MYPIN

TA Series of Temperature Controller

Instruction Manual

Thank you for selecting our controller!

Before operating this instrument, please carefully read this

manual and fully understand its contents. If any probroms,

please contact our sales or distributors whom you buy from.

This manual is subject to change without prior notice.

Warning

Please do not connect your controller to main power until

all of your wiring is complete and checked.Otherwise electrical shock, fire or malfunction may result.

Do not wire when the power is on. Do not turn on the

power supply when cleaning this instrument. Do not

disassemble, repair or modify the instrument. This may

cause electrical shock, fire or malfunction.Use this instrument in the scope of its specifications. Otherwise fire or

malfunction may result. The internal relay’s service life is

greatly dependent on the current and voltage switched by

its contacts. Over-stressing the contacts with too much

current or switching vltage above the contact rating will

greatly shorten the life of the relay.

Caution

This instrument is not rated foroutdoor use and should be used in

a climate controlled environment.

Installing in an environment heavy laden with dust or containing corrosive gasses will cause your controller to fail.

Do not install near water spray, oil spray, or in an environment where water can condense inside the unit.

Avoid running power leads in parallel with high voltage or

heavy current carrying conductors that may induce high

voltages into the unit. If you must run incoming power

near high voltage or heavy current carrying conductors, we

suggest that you run the power inside metal conduit that is

grounded on one end only.

If installing in an electrically noisy environment, we suggest that you protect the unit with a current suppressor or

noise filter.

Applications

TA series of temperature controller is available for many TC

or RTD input, adopt some advanced techonology such multi

digital filter circuit, autotune PID, fuzzy PID that make it

is very precise, stable, strong anti-interference and

simple operation. The instrument is widely applied to

automation systems of mechanism, chemical industrial,

chinaware, light industrial, metallurgy and petroleum chemical

industrial. It is also applied to the production line of foodstuff,

packing, printing, dry machine, metal heat process equipment

to control the temperature.

