Page 1

CONTROLSTIK II

Water Quality Instrumentation

Accuracy • Reliability • Simplicity

RINSE TANK SYSTEM

Model 597

Operation Manual

INSTALLATION • OPERATION • MAINTENANCE

21 October 08

ACCURACY • RELIABILITY • SIMPLICITY

Page 2

Page 3

PLEASE READ THIS THROUGH COMPLETELY BEFORE

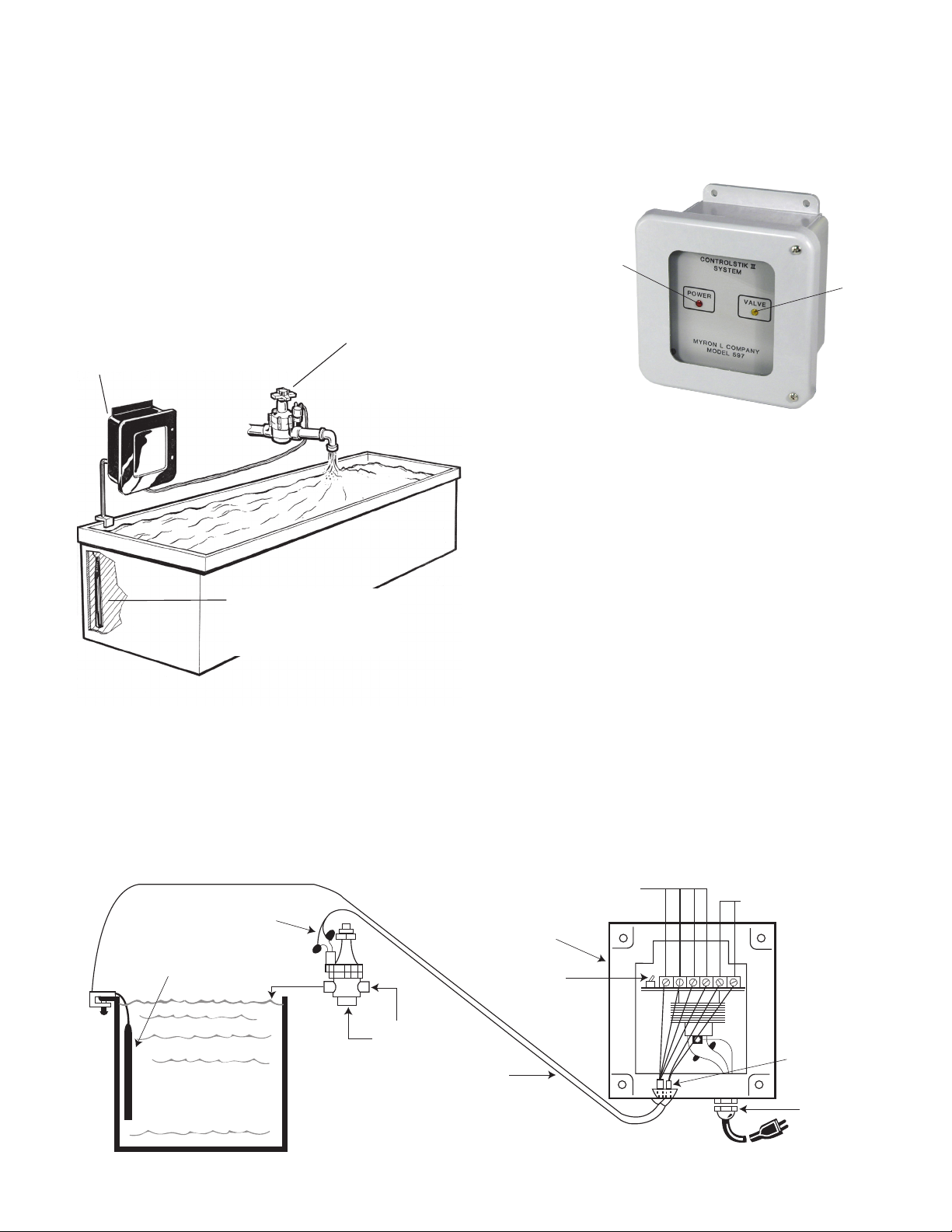

2. Solenoid Valve

Water Inlet

(Options)

1. Transformer Box

Controlstik

Valve

Cap Plug

Strain Relief

Range Switch

105-125 VAC, 50/60 Hz (no cord/plug

supplied with 210-250 VAC 50/60 Hz model)

Low Voltage Wire

(not supplied)

3. Controlstik (Sensor)

completely immersed

CAUTION: Maximum

operating temperature

is 82ºC (180ºF)

Red

Green

Black

White

POWER

Light

1. TRANSFORMER BOX

VA LV E

Light

ATTEMPTING TO INSTALL OR OPERATE THIS SYSTEM.

