ........44

A. Calibration of Ultrameter III for use in

User mode .......................... 44

B. Setting User mode Calibration “Linc” .........45

C. Canceling User mode Calibration “Linc” .......46

XVI. bluDock™ Wireless Data Transfer Instructions...........47

6

A. Software Installation ......................47

B. Hardware Setup .........................47

C. Memory Stack Download ..................48

XVII. CARE and MAINTENANCE ......................... 49

A. Temperature Extremes ....................49

B. Battery Replacement......................49

C. pH/ORP Sensor Replacement .............. 50

D. Cleaning Sensors ........................50

XVIII. TROUBLESHOOTING .............................52

XIX. ACCESSORIES................................... 54

A. Conductivity/TDS Standard Solutions ......... 54

B. Titration Standard Solutions ................54

C. Titration Reagent Solutions ................. 55

D. pH Buffer Solutions .......................55

E. pH Sensor Storage Solution ................55

F. ORP Sensor Conditioner Solution............55

G. Soft Protective Carry Cases ................55

H. Hard Protective Carry Cases ...............56

I. Replacement pH/ORP Sensor ..............56

J. Pipette Kit with Replacement Tips............ 56

K. Replacement M’Pet Pipette.................56

L. M’Pet Pipette Replacement Tips.............56

M. bluDockTM Wireless Data Transfer

Accessory Package................... 56

XX. TEMPERATURE COMPENSATION (Tempco)

of Aqueous Solutions.................. 56

A. Standardized to 25°C .....................56

B. Tempco Variation.........................57

C. An Example of 2 different solution selections

and the resulting compensation.......... 57

D. A Chart of Comparative Error ...............58

E. Other Solutions ..........................58

XXI. CONDUCTIVITY CONVERSION to

TOTAL DISSOLVED SOLIDS (TDS) ......59

A. How it’s Done ...........................59

B. Solution Characteristics ...................59

C. When does it make a lot of difference? ........ 60

XXII. TEMPERATURE COMPENSATION (Tempco)

and TDS DERIVATION ................60

A. Conductivity Characteristics ................60

B. Finding the Tempco of an Unknown Solution ...61

C. Finding the TDS Ratio of an Unknown Solution ... 61

XXIII. pH and ORP/FCE..................................62

A. pH ....................................62

B. ORP/Oxidation-Reduction Potential/REDOX ...64

C. FCE ...................................65

XXIV. ALKALINITY, HARDNESS AND LSI ................... 66

A. Alkalinity and Hardness Titrations............66

B. Langelier Saturation Index .................66

C. Hardness Units ..........................67

XXV. SOFTWARE VERSION .............................67

XXVI. GLOSSARY...................................... 68

7

III. RULES of OPERATION

A. Operation

NOTE: The cell extender does not interfere with normal operation.

Using the instrument is simple:

• Individual or multiple parameter readings may be obtained by

lling individual sensors or entire cell cup area.

• Rinse the conductivity cell and/or pH/ORP sensor well with test

solution 3 times and rell. Temperature and/or measurement

extremes will require additional rinses for maximum accuracy.

• Press the desired measurement key to start measurement.

• For titrations, user intuitive display prompts guide you through

the addition of reagents and measurements.

• Pressing any parameter key again in measurements restarts

the 15 second “Auto off” timer. Pressing any parameter key

again during titrations will cancel the titration in progress.

• Note the value displayed and/or press the MS key to store the

reading (ref. Memory Storage, pg. 36). It’s that simple!

B. Characteristics of the Keys

• Though your Ultrameter III has a variety of sophisticated

options, it is designed to provide quick, easy, accurate

measurements by simply pressing a key.

• All functions are performed one key at a time.

• THERE IS NO “OFF” KEY. If the instrument remains inactive

for 15 seconds after you press any parameter key (user

adjustable up to 75 seconds), the instrument turns itself off.

The instrument turns itself off after 60 seconds of inactivity in

CAL mode, 3 minutes of inactivity in each titration screen and

60 seconds of inactivity in each LSI calculator value screen.

• Rarely is it necessary to press and hold a key (as in Procedure

to Select a Solution, pg. 23; Conductivity or TDS Calibration,

pg. 28; and ORP/FCE Mode Selection, pg. 20).

