Page 1

Ultrameter

™

Operation

Manual

Model 3P

10 - 02 (WEB) EG

MYRON L

COMPANY

Page 2

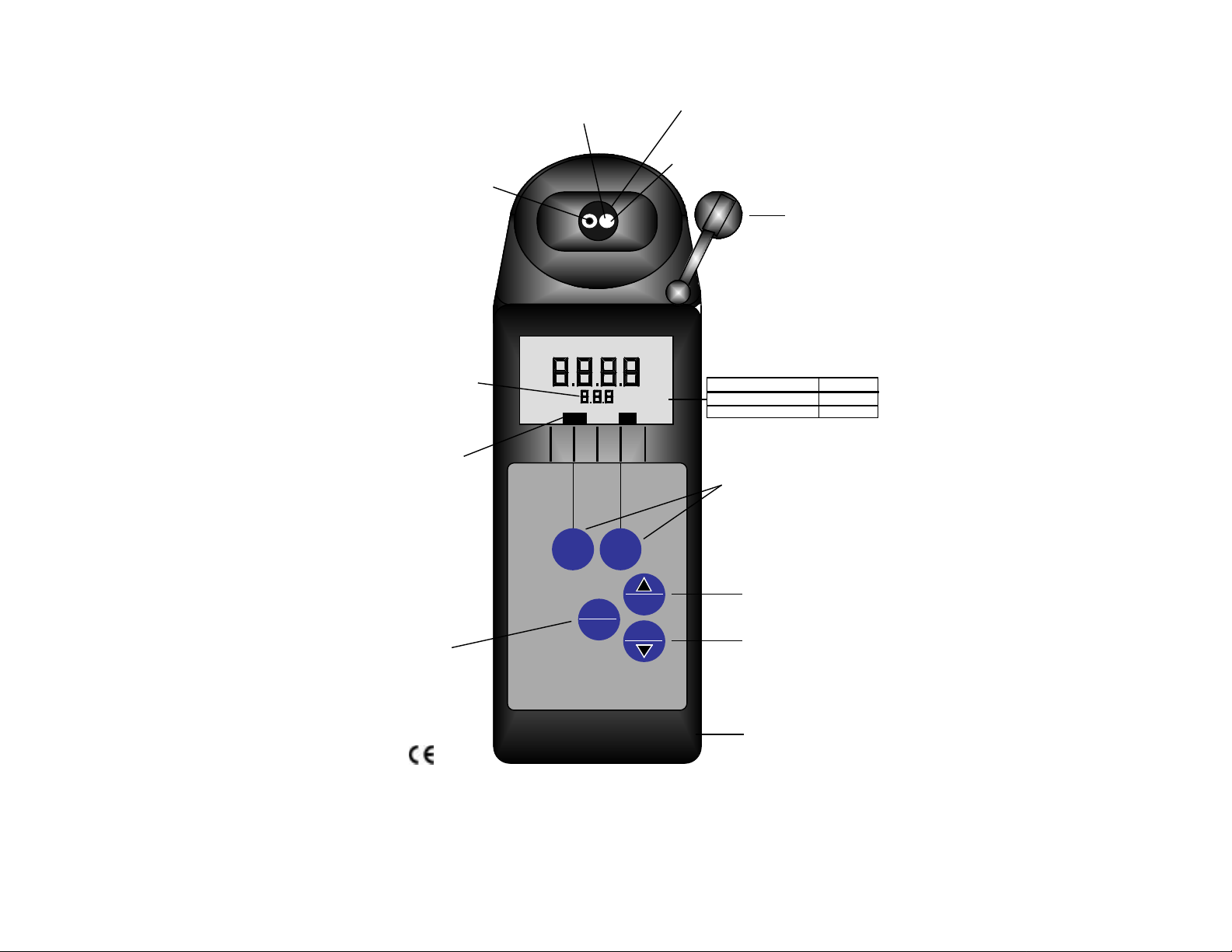

MS

MR

pH

MMYYRROONN LL

CCOOMMPPAANNYY

3P

ORP

These 2 Measurement keys will:

• Turn instrument on

• Measure parameter

• Exit any function

Parameters (2)

Wrist/neck strap slot

(user supplied)

pH/ORP Sensor

Protective Cap

This key for:

• Calibration

• Memory Clear

• Confirmation

Up key/Memory Store

Down key/Memory Recall

Displayed here:

• Temperature

readout

• Memory Storage/

Recall

• pH Calibration

Parameter

pH

ORP

Units of Measurement

None

mV - millivolts

* ™DuPont Company

** U.S. Patent #4128468

Teflon* Reference

Junction** under

Glass pH Bulb

ORP

Electrode

pH Glass

Electrode

pH/ORP Sensor

(Replaceable)

