Page 1

Ultrameter

™

Operation

Manual

Model 4P

10 - 02 (WEB) EG

MYRON L

COMPANY

Page 2

7-11-00

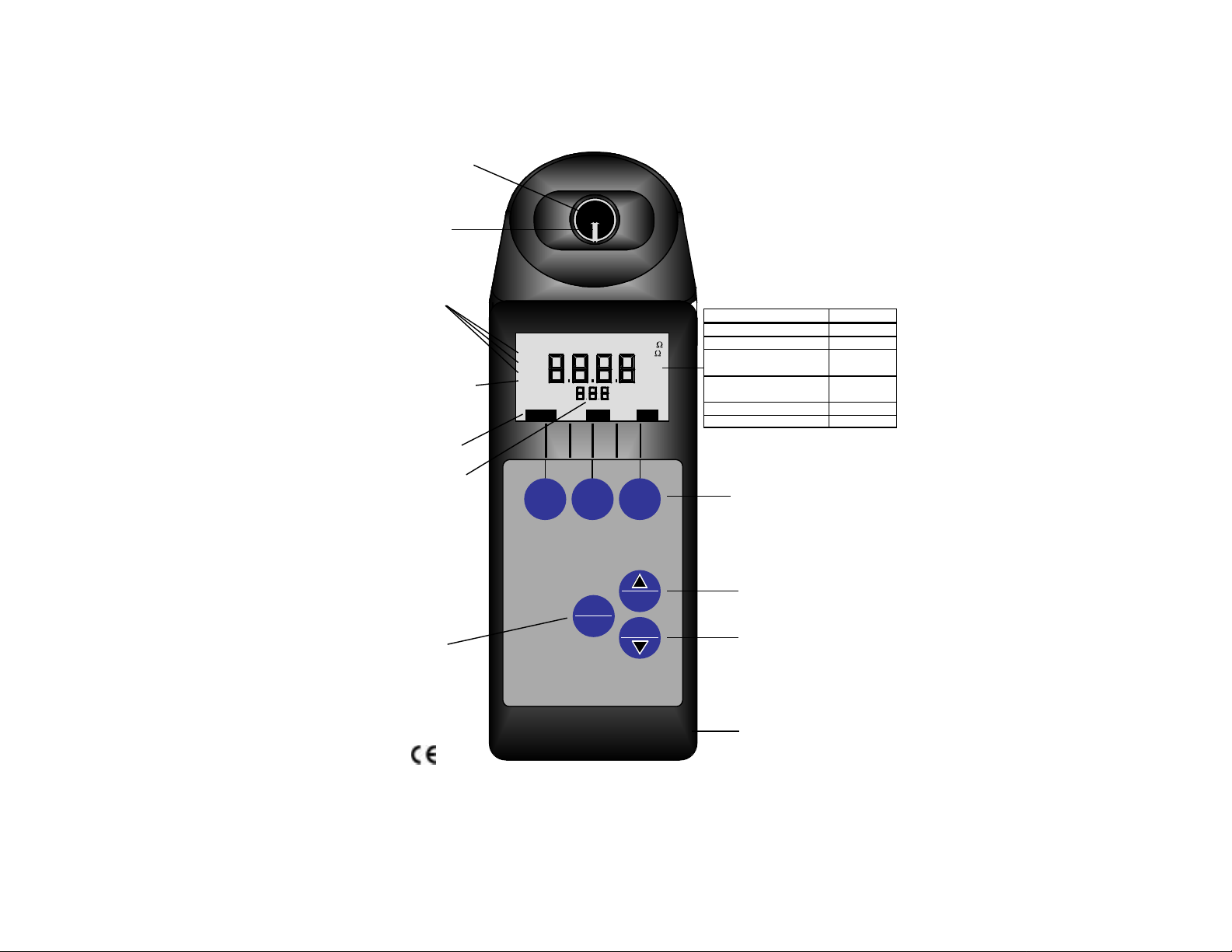

Instrument Illustration

MS

MR

MMYYRROONN LL

CCOOMMPPAANNYY

4P

COND

RES TDS

These 3 Measurement keys will:

• Turn instrument on

• Measure parameter

• Exit any function

(Built-in

Electrodes)

Preprogrammed

variable conductivity/

TDS ratios

Parameters (3)

Wrist/neck strap slot

(user supplied)

This key for:

• Calibration

• Memory Clear

• Solution selection

• Confirmation

Up key/Memory Store

Down key/Memory Recall

Conductivity Cell

USER mode

for programming

special temperature

compensation

factor and

conductivity/TDS

ratio

Displayed here:

• Temperature

readout

• USER temperature

compensation or

conductivity/TDS

ratio

• Memory Storage/

Recall

BUFFER

PPM

PPT

µS

mS

K

M

°C

RATIO

% /

KCl

442

NaCl

User

LOBATT CAL MEMORY

RES TDSCOND

For detailed explanations see Table of Contents

Units of Measurement

Ω

Megohms - cm

Ω

Kilohms - cm

mS - millisiemens/cm

(millimhos/cm)

µS - microsiemens/cm

(micromhos/cm)

PPM - parts per million

PPT - parts per thousand

Parameter

Resistivity

Resistivity

Conductivity

Conductivity

TDS

TDS

Temperature

Sensor

MCLR

CAL

1

ULTRAMETER

TM

Page 3

FEATURES and SPECIFICATIONS

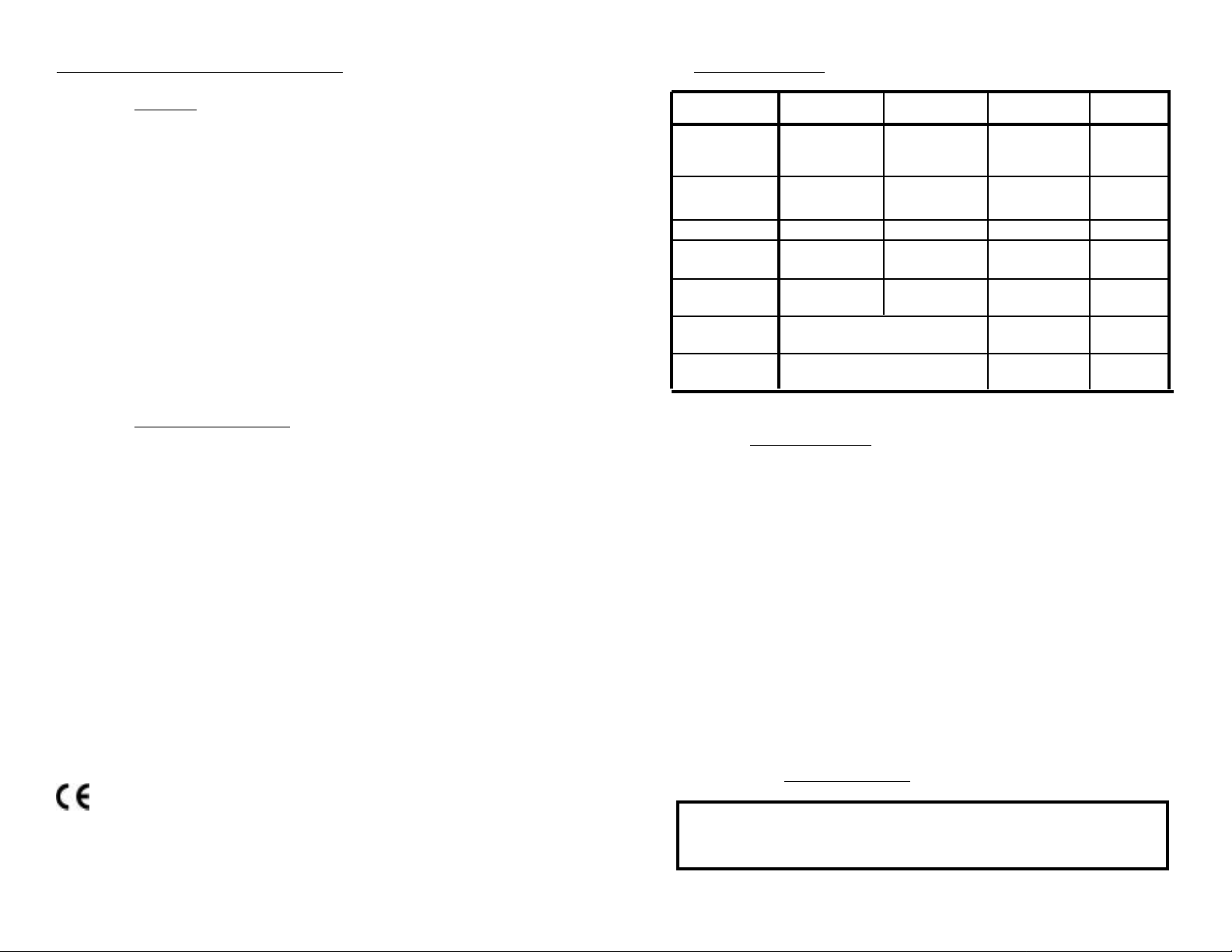

C. Specification Chart

A. Features

• Superior resolution 4 digit LCD displays full 9999 µS/ppm.