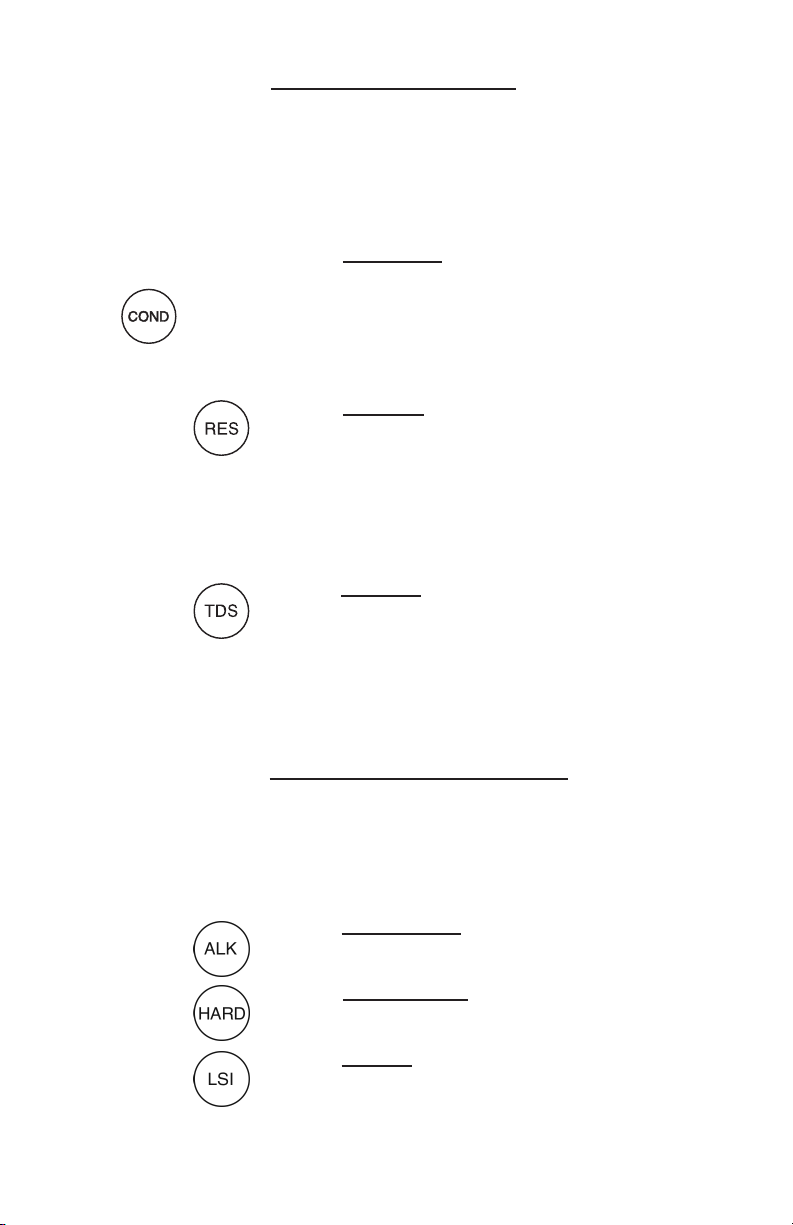

C. Operation of the Keys (See Instrument Illustration, pg. ii)

1. Measurement Keys in General

Any of the 8 measurement keys turns on the instrument in the mode

selected. The mode is shown at the bottom of the display for COND,

RES, TDS, ORP and pH. The ORP mode is indicated by the units

displayed, mV for ORP or ppm for free chlorine. Measurement units

appear at the right. Pressing any measurement key puts the unit in that

measurement mode even if you are in a calibration sequence and also

serves to cancel a change (ref. Leaving Calibration, pg. 27).

8

2. COND, RES and TDS Keys

These 3 keys are used with solution in the Conductivity Cell.

Precautions:

• While lling cell cup, ensure no air bubbles cling on the cell wall.

• If the proper solution is not selected (KCl, NaCl, 442™ or

User), refer to Why Solution Selection is Available, pg. 23 and

Procedure to Select a Solution, pg. 23.

a. COND Key

Solution to be tested is introduced into the conductivity cell and a press

of displays conductivity with units on the right. On the left is

shown the solution type selected for conductivity.

b. RES Key

A press of

is shown solution type selected for resistivity (ref. Solution Selection,

pg. 23). The range of display of resistivity is limited to between 10

kilohms (KΩ) and 30 megohms (MΩ). A solution outside that range will

only show [- - - -] in the display.

c. TDS Key

A press of

This is a display of the concentration of ionized material calculated from

compensated conductivity using the characteristics of a known material.

On the left is shown solution type selected for TDS (ref. Solution

Selection, pg. 23).

displays resistivity with units on the right. On the left

displays Total Dissolved Solids with units on the right.

3. Alkalinity, Hardness and LSI Keys

The ALK and HARD keys enter the titration measurement functions. The

LSI key also allows you to access the LSI Calculator.

NOTE: All titration measurements require the installation of the cell

extender.

a. Alkalinity Key

A press of

b. Hardness Key

A press of

c. LSI Key

A press of

used to measure LSI by pulling the most recent alkalinity, hardness, pH

and temperature values or for hypothetical water balance adjustments.

enters the Alkalinity titration function.

enters the unit in the Hardness titration function.

enters the unit in LSI calculator mode, which can be

9

4. pH and ORP/FC Keys

E

Measurements are made on solution held in the pH/ORP sensor well

(ref. pH and ORP/FCE, pg. 62). The protective cap is removed and

the sensor well is lled and rinsed with the sample enough times to

completely replace the storage solution.

After use, the pH/ORP sensor well must be relled with Myron L®

Storage Solution, and the protective cap reinstalled securely (ref.

Maintenance of the pH/ORP Sensor, pg. 11 and Cleaning Sensors, 2.

pH/ORP, pg. 50).

a. pH Key

A press of

displays pH readings. No units are displayed on the right.

b. ORP/Fr Chl Key

In ORP mode, a press of

displays Oxidation-Reduction Potential

/REDOX reading in millivolts; "mV" is displayed. When the FCE mode

is activated, a press of

reading in "ppm" alternating with the FCE predictive ORP reading in "mV".

displays the Free Chlorine Equivalent

5. CAL/MCLR Key

While measuring conductivity, TDS, or pH, a press of

allows

you to enter the calibration mode. Once in CAL mode, a press of this

key accepts the new value. If no more calibration options follow, the

instrument returns to measuring (ref. Leaving Calibration, pg. 27).

