Page 1

CONDUCTIVITY

MONITOR/CONTROLLER

Installation • Operation• Maintenance

User Manual for Models 755

756

757

758

767

6115 Corte del Cedro

Carlsbad, CA 92009-1516 USA

Tel 760-438-2021

Fax 800-869-7668 / 760-931-9189

www.myronl.com

pH/Conductivity Instrumentation

Accuracy • Reliability • Simplicity

Page 2

TABLE OF CONTENTS

SECTION PAGE

1 INTRODUCTION

1.1 SCOPE......................................................................................................................................................... 1

1.1.1 Functional Descriptions ................................................................................................................. 1

1.1.2 Applications ................................................................................................................................... 1

1.2 SPECIFICATIONS ....................................................................................................................................... 1

1.3 CONDUCTIVITY CELLS .............................................................................................................................. 2

1.3.1 Cell Specifications ......................................................................................................................... 2

1.4 OPTIONAL FEATURES ............................................................................................................................... 2

1.4.1 Accessories................................................................................................................................... 2

1.5 HOW TO ORDER ........................................................................................................................................ 2

2 INSTALLATION

2.1 GENERAL .................................................................................................................................................... 4

2.2 MECHANICAL INSTALLATION.................................................................................................................... 4

2.2.1 Surface Mounting with SMP Assembly .......................................................................................... 5

2.2.2 Surface Mounting without SMP Assembly ..................................................................................... 5

2.2.3 Panel Mounting .............................................................................................................................. 5

2.3 CELL INSERTION / DIP MOUNT ASSEMBLIES ......................................................................................... 5

2.3.1 Insertion Mode Assembly .............................................................................................................. 5

2.3.2 Alternate Dip Cell Assembly .......................................................................................................... 5

2.4 ELECTRICAL INSTALLATION ..................................................................................................................... 6

2.4.1 Main AC Power Installation............................................................................................................ 6

2.4.2 220 VAC Conversion ..................................................................................................................... 6

2.4.3 Connecting the Cell Cable ............................................................................................................. 7

2.4.4 Alarm Relay Installation ................................................................................................................. 7

2.5 0-10 VDC RECORDER OUTPUT ................................................................................................................ 7

2.6 CONNECTING THE MODEL 758 4-20 mA AND 420D OPTIONS ............................................................... 7

2.7 INSTALLATION OF THE MODEL 767 OPTIONS ........................................................................................7

2.7.1 Connecting the 420D Option ......................................................................................................... 7

3 OPERATING PROCEDURES

4 COMPONENT IDENTIFICATION, CALIBRATION AND PREVENTIVE CARE

5 APPENDIX

2.7.2 Connecting the RM Option ............................................................................................................ 7

3.1 SWITCH AND INDICATOR CONTROLS ..................................................................................................... 8

3.1.1 Red “Above Set Point” LED Indicator ............................................................................................ 8

3.1.2 Green “Below Set Point” LED Indicator ......................................................................................... 8

3.1.3 Set Point Adjustment Knob ............................................................................................................ 8

3.1.4 “Set Point Check” Switch ............................................................................................................... 8

3.1.5 Analog / Digital Meter Readouts .................................................................................................... 8

3.1.6 Three “Range” Select Switch ......................................................................................................... 8

3.1.7 Three “Cell” Select Switch ............................................................................................................. 8

3.2 MODEL 767 STANDARD AND OPTIONAL FEATURES.............................................................................. 9

3.3 SETUP PROCEDURES ............................................................................................................................. 10

3.3.1 Decreasing Set Point Conversion ................................................................................................ 10

3.3.2 Set Point Adjustment ................................................................................................................... 10

3.4 CHECK-OUT PROCEDURES ................................................................................................................... 10

3.4.1 Model 755 (Only) ......................................................................................................................... 10

3.4.2 Models 756, 757, 758 & 767 ........................................................................................................ 10

4.1 PRIMARY COMPONENT IDENTIFICATION ..............................................................................................11

4.2 METER MECHANICAL ZERO PROCEDURES......................................................................................... 12

4.3 CALIBRATION PROCEDURES ................................................................................................................. 12

4.3.1 Calibration Procedures using Standard Solution ......................................................................... 12

4.3.2 Calibration Procedures (Circuit Only) .......................................................................................... 12

4.3.2.1 Model 755 .................................................................................................................. 12

4.3.2.2 Models 756, 757 & 758 .............................................................................................. 12

4.3.3 Model 758 with 4-20mA or 420D Options .................................................................................... 12

4.3.4 Model 767 .................................................................................................................................... 13

4.3.5 Model 767 Equipped with the 420D Option ................................................................................. 13

4.4 PREVENTIVE CARE

A REPLACEABLE COMPONENTS CHART ................................................................................................. 14

Page 3

SECTION 1

Introduction

1.1 SCOPE

This manual provides the user with the necessary information to

install, operate and maintain the Myron L Company’s 750/760

Series Conductivity Monitors. Sections 1 through 3 provide Monitor

applicational descriptions, mounting, wiring and operational

procedures. Section 4 identifies their primary components and

provides the user with easy-to-use calibration and preventive care

procedures.

Section 5 (Appendix A) provides the 750/760 Series Monitor’s

Replaceable Components Chart.

1.1.1 FUNCTIONAL DESCRIPTIONS

All models have drip/weather-proof housings suitable for panel,

bench or surface mounting. The 750 models are a compact 6.0"

(152mm) x 4.8" (122mm). The 767 model is 6.0" (152mm) x 10.8"

(275mm).

Bright green/red LEDs indicate below/above set point readings.

All models except 756 feature a heavy-duty 10 amp output relay,

operating on either increasing or decreasing readings.

For specific Monitor configurations, reference the following

individual model descriptions.

Model 755

Small controller only. Provides a front panel accessible set point

adjustment knob in place of an analog or digital meter readout

display.

Model 756

Small monitor only. Standard front panel is equipped with a linear

analog meter display only (no relay, LED indicators or set point

check switch).

