Page 1

CTCII

Water Quality Instrumentation

Accuracy • Reliability • Simplicity

CONDUCTIVITY/TDS

Chemical Treatment Controller

(Cooling Tower Controller)

Operation

Manual

14 JANUARY 05

INSTALLATION • OPERATION • MAINTENANCE

Controller Only: CTCII, & CTCIIT

Monitor/controller: CTCIID, & CTCIITD

ACCURACY • RELIABILITY • SIMPLICITY

Page 2

Page 3

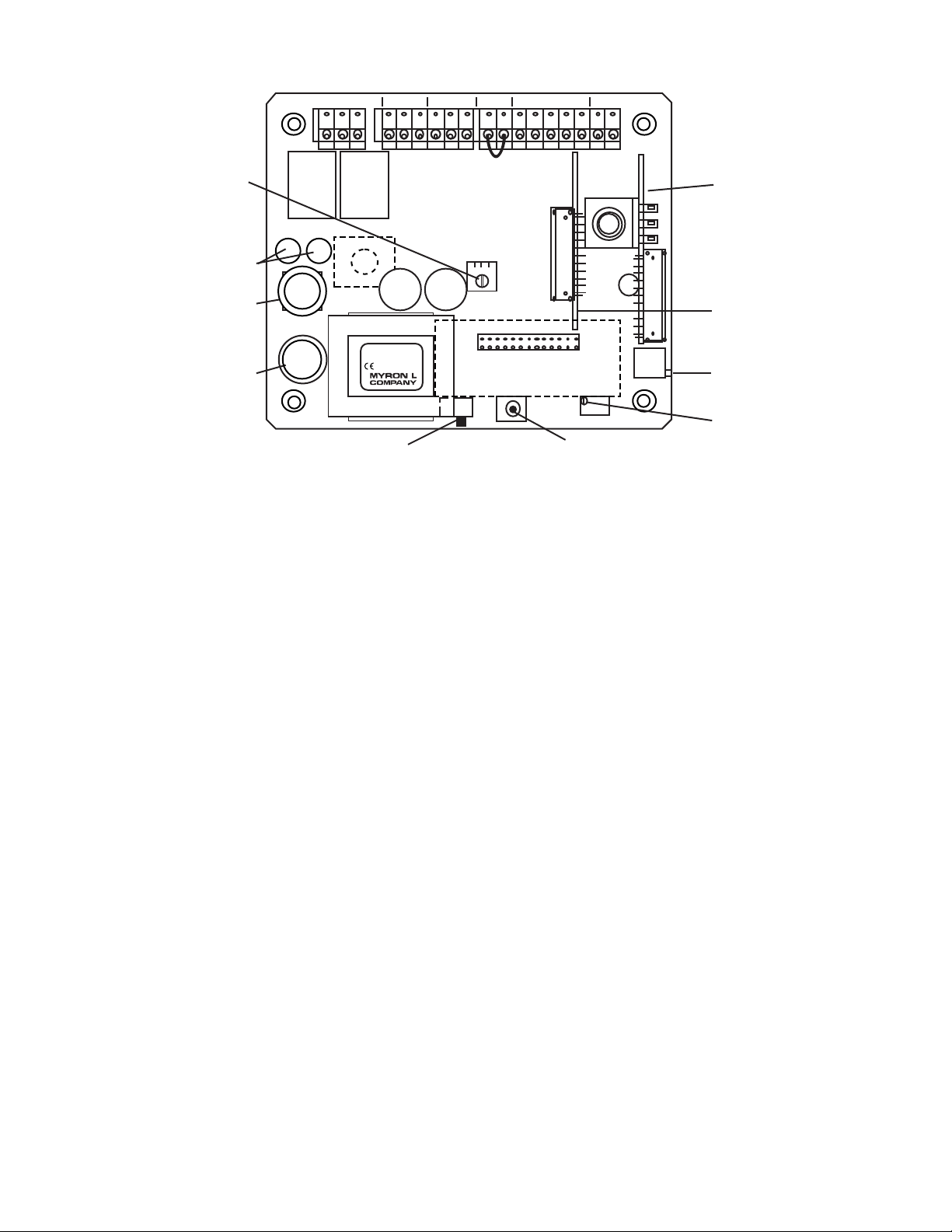

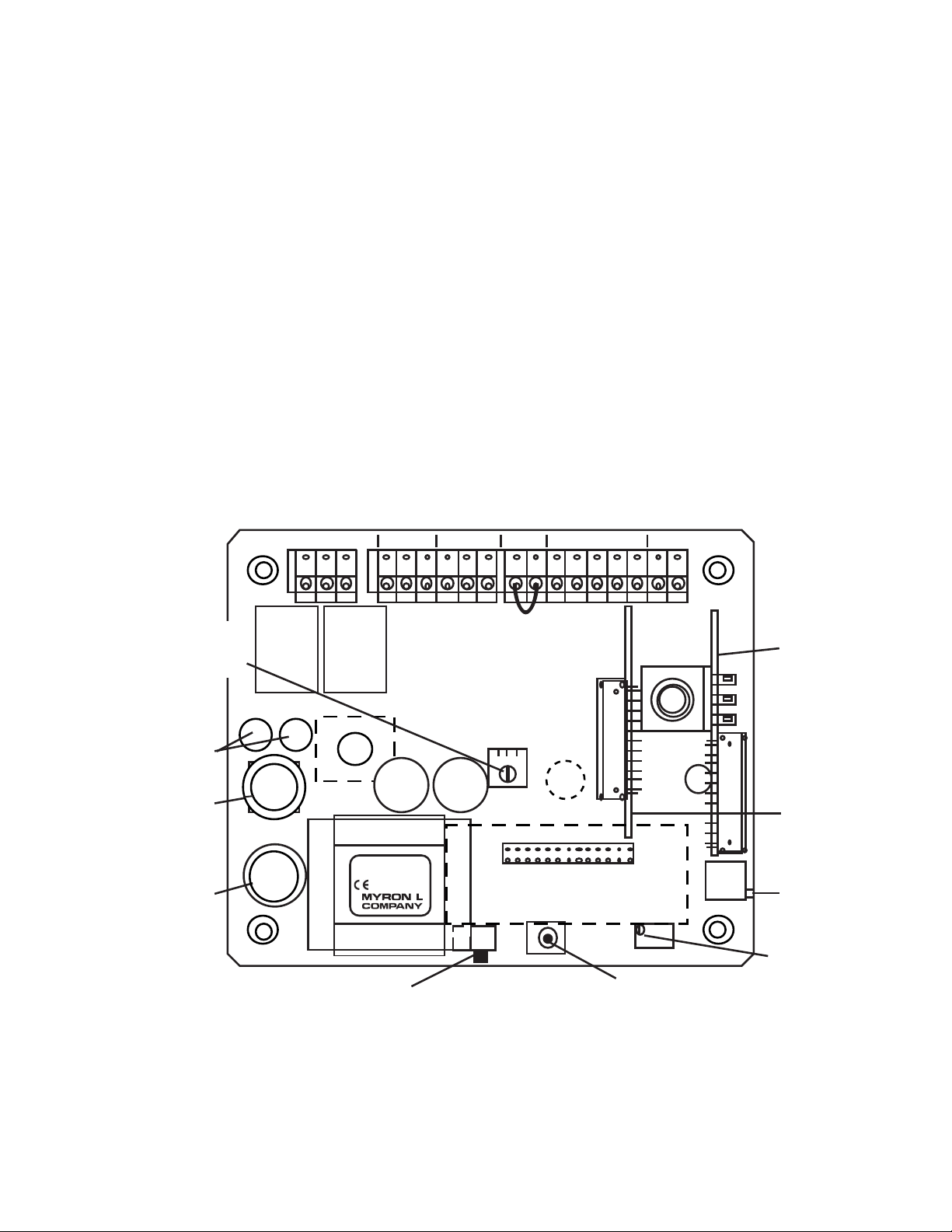

ELECTRONIC CALIBRATION (CIRCUIT ONLY) -

CTCII MAIN CIRCUIT BOARD

Figure V.A.1

115/230 VAC

SELECT SWITCH

100mA Slow Blow (T.10A)

115 & 230 VAC (V~)

Wickman Fuse 5 Amp

(#3741500041 or equiv)

115 VAC(V~)

SCALE SELECT

ELECTRONIC

CALIBRATION

MAIN

CALIBRATION

CONTROL

DISPLAY

CALIBRATION

CONTROL

(FACTORY SET)

OPTIONAL

LIMIT

TIMER

CONTROL

MODULE

OPTIONAL

4-20 mA

OUTPUT

MODULE

DIS

CAL

TDS COND

EC

CTCII

DISPLAY

TRANSFORMER

Yel

CAP CAP

C4AM

LTM

HYST

Flow Switch

Jumper Remove if

flow switch

installed.

SWITCH

FUSE

RELAY RELAY

BLEED FEED

FEED

PUMP

BLEED

VALVE

POWER

FLOW

SWITCH

SENSOR 0-10VDC

FS BK WTRD GN NU R- R+PWR C GDPWR C GDPWR C GD

SET POINT

HYSTERESIS

RIGHT INC

LEFT DEC

a. Set Point Control Calibration

1. Ensure power is OFF.

2. Using a standard slot screwdriver remove the four (4)

screws on the clear cover and remove cover.

3. The front panel is held in place with hook & loop strips

on each side. By carefully lifting at the slot on the top,

the front panel will pull toward you. Do not pull more than

about 8 inches/20CM.

DO NOT pull on control knob(s).

4. Rotate the front panel down so that the back side is

facing you. The Circuit Board is mounted to the back of

the front panel.

5. Turn power ON.

Caution: When handling CB, DO NOT touch component side.

Electrical shock may occur.

6. Press and hold the EC switch.

7. Rotate Set Point control from “0” toward EC. At EC the

relay should click, and the LED should change from RED

to GREEN. If not, set Set Point control to EC and adjust

the CALibration control.

Models with 3 1/2 digit LCD.

The display should indicate 2.50.

If not, adjust the DISplay calibration control.

8. Turn power OFF.

9. Re-install front panel and cover as described in

USING STANDARD SOLUTIONS - Section V.B.2.

The BEST method of verifying and recalibrating your CTCII

“REASSEMBLY”.

10. To operate, turn power ON.

b. 0-10VDC Recorder Output Calibration

Chemical Treatment Controller is with NIST traceable Standard

Solution (available from the Myron L Company). Because it

includes the sensor, the entire system is calibrated.

See section V.B.1.

See Section V.B.1.

The following procedure describes the easiest method for

standard solution calibration. We recommended using Myron L

442-3000 Standard Solution or equivalent. This standard solution

will calibrate either Conductivity µS (at 3900 µS) or TDS ppm (at

3000 ppm).

1. Rinse thoroughly, and ll a clean glass beaker with

standard solution.

2. Place sensor in beaker of standard solution. The level of

standard solution must be high enough to cover at least

1/2” above the electrodes.

3. Slowly shake the sensor to remove air bubbles from the

electrodes.

4. Allow 5-10 minutes for temperature to equilibrate. For

the quickest and the best results, both the sensor and

solution should be at the same temperature.

5. Turn power ON.

6. Rotated the Set Point control to 3900 for Conductivity

models or 3000 for TDS models. The relay should click

and the LED will change from GREEN to RED.

If the set point is different, adjust CALibration control

on the main circuit board until the reading matches the

solution.

Models with display (standard 3 1/2 digit).

The display should match the value of the standard

solution, 3900 µS (displayed as 3.90) or 3000 ppm

(displayed as 3.00).

If the reading is different, adjust DISplay calibration

control on the main circuit board until the reading

matches the solution.

7. After adjustment, turn power OFF.

8. Re-install front panel and cover as described below in

“REASSEMBLY”.

9. To operate, turn power ON.

TRANSFER STANDARD METHOD - See Section V.B.3.

Page 4

CTCII

CHEMICAL TREATMENT CONTROLLER

(COOLING TOWER CONTROLLER)

QUICK REFERENCE GUIDE!

If you read nothing else in this

manual please read this

Quick Reference Guide.

PLEASE READ and COMPREHEND ALL

WARNINGS, CAUTIONS and ADVISEMENTS

CONTAINED WITHIN THIS MANUAL.

Failure to comply is beyond the responsibility of the

Myron L Company.

WARNING: ALL CONTROLLERS ARE FACTORY SET TO

OPERATE ON 115 VAC. BEFORE APPLYING POWER ENSURE

THE INPUT POWER “115/230 VAC” SELECTION IS CORRECT

FOR YOUR REQUIREMENTS. FAILURE TO DO SO IS BEYOND

THE RESPONSIBILITY OF THE MYRON L COMPANY. See

section II.D.1. and gure II.E.1.

WARNING: ENSURE POWER IS OFF WHILE INSTALLING

ELECTRICAL EQUIPMENT. IF MONITOR/CONTROLLER

IS INSTALLED, ENSURE THE POWER IS OFF BEFORE

SERVICING. FAILURE TO DO SO COULD CAUSE DAMAGE

TO THE INSTRUMENT, AND COULD BE HARMFUL OR FATAL

TO PERSONNEL. ONLY QUALIFIED PERSONNEL SHOULD

INSTALL OR SERVICE ELECTRICAL EQUIPMENT.

CAUTIONS: Before installation, ensure you have the correct

model (with options), AND it is scaled for your application.

See sections I.A. & I.B.

Do you have the correct sensor? See section I.E.

Mounting requirements. What is needed? See section II.B.

The following will give the installer and user a quick

overview. See the sections listed for details.

REMOVING FRONT PANEL

1. Using a Phillips Head screwdriver remove the four (4)

screws on the clear cover.

2. Remove clear cover.

3. The front panel is held in place with hook & loop strips

on each side. By carefully lifting at the slot on the top,

the front panel will pull toward you. Do not pull more than

about 8 inches/20CM.

DO NOT pull on control knob(s).

4. Rotate the front panel down so that the back side is

facing you. The Main Circuit Board is mounted to the

back of the front panel.

