MM-SDM630-2C

Multi-Channel DIN Rail Smart Energy Meter

DIN RAIL SMART METER

FOR SINGLE AND THREE PHASE

ELECTRICAL SYSTEMS

USER MANUAL V4.1

1. Introduction

MM-SDM630-2C measures and displays the characteristics of

two three phase four wires circuits or 6 single phase circuits,

including voltage, frequency, current, power and active and

reactive energy, imported or exported. Energy is measured in

terms of kWh, kVArh. Maximum demand current can be

measured over preset periods of up to 60 minutes. In order

to measure energy, the unit requires voltage and current

inputs in addition to the supply required to power the

product. The requisite current input(s) are obtained via

current transformers (CT).

This meter can be congured to work with a wide range

of CTs, giving the unit a wide range of operation. Built-in

interfaces provide pulse and RS485 Modbus RTU outputs.

Conguration is password protected.

1.1 Unit Characteristics

The Unit can measure and display electronic information of

multi-channels:

• L-N voltage and THD% (total harmonic distortion) of

all phases

• Line Frequency

• Currents, Current demands and current THD% of all

phases

• Power, maximum power demand and power factor

• Active energy imported and exported

• Reactive energy imported and exported

The unit has password-protected set-up screens for:

• Changing password

• Supply system selection 1phase2wire, 3phase 4wires

• CT Ratio (1 to9999 )

• PT ratio (1 to 9999)

• Demand Interval time

• Reset for demand measurements

• Pulse output duration

A pulse output indicates real-time energy measurement. An

RS485 output allows remote

monitoring from another display or a computer.

1.2 Current Transformer Primary Current

The unit can be congured to operate with CT ratio between

Primary Current and Secondary Current. The secondar y CT

has two options: 1A / 5A

1.3 RS485 Serial - Modbus RTU

This uses an RS485 serial port with Modbus RTU protocol

to provide a means of remotely monitoring and controlling

the Unit

Set-up screens are provided for setting up the RS485 port.

1.4 Pulse Output

This provides 2 pulse outputs referring the energy consump-

tion of two circuits. Both pulse outputs are congurable.

The pulse width for active energy can be set from the Set-up

menu.