Model 757

Small analog monitor/controller. Single set point is internal to

discourage unauthorized adjustments. Standard front panel is

equipped with a linear analog meter display and a “SET POINT

CHECK” switch.

Model 758

Small digital monitor/controller. Single set point is internal to

discourage unauthorized adjustments. Standard front panel is

equipped with a digital LCD meter display and a “SET POINT

CHECK” switch.

Model 767

Large analog monitor/controller. Single set point is internal to

discourage unauthorized adjustments. Standard front panel is

equipped with a three (3) range select switch, analog meter display

and a “SET POINT CHECK” switch. Options include three (3) cell

input capability and dual set point control.

1.1.2 APPLICATIONS

1 Reverse Osmosis

2 Process Control

3 Seawater Desalinization

4 Waste Treatment

5 Food Processing

6 Power Plants

7 Laboratories

1.2 SPECIFICATIONS

RANGES:

Refer to Conductivity/ppm Ranges sheet on Page 3 for

Conductivity Ranges.

READOUT:

Model 756: 2 1/2" (63mm) analog meter

Model 757: 2

Model 758:

1

/2" (63mm) analog meter

1

/2" (13mm) 3 1/2 digit LCD

Model 767: 4 1/2" (114mm) analog meter

ACCURACY:

Model 758: ± 1 % of span

Other Models: ± 2% of span

SENSITIVITY:

0.05% of span

STABILITY:

0.05% of span

REPEATABILITY:

0.1% of span

CALIBRATION CHECK:

Built in

RECORDER OUTPUT:

0-10 VDC @ 5mA max. (linear); standard on all models

CELL INPUT:

1 (optional 3 Cell Input available on Model 767)

RELAY FUNCTION:

Models 755, 757, 758 and 767:

Single set point control continuously adjustable 0-100% of

span

Indicators:

“ABOVE” (red) and “BELOW” (green) set point LEDs

Contact Rating:

SPDT 10 amp @ 250 VAC, 30 VDC. Relay operates

increasing or decreasing reading (selectable).

Optional on Model 767 only:

Dual set point control, with above specifications

POWER SPECIFICATIONS:

115 VAC ± 15%, 50/60 Hz, 25 mA

220 VAC (User changeable)

DIMENSIONS 750 SERIES:

6.0" (152mm) H x 4.8" (122mm) W x 3.8" (96mm) D

DIMENSIONS 760 SERIES:

6.0" (152mm) H x 10.8" (275mm) W x 3.9" (99mm) D

AMBIENT TEMPERATURE RANGE:

-22°F (- 30°C) to 140°F (60°C)

HOUSING CONSTRUCTION:

Fully gasketed heavy-duty ABS for corrosion resistance. Rated

NEMA type 3.

WEIGHT:

750 Series: 2 Ibs. (0.9 kg)

760 Series: 3 Ibs. (1.4 kg)

1

Page 4

1.3 CONDUCTIVITY CELLS

Both 750 and 760 series conductivity models use the CS51 or

CS52 Series cell. The 1.0 cell constant CS51 model is

recommended for ranges of 0-20 through 20,000µS. Its compact

size allows mounting in the top of a standard 3/4" tee. The

sturdy polypropylene bushing is modular for easy, inexpensive

replacement.

CS52 cells have a 10.0 constant and are used for conductivity

values above 20,000µS.

1.3.1 CELL SPECIFICATIONS

CONSTANT:

CS51LC: 0.1

CS51: 1.0

CS52: 10.0

TEMPERATURE COMPENSATION:

Automatic to 25°C, between 32-212°F (0-100°C)

PRESSURE/TEMPERATURE LIMITS:

100 psi (689.6 kPa) at 212°F (100°C)

BUSHING:

CS51 (LC): Modular Polypropylene threaded 3/4" NPT

CS52: 316 stainless steel 3/4" NPT internal to cell body

CABLE:

Shielded; 10' (3 meters) standard; 25' (7 meters) and 100'

(30 meters) lengths also available.

DIMENSIONS:

CS51 (LC): Metal portion 1.2" (30mm) L; 0.5" (13mm) DIA

CS52: Contact factory for specifications

1.4 OPTIONAL FEATURES

-03: 3 cell input (767 only)

-420: 4-20 mA isolated output (758 only)

-420D: 4-20 mA self powered isolated output (758, 767 only)

-DP: Dual set point (767 only)

-RM: Remote meter (767 only)

1.4.1 ACCESSORIES

MODEL TYPE

PC: 110V Power cord (8 foot with plug and strain relief

fitting)

SMP50: Surface mounting plate for 750 series

SMP60: Surface mounting plate for 760 series

60AM: 4 1/2" analog meter for 767-RM (specify range)

