Page 1

Water Quality Instrumentation

Accuracy • Reliability • Simplicity

750 Series

CONDUCTIVITY/TDS

&

RESISTIVITY

MONITOR/CONTROLLER

Operation

Manual

25 January 06

INSTALLATION • OPERATION • MAINTENANCE

ACCURACY • RELIABILITY• SIMPLICITY

Page 2

750 Series II MONITOR/CONTROLLER

QUICK REFERENCE GUIDE!

If you read nothing else in this

manual please read this

Quick Reference Guide.

PLEASE READ and COMPREHEND ALL

WARNINGS, CAUTIONS and ADVISEMENTS

CONTAINED WITHIN THIS MANUAL.

Failure to comply is beyond the responsibility of

the Myron L Company.

WARNING: ALL MONITOR/CONTROLLERS ARE

FACTORY SET TO OPERATE ON 115 VAC. BEFORE

APPLYING POWER ENSURE THE INPUT POWER

“115/230 VAC” SELECTION IS CORRECT FOR YOUR

REQUIREMENTS. FAILURE TO DO SO IS BEYOND

THE RESPONSIBILITY OF THE MYRON L COMPANY.

See section II.E.2. and figure II.E.1.

NOTE: SOME MODELS MAY HAVE EITHER A 24 VAC

OR A 24 VDC INPUT POWER REQUIREMENT - CHECK

LABELS CAREFULLY.

WARNING: ENSURE POWER IS OFF WHILE

INSTALLING ELECTRICAL EQUIPMENT. IF

MONITOR/ CONTROLLER IS INSTALLED, ENSURE

THE POWER IS OFF BEFORE SERVICING. FAILURE

TO DO SO COULD CAUSE DAMAGE TO THE

INSTRUMENT, AND COULD BE HARMFUL OR FATAL

TO PERSONNEL. ONLY QUALIFIED PERSONNEL

SHOULD INSTALL OR SERVICE ELECTRICAL

EQUIPMENT.

WARNING: THE DISPLAY WILL BE IRREPARABLY

DAMAGED IF THE DISPLAY HARNESS IS INSTALLED

UPSIDE-DOWN OR MISALIGNED. THE HARNESS

MUST BE INSTALLED AS SHOWN IN FIGURE II.E.8.

CAUTIONS:

Before installation, ensure you have the correct

model (with options), AND it is ranged for your

application. See sections I.A., I.B. & I.G.

Do you have the correct sensor? See section I.E.

Mounting requirements. What is needed? See

section II.B.

The following will give the installer and user a quick

overview. See the sections listed for details.

REMOVING FRONT PANEL

NOTE: When opening instrument, remove front cover with care;

a ribbon cable connects the front panel and main board.

1. Ensure power is OFF.

2. Remove the two (2) screws on the front panel.

3. Carefully wiggle the front panel to loosen the gasket and

pull gently toward you. Do not pull more than about 8

inches/20CM or you could damage the wiring harness.

REASSEMBLY

1. Carefully reinstall the front panel, bottom first.

Ensure no wires have been pinched between enclosure

and front panel.

2. Reinstall the two (2) screws and tighten.

3. To operate, turn power ON.

INTRODUCTION - Section I.

This section covers the specifications of your new

Monitor/controller including sensor information.

INSTALLATION - Section II.

This section covers how to install your new Monitor/controller;

mechanically and electrically.

OPTIONS & ACCESSORIES - Section III.

This section covers the specifications, installation, set up, and

operation of each option.

QUICK LOCATOR

SC/SCO MODULE, (Second Relay), see section III.A.

4A/4AO MODULE (4-20mA), see section III.B.

TP/TPO MODULE (Temperature), see section III.C.

TH/THO MODULE (Alarm /control Harness), see section III.D.

DUAL (stacking) Temperature (TPO) & 4-20mA (4A/4AO), see

section III.E.

3SO/3SE MODULE (3 Sensor option) , see section III.F.

3RO/3RE MODULE (3 Range option), see section III.G.

3SRO/3SRE MODULE (Combined 3 Sensor & 3 Range option),

see section III.H.

PA/PAO (Piezo Alarm), see section III.I.

RA (Remote Alarm), see section III.J.

OPERATING PROCEDURES - Section IV.

This section covers a brief description of different models and

their features; how they work, and how to set them up for your

particular use.

QUICK SET POINT CONVERSION (SPC) /

REVERSING SET POINT - See Section IV.C.1.

Conductivity/TDS Monitor/controllers are configured to trigger the

alarm relay as the conductivity/TDS reading increases.

Resistivity Monitor/controllers are configured to trigger the alarm

relay as the resistivity reading decreases.

To reverse:

1. Locate the jumper block for the alarm to be configured.

See figure V.A.1.

2. Remove and rotate the jumpers 1/4 turn and reinstall

them on their posts.

QUICK CHECK-OUT PROCEDURE -

See Section IV.C.2.

It is assumed that the Monitor/controller power is ON, that it is

Continued

Page 3

connected to an appropriate Sensor, and that the Sensor is

immersed in water within the range that the Monitor/controller will

be required to read; and the front panel is removed.

1. Make a note of the reading on the display.

2. While pressing the Calibration/Full Scale Test Switch (FS

SW), verify that the front panel display is indicating a full

scale reading. If not, see Calibration, section V.C.

3. Press and hold the "SET POINT" switch on the front

panel. Using a tweaker or a small screwdriver, adjust the

Set Point trimmer adjustment screw on the circuit board

to sweep the display from zero to full scale. (A digital

display may be blank at the full scale end. This is

normal.) Listen for the alarm relay to click on and off as

the alarm set point moves past the water reading.

4. Adjust the alarm to the desired set point value. Release

the "SET POINT" switch.

NOTE: For Models with SC/SCO module, repeat STEPS 3 & 4 to

check out Set Point #2.

QUICK SET POINT ADJUSTMENT -

See Section IV.C.3.

The set point setting is based upon the user's particular water

purity specifications or requirements. NOTE: The optional

second relay/alarm is “stacked” on the first relay/alarm,

therefore, when setting the optional second relay/alarm Set

Point, the #1 Set Point must be ‘set’ first.

1. While pressing the "SET POINT" switch, turn the Set

Point #1 adjustment screw (see figure V.A.1) until the

desired set point value is indicated on the display.

HYSTERESIS (DEAD BAND) ADJUSTMENT -

See Section IV.C.4.