BUFFER

mV

°C% /

ORP pH

LOBATT CAL MEMORY

3-23-98

For detailed explanations see Table of Contents

Instrument Illustration

MCLR

CAL

1

ULTRAMETER

TM

Page 3

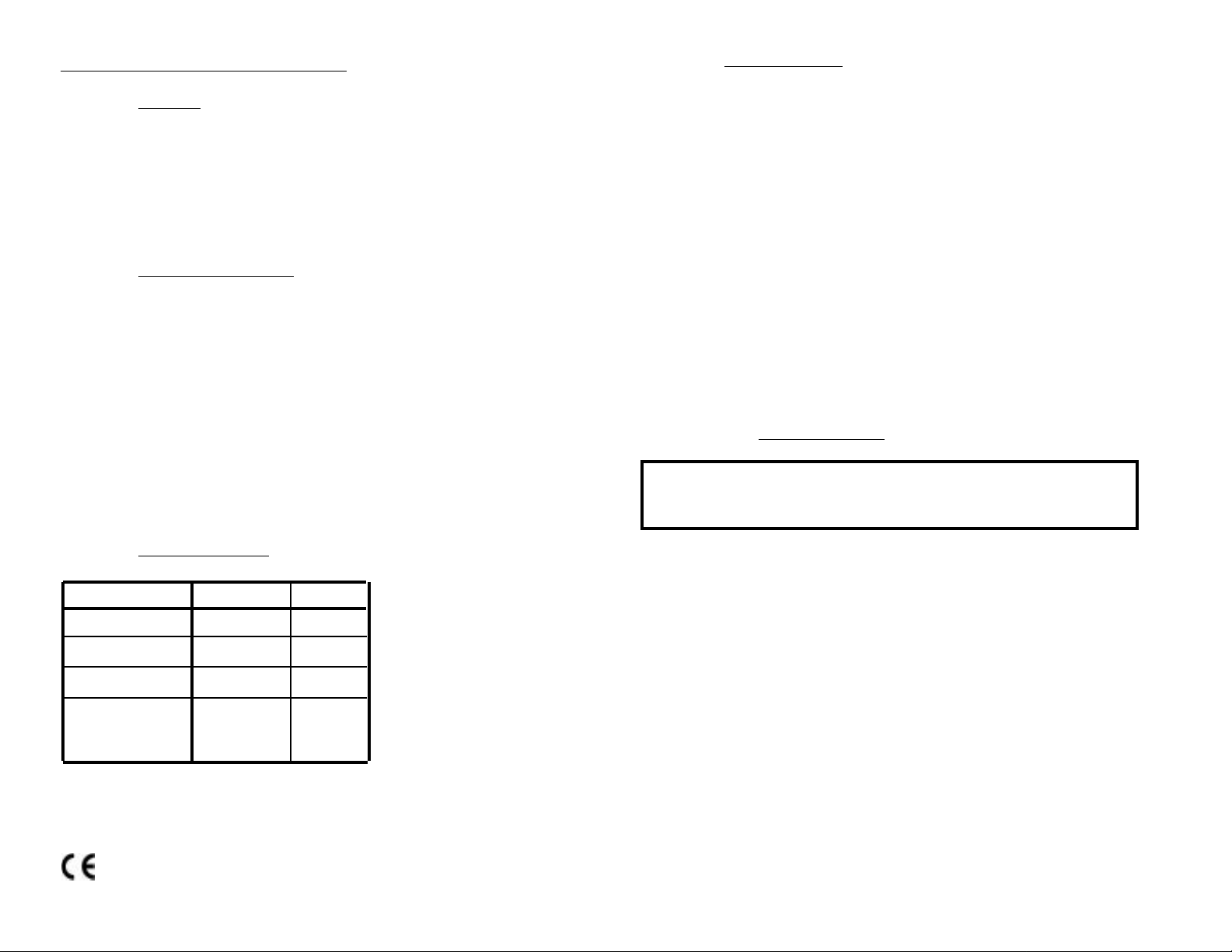

FEATURES and SPECIFICATIONS

A. Features

• Accuracy of ±.01 pH/±1 mV @ calibration point.

• All electrodes are internal for maximum protection.

• Waterproof to 3 feet/1 meter.

• Prompts for easy pH calibration.

• Memory saves 20 readings.

• Factory calibrations stored in microprocessor.

B. General Specifications

Display 4 Digit LCD

Dimensions (LxWxH) 7.7x2.7x2.5 in.

196x68x64 mm

Weight 13oz./369g

Case Material VALOX*

pH/ORP Sensor Well Capacity 0.04 oz./1.2 ml

Power 9V Alkaline Battery

Battery Life >100 Hours/5000 Readings

Operating/Storage Temperature 32-132°F/0-55°C

Protection Ratings IP67/NEMA 6 (waterproof to

3 feet/1 meter)

* ™ GE Corp.

D. Warranty/Service

All Myron L Ultrameters have a 2 year warranty except for pH sensors

which have a 6-month limited warranty. If an instrument fails to operate

properly, see the Troublshooting Chart, pg. 18. The battery and pH/ORP

sensor are user replaceable. For other service, return the instrument

prepaid to the Myron L Company.

MYRON L COMPANY

2450 Impala Drive

Carlsbad, CA 92010

USA

760-438-2021

If, in the opinion of the factory, failure was due to materials or

workmanship, repair or replacement will be made without charge. A

reasonable service charge will be made for diagnosis or repairs due to

normal wear, abuse or tampering. This warranty is limited to the repair or

replacement of the Ultrameter only. The Myron L Company assumes no

other responsibility or liability.