If is held down for about 3 seconds, CAL mode is not entered,

but “SEL” appears to allow Solution Selection (ref. pg. 23) with the UP

or DOWN keys. As in calibration, the CAL key is now an “accept” key.

While measuring ORP or Free Chlorine, holding CAL down for about

3 seconds allows ORP/FCE mode selection (ref. pg. 20).

For titrations and LSI Calculator, the CAL key steps you through the

procedure and accepts values for nal calculations.

Once in CAL mode, a press of this key accepts the new value.

While reviewing stored records, the MCLR side of the key is active to

allow clearing records (ref. Clearing a Record/Memory Clear, pg. 37).

6. UP or DOWN Keys

While measuring in any parameter, the or

keys activate

the Memory Store and Memory Recall functions. A single press steps

the display and holding either key scrolls the value rapidly.

10

While in calibration or calculator mode, the keys step or scroll the

displayed value up or down.

While in Memory Recall, the keys scroll the display up and down

through the stack of records (ref. Memory Recall, pg. 37).

IV. AFTER USING THE ULTRAMETER

A. Maintenance of the Conductivity Cell

Rinse out the cell cup with clean water. Do not scrub the cell. For

oily lms, squirt in a foaming non-abrasive cleaner and rinse (ref.

Cleaning Sensors, pg. 50). Even if a very active chemical discolors

the electrodes, this does not affect the accuracy; leave it alone.

B. Maintenance of the pH/ORP Sensor

The sensor well must be kept wet. Before replacing the rubber cap,

rinse and ll the sensor well with Myron L® pH Sensor Storage Solution.

Although not ideal, if Myron L® Storage Solution is not available, you

can temporarily use a strong KCl solution, a pH 4 Buffer Solution, or a

saturated solution of table salt and tap water until pH Storage Solution is

obtained. NEVER use distilled water.

If all ORP solutions are reporting approximately the same value,

clean ONLY the platinum ORP electrode with an MLC ORP

conditioner-soaked cotton swab, being careful not to touch the

swab to the glass bulb of the pH sensor.

V. SPECIFIC RECOMMENDED MEASURING PROCEDURES

A. Parameter Methods

For Conductivity and Total Dissolved Solids measurements, if the

proper solution is not selected (KCl, NaCl, 442TM or User), see Solution

Selection, pg. 23.

III

NOTE: After sampling high concentration solutions or temperature

extremes, more rinsing may be required. When sampling low

conductivity solutions, be sure the pH cap is well seated so that no

solution washes into the conductivity cell from around the pH cap.

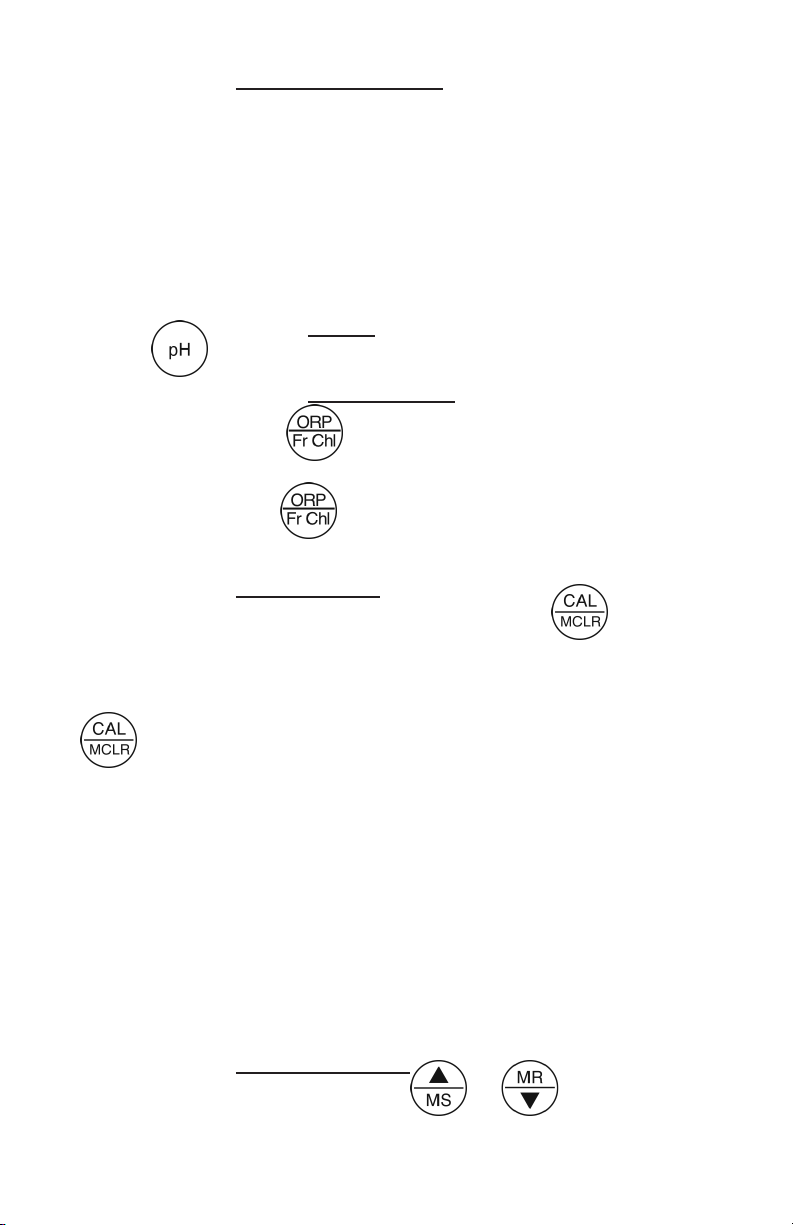

B. Titration Methods

For Alkalinity, Hardness titrations, assemble the required materials

before you begin: a pipette with 100µL tips, the required reagents, the

cell extender, and the T-plunger.