DESCRIPTION

The Myron L Controlstik Rinse Tank System is a fully automatic

control which will greatly reduce the amount of water used in

continuous ow rinse tanks. At the same time, it automatically

maintains water quality, insuring effective rinsing in water up to

82°C (180°F). It operates on the electrical conductivity principle

and is fully stable and protected against all environmental

conditions including temperature, line voltage, water

contamination and corrosion.

Controlstik Rinse Tank System has three major parts:

INSTALLATION AND OPERATION PROCEDURES

A. Mounting

Follow local electrical code

CAUTION: Do not apply power until all wiring has been

completed and connections checked.

1. TRANSFORMER BOX

Reduces line power to safe

level for sensor and solenoid valve.

3. CONTROLSTIK SENSOR

Adjustable set-point minimizes

tampering. Two ranges built-in for

tap and puried water.

2. SOLENOID VALVE

1”, corrosion-resistant

with ow control and

manual override.

24V For safety.

After installation, the Controlstik (sensor) is submerged in the

rinse water. When contamination (dragin) accumulates beyond

the point “safe” for good rinsing, the sensor automatically opens

the Solenoid Valve. Fresh water ows into the tank, and as

excessive contamination is diluted back to the “safe” level, the

sensor closes the valve, limiting water use.

1. Mount the Transformer Box near the correct AC power as

indicated on your unit. It may be hung on a wall, panel, or

post.

2. Hang Controlstik (sensor) in the tank by the cord, using the

securing clamp to hold the cord onto the edge of the tank.

The sensor should hang vertically, fully submerged at least

10 cm (4 in.) off the tank bottom and not closer than 60 cm

(2 ft.) to the inlet water line. If tank is small, locate sensor at

end opposite from inlet.

NOTE: If water rate is slow or if dragin rate and concentration

prevent good diffusion of contamination … the following

should be considered to insure the Controlstik senses

water that is “representative” of the entire tank:

1. Agitation - by air or other means

2. Installation of weir in tank perpendicular to water ow

3. Use of spider (sparge) on inlet

B. Piping

1. Install valve in inlet water line to rinse tank so that ow

direction is as indicated by the arrows on the top of

valve body.

2. Use Teon tape on all connections and plug the unused inlet.

3. Insure ow control is at least partially open by turning

counterclockwise.

1

Page 4

NOTE: The 1-inch NPT valve supplied requires at least 10 psi

Manual Override Knob

Adjustable

Flow Control

Solenoid

Direction

of Flow

2. SOLENOID VALVE

Set Screw / Pointer

High Scale

(500-5000 micromhos)

Inside Electrode

Outside Electrode

3. CONTROLSTIK

(Sensor)

Sliding Inside Probe

Low Scale

(5-500 micromhos)

(69 kPa) line pressure to operate. Increasing ow rate

may allow valve to operate at lower pressure.

C. Wiring

1. Connect the four color coded wires from the Controlstik

(sensor) to terminals in the Transformer Box marked

Controlstik.

2. Obtain enough low voltage wire (at least 20 gauge) to

connect solenoid valve to Transformer Box. Use pliers

to attach spade lugs (provided) to wire. Connect wires

to terminal strip in box as in diagram.

3. Recheck to be certain all connections are to correct

terminals.

CAUTION: DO NOT short or connect the Controlstik

(sensor) to the terminals marked VALVE;

damage may result.

D. Testing

1. If controlling ordinary tap water, make sure Transformer

Box range toggle switch is set on “Hl” (toward back

of box). If controlling puried (such as deionized)

water, switch should be forward in “LO” position. Also,

Controlstik sensor pointer should face in direction of

High (500-5000 micromhos) or Low (5-500) scale to

agree with Box range switch setting. To change pointer

loosen set screw with 9/64 inch Allen wrench. Turn

pointer to opposite scale. Lift the rod to the other side

of the set screw and place back under the wide part

of the pointer plate. Retighten set screw with ngers,

allowing inside probe to move within sheath.

2. Turn on the power by connecting the transformer box

to 120 Volt AC (or correct voltage for model being

installed). POWER light on Transformer Box will glow.