REASSEMBLY

1. Carefully reinstall the front panel.

2. Reinstall the clear cover.

3. Reinstall the four (4) screws and tighten.

4. If desired, install corner covers.

5. To operate, turn power ON.

INTRODUCTION - Section I.

This section covers the specications of your new CTCII

Chemical Treatment Controller including sensor information.

INSTALLATION - Section II.

This section covers how to install your new CTCII Chemical

Treatment Controller; mechanically and electrically.

OPTIONS & ACCESSORIES - Section III.

This section covers the specications, installation, set up, and

operation of each option.

OPERATING PROCEDURES - Section IV.

This section covers a brief description of different models and

their features; how they work, and how to set them up for your

particular use.

QUICK CHECK-OUT PROCEDURE -

See Section IV.B.1.

It is assumed that the Controller power is ON, that it is connected

to an appropriate sensor, and that the sensor is immersed in water

within the range that the Controller will be required to operate, and

the clear lid is removed from the Controller.

1. Rotate the large Set Point Control knob on the front

panel through its entire range.

2. Verify that the set point indicator light changes from RED

to GREEN and visa versa.

3. Verify that the relay clicks, and controls the bleed valve

and/or chemical feed pump.

4. Adjust the set point control to the desired set point value.

5. Re-install clear cover.

HYSTERESIS (DEAD BAND) ADJUSTMENT -

See Section IV.B.3.

PRIMARY COMPONENT IDENTIFICATION -

Section V.A.

Review the gure on the following page to familiarize yourself with

the Main circuit board assembly. The diagram shows the Limit

Timer and the optional 4-20 mA Output module installed.

QUICK CALIBRATION - Section V.B.

WARNING: When performing calibration procedures, the

technician must take extreme care to avoid contacting the

circuitry other than the CALibration control. Failure to do so

could result in damage to the equipment, property and/or

personal injury.

Page 5

60

80

100

120

0

1000

2000

3000

4000

5000

40

20

0

MICROSIEMENS / CM

CTCII

EC

MINUTES

CTCII

Basic

Model

1

Page 6

60

80

100

120

0

1000

2000

3000

4000

5000

40

20

0

MICROSIEMENS / CM

CTCII

EC

MINUTES

CTCII

w/ 3 1/2

Digit LCD

2

Page 7

60

80

100

120

0

1000

2000

3000

4000

5000

40

20

0

MICROSIEMENS / CM

CTCII

EC

MINUTES

CTCII w/

Feed Pump

Limit Timer

3

Page 8

60

80

100

120

0

1000

2000

3000

4000

5000

40

20

0

MICROSIEMENS / CM

CTCII

EC

MINUTES

CTCII

w/ 3 1/2

Digit LCD

Feed Pump Limit Timer

4

Page 9

TABLE OF CONTENTS

SECTION PAGE

CTC Series II ILLUSTRATIONS (CTCII, CTCIID, CTCIIT & CTCIITD)......................................................................1-4

I. INTRODUCTION .................................................................................................................................................................. 7

A. SCOPE................................................................................................................................................................... 7

1. Functional Descriptions ........................................................................................................................... 7

2. Applications.............................................................................................................................................. 7

B. SPECIFICATIONS.................................................................................................................................................. 7

C. OPTIONAL FEATURES..........................................................................................................................................8

D. ACCESSORIES...................................................................................................................................................... 8

E. SENSORS .............................................................................................................................................................. 9

1. Conductivity/TDS ..................................................................................................................................... 9

2. Sensor Specications ..............................................................................................................................9

F. ORDER INFORMATION......................................................................................................................................... 9

1. How to order a CTCII controller .............................................................................................................. 9

2. How to order Sensors .............................................................................................................................. 9

II. INSTALLATION ....................................................................................................................................................................10

A. GENERAL............................................................................................................................................................... 10

B. MECHANICAL INSTALLATION .............................................................................................................................. 10

1. Surface Mounting..................................................................................................................................... 10

C. SENSOR INSERTION / DIP MOUNT ASSEMBLIES ............................................................................................. 11

1. CSAR Insertion Mode Assembly.............................................................................................................. 11

2. CS51R Alternate Dip Sensor Assembly ................................................................................................... 11

D. ELECTRICAL INSTALLATION................................................................................................................................ 11

1. 115/230 VAC Conversion......................................................................................................................... 11

2. Connecting the Sensor Cable.................................................................................................................. 12

a. Modication for US Pharmaceutical 25 (No Temperature Compensation) ......................................... 12

3. Flow Switch.............................................................................................................................................. 12

E. 0-10 VDC OUTPUT ................................................................................................................................................ 13

1. Connection............................................................................................................................................... 13

2. Voltage Divider......................................................................................................................................... 13

F. RESCALE............................................................................................................................................................... 14

III. OPTIONS & ACCESSORIES INSTALLATION.................................................................................................................... 15

A. -LTM (LIMIT TIMER MODULE) ............................................................................................................................. 15

1. Description............................................................................................................................................... 15

2. Installation................................................................................................................................................ 15

a. Hysteresis.......................................................................................................................................................... 15

B. -C4A MODULE (4-20mA OPTION) ........................................................................................................................ 15

1. Description............................................................................................................................................... 15

2. Installation................................................................................................................................................ 16

3. Recalibration............................................................................................................................................ 17

IV. OPERATING PROCEDURES .............................................................................................................................................. 18

A. FRONT PANEL INDICATORS & CONTROLS ....................................................................................................... 18

1. Red LED Indicator ................................................................................................................................... 18

2. Green LED Indicator ................................................................................................................................ 18

3. Set Point Control...................................................................................................................................... 18

4. Digital Display Models.............................................................................................................................. 18

5. Limit Timer Models................................................................................................................................... 18

B. SETUP PROCEDURES......................................................................................................................................... 19

1. Check-Out Procedure .............................................................................................................................. 19

2. Set Point Adjustment ............................................................................................................................... 19

3. Hysteresis (Dead Band) Adjustment........................................................................................................ 19

4. Feed Pump Limit Timer............................................................................................................................ 19

V. COMPONENT IDENTIFICATION, CALIBRATION AND PREVENTIVE CARE...................................................................20

A. PRIMARY COMPONENT IDENTIFICATION ......................................................................................................... 20

B. CALIBRATION PROCEDURES - MAIN CIRCUIT BOARD.................................................................................... 21

1. Electronic Calibration (Circuit Only)......................................................................................................... 21

2. Calibration Using Standard Solution........................................................................................................ 21

3. Transfer Standard Method....................................................................................................................... 22

C. PREVENTIVE CARE.............................................................................................................................................. 22

5

Page 10

TABLE OF CONTENTS Continued

SECTION PAGE

VI. OPTIONS & ACCESSORIES............................................................................................................................................... 23

A. OPTIONS ORDERED WITH CTCII....................................................................................................................... 23

B. OPTIONS & ACCESSORIES ORDERED SEPARATELY ......................................................................................23

C. STANDARD SOLUTIONS...................................................................................................................................... 24

VII. REPLACEMENT PARTS ..................................................................................................................................................... 25

VIII. WARRANTY......................................................................................................................................................................... 26

IX. GLOSSARY.......................................................................................................................................................................... 27

X. NOTES ................................................................................................................................................................................. 28

XI. ADDENDUM......................................................................................................................................................................... 29

A. CONDUCTIVITY, TDS AND TEMPERATURE RELATIONSHIPS.......................................................................... 29

6

Page 11

I. INTRODUCTION

Thank you for selecting one of the Myron L Company’s latest

Chemical Treatment Controllers. The CTCII is based on input

from ‘you’ - our customers, time proven designs, and many years

of instrumentation experience.

Since 1957, the Myron L Company has been providing customers

with quality products at an affordable price by designing and

producing products that are Accurate, Reliable, and Simple to use.

Quality you have come to rely and depend on.

As you read through this operation manual you will see the CTCII

is truly designed to be user friendly and simple to install.

The CTCII is packaged as a complete set ready to install which

includes the sensor, input power cord (115VAC) and two (2)

output connectors (115VAC) in a fully waterproof enclosure.

A. SCOPE

This operation manual provides the user with the necessary

information to install, operate and maintain your

Myron L Company CTCII Chemical Treatment Controller.

Section I. Provides Descriptions, Applications, Specications.

Section II. Installation; mounting, wiring and set up.

Section III. Options and Accessory installation procedures.

Section IV. Operating procedures.

Section V. Identies their primary components and provides the

user with easy-to-use calibration and preventive care

procedures.

Section VI. Options & Accessories List.

Section VII. Replacement Components.

Section VIII. Warranty information.

Section IX. Glossary, denitions.

Section X. Notes.

Section XI. Addendum.

1. FUNCTIONAL DESCRIPTIONS

All models feature a water proof & corrosion resistant IP65/NEMA

4X enclosure for bench or surface mounting. The CTCII is a

compact 4.7” (120mm) x 6.3” (160mm).

Bright dual GREEN/RED LED indicates ON/OFF (above or below

set point). All models feature TWO heavy-duty 10 amp output

relays, operating on increasing concentrations.

All models include input power cord* (115 VAC powercord 8 ft.

with USA 3 prong plug - NOT for use with 230 VAC), two (2)

output power connectors, CSAR sensor, and appropriate strain

reliefs.

LED. A 120 minute Limit Timer is provided to stop the feed pump

from continuing to pump chemical(s) in to tower, tank or system. A

bright YELLOW LED indicates when Limit Timer is on.

Model CTCIID Chemical Treatment Controller

0-5000 µS(µM) / ppm TDS 442™ Monitor/controller (value

displayed as X.XX mS(mM) or ppt w/ standard LCD). Front panel

is equipped with a “SET POINT” control, RED/GREEN indicator

LED, and a 3 1/2 digit liquid crystal display (LCD)*.

Model CTCIITD Chemical Treatment Controller

0-5000 µS(µM) / ppm TDS 442™ Monitor/controller (value

displayed as X.XX mS(mM) or ppt w/ standard LCD). Front panel

is equipped with a “SET POINT” control, RED/GREEN indicator

LED, and a 3 1/2 digit liquid crystal display (LCD)*. A 120 minute

Limit Timer is provided to stop the feed pump from continuing to

pump chemical(s) in to tower, tank or system. A bright YELLOW

LED indicates when Limit Timer is on.

* A 35BL (3 1/2 digit) backlit, or a 45BL (4 1/2 digit) backlit

display is available as an option for a full 0-5000 µS(µM) or ppm

displayed value.

2. APPLICATIONS

Chemical Treatment

Cooling Towers

Process Control

Wastewater Treatment

Food Processing

Plating

Power Plants

Laboratories

Printing

Boiler

Agriculture/Aquaculture

Are just a few of the applications

B. SPECIFICATIONS

RANGE:

0-5000 µS(µM) or ppm TDS 442™ (user selectable)

DISPLAY:

Models CTCIID & CTCIITD:

1/2” (13mm) 3 1/2 digit LCD

Displayed value — 0-5.00 mS(mM) or ppt.

NOTE: 3 1/2 digit LCD may be replaced with either a 3 1/2 or a 4

1/2 digit back lit LCD - available as options.

4 1/2 digit displayed value — 0-5000 µS(µM) or ppm.

The CS51R sensor for more demanding applications may be

substituted at an additional cost.

For specic CTCII congurations, reference the following

individual model descriptions.

*NOTE: for 230 VAC or other power requirements the plug must

be cut off or removed and hard wired directly to the source or a

local plug or adapter may be installed.

Model CTCII Chemical Treatment Controller

0-5000 µS(µM) / ppm TDS 442™ Controller. Front panel is

equipped with a “SET POINT” control and RED/GREEN indicator

LED.

Model CTCIIT Chemical Treatment Controller

0-5000 µS(µM) / ppm TDS 442™ Controller. Front panel is

equipped with a “SET POINT” control and RED/GREEN indicator

ACCURACY

All Models: ± 2 % of Full Scale

SENSITIVITY

0.05% of span

STABILITY

0.05% of span

7

Page 12

REPEATABILITY

0.1% of span

CALIBRATION CHECK

Built in Electronic Calibration (EC) Mid scale 2500/2.50.

RECORDER OUTPUT

0-10 VDC @ 5 mA max. (linear); standard on all models

OUTPUT IMPEDANCE

100Ω ±5%

SENSOR INPUT

1 (sensor included)

CONTROL FUNCTION

ALL Models:

Single set point alarm/control continuously adjustable

0-100% of span

Hysteresis

Adjustable from 0.3-6% of full scale

Indicators

“HIGH” (red) and “LOW” (green) set point LED.

Relay Contact Rating X 2

SPDT 10 amp @ 115 VAC, 30 VDC. Relay operates on

increasing reading.

Fused Outputs (2)

5 amp @ 115/230 VAC.

WEIGHT

CTCII: average 2 Ibs. (0.9 kg)

C. OPTIONAL FEATURES

-45 4 1/2 digit backlit liquid crystal display (LCD)

-35BL 3 1/2 digit backlit LCD

-24V 24 VAC isolated power supply (special order)

-24VD 24 VDC isolated power supply (special order)

-C4A 4-20 mA Output Module

-CS51R More Rugged Sensor (replaces the CSAR)

D. OPTIONS & ACCESSORIES

(ordered separately)

45O 4 1/2 digit backlit liquid crystal display (LCD)

35BLO 3 1/2 digit backlit LCD

C4AO 4-20 mA Output Module

LTMO Limit Timer Module Kit

442-3000 Calibration Solution (3000 ppm / 3900 µM/µS)

INPUT POWER SPECIFICATIONS

115/230 VAC ±15%, 50/60 Hz (User selectable) overvoltage

category II

100 mA Maximum Current

Double Insulated

Fuse - 100mA Slow Blow (T.10A) for both 115 & 230 VAC

(V~) User replaceable

Humidity - 20-90% non-condensing

Max. Altitude -

40,000 ft/12,000 meters non-operating

10,000 ft/3000 meters operating

Pollution degree 2

24 VAC Option available on Special Order

Overvoltage category II

250 mA Maximum Current

Double Insulated

Fuse - 250mA Slow Blow (T.25A) User replaceable

24 VDC Option available on Special Order

250 mA Maximum Current

Double Insulated

Fuse - 250mA Slow Blow (T.25A) User replaceable

AMBIENT TEMPERATURE RANGE

32°F ( 0°C) to 140°F (60°C)

DIMENSIONS

4.7” (120mm) H x 6.3” (160mm) W x 3.6” (92mm) D

HOUSING CONSTRUCTION

Fully gasketed heavy-duty ABS waterproof and corrosion

proof.