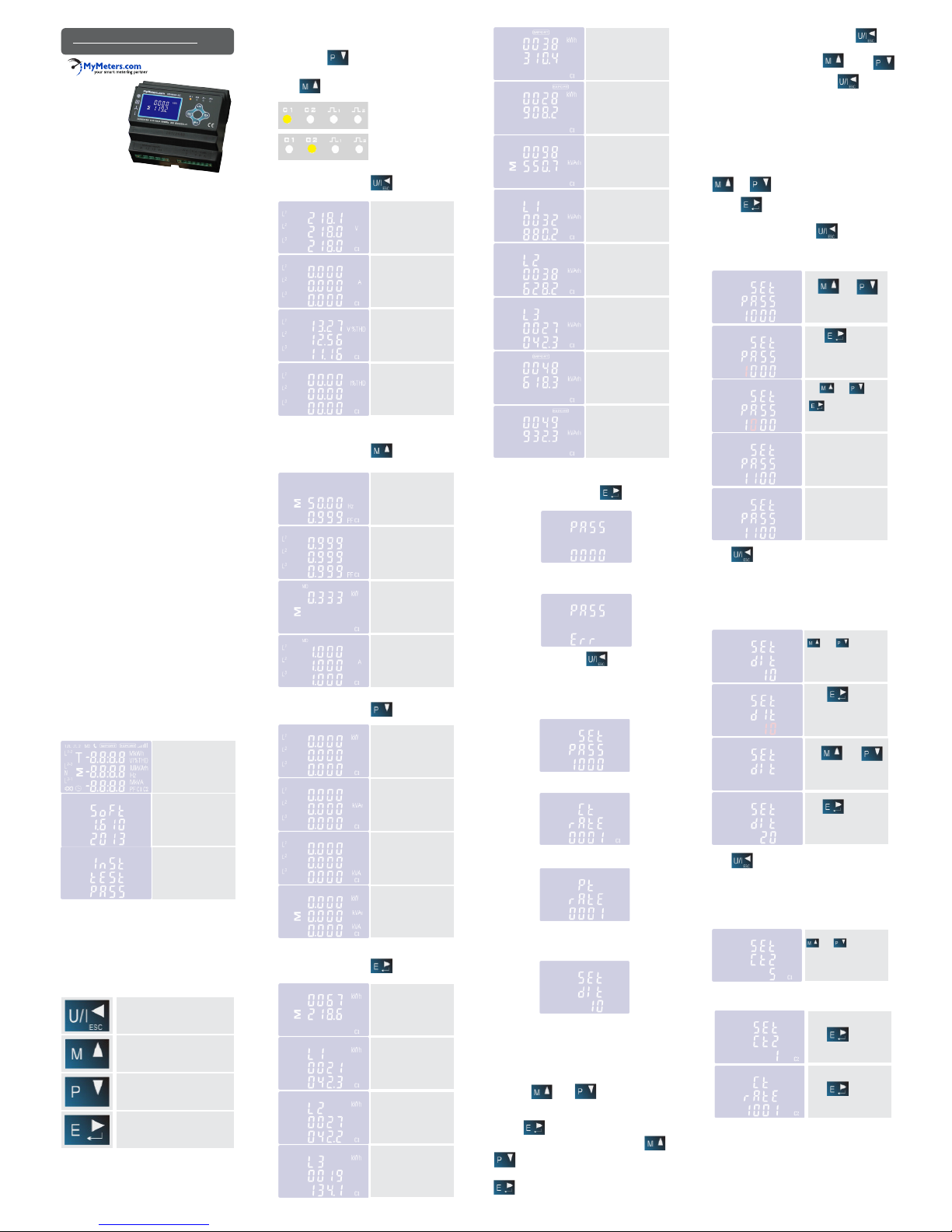

2. Start Up Screens

The rst screen lights all

display segments and can be

used as a display check.

The second screen

indicates the rmware

installed in the unit and its

build number.

Next the unit performs a

self-test and indicates if the

test passes.

After a short delay, the screen will display active energy

measurements.

3. Measurements

The MM-SDM630-2C measures all important electrical

parameters, which is shown on the LCD display and approachable via RS485. On the front panel there are four sensitive

buttons and four LED indicators.

The buttons operate as follows:

Selects the Voltage and Current display

screens In Set-up Mode, this is the

“Left” or “Back” button.

Select the Frequency and Power factor

display screens In Set-up Mode, this is

the “Up” button.

Select the Power display screens

In Set-up Mode, this is the “Down”

button.

Select the Energy display screens

In Set-up mode, this is the “Enter” or

“Right” button.

The default display after the meter is power on, the LCD

show “C1” circuit information.The way to shift “C1” circuit

information to “C2” circuit information is by pressing the

“Down” button .

If the meter are showing “C2”, and the user want to shift

it to be “C1” circuit, then he shall keep pressing the “UP”

button .

(Circuit 1)

(Circuit 2)

3.1 Voltage and Current

Each successive pressing of the button selects a

new range:

Phase to neutral voltages

Current on each phase

Phase to neutral voltage

THD%

Current THD% for each

phase

3.2 Frequency and Power Factor and

Demand

Each successive pressing of the button selects a

new range:

3.3 Power

Each successive pressing of the button selects a

new range:

Frequency

Power factor (total)

Power factor of each phase

Max. Power demand

Max. Current demand

Instantaneous active power

(kW)

Instantaneous reactive

power (kVAr)

Instantaneous Volt-amps

(KVA)

Total kW, kVAr, kVA

Total active energy in kWh

C1-L1 kwh

C1-L2 kwh

Imported active energy

in kWh

Exported active energy

in kWh

Total reactive energy

in kVAh

C1-L1 kVarh

C1-L2 kVarh

C1-L3 kVarh

Imported reactive energy

in kVArh

Exported reactive energy

in kVArh

4. Setting Up

To enter set-up mode, pressing the button for 3

seconds, until the password screen appears.

Setting up is password-protected so you must enter the

correct password (default ‘1000’) before processing. If an

incorrect password is entered, the display will show: PASS Err

To exit setting-up mode, press repeatedly until the

measurement screen is restored.

4.1 Set-up Menu Structure

Change password

nnnn 4-digit number-default ‘1000’

CT Set the value of the CT ratio

nnnn 4-digit number 0001~9999.v

PT set the value of PT Ratio

nnnn 4-digit number 0001~9999.