3CE: 3 cell switch with enclosure and trimplate

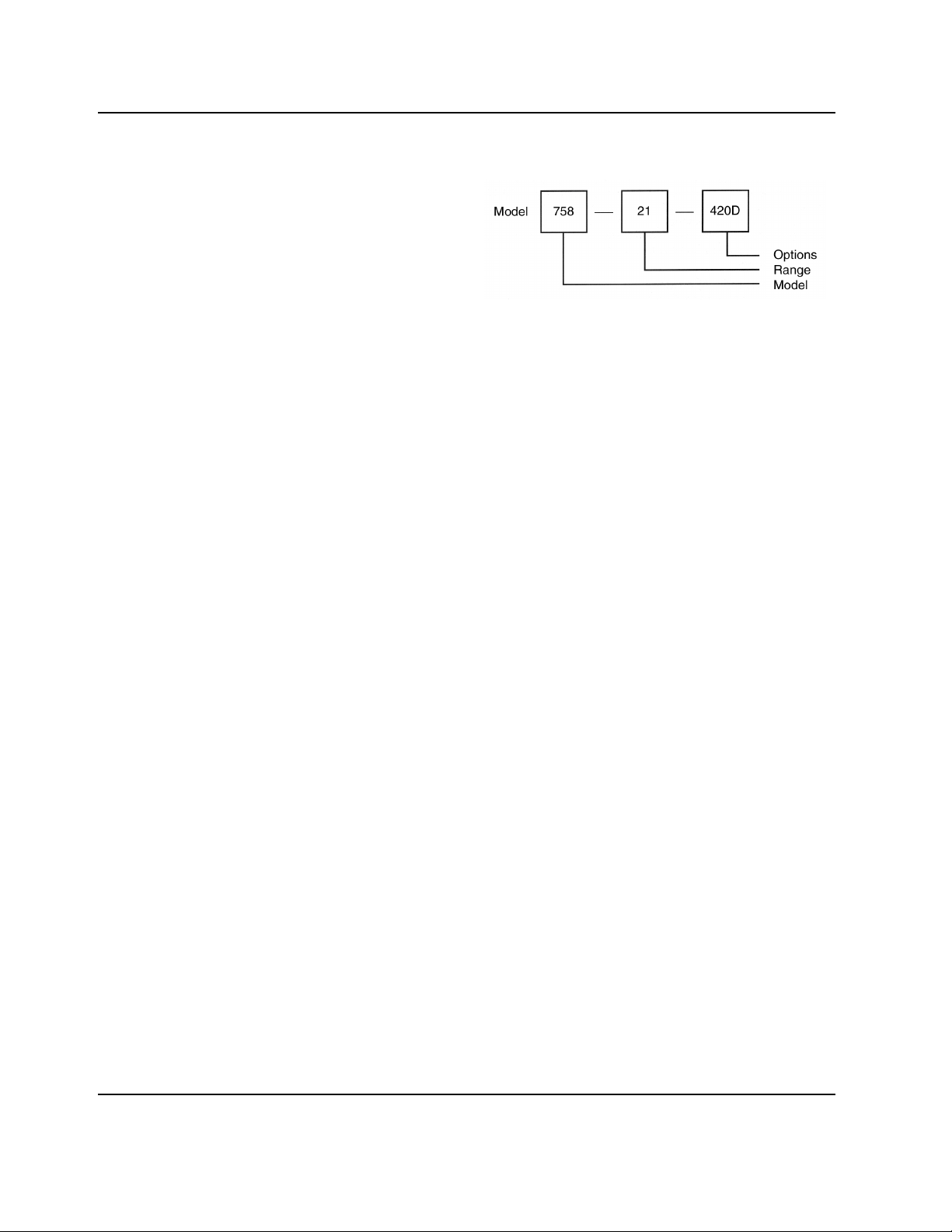

1.5 HOW TO ORDER MONITOR/CONTROLLERS

EXAMPLE:

This is a small digital monitor/controller with a 0-2000µS range

and 4-20mA output.

NOTE:

Monitor model number does not include cell. Please specify

cell required when ordering.

MODEL TYPES:

755: Small controller only

756: Small analog monitor only (no relay)

757: Small analog monitor/controller

758: Small digital monitor/controller

767: Large 3-range analog monitor/controller

RANGE SUFFIXES:

See CONDUCTIVITY/ppm RANGES sheet, Page 3.

1.5.1 HOW TO ORDER CELLS

CS51 LC: For 0-2µS range

CS51: For ranges 20 to 20,000µS or ppm

CS52: For ranges above 20,000µS or ppm see

CONDUCTIVITY/ppm RANGES sheet, Page 3.

CELL CABLE SUFFIX

-25: 25' (7 meters) shielded cell cable

-100: 100' (30 meters) shielded cell cable

2

Introduction

Page 5

Conductivity/ppm Ranges

CS51 SERIES CELLS SUITABLE FOR ALL EXCEPT THOSE NOTED

SUFFIX 755 756 757 758 767

TO CONTROL ANALOG ANALOG DIGITAL LG. ANALOG

RANGE MODEL NO. CONTROL CONTROL CONTROL

0-2 µS *** -6 X

0-20 µS-9 X X X X

0-20 ppm -10 X X X X

0-50 µS-11 X X X

0-50 ppm -12 X X X

0-100 µS -13 X X X X

0-100 ppm -14 X X X X

0-200 µS -15 X X X

0-200 ppm -16 X X X

0-500 µS -17 X X X X

0-500 ppm -18 X X X X

0-1000 µS -19 X X X X

0-1000 ppm -20 X X X X

0-2000 µS -21 X X X X

0-2000 ppm -22 X X X X

0-5000 µS -23 X X X**

0-5000 ppm -24 X X

0-10,000 µS -25 X X X**

0-10,000 ppm -26 X X

0-20,000 µS -27 X X use-29**

0-20,000 ppm -28 X X

0-20 mS -29 X

0-20, 200,

2,000 µS -30 X

0-20, 200,

2,000 ppm -31 X

0-50, 500,

5,000 µS -32 X

0-50, 500,

5,000 ppm -33 X

0-100, 1,000,

10,000 µS -34 X

0-100, 1,000,

10,000 ppm -35 X

0-200, 2,000,

20,000 µS -36 X

0-200, 2,000,

20,000 ppm -37 X

0-500, 5,000,

*50,000 µS -38 X

0-500, 5,000,

*50,000 ppm -39 X

*0-50,000 µS -40 X X

*0-50,000 ppm -41 X X

*0-100,000 µS -42 X X

*0-200,000 µS -44 X X

*0-200 mS -46 X

INSTRUMENT ONLY MONITOR MONITOR/ MONITOR/ MONITOR/

*CS52 SERIES CONDUCTIVITY CELLS REQUIRED FOR THESES RANGES

** READS IN MILLISIEMENS (mS)

*** CS51LC CELL (0.1 constant) REQUIRED FOR THIS RANGE

NOTE: UNLESS ppm/NaCl is specified with order, ppm type conductivity instruments will be calibrated on the

Myron L “442” Natural Water™ standard

3

Page 6

SECTION 2

Installation

2.1 GENERAL

This section provides the recommended procedures for properly

installing the 750/760 Series Conductivity Monitors and cells.

WARNING!

The Myron L Company recommends that all mounting and

electrical installation procedures be performed by trained and

authorized personnel ONLY! Failure to do so could result in

personal injury or loss of life. In addition, damage to the

equipment and/or property may occur.