• Accuracy of ±1% of reading (not merely full scale).

• All electrodes are internal for maximum protection.

• Latest 4 electrode cell technology.

• Waterproof to 3 feet/1 meter.

• Autoranging conductivity/TDS/resistivity.

• Memory saves 20 readings.

• Factory calibrations stored in microprocessor.

• 3 conductivity/TDS solution conversions preprogrammed into

microprocessor.

• USER feature allows:

Programming your own cond/TDS conversion factor.

Programming your own temperature compensation factor.

Disabling temperature compensation.

B. General Specifications

Display 4 Digit LCD

Dimensions (LxWxH) 7.7x2.7x2.5 in.

196x68x64 mm

Weight 12oz./341g

Case Material VALOX*

Cond/Res/TDS Cell Material VALOX*

Cond/Res/TDS Cell Capacity 0.2 oz./5 ml

Power 9V Alkaline Battery

Battery Life >100 Hours/5000 Readings

Operating/Storage Temperature 32-132°F/0-55°C

Protection Ratings IP67/NEMA 6 (waterproof to

3 feet/1 meter)

* ™ GE Corp.

Additional information available on our web site at:

www.myronl.com

4P

Ranges

Auto

Temperature

Compensation

Temperature

Compensation

Cond/TDS

Ratios

Preprogrammed

Adjustable

Cond/TDS Ratio

Factor

* up to 100mS/ppt; 100 - 200mS/ppt: ± 1 - 2% typ.

Conductivity TDS Resistivity

0-9999 µS

10-200 mS

in 5 autoranges

0.01 (<100 µS)

0.1 (<1000 µS)

1.0 (>1000 µS)

±1 % of reading* ±1 % of reading*

0-71°C

32 - 160°F

0 - 9.99%/°CAdjustable

KCl, NaCl, 442™

0.20 - 7.99

0-9999 ppm

in 5 autoranges

0.01 (<100 ppm)

0.1 (<1000 ppm)

1.0 (>1000 ppm)

32 - 160°F

0 - 9.99%/°C 0 - 9.99%/°C

10-200 ppt

0-71°C

10K - 30M ohms

0.01 (<100K ohmsΩ

0.1 (<1000K ohmsΩ

1.0 (>1 MΩ)

±1 % of reading**

**10K ohms - 10M ohms

Ω

0-71°C

32 - 160°F

Ω Ω

Temperature

0-71°C

32 - 160 °F

Ω

0.1 °C/FResolution

)

)

±0.1 °CAccuracy

D. Warranty/Service

All Myron L Ultrameters have a 2 year warranty except for pH sensors

which have a 6-month limited warranty. If an instrument fails to operate

properly, see the Troublshooting Chart, pg. 21. The battery and pH/ORP

sensor are user replaceable. For other service, return the instrument

prepaid to the Myron L Company.

MYRON L COMPANY

2450 Impala Drive

Carlsbad, CA 92010

USA

760-438-2021

If, in the opinion of the factory, failure was due to materials or

workmanship, repair or replacement will be made without charge. A

reasonable service charge will be made for diagnosis or repairs due to

normal wear, abuse or tampering. This warranty is limited to the repair or

replacement of the Ultrameter only. The Myron L Company assumes

other responsibility or liability.

E. Ultrameter Models

ULTRAMETER MODELS 3P 4P 6P

PARAMETERS pH/ORP/Temp. Conductivity/TDS Conductivity/TDS/pH

2

Resistivity/Temp. Resistivity/ORP/Temp.

3

Page 4

TABLE OF CONTENTS

Instrument Illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

FEA TURES and SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

A. Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

B. General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 2

C. Specification Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

D. Warranty/Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

E. Ultrameter Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

I. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

II. RULES of OPERA TION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

A. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

B. Characteristics of the Keys . . . . . . . . . . . . . . . . . . . . . . 7

C. Operation of the Keys . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1. Measurement Keys in General . . . . . . . . . . . . 8

2. COND, RES and TDS keys . . . . . . . . . . . . . . .8

3. CAL/MCLR key . . . . . . . . . . . . . . . . . . . . . . . . . 8

4. UP or DOWN keys . . . . . . . . . . . . . . . . . . . . . . .9

III. AFTER USING the UL TRAMETER

Maintenance of the Conductivity Cell . . . . . . . . . . . . . . . 9

IV. SPECIFIC RECOMMENDED MEASURING PROCEDURES . . . .9

A. Measuring Conductivity/Total Dissolved Solids . . . . .9

B. Measuring Resistivity . . . . . . . . . . . . . . . . . . . . . . . . . . 10

V. SOLUTION SELECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

A. Why Solution Selection is A vailable. . . . . . . . . . . . . . 10

B. The 4 Solution Types. . . . . . . . . . . . . . . . . . . . . . . . . . 10

C. Calibration of Each Solution T ype . . . . . . . . . . . . . . .10

D. Procedure to Select a Solution . . . . . . . . . . . . . . . . . 10

E. Application of USER Solution Type . . . . . . . . . . . . . .11

1. User Programmable Tempco . . . . . . . . . . . . 11

2. Disabling Temperature Compensation . . . . 12

3. User Programmable Conductivity to TDS

Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

VI. CALIBRA TION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

A. Calibration Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

B. Rules for Calibration in the Ultrameter . . . . . . . . . . . . 13

1. Calibration Steps . . . . . . . . . . . . . . . . . . . . . . .13

2. Calibration Limits . . . . . . . . . . . . . . . . . . . . . . .14

C. Calibration Procedures . . . . . . . . . . . . . . . . . . . . . . . . 14

1. Conductivity or TDS Calibration . . . . . . . . . .14

2. User Calibration Conductivity/TDS . . . . . . . .15

3. Resistivity Calibration . . . . . . . . . . . . . . . . . . . 15

4. Reloading Factory Calibration . . . . . . . . . . . .15

5. Temperature Calibration . . . . . . . . . . . . . . . . 16

VII. MEMORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

A. Memory Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

B. Memory Recall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

C. Clearing a Record/Memory Clear . . . . . . . . . . . . . . . . 16

VIII. CHANGING from CENTIGRADE to FAHRENHEIT . . . . . . . . . . . .17

IX. T OTAL RETURN to FACTOR Y SETTINGS . . . . . . . . . . . . . . . . . 18

X. CALIBRA TION INTER VALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

A. Suggested Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . .19

B. Calibration Tracking Records . . . . . . . . . . . . . . . . . . . 19

C. Conductivity , RES, TDS Practices . . . . . . . . . . . . . . .19

XI. CARE and MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

A. Temperature Extremes . . . . . . . . . . . . . . . . . . . . . . . . 20

B. Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 20

C. Cleaning Cell Cup . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

XII. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

XIII. ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

A. Conductivity/TDS Standard Solutions . . . . . . . . . . . 22

B. Soft Protective Case . . . . . . . . . . . . . . . . . . . . . . . . . . 22

C. Data Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

D. pH Buffer Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

E. pH Sensor Storage Solution . . . . . . . . . . . . . . . . . . . 23

XIV. TEMPERATURE COMPENSATION (Tempco)

of Aqueous Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

A. Standardized to 25°C . . . . . . . . . . . . . . . . . . . . . . . . . .23

B. Tempco Variation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

C. An Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

D. A Chart of Comparative Error . . . . . . . . . . . . . . . . . . . .25

E. Other Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4

5

Page 5

XV. CONDUCTIVITY CONVERSION to

TOTAL DISSOLVED SOLIDS (TDS) . . . . . . . . . . . . . . .26

A. How it’s Done . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

B. Solution Characteristics . . . . . . . . . . . . . . . . . . . . . . . .26

C. When does it make a lot of difference? . . . . . . . . . . . 27

XVI. TEMPERATURE COMPENSATION (Tempco)

and TDS DERIVA TION . . . . . . . . . . . . . . . . . . . . . . . . . . .27

A. Conductivity Characteristics . . . . . . . . . . . . . . . . . . . . 27

B. Finding the Tempco of an Unknown . . . . . . . . . . . . . 28

C. Finding the TDS Ratio of an Unknown . . . . . . . . . . . 28

XVII. GLOSSARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Addendum

I. HIGH RESISTIVITY MEASUREMENTS . . . . . . . . . . . . . . . . . . . . . .1

Offset Zero Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Cell Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

II. USER MODE GAIN CALIBRATION . . . . . . . . . . . . . . . . . . . . . . . . . 3

A. Calibration of Ultrameter for Use in User Mode . . . . . 3

B. Setting User mode Calibration “Link” . . . . . . . . . . . . . 3

C. Canceling User Mode Calibration “Link” . . . . . . . . . . . 4

* CHECKING YOUR INSTRUMENTS SOFTWARE VERSION . . . . . . . . . 5

I. INTRODUCTION

Thank you for selecting the Ultrameter™ Model 4P, one of the Myron L

Company’s latest in a new line of instruments utilizing advanced

microprocessor-based circuitry. This circuitry makes it extremely accurate

and very easy to use (see pages 2 & 3 for Features and Specifications on

this and other models). For your convenience, your Ultrameter has a brief

set of instructions on its bottom, and a pocket sized card with abbreviated

instructions is included with the instrument.