Rated IP65/NEMA 4X

Double Insulated

DOUBLE INSULATED

8

Page 13

E. SENSORS

1. CONDUCTIVITY/TDS

CTCII Conductivity/TDS Chemical Treatment Controllers come

standard with the CSAR. The CSAR is of one piece molded

construction with two 316 stainless steel pins (electrodes).

Standard 3/4” NPT installation. It is rated for applications that do

not exceed 75PSI@60°C.

Other sensors for more demanding applications maybe

substituted at an additional cost. All sensors include temperature

sensor for automatic temperature compensation.

The CS51R models compact size allows mounting in a standard

3/4” NPT tee. The sturdy polypropylene bushing is modular for

easy, inexpensive replacement. It is rated for applications that

do not exceed 100PSI@100°C. Add -CS51R to order number if

desired.

Special order High Temperature, High Pressure sensors.

For detailed descriptions of these and other sensors, see Sensor

Selection Guide and specic sensor data sheets available

from your local distributor, the Myron L Company, or on line at

www.myronl.com.

a. SENSOR SPECIFICATIONS

TEMPERATURE COMPENSATION

Automatic to 25°C, between 32-212°F (0-100°C)

except high temperature models - up to 205°C.

PRESSURE/TEMPERATURE LIMITS

CSAR - 75PSI (517.2 kPa) at 60°C (140°F)

CS51R - 100 psi (689.6 kPa) at 212°F (100°C)

For higher limits, see Special Order Models below.

FITTING/BUSHING

CSAR: 3/4” MNPT threaded ABS body

CS51R: Modular Polypropylene threaded 3/4” NPT

CS41HTR Cond/TDS High Temperature Model 250PSI@205°C

For additional information see sensor selection & specic data

sheets for details.

F. ORDERING INFORMATION

Follow steps 1, 2 & 3.

NOTE: CTCII model number includes the CSAR sensor as

standard. If other than the CSAR sensor is desired, please specify

when ordering.

1. HOW TO ORDER CTCII

Specify Model:

CTCII — Basic controller

CTCIID — w/ LCD

CTCIIT — w/ Limit Timer

CTCIITD — w/ Limit Timer and LCD

EXAMPLE A — a basic CTCII controller with a 4-20 mA output.

:

MODEL OPTION

CTCII — C4A

Written as — CTCII-C4A

EXAMPLE B -— a CTCIID controller with a 3 1/2 digit digital

display, a 4-20 mA output, and a CS51R sensor. The CS51R

sensor is for more demanding applications at a modest price

increase.

MODEL OPTION

CTCIID — C4A — CS51R

Written as — CTCIID-C4A-CS51R

2. HOW TO ORDER SPECIAL SENSOR

or Sensor Options

Select Special sensor and/or add options to sensor as in

examples below.

CABLE

Shielded; 10’ (3 meters) standard.

25’ (7 meters), and

100’ (30 meters) lengths also available.

DIMENSIONS

CSAR: 3/4 MNPT. Electrodes, Twin Pin ~3/4 (20mm) L.

CS51R: 3/4 MNPT. Electrode 1.2” (30mm) L; 0.5”

(13mm) Dia.

For additional information see sensor selection & specic data

sheets for details.

b. SENSOR OPTIONS

-25 25’ Shielded Cable

-100 100’ Shielded Cable

CS51R Only

-T Titanium - in place of Stainless Steel

-STF Sanitec Fitting.

1/2” thru 4”. State size, i.e. STF-1/2.

-PV 1/2” PVDF tting.

{replaces polypropylene}

-HPSS 1/2” 316 STAINLESS STEEL tting

(replaces polypropylene).

c. SPECIAL ORDER MODELS — 316 Stainless Steel

(1.0 cell constant)

CS40R Conductivity/TDS Valve Insertable 100PSI@150°C

CS40HTR Above High Temperature Model 250PSI@205°C

CS41R Cond/TDS High Temperature Model 100PSI@150°C

EXAMPLE C — a model CS51R sensor made with Titanium and a

100 foot cable.

MODEL OPTIONS

-CS51R — T-100

Written as — CS51R-T-100

EXAMPLE D — a Special Order High Temperature sensor made

of Titanium, and a Wet-Tap Valve.

MODEL OPTIONS

-CS40HTR — T-WTV

Written as — -CS40R-T-WTV

3. COMBINING CTCII and SPECIAL SENSOR

Add Steps 1 & 2.

EXAMPLE — Add above examples B and C. A CTCIID controller

with a 3 1/2 digit digital display, a 4-20 mA output, and a CS51R

sensor made with Titanium and a 100 foot cable.

Written as — CTCIID-C4A-CS51R-T-100

9

Page 14

II. INSTALLATION

SURFACE MOUNTING DIAGRAMS

DIMENSIONS IN INCHES

(MILLIMETERS)

Figure II.B.1.

5.83"

(148mm)

3.54"

(90mm)

A. GENERAL

This section provides the recommended procedures for properly

installing your CTC Series II Chemical Treatment Controller, and

sensors.

CAUTION - READ FOLLOWING CAREFULLY

!

WARNING: THE MYRON L COMPANY RECOMMENDS THAT

ALL MOUNTING AND ELECTRICAL INSTALLATIONS BE

PERFORMED BY QUALIFIED PERSONNEL ONLY. FAILURE

TO DO SO COULD CAUSE DAMAGE TO INSTRUMENT, AND

COULD BE HARMFUL OR FATAL TO PERSONNEL.

B. MECHANICAL INSTALLATION

All CTCII electronics are packaged inside a waterproof/weatherproof enclosure.

The enclosure is designed for surface mounting.

There are four basic guidelines to consider when selecting a

mounting location:

1. Select a site that limits the CTCII exposure to excessive

moisture and corrosive fumes (water owing or dripping

directly on the power cords may cause an unsafe

condition, and is NOT recommended).

2. For best results, position your CTCII controller and

sensor as close as possible to the point being controlled.

The CTCII controllers are not designed to operate with a

sensor cable length that exceeds 100’ (30 meters).

3. Mount your CTCII controller at eye level for viewing

convenience.

1. SURFACE MOUNTING

NOTE: Due to the many variables of installations mounting

screws are not supplied. It is recommended that suitable #6 (M4)

screws for the exact conditions be used, i.e. woodscrews, metal

or sheetmetal.

1. Select mounting site location.

2. Mark and drill the required mounting holes. For hole

drilling locations, see gure II.B.1.

3. Hold the CTCII in place while starting and tightening the

mounting screws.

DOUBLE INSULATED

10

Page 15

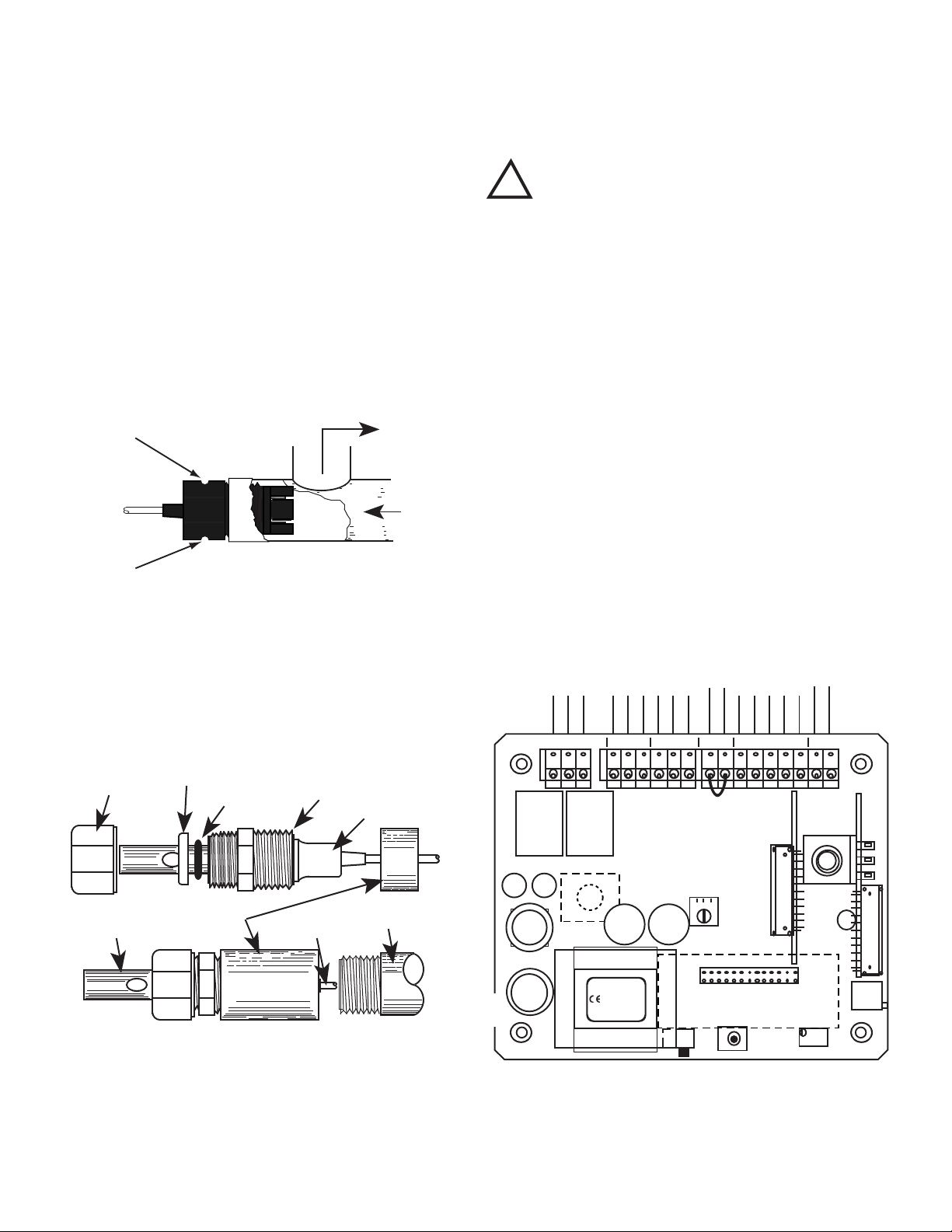

C. SENSOR INSERTION/IMMERSION MOUNTING

CSAR INSERTION MODE

Figure II.D.1

OUT

IN

DOT

DOT

CABLE

SENSOR TIP

COUPLING

3/4" NPT

EXTENSION TUBE

SECURING NUT

PLASTIC

WASHER

O-RING

THREADED FITTING

3/4" FNPT

FLANGE

FUSE

ELECTRICAL CONNECT DIAGRAM

Figure II.E.1

DIS

TRANSFORMER

DISPLAY

Yel

FEED

PUMP

BLEED

VALVE

POWER

FLOW

SWITCH

SENSOR 0-10VDC

C4AM

LTM

HYST

CAL

PWR C GDPWR C GDPWR C GD FS BK WT RD GN NU R- R+

Flow Switch

Jumper Remove if

flow switch

installed.

TDS COND

MYRON L

COMPANY

CTCII

BLK

WHT

RED

GRN

NEU

R-

R+

POWER

COMM

GROUND

POWER

COMM

GROUND

POWER

COMM

GROUND

INPUT POWER SENSOR

FEED

PUMP

BLEED

VALVE

FLOW

SWITCH

0-10 VDC

EC

SWITCH

BLEED FEED

CAP

CAP

RELAY

RELAY

115/230 VAC

SELECT SWITCH

The Sensor’s mounting orientation must provide a continuous and

adequate circulation ow to prevent the trapping of air bubbles

within the Sensor’s electrode area (CSAR shown in gure II.D.1).

Failure to do so will result in conditions that may prevent the

Sensor from functioning properly. The CSAR sensor is designed

for insertion (in-line installation). The optional CS51R sensor may

be ordered and installed as either insertion, or immersion (see

gure II.D.2).

1. INSERTION MODE (in-line installation)

Use approved sealant, i.e. Teon tape as required.

1. Pre-wind CSAR sensor before installation. Rotate sensor

counter clockwise (CCW) (as if removing sensor) 4-5

turns before installing into tting.

2. Insert the Sensor Fitting assembly into the “T” tting with

electrode aligned with direction of ow as shown in gure

II.D.1. and tightly secure. Note: The CS51R installs in

the same manner. (but does not require any turns)

D. ELECTRICAL INSTALLATION

As shipped from the factory, the input power cable, the two

(2) output connectors, and the sensor are pre-wired to the

controller. Electrical connection simply requires plugging in

the appropriate valve and pump, and input power as labeled.

WARNING !

!

A device to disconnect the Model CTCII from the power

supply is required. It is recommended that this switch or

circuit breaker be labeled as the disconnection device for the

Model CTCII.

WARNING: All CTCII controllers are factory set for 115 VAC.

Before starting, ensure the input power “115/230” selection

is correct for your requirements. Failure to do so is beyond

the responsibility of the Myron L Company. See section II.D.1.

below and gure II.E.1.

NOTE: Some models, if ordered, have either a 24 VAC or a 24

VDC input power requirement - check labels carefully.

The following instructions are if the input power, output power or

sensor cables are removed.

The electrical installation procedures provided in this manual are

common to all CTCII controllers. Unless otherwise instructed,

refer to gure II.E.1. for the CTCII controller’s terminal block

connector wiring designations.

