Page 1

YOUR

LITHO-KIT

GUIDE

™

Page 2

Page 3

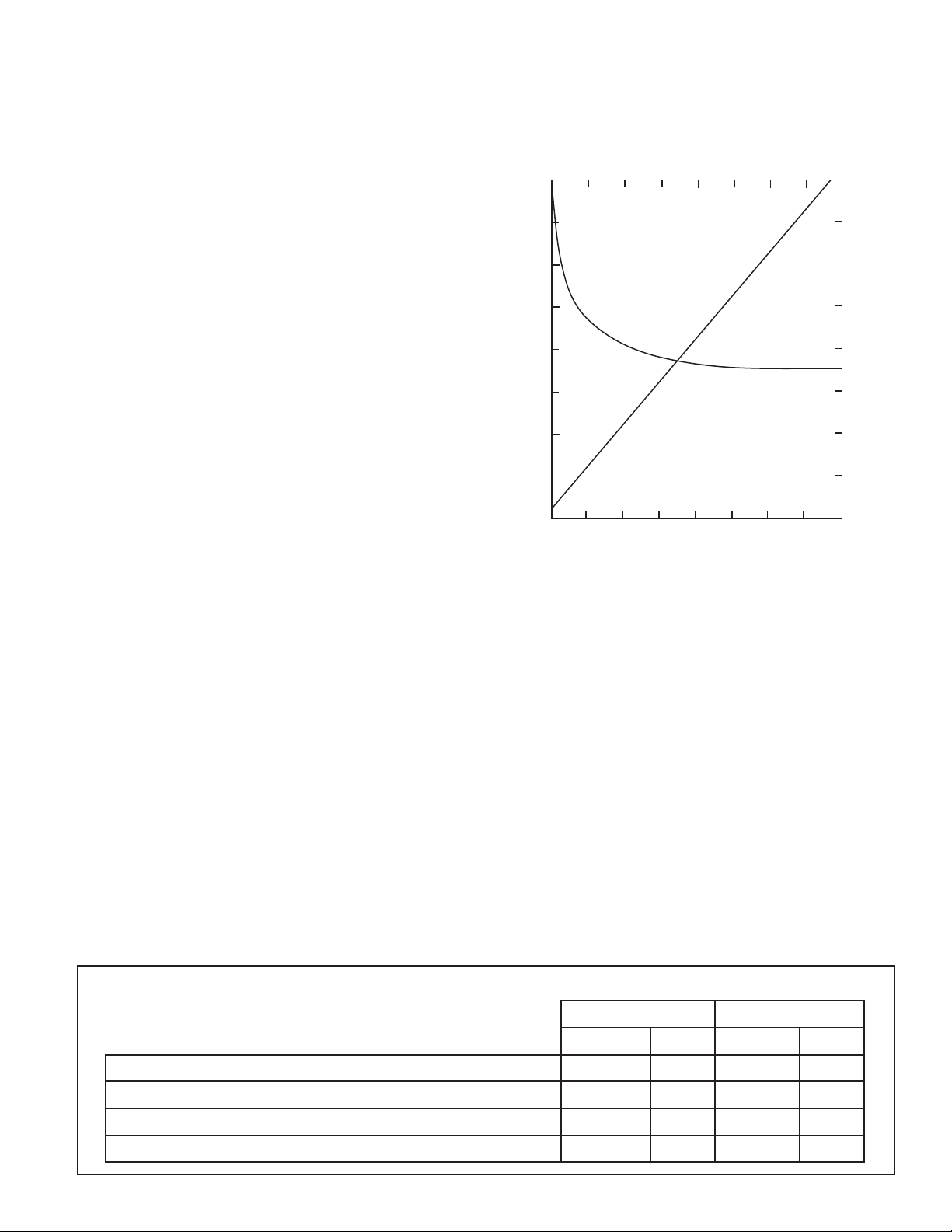

Conductivity (micromhos/cm)

pH

pH

Conductivity

Concentration (oz./gal.)

3500

3000

2500

2000

1500

1000

500

0 1 2 3 4 5 6 7 8

7

6

5

4

3

2

1

INTRODUCTION

Your Litho-Kit™ is a quality control "tool" to help you

print better. It and this Guide will improve your printing

through better control of fountain (dampening) solutions.

The rising popularity of alcohol-free solutions has

increased the need for very careful monitoring of their

conductivity, pH and temperature.

