Thank you for purchasing the MC10 CONVUM ejector. Please read the instruction manual thoroughly and make sure that you understand the operation

MC10 CONVUM instruction manual

procedures before using the product. This manual is important for future reference, so please keep it where it can be easily retrieved.

・The precautions described are intended for safe use of the product and to avoid bodily injury and damages.

・The precautions are divided into the three levels of [DANGER], [WARNING], [CAUTION] by the degree of bodily

injury or property damage that may be caused by improper handling of the product.

・Please make sure to read and understand all matters related to safety.

DANGER: Improper handling that may cause imminent danger and cause serious injuries or death.

WARNING: Improper handling that may cause danger and cause serious injuries or death.

CAUTION: Improper handling that may cause injuries or damage to property.

Caution regarding usage―――――――――――――――――――――――――――――――――――――

DANGER

・Please do not use in environments containing inflammable gas.

WARNING

・Make sure to design your system safely so that accidents cannot occur due to power failure or reduced vacuum

pressure. If there is a drop in vacuum pressure that causes the suction pads to lose their grip, the work pieces handled

will be dropped during transportation and may cause injuries and mechanical damage. Therefore, please make sure to

install a safety device that will protect against falling work pieces.

・When continuously using and having electricity applied to the electromagnetic valve for a long time, packings and

gaskets may be damaged due to overheating of the solenoid, which may cause air leakage and poor operation.

・Please make sure to use clean air. Do not use compressed air containing corrosive gases, chemicals, salty materials,

etc., as it may cause damage or malfunction.

・Please do not use this product in environments where corrosive gases, chemicals, seawater or steam are present, as it

may result in damage or poor operation.

・If the product is subjected to direct sunlight, please provide it with a cover.

・Please do not subject the product to heat radiation.

・If placing the product inside the control panel, please make sure that the temperature range is kept within the

temperature range specified for the product.

・Make sure not to subject the product to welding spatter that may cause burning of plastic parts and fires.

・Please do not use the product where there are strong magnetic fields or high-current electricity (large magnetic coils

or spot welders, etc.) that may cause malfunction of the vacuum sensor.

・Please do not use the product in places where the vacuum sensor and the electromagnetic valve may be subjected to

water, as this may cause short circuits or burning of the coil. Protect the product with a cover or install it inside a

panel.

・Please do not use the product where it may be subjected to strong shocks, as this may cause malfunction.

CAUTION

・When connecting two or more suction pads to one vacuum ejector and one work piece is removed from one of the

suction pads, the other suction pad(s) will also drop their work pieces. This happens because the vacuum pressure

drops when one work piece is removed from one of the suction pads.

・Please do not activate the electromagnetic valve for blow-off during vacuum generation, as the vacuum supply will be

broken, which may cause troubles.

・Please make sure to confirm the specifications and do not use the product outside of the specified pressure and

temperature ranges, as it may result in damage and malfunction.

・Please install an air filter. If there is any chips or foreign matters inside the piping, it may cause lowered performance

of the ejector. Please use an air filter with a minimum filtration rate of 5 µm at the supply port of the ejector.

・Please install an air dryer. Compressed air containing drainage may cause malfunction and lowered performance of

vacuum devices. By installing an air dryer, the humidity of the compressed air will be lowered and the drainage reduced.

・Please install a sludge filter or a mist cleaner. If sludge (deteriorated residue of compressor oil) enters the vacuum

devices, it may cause malfunction.

・Please use the product without lubrication. If using lubricator, oil will stick to the nozzle of the ejector, the diffuser and

the silencer element, which may cause a drop in vacuum pressure.

・In order to avoid drainage and solidification of water in the compressed air, please install an air dryer if the product is

used at temperatures lower than 5˚C.

・The vacuum ejector may not be subjected to shocks stronger than 147/S2 (15G) or vibrations stronger than 39.2 m/S2

(4G). If subjected to shock and vibration values above these, it may cause the vacuum ejector to malfunction.

INSTALLATION―――――――――――――――――――――――――――――――――――――――――

WARNING

・Please fasten the connectors with correct force to the vacuum ejector ports. Loose connections may cause the vacuum ejector to be disconnected.

・Please do not activate the system until you have checked that the devices work properly. After installing, please connect the compressed air and the power supply, and check that there is no leakage.

・Please make sure that there is enough space for maintenance and filter replacement, etc.

CAUTION

・Please do not erase or remove model nameplates, etc.

・Please tighten each screw to the following torques: M2.0: 0.07 (N·m), M2.5: 0.16 (N·m), M3:0.59 (N·m), M4: 1.37 (N·m), M5:2.84 (N· m) .