Special note ...... Conductivity, Resistivity, and TDS require mathematical

correction to 25°C values (ref. Temperature Compensation, pg. 23). On

the left of the Ultrameter’s liquid crystal display is shown an indicator of

the salt solution characteristic used to model temperature compensation

of conductivity and its TDS conversion. The indicator can be KCl, NaCl,

442 or USER. Selection affects the temperature correction of

conductivity, and the calculation of TDS from compensated conductivity

(ref. Conductivity Conversion to Total Dissolved Solids (TDS), pg. 26).

The selection can affect the reported conductivity of hot or cold

solutions, and will change the reported TDS of a solution. Generally,

using KCl for conductivity, NaCl for resistivity, and 442™ (Natural Water

characteristic)

standardization. This is how your instrument, as shipped from the factory,

is set to operate.

II. RULES of OPERATION

A. Operation

Using the instrument is simple:

• Rinse the conductivity cell with test solution 3 times and refill.

• Press the desired measurement key to start measurement.

Pressing the key again does no harm and restarts the 15 second

“off” timer.

• Note the value displayed or press the MS key to store

(ref. Memory Storage, pg. 16). It’s that simple!

for TDS will reflect present industry practice for

B. Characteristics of the Keys

• Though your Ultrameter has a variety of sophisticated options, it

is designed to provide quick, easy, accurate measurements by

simply pressing one key.

• All functions are performed one key at a time.

• There is no “off” key. After 15 seconds of inactivity the

instrument turns itself off (60 seconds in CAL mode).

• Rarely will a key be required to be held down (as in Procedure to

Select a Solution, pg. 10 or Conductivity or TDS Calibration, pg.

14).

6

7

Page 6

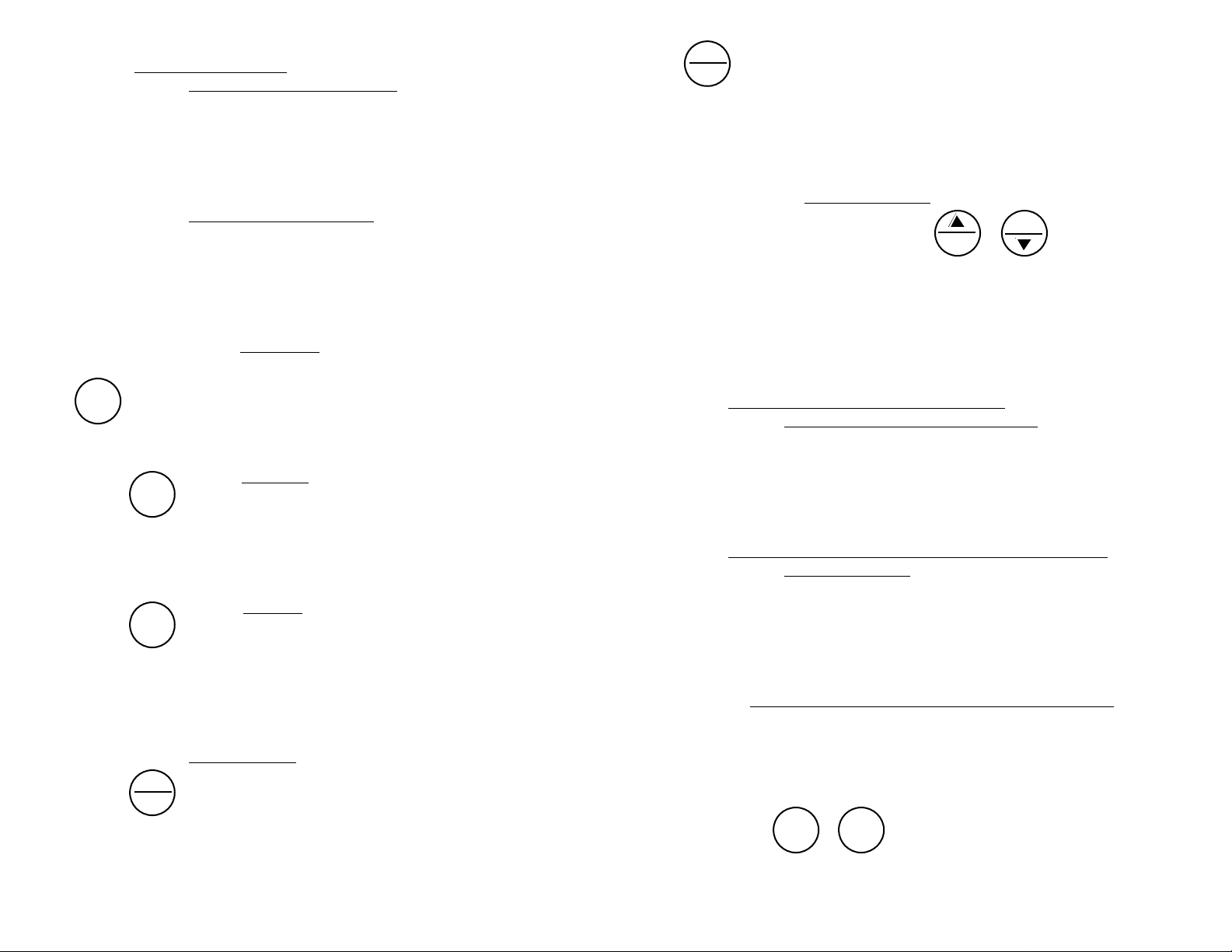

C. Operation of the Keys (See Instrument Illustration on page 1)

1. Measurement Keys in General

Any of the 3 measurement keys in the upper part of the keypad turns on

the instrument in the mode selected. The mode is shown at the bottom

of the display, and the measurement units appear at the right. Pressing a

measurement key does this even if you are in a calibration sequence and

also serves to abandon a change (ref. Leaving Calibration, pg. 14).

2. COND, RES and TDS keys

These 3 keys are used with solution in the Conductivity Cell.

Precautions:

• While filling cell cup, ensure no air bubbles cling on the cell wall.

• If the proper solution is not selected (KCl, NaCl, 442 or USER)

refer to Why Solution Selection is Available, pg. 10 and

Procedure to Select a Solution, pg. 10.

a. COND Key

Solution to be tested is introduced into the conductivity cell and a press

of displays conductivity with units on the right. On the left is

COND

shown the solution type selected for conductivity. An overrange

condition will show only [- - - -] (ref. Solution Selection, pg. 10).

b. RES Key

A press of displays resistivity with units on the right. On the left

RES

is shown solution type selected for resistivity (ref. Solution Selection, pg.

10). The range of display of Resistivity is limited to between 10 kilohms

(KΩ) and 30 megohms (MΩ). A solution outside that range will only show

[- - - -] in the display .

c. TDS key

A press of displays Total Dissolved Solids with units on the

TDS

right. This is a display of the concentration of material calculated from

compensated conductivity using the characteristics of a known material.

On the left is shown solution type selected for TDS (ref. Solution

Selection, pg. 10).