3. Bring Controlstik (sensor) electrodes together by sliding

the inside probe completely forward. Use a screwdriver

to “short” the inside cone electrode to the outside band

electrode. This “short” will turn on valve; VALVE light on

Transformer Box will glow and valve will open.

4. Remove “short” between electrodes. VALVE light will

go out and valve will shut off.

E. Initial Setting and Operation

1. Fill pail with water from rinse tank inlet water line.

2. Move inside probe of the Controlstik (sensor) back to

highest scale reading and submerge into pail of water.

3. Slowly push inside probe toward opposite end,

stopping when Solenoid Valve triggers and VALVE light

goes on. Water will begin to ow into the tank. Read

scale.

4. For the initial setting, move the inside probe back to

read at least 25% higher than the scale reading in step

3. Tighten set screw with 9/64" Allen wrench (nger

tight is not sufcient).

5. Place the Controlstik (sensor) back into the rinse tank

as described under Section A. Mounting, number 2.

Fasten the cord with the securing clamp provided.

6. Check setting and overall operation by rinsing parts or

by pouring a small amount of acid or alkaline solution

into the rinse tank to trigger the Solenoid Valve and

start water ow.

7. Adjust valve ow control handle to obtain desired

ow rate. Check through at least one complete on/off

cycle. This valve can also be operated manually. To

disengage the solenoid (convert valve to manual

operation) hold the cross handle rmly and loosen

(counterclockwise) the bolt in the center of the stem.

Some water will spurt out at the stem while it is under

manual control.

NOTE: The best Controlstik (sensor) setting can be determined

with experience. Since the main objective of the

system is to conserve water use, a high conductivity

setting on the sensor is desirable . . . as long as the

water does not become too dirty, preventing effective

rinsing. However, if the sensor is set too low, the water

will ow continuously due to the normal conductivity

(total dissolved solids) in source water - defeating the

purpose of the system.

MAINTENANCE

A. Controlstik (sensor)

Although this system is very stable, the sensor should be

regularly checked for hard water scale, which will lower

its sensitivity. Scale can be easily removed by agitating

sensor in a 2-10% hydrochloric acid solution. If scale

has been allowed to build up for a long period, a bristle

brush may also be used. The Controlstik (sensor) may be

disassembled by removing the set screw and thoroughly

cleaned if it should accidentally become completely fouled.

B. Valve

Should the Controlstik Rinse Tank System no longer

activate the Solenoid Valve when the inside probe is

intentionally “shorted,” unscrew the solenoid from the side

of the valve and check the chamber for any solid matter

which may prevent easy solenoid movement.

2

Page 5

WARRANTY

This Myron L CONTROLSTIK System has a Two-Year Warranty. If this system fails to function normally, return the faulty unit of the

system to the factory prepaid. If in the opinion of the factory, failure was due to materials or workmanship, repair or replacement will

be made without charge. A reasonable service charge will be made for diagnosis or repairs due to normal wear, abuse or tampering.

Warranty is limited to the repair or replacement of the units of the CONTROLSTIK System only. The Myron L Company assumes no

other responsibility or liability.

OTHER MYRON L INSTRUMENTS USEFUL FOR FINISHING APPLICATIONS

The waterproof and microprocessor-based

Ultrameter II Model 4P is a fast “on-the-spot”

water quality tester. It offers highly accurate

readings of 4 parameters: Conductivity, Total

Dissolved Solids, Resistivity, and Temperature.

The new Ultrameter II also offers download

capabilities with the optional uDock™, is

waterproof and bouyant, features a real time

clock, and much more.

Please visit www.myronl.com for more information on all Myron L products.

Model 6P has all the features of Ultrameter II

4P, but can also test for pH and ORP (redox).

All electrodes are built into the cell cup for

maximum protection. The extended-life

pH/ORP sensor is user replaceable. This

instrument is ideal for testing rinse water and

RO/DI systems. This meter makes setting

your Controlstik sensor even easier and

allows you to test high quality deionized water.

3

Page 6

Page 7

Page 8

Water Quality Instrumentation

Accuracy • Reliability • Simplicity

MYRON L COMPANY

2450 Impala Drive

Carlsbad, CA 92010-7226

USA

Tel: +1-760-438-2021

Fax: +1-760-931-9189

E-Mail: info@myronl.com

techquestions@myronl.com

www.myronl.com

Made in USA

ACCURACY • RELIABILITY • SIMPLICITY

© Myron L Company 2008 597OM 10-08

Loading...

Loading...