DIT Demand Integration Time

This is the period in minutes over which the current and

power readings are integrated for maximum demand measurement. Options are: 5 , 10, 15, 30 and 60minutes.

4.2 Set-up Entry Methods

Some menu items, such as password and CT, require a

four-digit number entry while others, such as supply system,

require selection from a number of menu options.

4.2.1 Menu Option Selection

5) Having completed a parameter setting, press to

return to a higher menu level. The SET indicator will be

removed and you will be able to use the and

buttons for further menu selection.

6) On completion of all setting-up, press repeatedly

until the measurement screen is restored.

4.2.2 Number Entry Procedure

When Setting up the unit , some screens require the entering

of a number. In par ticular, on entry to the setting up section, a

password must be entered. Digits are set individually, from left

to right.The procedure is as follows:

1)The current digit to be set ashes and is set using the

and buttons.

2) Press to conrm each digit setting. The SET

indicator appears after the last digit has been set.

3) After setting the last digit, press to exit the number setting routine. The SET indicator will be removed.

4.3 Change Password

Use and to

choose the change

password option.

Press to enter the

change password routine.

The new password screen

will appear with the rst

digit ashing.

Use and to set

the rst digit and press

to conrm your

selection. The next digit

will ash.

Repeat the procedure for

the remaining three digits

After setting the last digit,

SET will show.

Press to exit the number setting routine and return

to the Set-up menu. SET will be removed.

4.4 DIT Demand Integration Time

This sets the period in minutes over which the current and

power readings are integrated for maximum demand measurement.The options are: 5, 10,15 30,60 minutes.

From the set-up menu, use

and buttons

to select the dIT option.

The screen will show the

currently selected integration time.

Press to enter

the selection routine. The

current time interval

will ash.

Use and

buttons to select the time

required.

Press to conrm

selection. SET indicator

will appear.

Press to exit the DIT selection routine and return

to the menu.

4.5 CT

The CT option sets the current ratio (1~9999) and secondary

current (CT2 1A/5A) of the current transformer (CT) that

wires to the meter.

From the Set-up menu, use

and buttons

to select the CT option.

The screen will show the

current CT primary current

value.

C1.CT2 -> Circuit 1

C2.CT2 -> Circuit 2

There are four LED indicators on the front panel , namely C1,

C2, Pulse1 and Pulse2. The unit can measures and displays data

of two three phase circuits: C1 circuit and C2 circuit. If C1

LED shows, that means the reading on the LCD are for C1

circuit. While C2 is there, it means the measurements on the

LCD are for C2 circuit.

Each successive pressing of the button selects a

new range:

3.4 Energy Measurements

C1-L3 kwh

1) Use the and buttons to select the

required item from the menu shown in section 4.1. Selection

does not roll over between bottom and top of list.

2) Press to conrm your selection

3) If an item ashes, then it can be adjusted by the and

buttons. If not, there maybe a further layer.

4) Having selected an option from the current layer, press

to conrm your selection. The SET indicator will

appear.

Secondary CT setting

Press to enter

the CT secondary current

selection routine. 5A/1A

Set CT Ratio Value

Press to enter the

CT Ratio. The range is from

0001~9999.

Example: if set the ratio to be 100, that means the primary

current is secondary current x100.

4.6 PT

The PT option sets the secondary voltage (PT2 100~500V) of

the Voltage transformer (PT) that wires to the meter and the

PT ratio between PT1 to PT2. The default value is 400V for

Secondary PT (L-L), and the ratio between PT1 and PT2 is 1.

Secondary PT setting

The setting method is same

as Primary voltage setting

PT1. Max PT2 value is 500V

Set PT Ratio Value

Press to enter the

PT Ratio. The range is from

0001~9999.

From the Set-up menu, use

and buttons

to select the PT option.

The screen will show the

voltage PT secondary

voltage value.

Press to exit the system selection routine and return

to the menu. SET will disappear and you will be returned to

the main Set-up Menu.

4.7 Pulse Output

This option allows you to congure the pulse output. The

output can be set to provide 2 pulses, Pulse 1 is lock to C1,

and Pulse 2 is lock to C2. The setting will be effective for both

pulse outputs. Use this section to set up the pulse output

(Units: kWh, kVarh)

From the Set-up menu, use

and buttons

to select the Pulse output

option.