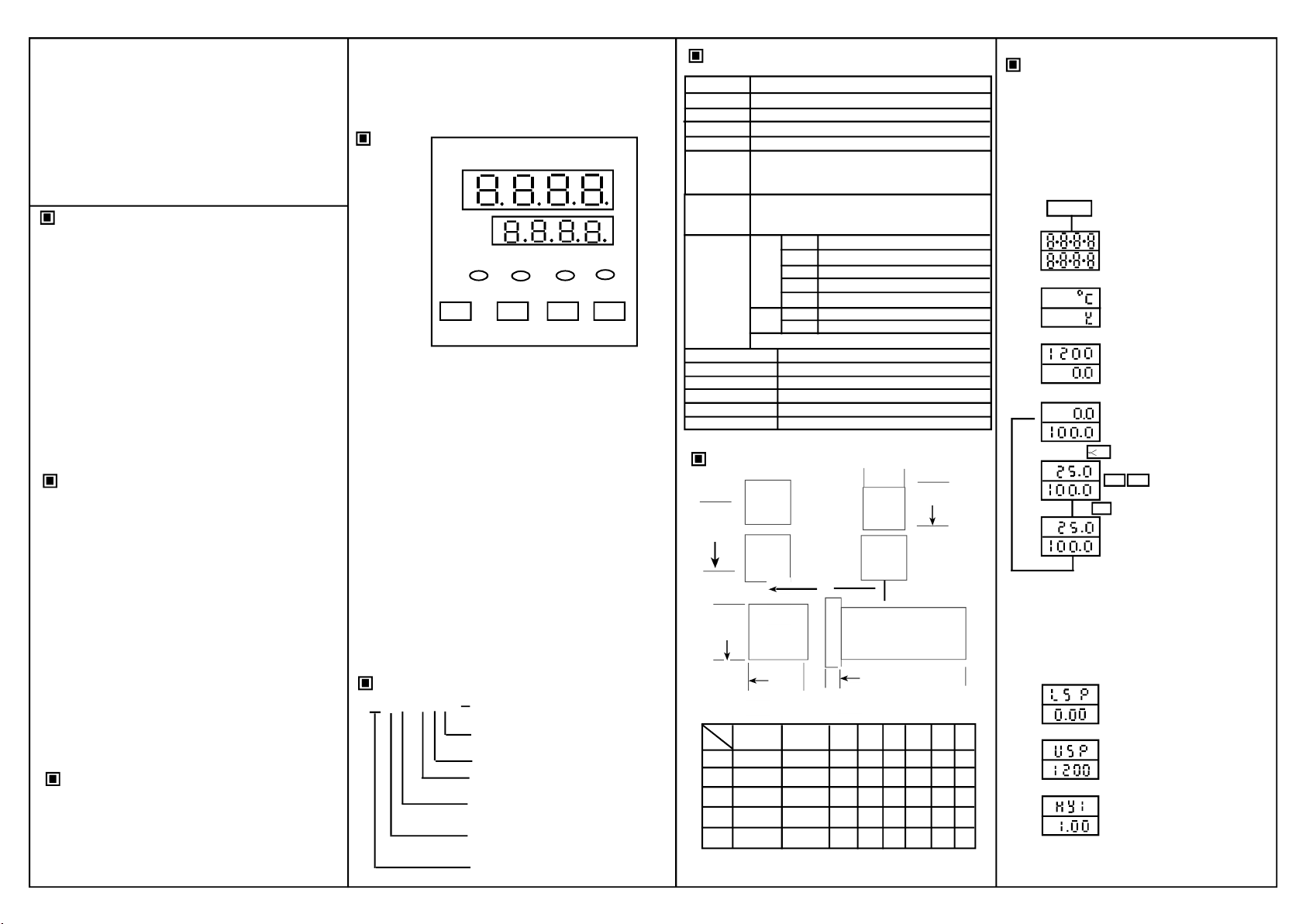

Panel

TEMPERATURE CONTROLLER

①

→

PV

SV

②

→

③

→

④

→

O U T 1 O U T 2

SET

>

>

/AT

>

>

↑↑

①. PV / parameter symbols

②. SV / parameters set value

③. Indication lamps

OUT1: Heating/Main control output lamp

On: Output Off: No output

OUT2:

On: Output Off: No output

AT: On: Autotune Off: Non-autotune

AL: Alarm 1 lamp On: Alarm Off: No Alarm

④.Set key Parameter Setting/Changing

⑤.Shift/Autotune key

Press this key to shift digit of parameter value setting.

Or hold this key for more than 3s can enter/quit autotune

estate. When enter autotune estate, AT lamp on. When

quit autotune estate, AT lamp off.

⑥.Up key ⑦.Down key

Alam2 output lamp

⑥⑤

℃

ATAL

⑦

↑

>>

TA

Models

□□ - □□□□

TA

7: 72H × 72W 8: 96H × 48W 9: 96H × 96W

Input signals:Default: K,J,E, S,PT100,Cu50

1:4-20mA/0-10V/0-75mV F: others

OUT2/AL2:R: RELAY S: SSR/Logic

T: SCR N: None

AL1:R:RELAY S:SSR/Logic T:SCR

OUT1: I: 4-20mA V:0-10V DC

R: RELAY S: SSR/Logic

Power supply: Default:90-260V AC/DC

E: 24VDC or 18-30V AC/DC

Sizes 4: 48H × 48W 6: 48H × 96W

TA series of temperature controller

Specifications

Power supply 90-260V AC/DC 50/60Hz

Consumption ≤ 5VA

Display range -199~1 800℃

Accuracy 0.3%F.S ± 2digit

Sampling cycle

Main output RELAY:normal open AC 250V/5A DC 30V/5A COS¢=1

Withstand voltage strength

Insulation resistance

Environment temperature

Storage temperature

Environment humidity

≤ 30 0ms

SSR/LOGIC:24V DC ± 2V/ 20mA

Alarm

Input

Weight

RELAY: normal open AC 250V/5A DC 30V/5A COS¢=1

SSR/LOGIC:24V DC ± 2V/ 30mA

K 0~1200℃(negtive temp customized)