11

NOTE: The accuracy of titration measurements

Plunger Button

is affected by your technique. Be careful when

removing the cap of the cell extender to add

reagents. Flicking the cap or popping it off can

Plunger Rod

cause solution to spill out of the cell extender.

Always use a new pipette tip when changing

solutions to avoid contamination.

CE

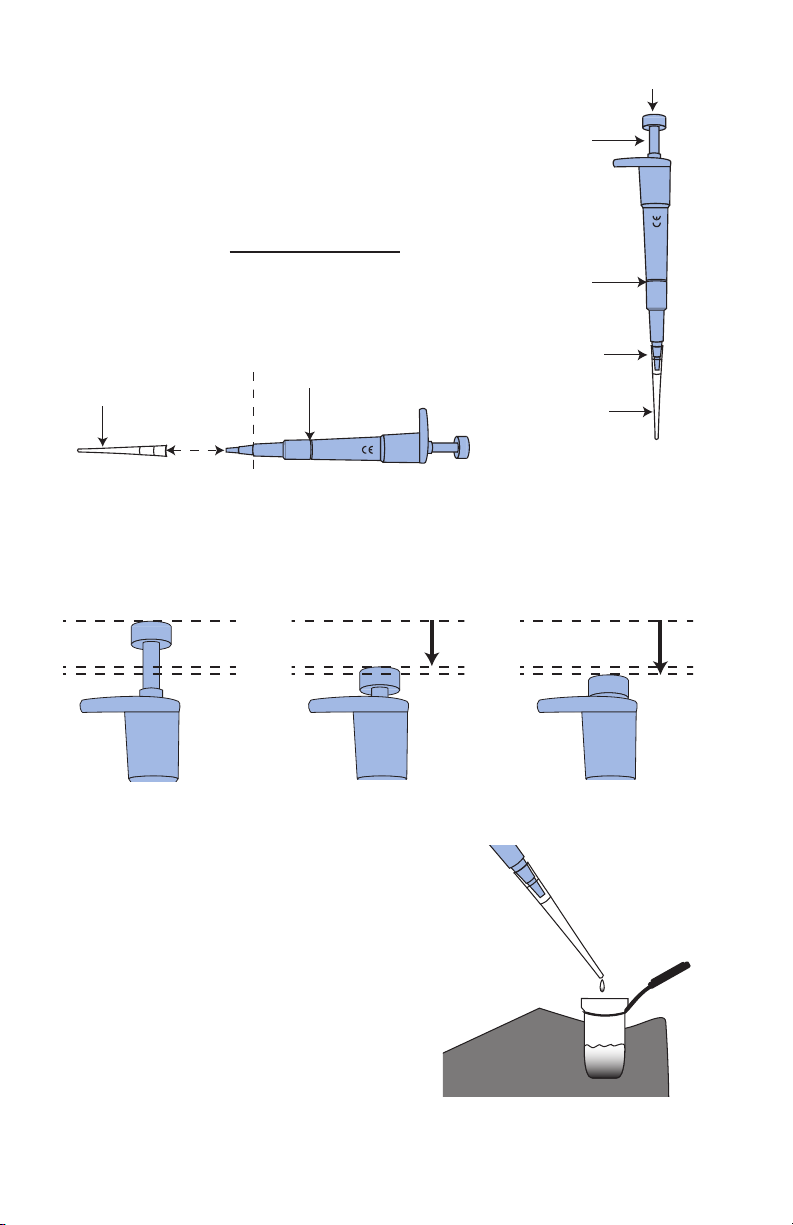

1. Pipette Instructions

100µl

Always use a clean tip when changing

solutions! To install a tip, press the wide end of

Shaft Coupling

100 µL

the tip on the end of the pipette until it is secure.

Avoid contaminating the pipette tips. To remove

a tip, simply pull it off the end of the pipette.

Disposable Tip

Shaft Coupling

100µl

100 µL

Pipette Assembly

CE

Shaft Bottom

Disposable Tip

Fully Assembled Pipette

NOTE: Do NOT twist the cap off as this may unscrew the shaft bottom

from the pipette.

The pipette has 3 positions: REST, FIRST STOP, and SECOND STOP.

Practice pushing in and letting up on the pipette to feel the different

positions.

Rest Position: The

plunger is all the way

U P.

First Stop: The plunger

is depressed until

resistance is felt.

a. To DRAW a

sample: Grasp the pipette by the shaft

with your hand. Rest your thumb on top

of the plunger button. Use your thumb

to depress the top of the pipette to the

FIRST STOP. Insert the tip end down into

sample until only the tip is submerged,

about 2-3mm / 1/8". Slowly release the

top and let it return to the REST position

being careful to keep the tip submerged.

b. To

DISPENSE a sample: With the pipette

in the REST position, place the tip end

12

Second Stop: The

plunger is depressed all

the way DOWN.