Press to enter the

selection routine. The unit

symbol will ash.

Use and

buttons to choose kWh

or kVArh.

On completion of entry procedure, press to conrm

the setting and press to return to the main set

up menu.

4.7.1 Pulse Rate

Use this to set the energy represented by each pulse. Rate can

be set to 1 pulse per 0.01/0.1/1/10/100/1000kWh/KVArh.

(It shows 1 impulse =

10kWh/kVArh)

Press to enter the

selection routine. The cur-

rent setting will ash. Use

and and buttons

to choose pulse rate.

From the Set-up menu, use

and buttons

to select the Pulse Rate

option.

On completion of the entry procedure, press to

conrm the setting and press to return to the main

set up menu.

4.7.2 Pulse Duration

The energy monitored can be active or reactive and the pulse

width can be selected as 200, 100 or 60ms.

(It shows pulse width

of 200ms)

From the Set-up menu, use

and buttons

to select the Pulse width

option.

Press to enter the selection routine. The current

setting will ash.

200/100/60ms

Use and

buttons to choose pulse

width.

On completion of the entry procedure, press to

conrm the setting and press to return to the main

set up menu.

4.8 Communication

There is a RS485 port can be used for communication using

Modbus RTU protocol. For Modbus RTU, parameters are

selected from Front panel.

From the Set-up menu, use

and buttons to

select the Address ID.

Press to enter

the selection routine. The

current setting will be

ashing.

Use and

buttons to choose Modbus

Address (001 to 247).

On completion of the entry procedure, press button

to conrm the setting and press button to return to

the main set-up menu.

4.8.2 Baud Rate

From the Set-up menu, use

and buttons to

select the Baud rate option.

Press to enter

the selection routine. The

current setting will ash.

Use and

buttons to choose Baud

rate 2.4k, 4.8k, 9.6k, 19.2k,

38.4k.

On completion of the entry procedure, press to

conrm the setting and press to return to the main

set-up menu.

4.8.3 Parity

From the Set-up menu, use

and buttons to

select the Parity option.

Press to enter

the selection routine. The

current setting will ash.

Use and

buttons to choose Parity

(EVEN / ODD / NONE).

Default is NONE.

On completion of the entry procedure, press to

conrm the setting and press to return to the main

set-up menu.

4.8.4 Stop Bits

From the Set-up menu, use

and buttons to

select the Stop Bit option.

Press to enter

the selection routine. The

current setting will ash.

Use and

buttons to choose Stop Bit

(2 or 1).

On completion of the entry procedure, press to

conrm the setting and press to return to the main

set-up menu.

5. Specications

5.1 Measured Parameters

The unit can monitor and display the following parameters of

a single phase, 3-phase 4-wire supply.

5.1.1 Voltage and Current

• Phase to neutral voltages 100 to 289V a.c.

• Voltages between phases 173 to 500V a.c.

• Percentage total voltage harmonic distortion (THD%) for

each phase to N

• Percentage voltage THD% between phases

• Current on each phase – 1 to 9999A range, set by external

current transformer(s) (CTs)

• Current THD% for each phase

5.1.2 Power Factor and Frequency and

Max. Demand

• Frequency in

• Hz Instantaneous power

• Power 0 to 3600 MW

• Reactive Power 0 to 3600 MVAr

• Volt-amps 0 to 3600 MVA

• Maximum demanded power since last

• Demand reset Power factor

• Maximum neutral demand current, since the last Demand

reset

5.1.3 Energy Measurements

• Imported active energy 0 to 9999999.9 kWh

• Exported active energy 0 to 9999999.9 kWh

• Imported reactive energy 0 to 9999999.9 kVArh

• Exported reactive energy 0 to 9999999.9 kVArh

• Total active energy 0 to 9999999.9 kWh

• Total reactive energy 0 to 9999999.9 kVArh

5.2 Measured Inputs

Voltage inputs through 4-way xed connector with 2·5mm2

stranded wire capacity. Line frequency measured from L1

voltage or L3 voltage.

Three current inputs (six physical terminals) with 2.5mm2

stranded wire capacity for connection of external CTs.