T/C

J 0~1200℃(negtive temp customized)

T -150~400℃ (customized only)

S 0~1600℃

E 0~1000℃

Rt Pt100 -199~600℃

Cu50 -50~150℃

Please mention when ordering

Others

1500V Rms

Min 50MΩ(500VD C)(Between power terminal and the housing)

Mounting and Sizes

↑

+

(Between power terminal and the housing)

0~50℃

-10~60℃

35~85%RH

≤ 350g

A

↑

+

↑

↑

B

D

+

+

↑

C

↑

F

↑

↑

E

Sizes

A B C D E F G H

Model

TA4

44.5+0.5 45+0.5 65 65 48 48 8 80

TA6

43.5+0.5 91+0.5 65 115 48 96 12 80

TA7

67.5+0.5 67.5+0.5 115 115 72 72 12 80

TA8

91+0.5 43.5+0.5 65 115 96 48 12 80

TA9

91+0.5 91+0.5 95 95 96 96 12 80

G

H

↑

Parameter Setting

Setting steps

A: Select the parameter you want to modify

B: Press the

want to modify

C: Press key and key to modify the numerals

D: Press SET key to confirm

Power on

↓

In Non-autotune estate, press and hold / key for more

than 5 seconds can enter/quit the under menu: (Normally

the program will refresh the value of the parameters

by itself, the user no need make modifications. )

/AT key to select the digit you

<<

>

>>

↓

↓

↓

↓

↓

↓

↓

↓

>

Self-check

All LED on

3S

Displays temperature unit

Input type

3S

Input UP limit

Input LOW limit

3S

Measured displaying(PV)

Set displaying(SV)

/AT

Confirm

>

>

>>

Modify SV preset value

Shift and flashes

SET

Stop flashing

Low display value, it is adjustable by the input signal.

eg. K type 0-800C, LSP=0.0

SET

Up display value, it is adjustable

by the input signal.

eg. K type 0-800C, USP=100.0

SET

AL1 hysteresis setting value.

Range ± 90, factory setting 1.0

SET

>

>

>>

AL2 hysteresis setting value.

Range ± 90, factory setting 1.0

SET

↓

Decimal point setting:

0: INT display 1: One decimal point

SET

↓

Password setting.