Do not allow the pipette tip to touch

the cell wall or the sample.

over the conductivity cell being careful

not to touch the tip to the existing

solution. Depress the top of the pipette

to the SECOND STOP (all the way

down) being careful to keep the tip over

the cell. Release the plunger button and

let it return to the REST position.

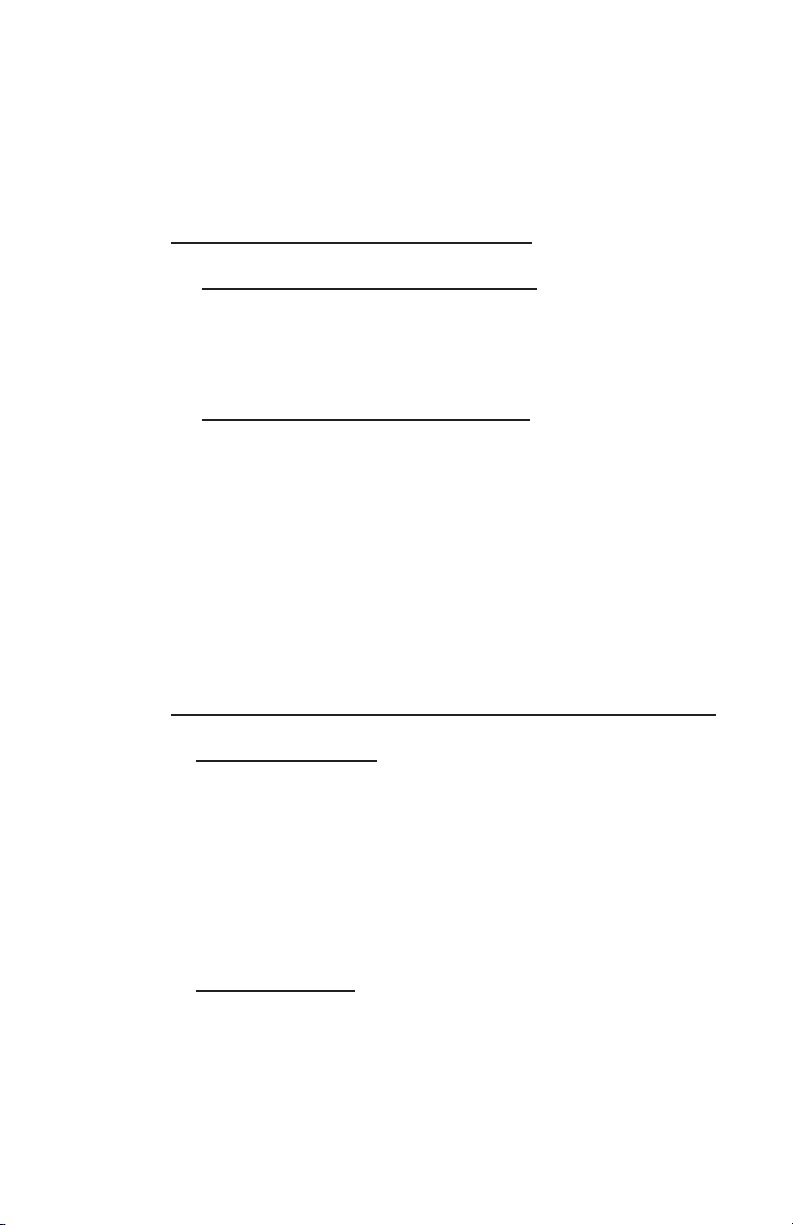

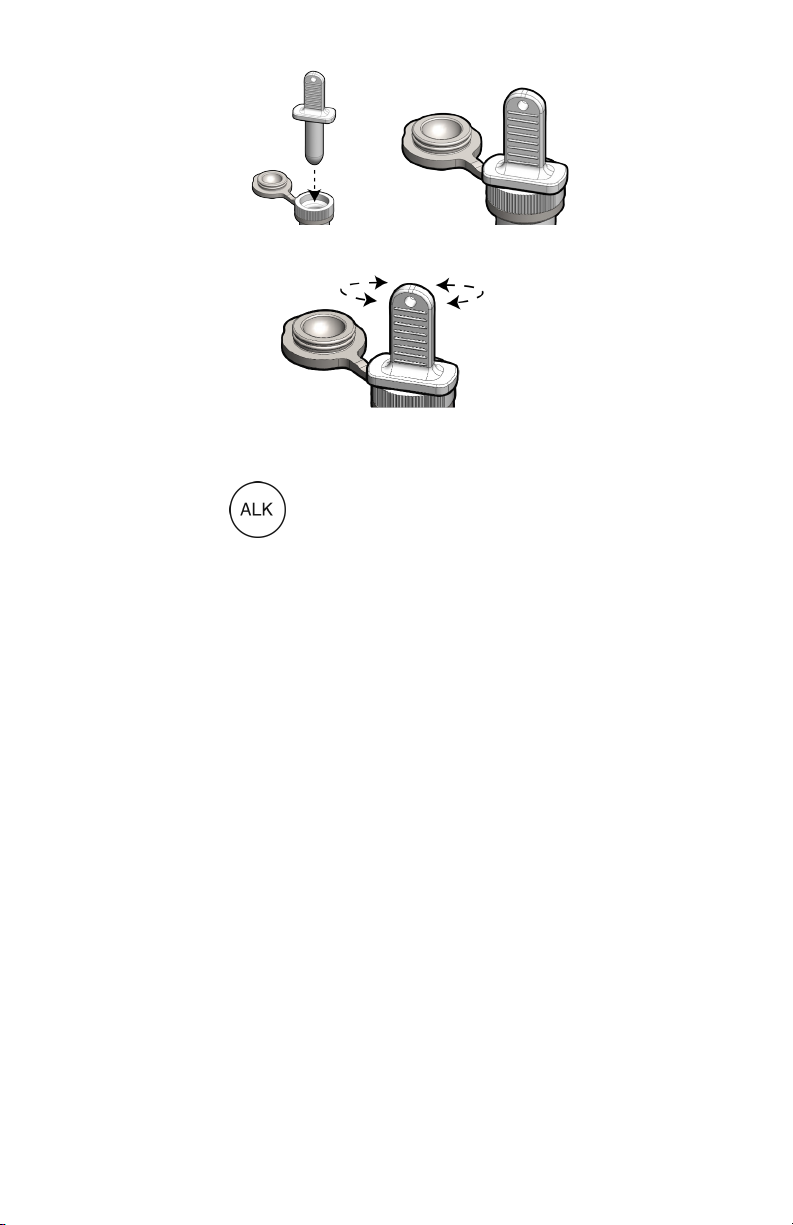

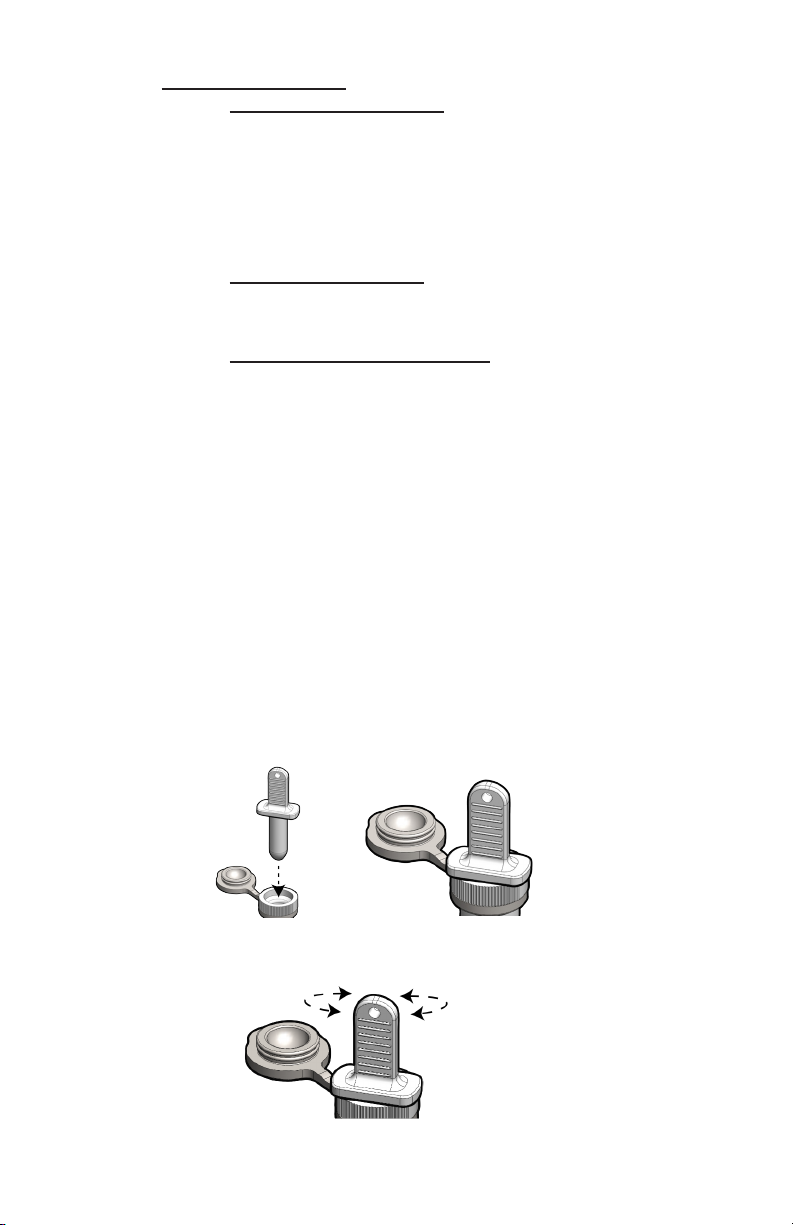

2. T-Plunger Instructions

To PLUNGE the cell:

Clean and dry the T-plunger. With the

cell extender installed and solution in

the cell, insert the tip of the T-plunger

in the cell extender until the arms of the

T-plunger are ush against the rim of the

cell extender. Solution will overow the

cell.

Keeping the arms of the T-plunger ush

against the rim of the cell extender, rotate

the T-plunger from side to side, allowing

the arms of the T-plunger to slide along

the rim of the cell extender.

Remove the T-plunger from the cell by

lifting it straight up out of the cell, being

careful to keep it centered over the mouth

of the cell extender. When the T-plunger

is completely out of solution, tap the

T-plunger on the inside rim of the cell

extender to dispel any clinging solution

back into the cell.

Insert the T-plunger all the way

down into the cell extender then

rotate it from side to side.

Hold the T-plunger over the cell

then tap rmly so that solution is

dispelled back into the cell cup.

Remove the T-plunger completely from

the cell area.