E. Ultrameter Models

ULTRAMETER MODELS

PARAMETERS pH/ORP/Temp. Conductivity/TDS Conductivity/TDS/pH

3P 4P 6P

Resistivity/Temp. Resistivity/ORP/Temp

C. Specification Chart

pH ORP3P

Ranges 0-14 pH ±999 mV

Resolution

±.01 pH ±1 mV

Accuracy ±.01 pH ±1 mV

Auto

Temperature

0-71°C

32 - 160°F

Compensation

Additional information available on our web site at:

www.myronl.com

2

3

Page 4

TABLE OF CONTENTS

VII. CHANGING from CENTIGRADE to FAHRENHEIT . . . . . . . . . . . .14

Instrument Illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

FEA TURES and SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . 2

A. Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

B. General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 2

C. Specification Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

D. Warranty/Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

E. Ultramter Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

I. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

II. RULES of OPERA TION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

A. Operation in a Nutshell . . . . . . . . . . . . . . . . . . . . . . . . . 6

B. Characteristics of the Keys . . . . . . . . . . . . . . . . . . . . . . 6

C. Operation of the Keys . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1. Measurement Keys in General . . . . . . . . . . . . 6

2. pH and ORP keys . . . . . . . . . . . . . . . . . . . . . . . 6

3. CAL/MCLR key . . . . . . . . . . . . . . . . . . . . . . . . . 7

4. UP or DOWN keys . . . . . . . . . . . . . . . . . . . . . . .7

III. AFTER USING the ULTRAMETER

Maintenance of the pH/ORP Sensor . . . . . . . . . . . . . . . . .7

IV. THE SPECIFIC RECOMMENDED MEASURING

PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

A. Measuring pH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

B. Measuring ORP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

V. CALIBRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

A. Calibration Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

B. Rules for Calibration in the Ultrameter . . . . . . . . . . . . . 9

1. Calibration Steps . . . . . . . . . . . . . . . . . . . . . . . .9

2. Calibration Limits . . . . . . . . . . . . . . . . . . . . . . . .9

C. Calibration Procedures . . . . . . . . . . . . . . . . . . . . . . . . 10

1. pH Calibration . . . . . . . . . . . . . . . . . . . . . . . . . 10

2. ORP Calibration . . . . . . . . . . . . . . . . . . . . . . . .12

3. Temperature Calibration . . . . . . . . . . . . . . . . 12

VIII. TOTAL RETURN to FACTORY SETTINGS . . . . . . . . . . . . . . . . . 14

IX. CALIBRA TION INTER VALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

A. Suggested Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . .15

B. Calibration Tracking Records . . . . . . . . . . . . . . . . . . . 15

C. pH and ORP Practices . . . . . . . . . . . . . . . . . . . . . . . . . 15

X. CARE and MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

A. Temperature Extremes . . . . . . . . . . . . . . . . . . . . . . . . 16

B. Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 16

C. pH/ORP Sensor Replacement . . . . . . . . . . . . . . . . . .16

D. Cleaning Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

XI. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

XII. ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

A. pH Buffer Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

B. pH Sensor Storage Solution . . . . . . . . . . . . . . . . . . . 19

C. Soft Protective Case . . . . . . . . . . . . . . . . . . . . . . . . . . 19

D. Replacement pH/ORP Sensor . . . . . . . . . . . . . . . . . .19

E. Data Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

F. Conductivity/TDS Standard Solutions . . . . . . . . . . . 19

XIII. pH and ORP MEASURING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

A. pH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

B. ORP/Oxidation-Reduction Potential/REDOX . . . . . .21

XIV. GLOSSARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

VI. MEMORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

A. Memory Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

B. Memory Recall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

C. Clearing a Record/Memory Clear . . . . . . . . . . . . . . . . 13

4

5

Page 5

I. INTRODUCTION

Thank you for selecting the Ultrameter™ Model 3P, one of the Myron L

Company’s latest in a new line of instruments utilizing advanced

microprocessor-based circuitry. This circuitry makes it extremely accurate

and very easy to use (see pages 2 & 3 for Features and Specifications on

this and other models). For your convenience, on the bottom side of your

Ultrameter is a brief set of instructions, and a pocket sized card with

abbreviated instructions is included with the instrument.

II. RULES of OPERATION

A. Operation

Using the instrument is simple:

• Rinse the pH/ORP sensor well with test solution 3 times and refill.

• Press the desired measurement key to start measurement.

Pressing the key again does no harm and restarts the 15 second

“off” timer.

• Note the value displayed or press the MS key to store

(ref. Memory Storage, pg. 12). It’s that simple!

B. Characteristics of the Keys

• Though your Ultrameter has a variety of sophisticated options, it

is designed to provide quick, easy, accurate measurements by

simply pressing one key.

• All functions are performed one key at a time.

• There is no “off” key. After 15 seconds of inactivity the

instrument turns itself off (60 seconds in CAL mode).

• Rarely will a key be required to be held down.