Use approved sealant, i.e. Teon tape as required.

2. IMMERSION OR DIP SENSOR ASSEMBLY

1. Verify that the CS51R Sensor’s Fitting assembly is

properly assembled as shown in gure II.D.2.

2. Insert and pull the Sensor’s cable through the extension

tube and then tightly attach extension tube to Sensor

assembly as shown in gure II.D.2.

IMMERSION OR DIP CS51R SENSOR

ASSEMBLY SHOWN

Figure II.D.2

11

Page 16

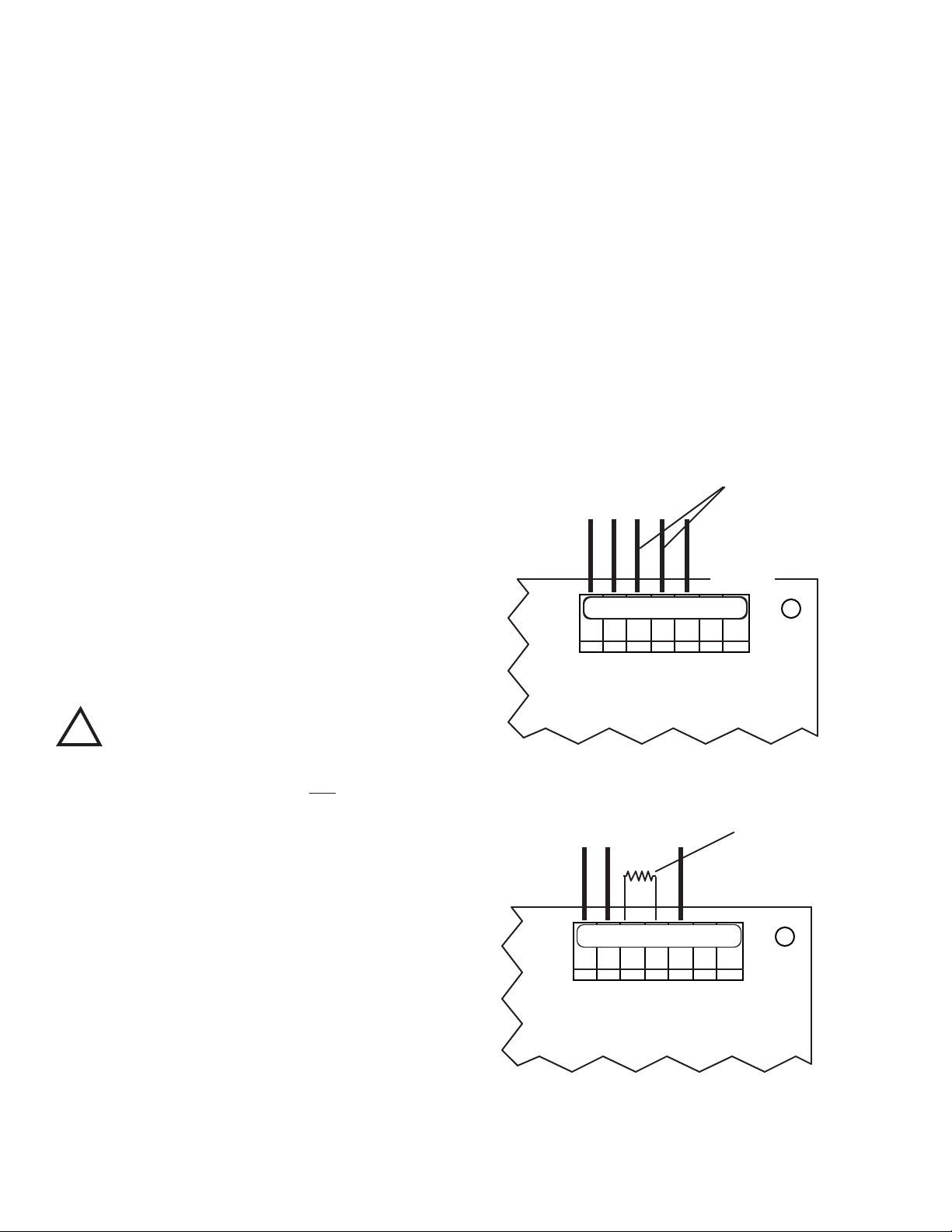

1. 115/230 VAC CONVERSION

INSTALL 1.1K�

RESISTOR HERE

BK WT RD GN NU R- R+

SENSOR LEADS

Main CB Assembly

Figure II.E.3

Main CB Assembly

Figure II.E.2

SENSOR LEADS

REMOVE THESE TWO LEADS

BK WT RD GN NU R- R+

0-10VDC

OUTPUT

1. Before turning power on to the CTCII controller ensure

the proper input voltage has been selected. Failure to

do so will blow the fuse. It could, under some conditions,

cause injury and damage the instrument voiding the

warranty.

2. Locate switch located next to the fuse holder.

3. Using a screwdriver, turn switch to required voltage.

2. CONNECTING THE SENSOR CABLE

If the sensor has been removed or requires replacement for any

reason.

1. Place the Sensor’s interface cable through the supplied

watertight cable restraint into the enclosure’s appropriate

access hole.

2. Install the sensor cable wire to comply with local

electrical codes*. Follow the color code as marked. See

gure II.E.1.

a. MODIFICATION FOR US PHARMACEUTICAL 25

(No Temperature Compensation)

This simple modication will allow your CTCII Chemical

Treatment Controller to meet USP 25 requirements by defeating

the normal temperature compensation circuit thus giving

“uncompensated” readings as required. Rarely will this be

required in the normal applications of this type of controller.

However, if it becomes necessary, the following will step you

through it.

5. If sensor is installed, locate and remove the RED (RD)

and the GREEN (GN) leads from MAIN Circuit Board, as

shown in gure II.E.2.

6. Cut off or tape RED (RD) and the GREEN (GN) leads

from sensor.

7. Install 1.1kΩ resistor at RED (RD) and the GREEN (GN)

connector locations, as shown in gure II.E.3.

8. Carefully reinstall the front panel.

9. Reinstall the clear cover

10. Reinstall the four (4) screws and tighten.

11. To operate, turn power ON.

NOTE: Recalibration will require both the solution and sensor be

at 25°C for maximum accuracy.

3. FLOW SWITCH

A ow switch may be installed (electrically connected) utilizing the

FS connection*, see gure II.E.1, remove jumper and connect ow

switch leads to terminals.

*CAUTION: The connectors require only a small screwdriver or

a pen to push on the release levers. The release levers may be

broken or damaged if not pushed straight toward the circuit board.

DO NOT push the release levers sideways.

Specications:

As required to meet USP 25.

Installation

Briey A resistor is installed in place of the sensor “temperature” sensing

leads.

The extra sensor leads are either cut off or the ends are wrapped

in tape to prevent shorting.

CAUTION - READ FOLLOWING CAREFULLY

!

WARNING: BEFORE STARTING, IF CTCII CONTROLLER IS

INSTALLED, ENSURE THE POWER IS OFF. FAILURE TO DO

SO COULD CAUSE DAMAGE TO THE INSTRUMENT, AND

COULD BE HARMFUL OR FATAL TO PERSONNEL. ONLY

QUALIFIED PERSONNEL SHOULD INSTALL OR SERVICE

ELECTRICAL EQUIPMENT.

Requirements:

One 1.1kΩ .1% resistor, user supplied or may be ordered from the

Myron L Company.

NOTE: When opening instrument, remove front panel with care.

1. Using a Phillips Head screwdriver remove the four (4)

screws on the clear cover.

2. Remove clear cover.

3. The front panel is held in place with hook & loop strips

on each side. By carefully lifting at the slot on the top,

the front panel will pull toward you. Do not pull more than

about 8 inches/20CM.

DO NOT pull on control knob(s).

4. Rotate the front panel down so that the back side is

facing you. The Circuit Board is mounted to the back of

the front panel.

12

Page 17

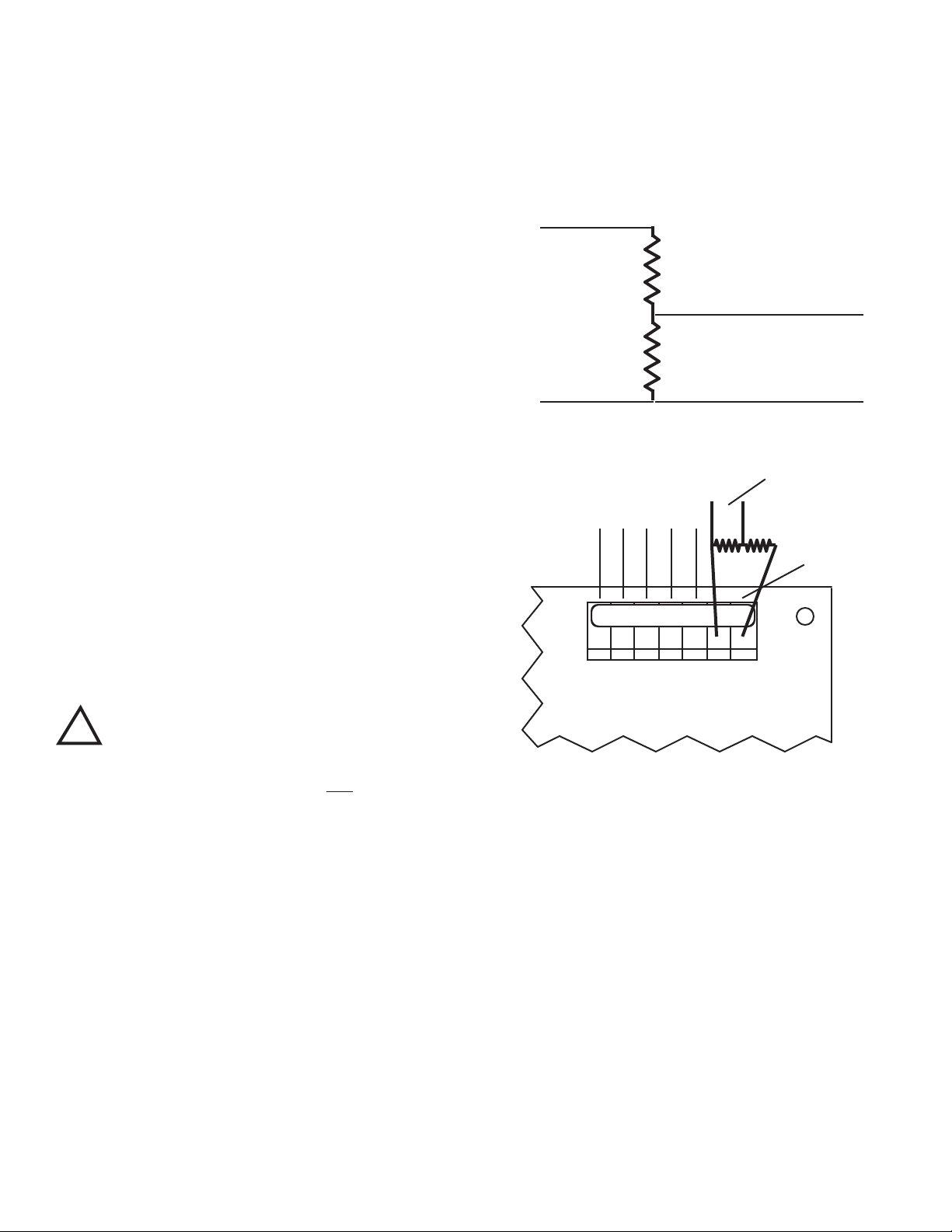

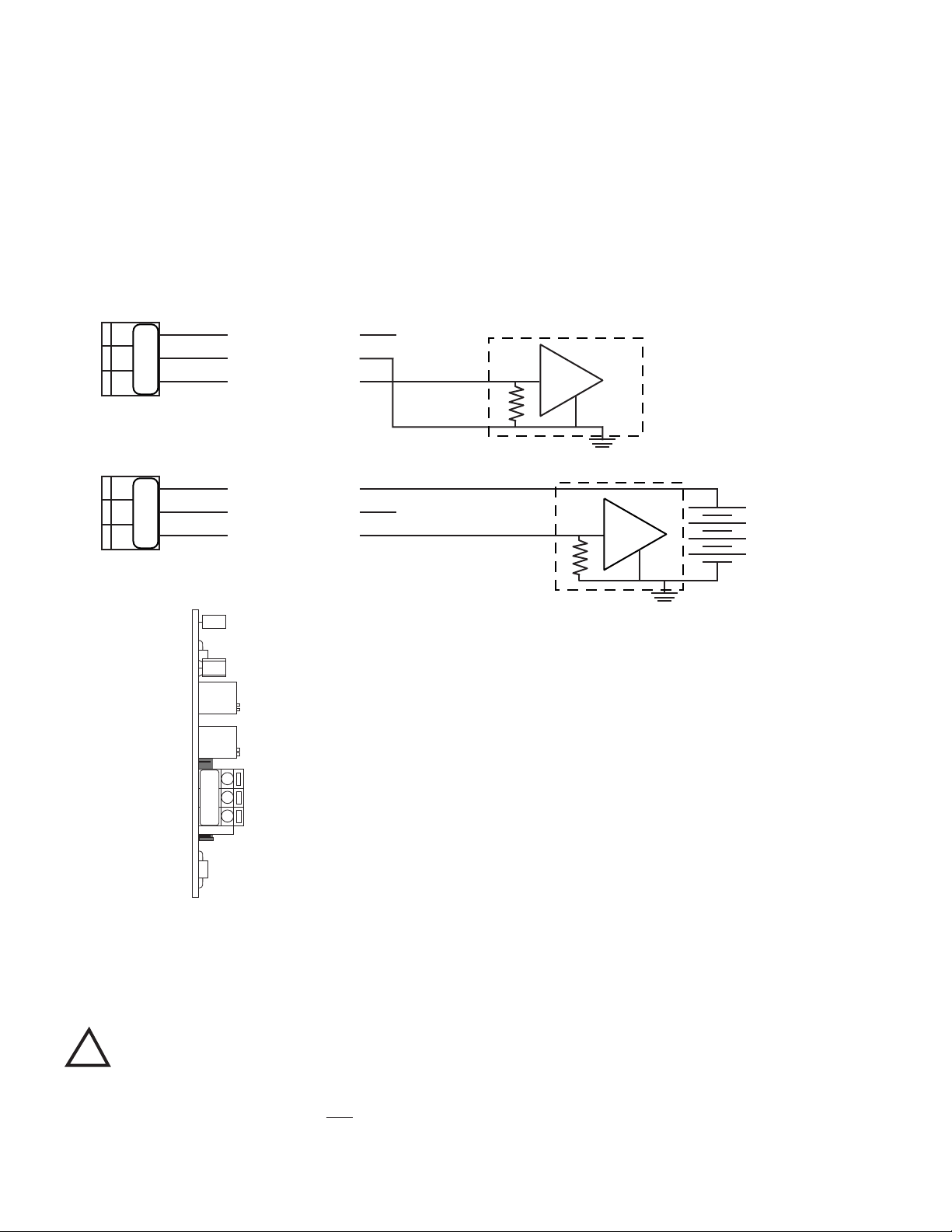

E. 0-10 VDC RECORDER OUTPUT

Figure II.F.1

0-10V Output

+

-

A

B

+

-

Recording

Device

Figure II.F.2

BK WT RD GN NU R- R+

SENSOR LEADS

Main CB Assembly

0-10VDC

OUTPUT

- +

NEW

OUTPUT

AS

SELECTED

The 0-10 VDC output is designed to give the user the capability

of sending a signal to a remote meter, recorder, PLC or SCADA

system.