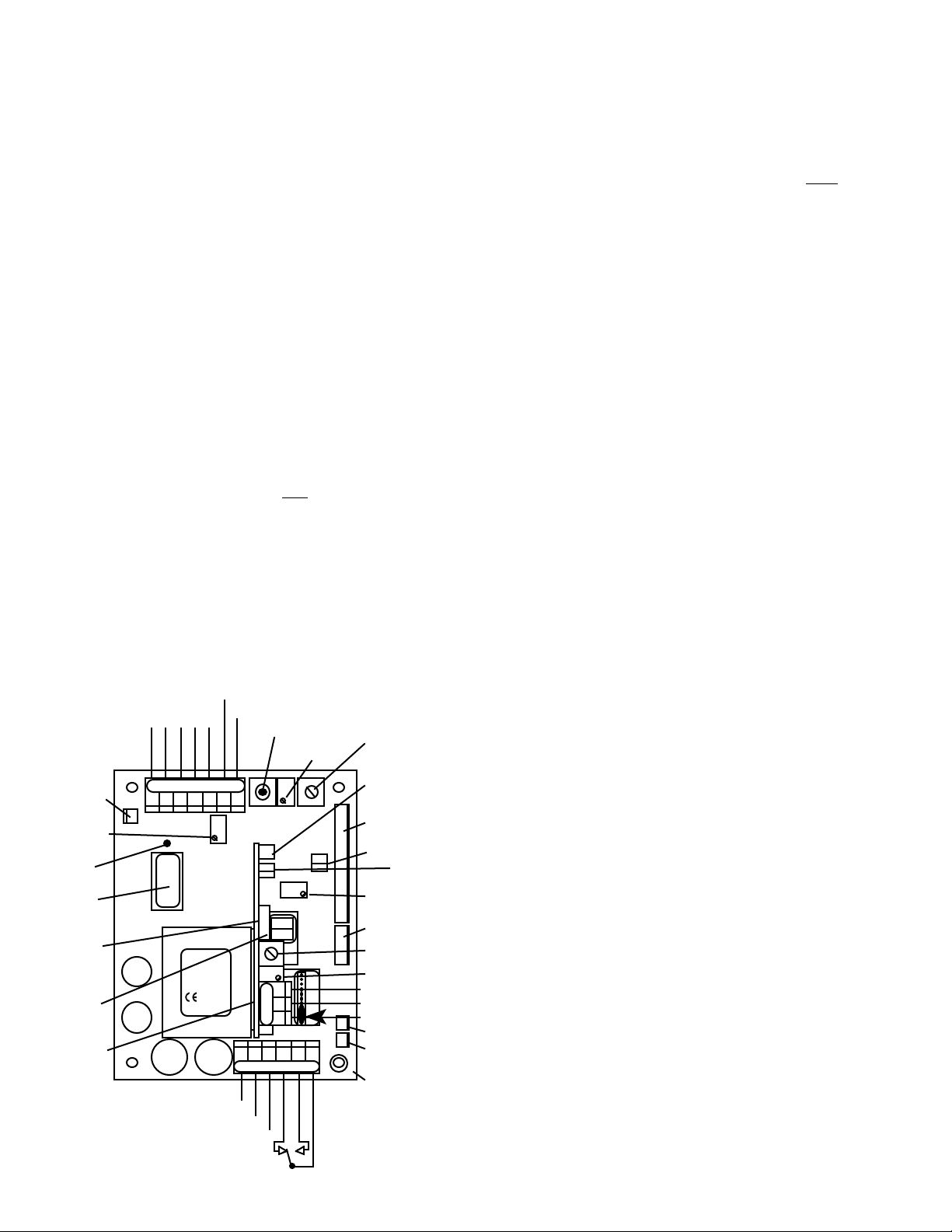

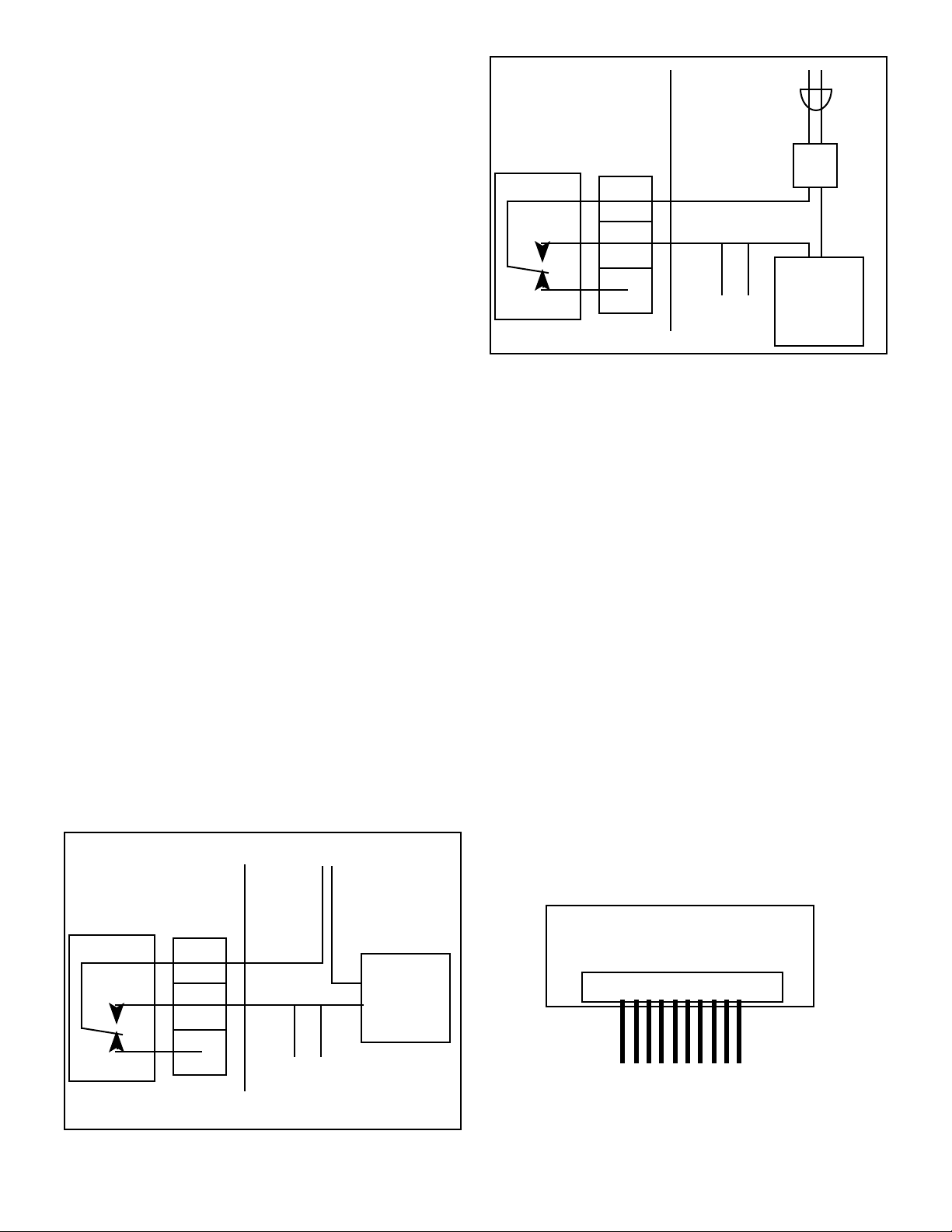

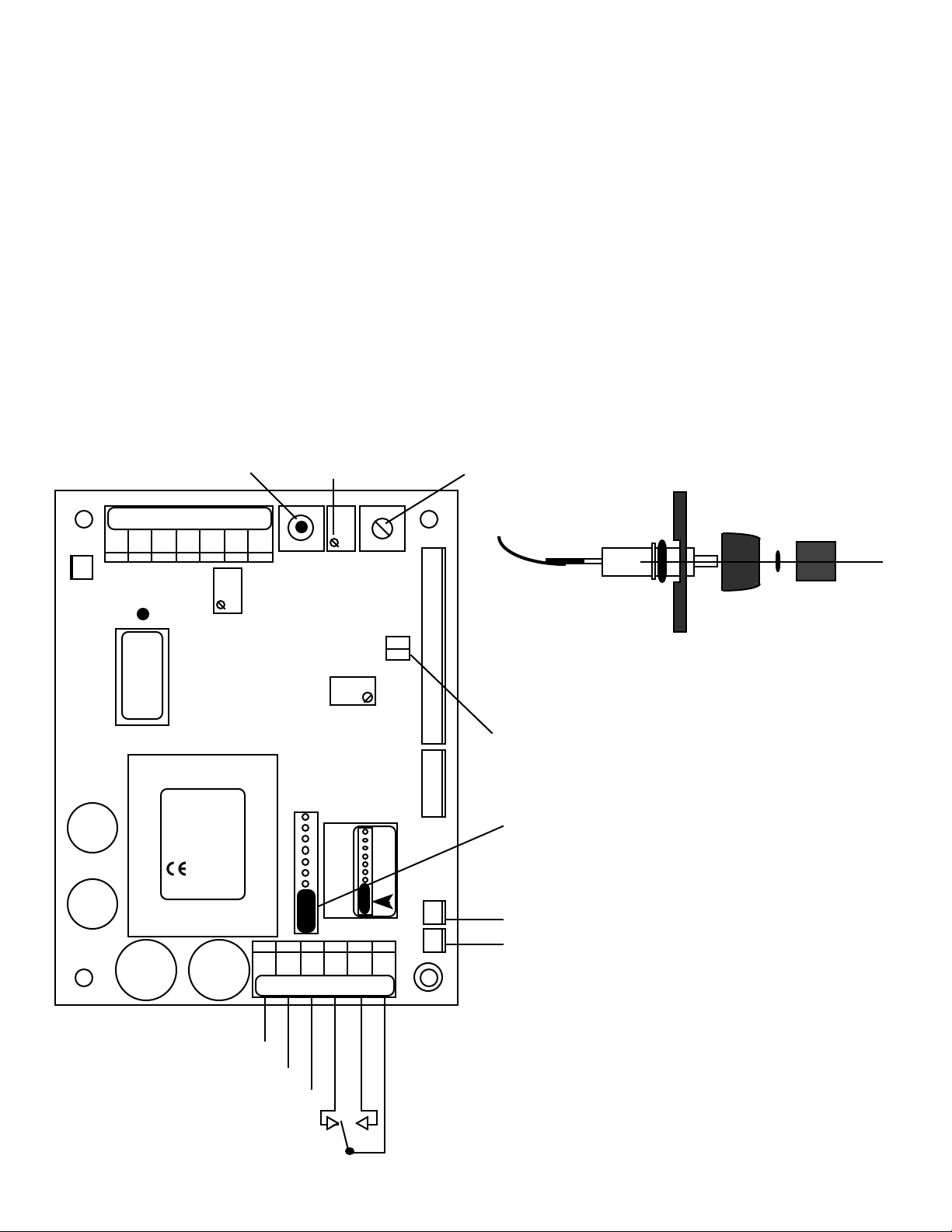

PRIMARY COMPONENT IDENTIFICATION -

Section V.A.

Review the figure below to familiarize yourself with the Main circuit

(-)

0-10VDC OUTPUT

3SO/3SE &/OR

3RO/3RE

SWITCH

CONNECTION

MAIN

CALIBRATION

CONTROL

RANGE

MODULE

ALIGNMENT

RANGE

MODULE

SC/SCO

OPTIONAL

SECOND

ALARM/

CONTROL

MODULE

#2 RELAY

LIGHTS &

SWITCH

CONNECTOR

RUBBER TAPE

(DO NOT

REMOVE)

Figure V.A.1

SENSOR

B

W

R

L

H

E

K

T

D

BK WT RD GN NU R- R+

3S

}

UP

-121

2000µS

TRANSFORMER

115/

230

POWER

{

G

N

R

E

N

U

CAL

INC

751 756

752 757

753 758

754 759

MYRON L

COMPANY

FUSE*

AC AC GD NC NO CM

AC HOT/ +DC

AC NEUTRAL/ -DC

GROUND

(+)

FULL SCALE

PUSH TO TEST

SET POINT

#1 CONTROL

PA

INC

DIS

SPC

INC

CM NO NC

NC NO

HYS1SP1FS SW

SPC

SECOND RELAY

REMOVE TO INSTALL

COM

DEC

SET POINT #1

HYSTERESIS

RIGHT INC

LEFT DEC

SOLID STATE (24VDC 30mW)

OUTPUT

PA™ PIEZO ELECTRIC ALARM

OR

RA™ REMOTE ALARM OR

CUSTOMER CONNECTION

DISPLAY/METER

CONNECTOR

SET POINT #1

CONVERSION

DISPLAY CALIBRATION

CONTROL (FACTORY SET)

4-20 CONNECTOR

SET POINT #2 HYSTERESIS

RIGHT INC / LEFT DEC

SET POINT #2 CONTROL

NC

NO

COM

+

SOLID STATE (24VDC 30mW)

+

OUTPUT

PA RA

RA™ REMOTE ALARM AND

PA™ PIEZO ELECTRIC ALARM

OR

CHS

GND

CUSTOMER CONNECTION

CHASSIS GROUND - OEM

RELAY #1

}

SET POINT #2

CONVERSION

RELAY #2

}

board assembly. The diagram has the second alarm/control

module option installed.

QUICK CALIBRATION - Section V.C.

WARNING: When performing calibration procedures,

the technician must take extreme care to avoid

contacting the circuitry other than the CALibration

control. Failure to do so could result in damage to

the equipment, property and/or personal injury.

The following assumes the front panel has been

removed and the power is ON.

ELECTRONIC CALIBRATION (CIRCUIT ONLY) -

See Section V.C.1.

Full Scale Adjustment

1. Press and hold the Full Scale Test switch. The display

should indicate Full Scale for the particular range

selected, i.e. 0-500 ppm should indicate 500. If not, set

to Full Scale with the CALibration control.

2. Turn power OFF.

3. Re-install front panel as described in “REASSEMBLY”.

4. To operate, turn power ON.

10VDC Calibration - See Section V.C.1.b.

Using Standard Solutions - Section V.C.2.

The BEST method of verifying and recalibrating your

conductivity/TDS Monitor/controller is with NIST traceable

Standard Solution (available from the Myron L Company).

Because it includes the sensor, the entire system is recalibrated.

NOTE: Since standard solution calibrations are NOT practicable

with resistivity models, another means of verification or

calibration of resistivity models is to use the transfer standard

method, using a hand-held or portable instrument capable of

resistivity measurements, i.e. the Myron L Ultrameter™. See

section V.C.4 for description.

The following procedure describes the easiest method for

standard solution calibration of your Conductivity/TDS

Monitor/controller.

1. Using a standard solution which is 60-90% of full scale

of the instrument, rinse thoroughly and fill a clean glass

beaker with the standard solution.

2. Place sensor in the beaker of standard solution. The

level of standard solution must be high enough to cover

at least 1/2" above cross hole.

3. Slowly shake the sensor to remove air bubbles from

inside the sensor bore hole.

4. Allow 5-10 minutes for temperature to equilibrate. For the

quickest and the best results, both the sensor and

solution should be at the same temperature.

5. Turn power ON.

6. If the reading is different from the standard solution,

adjust CALibration control on the main circuit board until

the reading matches the solution value.

7. After adjustment, turn power OFF.

8. Re-install front panel as described in “REASSEMBLY”.

9. To operate, turn power ON.

SENSOR SUBSTITUTE CALIBRATION -

See Section V.C.3.

TRANSFER STANDARD METHOD - See Section V.C.4.

14 Jan 03

Page 4

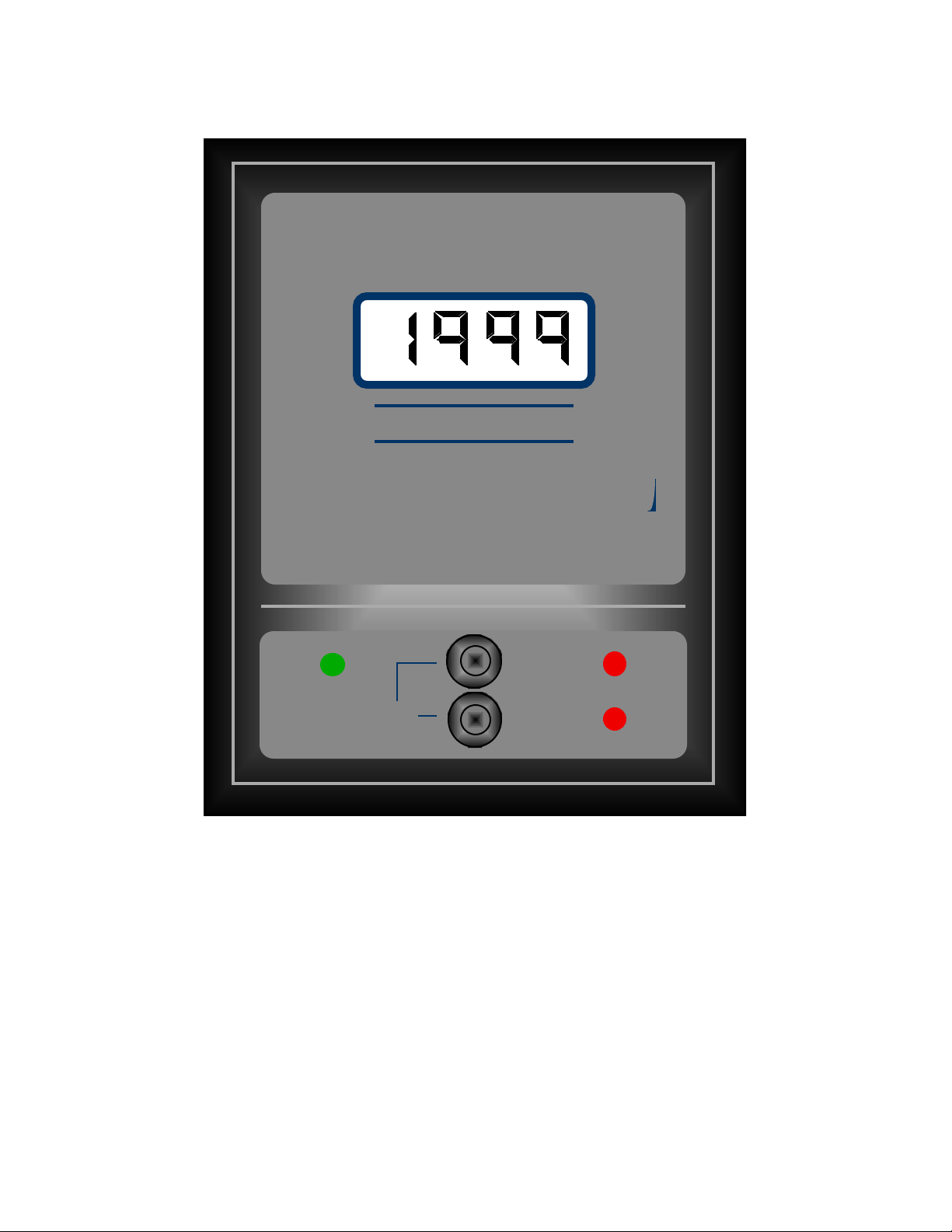

MICROSIEMENS / CM

750II

MYRON L

COMPANY

HIGH

LOWSET POINT

750 Series II

Model 758II-121-SC

(A Digital Conductivity

Monitor/controller,

with a Range of 0-2000 µS,

and a Second Alarm/Control)

1

Page 5

TABLE OF CONTENTS

SECTION PAGE

750 Series II ILLUSTRATION (758II-121-SC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

I. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

A. SCOPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1. Functional Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

B. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

C. OPTIONAL FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

D. ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

E. SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1. Conductivity/TDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2. Resistivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3. Sensor Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

F. ORDER INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1. How to order Monitor/controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2. How to order Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

G. RANGE SELECTION GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

II. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

B. MECHANICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1. Surface Mounting with SMP (surface mounting plate) Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 9

2. Surface Mounting without SMP Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3. Panel Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

C. OEM MECHANICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1. Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2. Analog Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3. Digital Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

D. SENSOR INSERTION / DIP MOUNT ASSEMBLIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

1. Insertion Mode Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2. Alternate Dip Sensor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

E. ELECTRICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1. Main AC Power Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2. 115/230 VAC Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3. Connecting the Sensor Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

a. Modification for US Pharmaceutical 25 (No Temperature Compensation) . . . . . . . . . . . . . . 12

4. Solid State Output Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

a. Piezo Electric Alarm Installation (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

b. Remote Alarm Connection (RA option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

c. Connect to your own alarm or ? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5. Alarm/Control Relay Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6. Connecting Display Harness to Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

F. 0-10 VDC OUTPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1. Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2. Voltage Divider . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