C. Operation of the Keys (See Instrument Illustration on page 1)

1. Measurement Keys in General

Both of the measurement keys in the upper part of the keypad turn on

the instrument in the mode selected. The mode is shown at the bottom

of the display, and the measurement units appear at the right. Pressing a

measurement key does this even if you are in a calibration sequence and

also serves to abandon a change. (ref. Leaving Calibration, pg. 9)

2. pH and ORP keys

Measurements are made on solution held in the pH/ORP sensor well (ref.

pH and ORP Measuring, pg. 19). The protective cap is removed and the

sensor well is filled and rinsed with sample enough times to completely

replace the storage solution.

After use, the pH/ORP sensor well must be refilled with Myron L Storage

Solution and the protective cap reinstalled securely (ref. Maintenance of

the pH/ORP Sensor, pg. 7 and Cleaning pH/ORP Sensors, pg. 16).

6

a. pH key

A press of displays pH readings. No units are displayed.

pH

b. ORP key

A press of displays Oxidation-Reduction Potential/REDOX

ORP

reading in millivolts.

3. CAL/MCLR key

A press of allows you to enter the calibration mode while

CAL

MCLR

measuring pH. Once in CAL mode, a press of this key accepts the new

value. If no more calibration options follow, the instrument returns to

measuring (ref. Leaving Calibration, pg. 9).

While reviewing stored records, the MCLR side of the key is active to

allow clearing records (ref. Clearing a Record/Memory Clear, pg. 13).

4. UP or DOWN keys

While measuring in any parameter, the or keys activate the

MS

MR

Memory Store and Memory Recall functions.

While in CAL mode, the keys step or scroll the displayed value up or

down. A single press steps the display and holding either key scrolls the

value rapidly.

While in Memory Recall, the keys move the display up and down the stack

of records (ref. Memory Recall, pg. 12).

III. AFTER USING the ULTRAMETER

Maintenance of the pH/ORP Sensor

The sensor well must be kept wet with a solution. Before replacing the

rubber cap, rinse and fill the sensor well with (in order of preference):

Myron L Storage Solution, an almost saturated KCl solution, pH 4 buffer

or at least a strong table salt solution. Not distilled water. (ref. Cleaning

pH/ORP Sensors, pg. 16).

IV. THE SPECIFIC RECOMMENDED MEASURING

PROCEDURES

NOTE

After sampling high concentration solutions or temperature

extremes, more rinsing may be required.

A. Measuring pH

1. Remove protective cap by squeezing its sides and pulling up.

7

Page 6

2. Rinse sensor well 3 times with sample to be measured. Shake

out each sample to remove any residual liquid.

3. Refill sensor well with sample.

V. CALIBRATION

A. Calibration Intervals

Generally, calibration with pH solutions should be checked twice a month.

Calibration of ORP is not necessary. (ref. Calibration Intervals, pg. 15)

4. Press .

pH

5. Take reading.

6. IMPORTANT : After use, fill pH/ORP sensor well with Myron L

Storage Solution, a strong KCl solution or pH 4 buffer, and

replace protective cap. Do not allow pH/ORP sensor to dry out.

NOTE: If none of the above are available, use a saturated solution of

table salt and tap water (ref. Cleaning pH/ORP Sensors, pg. 16).

B. Measuring ORP

1. Remove protective cap by squeezing its sides and pulling up.

2. Rinse sensor well 3 times with sample to be measured. Shake

out each sample to remove any residual liquid.

3. Refill sensor well with sample.

4. Press .

ORP

5. Take reading.

6. IMPORTANT : After use, fill pH/ORP sensor well with Myron L

Storage Solution, a strong KCl solution or pH 4 buffer and

replace protective cap. Do not allow pH/ORP sensor to dry out.

NOTE: If none of the above are available, use a saturated solution of

table salt and tap water (ref. Cleaning pH/ORP Sensors, pg. 16).

B. Rules for Calibration in the Ultrameter

1. Calibration Steps

a. Starting Calibration

Calibration is begun by pressing while measuring pH.

CAL

MCLR

Measuring continues, but the CAL icon is on, indicating calibration is now

changeable.

The reading is changed with the and to match the known

value.

MS

MR

b. Calibration Steps

Depending on what is being calibrated, there may be 1, 2 or 3 steps to

the calibration procedures.

CAL

The becomes an “ACCEPT” key. At each point, pressing

MCLR

CAL

MCLR

accepts the new calibration value and steps you to the next adjustment

(or out of CAL mode if there are no more steps).

To bypass a calibration step, just press to accept the present value

as is.

CAL

MCLR

c. Leaving Calibration

You know you are finished when the “CAL” icon goes out. Pressing

either measurement key abandons changes not yet accepted and exits

calibration mode.

Leaving pH after the 2nd buffer results in the same gain being entered in

place of the 3rd buffer.

In the first four sections, you have learned

all you need to make accurate measurements.

The following sections contain calibration,

advanced operations and technical information.

There are calibration limits. A nominal “FAC” value is an ideal value stored

by the factory. Attempts to calibrate too far from there will cause the

displayed value to be replaced with “FAC”. If you accept it, you will get the

2. Calibration Limits

original default factory calibration for this measurement. The need to

calibrate so far out that “FAC” appears indicates a procedural problem,

wrong standard solution, a very dirty cell cup or a dying pH/ORP sensor

(ref. Troubleshooting Chart, pg. 18).