Factory setting 015

------------------------------------------

HOLD SET

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

>3 S

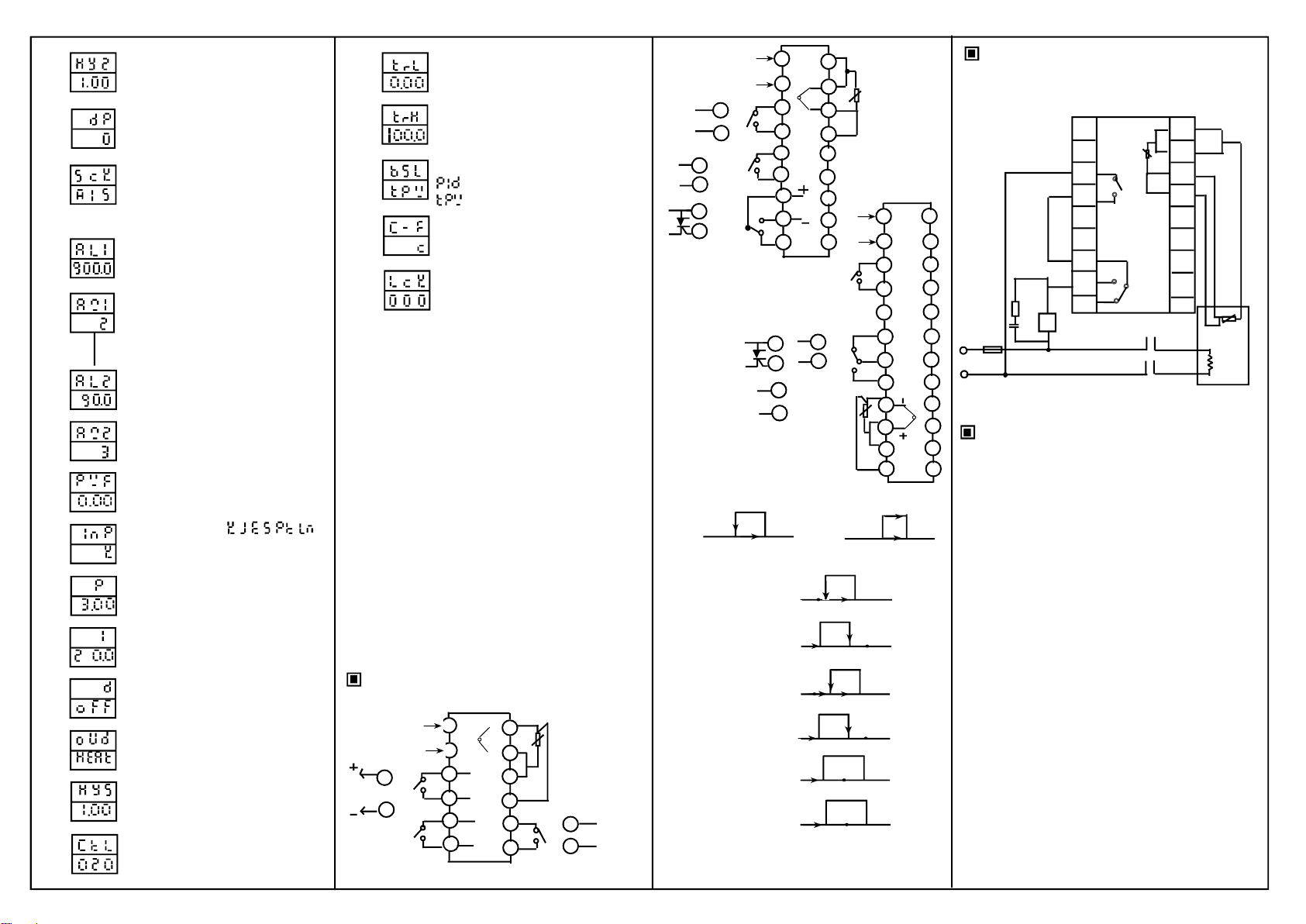

AL1 set range: –1999-9999

AL1 mode:

SET

0: Deviation HI alarm 1: Deviation LO alarm

2: PV HI alarm 3: PV LO alarm

4: SV-PV > AL1 alarm 5: SV-PV <AL1 alarm

SET

6: TC broken alarm, 7:The first Low won’t alarm

The factory setting is 2

AL2 set range: –1999-9999.

SET

AL2 mode: The same as AL1.

SET

Offset value,range: ±100.

Display valuePV = Measured value - PVF

SET

Input signal selection

stands for K, J, E, S,Pt100,Cu50 or mA/V/mV

The factory setting is K

SET

Proportional band (%) range 0.1-3600.

If P=OFF, it means ON/OFF control

SET

Integral time range 0.1-3600.

I=OFF means cancel integral time.

SET

Derivative time range 0.1-3600. D=OFF means

cancel derivative time.

SET

Control directions: HEAt: heating

COOL: cooling

SET

↓

Control hysteresis, range: ± 100.

It is not available when P≠ OFF

SET

↓

Control Cycle Time(adjust to best fit your process)

Recommended starting settings: Relaly = 020sec

SSR =001sec. 4-20mA = 000 sec.

SET

Low analog output (when available)

for 4-20mA output, trL=10

℃

℃

for 4-20mA output, trH=100

Note:

eg. 10-100

SET

↓

High analog output(when available)

eg. 10-100

SET

↓

Only function for 4-20mA/0-10V

means PID control;

means 4-20mA/0-10V analog output

SET

↓

Temperature unit. C: ℃ degree,

F: F degree.

SET

↓

Parameter lock code setting. LcK=000

means unlocked. LcK=010 means locked.

Please operate according to the process in this instruc

tion manual. Press <</AT key2s to enter auto-tune mode,

AT lamp ON, it goes off when auto-tuned.