G. RE-RANGE YOUR MONITOR/CONTROLLER (Range Module Installation) . . . . . . . . . . . . . . . . . . . . . . . . 16

1. Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3. Changing Analog Meter Scale (dial) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4. Label Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

III. OPTIONS & ACCESSORIES INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

A. SC/SCO MODULE (SECOND ALARM/CONTROL OPTION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1. Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

a. Set Point Conversion (SPC) / Reversing Set Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

b. Set Point Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

c. Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

d. Second Relay Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

e. Solid State Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2

Page 6

TABLE OF CONTENTS Continued

SECTION PAGE

B. 4A/4AO MODULE (4-20mA OPTION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

1. Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2. Installation . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3. Recalibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4. Converting a Current to a Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

C. TP/TPO MODULE (TEMPERATURE OPTION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1. Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3. Recalibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

a. TPC “Calibration”Module Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

b. Precision Resistor Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

c. System Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4. Alarm/control Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5. OEM Installation (Single Display) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6. OEM Installation (Dual Display) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

D. TH/THO MODULE (ALARM /CONTROL HARNESS OPTION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

1. Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

E. DUAL (stacking) TEMPERATURE MODULE (TPO) & 4-20mA MODULE (4AO) . . . . . . . . . . . . . . . . . . . . . 39

1. Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

F. 3SO/3SE MODULE (3 SENSOR OPTION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

1. Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

3. Alarm/control Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

G. 3RO/3RE MODULE (3 RANGE OPTION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

1. Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

3. Alarm/control Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

H. 3SRO/3SRE MODULE (COMBINED 3 SENSOR & 3 RANGE OPTION) . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

1. Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3. Alarm/control Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

I. PA PIEZO ALARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1. Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

J. RA REMOTE ALARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

1. Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

IV. OPERATING PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

A. FRONT PANEL INDICATORS & CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

1. Red "Set Point" LED Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2. Green "Set Point" LED Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

3. "Set Point" Switch(es) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4. Analog Meter or Digital Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5. Optional Front Panel Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

B. OEM FRONT PANEL INDICATORS & CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

1. Red "Set Point" LED Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

2. Green "Set Point" LED Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3. "Set Point" Switch(es) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

4. Analog Meter or Digital Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5. Optional Panel Mounted Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

C. SETUP PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

1. Set Point Conversion (SPC) or Reversing Set Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

2. Check-Out Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

3. Set Point Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4. Hysteresis (Dead Band) Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3

Page 7

TABLE OF CONTENTS Continued

SECTION PAGE

V. COMPONENT IDENTIFICATION, CALIBRATION AND PREVENTIVE CARE . . . . . . . . . . . . . . . . . . 56

A. PRIMARY COMPONENT IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

B. METER MECHANICAL ZERO PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

C. CALIBRATION PROCEDURES - MAIN CIRCUIT BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

1. Electronic Calibration (Circuit Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

2. Calibration Using Standard Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

3. Sensor Substitute Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4. Transfer Standard Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

D. PREVENTIVE CARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

VI. OPTIONS & ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

A. OPTIONS ORDERED WITH MONITOR/CONTROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

B. OPTIONS & ACCESSORIES ORDERED SEPARATELY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

C. STANDARD SOLUTIONS & BUFFERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

VII. REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

VIII. WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

IX. GLOSSARY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

X. NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

XI. ADDENDUM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

A. CONDUCTIVITY, TDS AND TEMPERATURE RELATIONSHIPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4

Page 8

I. INTRODUCTION

Thank you for selecting one of the Myron L Company’s new 750

Series II Monitor/controllers. The 750 Series II is based on input

from ‘you’ - our customers, time proven designs, and many years

of instrumentation experience.

Since 1957, the Myron L Company has been providing customers

with quality products at an affordable price by designing and

producing products that are Accurate, Reliable, Simple to use.

Quality you have come to rely and depend on.

As you read through this operation manual you will see the 750

Series II is truly designed to be user friendly with simple to install

options, and easy re-rangeability as conditions or applications

change. This manual is actually more complex than the 750

Series II Monitor/controller.

Where applicable the Original Equipment Manufacture (OEM)

models are separated as necessary to clarify and define their

differences. As defined by the Myron L Company, an OEM model

does not have an enclosure. However, many OEMs use our

enclosure just as if it were a standard model, therefore, as an end

user you must decide whether to follow the OEM instructions or

the “standard” models with enclosure.

All OEMs mount the circuit board assemblies in differing locations

making it impossible for us to describe exactly where to find them.

By looking in section V. for the Main circuit board (CB) assembly,

you will have a picture of what it looks like. If your OEM has a

display, follow the display harness back to the Main CB. Once

located you will be able to locate any installed options by following

the harnesses, i.e. 4A (4-20mA output).

A. SCOPE

This operation manual provides the user with the necessary

information to install, operate and maintain the

Myron L Company's 750 Series II Conductivity/TDS & Resistivity

Monitors/controllers.

Section I. provides Descriptions, Applications, Specifications.

Section II. Installation; mounting, wiring and set up.

Section III. Options and Accessory installation procedures.

Section IV. Operating procedures.

Section V. Identifies their primary components and provides the

user with easy-to-use calibration and preventive care

procedures.

Section VI. Options & Accessories List.

Section VII. Replacement Components.

Section VIII. Warranty information.

Section IX. Glossary, definitions.

Section X. Notes.

Section XI. Addendum.

1. FUNCTIONAL DESCRIPTIONS

All models except OEMs have water & corrosion resistant

IP64/NEMA 3 housings suitable for panel, bench or surface

mounting. The 750 Series II are a compact 6.0" (152mm) x 4.8"

(122mm).

Bright green/red LEDs indicate HIGH/LOW set point readings. All

models except 751II, 754II, 756II, & 759II, (see below) feature

a heavy-duty 10 amp output relay, operating on either increasing

or decreasing readings.

For specific Monitor/controller configurations, reference the

following individual model descriptions.

Models 757II Conductivity/TDS & 752II Resistivity

Analog Monitor/controller. Standard front panel is equipped with a

linear analog meter display and a "SET POINT" switch with

High/Low indicator lights. Single set point is internal to discourage

unauthorized adjustments. A second set point alarm/control is

available as an option. 4-20mA output option is available on OEM

models only.

Models 758II Conductivity/TDS & 753II Resistivity

Digital Monitor/controller. Standard front panel is equipped with a

3 1/2 digit liquid crystal display (LCD), and a "SET POINT" switch

with High/Low LED indicator lights. Single set point is internal to

discourage unauthorized adjustments. A second set point

alarm/control is available as an option. May use an optional 420mA output for PLC or SCADA operations.

Models 756II Conductivity/TDS & 751II Resistivity

Analog monitor ONLY. Standard front panel is equipped with a

linear analog meter, no relay, LED indicators or set point switch. A

4-20mA output option is available on OEM models only.

Models 759II Conductivity/TDS & 754II Resistivity

Digital monitor ONLY. Standard front panel is equipped with a

3 1/2 digit liquid crystal display (LCD) only, no relay, LED

indicators or set point switch. May use an optional 4-20mA output

for PLC or SCADA operations.

2. APPLICATIONS

Conductivity/TDS

Reverse Osmosis

Process Control

Seawater Desalinization

Wastewater Treatment

Food Processing

Plating

Power Plants

Laboratories

Printing

Boiler

Cooling Tower

Agriculture/Aquaculture

Are just a few of the applications

Resistivity

Deionization (DI) and Distillation Ultrapure Water

Treatment Systems

Electronics

Pharmaceutical

Laboratories

Food Processing

Plating

Power Plants

Are just a few of the applications

B. SPECIFICATIONS

RANGES: 34 Conductivity/TDS ranges from

0-1µS/µM/ppm to 0-200mS/mM/ppt

7 Resistivity ranges from 0-200KΩ to 0-20MΩ.

Refer to Range Selection Guide on Page 8.

DISPLAY:

Models 756II, 757II & 751II, 752II:

2 1/2” (63mm) analog meter

Models 758II, 759II & 753II, 754II:

5

Page 9

13 mm/1/2 in. 3 1/2 digit LCD

NOTE: 3 1/2 digit LCD may be replaced with either a 3 1/2 or

a 4 1/2 digit backlit LCD - available as options.

ACCURACY

Analog Models: ±2% of Full Scale

Digital Models: ±1 % of Full Scale

SENSITIVITY

0.05% of span

STABILITY

0.05% of span

AMBIENT TEMPERATURE RANGE

0 - 60°C/32 - 140ºF

DIMENSIONS

152 H x 122 W x 96 D mm / 6.0 H x 4.8 W x 3.8 D in.

HOUSING CONSTRUCTION

Fully gasketed heavy-duty ABS for splashproof and corrosion

resistance.

Rated IP64/NEMA 3

Double Insulated (with circuit board ground for OEM operation)

DOUBLE INSULATED

REPEATABILITY

0.1% of span

CALIBRATION CHECK

Built in full scale value

RECORDER OUTPUT

0-10 VDC @ 5 mA max. (linear); standard on all models

OUTPUT IMPEDANCE

100Ω ±5%

SENSOR INPUT 1 (optional 3 sensor Input available)

CONTROL FUNCTION

Models 757 , 758 & 752 , 753 :

Single set point alarm/control continuously adjustable

0-100% of span

Second set point alarm/control (Optional).

Continuously adjustable - 0-100% of span

Hysteresis

Adjustable from 0.3-3% of full scale

Indicators

"HIGH" (red) and "LOW" (green) set point LEDs - reversible.

Relay Contact Rating

SPDT 10 amp @ 250 VAC, 30 VDC. Relay operates

increasing or decreasing reading (user selectable).

Solid State Output

24 VDC unregulated, 30 mA Maximum.

Powers optional PA - Piezo Electric Alarm, RA - Remote

Alarm™, or ?

Second Alarm/control Module, with above specifications, opt. on

Models 757 , 758 & 752 753

POWER SPECIFICATIONS

115/230 VAC ±15%, 50/60 Hz (User selectable)

overvoltage category II

100 mA Maximum Current

Double Insulated (with circuit board ground for OEM operation)

Fuse - 100 mA Slow Blow (T.10A) for both 115 & 230 VAC (V~)

User replaceable

Humidity - 20-90% non-condensing

Max. Altitude -

12,000 meters/40,000 ft. non-operating

3000 meters/10,000 ft. operating

Pollution degree 2

24 VAC or 24 VDC Option available on Special Order

Overvoltage category II (24 VAC)

250 mA Maximum Current

Double Insulated (with circuit board ground for OEM operation)

Fuse - 250 mA Slow Blow (T.25A) User replaceable

WEIGHT

750 Series : average 0.9 kg/2 Ibs.

C. OPTIONAL FEATURES

D. ACCESSORIES (ordered separately)

† Add C = Cond or R = Res to part number

* Customer mounted separately

See sections VI & VII for complete selection and details.

-SC Second Alarm/control Module (M/c only)

-4A 4-20 mA Isolated Output Module (digital models only)

-PA 70 db Piezo Electric Alarm (digital M/c only)

-PAT Piezo Alarm & Timer Module (digital M/c only)

-45BL 4 1/2 Digit Backlit Liquid Crystal Display (LCD)

-35BL 3 1/2 Digit Backlit Liquid Crystal Display (LCD)

-TP Temperature Module 0-200ºC, requires -TP Sensor

(digital Monitor/controllers only)

-TH TP/TPO Alarm/control Harness (req. SC & TP) (digital only)

-PC 115 VAC Power cord (8 ft./2,44 meters) with USA plug

and strain relief) - NOT for use with 230 VAC.

-24VA 24 VAC Isolated Power Supply (special order)

-24VD 24 VDC Isolated Power Supply (special order)

-PTS Panel mounted Full Scale Test switch (special order)

See sections VI & VII for complete selection and details.

Aquaswitch , auto RO/DI switching system (req. M/c)

SCO Second Alarm/control Module (Monitor/controllers only)

4AO 4-20 mA Self-Powered Isolated Output Module (digital only)

3SE 3 Sensor Input Module with Enclosure

3SO 3 Sensor Input Switch Module with 1 meter/3 ft. cable*

3RE 3 Range Switch with Enclosure†

3RO 3 Range Switch with 1 meter/3 ft. cable†*

3SRO

3SRE

PAO 70 db Piezo Electric Alarm only (753 /758 )

PATO Piezo Alarm & Timer Module (753 /758 )

45BLO 4 1/2 Digit Backlit Liquid Crystal Display (LCD)

35BLO 3 1/2 Digit Backlit Liquid Crystal Display (LCD)

TPO Temperature Module 0-200ºC - requires -TP Sensor

THO TP/TPO Alarm/control Harness only

PCO Power Cord 115 VAC (8 ft./2,44 meters) with USA plug

SMP50 Surface Mounting Plate

RA Remote Alarm™ - RA (Monitor/controllers only)

VR Power Supply, 24 VAC, 20 VA. (115 VAC, indoor use)

024-1 1 in. NPT 24 VAC Solenoid Valve

CS-11 20 MΩ Resistivity Calibration Module (NIST Traceable)

CS-14 2 MΩ Resistivity Calibration Module (NIST Traceable)

CS-17 200 KΩ Resitivity Calibration Module (NIST Traceable)

Above 3SO & 3RO combined with enclosure†.

Above 3SO & 3RO combined†*

(digital models only)

(requires SCO & TPO)

and strain relief) - NOT for use with 230 VAC.

6

Page 10

E. SENSORS

1. CONDUCTIVITY/TDS

750 series Conductivity/TDS Monitor/controllers use the

CS51LC, CS51 or CS52 Series sensor depending on range. The

1.0 cell constant CS51 model is recommended for ranges of 0-10

through 20,000 µS/ppm. Its compact size allows mounting in a

standard 3/4" tee. The sturdy polypropylene bushing is modular

for easy, inexpensive replacement. Other models available by

special order.