2.2 MECHANICAL INSTALLATION

All Monitor electronics are packaged inside drip/weather-proof

housings. The physical dimensions of both small and large

housings are suitable for panel, bench or surface mounting.

There are three basic guidelines to consider when selecting a

Monitor’s mounting location:

STEP 1 Select a site that limits the Monitor’s exposure to

excessive moisture and corrosive fumes.

STEP 2 For best results, position your control area as close as

possible to the point(s) being controlled.

4

Page 7

NOTE:

The 750/760 Series Conductivity Monitors are not designed to

operate with a Cell cable length that exceeds 100' (30 meters).

STEP 3 If at all possible, mount the Monitor at eye level for

viewing convenience.

2.2.1 SURFACE MOUNTING WITH SMP ASSEMBLY

NOTE:

A Surface Mounting Plate (SMP) will be required when access to

the far side of the mounting site is impractical. For 750 series

monitors, use the SMP-50 and for 760 series monitors, use the

SMP-60. Surface mounting will require two (2) 1/4" X 20

mounting screws. (The mounting screws are packaged with the

SMP assemblies.) If an SMP is being used, the user must

supply four (4) additional screws or bolts. Their size is to be

determined by the user.

STEP 1 Select your mounting location. Mark and drill the four

(4) required mounting holes. For hole locations, use the

SMP as a template. Install any lags or threads required.

STEP 2 Drill the corner holes in the SMP according to the size

of the screws or bolts selected.

STEP 3 Attach and securely fasten the SMP to the Monitor

using the 1/4" X 20 X 3/8" screws provided.

STEP 4 Mount the SMP to the prepared site using the selected

screws or bolts.

2.2.2 SURFACE MOUNTING WITHOUT SMP ASSEMBLY

NOTE:

Surface mounting will require two (2) 1/4 “ X 20 screws of a

length equal to the thickness of the mounting site plus 3/8”

STEP 1 Select mounting site location. Mark and drill the

required mounting holes. For hole drilling locations, see

Fig. 2-1.

STEP 2 Insert the 1/4" X 20 screws into the holes from the side

opposite the mounting site.

STEP 3 Hold the Monitor in place while starting and tightening

the mounting screws.

2.2.3 PANEL MOUNTING

A panel mounting fastening kit is provided with all Conductivity

Monitors. Panel mounting will require the use of the fastening

kit’s two (2) 4-40 mounting screws/nuts or two (2) #4 x 1/2"

sheet metal screws. See Fig. 2-1 for panel cutout dimensions.

STEP 1 Select your mounting location. Mark the appropriate

panel cutout and complete the necessary panel cut.

STEP 2 Carefully unfasten and separate the Monitor’s front

panel from its enclosure.

STEP 3 Disconnect all panel cable(s)/wires from the Monitor’s

Control board.

STEP 4 Slide the enclosure through the panel cutout until its

flange contacts the panel.

STEP 5 Insert mounting screws through the flange mounting

holes and tightly secure.

STEP 6 Reconnect all panel cable(s)/wires and re-secure the

front panel.

2.3 CELL INSERTION/DIP MOUNT ASSEMBLIES

A CS51 Cell’s mounting orientation must provide a continuous

and adequate circulation flow to prevent the trapping of air

bubbles within the Cell’s electrode area. Failure to do so will

result in conditions that will prevent the Cell from functioning

properly.

2.3.1 INSERTION MODE ASSEMBLY

STEP 1 Verify that the Cell’s Fitting assembly is properly

assembled as shown in Fig. 2-2.

STEP 2 Insert the Cell Fitting assembly into the “T” fitting as

shown in Fig 2-2 and tightly secure.

2.3.2 ALTERNATE DIP CELL ASSEMBLY

STEP 1 Verify that the Cell’s Fitting assembly is properly

assembled as shown in Fig. 2-3.

STEP 2 Insert and pull the Cell’s cable through the extension

tube and then tightly attach extension tube to Cell

assembly as shown in Fig. 2-3.

Installation

5

Page 8

2.4 ELECTRICAL INSTALLATION

The electrical installation procedures provided in this manual are

common to all Conductivity Monitors. See Fig. 2-1 for the hole

dimensions of the enclosure’s cable access holes. Unless

otherwise instructed, refer to Fig. 2-4 and 2-5 for the 750/760

Series Monitor’s terminal block (TB) connector wiring

designations.

NOTE:

After removing an enclosure’s access hole plug, it is suggested

that the user mount a watertight restraint fixture prior to installing

a cable.

2.4.1 MAIN AC POWER INSTALLATION

The following procedures are to be used to install a standard

115 VAC main power source. For the procedures to install the

optional 220 VAC main power source, the user must first

complete the conversion procedures in Section 2.4.2.

STEP 1 Verify that the facility’s main AC power source is turned

STEP 2 Carefully remove front panel, leaving the cable and

STEP 3 Place the facility’s AC power cord and user supplied

STEP 4 Neatly connect cable wires to the Monitor’s TB

“OFF” or disconnected.

wires connected.

watertight cable restraint into the enclosure’s

appropriate access hole.

connectors, as shown in Fig. 2-4 and 2-5.

6

Installation

Page 9

2.4.2 220 VAC CONVERSION

STEP 1 Verify that the facility’s main AC power source is turned

“OFF” or disconnected.

STEP 2 Locate and remove the Control board jumpers E1 and

E3. (See Fig. 2-6.)

STEP 3 Using one of the removed jumpers, insert it into jumper

E2’s connection holes as shown in Fig. 2-6.

2.4.3 CONNECTING THE CELL CABLE

STEP 1 Place the Cell’s interface cable and user supplied

watertight cable restraint into the enclosure’s

appropriate access hole.

STEP 2 Neatly connect the Cell’s cable wires to the Monitor’s

appropriate TB connectors. (See Fig. 2-4 or 2-5.)

2.4.4 ALARM RELAY INSTALLATION

STEP 1 Place the user supplied Alarm relay interface cable and

watertight cable restraint into the enclosure’s

appropriate access hole.