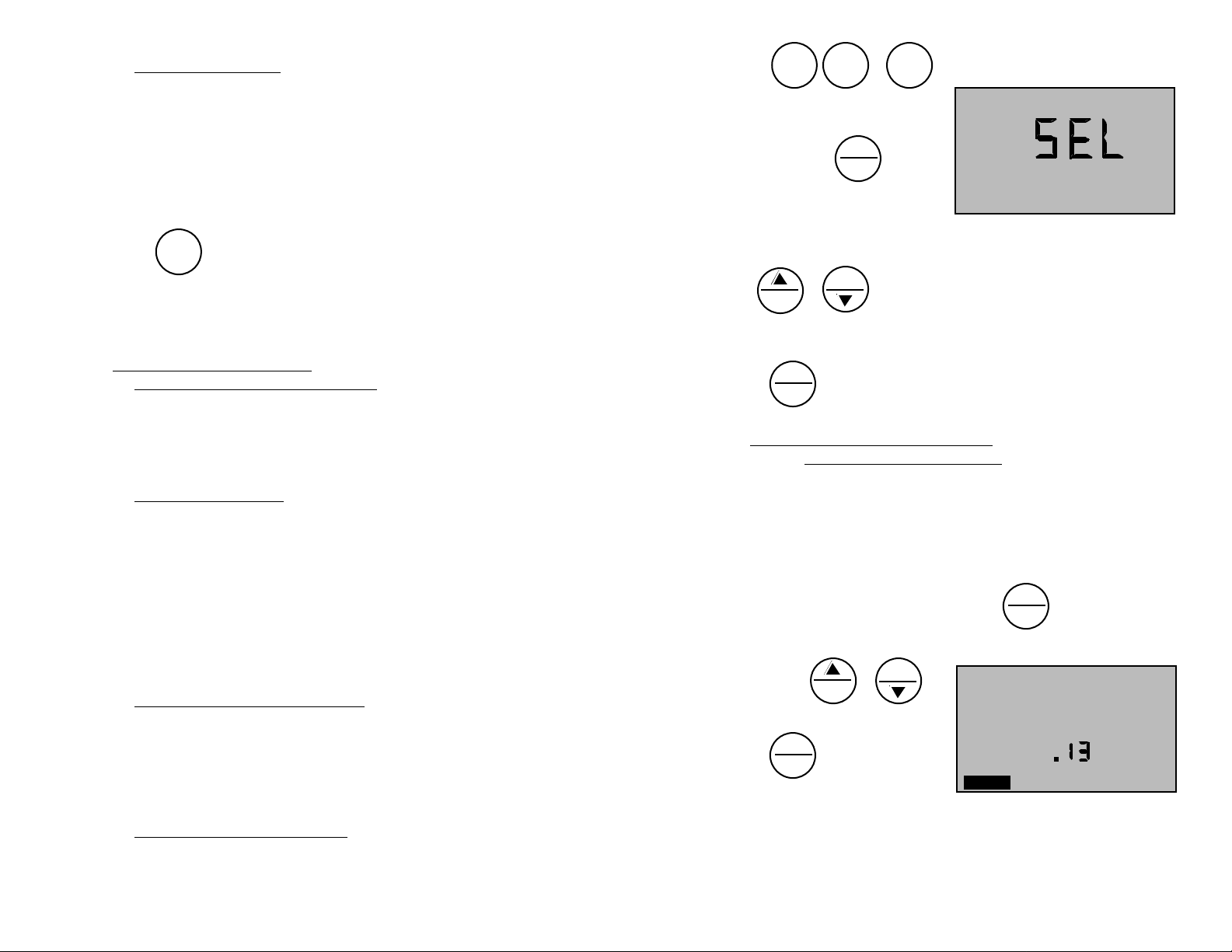

3. CAL/MCLR key

CAL

If is held down for about 3 seconds, CAL mode is not entered, but

MCLR

“SEL” appears to allow Solution Selection (ref. pg. 10) with the Up or

Down keys. As in calibration, the CAL key is now an “accept” key.

While reviewing stored records, the MCLR side of the key is active to

allow clearing records (ref. Clearing a Record/Memory Clear, pg. 16).

4. UP or DOWN keys

While measuring in any parameter, the or keys activate the

MS

MR

Memory Store and Memory Recall functions.

While in CAL mode, the keys step or scroll the displayed value up or

down. A single press steps the display and holding either key scrolls the

value rapidly.

While in Memory Recall, the keys move the display up and down the stack

of records (ref. Memory Recall, pg. 16).

III. AFTER USING the ULTRAMETER

Maintenance of the Conductivity Cell

Rinse out the cell cup with clean water. Do not scrub the cell. For oily

films, squirt in a foaming non-abrasive cleaner and rinse. Even if a very

active chemical discolors the electrodes, this does not affect the

accuracy; leave it alone (ref. Cleaning Conductivity/TDS/Resistivity Cell

Cup, pg. 20).

IV. THE SPECIFIC RECOMMENDED MEASURING

PROCEDURES

If the proper solution is not selected (KCl, NaCl, 442 or USER), see

Solution Selection, Pg. 10.

NOTE

: After sampling high concentration solutions or temperature

extremes, more rinsing may be required.

A. Measuring Conductivity/Total Dissolved Solids (TDS)

1. Rinse cell cup 3 times with sample to be measured. (This

conditions the temperature compensation network and prepares

the cell.)

A press of allows you to enter the calibration mode while

CAL

MCLR

measuring conductivity or TDS. Once in CAL mode, a press of this key

accepts the new value. If no more calibration options follow, the

instrument returns to measuring (ref. Leaving Calibration, pg. 14).

8

2. Refill cell cup with sample.

3. Press or .

COND

TDS

4. Take reading. A display of [- - - -] indicates an overrange

condition.

9

Page 7

B. Measuring Resistivity

Resistivity is for low conductivity solutions. In a cell cup the value may drift

from trace contaminants or absorption from atmospheric gasses, so

measuring a flowing sample is recommended.

1. Hold instrument at 30° angle (cup sloping downward).

1. Press , or to select the parameter on which

COND

RES

TDS

you wish to change the

solution type.

2. Press and hold key

CAL

MCLR

KCl

NaCl

442

User

2. Let sample flow continuously into conductivity cell with no

aeration.

3. Press key; use best reading.

RES

NOTE: If reading is lower than 10 kilohms, display will be dashes: [ - - - - ].

Use Conductivity.

V. SOLUTION SELECTION

A. Why Solution Selection is Available

Conductivity, Resistivity, and TDS require temperature correction to 25°C

values (ref. Standardized to 25°C, pg. 23). Selection determines the

temperature correction of conductivity and calculation of TDS from

compensated conductivity (ref. Cond. Conversion to TDS, pg. 26).

B. The 4 Solution Types

On the left side of the display is the salt solution characteristic used to

model temperature compensation of conductivity and its TDS

conversion. Generally, using KCl for conductivity, NaCl for resistivity and

442 (Natural Water characteristic) for TDS will reflect present industry

practice for standardization. This is the setup as shipped from the factory

(ref. Solution Characteristics, pg. 26).

The USER selection allows a custom value to be entered for the

temperature compensation of conductivity and also the conversion ratio if

measuring TDS.

C. Calibration of Each Solution Type

There is a separate calibration for each of the 4 solution types. Note that

calibration of a 442 solution does not affect the calibration of a NaCl

solution. For example: Calibration (ref. Conductivity or TDS Calibration,

pg. 14) is performed separately for each type of solution one wishes to

measure (ref. Conductivity/TDS Standard Solutions, pg. 22).

D. Procedure to Select a Solution

NOTE: Check display to see if solution displayed (KCl, NaCl, 442 or

USER) is already the type desired. If not:

10

about 3 seconds to make

“SEL” appear (see Figure 1).

(For demonstration purposes,

Figure 1

all 4 solution types are shown simultaneously.)

3. Use or key to obtain type of solution desired (ref.

MS

MR

Solution Characteristics, pg. 26). The selected solution type will

be displayed: KCl, NaCl, 442 or User.

4. Press to accept new solution type.

CAL

MCLR

E. Application of USER Solution Type

1. User Programmable Tempco

This feature allows you to change your Ultrameter’s temperature

compensating

factor

to another factor between 0-9.99%/°C

(ref.

Temperature Compensation, pg. 23).

a. As in Procedure to Select a Solution, pg. 10, select “USER”

mode.

b. With “USER” mode now selected, press . You may now

CAL

MCLR

adjust a temperature compensation from .00%/°C to 9.99%/°C,

by pressing or .

MS

MR

See example in Figure 2.

c. Press twice to skip

CAL

MCLR

calibration adjustment and

accept the new tempco (3

User

°C% /

COND

Figure 2

times if in TDS mode). You are now ready to measure samples

with your new temperature compensation factor.

11

Page 8

2. Disabling Temperature Compensation

a. As in Procedure to Select a Solution, pg. 10, select “USER”

mode.

b. With “USER” selected, press . If the display does not

show .00%/°C, hold long enough to bring the tempco to

MR

CAL

MCLR

.00%/°C (see Figure 3).

In the first five sections, you have learned all

you need to make accurate measurements. The

following sections contain calibration, advanced

operations and technical information.

VI. CALIBRATION

A. Calibration Intervals

Generally, calibration is recommended about once per month with

Conductivity or TDS solutions (ref. Calibration Intervals, pg. 19).

c. Press twice (3 times

if in TDS mode). Temperature

compensation is now disabled

(=0) for measurements in

USER mode.