* -TP Sensor 8 wire cable contact the Myron L Company

TEMPERATURE COMPENSATION

Automatic to 25°C, between 0-100°C/32-212°F

except high temperature models - up to 205°C.

PRESSURE/TEMPERATURE LIMITS

CS10 & CS51 - 100 psi/689.6 kPa at 100°C/212°F

For higher limits, see specifications below.

CS52 sensors have a 10.0 cell constant and are used for

conductivity/TDS values above 20,000 µS/ppm.

CS51LC sensor has a cell constant of 0.1 and is used for

conductivity/TDS values of 0-1 to 0-5 µS/ppm.

Special order High Temperature, High Pressure sensors; and Low

Cost, Low Temperature, Low Pressure sensors are available.

For detailed descriptions of these and other sensors, see Sensor

Selection Guide and specific sensor data sheets available from

your local distributor, the Myron L Company, or on line at

www.myronl.com.

2. RESISTIVITY

750 series Resistivity Monitor/controllers use the CS10

sensor. It has a cell constant of 0.05 and is used for ultra pure

water applications. Other models available by special order.

3. SENSOR SPECIFICATIONS

See sensors price list for complete selection and details.

STANDARD MODELS — 316 Stainless Steel CONSTANT

CS51LC: For ranges 0-5 µS/ppm & below 0.1

CS51: For ranges between 0-10 & 0- 20,000 µS/ppm 1.0

CS52: For ranges above 20,000 µS/ppm 10.0

CS10: For ALL Resistivity ranges 0.05

See Range Selection Guide, Page 8.

SPECIAL ORDER MODELS — 316 Stainless Steel

CS40 Conductivity/TDS Valve Insertable 100 psi

@ 150°C (10.0, 1.0, 0.1 & 0.05)

CS40HT Above High Temp Model 250 psi @ 205°C

CS41 Cond/TDS High Temp Model 100 psi @ 150°C

CS41HT Cond/TDS High Temp Model 250 psi @ 205°C

CS50 Conductivity/TDS 100 psi @ 95°C (1.0 & 0.1)

CSA Low Cost Conductivity/TDS - NO Temperature

Compensation 75 psi @ 60°C (1.0)

CSATC Low Cost Conductivity/TDS - with Temperature

Compensation 75 psi @ 60°C (1.0)

4. SENSOR OPTIONS

-T Titanium - in place of Stainless Steel

-TP Temperature Sensor 0-200°C (special order)

-WTV Wet-Tap Valve for CS40 (0.1 & 1.0 only)

-JB Junction Box - Class I, Group D, Div. S,

explosion and weather proof aluminum. For

CS40/CS40HT.

-STF Sanitec Fitting for CS10, CS51 & CS51LC. 1/2”

thru 4”. State size, i.e. STF1/2

-25 25’ Shielded Cable (Standard 5 wire sensor)*

-100 100’ Shielded Cable (Standard 5 wire sensor)*

-PV 1/2" PVDF fitting for CS10 & CS51 ONLY

{replaces polypropylene}

-HPSS 1/2" 316 STAINLESS STEEL fitting

for CS10 & CS51 ONLY (replaces

polypropylene).

BUSHING

CS51 (LC): Modular Polypropylene threaded 3/4" NPT

CS52: 316 stainless steel 3/4" NPT internal to cell body

CS10: Modular Polypropylene threaded 3/4" NPT

CABLE

Shielded; 10 ft./3 meters standard

25 ft./7 meters, and

100 ft./30 meters lengths also available

DIMENSIONS

CS51(LC): Metal portion 30 mm/1.2 in. L; 13 mm/0.5 in. DIA

CS10: Metal portion 30 mm/1.2 in. L; 13 mm/0.5 in. DIA

For other models see sensor selection & specific data sheets for

details.

F. ORDERING INFORMATION

1. HOW TO ORDER MONITOR/CONTROLLERS

MODEL RANGE OPTIONS

758 — 121 — SC - 4A - PA

Written as — 758 -121-SC-4A-PA

This is a Digital Monitor/controller with a 0-2000 µS range, a

Second Alarm/control, a 4-20 mA output and a Piezo Electric

Alarm.

NOTE: Monitor model number does not include sensor. Please

specify sensor required when ordering.

RANGE SUFFIXES:

See RANGE SELECTION GUIDE, Page 8.

2. HOW TO ORDER SENSORS

Add option to model number as in examples below.

MODEL OPTIONS

CS51 — T-TP-100

Written as — CS51-T-TP-100

The above is a model CS51 sensor made with Titanium, with the

Temperature sensor, and a 100 foot cable.

EXAMPLE:

MODEL OPTIONS

CS40HT — 01-T-WTV-TP

Written as — CS40-01-T-WTV-TP

The above is a Special Order High Temperature sensor with a cell

constant of 0.1, made of Titanium, a Wet-Tap Valve and a

Temperature sensor.

7

Page 11

G. 750 SERIES II RANGE SELECTION GUIDE

CONDUCTIVITY/TDS & RESISTIVITY

Add Range NUMBER below to instrument model number, i.e. 758II-"112" = 0-50 ppm Digital Monitor/controller .

756II, 757II, 758II & 759II

RANGE

Resistivity

0-20 MΩ

0-10 Mن

0-5 Mن

0-2 MΩ

0-1 Mن

0-500 Kن

0-200 KΩ

Conductivity

0-1 µS*†

0-1 ppm*†

0-2 µS*†

0-2 ppm*†

0-5 µS*†

0-5 ppm*†

0-10 µS†

0-10 ppm†

0-20 µS

0-20 ppm

0-50 µS

0-50 ppm

0-100 µS

0-100 ppm

0-200 µS

0-200 ppm

0-500 µS

0-500 ppm

0-1000 µS

0-1000 ppm

0-2000 µS

0-2000 ppm

0-5000 µS††

0-5000 ppm††

0-10,000 µS/0-10 mS††

0-10,000 ppm/0-10 ppt††

0-20,000 µS/0-20 mS††

0-20,000 ppm/0-20 ppt††

0-50,000 µS/0-50 mS**††

0-50,000 ppm/0-50 ppm**††

0-100 mS**††

0-100 ppt**††

0-200 mS**††

0-200 ppt**††

*CS51LC conductivity sensor (0. 1 constant) required for these ranges.

**CS52 conductivity sensor (10.0 constant) required for these ranges.

† Available in Digital models only.

†† Available with 4 1/2 Digit Backlit LCD. Other ranges available as OEM ONLY. Price & delivery on request.

Except as noted, Conductivity/TDS Monitor/controllers require a sensor with a cell constant of 1.0. The Model CS51

is the most commonly selected sensor due to its ease of use and low cost.

Resistivity Monitor/controllers require a sensor with a cell constant of 0.05. The Model CS10 is the most common

selected due to its ease of use and low cost.

NOTE: UNLESS ppm/NaCl is specified with order, TDS/ppm type conductivity instruments will be calibrated to the

Myron L "442™" Natural Water standard. For NaCl ppm/ppt add the letter "N" after the number, i.e. -124N.

CONDUCTIVITY/TDS

Dash #

-101

-102

-103

-104

-105

-106

-107

-108

-109

-110

-111

-112

-113

-114

-115

-116

-117

-118

-119

-120

-121

-122

-123

-124

-125

-126

-127

-128

-129

-130

-131

-132

-133

-134

751II, 752II, 753II & 754II

RESISTIVITY

Dash #

-11

-12

-13

-14

-15

-16

-17

8

Page 12

II. INSTALLATION

A. GENERAL

This section provides the recommended procedures for properly

installing the 750 Series II Conductivity/Resistivity

Monitor/controller, and sensors. For OEM models see section C.

CAUTION - READ FOLLOWING CAREFULLY

!

WARNING: THE MYRON L COMPANY RECOMMENDS

THAT ALL MOUNTING AND ELECTRICAL

INSTALLATIONS BE PERFORMED BY QUALIFIED

PERSONNEL ONLY. FAILURE TO DO SO COULD

CAUSE DAMAGE TO INSTRUMENT, AND COULD BE

HARMFUL OR FATAL TO PERSONNEL.

B. MECHANICAL INSTALLATION

All Monitor electronics are packaged inside drip/weather-proof

housings. The physical dimensions of the housing is suitable for

panel, bench or surface mounting.

There are four basic guidelines to consider when selecting a

Monitor's mounting location:

1. Select a site that limits the Monitor's exposure to

excessive moisture and corrosive fumes.

2. For best results, position your Monitor/controller and

sensor as close as possible to the point(s) being

controlled. The 750 Series II Conductivity/TDS &

Resistivity Monitor/controllers are not designed to

operate with a Sensor cable length that exceeds 100' (30

meters).

3. If at all possible, mount the Monitor at eye level for

viewing convenience.

4. If needed, the enclosure may be rotated or mounted

upside down so that the cutouts are on the opposite

side.

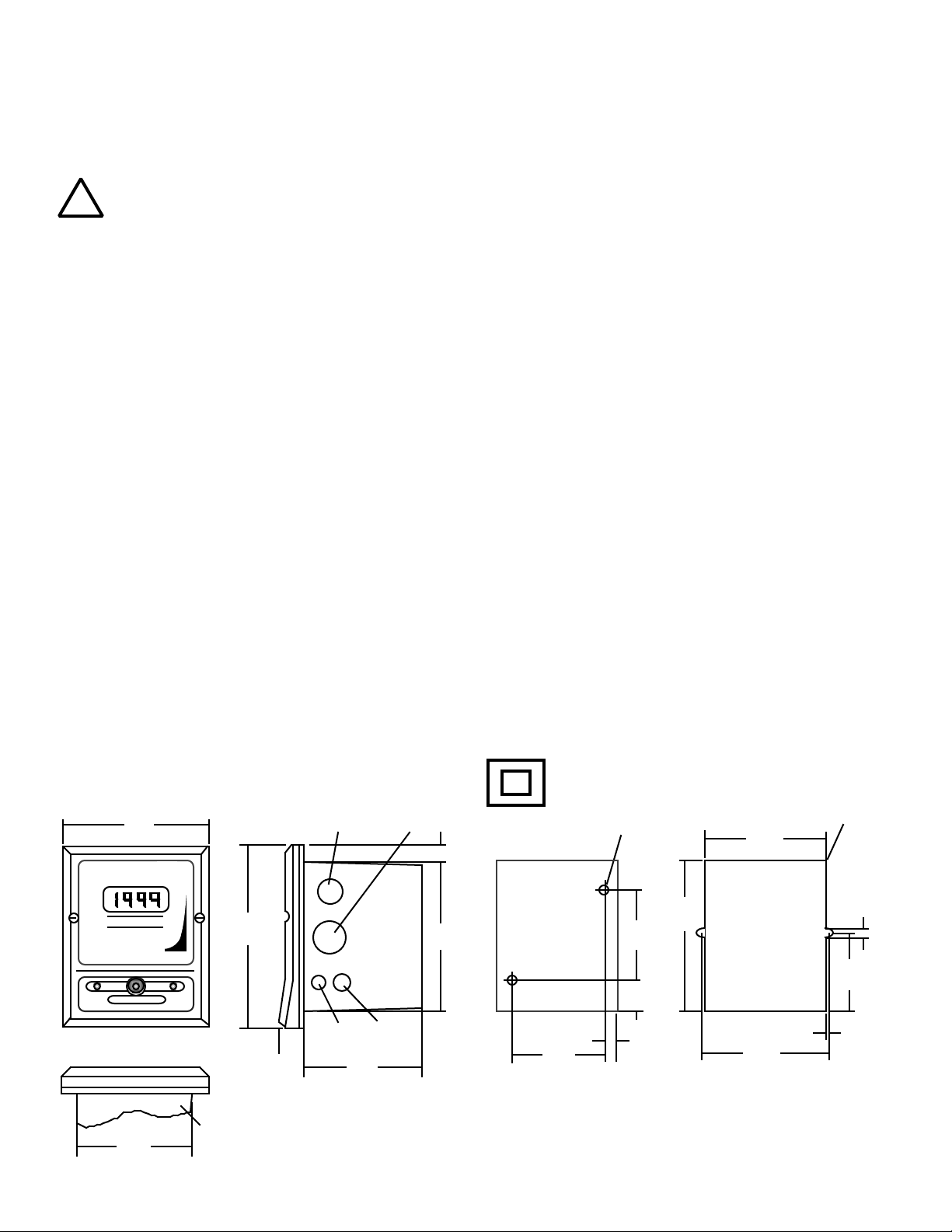

1. SURFACE MOUNTING WITH SMP

NOTE: A Surface Mounting Plate (SMP50) may be required when

access to the back side of the mounting site is impractical or if

4.80

(122)

0.88 DIA

(22)

1.13 DIA

(29)

the Monitor/controller must be mounted on a solid wall. The

SMP50 comes with the proper hardware to mount the

Monitor/controller to the SMP, however, the installer must provide

the four (4) additional screws/bolts to mount the SMP to the wall or

fixture. Their size is to be determined by the user.

1. Select your mounting location. Mark and drill the four (4)

required mounting holes. For hole locations, use the SMP

as a template.

2. Drill the corner holes in the SMP according to the size of

the screws or bolts selected.

3. Attach and securely fasten the SMP to the Monitor using

the 1/4" X 20 X 3/8" screws provided.

4. Mount the SMP to the prepared site using the selected

screws or bolts.