While this Guide offers information we hope will be very

useful, it makes no specic recommendations regarding

fountain solution temperature, concentration, pH or

conductivity values. A good source for such information

is your solution supplier, who is most familiar with

your local conditions. Another source is the Graphic

Arts Technical Foundation, a non-prot research and

educational organization which provided much of the

information in this Guide.

CONDUCTIVITY AND pH: HOW THEY CAN

HELP YOU

The Myron L instrument which is the "heart" of your kit

is either a conductivity instrument or a conductivity/pH

instrument. Both are industrial-quality instruments for

professionals. Reliable even in demanding conditions, they

feature electrodes mounted inside a cell cup for maximum

protection. Details of specications and operation can be

found in the instruction manual in each kit.

Conductivity is the ability of a solution to pass an

electrical current. The amount of current passed

depends on the concentration of ions, or electrically

charged particles in the solution. The higher the

concentration of ions, the higher the degree of

conductivity. The unit of conductivity measurement is the

microsiemen (also called the micromho).

Traditionally, pH, a measure of the degree of acidity

or alkalinity, was used to check fountain solution

concentration. Today, however, conductivity testing

is recognized as a much more accurate method.

Many modern dampening solutions are pH stabilized

(or buffered), so only small changes in pH are seen,

even when solution strength is dramatically changed.

The conductivity, however, increases as solution

concentration rises.

The advantage of checking fountain solution

concentration with conductivity, rather than pH, can be

seen in the following graph.

Concentration vs. pH and Conductivity for a hypothetical

combination of fountain solution concentrate and water

Notice how the pH levels off, but conductivity values rise

on a straight-line basis as the concentration increases.

This "linear" relationship allows you to easily match the

conductivity value to a specic concentration of your

own solution.

Even though pH usually is not the best method to check

the concentration of fountain solution, it is still very

important and must be checked regularly. The pH of acid

dampening solution affects sensitivity, plate-life, inkdrying, etc. Also, pH can change during a run if the paper

has a high acid or alkaline content. Conclusion: pH must

be maintained at the proper level for good printing.

The table below lists recommendations for checking

fountain solution conductivity and pH.

RECOMMENDED TESTING METHOD

TYPE OF FOUNTAIN SOLUTION

ACID X X X X

BUFFERED ACID X X X

NEUTRAL X X X

ALKALINE X X X

MIXING ON PRESS

COND. pH COND. pH

Page 4

Because contaminants in water are often ionized,

conductivity has long been recognized as a good

overall indicator of water quality. Portable conductivity

instruments and/or in-line conductivity monitor/

controllers are normally included in industrial reverse

osmosis and deionization water treatment systems.

If the system in your plant did not include a Myron L

portable instrument, the instrument in your Litho-Kit™

can be used to check:

1. System Efciency

2. Tap Water Quality Fluctuations

Other models designed specically for water

treatment equipment testing can be found in the

REPLACEMENTS/OPTIONS section of this Guide.

ACCESSORIES IN YOUR LITHO-KIT

Calibration solutions ensure continued instrument

accuracy. Information on the procedures and frequency

of recalibration will be found in your instrument

Operating Instructions booklet. The small bottles

included in the kit can be relled with the 1 L/32 oz.

solutions found in REPLACEMENTS/OPTIONS.

™

provide is a solution concentration graph. After plotting

various mixtures of etch with your water, it will be very

easy to later check the strength of your dampening

solution on the press. Then, you can see which

concentration results in the best quality printing.

The following procedure can be accomplished using the

blank graph form at the end of this guide. This form may

be copied for future use.

1. Measure the conductivity and pH

of water normally used to make the

dampening solution. Fill a clean

3,8 L /1 gallon bottle with water.

2. Add 29,6 mL/1 oz. of fountain solution

concentrate. Remeasure both conductivity

and pH. Record these values.

3. Add another ounce (59,15 mL/2 oz. total) of

fountain solution concentrate and

remeasure both conductivity and pH.

Repeat this process (in 14,79 mL/1/2 oz.

additions, if preferred) until the amount

of fountain solution added exceeds the

manufacturer's recommendations.

The syringe included in your kit is the easiest way to take

a dampening solution sample. This is especially true

when the sample is drawn from the fountain pan (the

most representative source). Carefully transfer solution

directly into the meter's cell cup for testing. Make sure to

always rinse the syringe with clean water after use.

Using the thermometer to check dampening solution

temperature regularly during a run is important for

continued quality printing. Dampening solutions,

especially alcohol-free types are more viscous (therefore,

more effective) when chilled to 10-13º C/ 50-55°F.