8

9

Page 7

C. Calibration Procedures

1. pH Calibration

Important: Always “zero” your Ultrameter with a pH 7 buffer solution

before adjusting the gain with acid or base buffers, i.e., 4 and/or 10, etc.

a. pH Zero Calibration

1. Rinse sensor well 3 times with 7 buffer solution.

2. Refill sensor well with 7 buffer solution.

CAL

3. Press to verify the pH

pH

calibration. If the display

reads 7.0, skip the pH Zero

Calibration and proceed to

section b. pH Gain Calibration.

4. Press to enter calibration mode. The “CAL”, “BUFFER”

CAL

MCLR

Figure 1

BUFFER

pH

and “7” annunciators will appear (see Figure 1). Displayed value

will be the uncalibrated sensor.

NOTES: If a wrong buffer is added (outside of 6-8 pH),“7” and

BUFFER” will flash, and the Ultrameter will not adjust.

The uncalibrated pH value displayed in step 4 will assist in determining

the accuracy of the pH sensor. If the pH reading is above 8 with pH 7

buffer solution, the sensor well needs additional rinsing or the pH sensor

is defective and needs to be replaced.

5. Press or until the display reads 7.0.

MS

MR

6. Press to accept the new value. The pH Zero Calibration is

CAL

MCLR

now complete. You may continue with pH Gain Calibration or exit

by pressing either measurement key.

b. pH Gain Calibration

Important: Always calibrate or verify your Ultrameter with a pH 7 buffer

solution before adjusting the gain with acid or base buffers, i.e. 4 and/or

10, etc. Either acid or base solution can be used for the 2nd point “Gain”

calibration and then the opposite for the 3rd point. The display will verify

that a buffer is in the sensor well by displaying either “Acd” or “bAS”.

1. The pH calibration mode is initiated by either completion of the

pH Zero Calibration, or verifying 7 buffer and pressing the

twice while in pH measurement mode.

CAL

MCLR

2. At this point the “CAL”, “BUFFER” and “Acd” or “bAS”

annunciators will be lit (see Figures 2 and 3).

CAL

BUFFER

pH

CAL

BUFFER

pH

Figure 3Figure 2

NOTE: If the “Acd” and “bAS ” indicators are blinking, the unit is

indicating an error and needs either a acid or base solution present in the

sensor well.

NOTE: Attempted calibration of >1 pH point from factory calibration will

cause “FAC ” to appear. This indicates the need for sensor replacement

(ref. Troubleshooting Chart, pg. 18) or fresh buffer solution. The “FAC”

internal electronic calibration is not intended to replace calibration with pH

buffers. It assumes an ideal pH sensor. Each “FAC” indicates a factory

setting for that calibration step (i.e., 7, acid, base).

You can press to accept the preset factory value, or you can

reduce your variation from factory setting by pressing or .

10

CAL

MCLR

MR

MS

3. Rinse sensor well 3 times with acid or base buffer solution.

4. Refill sensor well again with same buffer solution.

5. Press or until display agrees with buffer value.

6. Press to accept 2nd point of calibration. Now the display

MS

CAL

MCLR

MR

shows the next type of buffer to be used.

11

Page 8

Single point Gain Calibration is complete. You may continue for

the 3rd point of Calibration (2nd Gain) or exit by pressing either

measurement key. Exiting causes the value accepted for the

buffer to be used for both acid and base measurements.

To continue with 3rd point calibration, use basic buffer if acidic

buffer was used in the 2nd point, or vice-versa. Again, match the

display to the known buffer value as in step 2 and continue with

the following steps.

7. Repeat steps 3 through 6 using opposite buffer solution.

8. Press to accept 3rd point of calibration which ends

Calibration Procedure. Replace protective cap.

2. ORP Calibration

ORP electrodes rarely give false readings without problems in the

reference electrode. For this reason, and because calibration solutions

for ORP are highly reactive and potentially hazardous, your Ultrameter

has an electronic ORP calibration. This causes the zero point on the

reference electrode to be set whenever pH 7 calibration is done.

3. Temperature Calibration

Temperature calibration is not necessary in the Ultrameter.

VI. MEMORY

This feature allows up to 20 readings with their temperatures to be stored

simultaneously for later recall.

A. Memory Storage

1. While displaying a measurement, press to record the

displayed value.

2. “MEMORY” will appear and

the temperature display will be

momentarily replaced by a

number (1-20) showing the

position of the record. Figure

4 shows a reading of 10.00 pH

stored in memory record #5.

B. Memory Recall

1. Press either measurement key.

2. Press , “MEMORY” will appear, and the display will show

the last record stored.

3. Press the or to scroll to the record location desired

(the temperature display alternates between temperature

recorded and location number).

4. Press a measurement key to leave memory recall or allow to

automatically turn off.

C. Clearing a Record/Memory Clear

After recalling a certain record location, press to clear that

memory . This space will be the place for the next memory record,

unless you scroll to another position before ending the recall

sequence. The next memory stored will go into the next highest

available memory location.