2. SURFACE MOUNTING WITHOUT SMP

NOTE: Surface mounting will require two (2) 1/4 " X 20 screws of

a length equal to the thickness of the mounting site plus 3/8"

1. Select mounting site location. Mark and drill the required

mounting holes. For hole drilling locations, see figure

II.B.1.

2. Insert the 1/4" X 20 screws into the holes from the side

opposite the mounting site.

3. Hold the Monitor in place while starting and tightening the

mounting screws.

3. PANEL MOUNTING

A panel mounting fastening kit is provided with all

Monitor/controllers. Panel mounting will require the use of the

fastening kit's two (2) 4-40 mounting screws/nuts or two (2) #4 x

1/2" sheet metal screws. See figure II.B.1. for panel cutout

dimensions.

1. Select your mounting location. Mark the appropriate

panel cutout and complete the necessary panel cut.

2. Carefully unfasten and separate the Monitor's front panel

from its enclosure.

3. Disconnect all panel cable(s)/wires from the Monitor's

Control board.

DOUBLE INSULATED

0.31 DIA, X2

(8)

0.53

(14)

0.13 RAD MAX, X4

(3)

3.96

(101)

750 II

MICROSIEMENS / CM

SET POINT

3.89

(99)

5.00

6.00

(152)

MYRON L

COMPANY

HIGHLOW

0.63 THK

(16)

0.50 DIA

(13)

0.75

(19)

Figure II.B.1.

0.60 DIA

(15)

3.78

(96)

4.94

(126)

SURFACE AND PANEL MOUNTING DIAGRAMS

SURFACE

MOUNT

3.10

(79)

NOT TO SCALE

DIMENSIONS IN INCHES

(MILLIMETERS)

2.84

(72)

1.05

(27)

0.40

(10)

(127)

PANEL

CUTOUT

4.17

(106)

0.113

(3)

2.54

(64)

0.11

(3)

9

Page 13

4. Slide the enclosure through the panel cutout

until its flange contacts the panel.

5. Insert mounting screws through the flange

mounting holes and tightly secure.

6. Reconnect all panel cable(s)/wires and resecure the front panel.

C. OEM MECHANICAL INSTALLTION

This section provides the recommended procedures for properly

installing the OEM 750 Series II Conductivity/Resistivity

Monitor/controller.

NOTE: Mounting of the OEM monitor/controller circuit board is

left up to the OEM. It is recommended that the following be noted

and observed.

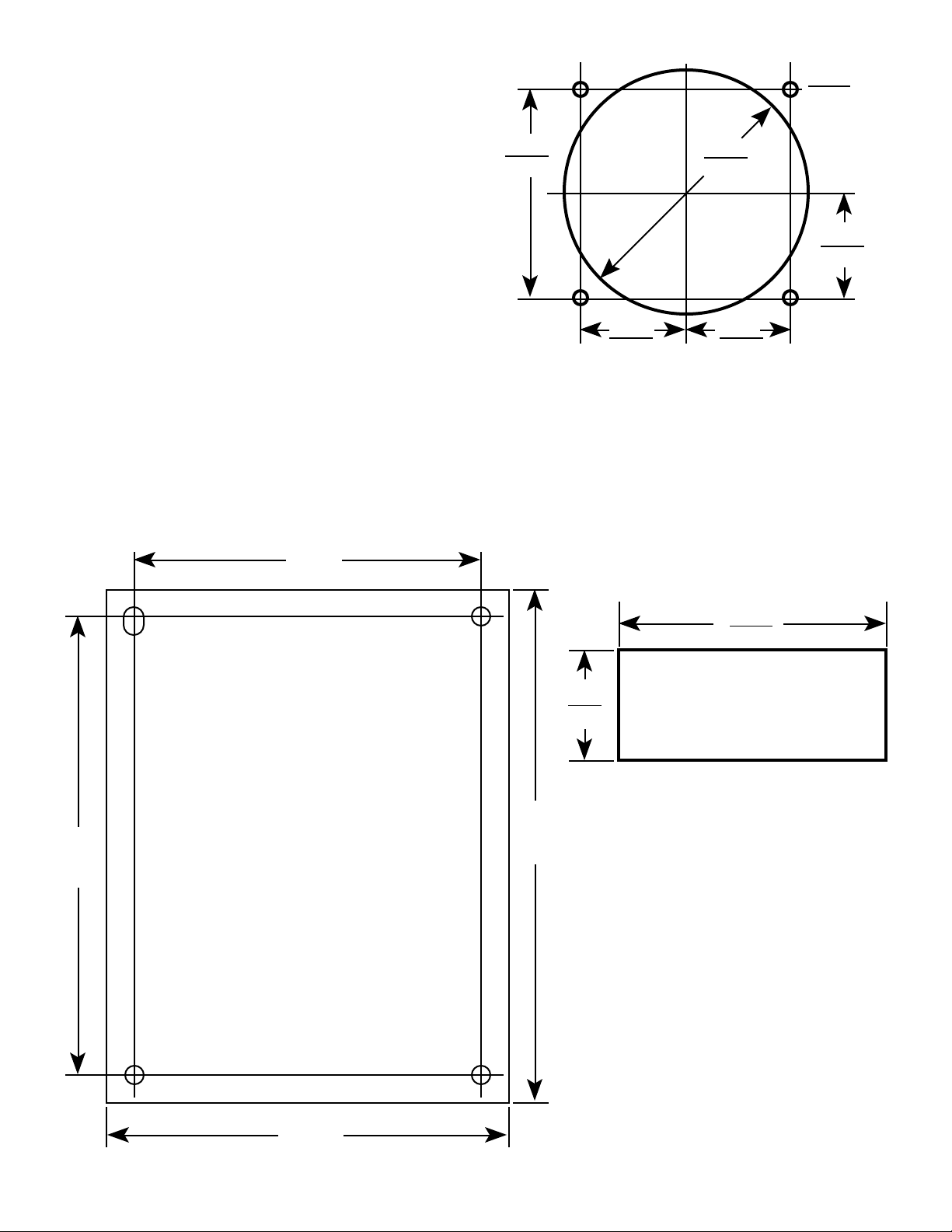

1. CIRCUIT BOARD

Total heigth of CB is 1.40” (36mm).

The circuit board has four .175” (4.4 mm) holes for mounting. The

centers are 3.10” (78.7 mm) x 4.10” (104.1 mm) see figure II.C.1.

CB must be mounted on at least .250” (6.35 mm) standoffs to

prevent shorting to metal chassis (standoffs user supplied).

CB must be mounted in a clean and dry environment.

Allow working room for inserting wires, testing and calibration.

Indicator lights and switches require 1/4” (6.35mm) holes.

1.880

(47.75)

2.218 Dia.

56.34

.940

Analog Meter Hole Pattern

Figure II.C.2

2. METER MOVEMENT

Refer to figure II.C.2 for dimensions.

1. Cut opening in user panel.

2. Drill four holes at locations as shown.

3. Install meter movement using supplied hardware.

.125 X4

(3.125)

.940

(23.88)

.940

(23.88)(23.88)

4.100

(104.1)

3.100

(78.74)

Figure II.C.1

2.390

(60.71)

.980

(24.89)

Digital Display Cutout Pattern

Figure II.C.3

4.585

(116.5)

3. DIGITAL DISPLAY

Refer to figure II.C.3 for dimensions.

1. Cut opening in user panel

2. Install LCD with brackets supplied.

3.600

(91.44)

10

Page 14

D. SENSOR INSERTION/IMMERSION MOUNTING

11

E. ELECTRICAL INSTALLATION

The electrical installation procedures provided in this manual are

common to all Conductivity & Resistivity Monitor/controllers. See

figure II.B.1. for the hole dimensions of the enclosure's cable

access holes. Unless otherwise instructed, refer to figure II.E.1.

for the 750 Series Monitor's terminal block connector wiring

designations.

NOTE: After removing an enclosure's access hole cutout, it is

suggested that the user mount a watertight restraint fixture prior

to installing a cable.

!

WARNING !

The Sensor’s mounting orientation must provide a continuous and

adequate circulation flow to prevent the trapping of air bubbles

within the Sensor’s electrode area (CS51 shown in figure II.D.1).

Failure to do so will result in conditions that will prevent the Sensor

from functioning properly.

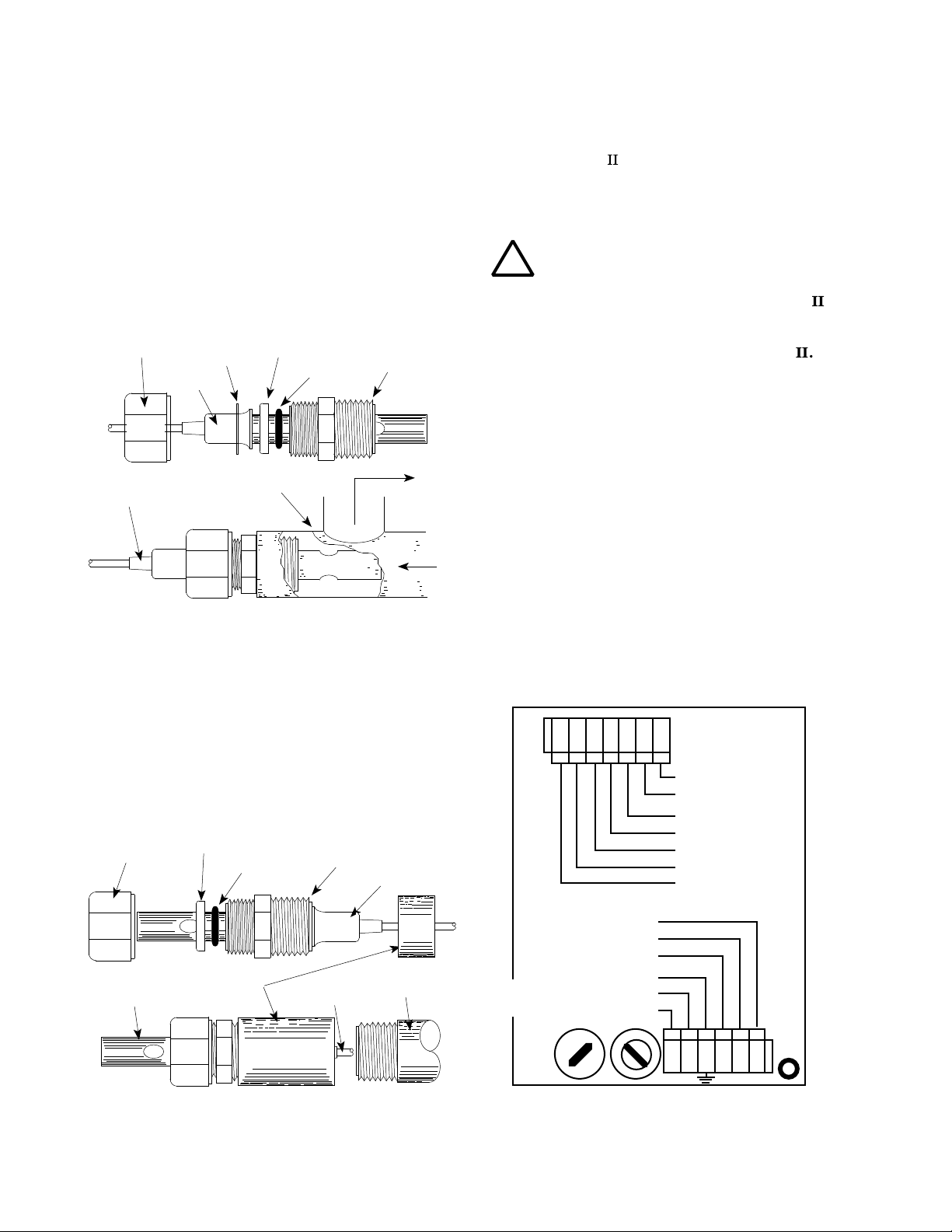

1. INSERTION MODE (in-line installation)

Use approved sealant, i.e. Teflon tape as required.

1. Verify that the Sensor’s Fitting assembly is properly

assembled as shown in figure II.D.1.

2. Insert the Sensor Fitting assembly into the "T" fitting with

electrode aligned as shown in figure II.D.1. and tightly

secure.