STEP 2 Neatly connect the Relay cable wires to the Monitor’s

TB connectors (See Fig 2-4-1 or 2-5-1) as explained

below. All Myron L Company Conductivity Monitor/

Controllers (except Model 756) are equipped with a

relay which is designed to energize/de-energize when

the set point is crossed. (See P.10, sec 3.3.2 for set

point adjustment procedure) The relay energizes on

increasing readings. The easiest method of connecting

the relay is shown below in FlGs 2-4-1 and 2-5-1.

These show how the dry contact relay can use

incoming power to activate a controlled device (alarm,

solenoid valve, etc.) of 10 amps or less. A usersupplied transformer is necessary if the controlled

device operates on a voltage different from the voltage

which powers your Myron L monitor/controller. An

alternative (necessary if the device is DC powered) is

to connect a separate, second power source to the

relay.

When energized (above set point), the Common (COM) will

disconnect from the Normally Closed NC contact and connect to

the Normally Open (NO) contact. Devices may be operated

using either the Normally Open contact or Normally Closed

contact; or both relay contacts may be used to activate two

devices of the same voltage.

2.5 0-10 VDC RECORDER OUTPUT

STEP 1 Place the user supplied interface cable and watertight

cable restraint into the enclosure’s appropriate access

hole.

STEP 2 Connect the Recorder’s plus (+) and minus (-) terminal

wires to the Recorder output’s TB connectors. (See Fig.

2-4 or 2-5)

STEP 3 Refer to Section 4.3.2 for the procedures to calibrate

the 0-10 VDC voltage output

2.6 CONNECTING THE MODEL 758 4-20mA AND 420D

OPTIONS

STEP 1 Place the user supplied cable and watertight cable

restraint into the enclosure’s appropriate access hole.

STEP 2 Neatly insert cable wires into the 758 Panel board’s

plus (+) and minus (-) TB1 terminal block connectors as

shown in Fig. 2-7.

STEP 3 See Section 4.3.3 to calibrate the 4-20mA minimum

and maximum current outputs.

2.7 INSTALLATION OF THE MODEL 767 OPTIONS

The Model 767 Conductivity Monitor/Controller can be

configured with a combination of options. Based upon user

requirements, the electrical installation of one or more of the

following options may be required.

2.7.1 CONNECTING THE 767-420D OPTIONS

STEP 1 Place the user supplied cable and watertight cable

restraint into the enclosure’s appropriate access hole.

STEP 2 Neatly connect the cable wires to the Monitor’s plus (+)

and minus (-) terminals TB1-4 & 5. (See Fig. 2-5.)

STEP 3 Refer to Section 4.3.5 for the procedures to calibrate

the Model 767’s 4-20mA minimum and maximum

current outputs.

NOTE:

The maximum impedance of the user’s current sensor should

not exceed 400 ohms.

2.7.2 CONNECTING THE REMOTE METER OPTION

STEP 1 Connect the Remote Meter cable and user supplied

restraint into the enclosure’s appropriate access hole.

STEP 2 Neatly connect the Remote Meter’s positive (+) and

minus (-) wires to terminals TB1-13 &14. (See Fig. 2-5.)

STEP 3 Refer to Section 4.3 for the procedures to calibrate the

Model 767’s Remote Meter output.

Installation

7

Page 10

SECTION 3

Operating Procedures

3.1 SWITCH AND INDICATOR CONTROLS

The front panel illustrations, switch and indicator operational

descriptions have been provided to assist the user in identifying

and operating the 750/760 Series Conductivity Monitors.

Refer to Section 3.3 for a Monitor’s Setup procedures and

Section 3.4 for Check-Out procedures.

3.1.1 RED “ABOVE SET POINT” LED INDICATOR

Standard on all models except the 756 small Monitor.

The red LED indicator light is ON only when the water’s

conductivity reading is ABOVE the Monitor’s set point

adjustment.

3.1.2 GREEN “BELOW SET POINT” LED INDICATOR

Standard on all models except the 756 small Monitor.

The green LED indicator light is ON only when the water’s

conductivity reading is BELOW the Monitor’s set point

adjustment.

3.1.3 SET POINT ADJUSTMENT KNOB

Available on the 755 controller only.

Front panel adjustment knob provides immediate access for

adjusting the Monitor’s set point setting and to verify its full scale

reading.

3.1 A “SET POINT CHECK” SWITCH

Available on the 757, 758 and 767 Monitor/Controllers only.

When the “SET POINT CHECK” switch is depressed, the

internal set point reading is immediately displayed on the front

panel display.

3.1.5 ANALOG/DIGITAL METER READOUTS

Models 756, 757 and 767 equipped with analog meters only.

Model 758 equipped with 1/2” digital meter only.

Front panel analog or digital meters provide a continuous

readout of the water being monitored.

3.1.6 3 “RANGE” SELECT SWITCH 767

Monitor/Controller only.

The “RANGE” select switch provides three (3) decades of

indication corresponding to 1, 10, or 100 times the meter

reading.

3.1.7 3 “CELL” INPUT SELECT SWITCH

Available as an optional feature on the 767 Monitor/Controller

only.

“CELL” input switch selects one (1) of three (3) Cells as the

active monitoring Cell input.

8

Page 11

3.2 MODEL 767 STANDARD AND OPTIONAL FEATURES

This section describes the standard and optional features of the

Model 767 Conductivity Monitor/Controller. (Refer to Fig. 3-1.)

Power Supply

The standard Monitor/Controller has a single power supply that

provides voltages for all circuit functions. It may be configured

for either a 110 VAC or a 220 VAC supply.

Conductivity

The conductivity circuit is designed as a three range device with

extremely accurate tracking between ranges. It receives raw

conductivity and temperature information from the Cell and

translates this into a voltage that may range from 0 to + 10 VDC.

This is the Recorder output. The Recorder output signal

represents the conductivity of the fluid at 25°C. This signal is

available at terminals TB1-6 & 7

Meter Drive Section

The 0-10 V signal is also taken to the display section where it is

used to drive the analog meter.