Requirements

A hole of the proper size must be drilled in the enclosure. The

user/installer must choose a location that will NOT interfere with

normal operation. To ensure waterproof integrity, a watertight

cable restraint must be used. Failure to do so or improper

installation will void the warranty and may be costly to repair.

1. CONNECTION

1. Drill appropriate size hole.

2. Place the user supplied interface cable and watertight

cable restraint into the hole.

3. Connect the Recorder’s plus (+) and minus (-) terminal

wires to the Recorder output connectors. (See gure

II.E.2.)

4. Refer to Section V.B.1.b for the procedures to calibrate

the 0-10 VDC voltage output.

2. VOLTAGE DIVIDER

A voltage divider gives the user the ability to scale or tailor the

output to a particular need or requirement due to the input of

another device, i.e. the output of the Main CB is 0-10V while the

input requirement of a particular recording device is 0-5V.

6. Attach leads to recording device as shown in gure II.F.1.

7. Attach resistors to 0-10V Output as shown in gure II.F.2.

Ensure resistors and leads DO NOT short to each other

or to any part of the CB assembly.

8. Recalibration is required, see Calibration Procedures,

section V.B.

Briey—

Two resistors are installed across the 0-10V output.

The output is recalibrated to required voltage.

Requirements

Select two (2) resistors as listed;

For 0-5V Output both “A & B” are 2K Resistors.

For 0-1V Output “A” is a 9K resistor and “B” is a 1K resistor.

!

WARNING: BEFORE STARTING, IF MONITOR/CONTROLLER

IS INSTALLED, ENSURE THE POWER IS OFF. FAILURE TO

DO SO COULD CAUSE DAMAGE TO THE INSTRUMENT, AND

COULD BE HARMFUL OR FATAL TO PERSONNEL. ONLY

QUALIFIED PERSONNEL SHOULD INSTALL ELECTRICAL

EQUIPMENT.

Physical

If the front panel has all ready been removed from the enclosure

skip to #3.

1. Using a Phillips Head screwdriver remove the four (4)

2. Remove clear cover.

3. The front panel is held in place with hook & loop strips

4. Rotate the front panel down so that the back side is

5. Solder two selected resistors together as shown in gure

a. INSTALLATION

CAUTION - READ FOLLOWING CAREFULLY

screws on the clear cover.

on each side. By carefully lifting at the slot on the top,

the front panel will pull toward you. Do not pull more than

about 8 inches/20CM.

DO NOT pull on control knob(s).

facing you. The Circuit Board is mounted to the back of

the front panel.

II.F.1.

Reassembly

1. Carefully reinstall the front panel, ensure no wires have

been pinched.

2. Reinstall the clear cover.

3. Reinstall the four (4) screws and tighten.

4. If desired, install corner covers.

5. To operate, turn power ON.

13

Page 18

F. RE-SCALE YOUR CTCII CONTROLLER

Main CB Assembly

Figure II.F.1

SET POINT

HYSTERESIS

RIGHT INC

LEFT DEC

115/230 VAC

SELECT SWITCH

100mA Slow Blow (T.10A)

115 & 230 VAC (V~)

SCALE SELECT

ELECTRONIC

CALIBRATION

MAIN

CALIBRATION

CONTROL

DISPLAY

CALIBRATION

CONTROL

(FACTORY SET)

OPTIONAL

LIMIT

TIMER

CONTROL

MODULE

OPTIONAL

4-20 mA

OUTPUT

MODULE

DIS

CAL

TDS COND

EC

CTCII

DISPLAY

TRANSFORMER

Yel

CAP CAP

C4AM

LTM

HYST

Flow Switch

Jumper Remove if

flow switch

installed.

SWITCH

FUSE

RELAY RELAY

BLEED FEED

FEED

PUMP

BLEED

VALVE

POWER

FLOW

SWITCH

SENSOR 0-10VDC

FS BK WTRD GN NU R- R+PWR C GDPWR C GDPWR C GD

Wickman Fuse 5 Amp

(#3741500041 or equiv)

115 VAC(V~)

1. DESCRIPTION

The CTC Series II controller, has been designed for easy eld rescaleability. To re-scale your 0-5000 µS CTCII to 0-5000 “PPM”

TDS 442™ or visa versa requires the simple slide of a switch.

CAUTION - READ FOLLOWING CAREFULLY

!

WARNING: BEFORE STARTING, IF MONITOR/CONTROLLER

IS INSTALLED, ENSURE THE POWER IS OFF. FAILURE TO

DO SO COULD CAUSE DAMAGE TO THE INSTRUMENT, AND

COULD BE HARMFUL OR FATAL TO PERSONNEL. ONLY

QUALIFIED PERSONNEL SHOULD INSTALL OR SERVICE

ELECTRICAL EQUIPMENT.

Physical

NOTE: When opening instrument, remove front panel with care. If

the front panel has already been removed from the enclosure skip

to #3.

1. Using a Phillips Head screwdriver remove the four (4)

screws on the clear cover.

2. Remove clear cover.

3. The front panel is held in place with hook & loop strips

on each side. By carefully lifting at the slot on the top,

the front panel will pull toward you. Do not pull more than

about 8 inches/20CM.

DO NOT pull on control knob(s).

4. Rotate the front panel down so that the back side is

facing you. The Circuit Board is mounted to the back of

the front panel.

5. Locate the switch next to the transformer. See gure

II.F.1.

6. Slide knob toward the desired scale - TDS/ppm or

COND/µM(µS).

7. Recalibrate, see CALIBRATION PROCEDURES, section

V.B.

8. Install (remove) Parts Per Million - TDS label (supplied

inside).

9. Reassemble front panel.

14

Page 19

III. OPTIONS &

ACCESSORIES

A. LIMIT TIMER MODULE OPTION

LTMO Limit Timer Module Kit ordered separately.

1. DESCRIPTION

This module allows the user to set a “limit” of up to 120 minutes

on the length of time the feed pump will operate.

Specications:

Control Function:

Controls the Feed Pump Relay only.

2. INSTALLATION

Briey The Limit Timer Module simply plugs into the CTCII circuit board,

see gure III.B.4.

4. Rotate the front panel down so that the back side is

facing you. The Circuit Board is mounted to the back of

the front panel.

5. Carefully press the LT Limit Timer Module into the Circuit

Board as shown in gure III.A.4.

When fully seated the LTMO option will snap into place.

6. Reassemble front panel.

7. Turn shaft fully counter-clockwise.

8. Install knob on shaft and align to “DOT”.

9. Reinstall clear cover.

B. C4A MODULE

(4-20 mA OPTION)

-C4A 4-20 mA Self/Remote-powered Isolated output module

ordered with controller.

C4AO 4-20 mA Self/Remote-powered Isolated output module

ordered separately.

1. DESCRIPTION

The 4-20 mA option gives the CTCII controller the ability to

send a signal very long distances with minimal interferences and

signal degradation. The output is an Isolated 4-20 mA signal that

corresponds to the full scale range of the controller into which it is

installed. This output is easily congured to be either self-powered

or remote-powered as required for your particular application.

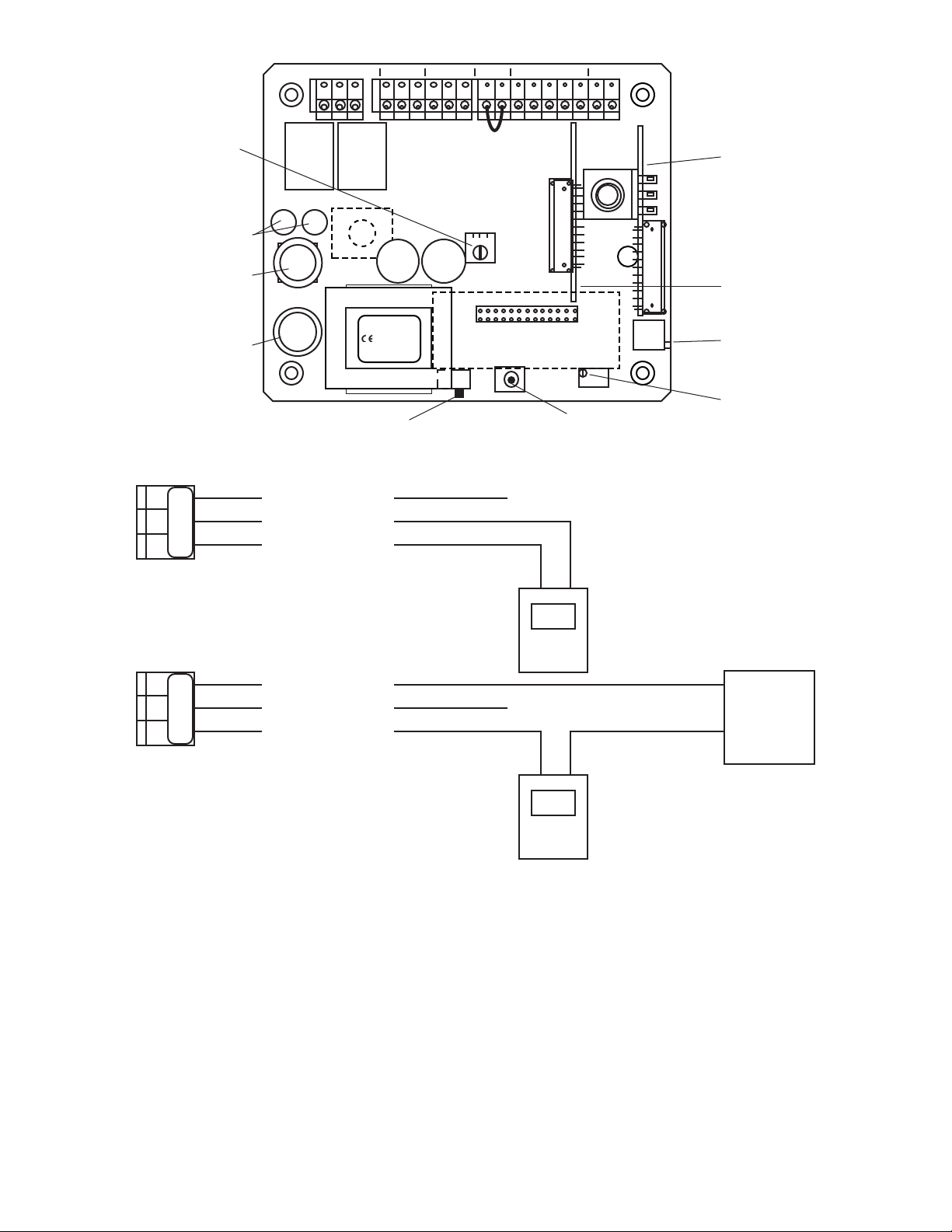

Figure III.A.1

CAUTION - READ FOLLOWING CAREFULLY

!

WARNING: BEFORE STARTING, IF MONITOR/CONTROLLER

IS INSTALLED, ENSURE THE POWER IS OFF. FAILURE TO

DO SO COULD CAUSE DAMAGE TO THE INSTRUMENT, AND

COULD BE HARMFUL OR FATAL TO PERSONNEL. ONLY

QUALIFIED PERSONNEL SHOULD INSTALL OR SERVICE

ELECTRICAL EQUIPMENT.

Physical

NOTE: When opening instrument, remove front panel with care. If

the front panel has already been removed from the enclosure skip

to #3.

1. Using a Phillips Head screwdriver remove the four (4)

screws on the clear cover.

2. Remove clear cover.

3. The front panel is held in place with hook & loop strips

on each side. By carefully lifting at the slot on the top,

the front panel will pull toward you. Do not pull more than

about 8 inches/20CM.

DO NOT pull on control knob(s).

NOTE: The maximum impedance of the user’s current input

instrument should not exceed 600 ohms.

Since the output is an isolated current loop, it is the ideal choice

for applications requiring; a control signal to be run very long

distances, systems requiring a 4-20mA input or in instances where

isolation is necessary.

As the output is isolated, and a current, it is useful for long

distance interface, especially where wiring resistances may be

high, and/or the ground potentials may differ between the sensor

input ground and the current receiving instruments ground.

The 4-20 mA output will not be degraded in accuracy even

when the ground differences are as much as 120 VAC @ 60Hz.

Interface wire resistance of 350Ω will not degrade the accuracy of

the output when interfaced to a typical 250Ω input impedance of a

transmitter current input device.