Example: You have locations 1-7 filled. You want to clear the ORP

reading stored in record location #3 and replace it with a pH reading.

1. Press and scroll to location #3 .

2. Press to clear old record #3.

3. Fill pH/ORP sensor well with sample.

4. Press to measure sample and press to store

reading in location #3.

5. The next memory stored will go into location #8.

6. To clear all records: After

pressing , scroll down

to “CLr ALL” in measurement

and temperature area

(see Figure 5).

7. Press . All records will be cleared.

12 13

CAL

MCLR

MS

pH

MR

CAL

MCLR

MS

MR

Figure 5

CAL

MCLR

MR

CAL

MCLR

MS

MR

Figure 4

pH

MEMORY

MEMORY

Page 9

VII. CHANGING from CENTIGRADE to FAHRENHEIT

1. Press .

2. Press to display the stored memory records.

pH

MR

3. Press repeatedly until

MR

you pass the CLr ALL and the

C-F locations. The display will

show a “FAC SEL”

(see Figure 8).

3. Press repeatedly until you pass the memory “CLr ALL”

MR

location”. The display will show a “C” or “F” (see Figures 6 & 7).

Figure 6 Figure 7

4. Press ; the display will change to the other unit.

5. Press ; all temperature readings are now in degrees last

CAL

MCLR

pH

shown.

NOTE: Units symbol “°F” is not displayed in Fahrenheit mode. Tempco

will still be shown in %/°C.

VIII. TOTAL RETURN to FACTORY SETTINGS “FAC SEL”

There may come a time when it would be desirable to quickly reset all the

recorded calibration values in the instrument back to the factory settings.

This might be to ensure all calibrations are set to a known value, or to give

the instrument to someone else free of adjustments or recorded data for

a particular application.

1. Press .

2. Press to display the stored memory records.

pH

MR

4. Press to accept the resetting.

CAL

MCLR

Figure 8

IX. CALIBRATION INTERVALS

There is no simple answer to how often one should calibrate an

instrument. The Ultrameter is designed to not require frequent

recalibration. The most common sources of error were eliminated in the

design, and there are no mechanical adjustments. Still, to ensure

specified accuracy, any instrument has to be checked against chemical

standards occasionally.

A. Suggested Intervals

On the average, the pH function should be checked every 2 weeks to

ensure accuracy. Measuring some solutions will require more frequent

intervals.

B. Calibration Tracking Records

To minimize your calibration effort, keep records. If adjustments you are

making are minimal for your application, you can check less often.

Calibration is purposely limited in the Ultrameter to ±1 pH unit because

more than that indicates the end of the sensor lifetime and it should be

replaced.

C. pH and ORP Practices to Maintain Calibration

1. Keep the sensor wet with Myron L Storage Solution.

2. Rinse away caustic solutions immediately after use.

ORP calibration solutions are not only caustic, but 5% is considered very

accurate. By using the pH zero setting (0 mV = 7 pH) for ORP and

precision electronics for detection, the Ultrameter delivers better

accuracy without calibration than a simpler instrument could using

calibration solutions.

14

15

Page 10

X. CARE and MAINTENANCE

Ultrameters should be rinsed with clean water after use. Solvents should

be avoided. Shock damage from a fall may cause instrument failure.

A. Temperature Extremes

Solutions in excess of 160°F/71°C should not be placed in the cell cup

area; this may cause damage. The pH sensor may fracture if the

Ultrameter temperature is allowed to go below -10°C (14°F). Care should

be exercised not to exceed rated operating temperature.

Leaving the Ultrameter in a vehicle or storage shed on a hot day can

easily subject the instrument to over 150°F. This will void the warranty.

B. Battery Replacement

Dry Instrument THOROUGHLY . Remove the four (4) bottom

screws. Open instrument carefully; it may be necessary to rock the

bottom slightly side to side to release it from the RS-232 connector.

Carefully detach battery from circuit board. Replace with 9 volt alkaline

battery. Replace bottom, ensuring the sealing gasket is installed in the

groove of the top half of case. Re-install screws, tighten evenly and

securely.

NOTE: Because of nonvolatile EEPROM circuitry, all data stored in

memory and all calibration settings are protected even during power loss

or battery replacement.

C. pH/ORP Sensor Replacement

Order model RPR. When ordering, be sure to include the model and

serial number of your instrument to ensure receiving the proper type.

Complete installation instructions are provided with each replacement

sensor.

D. Cleaning pH/ORP Sensors

The unique pH/ORP sensor in your Ultrameter is a nonrefillable

combination type which features a porous liquid junction. It should not be

allowed to dry out. If it does, the sensor can sometimes be rejuvenated

by first cleaning the sensor well with a liquid spray cleaner such as

Windex™ or Fantastic™ and rinsing well. Do not scrub or wipe the

pH/ORP sensor.

2. Pour DI water in the sensor well and allow to stand for no more

than 4 hours (longer can deplete the reference solution and

damage the glass bulb). Retest.

If neither method is successful, sensor must be replaced.

"Drifting" can be caused by a film on the pH sensor bulb. Spray a liquid

cleaner such as Windex™ or Fantastic™ into the sensor well to clean it.