CAL

MCLR

User

°C% /

COND

Figure 3

3. User Programmable Conductivity to TDS Ratio

This feature allows you to select a custom conductivity to TDS conversion

ratio for USER mode measurements.

For example: The conversion ratio range is 0.20-7.99 (ie., if conductivity

is 100 µS and TDS is 75 ppm, you would adjust to 0.75) (ref. Conductivity

Conversion to TDS, pg. 26).

a. While in “USER” mode, press .

b. Press twice (to skip over tempco adjustment), and

CAL

MCLR

TDS

“RATIO” will appear (see Figure 4).

c. Adjust with or

MS

MR

keys until new conversion

ratio is displayed.

d. Press twice (to skip

CAL

MCLR

over calibration adjustment)

User

RATIO

TDS

Figure 4

to accept new conversion ratio.

You are now ready to measure samples with the new

conductivity/TDS ratio.

B. Rules for Calibration in the Ultrameter

1. Calibration Steps

a. Starting Calibration

Calibration is begun by pressing while measuring Conductivity or

CAL

MCLR

TDS. Measuring continues, but the CAL icon is on, indicating calibration

is now changeable.

The reading is changed with the and to match the known

MS

MR

value. The calibration for each of the 4 solution types may be performed

from either conductivity or TDS mode.

b. Calibration Steps

Depending on what is being calibrated, there may be 1, 2 or 3 steps to

the calibration procedures.

KCl, NaCl or 442 User

Cond Gain only Tempco, then Gain

Res Done in conductivity Done in conductivity or TDS

TDS Gain only Tempco, Ratio, then Gain

CAL

The becomes an “ACCEPT” key. At each point, pressing

MCLR

CAL

MCLR

accepts the new calibration value and steps you to the next adjustment

(or out of CAL mode if there are no more steps).

To bypass a calibration step, just press

CAL

to accept the present value

MCLR

as is.

12

13

Page 9

c. Leaving Calibration

You know you are finished when the “CAL” icon goes out. Pressing any

measurement key abandons changes not yet accepted and exits

calibration mode.

2. Calibration Limits

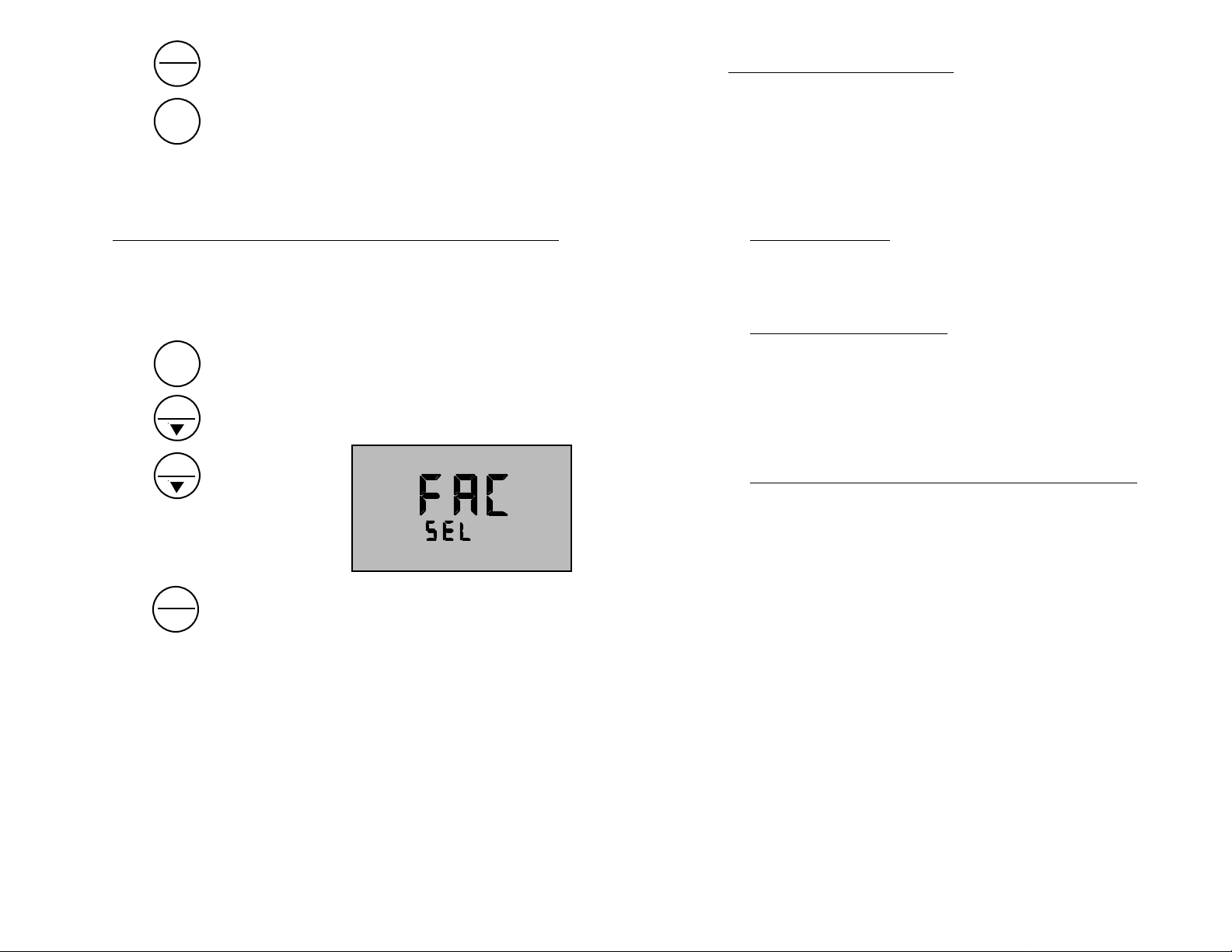

There are calibration limits. A nominal “FAC” value is an ideal value stored

by the factory. Attempts to calibrate too far, up or down, from there will

cause the displayed value to be replaced with “FAC”. If you accept it

(press the “Cal” key), you will have the original default factory calibration

for this measurement. The need to calibrate so far out that “FAC” appears

indicates a procedural problem, wrong standard solution, or a very dirty

cell cup (ref. Troubleshooting Chart, pg. 21).

C. Calibration Procedures

1. Conductivity or TDS Calibration

2. User Calibration Conductivity/TDS

a. Rinse conductivity cell three times with your standard.

b. Refill conductivity cell with same standard.

c. Press or , then press twice in COND/three

COND

TDS

CAL

MCLR

times in TDS. The “CAL” icon will appear on the display .

d. Press or to step the displayed value toward the

MS

MR

standard’s value or hold a key down to cause rapid scrolling of the

reading.

e. Press once to confirm new value and end the calibration

CAL

MCLR

a. Rinse conductivity cell three times with proper standard (KCl,

NaCl, or 442) (ref. Con./TDS Standard Solutions, pg. 22). For

user calibration see User Calibration Cond./TDS, pg. 15.

b. Refill conductivity cell with same standard.

c. Press or , then

press , “CAL” icon will

appear on the display (see

Figure 5).

d. Press or to step the displayed value toward the

COND

CAL

MCLR

MS

TDS

442

COND

MR

CAL

µS

°C

Figure 5

standard’s value or hold a key down to cause rapid scrolling of the

reading.

e. Press once to confirm new value and end the calibration

CAL

MCLR

sequence for this particular solution type.

If another solution type is also to be measured, change solution type now

and repeat this procedure.

sequence for this particular solution type.

3. Resistivity Calibration

Resistivity is the reciprocal of Conductivity. Resistivity is calibrated only if

conductivity is calibrated for the same solution type.

4. Reloading Factory Calibration (Cond or TDS)

If calibration is suspect or known to be wrong, and no standard solution is

available, the calibration value can be replaced with the original factory

value for that solution. This “FAC” value is the same for all Ultrameters,

and returns you to a known state without solution in the cell. The “FAC”

internal electronics calibration (which bypasses the electrodes and cell) is

not intended to replace calibration with conductivity standard solutions. If

another solution type requires resetting, change solution type and

repeat this procedure.

a. Press or .

b. Press . (If in USER solution mode, press CAL key twice if

COND

CAL

MCLR

TDS

in Conductivity, and three times if in TDS to skip over tempco and

ratio adjustments.)

c. Press key until “FAC” appears and release.

MS

14

d. Press to accept the factory calibration setting.

CAL

MCLR

15

Page 10

5. Temperature Calibration

Temperature calibration is not necessary in the Ultrameter.

VII. MEMORY

This feature allows up to 20 readings with their temperatures to be stored

simultaneously for later recall.

A. Memory Storage

1. While displaying a measurement, press to record the

displayed value.