The output is capable of driving a minimum of 600Ω worse case,

therefore, will satisfy virtually all modern interface requirements.

Current input devices usually have an input impedance of 250Ω,

however, some older designs can have as high as 500Ω or as

low as 10Ω. This “-C4A” option will drive any impedance from 0 to

600Ω without any degradation of performance.

There are two modes in which current loop transmitters operate;

Self-Powered and Remote-Powered.

Self-Powered — the transmitter provides the power to drive

the 4 to 20 mA current. See gure III.B.1.

Remote-powered — the receiving instrument provides the

power to drive the 4 to 20 mA current. See gure III.B.2.

15

Page 20

Specications

-

Figure III.B.1

(-)

CURRENT INPUT INSTRUMENT

Self - Powered

(+)

+

SIGNAL OUT(+)

POWER OUT

POWER IN

+

NC

-

CURRENT INPUT INSTRUMENT

Figure III.B.2

Remote - Powered

(+)

(-)

+

NC

+ 35 VDC

MAXIMUM

(+)

+

SIGNAL OUT

POWER IN

POWER OUT

SO PO PI

SO PO PI

PO

SO PI

POT1

D1

POT2

U4

R3

Self-Powered and Remote-Powered

Drive Impedance — 0 to 600Ω

Common Mode Maximum — 120 VAC @ 60 Hz

Isolation — 100pf max. to Model 750II circuit common

100pf max. to input power line

Calibration

Two multi-turn pots — Factory Set.

4mA = Zero (0)

20mA = 12 mA - Mid Scale

Calibration is NOT required. However, if you feel you must verify

or recalibrate, see RECALIBRATION.

DO SO COULD CAUSE DAMAGE TO THE INSTRUMENT, AND

COULD BE HARMFUL OR FATAL TO PERSONNEL. ONLY

QUALIFIED PERSONNEL SHOULD INSTALL OR SERVICE

ELECTRICAL EQUIPMENT.

Physical

1. Using a Phillips Head screwdriver remove the four (4)

screws on the clear cover.

2. Remove clear cover.

3. The front panel is held in place with hook & loop strips

on each side. By carefully lifting at the slot on the top,

the front panel will pull toward you. Do not pull more than

about 8 inches/20CM.

DO NOT pull on control knob(s).

Figure III.B.3

Briey The C4A Module simply plugs into the CTCII circuit board, see

Figure III.B.4. Connect signal wires per gure III.B.1 or III.B.2.

2. INSTALLATION

!

WARNING: BEFORE STARTING, IF MONITOR/CONTROLLER

IS INSTALLED, ENSURE THE POWER IS OFF. FAILURE TO

16

CAUTION - READ FOLLOWING CAREFULLY

4. Rotate the front panel down so that the back side is

facing you. The Circuit Board is mounted to the back of

the front panel.

5. Locate the connector on the Circuit Board labeled C4AM.

6. Align as shown.

7. Press into place. The module will click when fully seated.

Electrical

1. Connect the signal and power wires as required, as

shown in gures III.B.1. & III.B.2. This assumes you have

already connected the other end of the wires as required.

a. Place the remote interface cable and user supplied

watertight cable restraint into the enclosure’s

appropriate access hole.

b. Neatly connect the signal cable wires to the CTC’s

appropriate connectors as shown in gure III.B.3.

2. To test, turn power ON.

3. Press the EC switch and monitor the output at your

remote site, or with a DVM set to DC milliamps. Attach

the DVM to the output connectors per your requirements,

i.e. self-powered or remote-powered, see gures III.B.1.

& III.B. 2. If the C4A module is connected properly it will

indicate 12mA.

4. Turn power OFF.

5. Carefully reinstall the front panel.

6. Reinstall the clear cover

7. Reinstall the four (4) screws and tighten.

8. To operate, turn power ON.

Page 21

-

+

POWER IN

NC

+

Remote

Power

Supply

(+)

(-)

(+) SIGNAL OUT

POWER OUT

POWER IN

+

-

(+)

(-)

(+) SIGNAL OUT

POWER OUT

Figure III.B.5.

Remote - Powered

NC

Self - Powered

+

-

+

SO PO PI

SO PO PI

DVM

DVM

MYRON L

COMPANY

Flow Switch

Jumper Remove if

flow switch

installed.

C4AM

LTM

ELECTRONIC

CALIBRATION

DIS

Figure III.B.4.

SCALE SELECT

SET POINT

HYSTERESIS

RIGHT INC

LEFT DEC

115/230 VAC

SELECT SWITCH

100mA Slow Blow (T.10A)

115 & 230 VAC (V~)

SWITCH

FUSE

RELAY RELAY

CAP CAP

HYST

BLEED

BLEED

VALVE

POWER

FEED

PUMP

FLOW

SWITCH

SENSOR 0-10VDC

PWR C GDPWR C GDPWR C GD FS BK WTRD GN NU R- R+

DISPLAY

Yel

CAL

MAIN

CALIBRATION

CONTROL

DISPLAY

CALIBRATION

CONTROL

(FACTORY SET)

OPTIONAL

LIMIT

TIMER

CONTROL

MODULE

OPTIONAL

4-20 mA

OUTPUT

MODULE

TDS COND

CTCII

EC

FEED

TRANSFORMER

Wickman Fuse 5 Amp

(#3741500041 or equiv)

115 VAC(V~)

The 4-20 Module was calibrated at the factory, however, if you

wish to check the calibration the following procedure will help you

to accomplish this task. Exercise caution while performing this

procedure.

Requirements; a DVM set to DC milliamps, a tweaker or small

standard slot screwdriver.

This procedure assumes the front panel is removed.

3. RECALIBRATION

1. If sensor is connected, disconnect sensor wires from

sensor terminal block.

2. Attach the DVM to the output connectors per your

requirements, i.e. self-powered or remote-powered, see

gure III.B.5.

3. Turn power ON, with the display (if included) at ZERO or

ZERO DC volts out at Recorder, the DVM should indicate

4 mA at the signal out.

4. If not, adjust the CAL control marked “4mA” until the

DVM indicates 4 mA, see gure III.B.3.

5. Press the EC switch, the DVM should indicate 12 mA.

6. If not, adjust the CAL control marked “20mA” until the

DVM indicates 12 mA. See gure III.B.3.

NOTE: The C4A is linear, calibration at mid scale will not effect the

7. Calibration is complete.

8. Turn power OFF.

9. Reinstall the clear cover

10. Reinstall the four (4) screws and tighten.

11. To operate, turn power ON.

accuracy.