Alarm Section and Relay

The alarm circuit compares the signal from the conductivity

circuit with a “set point” signal controlled by the user. The user

may check the current set point by pressing the “SET POINT

CHECK” switch on the front panel. This feeds the set point

signal to the Meter Drive section, which then displays the set

point on the meter.

Normally, if the conductivity signal becomes greater than the set

point signal, the alarm relay will be energized. The user may

adjust two jumpers that will cause the alarm relay to be

energized when the conductivity signal is less than the set point

signal.

Options:

03: the “03” option replaces the single Cell with three

separate Cells and a switch that allows you to switch

between each Cell.

420D: The “420D” option replaces the standard 0-10 V Recorder

output with a completely isolated 0-10 V output. In

addition, a 4-20 mA current loop output is available at

terminals TB1-4 & 5. These circuits have their own

completely separate power supply.

DP: The “DP” option adds a second alarm circuit (Alarm B),

which is identical to the first.

RM: The “RM” option adds circuitry to drive a remote 1 mA

analog meter movement.

3.3 SETUP PROCEDURES

These Setup procedures cover (1) setting the alarm circuit set

point(s), and (2) converting the alarm circuit to trigger on a

decreasing reading.

Operating Procedures

9

Page 12

3.3.1 DECREASING SET POINT CONVERSION

The alarm circuit(s) on all 750/760 Series Conductivity Monitors

are configured to trigger the alarm relay as the conductivity (or

ppm) reading increases. If the user’s application requires it, the

alarm circuit may be easily reconfigured to trigger the alarm

relay as the conductivity (or ppm) reading decreases. Refer to

Fig. 4-1 for the locations of the jumpers referred to in this

section.

NOTE:

These instructions describe the general procedures for

converting the Monitor without reference to jumper numbers or

orientation. Refer to Fig. 3-2 or 3-3 for the specifics on your

Monitor.

STEP 1 Turn OFF or disconnect the Monitor’s main AC power.

STEP 2 Locate the jumper block for the alarm to be configured.

STEP 3 Make a note of the current orientation of the jumpers.

STEP 4 Remove both jumpers. This is easily done by hand.

Take care not to crush the jumpers if using pliers.

STEP 5 Rotate the jumpers,/turn and reinstall them on their

posts.

3.3.2 SET POINT ADJUSTMENT

NOTE:

Because the Model 755 is equipped with a standard front panel

Set Point trimmer adjustment knob, it does not have an internal

set point adjustment setting. Refer to Section 3.4.1 for

procedures to adjust the 755’s set point.

STEP 1 Being careful not to strain the cable, unfasten and

remove the Monitor’s front panel.

STEP 2 While depressing the “SET POINT CHECK” switch,

turn the Monitor’s Set Point trimmer adjustment screw

(See Fig. 4-1) until the desired set point value is

indicated on the meter display.

NOTE:

The Monitor’s set point setting is based upon the user’s

particular water purity specifications.

STEP 3 After successfully completing STEP 2, remount the

front panel and tightly secure both retaining screws.

3A CHECK-OUT PROCEDURES

The following check-out procedures are used to verify that a

750/760 Series Conductivity Monitor is operating properly. It is

assumed that the Monitor is powered ON, that it is connected to

a CS51 or CS52 Cell, and that the Cell is immersed in water

within the range that the Monitor will be required to read. Refer

to Fig. 4-1 for the locations of the components referred to in this

section.

3.4.1 MODEL 755 (Only)

STEP 1 Turn the front panel adjustment knob to its full scale

setting. The green “BELOW SET POINT” light should

be ON indicating that the water being monitored is

BELOW the controller’s monitoring set point.

STEP 2 Turn the front panel adjustment knob to its zero scale

setting. The red “ABOVE SET POINT” light should be

ON indicating that the water being monitored is ABOVE

the controller’s monitoring set point.

STEP 3 Turn the adjustment knob back and forth and note the

reading where the ABOVE and BELOW LED indicator

lights switch. Also note an audible click as the relay

picks up and drops out. This reading corresponds to

the actual water purity.

STEP 4 Reset the Set Point trimmer adjustment knob to the

desired set point.

3.4.2 MODELS 756, 757, 758, & 767

NOTE:

A small screwdriver will be required.

STEP 1 Make a note of the reading on the Monitor’s display.

STEP 2 Being careful not to strain the connecting cable(s),

unfasten and remove the Monitor’s front panel.

STEP 3 (For the Model 767 only!) Place the “RANGE” select

switch to its “X1” setting.

STEP 4 While holding the Calibration Test switch (SW1) to its

TEST position, verify that the front panel meter is

indicating a full scale reading.

STEP 5 Press and hold the “SET POINT CHECK” switch on the

front panel. Using the small screwdriver, adjust the Set

Point trimmer adjustment screw on the circuit board to

sweep the display from zero to full scale. (A digital

display may be blank at the full scale end. This is

normal.) Listen for the alarm relay to click on and off as

the alarm set point moves past the water reading.

STEP 6 Adjust the alarm to the desired set point. Release the

“SET POINT CHECK” switch.

NOTE:

For Model 767-DP, repeat STEPS 5 & 6 to check out Alarm B.

10

Operating Procedures

Page 13

SECTION 4

Component Identification/Calibration and Preventive Maintenance

4.1 PRIMARY COMPONENT IDENTIFICATION

As identified in Section 3, the Conductivity Monitors’ switch and

indicator components are mounted directly to the front panel.

The Conductivity Monitors’ Control boards are contained within

and mounted to the back of the enclosure. The 767 Monitor,

when equipped with the 3 Cell Input option, has a second

component board mounted on the back of the front panel.

Model 758-420 and 758-420D have an additional board

mounted behind the front panel.

11

Page 14

4.2 METER MECHANICAL ZERO PROCEDURES

Models 756, 757 & 767 (Analog Meters Only)

STEP 1 Turn OFF or disconnect the Monitor’s main AC power.