The sensor bulb is very thin and delicate. Do not scrub or wipe the

pH/ORP sensor.

ORP

Electrode

Sensor

Body

pH Glass

Electrode

Reference

Junction

under Glass

pH Bulb

pH/ORP Sensor

Top View

Leaving high pH (alkaline) solutions in contact with the pH sensor for long

periods of time can damage it. Rinsing such liquids from the pH/ORP

sensor well and refilling well with Myron L Storage Solution, a saturated

KCl solution, pH 4 buffer, or a salty tap water will extend the sensor’s

useful life.

Samples containing chlorine, sulfur, or ammonia can "poison" any pH

electrode. If it is necessary to measure the pH of any such sample,

thoroughly rinse the sensor well with clean water immediately after taking

the measurement. Any sample element which will reduce (add an

electron to) silver, such as cyanide, will attack the reference electrode.

Replacement sensors are available only from the Myron L Company or its

authorized distributors.

Then use one of the following methods:

1. Pour a HOT salt solution ~60°C (140°F), preferably potassium

chloride (KCI) solution — HOT tap water with table salt (NaCl) will

work fine — in the sensor well and allow to cool. Retest.

Or

16

17

Page 11

displayed repeatedly

1. Temporary condition due to “memory”

of solution in pH sensor well for long

periods.

2. Bulb dirty or dried out.

3. Reference junction clogged or coated.

Will not adjust down to pH 7 pH/ORP sensor has lost KCl.

No response to pH changes Sensor bulb is cracked or an

electromechanical short caused by an

internal crack.

3. Calibration with expired pH buffers.

pH readings drift or respond

slowly to changes in

buffers/samples or “FAC” is

Inaccurate pH readings 1. pH calibration needed. (ref. pH Cal. pg. 10)

measurement key pressed

2. Cross-contamination from residual pH

buffers or samples in sensor well.

Symptom Possible Cause Corrective Action

No display, even though

Battery weak or not connected. Check connections or replace battery.

XI. TROUBLESHOOTING CHART

:

XII. ACCESSORIES

A. pH Buffer Solutions

pH buffers are available in pH values of 4, 7 and 10. Myron L Company

buffer solutions are traceable to NIST certified pH references and are

color-coded for instant identification. They are also mold inhibited and

accurate to within ±0.01 pH units @ 25°C. Order 4, 7 or 10 Buffer.

B. pH Sensor Storage Solution

Myron L Storage Solution prolongs the life of the pH sensor. It is available

in quarts and gallons. Order SSQ or SSG.

C. Soft Protective Case

Padded Cordura® Nylon carrying case features a belt clip for hands-free

mobility. Model: UCC

® Registered trade mark of DuPont

D. Replacement pH/ORP Sensor

Model RPR is gel filled and features a unique porous liquid junction. It is

user-replaceable and comes with easy to follow instructions.

E. Data Port

There is a 4 pin connector marked “Factory Use Only” on the bottom of

the Ultrameter. It is used to interrogate the instrument during final

inspection. Applications in the future for downloading recorded data are

being considered, but not implemented, as of this printing.

Clean and rejuvenate sensor (ref. Cleaning

pH/ORP Sensor, pg. 16) and recalibrate. If

no improvement, replace pH/ORP sensor

(ref. pH/ORP Sensor Replacement, pg.

16).

Clean and rejuvenate sensor (ref.

Cleaning pH/ORP Sensor, pg. 16) and

recalibrate. If no improvement,

replace pH/ORP sensor (ref. pH/ORP

Sensor Replacement, pg. 16).

18

Replace pH/ORP sensor (ref.

pH/ORP Sensor Replacement

pg. 16).

2. Thoroughly rinse sensor well.

3. Recalibrate using fresh buffers

(ref. pH Buffer Solutions, pg. 19).

(ref. Battery Replacement, pg. 16)

1. Recalibrate instrument

F. Conductivity/TDS Standard Solutions

For your other Myron L instruments, our NIST standard solutions are

available in a variety of salts and concentrations to fit your needs. Call or

write for information.

XIII. pH and ORP MEASURING

A. pH

1. pH as an Indicator

pH is the measurement of Acidity or Alkalinity of an aqueous solution. It is

also stated as the Hydrogen Ion activity of a solution. pH measures the

effective, not the total, acidity of a solution.

A 4% solution of acetic acid (pH 4, vinegar) - can be quite palatable, but a

4% solution of sulfuric acid (pH 0), is a violent poison. pH provides the

needed quantitative information by expressing the degree of activity

of

an acid or base.

19

Page 12

In a solution of one known component, pH will indicate concentration

indirectly. However, very dilute solutions may be very slow reading, just

because the very few ions take time to accumulate.

2. pH Units

The acidity or alkalinity of a solution is a measurement of the relative

availabilities of hydrogen (H ) and hydroxide (OH ) ions. An increase in

(H ) ions will increase acidity, while an increase in (OH ) ions will increase

-+

-+

alkalinity. The total concentration of ions is fixed as a characteristic of

water, and balance would be 10 mol/liter (H ) and (OH ) ions in a

-7 + -

neutral solution (where pH sensors give 0 voltage).

pH is defined as the negative logarithm of hydrogen ion concentration.