17

Page 22

IV. OPERATING PROCEDURES

60

80

100

120

0

1000

2000

3000

4000

5000

40

20

0

MICROSIEMENS / CM

CTCII

EC

MINUTES

60

80

100

120

0

1000

2000

3000

4000

5000

40

20

0

MICROSIEMENS / CM

CTCII

EC

MINUTES

60

80

100

120

0

1000

2000

3000

4000

5000

40

20

0

MICROSIEMENS / CM

CTCII

EC

MINUTES

60

80

100

120

0

1000

2000

3000

4000

5000

40

20

0

MICROSIEMENS / CM

CTCII

EC

MINUTES

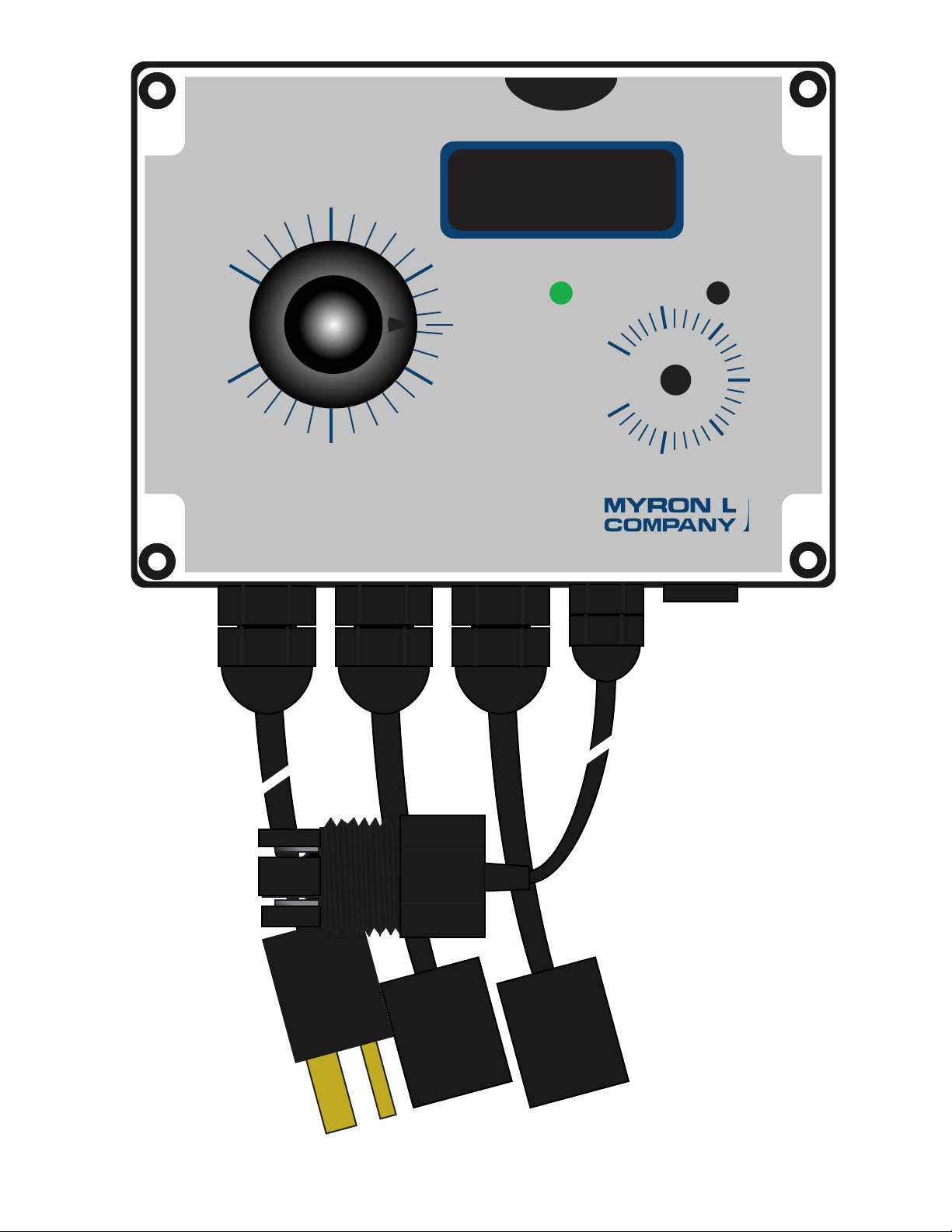

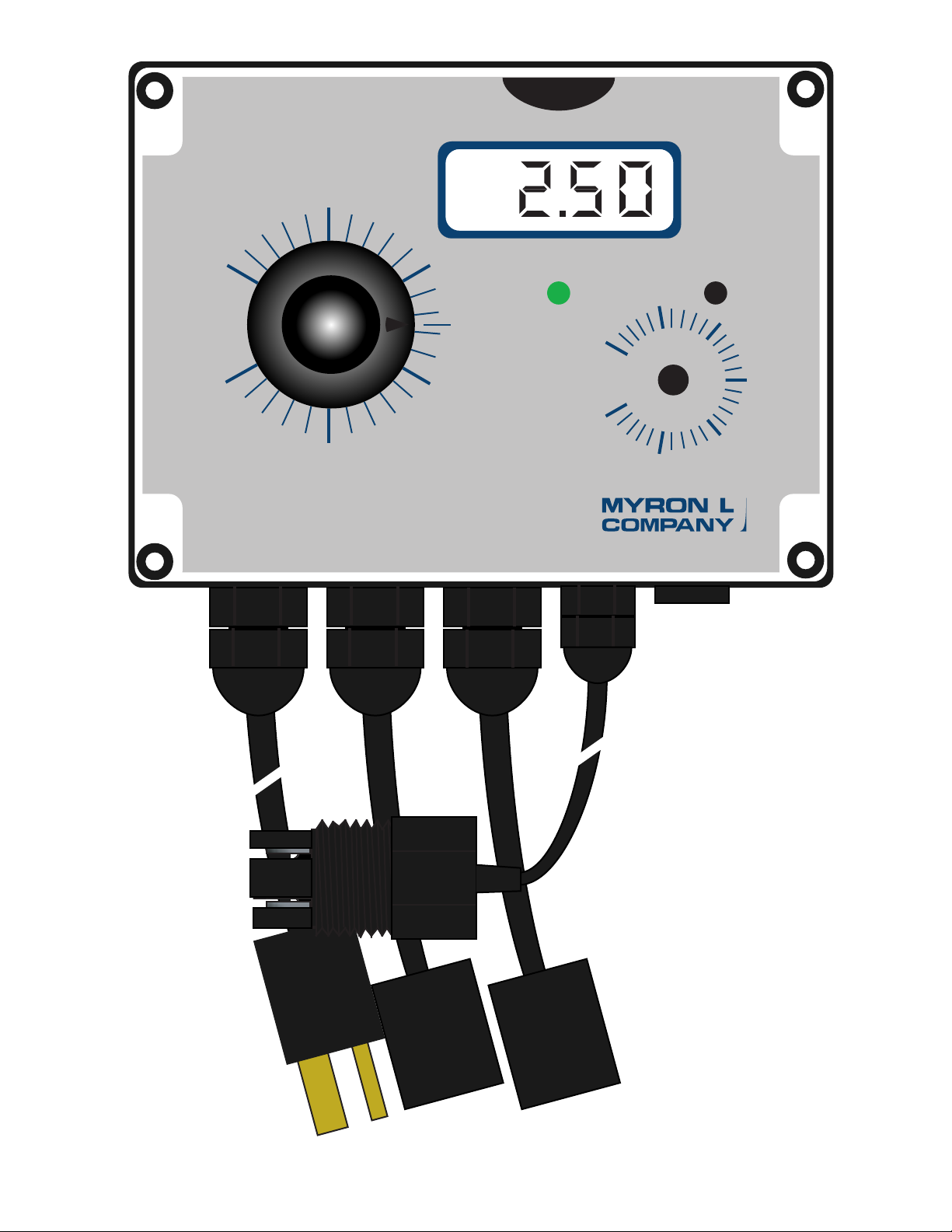

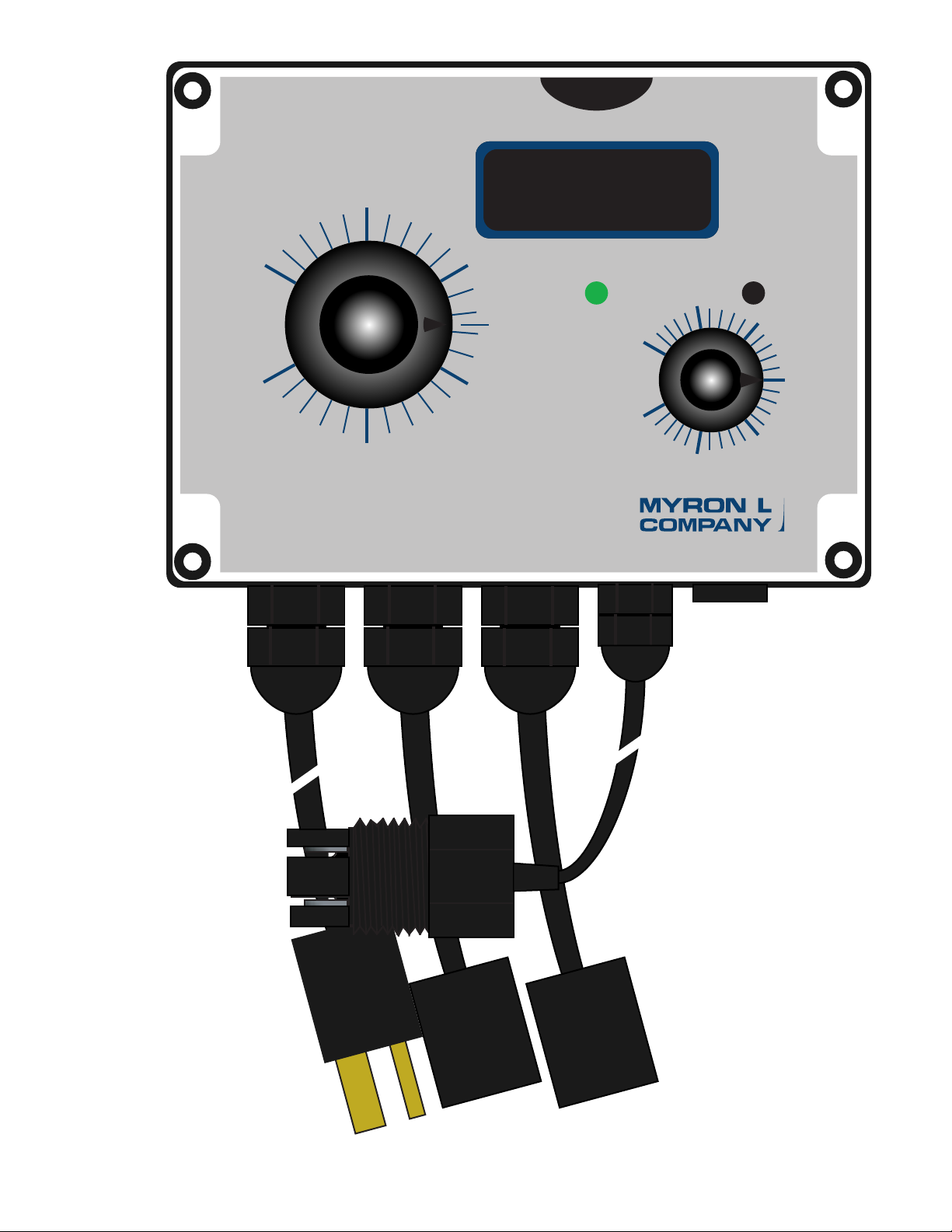

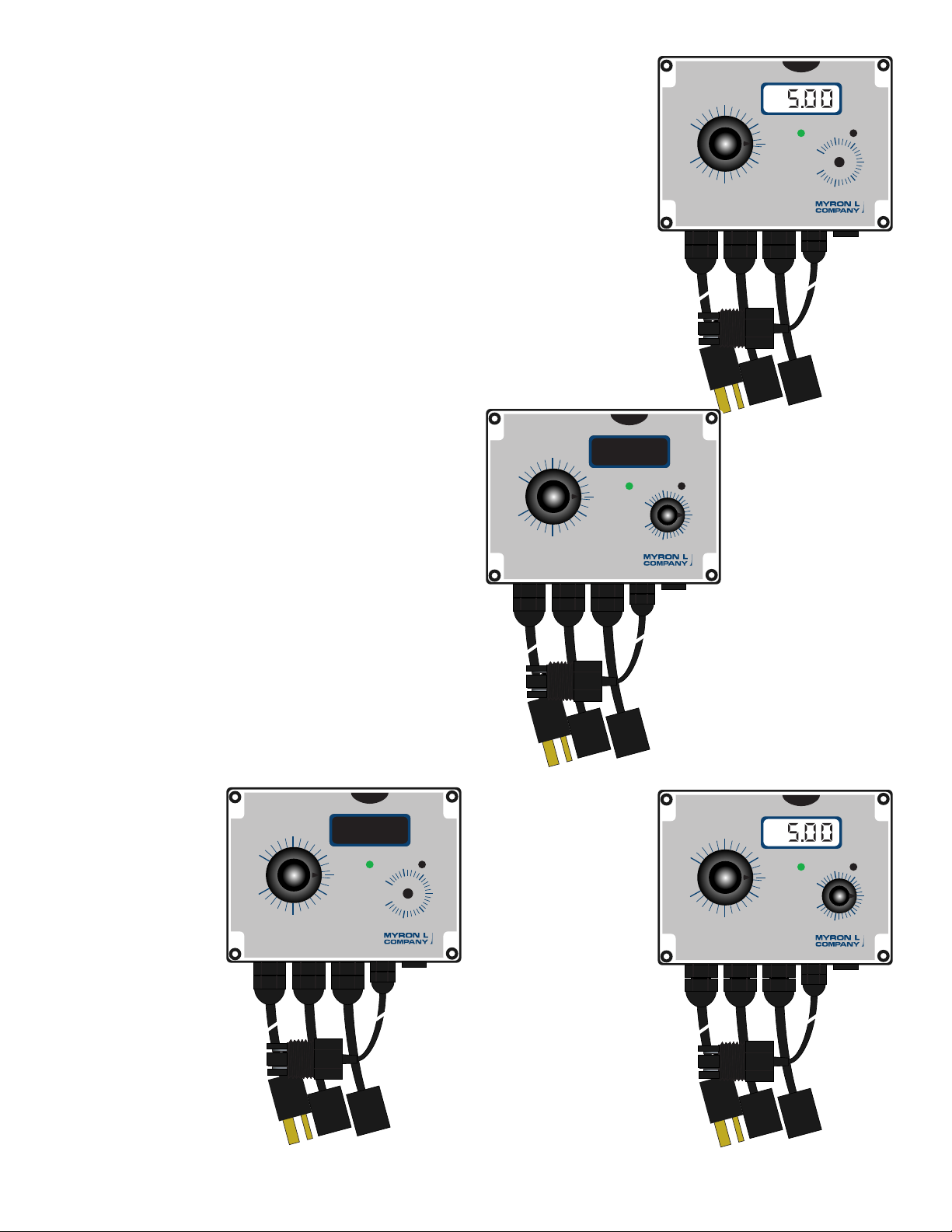

A. FRONT PANEL INDICATORS & CONTROLS

The front panel illustrations to the right and operational

descriptions have been provided to assist the user in identifying

and operating their CTCII controller.

Refer to Section IV.B for Setup procedures and Section IV.B.1 for

Check-Out procedures.

Controller with

LCD Display

CTCIID

1. GREEN LED INDICATOR

When the GREEN LED indicator light is ON the conductivity/TDS

reading is LOW or BELOW the set point. Controller relays are

OFF.

2. RED LED INDICATOR

When the RED LED indicator light is ON the conductivity/TDS

reading is HIGH or ABOVE the set point AND the controller relays

are ON.

3. SET POINT CONTROL

When the “SET POINT” control is rotated the LED indicator light

will change from GREEN to RED and back as the knob is rotated.

The relay will switch ON and OFF. See gures IV.A.1 thru 4.

4. DIGITAL DISPLAY MODELS

Digital display provide a continuous readout of the water being

controlled.

Models CTCIID & CTCIITD are equipped with a 3 1/2 digit, 1/2”

Liquid Crystal Digital Display, as shown in gures IV.A.2 & 4, with

a 4 1/2 digit backlit LCD as an option.

5. LIMIT TIMER MODELS

Models CTCIIT & CTCIITD incorporate a Limit Timer for the feed

pump. The time may be set up to 120 minutes after which the

pump will turn off even though the controller may still be bleeding.

While the feed pump Limit Timer is ON a YELLOW LED will turn

ON. When the Limit Timer times out the YELLOW LED will turn

OFF.

Figure IV.A.2

Controller

with Timer

CTCIIT

Figure IV.A.3

Basic

Controller

18

CTCII

Figure IV.A.1

Controller

with LCD

Display and

Timer

CTCIITD

Figure IV.A.4

Page 23

CAUTION - READ FOLLOWING CAREFULLY

!

B. SETUP PROCEDURES

These Setup procedures cover (1) checking out your new CTCII

Chemical Treatment Controller, (2) setting the control set point,

and (3) adjusting the hysteresis.

NOTE: A small screwdriver or tweaker will be required for some of

the following operations.

point at full scale as it leaves the factory. Under normal (most)

conditions it will not be necessary to adjust.

However, if you desire to make an adjustment please keep the

following in mind.

The adjustment is very simple and is based on set point location.

If the set point is in the upper 75-100% of the scale, the hysteresis

control pot should be turned fully to the right.

If the set point is in the lower portion of the scale, i.e. 5-25% of

scale, the control pot may be turned fully to the left.

If you are operating in the center, 25-75% of scale, the control pot

may be adjusted in the center.

Or the hysteresis or dead band may be adjusted to tighten the

control of a particular process.

1. CHECK-OUT PROCEDURES

The following check-out procedures are used to verify that the

CTCII Controller is operating properly. Refer to gure V.A.1. for

the locations of the components referred to in this section.

a. Assumed that the clear cover and the front panel are removed,

the power is ON.

b. Assumes above PLUS that the controller is connected to an

appropriate Sensor, and that the Sensor is immersed in water

within the range that the Controller will be required to operate.

c. Limit Timer check out procedure.

a. Sensor OUT of water.

1. While pressing the Electronic Calibration Switch (EC),

rotate the Set Point Control toward “EC” on the dial.

Listen for the control relays to click ‘ON and OFF’ as the

set point moves past the EC location. The indicator light

(LED) will change from RED to GREEN.

If equipped with a display, verify that the display

is indicating a reading of approx. 2.50. If not, see

Calibration, section V.B.

2. Adjust the Set Point Control to the desired set point

value.

3. Reassemble.

b. Sensor IN water.

1. Rotate the Set Point Control on the front panel.

The relays will click and the indicator light (LED) will

change from RED to GREEN and GREEN to RED as the

knob is rotated. As the relays click and the LED changes

from RED to GREEN this is the value of the water.

Make a note of the reading on the display if so equipped.

It will be very close to the value indicated by the set point

control knob.

2. Set the Set Point Control to the desired set point value.

3. Reassemble.

CAUTION: Adjusting the hysteresis too narrow may cause the

controller to uctuate (on-off) due to ow, chemical mixing or

bubbles causing the relay to chatter. This condition is to be

avoided, it could damage your valves, pumps, etc. and will

eventually damage the relay.

The following is assuming the front panel is already removed and

the set point has been set, if not see “Set Point Adjustment”.

1. Turn power ON.

2. Locate the Hysteresis Control (HYST) - it is a single turn

pot. See gure V.A.1.

3. Adjust as described in “Hysteresis (Dead Band)

Adjustment” or as desired.

4. Rotate set point control on the front panel to verify

Hysteresis is set as desired.

5. Turn power OFF.

4. “FEED PUMP” LIMIT TIMER

If installed, adjust timer control knob as desired, to limit the ON

time of the feed pump.

REASSEMBLY

1. Carefully reinstall the front panel.

2. Reinstall the clear cover.

3. Reinstall the four (4) screws and tighten.

4. To operate, turn power ON.

c. Limit Timer Check Out Procedure

If the Limit Timer is installed, a YELLOW LED located above the

timer knob will also be ON. To test:

1. Rotate the Limit Timer Control on the front panel from

its highest position to its lowest position. Only the FEED

PUMP relay will click OFF (the YELLOW indicator light

will turn OFF).

2. Adjust the Limit Timer to the desired time.

2. SET POINT ADJUSTMENT

The set point setting is based upon the user’s particular water

purity specications or requirements. Remove clear cover and

adjust control knob to desired set point value.