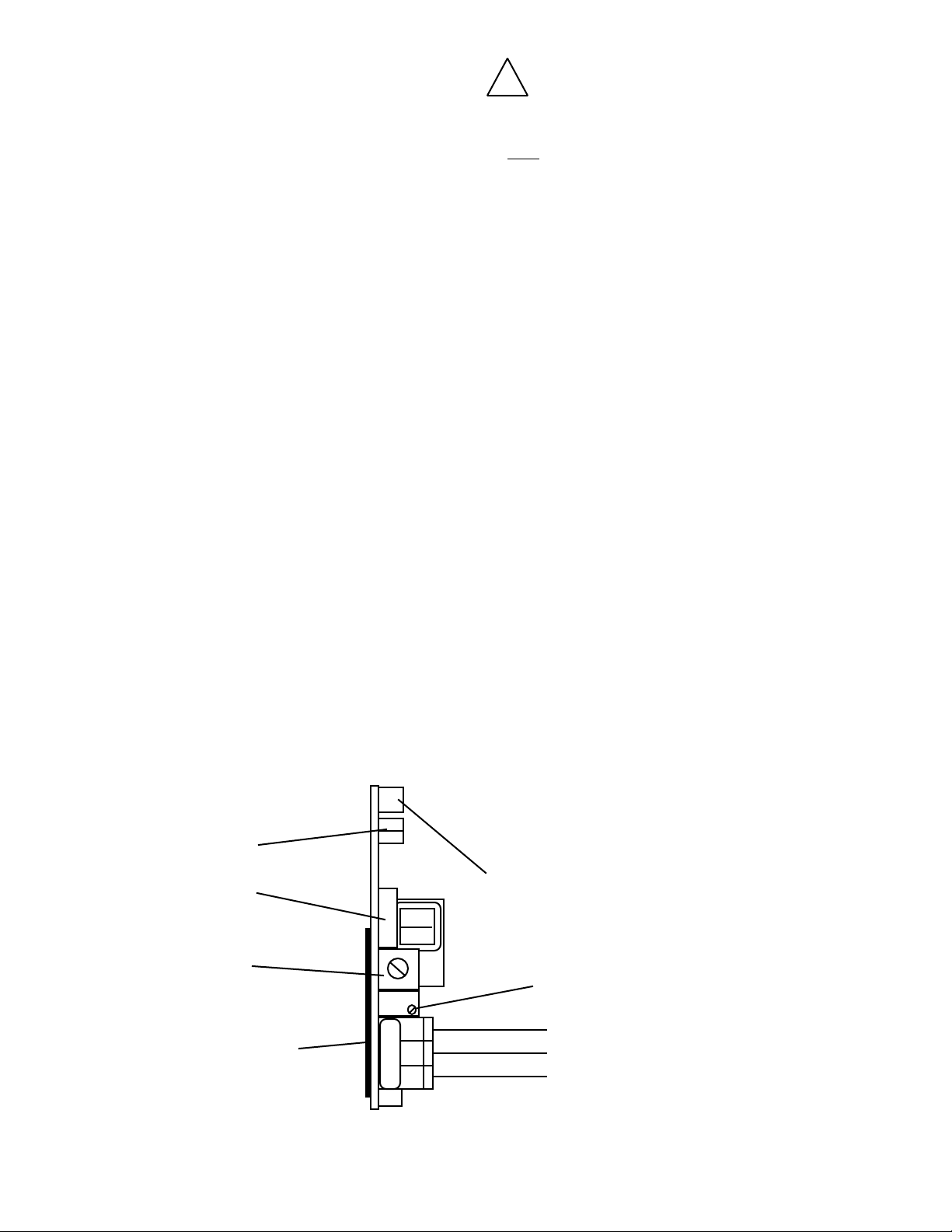

SECURING NUT

FLANGE

CABLE

INSERTION MODE ASSEMBLY

SS

WASHER

"T" FITTING

PLASTIC

WASHER

O-RING

THREADED FITTING

3/4" FNPT

OUT

IN

Figure II.D.1

2. IMMERSION OR DIP SENSOR ASSEMBLY

Use approved sealant, i.e. Teflon tape as required.

A device to disconnect the Model 750 from the

power supply is required. It is recommended that this

switch or circuit breaker be labeled as the

disconnection device for the Model 750

1. MAIN INPUT POWER INSTALLATION

WARNING: All AC line powered Monitor/controllers

are factory set for 115 VAC. Before starting, ensure

the input power “115/230” selection is correct for

your requirements. Failure to do so is beyond the

responsibility of the Myron L Company. See section

II.E.2. below and figure II.E.1.

NOTE: Some models may have either a 24 VAC or a

24 VDC input power requirement - check labels

carefully.

For OEM models skip to step #7.

1. Verify that the main AC power source is turned "OFF " or

disconnected.

2. Using a standard slot screwdriver remove the two (2)

screws on the front panel.

3. Carefully wiggle the front panel to loosen the gasket and

pull gently toward you. Do not pull more than about 8

inches/20CM or you could damage the wiring harness.

1. Verify that the Sensor’s Fitting assembly is properly

assembled as shown in figure II.D.2.

2. Insert and pull the Sensor’s cable through the extension

tube and then tightly attach extension tube to Sensor

assembly as shown in figure II.D.2.

PLASTIC

SECURING NUT

SENSOR TIP

IMMERSION OR DIP SENSOR ASSEMBLY

WASHER

O-RING

COUPLING

3/4" NPT

THREADED FITTING

3/4" FNPT

FLANGE

EXTENSION TUBE

CABLE

Figure II.D.2

(+)

(-)

NEU

GRN

RED

WHT

BLK

{

COM

NO

NC

L N

FUSE

ALARM

CONTROL

RELAY

MAIN

INPUT

POWER

GND-GRN

NEU-WHT/-DC

{

HOT-BLK/+DC

115/230

SWITCH

ELECTRICAL CONNECT DIAGRAM

Figure II.E.1

0-10VDC

}

OUTPUT

SENSOR

}

CHASSIS GROUND for

OEM INSTALLATIONS ONLY

Page 15

4. Turn the front panel around so that the back side is

Y

facing you and set aside for now.

5. Carefully remove front panel, leaving the harness

connected.

6. Using the enclosure cutouts, install the proper wire and

watertight cable restraint (not provided) to comply with

local electrical codes.

7. Neatly connect wires to the Main Circuit Board

connectors, as shown in figure II.E.1.

*CAUTION: The input power connectors require only a small

screwdriver or a pen to push on the release levers. The release

levers may be broken or damaged if not pushed straight toward

the circuit board. DO NOT push the release levers sideways.

2. 115/230 VAC CONVERSION

1. Before turning power on to the Monitor/controller ensure

the proper input voltage has been selected. Failure to do

so will blow the fuse. It could, under some conditions,

cause injury and damage the instrument voiding the

warranty.

2. Locate switch located next to the fuse holder.

3. Using a screwdriver, turn switch to required voltage.

3. CONNECTING THE SENSOR CABLE

For OEM models skip #1.

1. Place the Sensor’s interface cable and user supplied

watertight cable restraint into the enclosure's

appropriate access hole.

2. Install the sensor cable wire to comply with local

electrical codes. Follow the color code as marked. See

figure II.E.1.

*CAUTION: The sensor connectors require only a small

screwdriver or a pen to push on the release levers. The release

levers may be broken or damaged if not pushed straight toward

the circuit board. DO NOT push the release levers sideways.

Requirements:

For Conductivity/TDS; one 10k

may be ordered from the Myron L Company.

For Resistivity; one 100k

resistor, user supplied or may be ordered from the Myron L

Company.

NOTE: When opening instrument, remove front cover with care; a

ribbon cable connects the front panel and main board. If the front

panel has all ready been removed from the enclosure skip to #4.

1. Using a standard slot screwdriver remove the two (2)

screws on the front panel.

2. Carefully wiggle the front panel to loosen the gasket and

pull gently toward you. Do not pull more than

about 8 inches/20CM or you could damage the wiring

harness.

3. Turn the front panel around so that the back side is

facing you and set aside.

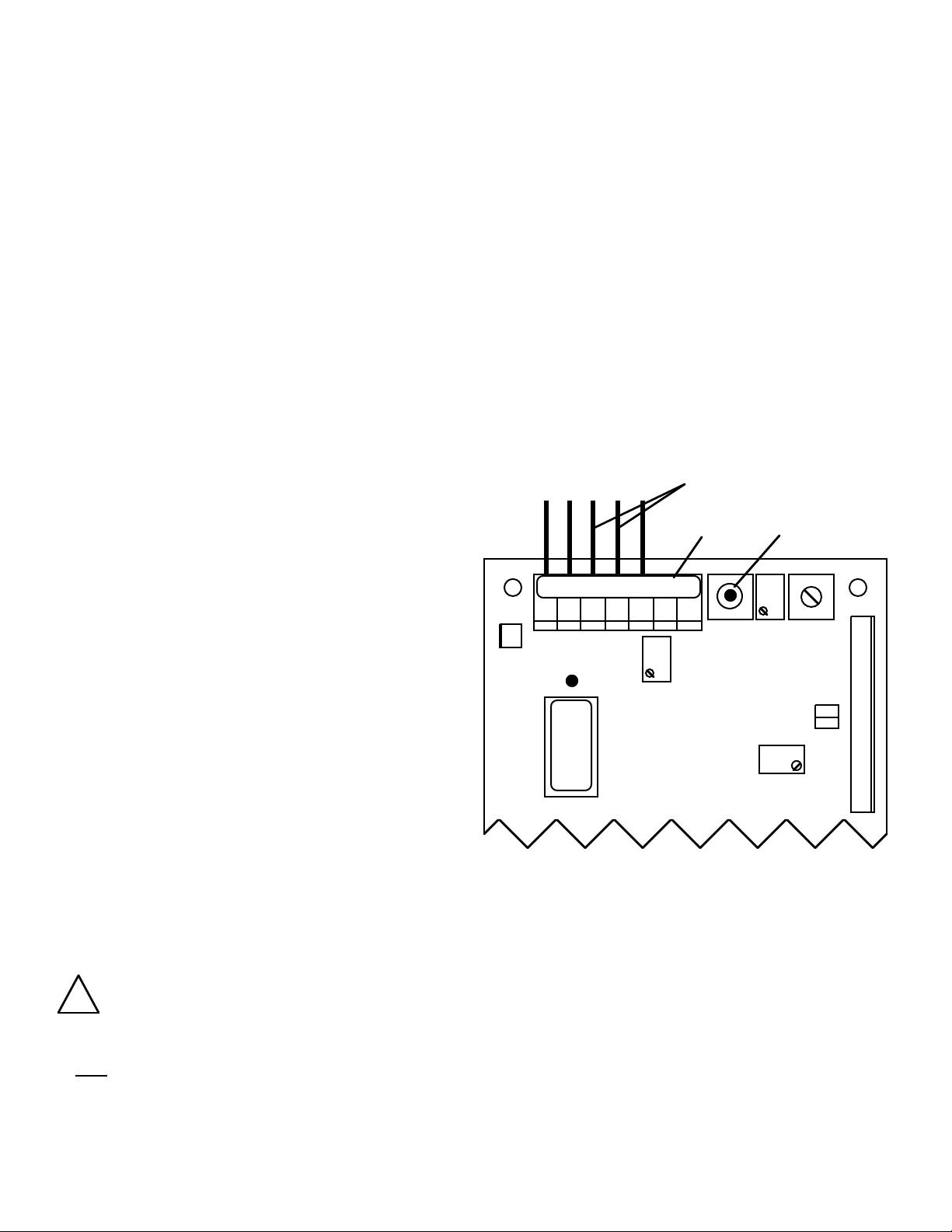

4. For Conductivity/TDS Monitor/controllers;

a. If sensor is installed, locate and remove the RED

(RD) and the GREEN (GN) leads from MAIN

Circuit Board, as shown in figure II.E.2.

b. Cut off or tape RED (RD) and the GREEN (GN) leads

from sensor.

SENSOR LEADS

BK WT RD GN NU R- R+

3S

1% resistor, user supplied or

1% resistor, and one 5.49K 1%

REMOVE THESE TWO LEADS

0-10VDC

OUTPUT

FULL SCALE

PUSH TO TEST

HYS1SP1FS SW

a. MODIFICATION FOR US PHARMACEUTICAL

25 (No Temperature Compensation)

This simple modification will allow your Monitor/controller to meet

the USP 25 requirements by defeating the normal temperature

compensation circuit thus giving “uncompensated” readings as

required.

Specifications:

As required to meet USP25.

Installation

Briefly For Conductivity/TDS, a resistor is installed in place of the sensor

“temperature” sensing leads.

For Resistivity, two resistors are installed in place of the sensor

“temperature” sensing leads.

The extra sensor leads are either cut off or the ends are wrapped

in tape to prevent shorting.

CAUTION - READ FOLLOWING CAREFULL

!

WARNING: BEFORE STARTING, IF MONITOR/

CONTROLLER IS INSTALLED, ENSURE THE POWER

IS OFF. FAILURE TO DO SO COULD CAUSE DAMAGE

TO THE INSTRUMENT, AND COULD BE HARMFUL OR

FATAL TO PERSONNEL. ONLY QUALIFIED

PERSONNEL SHOULD INSTALL OR SERVICE

ELECTRICAL EQUIPMENT.

CAL

}

UP

INC

DIS

-121

2000µS

Conductivity/TDS Main CB Assembly

Figure II.E.2

c. Install 10k

(GN) connector locations, as shown in figure

II.E.3.

For Resistivity Monitor/controllers;

a. If sensor is installed, locate and remove the

GREEN (GN), RED (RD), and the NEUTRAL (NU)

leads from MAIN Circuit Board, as shown in figure

II.E.4.

b. Cut off or tape GREEN (GN), RED (RD), and the

NEUTRAL (NU) leads from sensor.

c. Install 100k

(GN) connector locations, as shown in figure

II.E.5.

resistor at RED (RD) and the GREEN

resistor at BLACK (BK) and GREEN

SPC

DEC

12

Page 16

d. Install 5.49kΩ resistor at RED (RD) and the

NEUTRAL (NU) connector locations, as shown in

figure II.E.5.

5. Carefully reinstall the front panel, bottom first. Ensure no

wires have been pinched between enclosure and front

panel.

6. Reinstall the two (2) screws and tighten.

7. To operate, turn power ON.

NOTE: Recalibration will require both the solution and sensor be

at 25°C for maximum accuracy.