Where (H ) concentration falls below 10 , solutions are less acidic than

+

neutral, and therefore are alkaline. A concentration of 10 mol/liter of (H )

would have 100 times less (H ) ions than (OH ) ions and be called an

+

-7

-

9

+

-

alkaline solution of pH 9.

3. The pH Sensor

The active part of the pH sensor is a thin glass surface which is selectively

receptive to hydrogen ions. Available hydrogen ions in a solution will

accumulate on this surface and a charge will build up across the glass

interface. The voltage can be measured with a very high impedance

voltmeter circuit; the trick is to connect the voltmeter to solution on each

side.

The glass surface encloses a captured solution of potassium chloride

holding an electrode of silver coated with silver chloride. This is as inert a

connection as can be made from metal to an electrolyte. It still can

produce an offset voltage, but using the same materials to connect to the

solution on the other side of the membrane allows the 2 equal offsets to

cancel.

Glass surface

The problem is...the other side of the

membrane is some test solution,

H+ ions

Junction plug

not potassium chloride. The outside

electrode, also called the Reference

Junction, is of the same construction

with a porous plug in place of a glass

barrier to allow the junction fluid to

contact the test solution without

significant migration of liquids

through the plug material. Figure

9 shows a typical 2 component pair.

Migration does occur, and this limits

20

Electrode wire

Electrode wire

KCl solution

Figure 9

the lifetime of a pH junction from depletion of solution inside the

reference junction or from contamination. The junction is damaged by

drying out because insoluble crystals may form in a layer, obstructing

contact with test solutions. See Cleaning Sensors, pg. 16.

4. The Myron L Integral pH Sensor

The sensor in the Ultrameter (Figure 10)

is a single construction in an easily

Glass

Surface

H+ ions

Junction plug

Platinum button

replaceable package. The sensor body

holds an oversize solution supply for long

KCl solution

life. The reference junction “wick” is

porous teflon to provide a very stable,

low permeability interface. It is formed

in a ring around the pH sensing electrode.

Glass

Sleeve

The construction combines all the best

features of any pH sensor known.

5. Sources of Error

The basics are presented in Cleaning

Figure 10

Electrode wires

Sensors, pg. 16.

a. Reference Junction

The most common sensor problem will be a clogged junction because a

cell was allowed to dry out. The symptom is a drift in the “zero” setting at 7

pH. This is why the Ultrameter does not allow more than 1 pH unit of offset

during calibration. At that point the junction is unreliable.

b. Sensitivity Problems

Sensitivity is the receptiveness of the glass surface, which can be

diminished by a film on the surface, or a crack in the glass. These

problems also cause long response time.

c. Temperature Compensation

pH sensor glass changes its sensitivity slightly with temperature, so the

further from pH 7 one is, the more effect will be seen. A pH of 11 at 40°C

would be off by 0.2 units. The Ultrameter senses the cell temperature and

compensates the reading.

B. ORP/Oxidation-Reduction Potential/REDOX

1. ORP as an Indicator

ORP is the measurement of the ratio of oxidizing activity to reducing

activity in a solution. It is the potential of a solution to give up electrons

(oxidize other things) or gain electrons (reduce).

21

Page 13

Like acidity and alkalinity, the increase of one is at the expense of the

other, so a single voltage is called the Oxidation-Reduction Potential,

with a positive voltage showing a solution wants to steal electrons

(oxidizing agent). Chlorinated water will show a positive ORP value, for

instance.

2. ORP Units

ORP is measured in millivolts, with no correction for solution temperature.

Like pH, it is not a measurement of concentration directly, but of activity

level. In a solution of only one active component, ORP does indicate

concentration. Also, as with pH, a very dilute solution will take time to

accumulate a readable charge.

XIV. GLOSSARY

Logarithm - An arithmetic function. pH Units, pg. 20.

ORP - Oxidation-Reduction Potential or REDOX, See ORP/

Oxidation-Reduction Potential/REDOX, pg. 21.

3. The ORP Sensor

An ORP sensor uses a small platinum surface to accumulate charge

without reacting chemically. That charge is measured relative to the

solution, so the solution “ground” voltage comes from a reference

junction - same as the pH sensor uses.

4. The Myron L ORP Sensor

Figure 10 pg. 21 shows the platinum button in a glass sleeve. The same

reference is used for both the pH and the ORP sensors. Both pH and

ORP read out 0 for a neutral solution. Calibration at zero compensates for

error in the reference junction.

A zero calibration solution for ORP is not practical, so the Ultrameter uses

the offset value determined during calibration to 7 in pH calibration (pH 7

= 0 mV). Sensitivity of the ORP surface is fixed, so there is no gain

adjustment either.

5. Sources of Error

The basics are presented in Cleaning pH/ORP Sensors, pg. 16 because

sources of error are much the same as for pH. The junction side is the

same, and though the platinum surface will not break like the glass pH

surface, its protective glass sleeve can be broken. A surface film will slow

the response time and diminish sensitivity. It can be cleaned off with

detergent or acid, as with the pH glass.

For details on specific areas of interest refer to Table of Contents.

22

23

Loading...

Loading...