2. “MEMORY” will appear and

the temperature display will be

momentarily replaced by a

number (1-20) showing the

position of the record. Figure

6 shows a reading of 1806 µS

stored in memory record #4.

B. Memory Recall

1. Press one of the measurement keys.

2. Press , “MEMORY” will appear, and the display will show

the last record stored.

3. Press the or to scroll to the record location desired

(the temperature display alternates between temperature

recorded and location number).

4. Press a measurement key to leave memory recall or allow to

automatically turn off.

C. Clearing a Record/Memory Clear

After recalling a certain record location, press to clear that

memory. This space will be the place for the next memory record,

unless you scroll to another position before ending the recall

sequence. The next memory stored will go into the next highest

available memory location.

Example: You have locations 1-7 filled.

You want to clear the conductivity

reading stored in record location #3 and replace it with a TDS reading.

1. Press and scroll to location #3 .

2. Press to clear old record #3 .

3. Fill conductivity cell with sample.

4. Press to measure sample and press to store

reading in location #3.

5. The next memory stored will go into location #8.

6. To clear all records: After

pressing , scroll down

to “CLr ALL” in measurement

and temperature area

(see Figure 7).

7. Press . All records will be cleared.

VIII. CHANGING from CENTIGRADE to FAHRENHEIT

1. Press .

2. Press to display the stored memory records.

3. Press repeatedly until you pass the memory “CLr ALL”

location. The display will show a “C” or “F” (see Figures 8 & 9).

16 17

Figure 8 Figure 9

COND

MR

MR

Figure 7

CAL

MCLR

MR

MS

MR

CAL

MCLR

COND

CAL

MCLR

MR

MS

MR

MS

Figure 6

COND

µS

°C

MEMORY

442

MEMORY

Page 11

4. Press ; the display will change to the other unit.

5. Press ; all temperature readings are now in degrees last

CAL

MCLR

COND

shown.

NOTE: Tempco will still be shown in %/°C.

X. CALIBRATION INTERVALS

There is no simple answer as to how often one should calibrate an

instrument. The Ultrameter is designed to not require frequent

recalibration. The most common sources of error were eliminated in the

design, and there are no mechanical adjustments. Still, to ensure

specified accuracy, any instrument has to be checked against chemical

standards occasionally.

IX. TOTAL RETURN to FACTORY SETTINGS “FAC SEL”

There may come a time when it would be desirable to quickly reset all the

recorded calibration values in the instrument back to the factory settings.

This might be to ensure all calibrations are set to a known value, or to give

the instrument to someone else free of adjustments or recorded data for

a particular application.

1. Press .

2. Press to display the stored memory records.

3. Press repeatedly until

COND

MR

MR

you pass the CLr ALL and the

C-F locations. The display will

show a “FAC SEL”

(see Figure 10).

4. Press to accept the resetting.

CAL

MCLR

Figure 10

A. Suggested Intervals

On the average, we expect calibration need only be checked monthly for

the Conductivity, RES or TDS functions. Measuring some solutions will

require more frequent intervals.

B. Calibration Tracking Records

To minimize your calibration effort, keep records. If adjustments you are

making are minimal for your application, you can check less often.

Changes in conductivity calibration should be recorded in percent.

Calibration is purposely limited in the Ultrameter to ±10% because more

than that indicates damage, not drift.

C.

Conductivity, RES, TDS Practices to Maintain Calibration

1. Clean oily films or organic material from the cell electrodes with

foaming cleaner or mild acid. Do not scrub inside the cell.

2. Calibrate with solutions close to the measurements you make.

Readings are compensated for temperature based on the type

of solution. If you choose to measure tap water with a KCl

compensation, which is often done (ref. An Example, pg. 24),

and you calibrate with 442 solution because it is handy, the

further away from 25°C you are, the more error you have. Your

records of calibration changes will reflect temperature changes

more than the instrument’s accuracy.

18

3. Rinse out the cell with pure water after making measurements.

Allowing slow dissolving crystals to form in the cell contaminates

future samples.

19

Page 12

XI. CARE and MAINTENANCE

Ultrameters should be rinsed with clean water after use. Solvents should

be avoided. Shock damage from a fall may cause instrument failure.

A. Temperature Extremes

Solutions in excess of 160°F/71°C should not be placed in the cell cup

area; this may cause damage. Care should be exercised not to exceed

rated operating temperature.

Leaving the Ultrameter in a vehicle or storage shed on a hot day can

easily subject the instrument to over 150°F. This will void the warranty.

B. Battery Replacement

Dry Instrument THOROUGHLY. Remove the four (4) bottom

screws. Open instrument carefully; it may be necessary to rock the

bottom slightly side to side to release it from the RS-232 connector.

Carefully detach battery from circuit board. Replace with 9 volt alkaline

battery. Replace bottom, ensuring the sealing gasket is installed in the

groove of the top half of case. Re-install screws, tighten evenly and

securely.

XII. TROUBLESHOOTING CHART

(ref. Measuring Resistivity , pg. 10).

2. See Measuring Resistivity, pg. 10.

NOTE: Because of nonvolatile EEPROM circuitry, all data stored in

memory and all calibration settings are protected even during power loss

or battery replacement.

C. Cleaning Conductivity/TDS/Resistivity Cell Cup

The conductivity cell cup should be kept as clean as possible. Flushing

with clean water following use will prevent buildup on electrodes.

However, if very dirty samples — particularly scaling types — are allowed

to dry in the cell cup, a film will form. This film reduces accuracy. When

there are visible films of oil, dirt, or scale in the cell cup or on the

electrodes, use a foaming non-abrasive household cleaner. Rinse out

the cleaner and your Ultrameter is ready for accurate measurements.

20

Symptom Possible Cause Corrective Action

No display, even though Battery weak or not connected. Check connections or replace battery

measurement key pressed (ref. Battery Replacement, pg. 20).

Unstable 1. Dirty electrodes. 1. Clean cell cup and electrodes (ref.

Conductivity/TDS/ 2. Test samples greater than Cleaning Cell Cup, pg. 20).

Resistivity readings 1 megohm. 2. Minimize test sample exposure to air

Unable to calibrate Film or deposits on electrodes. Clean cell cup and electrodes (ref.

Conductivity/TDS Cleaning Cell Cup, pg. 20).

2. Carbon dioxide in test sample. in place.

Resistivity readings 1. Contamination from previous 1. Rinse cell cup more thoroughly before

much lower than expected sample or from pH sensor well. measurement. Insure pH cap is snugly

21

Page 13

XIII. ACCESSORIES

A. Conductivity/TDS Standard Solutions

Your Ultrameter has been factory calibrated with the appropriate Myron L

Company NIST traceable KCl, NaCl, and our own 442 standard solutions.

Most Myron L conductivity standard solution bottles show three values

referenced at 25°C: Conductivity in microsiemens/micromhos and the

ppm/TDS equivalents based on our 442 Natural Water™ and NaCl

standards. All standards are within ±1.0% of reference solutions.

1. Potassium Chloride (KCl)

The concentrations of these reference solutions are calculated from data

in the International Critical Tables, Vol. 6. The 7000 µS is the

recommended standard. Order KCl-7000.

2. 442 Natural Water™

442 Natural Water Standard Solutions are based on the following salt

proportions: 40% sodium sulfate, 40% sodium bicarbonate, and 20%

sodium chloride, which represent the three predominant components

(anions) in freshwater. This salt ratio has conductivity characteristics

approximating fresh natural waters and was developed by the Myron L

Company over three decades ago. It is used around the world for

measuring both conductivity and TDS in drinking water,

ground

water,

lakes, streams, etc. The 3000 ppm is the recommended standard. Order

442-3000.

3. Sodium Chloride (NaCl)

This is especially useful in sea water mix applications, as sodium chloride

is its major salt component. Most Myron L standard solution labels show

the ppm NaCl equivalent to the conductivity and to ppm 442 values. The

14.0 mS is the recommended standard. Order NaCl-14.0.

B. Soft Protective Case

Padded Cordura® Nylon carrying case features a belt clip for hands-free

mobility. Model: UCC

® Registered trade mark of DuPont

C. Data Port

There is a 4 pin connector marked “Factory Use Only” on the bottom of

the Ultrameter. It is used to interrogate the instrument during final

inspection. Applications in the future for downloading recorded data are

being considered, but not implemented, as of this printing.

D. pH Buffer Solutions

pH buffers are available for your other Myron L Company instruments in

pH values of 4, 7 and 10. The Myron L buffer solutions are traceable to

NIST certified pH references and are color-coded for instant

identification. They are also mold inhibited and accurate to within ±0.01

pH units @ 25°C. Order 4, 7 or 10 Buffer.

E. pH Sensor Storage Solution

Myron L Storage Solution prolongs the life of the pH sensor. It is available

in quarts and gallons. Order SSQ or SSG.