STEP 2 Note the position of the meter needle. If it has come to rest

pointing at the zero mark on the scale, turn the Monitor back

ON and continue on the Section 4.3.

STEP 3 Locate the small (approx.

1

/4”), black plastic button directly

below the center of the meter. Use a small screwdriver or a

fingernail to gently pry it loose and remove it from the access

hole.

STEP 4 Insert a small standard screwdriver into the access hole and

carefully locate the slot in the mechanical adjustment plug.

STEP 5 Turn the adjustment plug slightly until the needle rests on

zero.

STEP 6 Insert the small plastic button into the access hole.

STEP 7 Turn ON or reconnect the Monitor’s main AC power.

4.3 CALIBRATION PROCEDURES

All Myron L Conductivity Monitors/Controllers are factory calibrated

prior to shipping and are ready to install without further calibration.

Calibration should be checked occasionally with the internal

Calibration Test switch (SW1) to ensure continued accuracy. The

following procedures are provided in the event that re-calibration

becomes necessary. The only equipment required are a small

screwdriver, standard solution, and an accurate multimeter. Calibration

should be accomplished by a qualified technician.

Refer to Fig. 4-1 to locate the components described in this section.

CAUTION!

When performing calibration procedures, the technician must take

extreme care to avoid contacting the fuse or control circuitry other than

trimmer calibration screws. Failure to do so could result in damage to

the equipment and/or property.

4.3.1 CALIBRATION PROCEDURES USING STANDARD SOLUTION

The best method of recalibrating your conductivity monitor/controller is

with NIST traceable Standard Solution (available from your Myron L

Company distributor, or elsewhere). Because it includes the sensor,

the entire instrument is recalibrated.

Step 1 Obtain a standard solution which is 60-90% of full scale of

the instrument.

Step 2 Adjust the temperature of the standard solution to 25°C. This

may be accomplished by using a warm or cool bath for the

bottle.

Step 3 Obtain a clean glass beaker. Rinse beaker thoroughly with

the standard solution. Place cell (sensor) of instrument in the

beaker of standard solution. Level of standard solution

should be high enough to cover

1

/2" above bore hole. Slowly

shake the sensor to remove air bubbles from inside the

sensor bore hole.

Step 4 Allow 3-4 minutes for temperature to equilibrate. Read the

display of the instrument. The display should match the

value and units of measure located on the bottle of standard

solution. If the reading is different, adjust R25 on the main

circuit board until the reading matches the solution value.

This will require removal of the front cover. NOTE: Remove

front cover with care; a ribbon cable connects the front

panel and main board.

4.3.2 CALIBRATION PROCEDURES (CIRCUIT ONLY)

This method is faster than the method using standard solution, but it

does not include the sensor. Therefore, it should be used only in

applications where the chance of sensor contamination or damage are

slight.

4.3.2.1 MODEL 755

STEP 1 Connect a voltmeter (0-10 VDC) to the Recorder output

terminals TB2-6 & 7 with the positive (+) lead on TB2-7.

STEP 2 Press and hold the Calibration Test switch (SW1). The

voltmeter should indicate +10 volts. If not, set to +10 volts

with the Main Calibration trimmer (R9).

STEP 3 Set the front panel control knob to the full scale setting. With

the Calibration Test switch (SW1) still depressed, rotate the

front panel control knob above and below the full scale

setting several times to locate the setting at which the front

panel LEDs switch. You should find one upper setting where

the LEDs switch from red to green and one lower setting

where they switch from green to red. The full scale index

mark should be halfway between these two settings. If

necessary, loosen the control knob set screws and reposition

the knob. This completes the calibration.

4.3.2.2 MODELS 756, 757 & 758

STEP 1 Connect a voltmeter (0-10 VDC) to the Recorder output

terminals TB2-6 & 7 with the positive (+) lead on TB2-7.

STEP 2 Press and hold the Calibration Test switch (SW1). The

voltmeter should indicate +10 volts. If not, set to +10 volts

with the Main Calibration trimmer (R9).

STEP 3 With the Calibration Test switch (SW1 ) still depressed, set

the Front Panel Meter trimmer (R25) for a full scale

indication on the panel meter. If you have a digital readout

(model 758), set it to 1999 (decimal point omitted) for ranges

0-20, 200 or 2000. For all other ranges, set it to read the

range maximum. If not known, this can be determined by

looking up the range suffix on the enclosure’s model label in

the list on page 3 of this manual.

Example: For model 758-11 (0-50 µS), set front panel LCD to indicated

50.0 µS.

4.3.3 MODEL 758 WITH 4-20 mA OR 4-20D OPTION

NOTE: FOR 4-20D, PROCEED TO STEP 1.

CAUTION! FOR 4-20mA OPTION ONLY

The proper supply voltage (V Supply) and load resistance (R) must be

selected. Failure to do so could result in damage to the 758 optional

panel board.

NOTE:

The proper load resistance (in ohms) is found by using the formula

and/or chart as shown in Fig. 4-2.

STEP 1 Set the controls of a test meter to read at least 20mA and

connect it between the positive terminals of the Transmitter

and Receiver as shown in Fig. 4-3 (4-20 mA option) and Fig.

4-4 (4-20D option).

STEP 2 Press and hold the “SET POINT CHECK” switch. It must be

depressed during all the following adjustment steps.

STEP 3 Turn the Set Point trimmer (R28) until the meter displays a

reading 0.00.

STEP 4 Turn the 4-20 mA Null trimmer (R23) (see Fig. 4-1 ) until the

test meter indicates 4 mA.

STEP 5 Readjust the Set Point trimmer (R28) until the meter displays

1999 (decimal point omitted).

STEP 6 Turn the 4-20 mA Full Scale trimmer (R20) (See Fig. 4-1 )

until the test meter indicates 20 mA.

STEP 7 Repeat STEP 3 through STEP 6, readjusting as required.

STEP 8 Reset the set point to the desired setting. Release the “SET

POINT CHECK” switch.