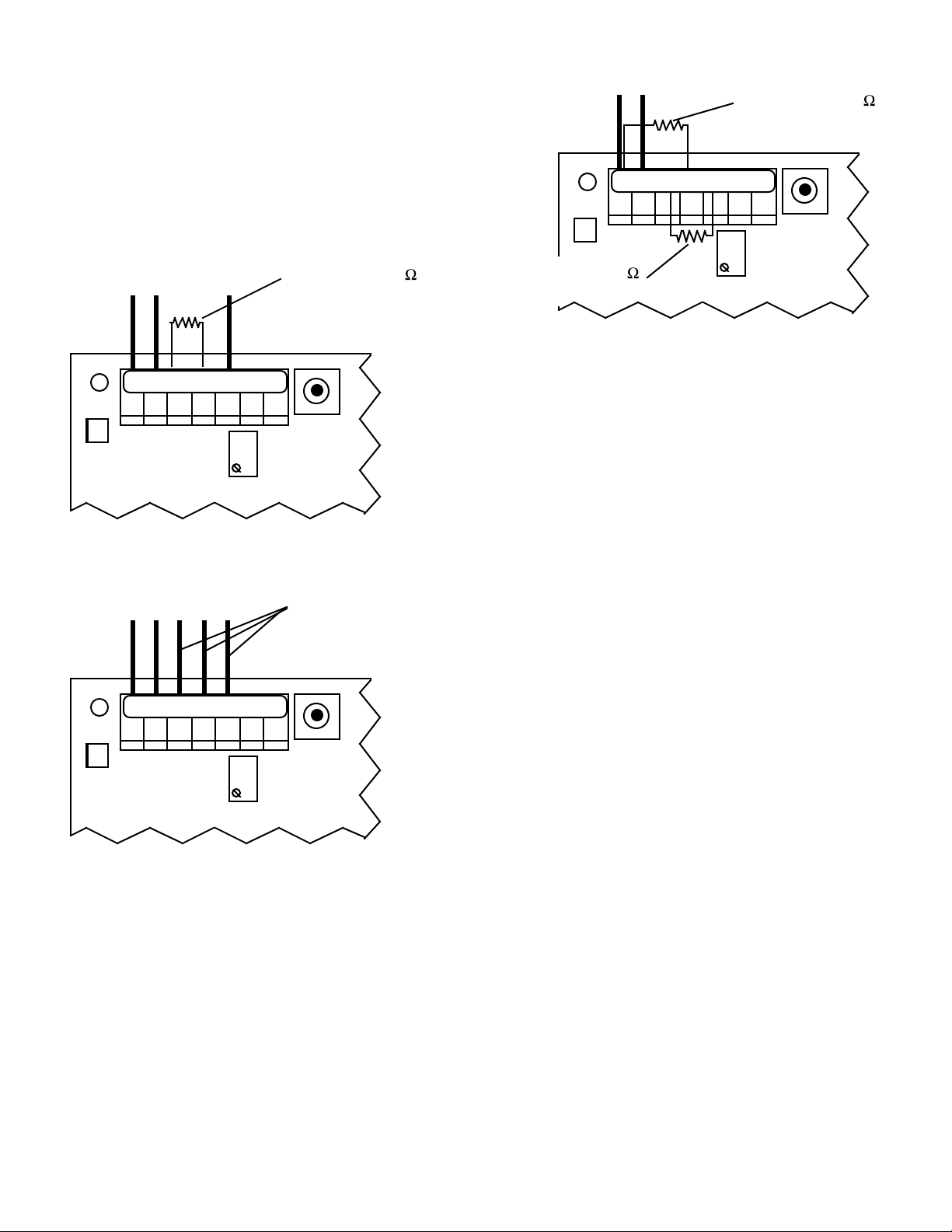

SENSOR LEADS

INSTALL 100K

RESISTOR HERE

BK WT RD GN NU R- R+

3S

FS SW

SENSOR LEADS INSTALL 10K

RESISTOR HERE

BK WT RD GN NU R- R+

3S

FS SW

CAL

Conductivity/TDS Main CB Assembly

Figure II.E.3

SENSOR LEADS

REMOVE THESE

THREE LEADS

BK WT RD GN NU R- R+

3S

FS SW

CAL

Resistivity Main CB Assembly

Figure II.E.4

4. SOLID STATE OUTPUT

24 VDC Unregulated 30mA max. The following instructions are

assuming the Monitor/controller enclosure is already open.

a. Piezo Electric Alarm - PA/PAO (option)

For additional information, see Piezo Alarm under Options in

section III.I.

1. If not already installed, peel tape backing from PIEZO

and press into place per figure III.I.3.

2. Attach connector to main control circuit board per figure

III.I.4.

NOTE: If remotely mounted; cut wires and splice as necessary,

use comparable wire. Piezo requires 1/4” (6.35mm) hole in user

panel.

INSTALL 5.49K

RESISTOR HERE

CAL

Resistivity Main CB Assembly

Figure II.E.5

b. Remote Alarm - RA™ (option)

For additional information,see RA Instructions under options in

section III.J.

1. Run user supplied #22, 2 conductor speaker type wire

from Monitor/controller to RA location as necessary.

Additional wire may be ordered, part #RAW-200, see

Options & Accessories.

2. Open the RA by removing the four screws.

3. Locate and remove the 8” 2 conductor wire attached to

RA.

4. At the controller, connect the extension wires to the 8”

2 conductor wire with the wire nuts provided — Black to

Positive (+) and White to Negative (-). Be sure to first

pass the wire through the user supplied waterproof strain

relief in the enclosure.

5. Plug the reddish brown female connector into the male

connector on the controller CB marked either RA or PA

(see inside case label for location). It will only go on the

connector one way.

6. At the RA, connect the wires to the connector — Black

to Positive (+) and White to Negative (-).

7. To test, simply turn on the controller and adjust controller

set point until the alarm/piezo sounds off. If controller is

not yet connected to a functioning sensor, on

conductivity/TDS controllers it will be necessary to press

and hold the Full Scale test switch.

The black button on the front of the RA will mute the

piezo alarm for approximately three minutes or until you

improve the water quality (readjust controller set point).

The piezo alarm will continue to sound off every three

minutes until the user has improved the alarm condition

inside the controller. If three minutes muting is fine for

your application, skip to step 9.

8. If three minutes is too long or too short, adjust time delay

control inside RA until desired mute time is achieved

adjustable from approximately 6 seconds to 10 minutes).

9. Replace the bottom of the RA, and secure RA to the

surface you have selected for its installation.

NOTE: If the RA does not sound off;

1. Check the polarity of the extension wire connections.

2. Be sure the controller is actually switching (relay will

click).

13

Page 17

c. Connect to your own alarm or ?

Use the following as guidelines.

Connector is a standard 2 wire Methode* style

connector. Connector with 8” wires, part #RAH, is

available from the Myron L Company.

Ensure your requirements do not exceed the 24VDC

Unregulated 30mA maximum.

Ensure the polarity is correct (RED is positive), see

figure V.A.1.

Attach wires to RA.

Attach connector to controller connector (RA) per figure

V.A.1.

MONITOR/CONTROLLER

CIRCUIT BOARD

CM

NO

115VAC

POWER

SOURCE

115 to 24VAC

TRANSFORMER

COM

NO

X

VR

*Methode is registered trademark of Methode Electronics, Inc.

5. ALARM/CONTROL RELAY CONNECTIONS

Myron L Company Monitor/controllers are equipped with a “Dry

Contact” relay which is designed to energize/de-energize when

the set point is crossed. (See section IV.C.3) for set point

adjustment procedure) The relay energizes on increasing or

decreasing readings as set by the user, see section IV.C.1.

When energized (above set point), the Common (COM) will

disconnect from the Normally Closed (NC) contact and connect to

the Normally Open (NO) contact. Devices may be operated using

either the Normally Open contact or Normally Closed contact; or

both relay contacts may be used to control two devices of the

same voltage.

NOTE: A flow switch may be installed (electrically connected)

utilizing one of two convenient methods; the 3S connection, see

figure II.E.2, (remove jumper and connect flow switch across

terminals - 8” harness (RAH) available from the Myron L

Company), or inline with either relay connection, see figure II.E.6

or II.E.7.

WARNING: CONNECTING BOTH POWER SOURCE

LEADS TO THE RELAY TERMINAL BLOCK

CONNECTERS WILL DAMAGE THE CIRCUIT BOARD

AND MAY CAUSE PERSONAL INJURY.

1. Place the user supplied Alarm relay interface cable and

watertight cable restraint into the enclosure's

appropriate access hole. Skip for OEM.

2. Neatly connect the relay interface cable wires to the

Monitor/controller's terminal block connectors, see

figures II.E.1, II.E.6 or II.E.7.

POWER

MONITOR/CONTROLLER

CIRCUIT BOARD

SOURCE

DEVICE

RELAY

NC

RELAY

TERMINAL BLOCK

OPT.

FLOW

SWITCH

TO BE

CONTROLLED

Figure II.E.7

CAUTION: The connectors require only a small screwdriver or a

pen to push on the release levers. The release levers may be

broken or damaged if not pushed straight toward the circuit board.

DO NOT push the release levers sideways.

The easiest method of connecting the relay is shown in figures

II.E.1, and II.E.6. These show how the dry contact relay can use

incoming power to activate a controlled device (alarm, solenoid

valve, etc.) of 10 amps or less.

For 24 VAC applications, the Myron L Company offers a 115 VAC

to 24 VAC transformer, Model #VR, see figure II.E.7. Other

voltages must be user-supplied.

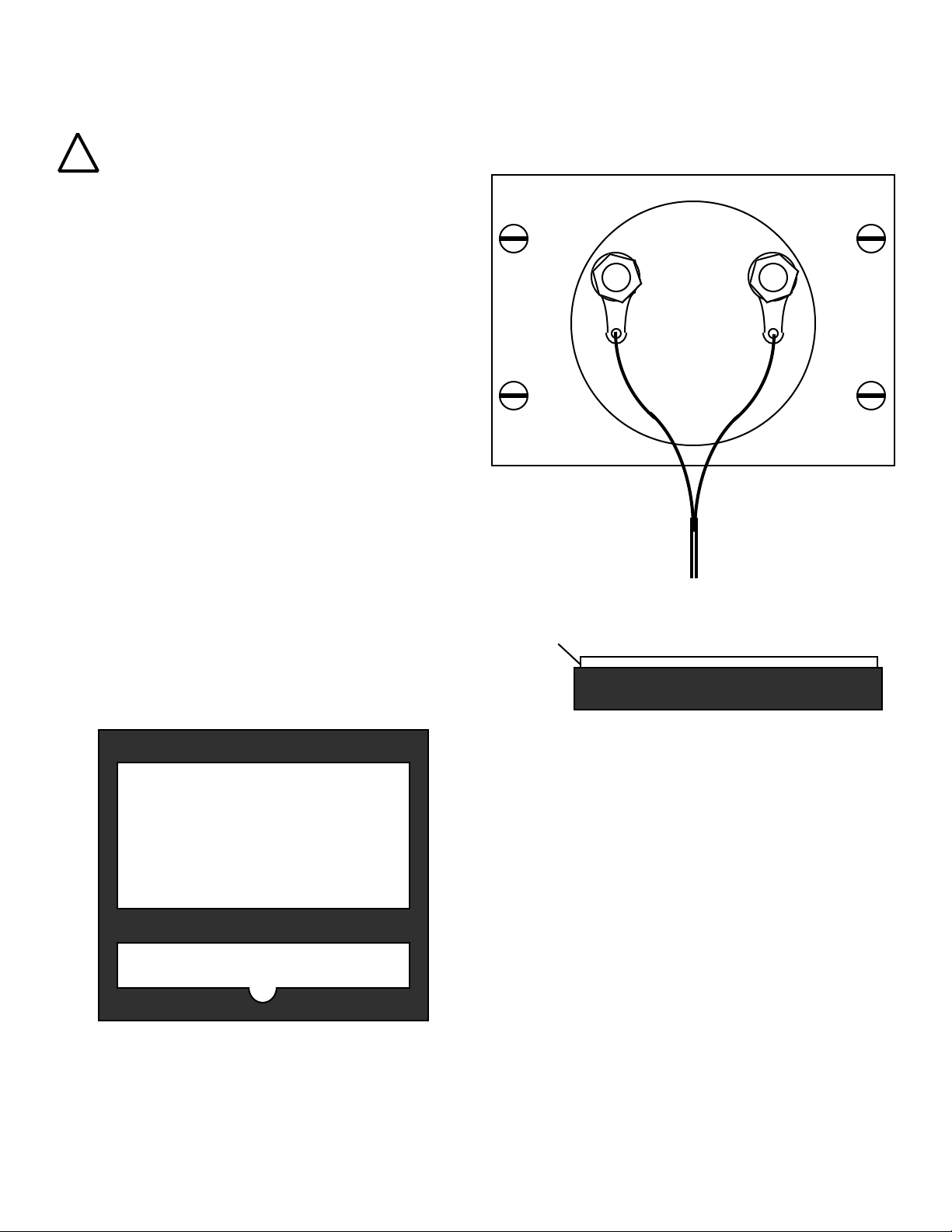

6. CONNECTING DISPLAY HARNESS TO DISPLAY

If the installation required the removal of the display harness from

the display (OEM installation requires connection), the following

procedure will ensure it is reinstalled without damaging the

display.

WARNING: THE DISPLAY WILL BE IRREPARABLY

DAMAGED IF THE HARNESS IS INSTALLED UPSIDEDOWN OR MISALIGNED. THE HARNESS MUST BE

INSTALLED AS SHOWN IN FIGURE II.E.8.

1. Grasp connector and align wires DOWN on display or with

the small edge of the display as shown in figure II.E.8.

2. Press connector onto display pins. Ensure pins are

aligned or they may become bent. Wiggle connector

slightly “end to end” if necessary.

RELAY

CM

NO

NC

RELAY

TERMINAL BLOCK

Figure II.E.6

COM

NO

X

OPT.