3. Mixing Solution in Cell

a. Agitate

When the display says to agitate (“AGit”):

Grasp the instrument on both sides of

the keypad (keypad facing up) with your

hands so you don’t accidentally drop or

release it. Agitate the solution in the cell

by swinging the cell cup area of the 9P up

“AGit”: When “AGit” displays, swing

the cell end of the 9P up and down

ve or more times.

and down ve or more times.

b. Hold

When the display says to hold (“HOLd”):

Hold the instrument steady in the

horizontal position while the instrument

records a measurement.

“HOLd”: When “HOLd” displays, hold

the 9P still with bottom of case parallel

to the ground.

13

C. Measuring Conductivity & Total Dissolved Solids (TDS)

1. Rinse cell cup 3 times with sample to be measured. (This

conditions the temperature compensation network and prepares

the cell.)

2. Rell cell cup with sample.

3. Press or

4. Take reading. A display of [- - - -] indicates an overrange

condition.

D. Measuring Resistivity

Resistivity is for low conductivity solutions. In a cell cup the value may

drift from trace contaminants or absorption from atmospheric gasses, so

measuring a owing sample is recommended.

1. Ensure pH protective cap is secure to avoid contamination.

2. Hold instrument at 30° angle (cup sloping downward).

3. Let sample ow continuously into conductivity cell with no aeration.

4. Press

NOTE: If reading is lower than 10 kilohms, display will be dashes:

[ - - - - ]. Measure solution Conductivity instead.

E. Measuring Alkalinity

Prepare the materials required for titration: Reagent: A1, cell extender,

T-plunger, and 100µL pipette with a clean tip installed.

NOTE: If you do not complete each titration point within the 3-minute

timeout period, the unit exits the Alkalinity function. Start the titration

process over.

key; use best reading.

.

If you make a gross error in your titration method, e.g., you forget to add

sample to the cell, “Err” will display. Start the titration over.

1. Ensure pH protective cap is secure to avoid contamination.

2. Install the cell extender by pushing the base of the cell extender

into the conductivity cell until it is fully seated.

3. Rinse the conductivity cell cup and cell extender 3 times with

solution to be measured.

4. Rell cell cup and cell extender with sample solution.

5. Insert T-plunger into open cell extender until the “T” rests ush

on the lip of the cell extender. This will cause uid beyond what

is required for titration to overow the cell extender.

14

6. Rotate the T-plunger from side to side, allowing the arms of the

T-plunger to slide along the rim of the cell extender.

7. Carefully remove the T-plunger so as not to ick or spill remaining

sample. Tap the T-plunger on the inside rim of the cell extender

to remove sample that may be stuck to the T-plunger.

8. Press . “AL” alternating with “tdS” briey displays along

with the “PPM” value of the sample. “PrES CAL” will display

when the reading stabilizes.

9. Press CAL to accept and advance to the rst titration prompt.

“Add” alternating with “A1” displays.

10. Using the pipette, add 100µL of Reagent: A1, close the cell

extender cap securely, Press CAL to continue.

11. “AGit t1” ashes on the screen. Agitate to mix the sample. When

agitation is done, tap the cell extender cap to dispel any solution

clinging to the cap back into the cell. Press CAL to continue.

(The number after "t" indicates which titration point you are on.

The number "1" here indicates this is the rst titration point.

Subsequent titration points are sequenced numerically: 2, 3, 4,

etc.)

12. “HOLd” displays. Keep holding the meter steady until “Add”

alternating with “A1” displays. Open the cell extender cap carefully

to avoid spilling, and use the pipette to add 100µL of Reagent A1.

Close the cell extender cap securely. Press CAL to continue.

13. Repeat Steps 11 and 12 until the meter reports the alkalinity

result.

14. Note the value for your records or press MS to store the value.

The unit will automatically power off.

15

F. Measuring Hardness

1. Hardness Unit Selection

The 9P offers the ability to set the hardness unit preference to either

“PPM” CaCO3 or grains of hardness. To change hardness units, press

HARD, then press and hold CAL down until “HArd” and “SEL” are

displayed. Press UP or DOWN to toggle between “PPM” and grains (no

units are displayed for grains). Press CAL to accept. This also sets the

hardness unit preference for the LSI Calculator simultaneously.

2. Select EDTA Reagent

0-200 ppm- Reagent H4, EDTA-B-LC (optimal for 0-100 ppm)

0-1710 ppm- Reagent H5, EDTA-B-HC (optimal for 100-1710 ppm)

3. Hardness Titration Procedure

Prepare the materials required for titration: Reagent: HB, Reagent: H4,

or Reagent: H5, cell extender, T-plunger, 100µL pipette with a clean tip

installed, and one extra clean tip.

NOTE: If you do not complete each titration point within the 3-minute

timeout period, the unit exits the Hardness function. Start the titration

process over.

1. Ensure pH protective cap is secure to avoid contamination.

2. Install the cell extender by pushing the base of the cell extender

into the conductivity cell until it is fully seated.

3. Rinse the conductivity cell cup and cell extender 3 times with

solution to be measured.

4. Rell cell cup and cell extender with sample solution.

5. Insert T-plunger into open cell extender until the “T” rests ush

on the lip of the cell extender. This will cause uid beyond what

is required for titration to overow the cell extender.

6. Rotate the T-plunger from side to side, allowing the arms of the

T-plunger to slide along the rim of the cell extender.

16

7. Carefully remove the T-plunger so as not to ick or spill remaining

sample. Tap the T-plunger on the inside rim of the cell extender

to remove sample that may be stuck to the T-plunger.