Nominal rated input current 5A or 1A a.c. Rms.

5.3 Accuracy

Voltage 0.5% of range maximum

Current 0.5% of nominal

Frequency 0.2% of mid-frequency

Power factor 1% of unity (0.01)

Active power (W) ±1% of range maximum

Reactive power (VAr) ±1% of range maximum

Apparent power (VA) ±1% of range maximum

Active energy (Wh) Class 1 IEC 62053-21

Reactive energy (VARh) ±1% of range maximum

Total harmonic distortion 1% up to 31st harmonic

5.4 Power Supply

Two-way xed connector with 2.5mm2 stranded wire capacity.

The meter is powered from Phase L1. The user must make

sure the meter Phase 1 has power on.

5.5 Interfaces for External Monitoring

Three interfaces are provided:

• an RS485 communication channel that can be programmed

for Modbus RTU protocol.

• an output indicating real-time measured energy.

(congurable)

• an pulse output 3200imp/kWh (not congurable).

The Modbus conguration (Baud rate etc.) and the pulse

output assignments (kW/kVArh, import/export etc.) are

congured through the Set-up screens.

5.5.1 Pulse Output

The pulse output can be set to generate pulses to represent

kWh or kVArh.

Rate can be set to generate 1 pulse per:

0.01 = 10 Wh/VArh

0.1 = 100 Wh/VArh

1 = 1 kWh/kVArh

10 = 10 kWh/kVArh

100 = 100 kWh/kVArh

1000 = 1000 kWh/kVArh

Pulse width 200/100/60 ms.

5.5.2 RS485 Output for Modbus RTU

For Modbus RTU, the following RS485 communication

parameters can be congured from the Set-up menu:

Baud rate 2400, 4800, 9600, 19200, 38400

Parity none/odd/even

Stop bits 1 or 2

RS485 network address nnn – 3-digit number, 001 to 247

MyMeters.com

Unit 4, 59 Beattie St, Kallangur QLD 4503 Australia

Tel: 1300 METERS (1300 638 377)