PIPING―――――――――――――――――――――――――――――――――――――――――――――

CAUTION

・Please do not use spiral piping. Using spiral piping for the vacuum line may cause delay in reaching the maximum vac-

uum level and reduced flow, causing drop in vacuum pressure and malfunction.

・When using manifolds, please pay attention to their diameter. Depending on the number of units connected to the

manifold, the flow may become insufficient. Please connect pipes for supply to both sides of the manifold.

・Please flush the interior of the piping to make sure it is free of cutting particles, oil and dust before connecting it to

the vacuum ejector.

・Do not reverse the connection of piping. Please refer to the catalogue for correct connection to the compressed-air

supply port and the vacuum port.

・When connecting the piping and fittings, please make sure that there are no cutting particles or sealing material in the

pipes. Please tighten each screw to the following torques: Rc1/8: 7.0 – 9.0 (N·m), Rc1/4: 7.0 – 9.0 (N·m).

・Compressed-air supply side (P port): Supply pressure: 0.3 – 0.4 (MPa). If using a manifold and operating all units simultaneously, the vacuum pressure may drop, so please increase the pressure by 0.05 (MPa) – 0.1 (MPa). If the manifold is

connected to a minimum of five units, please connect the pipes to both sides of the manifold. Please separate the air

supply from other actuators and connect the air supply to the manifold as close as possible to the compressed-air

supply source.

・If the piping to the vacuum pad connection (V port) is too narrow or too long, the vacuum pressure might remain at a

high level and the vacuum sensor might remain ON. Please try using a larger pipe diameter or shorten the length of the

piping.

WIRING――――――――――――――――――――――――――――――――――――――――――――

WARNING

・Make sure to carry out wiring work after having turned off the compressed-air supply and the electric power. If not turning

these off when carrying out wiring work, electrical shock or malfunction may cause bodily injury or property damage.

・Please make sure not to reverse the wiring. When wiring to the electromagnetic valve, check the lead colour indicating

the polarity, the code, the catalogue and the product itself to make sure the wiring is carried out correctly. If the wiring

is incorrect, no switching of the electromagnetic valve will take place.

・Please make sure not to bend the lead wire or to apply repeated tensile stress to it. The lead wire may break if subjected to repeated bending or tensile stress. Please leave some slack in the wiring.

・Please make sure to use the correct voltage. If connecting incorrect voltage to the electromagnetic valve, it will result

in malfunction and damage to the coil. After having done the wiring, please make sure that it is correct.

・Please do not carry out the wiring together with the power supply and high-voltage cables. When installing at the

power line and moving parts, do not install so that the lead wire of the electromagnetic valve is subjected to tensile

stress, as this will cause malfunction and breakage of the lead wire. (When installing on a moving part, make sure to

fasten the lead wire and ensure that the connectors do not move.)

・When installing to a moving part, please not connect so that the lead wire of the electromagnetic valve is subjected to

tension, as this may lead to poor connection or breakage of the lead wire. (When installing on a moving part, make sure to

fasten the lead wire and ensure that the connectors do not move.)

MAINTENANCE――――――――――――――――――――――――――――――――――――――――

WARNING

・In order to ensure proper quality of the air, please drain the air filter at regular intervals.

・Please do not disassemble the vacuum ejector. Disassembly may cause loss of the internal components or damage to

the vacuum ejector.