8. Press . “CA” alternating with “tdS” displays along with

“PPM” sample value. “PrES CAL” displays when the reading

stabilizes.

9. Press CAL. "HC" or "LC" will display; use the UP or DOWN

keys to switch to HC for the higher range (0-1710 ppm) or

LC for the lower range (0-200ppm). Press CAL to accept and

continue.

10. “Add” alternating with “buFF” displays. Using the pipette, add

100µL of Reagent HB to the sample, close the cell extender cap

securely. Change the pipette tip for adding EDTA in following

steps. Press CAL to continue.

11. “AGit” ashes on the screen. Agitate to mix the sample. When

agitation is done, tap the cell extender cap to dispel any solution

clinging to the cap back into the cell. Press CAL to continue.

12. “HOLd” displays. Keep holding the meter steady until “Add”

alternating with “EdtA” displays. Open the cell extender cap

carefully to avoid spilling, and use the pipette to add 100µL of

EDTA-B-HC or EDTA-B-LC, as indicated on the display. Close

the cell extender cap securely. Press CAL to continue.

13. “AGit t1” ashes on the screen. Agitate to mix the sample. When

agitation is done, tap the cell extender cap to dispel any solution

clinging to the cap back into the cell. Press CAL to continue.

(The number after “t” indicates which titration point you are on.

The number “1” here indicates this is the rst titration point.

Subsequent titration points are sequenced numerically: 2, 3, 4,

etc.)

14. Repeat Steps 12 and 13 until the meter reports the hardness result.

15. Note the hardness value for your records or press MS to store

the value. The unit will automatically power off.

NOTE: If there is a gross error in your titration method, e.g., you forgot

to add sample to the cell, “rEAd Err” will alternate with “rEPt tit”.

Repeat the titration from Step 1 to obtain a reading. If the reading is

over range, the display indicates “Or”. If the reading is under range, the

display indicates “0.00”.

17

G. LSI Calculator Functions

The Ultrameter III features an LSI Calculator that can be used to perform

actual LSI or for hypothetical water balance calculations.

The LSI Calculator computes a Langelier Saturation Index value using

measured, default, or user-adjusted values for alkalinity, hardness, pH

and temperature.

If you have stored alkalinity, hardness or pH and temperature values,

the calculator will automatically display the most recent stored value. All

other values will display as default. You can adjust any or all of the values

displayed to determine the effect of the change(s) on the LSI value.

1. Measuring LSI

To compute the actual saturation index of a solution:

Before you enter the calculator function, you must measure and store

values for all water balance variables used by the calculator to compute

saturation index.

1. Perform an alkalinity titration of the sample solution (ref.

Measuring Alkalinity, pg. 14). Press MS to store the reading in

memory.

2. Perform a hardness titration of the sample solution (ref.

Measuring Hardness, pg. 16). Press MS to store the reading in

memory.

3. Measure the pH of the sample solution (ref. Measuring pH, pg.

19) Press MS to store the reading in memory.

4. Press

5. The last stored alkalinity value is displayed.

6. Press CAL to accept value and advance to the hardness value

screen. The last stored hardness value is displayed.

7. Press CAL to accept value and advance to the pH value screen.

The last stored pH value is displayed.

8. Press CAL to accept value and advance to the temperature

value screen. The last stored temperature value (taken from

the last stored hardness or alkalinity titration) is displayed.

9. Press CAL to accept and calculate LSI. The saturation index

value will display. Press MS to store the reading. The unit will

automatically power off after the period of inactivity dened in

the AUTO OFF setting (ref. AUTO OFF, pg. 43).

18

.

If you want to modify any of the input values and recalculate LSI based

on those changes, press CAL again and repeat Steps 5-9 using the UP

and DOWN keys to change the values. If you want to change hardness

units (ppm/grains), you must do so in the hardness parameter. See

Hardness Unit Selection, pg. 16.

2. Hypothetical LSI Calculations

To compute saturation index using hypothetical alkalinity, hardness, pH

or temperature values:

1. Press

2. Either the last stored value or the default value of “120” is

displayed.

3. Press the UP or DOWN keys to adjust the alkalinity value or

leave as displayed.

4. Press CAL to accept and advance to the hardness value

screen. Either the last stored value or the default value of “166”

is displayed.

5. Press the UP or DOWN keys to adjust the hardness value or

leave as displayed.

6. Press CAL to accept hardness value and advance to the pH

value screen. Either the last stored value or the default value of

“7.20” is displayed.

7. Press UP or DOWN to adjust the pH value or leave as displayed.

8. Press CAL to accept pH value and advance to the temperature

value screen. Either the last stored value (taken from the last

stored hardness or alkalinity titration) or the default value of

“25 ºC” is displayed.

9. Press UP or DOWN to adjust the temperature value or leave as

displayed.

10. Press CAL to accept and calculate LSI. A saturation index value

will display.

If you want to modify any of the input values and recalculate LSI based

on those changes, press CAL again and repeat Steps 3-10. If you want

to change hardness units, you must do so in the hardness parameter.

See Hardness Unit Selection, pg. 16.

.

H. Measuring pH

1. Remove protective cap by rotating while grasping and pulling up.

2. Rinse pH/ORP sensor well and conductivity cell cup 3 times

with sample to be measured. Shake out each sample to remove

any residual liquid.

19

Loading...

Loading...