Email: info@mymeters.com

web: www.mymeters.com

MID

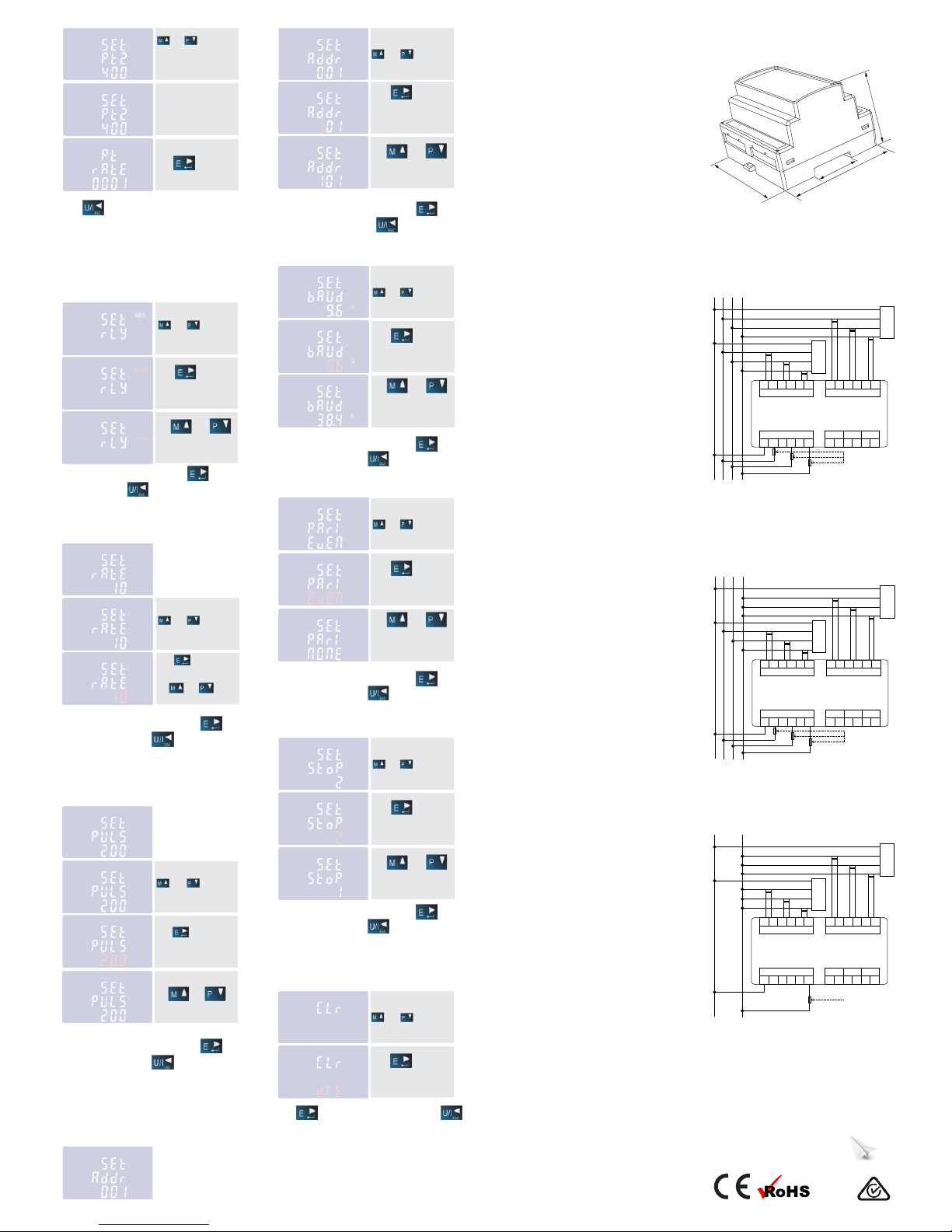

7.3 Six Circuits Single Phase Two Wire

7.2 One Circuit Three Phase Four Wire +

Three Circuits Single Phase Two Wire

7.1 Two Circuits Three Phase Four Wire

7. Installation

6. Dimensions

105mm

35mm

92mm

65mm

4.8.1 RS485 Address

(The range is from 001 to 247)

4.9 CLR

The meter provides a function to reset the maximum demand

value of current and power.

From the Set-up menu, use

and buttons to

select the reset option.

Press to enter the

selection routine. The dlt

will ash.

Press button to conrm the setting and press

to return to the main set up menu.

Modbus™ Word order Hi/Lo byte order is set automatically

to normal or reverse. It cannot be congured from the

set-up menu.

5.6 Reference Conditions of Inuence

Quantities

Inuence Quantities are variables that affect measurement

errors to a minor degree. Accuracy is veried under nominal

value (within the specied tolerance) of these conditions.

• Ambient temperature 23°C ±1°C

• Input waveform 50 or 60Hz ±2%

• Input waveform Sinusoidal (distortion

factor < 0.005)

• Magnetic eld of external origin Terrestrial ux

5.7 Environment

• Operating temperature -25°C to +55°C*

• Storage temperature -40°C to +70°C*

• Relative humidity 0 to 90%, non-condensing

• Altitude Up to 3000m

• Warm up time 1 minute

• Vibration 10Hz to 50Hz, IEC 60068-

2-6, 2g

• Shock 30g in 3 planes

CT3

CT2

CT1

CT3

CT2

CT1

Circuit 1

Circuit 2

N L3 L2 L1

1a fast blow fuses

CT input for Circuit 1 CT input for Circuit 2

L32 L31 L22 L21 L12 L11 L32 L31 L22 L21 L12 L11

Voltage Input Pulse 1Pulse 2 RS485

N L3 L2 L1 - + - + B A

CT3

CT2

CT1

CT3

CT2

CT1

Circuit 1

Circuit 2

N L3 L2 L1

1a fast blow fuses

CT input for Circuit 1 CT input for Circuit 2

L32 L31 L22 L21 L12 L11 L32 L31 L22 L21 L12 L11

Voltage Input Pulse 1

Pulse 2

RS485

N L3 L2 L1 - + - + B A

CT3

CT2

CT1

CT3

CT2

CT1

Circuit 1

Circuit 2

N L1

1a fast blow fuses

CT input for Circuit 1 CT input for Circuit 2

L32 L31 L22 L21 L12 L11 L32 L31 L22 L21 L12 L11

Voltage Input Pulse 1Pulse 2 RS485

N L3 L2 L1 - + - + B A

Loading...

Loading...