Since it is normal for the temperature to increase slightly in

the fountain pan, it is preferable to check temperature there,

rather than in the recirculator. The temperature difference

between the recirculator and pan usually should not be

more than + 1 °C/2 °F. If the difference is greater, and pan

solution temperature is not within the ideal range, steps can

be taken to reduce the differential. These include insulating

solution supply and return lines and moving the recirculator.

For advice on ideal solution and how to maintain it, see

your local supplier.

RECOMMENDATIONS FOR USING YOUR

LITHO-KIT

PLOTTING A CONCENTRATION GRAPH

One of the most useful benets your Litho-Kit™ can

™

4. Plot these values on the graph form

provided.

5. Make new charts when changing

brands of dampening solution, or tap

water quality changes more than

+ 50 microsiemens (micromhos).

ADDITIONAL RECOMMENDATIONS

1. Discuss your printing requirements with your

chemical supplier to obtain the best dampening

solution for your local water and other conditions.

2. Carefully follow the manufacturer's mixing

instructions.

3. Run the recommended mixture of dampening

solution and monitor its printability. Communicate

this information back to the dampening solution

manufacturer.

4. Check dampening solutions regularly with your

Myron L instrument and thermometer. Paper

coating, ink bleed, and blanket or roller cleaners

can contaminate dampening solution. Take

temperature, pH and conductivity readings after

every 1-3 hours of press operation. Record these

readings in the press log book. Keep the solution

at the concentration you have found works best.

Page 5

5. As the press run continues, observe the

changes in pH and conductivity. When printing

problems such as plugging or scumming

begin, the dampening solution is probably

contaminated. Record your ndings in the press

log book and remix a fresh batch of solution.

6. If alcohol is used in your fountain solution, it

should be added after the solution has been

mixed to the desired conductivity range. Alcohol

has no conductivity, and it dilutes the solution

conductivity value. To properly monitor a

solution containing alcohol while running, the

reading after dilution should be used as the

"standard”.

7. Drain and clean your dampening system

weekly.

M6/pH

512M5

6PII

REPLACEMENT/OPTIONS

These items can be obtained from your local dealer:

Item Description

M6/PH Conductivity/pH meter (Ranges:

0-5000 µS; 2-12 pH)

512M5 Conductivity meter (Range: 0-5000 µS)

EP Conductivity meter for DI water system

testing

(5 ranges: 0-0.5, 5, 50, 500, 5000 µS)

EP11/PH Conductivity/pH meter for checking

reverse osmosis water treatment

systems

(4 conductivity ranges: 0-10, 100, 1000,

10,000 µS; pH range 2-12)

6PII Conductivity, TDS, Resistivity, pH, ORP

& Temperature

CLK Litho-Kit only (without instrument) for

512M5 or other conductivity model

PLK Litho-Kit only (without instrument) for

M6/PH or other conductivity/pH model

ULK Litho-Kit only (without instrument) for

Ultrameter 6PII instruments

pH 4 Buffer* pH calibration solution

pH 7 Buffer* pH calibration solution

pH 10 Buffer* pH calibration solution

442-3000* 3900 microsiemens Conductivity

Standard Solution

KCl-7000* 7000 microsiemens Conductivity

Standard Solution

CSFP Calibrating Solution Four-Pack (1 ea., 2oz

bottles pH 4, 7, 10 & 442-3000)

PS35 Plastic Syringe (35 CC)

TM Thermometer

*Available in 2oz., quart and gallon sizes

Page 6

FOUNTAIN CONCENTRATE CONTROL WORKSHEET

FOR

DATE

OPERATOR

WATER pH

WATER CONDUCTIVITY

FOUNTAIN BRAND

3500

Concentration

(oz. per gallon)

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

Conductivity

(Microsiemens)

pH

9

Conductivity

(microsiemens)

3000

2500

2000

1500

1000

500

0

8

7

6

pH

5

4

3

2

0 1 2 3 4 5 6

Concentration

(oz. per gallon)

Page 7

Page 8

MYRON L COMPANY

2450 Impala Drive

Carlsbad, CA 92010-7226

USA

Tel: +1-760-438-2021

Fax: +1-760-931-9189

E-Mail: info@myronl.com

techquestions@myronl.com

www.myronl.com

Made in USA

ACCURACY • RELIABILITY • SIMPLICITY

© Myron L Company 2008 LKG 10-08

Loading...

Loading...