3. HYSTERESIS (DEAD BAND) ADJUSTMENT

The hysteresis or dead band is approximately ±6% of the set

19

Page 24

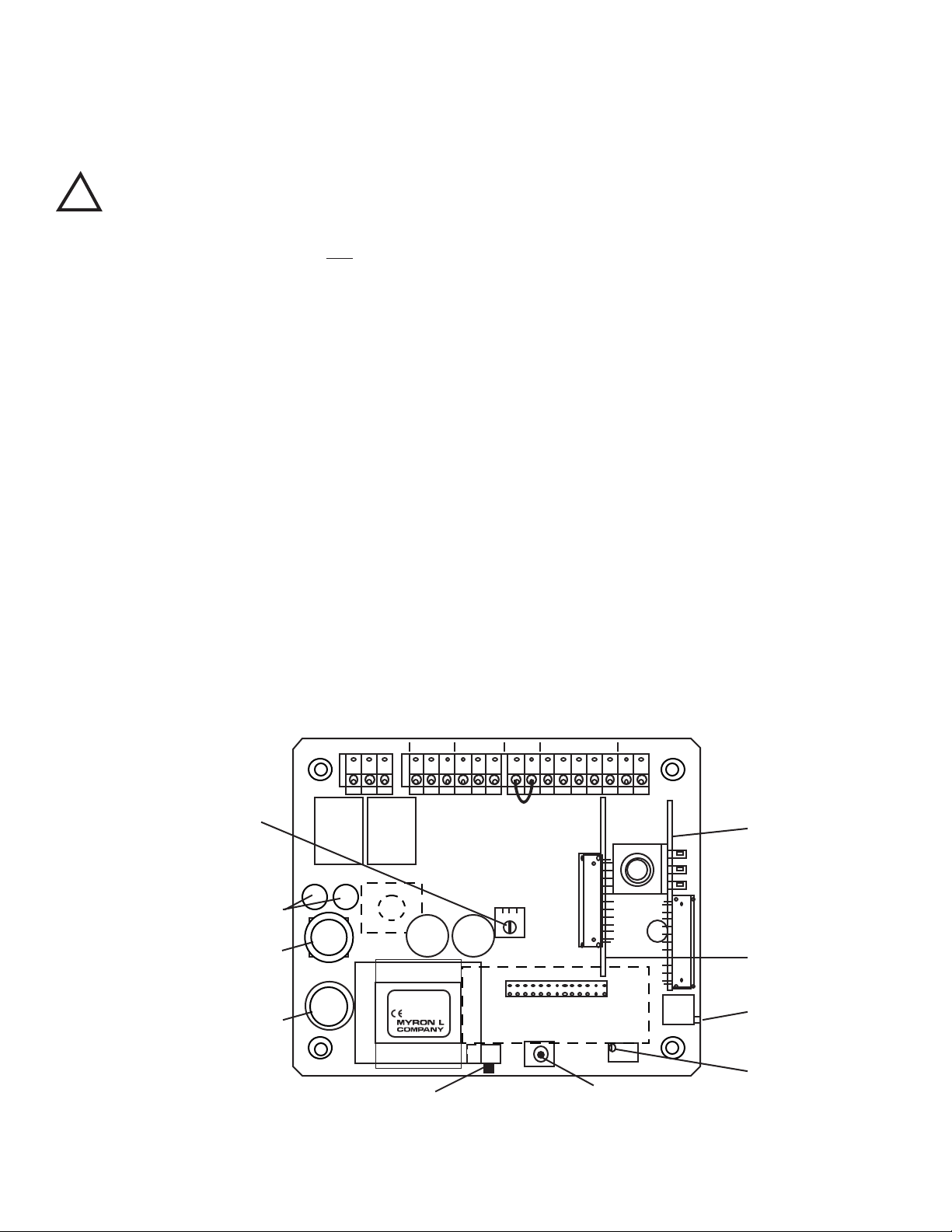

V. COMPONENT IDENTIFICATION,

CTCII MAIN CIRCUIT BOARD

Figure V.A.1

115/230 VAC

SELECT SWITCH

100mA Slow Blow

(T.10A)

115 & 230 VAC (V~)

SCALE SELECT

ELECTRONIC

CALIBRATION

MAIN

CALIBRATION

CONTROL

DISPLAY

CALIBRATION

CONTROL

(FACTORY SET)

OPTIONAL

LIMIT

TIMER

CONTROL

MODULE

OPTIONAL

4-20 mA

OUTPUT

MODULE

DIS

CAL

TDS COND

EC

CTCII

DISPLAY

TRANSFORMER

Yel

CAP CAP

C4AM

LTM

HYST

Flow Switch

Jumper Remove if

flow switch

installed.

SWITCH

FUSE

RELAY RELAY

BLEED FEED

FEED

PUMP

BLEED

VALVE

POWER

FLOW

SWITCH

SENSOR 0-10VDC

FS BK WTRD GN NU R- R+PWR C GDPWR C GDPWR C GD

SET POINT

HYSTERESIS

RIGHT INC

LEFT DEC

R/G

Wickman Fuse 5 Amp

(#3741500041 or equiv)

115 VAC(V~)

CALIBRATION AND PREVENTIVE CARE

A. PRIMARY COMPONENT IDENTIFICATION

As identied in Section III, the CTCII Chemical Treatment

Controllers main circuit board, controls and indicator lights are

mounted directly to the front panel.

Review gure V.A.1 below to familiarize yourself with the Main

circuit board assembly. The following diagram has the optional

Limit Timer Module and 4-20 mA Output Module installed.

20

Page 25

CAUTION - READ FOLLOWING CAREFULLY

!

B. CALIBRATION PROCEDURES

All Myron L CTCII Chemical Treatment Controllers are factory

calibrated prior to shipping and are ready to install without further

calibration. Calibration should be checked occasionally with

the internal Electronic Calibration Test switch (EC) to ensure

continued accuracy.

The following procedures are provided in the event that

recalibration becomes necessary. The only equipment required

are a tweaker or small screwdriver, and standard solution.

Refer to Figure V.A.1. to locate the components described in this

section.

WARNING: When performing calibration procedures, the

technician must take extreme care to avoid contacting the

circuitry other than the CALibration control. Failure to do so

could result in damage to the equipment, property and/or

personal injury.

1. ELECTRONIC CALIBRATION

(CIRCUIT ONLY)

This method is faster than the method using standard solution,

but it does not include the sensor. Therefore, it should be used

only in applications where the chance of sensor contamination or

damage are slight.

The Set Point control will be used to check the calibration.

NOTE: The DISplay calibration control (if display is installed)

has been set and sealed prior to leaving the factory, and under

normal conditions will not require readjustment. This allows the

user to observe the panel display (if installed) to visually set

the electronic value. If the DISplay calibration control has been

adjusted it will be necessary to, rst, verify or adjust the Set Point

Control Calibration as described in “Set Point Control Calibration”

below.

a. Set Point Control Calibration

1. Ensure power is OFF.

2. Using a Phillips Head screwdriver remove the four (4)

screws on the clear cover.

3. Remove clear cover.

4. The front panel is held in place with hook & loop strips

on each side. By carefully lifting at the slot on the top,

the front panel will pull toward you. Do not pull more than

about 8 inches/20CM.

DO NOT pull on control knob(s).

5. Rotate the front panel down so that the back side is

facing you. The Circuit Board is mounted to the back of

the front panel.

6. Turn power ON.

CAUTION: When handling Circuit Borad, DO NOT touch

component side. Electrical shock may occur.

7. Press and hold the Electronic Calibration switch (EC).

8. Rotate Set Point Control from “0” toward EC. At EC the

relay should click, and the LED should change from RED

to GREEN. If not, set Set Point control to EC and adjust

the CALibration control.

Models with 3 1/2 digit LCD.

The display should indicate 2.50.

If not, adjust the DISplay calibration control.

9. Turn power OFF.

10. Re-install front panel and cover as described in

“REASSEMBLY”.

11. To operate, turn power ON.

b. 0-10VDC Recorder Output Calibration

For output voltages other than 10VDC, substitute as required, i.e.

5.00VDC or 2.00VDC per Section II.F.2.

Requires a DVM set to DC Volts.

1. Ensure power is OFF.

2. Attach DVM to RECORDER output connection.

3. Turn power ON.

4. Press and hold the Electronic Calibration switch (EC).

5. The DVM should indicate 5.00VDC.

6. If not, adjust CALibration control until DVM indicates

5.00VDC.

7. Verify the set point control is set at EC point. If not,

loosen knob on shaft and reset to EC.

8. Verify the display (if installed) is indicating a reading

of 2.50. If not, adjust DISplay control until a full scale

reading is displayed.

9. Turn power OFF.

10. Re-install front panel and cover as described in

“REASSEMBLY” or continue.

11. To operate, turn power ON.

2. CALIBRATION USING

STANDARD SOLUTION

The best method of recalibrating your conductivity/TDS CTCII

Chemical Treatment Controller is with a NIST traceable Standard

Solution (available from the Myron L Company). Because it

includes the sensor, the entire system is recalibrated.

The following procedure describes the easiest method for

standard solution calibration of your Conductivity/TDS CTCII

Chemical Treatment Controller. We recommended using Myron L

442-3000 Standard Solution. This standard solution will calibrate

both Conductivity µS (at 3900 µS) and TDS ppm (at 3000 ppm)

modes.

1. Rinse thoroughly, and ll a clean glass beaker with the

standard solution.

2. Place sensor in the beaker of standard solution. The

level of standard solution must be high enough to cover

at least 1/2” above the electrodes.

3. Slowly shake the sensor to remove air bubbles from the

electrodes.

4. Allow 5-10 minutes for temperature to equilibrate. For

the quickest and the best results, both the sensor and

solution should be at the same temperature.

5. Turn power ON.

6. Rotated the Set Point control to 3900 for Conductivity

modes or 3000 for TDS modes. The relay should click

and the LED will change from RED to GREEN. Display

models (standard 3 1/2 digit).

The display should match the value of the standard

solution, 3900 µS (displayed as 3.90) or 3000 ppm

(displayed as 3.00).

If the reading is different, adjust CALibration control

on the main circuit board until the reading matches the

solution value.

7. After adjustment, turn power OFF.

8. Re-install front panel and cover as described in

“REASSEMBLY”.

9. To operate, turn power ON.

21

Page 26

3. TRANSFER STANDARD METHOD

For maximum accuracy of any Monitor/controller, the transfer

standard method should be utilized. Instead of removing the

entire Monitor/controller and sensor, and either returning it to

the manufacture or sending it to a third party laboratory for

recertication, the transfer standard allows quick recertication

and return to service — less down time. While being the most

accurate method it is also very easy to perform, and may be used

to calibrate ANY manufacture Monitor/controller — resistivity or

conductivity/TDS. This method still has the benet of third party

verication, if so desired.

1. A high quality hand-held instrument, one capable of

accurate conductivity/TDS readings such as the Myron L

Ultrameter™, is calibrated using a standard solution, or if

so desired, sent to a third party laboratory for calibration

& certication. Preferably the standard solution should

be as close as practicable to the area of the Monitor/

controller operation, i.e. for a conductivity Monitor/

controller that is operating between 1500 and 2000µS,

the recommended Myron L standard solution is KCl-

1800.

2. Once the Ultrameter is calibrated, the process water is

measured.

3. Finally, the Monitor/controller is calibrated/adjusted to

match the value measured by the Ultrameter by adjusting

the Main CALibration control shown in gure V.A.1.

4. Turn power OFF.

5. Re-install front panel as described below in

“REASSEMBLY”.

REASSEMBLY

1. Carefully reinstall the front panel.

2. Reinstall the clear cover.

3. Reinstall the four (4) screws and tighten.

4. If so desired, install corner covers.

5. To operate, turn power ON.

C. PREVENTIVE CARE

The Myron L Company recommends that the following Preventive

Care procedures be observed.

1. Try to prevent exposure to excessive heat and moisture.

2. The main AC power source should be protected against

excessive voltage “spikes.”

3. Take care not to damage the Monitor or sensor during

handling.

NOTE: Daily, weekly or monthly maintenance schedules are

based upon the frequency of use and the severity of the CTCII

Chemical Treatment Controllers environment and operating

conditions.

4. Repeat the Check-Out procedures to verify satisfactory

operation and/or isolate possible troubleshooting

symptoms.

5. Check all cable connections to ensure that they are free

of moisture and contamination.

6. Inspect and replace damaged component boards and

cable assemblies.

7. Periodically remove, clean and inspect the Sensor.

CLEANING - clean clear cover with soap and water, and soft nonabrasive cloth.

22

Page 27

VI. OPTIONS & ACCESSORIES

A. OPTIONS ORDERED WITH CTCII CONTROLLER

PART # DESCRIPTION

-C4A 4-20mA Self-Powered Isolated Output Module (Digital & OEM Only)

-45 4 1/2 Digit “Backlit” Liquid Crystal Display (LCD)

-35BL 3 1/2 Digit “Backlit” Liquid Crystal Display (LCD)

-51R CS51R, 316 SS conductivity sensor w/ 10 ft/3mtr cable (sensor upgrade)

SPECIAL ORDER OPTIONS

-24V 24 VAC Isolated Power

-24VD 24 VDC Isolated Power

-SQC Quik-connect, sensor cable M/F

* allow approximately three (3) weeks.

B. OPTIONS & ACCESSORIES ORDERED SEPARATELY

PART # DESCRIPTION

CLTMO Limit Timer Module w/ small knob (when ordered after initial purchase)

C4AO 4-20mA Self-Powered Isolated Output Module (Digital & OEM Only)

45O 4 1/2 Digit Backlit Liquid Crystal Display (LCD)

35BLO 3 1/2 Digit “Backlit” Liquid Crystal Display (LCD)

VR Powersupply, 24 VAC, 20VA. (115 VAC - Indoor use Only)

CC NIST Certicate without Sensor

CCS NIST Certicate with Sensor in Standard Solution

23

Page 28

C. STANDARD SOLUTIONS & BUFFERS

1. CONDUCTIVITY/TDS

STANDARD SOLUTIONS

Your CTCII Chemical Treatment Controller has been factory

certied to meet certain specications based on the appropriate

Myron L Company NIST traceable standard solution. This same

solution is available to you.

442-3000 3900 µS/µM Conductivity and 3000 ppm TDS

Other standard solutions are available to meet your needs or

requirements.

also mold inhibited and accurate to within ±0.01 pH units @ 25°C.

Order 4, 7 or 10 Buffer.

b. pH Sensor Storage Solution