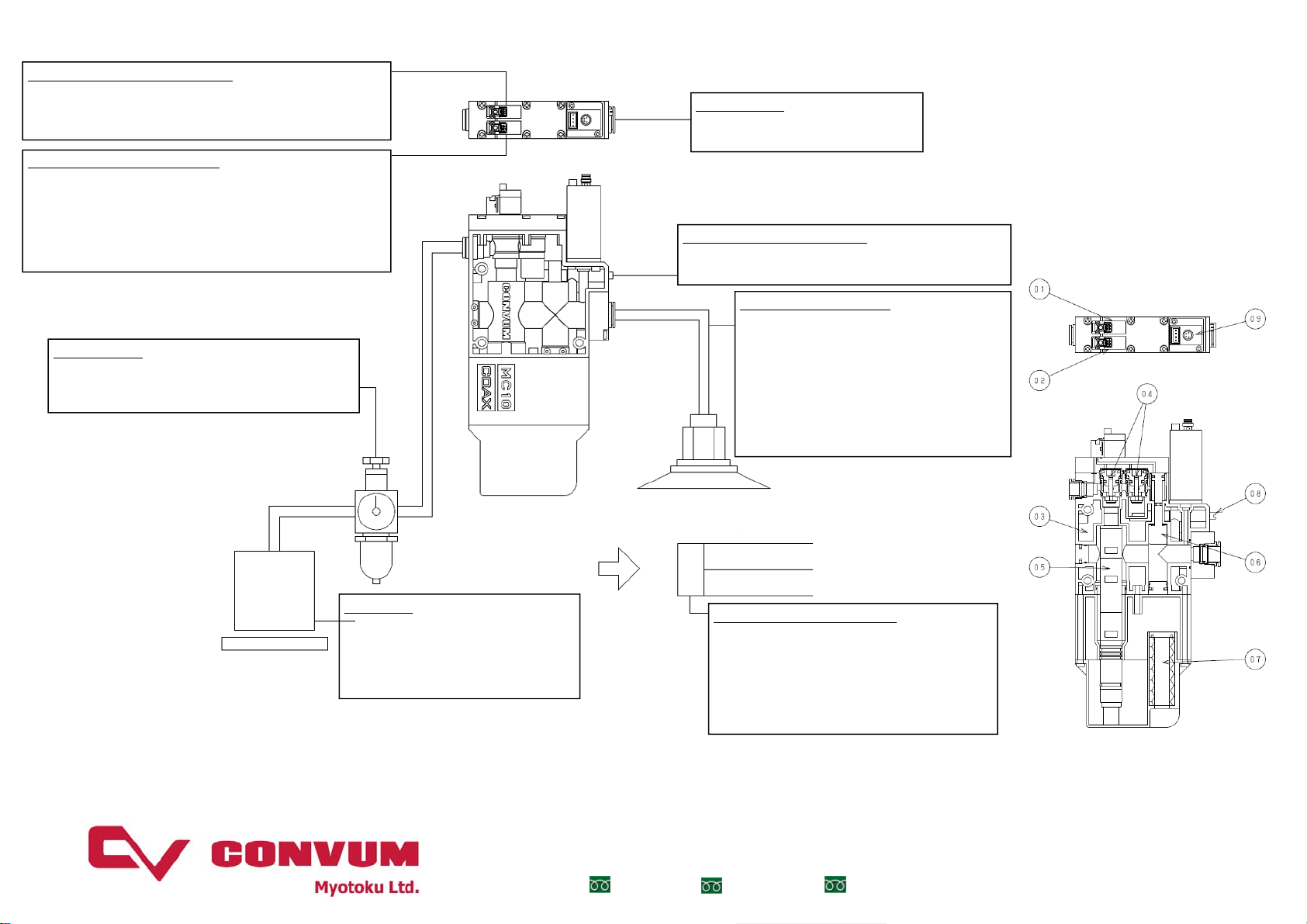

■ MC10 CONVUM vacuum ejector Instruction manual (● Functions / ◎ Precautions)

Solenoid valve (blow-off generation)

●This solenoid valve controls blow-off generation.

◎If contaminants enter the valve, it will lead to malfunction.

Please take necessary measure to prevent it.

Solenoid valve (vacuum generation)

●This solenoid valve controls vacuum generation.

When the airflow route is closed, no electricity is supplied and no

vacuum is generated, and when electricity is supplied vacuum is

generated.

◎If contaminants enter the valve, it will lead to malfunction.

Please take necessary measure to prevent it.

Filter regulator

◎Please set the supply pressure within the range of

0.1-0.55 MPa.

◎Please do not use any lubricator.

Vacuum sensor

●Sensor sends an output signal when

set pressure value is reached.

Blow-off flow adjustment needle

●Turning the needle to the right decreases the blow-off

air and turning it to the left increase the blow-off air.

Piping at the vacuum port

◎Please make sure to use a tube that is larger in diameter than 2. 5 mm at the vacuum

port.

◎If the piping is too narrow or too long at the

vacuum port, the resistance of the piping will

be higher. Be aware of this, otherwise the

vacuum performance will be reduced, resulting in poor grip of the suction pads.

Construction

Parts

01: Solenoid valve (vacuum generation)

02: Solenoid valve (blow-off generation)

03: MC10 body

04: Poppet valve

05: Nozzle kit

06: Sealing plug

07: Silencer

08: Blow-off flow control needle

09: Pressure sensor

Air compressor

Compressor

●While the CONVUM ejector is generating vacuum, air is consumed, so

please make sure that the capacity of

the compressor is sufficient even for

other actuators.

Home page http://www.convum.co.jp

E-mail faq@convum.co.jp

Suction pad

0120-340095

Air cylinder

To other pneumatic equipments

◎Please branch the piping to the air-pressure

actuator (air-pressure cylinder) and to the CONVUM ejector as close to the air source

(compressor) as possible. (If not doing so, the

supply pressure and flow to the CONVUM ejector will be reduced, resulting in insufficient

vacuum performance.)

0120-498586 0120-41564 Customer service center:

MANUAL No.MC10-000-M002

Loading...

Loading...