FLOW

SWITCH

DEVICE

TO BE

CONTROLLED

DISPLAY

DISPLAY CONNECTION

DISPLAY

HARNESS

PANEL MOUNTED DISPLAY

REAR VIEW

Figure II.E.8

14

Page 18

F. 0-10 VDC RECORDER OUTPUT

The 0-10 VDC output is designed to give the user the capability of

sending a signal to a remote meter, recorder, PLC or SCADA

system.

1. CONNECTION

1. Place the user supplied interface cable and watertight

cable restraint into the enclosure's appropriate access

hole. Skip for OEM.

2. Connect the Recorder's plus (+) and minus (-) terminal

wires to the Recorder output connectors. (See figure

II.E.1.)

3. Refer to Section V.C.1.b for the procedures to calibrate

the 0-10 VDC voltage output.

+

0-10V Output

-

A

B

Figure II.F.1

+

Recording

Device

-

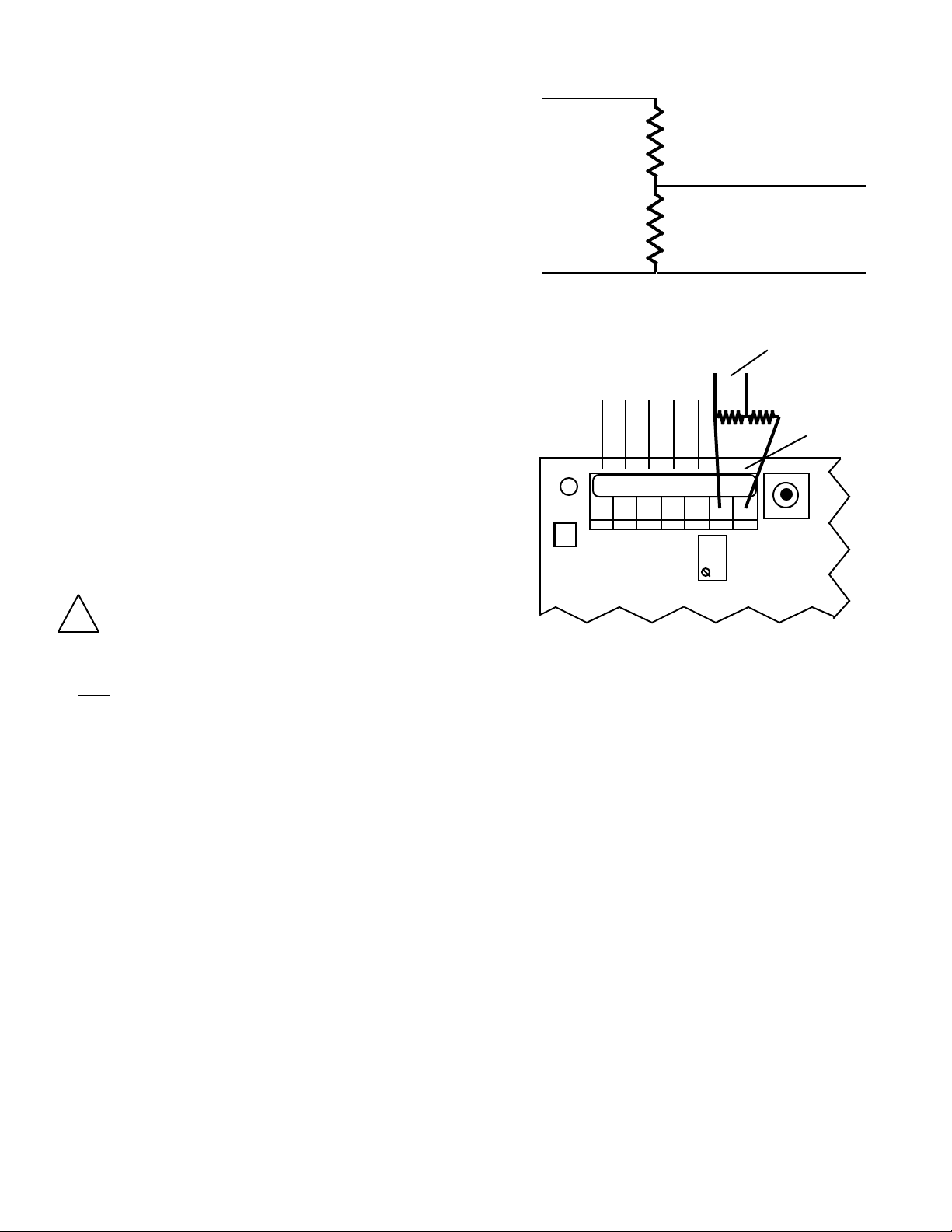

2. VOLTAGE DIVIDER

A voltage divider gives the user the ability to scale or tailor the

output to a particular need or requirement due to the input of

another device, i.e. the output of the Main CB is 0-10V while the

input requirement of a particular recording device is 0-5V.

a. INSTALLATION

Briefly—

Two resistors are installed across the 0-10V output.

The output is recalibrated to required voltage.

Requirements

Select two (2) resistors as listed;

For 0-5V Output both "A & B" are 2K Resistors.

For 0-1V Output "A" is a 9K resistor and "B" is a 1K resistor.

CAUTION - READ FOLLOWING CAREFULLY

!

WARNING: BEFORE STARTING, IF MONITOR/

CONTROLLER IS INSTALLED, ENSURE THE POWER

IS OFF. FAILURE TO DO SO COULD CAUSE DAMAGE

TO THE INSTRUMENT, AND COULD BE HARMFUL OR

FATAL TO PERSONNEL. ONLY QUALIFIED

PERSONNEL SHOULD INSTALL ELECTRICAL

EQUIPMENT.

Physical

If the front panel has all ready been removed from the enclosure

skip to #3.

1. Using a standard slot screwdriver remove the two (2)

screws on the front panel.

2. Carefully wiggle the front panel to loosen the gasket and

pull gently toward you. Do not pull more than about 8

inches/20CM or you could damage the wiring harness.

3. Turn the front panel around so that the back side is

facing you and set aside for now.

4. Solder two selected resistors together as shown in figure

II.F.1.

5. Attach leads to recording device as shown in figure

II.F.1.

6. Attach resistors to 0-10V Output as shown in figure

II.F.2.

Ensure resistors and leads DO NOT short to each other

or to any part of the CB assembly.

7. Recalibration is required, see Calibration Procedures,

section V.C.

NEW

OUTPUT

AS

SENSOR LEADS

BK WT RD GN NU R- R+

3S

- +

SELECTED

0-10VDC

OUTPUT

FS SW

CAL

Main CB Assembly

Figure II.F.2

Reassembly

1. Carefully reinstall the front panel, bottom first, ensure no

wires have been pinched.

2. Reinstall the two (2) screws and tighten.

3. To operate, turn power ON.

15

Page 19

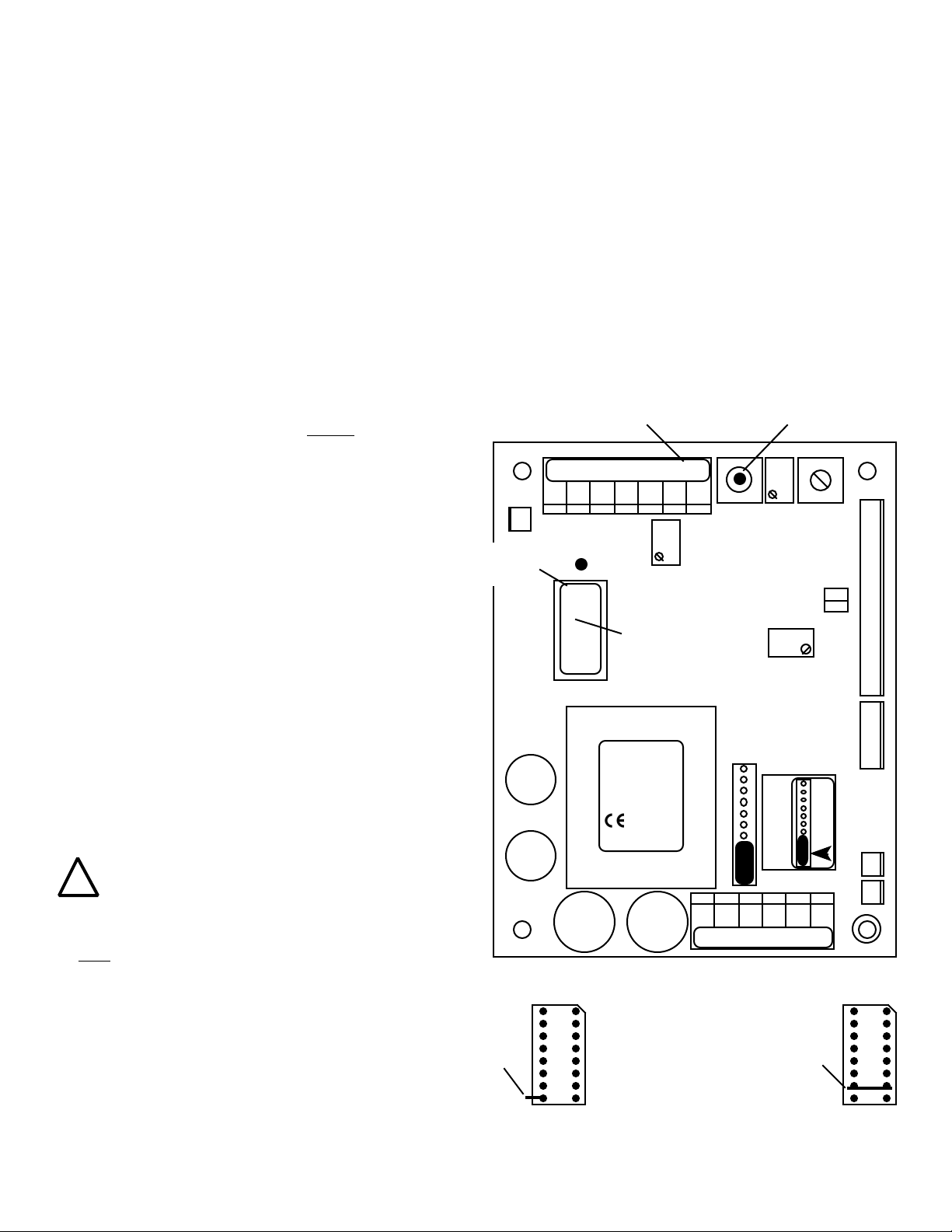

G. RE-RANGE YOUR MONITOR/CONTROLLER

!

(Range Module Installation)

1. DESCRIPTION

The 750 Series II Monitor/controllers have been designed for

easy field re-rangeability. The Range Module consists of a 16 pin

Header that plugs into a 16 pin socket.

For available ranges, see Range Selection Guide I.G. When

making large range changes, i.e. 5000 ppm to 50 ppt, a different

sensor may also be required as noted in the Range Selection

Guide. Order Range Module by adding the prefix “RM” to the range

number as in examples below.

Conductivity/TDS Range Modules —

RMXXX i.e. = RM121 is a 0-2000µS

Resistivity Range Modules —

RMXX i.e. = RM11 is a 0-20MΩ

NOTE: Some OEM models may not be re-ranged being originally

manufactured with a fixed range. If your application requires reranging an OEM model, first contact the system manufacture for

help. The Myron L Company may re-range or exchange your

instrument at a cost.

screws on the front panel.

2. Carefully wiggle the front panel to loosen the gasket and

pull gently toward you. Do not pull more than about 8

inches/20CM or you could damage the wiring harness.

3. Turn the front panel around so that the back side is

facing you and set aside.

4. Locate and remove existing Range Module from MAIN

Circuit Board, as shown in figure II.G.1. It is not easy to

remove, it was designed to stay in place under adverse

conditions.

5. With the pointer up, carefully align the new Range Module

to the socket on the MAIN Circuit Board as shown in

figure II.G.1.

6. Press firmly into place.

7. For analog models, add multiplier label to front panel. See

figures II.G.10 and II.G.11 for suggested locations. In

some cases changing the meter scale will be necessary.

See Changing Analog Meter Scale, section II.G.3.

8. Recalibrate, see CALIBRATION PROCEDURES, section

V.C.

0-10VDC

OUTPUT

BK WT RD GN NU R- R+

FULL SCALE

PUSH TO TEST

2. INSTALLATION

Briefly The new Range Module simply replaces the Range Module

presently installed, see figure II.G.1.

Multiplier label is added to analog models*.

Type label may be required if changing from Microsiemens to

Millisiemens or PPM/PPT.

The Full Scale reading is recalibrated.

IMPORTANT NOTES:

1. When changing ranges on Digital Monitor/

controllers with the -45 option (4 1/2 digit backlit

display), the following modifications may be required

to the range module; RM123 thru 128 and RM16

require pin number 9 be removed or bent toward the

side, see Fig. II.G.2. On RM117 thru 122 a jumper

wire must be soldered to the RM, see Fig. II.G.3.

*2. Analog Monitor/controllers may require a scale

change. See section II.G.3 for the specific

instructions.

POINTER

CAUTION - READ FOLLOWING CAREFULLY

WARNING: BEFORE STARTING, IF MONITOR/

CONTROLLER IS INSTALLED, ENSURE THE POWER

IS OFF. FAILURE TO DO SO COULD CAUSE DAMAGE

TO THE INSTRUMENT, AND COULD BE HARMFUL OR

FATAL TO PERSONNEL. ONLY QUALIFIED

PERSONNEL SHOULD INSTALL OR SERVICE

ELECTRICAL EQUIPMENT.

Physical

NOTE: When opening instrument, remove front cover with care;

a ribbon cable connects the front panel and main board. If the

front panel has already been removed from the enclosure skip to

#4.

1. Using a standard slot screwdriver remove the two (2)

3S

REMOVE

PIN #9