XIV. TEMPERATURE COMPENSATION (Tempco)

of Aqueous Solutions

Electrical conductivity indicates solution concentration and ionization of

the dissolved material. Since temperature greatly affects ionization,

conductivity measurements are temperature dependent and are normally

corrected to read what they would be at 25°C.

A. Standardized to 25°C

Conductivity is very accurately measured in the Ultrameter by a method

that ignores fill level, electrolysis, electrode characteristics, etc., and uses

a microprocessor to perform temperature compensation. In simpler

instruments, conductivity values are usually assigned an average

correction similar to KCl solutions for correction to 25°C. The correction to

an equivalent KCl solution is a standard set by chemists. It standardizes

the measurements and allows calibration with precise KCl solutions. In

the Ultrameter, this correction can be set to other solutions or tailored for

special measurements or applications.

B. Tempco Variation

Most conductivity instruments use an approximation of the temperature

characteristics of solutions, perhaps even assuming a constant value.

The value for KCl is often quoted simply as 2%/°C. In fact, KCl tempco

varies with concentration and temperature in a non-linear fashion. Other

solutions have more variation still. The Ultrameter uses corrections that

change with concentration and temperature instead of single average

values. See Chart 1 on next page.

22

23

Page 14

2.500%

2.400%

2.300%

2.200%

2.100%

2.000%

% / °C

D. A Chart of Comparative Error:

In the range of 1000 µS, the error using KCl on a solution that should be

compensated as NaCl or as 442, is shown in the graph below.

7%

442 error with KCl tempco

6%

NaCl error with KCl tempco

5%

1.900%

1.800%

1.700%

1.600%

1.500%

0 5 10 15 20 25 30 35 40 45 50 55 60

C. An Example of 2 different solution selections and the

resulting compensation:

How much error results from treating natural water as if it were KCl at

15°C?

A tap water solution should be compensated as 442 with a tempco of

1.68 %/°C, where the KCl value used would be 1.90 %/°C.

Suppose a measurement at 15°C (or 59°F) is 900 microsiemens of true

uncompensated conductivity.

Using a 442 correction of 10 (degrees below 25) x 1.68% indicates the

solution is reading 16.8% low. For correction, dividing by (.832) yields

1082 microsiemens as a compensated reading.

A KCl correction of 10 (degrees below 25) x 1.9% indicates the solution

is reading 19% low. Dividing by (.81) yields 1111 microsiemens for a

compensated reading. The difference is 29 out of 1082 = 2.7%.

Temperature

Chart 1

KCl % / °C

4%

3%

2%

1%

0%

(1)%

T emperature

(2)%

0 5 10 15 20 25 30 35 40 45 50 55

Chart 2

Users wanting to measure natural water based solutions to 1% would

have to alter the internal compensation to the more suitable preloaded

“442” values or stay close to 25°C. Some who have standardized to KCl

based compensation may want to stick with it, regardless of increasing

error as you get further from 25°C. The Ultrameter will provide the

repeatability and convertibility of data needed for relative values for

process control.

E. Other Solutions

A salt solution like sea water or liquid fertilizer acts like NaCl. An internal

correction for NaCl can be selected for greatest accuracy with such

solutions. Many solutions are not at all similar to KCl, NaCl or 442. A sugar

solution, or a silicate, or a calcium salt at a high or low temperature may

require a “User” value peculiar to the application to provide readings

close to the true compensated conductivity.

24

Clearly, the solution characteristics should be chosen to truly represent

the actual water under test for rated accuracy of ±1%. Many industrial

applications have always been relative measurements seeking a number

25

Page 15

to indicate a certain setpoint or minimum concentration or trend. The

Ultrameter gives the user the capability to take data in “KCl conductivity

units” to compare to older published data, in terms of NaCl or 442, or as

may be appropriate. The Ultrameter can be used to reconcile data taken

with other compensation assumptions, especially with its ability to allow

custom characteristics through the USER mode.

XV. CONDUCTIVITY CONVERSION to

TOTAL DISSOLVED SOLIDS (TDS)

Electrical conductivity indicates solution concentration and ionization of

the dissolved material. Since temperature greatly affects ionization,

conductivity measurements are temperature dependent and are normally

corrected to read what they would be at 25°C (ref. Temperature

Compensation, pg. 23).

A. How it’s Done

Once the effect of temperature is removed, the compensated

conductivity is a function of the concentration (TDS). Temperature

compensation of the conductivity of a solution is performed automatically

by the internal processor, using data derived from chemical tables. Any

dissolved salt at a known temperature has a known ratio of conductivity to

concentration. Tables of conversion ratios referenced to 25°C have been

published by chemists for decades.

B. Solution Characteristics

Real world applications have to measure a wide range of materials and

mixtures of electrolyte solutions. To solve this problem, industrial users

commonly use the characteristics of a standard material as a model for

their solution, like the KCl favored by chemists for its stability.

Users dealing with sea water, etc., use NaCl as the model for their

concentration calculations. Users dealing with freshwater work with

mixtures including sulfates, carbonates and chlorides, the three

predominant components “anions” in freshwater that the Myron L

Company calls “natural water”. These are modeled in a mixture called

“442” which the Myron L Company markets for use as a calibration

standard, as it does standard KCl and NaCl solutions.

The Ultrameter contains internal algorithms for these 3 most commonly

referenced compounds. In the LCD display, the solution type being used

is shown on the left. Besides KCl, NaCl, and 442, there is the “USER”

choice. The benefit of USER is that one may enter the temperature

compensation and TDS ratio by hand, greatly increasing accuracy of

readings for a specific solution. That value remains a constant for all

26

measurements, and should be reset for different dilutions or

temperatures.

C. When does it make a lot of difference?

First, the accuracy of temperature compensation to 25°C determines the

accuracy of any TDS conversion. Assume we have industrial process

water to be pretreated by R.O. Assume it is 45°C and reads 1500 µS

uncompensated.

1. If NaCl compensation is used, an instrument would report 1035

µS compensated, which corresponds to 510 ppm NaCl.

2. If 442 compensation is used, an instrument would report 1024

µS compensated, which corresponds to 713 ppm 442.

The difference in values is 40%.

In spite of such large error, some users will continue to take data in the

NaCl mode because their previous data gathering and process

monitoring was done with an older NaCl referenced device.

Those who want true TDS readings that will correspond to evaporated

weight will select the correct Solution Type. If none of the 3 standard

solutions apply, the User mode must be used. Temperature

Compensation (Tempco) and TDS Derivation below, details the USER

mode.

XVI. TEMPERATURE COMPENSATION (Tempco)

and TDS DERIVATION

The Ultrameter contains internal algorithms for characteristics of the 3

most commonly referenced compounds. In the display, the solution type

being used is shown on the left. Besides KCl, NaCl, and 442, there is the

“USER” choice. The benefit of USER mode is that one may enter the

tempco and TDS conversion values of a unique solution from the

keyboard.

A. Conductivity Characteristics

When making conductivity measurements, the Solution Selection

determines the characteristic assumed as the instrument reports what a

measured conductivity would be if it were at 25°C. The characteristic is

represented by the tempco, expressed in %/°C. If a solution of 100 µS at

25°C increases to 122 µS at 35°C, then a 22% increase has happened

over this change of 10°C. The solution is said to have a tempco of 2.2

%/°C.

27

Page 16

Another solution would have a different tempco because of its ionization

activity. And, that tempco may be a little different at a different

concentration or temperature. This is why the Ultrameter uses

mathematically generated models for known salt characteristics that vary

with concentration and temperature.

B. Finding the Tempco of an Unknown Solution

One may need to measure compensated conductivity of some solution

unlike any of the 3 standard salts. In order to enter a custom fixed tempco

for a limited measurement range, enter a specific value through the

“USER” function. The tempco can be determined by 2 different

methods:

XVII. GLOSSARY

Anions - Negatively charged ions.

See Solution Characteristics, pg. 26.

Algorithm - A procedure for solving a mathematical problem.

See Temperature Compensation and TDS Derivation,

pg. 27.

TDS - Total Dissolved Solids or the Total Conductive Ions

in a solution. See Conductivity Conversion to TDS,

pg. 26.

1. Heat or cool a sample of the solution to 25°C, and measure its

conductivity. Heat or cool the solution to a typical temperature

where it is normally measured. After selecting USER function,

set the tempco to 0 %/°C as in Disabling Temperature

Compensation, pg. 12 (No compensation). Measure the new

conductivity and the new temperature. Divide the % decrease

or increase by the 25°C value. Divide that difference by the

temperature difference.