12

Component Identification/Calibration and Preventive Maintenance

Page 15

4.3.4 MODEL 767

NOTE:

The following procedures are for the standard Model 767 Refer

to Section 4.3.5 for the procedures to calibrate a Model 767

which is equipped with the 420D self-powered isolated output

option.

STEP 1 Set the “RANGE” select switch to its “X1” position.

STEP 2 Connect an accurate DC voltmeter to the Recorder

output terminals TB1-6 & 7 with the positive (+) lead on

TB1 -6.

STEP 3 While holding the Calibration Test switch to its TEST

position, set the Main Calibration trimmer to indicate a

+10 volt reading on the test meter.

STEP 4 While holding the Calibration Test switch to its TEST

position, set the Front Panel Meter trimmer (R25) to

indicate a full scale reading on the front panel meter. If

the Monitor/Controller is equipped with the Remote

Meter option, adjust the Remote Meter trimmer (R28) in

the same manner.

4.3.5 MODEL 767 EQUIPPED WITH THE 420D OPTION

For this calibration procedure, the Monitor/Controller must be

connected to a conductivity sensor with the white and black

wires disconnected. If a sensor is not available, it can be

simulated with a 10,000 ohm resistor connected between

terminals TB1-10 and TB1-11.

STEP 1 Set the “RANGE” select switch to its “X1” setting.

STEP 2 While holding the Calibration Test switch (SW1) to its

TEST position, set the Main Calibration trimmer (R6) to

indicate a full scale setting on the front panel meter.

STEP 3 Connect an accurate DC voltmeter to the Recorder

Output terminals TB1-6 & 7 with the positive (+) lead on

TB1-6.

STEP 4 While holding the Calibration Test switch (SW1) to its

TEST position, set the Isolated Output trimmer (R57) to

indicate a +10 volt reading on the test meter.

STEP 5 Connect an accurate DC milliammeter to the 4-20 mA

output terminals TB1-4 & 5 with the positive (+) lead on

TB1-4.

STEP 6 Leaving the Calibration Test switch (SW1) at its

OPERATE position, set the 4-20 mA Null trimmer (R63)

to indicate 4 mA on the test meter.

STEP 7 While holding the Calibration Test switch (SW1) to its

TEST position, set the 4-20 mA Full Scale trimmer

(R60) to indicate 20 mA on the test meter.

STEP 8 If your Model 767 is equipped with the Remote Meter

option (RM), hold the Calibration Test switch (SW1) to

its TEST position and set the Remote Meter trimmer

(R28) to indicate a full scale reading on the remote

meter.

4.4 PREVENTIVE CARE

The Myron L Company recommends that the following

Preventive Care procedures be observed.

STEP 1 Try to prevent exposure to excessive heat and

moisture.

STEP 2 The Monitor’s main AC power source must be

protected against excessive voltage “spikes.”

STEP 3 Take care not to damage the Monitor during handling.

NOTE:

Daily, weekly or monthly maintenance schedules are based

upon the frequency of use and the severity of the Monitor’s

environment and operating conditions.

STEP 4 Repeat the Monitor’s Check-Out procedures to verify

satisfactory operation and/or isolate possible

troubleshooting symptoms.

STEP 5 Check all cable connections to ensure that they are

free of moisture and contamination.

STEP 6 Inspect and replace damaged component boards and

cable assemblies.

STEP 7 Periodically remove and clean and inspect the

conductivity Cell.

Component Identification/Calibration and Preventive Maintenance

13

Page 16

WARRANTY

All Myron L monitors and cells have a one-year warranty. If any monitor or cell fails to function normally,

return the faulty unit to the factory prepaid. If, in the opinion of the factory, failure was due to materials or

workmanship, repair or replacement will be made without charge. A reasonable service charge will be made

for diagnosis or repairs due to normal wear, abuse or tampering. Warranty is limited to the repair or

replacement of monitor or cell only. The Myron L Company assumes no other responsibility or liability.

SECTION 5 REPLACEABLE

Appendix COMPONENTS CHART

DESCRIPTION MLC PART NO.)

755 Control Board 55RM*

755 Panel Cable Assembly 55RCA

756 Control Board 56RM*

756 Panel Cable Assembly 56RCA

1

/2" Analog Meter 50AM*

756 2

757 Control Board 57RM*

757 Panel Cable Assembly 57RCA

757 2 1/2" Analog Meter 50AM*

758 Control Board 58RM*

758 Panel Digital Assembly 58RCA

758 Digital Panel Meter 58DPM*

758 Digital Panel Meter with -420 Option 420MO1*

758 Digital Panel Meter with -420D Option 420DMO1*

750 Series Enclosure 50EC

750 Series Front Panel w/Lbl., Gasket and Screws 50FP

767 Control Board 67RM*

767 Control Board with -420D Option 674RM*

767 Control Board with -DP Option 67DPRM*

767 Control Board with -RM Option 67MRM*

767 Control Board with -420D-DP Options 674DPRM*

767 Control Board with -420D-RM Options 674MRM*

767 Control Board with -DP-RM Options 67DPMRM*

767 Control Board with -420D-DP-RM Options 674DPMRM*

767 Panel Cable Assembly 67RCA

767 Panel Cable Assembly for -DP Option Model 67DPRCA

767 3 Cell (-03) Option Board w/Cable Assembly 6703RCA

767 3 Cell (-03) Board for -DP Models w/Cable Assembly 6703DPRCA

1

767 4

/2" Analog Meter 60AM*

760 Series Enclosure w/Gasket 60EC

760 Series Front Panel w/Labels and Screws 60FP

Control Board Fuse

1

/8 AMP AGC 1/8 (all models) FUSE

WHEN ORDERING ANY PART, COMPLETE MODEL NUMBER MUST BE SPECIFIED.

* WHEN ORDERING THESE PARTS, RANGE SHOULD ALSO BE SPECIFIED.

pH Conductivity Instrumentation

Accuracy • Reliability • Simplicity

6115 Corte del Cedro

Carlsbad, CA 92009-1516 USA

Tel 760-438-2021

Fax 800-869-7668 / 760-931-9189

www.myronl.com

Loading...

Loading...