In most cases you should start-out by placing your con

troller in auto-tune mode. Once auto-tuned, your con

trollers should not require additional auto-tune cycle if

the environment its working in changes little. If your

controllers is being used to heat or cool a load with a large

thermal mass, then the auto-tuned values need to be re

duced by 5% -10%.

The CtL setting.In most cases our control cycle should be

set to 10-20 seconds. For heating or coolin a load with a

large thermal mass, the value should be set to 30-40

seconds. If you are using a controller with a relay, setting

longer values will help to extend the life of your relay

contacts. Unless your process dictates longer cycle times,

the value should be set to 1-3 seconds to non-relay(SSR)

controls.The value should be set to 000 if 4-20mA cur

rent controls.

Terminal configurations

(If any changed, please refer to the product showing.)

←

B

-

90-260V AC/DC

3

OUT1

4-20mA

Relay

4

AL1

1

2

3

4

5

6

-

SSR

+

-

SSR

+

7

RTD

←

TC/mV

8

+

A

9

1 0

B

1 1

1 2

AL2

1 1

1 2

-

SSR

+

TA4

SSR

+

SSR

-

T1

▲

T2

90-260V AC/DC

+

AL1

3

Relay

4

-

7

8

OUT2/AL2

OUT1

7

Relay

9

G

COM

NO

NC

TA7

1

2

3

4

5

6

7

8

9

TC

A

1 0

-

1 1

RTD

B

+

1 2

B

1 3

1 4

1 5

4-20mA

1 6

1 7

1 8

AL1

1

2

90-260V AC/DC

3

4

5

T1

T2

4-20mA

TA6/TA8/TA9

on the product.

ON/OFF control: ▲ Set value

Heating

are subject to the drawing

←

ON OFF

HYS

LO HI

Alarm mode:▲ Set value △ Alarm value AL

0:Deviation HI alarm

1: Deviatian LO alarm

+

6

SSR

▲

8

-

G

+

6

8

-

↑

▲

LO HI

LO HI

2: Absolute value HI alarm

LO HI

3: Absolute value LO alarm

4: Section outside alarm

5: Section inside alarm

ON OFF

LO HI

OFF ON OFF

Note:

OFF ON

ON OFF

ON OFF ON

COM

7

NO

8

OUT1

NC

RTD

Cooling

OFF ON

LO HI

HY

↑

▲ △

HY

↑

←

△ ▲

OFF ON

HY

↑

▲ △

HY

↑

←

△ ▲

△ ▲ △

HI

△ ▲ △

HI

B

A

B

▲

▲

←

←

1 0

1 2

6

7

8

9

1 1

HYS

TC

↑

↑

All the factory setting value of deiation alarm is 1.0.

Application examples

1.Relay output control (for TA7)

←

1 3

1 4

1 5

1 6

1 7

1 8

1 9

90-260V AC

FUSE

Power supply

1

←

2

3

4

AL1

5

6

OUT1

7

8

R

J

9

C

NC

J-1

P t

NO

10

11

12

13

14

15

16

17

18

2 0

2 1

2 2

2 3

2 4

Malfunction estimate

①

No Display : Check all the connection and wiring if it is all

correct. Specially pay attention to the power supply terminals and

signal input ternimals.

Incorrect Didplay: Check if the input signal is conformity with

②

the selected symbol.

For TC input, please use the relative compensation cable.

For RTD input, please use low impedence cable. The 3 wires

should at the same length.

If all above mentioned is collect , pleaase use parameter

PVF to modify.

③ Incorrect Control :

time, the user find the temperature is hard to rise up to the set

value, meanwhile the outsidesystem running well, there must be

something wrong with the parameters of the instrument.

The user need to re-autotuning the instrument. If the instrument

lost control, please check if the connection of the control is correct.

If external load is shorted, broken, wrong connection or components is damaged, it will cause lost control as well.

Display malfunction : “UUUU”: The input signal exeed

④

the measured range, or check “USP” value.

If the instrument has been used for a long

RTD

Heating cord

Heating

equipment

Loading...

Loading...