2. Heat or cool a sample of the solution to 25°C, and measure its

conductivity. Change the temperature to a typical measuring

temperature. Set the tempco to an expected value as in User

Programmable Tempco, pg. 11. See if the compensated value

is the same as the 25°C value. If not, raise or lower the tempco

and measure again until the 25°C value is read.

C. Finding the TDS Ratio of an Unknown Solution

Once the effect of temperature is removed, the compensated

conductivity is a function of the concentration (TDS). There is a ratio of

TDS to compensated conductivity for any solution, which varies some

with concentration. The ratio is set during calibration in USER as in User

Programmable Conductivity to TDS Ratio, pg. 12. A truly unknown

solution has to have its TDS determined by evaporation and weighing.

Then the solution whose TDS is now known can be measured for

conductivity and the ratio calculated. Next time the same solution is to be

measured, the ratio is known.

Tempco - Temperature Compensation

See Temperature Compensation, pg. 23.

USER - A mode of operation that allows the instrument user

(operator) to set a tempco and/or a TDS factor for their

specific solution type. See Temperature Compensation,

pg. 23 and Temperature Compensation (Tempco) and

TDS Derivation, pg. 27.

For details on specific areas of interest refer to Table of Contents.

28

29

Page 17

Ultrameter™

Operation

Manual

Addendum

Models 4P & 6P

Software Versions 2.03, 2.10, 2.51 & Later*

* See page 5 to determine the version of software of your Ultrameter™.

UMMA10-01

WEB

Page 18

I. ENHANCED HIGH RESISTIVITY MEASUREMENTS

The resistivity calculations in the Ultrameter have been improved for

measuring waters greater than 10 Megohms. When the Ultrameter is in

one of the solution modes (i.e. KCl, NaCl or 442) and the resistivity

reading is greater than 10 Megohms, the Ultrameter performs automatic

temperature compensation for high purity water. As such, the maximum

possible value that should be displayed for water is 18.2. It may be

possible to display readings higher than 18.2 if the instrument is not

calibrated or if solutions other than water are being measured. To

insure proper use of the instrument in this mode, readings greater than

20 Megohms will display "- - - -" indicating an over-range condition. To

obtain resistivity readings for solutions other than water, the User

mode should be selected. In User mode the Ultrameter will display

resistivity measurements up to 30 Megohms.

An Offset Zero Calibration feature was added to software version

2.03, and must be performed by the user, see below. On all later versions

this function is performed at time of manufacture.

A Cell Check feature was added to these later versions. See page 2.

Offset Zero Calibration For Instruments with Software Version 2.03

When performing measurements of waters

above 10 Megohms, the

accuracy of the Ultrameter may be improved by performing an offset zero

calibration. Follow the steps below to perform an offset zero calibration.

Cell Check For Instruments with Software Version 2.10 & Later.

In these versions, a Cell Check feature has been added to further

increase the performance of your instrument. This is especially important

when in RES mode reading High Resistivity or Ultrapure waters. This

feature, utilizing technological improvements, knows when the

Conductivity Cell cup is dirty and calls it to your attention. You may then

choose to clean the Conductivity Cell cup or ignore it by pressing the

CAL key. Follow the steps below to perform a Cell Check.

1. Press key to power up the unit.

RES

2. Verify that the cell cup is empty

of any solution and "- - - -" is

displayed by the Ultrameter. If

a reading other than "- - - -" is

displayed, clean the cell cup

and repeat steps 1 & 2. See

"Cleaning Sensors".

Figure 2

3. Press the key until

MR

"CELL ch" appears. Fig. 2.

4. Press the key. If the cell

CAL

MCLR

1. Press key to power up the unit.

RES

2. V erify that the cell cup is empty of any solution and "- - - -" is

displayed by the Ultrameter. If a reading other than "- - - -" is

displayed, clean the cell cup and repeat steps 1 & 2. See

"Cleaning Sensors".

3. Press the key until

MR

"CAL0" appears. Fig. 1.

4. Press the key. The

instrument should momentarily

CAL

MCLR

Figure 1

display a number of counts, and return to Resistivity mode.

5. If the calibration has failed the display will show "Err". If an error

occurs during this step, the cell cup is probably contaminated.

Rinse the cup with DI water several times to clean and Repeat

steps 1-4.

1

is clean, “Good” will

momentarily be displayed. Fig. 3.

5. If the Cell Check has failed

the display will show

“CELL cLn”, Fig. 4, alternating

with a number such as “53”,

Fig. 5, indicating a relative

amount of contamination or dirt

in the Conductivity Cell. To

insure the highest quality

readings, the Conductivity Cell

cup should be cleaned before

measuring High Resistivity

solutions. Rinse the cup with

DI water several times to clean,

and Shake instrument well to

remove excess water.

Repeat steps 1-4.

Figure 3

Figure 4

Figure 5

2

Page 19

II. USER MODE CALIBRATION LINK

A new function has been added to the Ultrameter that makes calibration

of the unit while in "User" mode easier, and more repeatable and accurate

than other calibration methods. It is recommended that this calibration

method be used to provide the highest degree of confidence when the

Ultrameter is used in "User" mode.

A. Calibration of Ultrameter for use in User Mode

1. Press the or key to power up the Ultrameter.

COND

TDS

2. Calibrate the unit using a Standard Solution. Refer to

CALIBRA TION in Operation Manual.

3. Place the Ultrameter in User mode. Refer to SOLUTION

SELECTION in Operation Manual.

4. Verify/Set the calibration link. (See below – Setting User Mode

Calibration Link).

B. Setting User Mode Calibration "Link"

The link function sets or "links" the calibration gain factor of a Standard

Solution to the User solution mode. Once set, the "link" will stay intact

with future calibrations unless the link has been canceled. For more

information on canceling the User Mode Calibration Link refer to the

section below "Canceling User Mode Calibration Link". Follow the steps

below to set either the KCl, NaCl or 442 calibration factor to the User

solution mode.

4. Press the key. The

CAL

MCLR

instrument will display "SEL"

and the “User” Icon. Fig. 7.

User

Figure 7

Any additional display of KCl, NaCl or 442 icons indicates a link between

the User solution and the other solution displayed.

5. Press the keys to

MS

MR

KCl

select a Standard Solution to be

linked to the User mode

calibration constant.

User

(see Fig. 8, User linked to KCl).

Figure 8

Note: If none of the Solution Selection icons are displayed (i.e. KCl,

NaCl or 442) nothing has been linked to User mode.

6. Press the key to accept the setting. Pressing any of the

CAL

MCLR

measurement keys will exit without changing the setting. User

mode "link" is now complete. The User mode will now use the

calibration gain constant used for the calibration of the Standard

Solution as outlined above.

C. Canceling User Mode Calibration "Link"

1. Press measurement key desired to be “Linked”, i.e., ,

or .

TDSRES

2. Place the Ultrameter in User mode. Refer to SOLUTION

SELECTION in Operation

Manual for selecting the User

Mode.

3. Press the arrow key until

MR

the menu "Linc" appears.

Fig. 6.

Figure 6

3

COND

The Ultrameter must be in User linked mode in order to cancel the "link".

Refer to SOLUTION SELECTION in Operation Manual.

1. Press “Linked” measurement key , or .

COND

RES

TDS

Two solution icons will be shown the left side of display - “User”

and another, i.e., “KCl”.

2. Press the key until the menu "Linc" appears. Fig. 5.

3. Press the key, the unit will display "SEL" and the “User”

Icon.

MR

CAL

MCLR

4

Page 20

4. Press the key until "User" is the only solution icon being

displayed.

5. Press the key.

6. The User mode calibration "Link" has now been canceled.

NOTES:

1. To maintain repeatability, use the same standard solutions for future

calibrations.

2. Calibration of the Ultrameter Gain Factor for User mode is not available

when the calibration link has been established. The other calibration

functions (i.e. Temperature Compensation %/C settings and TDS Ratio

settings) are still intact. To perform a calibration of the User mode as

described in the manual, the User Mode Link should be canceled. See

above Canceling User Mode calibration "Link".

3. Once a "link" has been established for User mode, the "link" will apply

to all measurement modes using User solution selection (i.e. TDS/User,

Cond/User or Res/User).

* YOUR INSTRUMENTS SOFTWARE VERSIONCHECKING

1. Press key to power up the unit.

2. Press the key until three numbers are displayed as shown.

in Fig. 9. If one of the listed

versions is displayed, the

ENHANCED HIGH RESISTIVITY

MEASUREMENTS, and the

USER MODE CALIBRA TION

LINK are available.

3. Press key, instrument

will time out in ~15 seconds.

If one of the listed versions is NOT displayed, and these functions are

required, contact the Myron L Company for information on upgrading

your instrument.

5

MR

CAL

MCLR

COND

MR

COND

Figure 9

Loading...

Loading...