1

Table of Contents

Installation of Quadron 3D®1001 Printer

& Operating Manual

Technical Parameters ............................................................................................... 4

Description of the Equipment Use ..................................................................... 4

Electrical Parameters ................................................................................................ 4

Quadron Printer Assembly .................................................................................... 5

Movement of Electrical Devices ........................................................................... 5

Safety Information .................................................................................................... 5

Preparation of the Printer for Printing ............................................................... 6

Preparation of the Glass for Printing .................................................................. 6

Wiring ............................................................................................................................ 6

Manual Calibration ................................................................................................... 6

Introduction of Filament into the Print Head .................................................. 7

LCD Display Control .................................................................................................. 7

Materials: PLA, PETG, CARBON, FLEX, PVA ........................................................ 8

Printing .......................................................................................................................... 8

Peeling the Model o the Pad .............................................................................. 8

Glass Cleaning ............................................................................................................ 8

Printing Speed and Quality .................................................................................... 8

Printing of Own Models .......................................................................................... 9

Slic3r Environment .................................................................................................... 9

Printing of Nonstandard Objects ...................................................................... 10

Assisted Printing ...................................................................................................... 10

Change of the Size of the Printed Object ....................................................... 10

Printer Maintenance and Troubles During Printing .................................... 10

Extruder - Print Head Cleaning; Access to the Feed Rollers ..................... 10

Maintenance of the Extruder Outside the Printer ....................................... 10

X Axis Swivel Settings ............................................................................................ 11

Cleaning the Nozzle from the Outside ............................................................ 12

Post-Printing Problems with the Object.......................................................... 12

Correct Wiring of Connectors ............................................................................. 12

Fluidity of Axes ......................................................................................................... 12

General Information ............................................................................................... 12

Disposal of the Device............................................................................................ 13

WARRANTY CERTIFICATE ...................................................................................... 14

EC DECLARATIONOF CONFORMITY.....................................................................15

Manufacturer: MYMEDIA, s.r.o., Popradská 40, 821 06 Bratislava, Slovakia

Technical support: info@3dimenzia.sk

3

Technical Parameters

Quadron 3D ® 1001

Build volume: (mm) x 1000 - y 1000 - z 1000

Layer resolution: 50-1000 microns

Positioning accuracy: 100 microns

Extruder: Two modular removeable

extrusion heads

Resolution of bed-leveling:

<100 microns

Fabrication methods: FFF

Printable materials: PLA, PETG, Carbon, Flex

Software: CURA

Printer weight: 50 kg

Size: (mm) x1400 y1400 z1400

Power: 220-240V

PC Remote: app for Linux, Mac OS X,

Windows, iOS, Android

Port: SD CARD

Description of

the Equipment Use

The application of any method other

than indicated by the manufacturer

is inconsistent with the device speci-

cation! This device may be operated only by persons, who have been made familiar with its properties and understand

the relevant regulations of its operation.

Any changes made to this device without

the manufacturer's permission relieve the

manufacturer from liability for consequential damages or injuries. If the user wants to use the

device for other purposes that are not listed in

its specications, or for prohibited activities, the

user is required to inform the manufacturer of

his/her intention to do so. Follow the safety

instructions at work to avoid a danger of own injury and injury to the persons in the vicinity.

Pre-operation check of the device: Before proceeding to the check of the device, the operator

is required to nd out, whether the device shows

any signs of damage or other features that could

endanger health or property. Do not touch

the moving parts of the device with a block or

objects and tools. Never carry out any structural

modications on, or interventions in, the device

that were not recommended and approved by

the manufacturer of the device; the same applies

to the replacement of parts with parts of other

types. Do not operate the device without covers.

Do not operate the device when it shows any

faults in the structure or mechanism of the device, and without safety features. Do not use the

device in a humid and explosive atmosphere.

The device is intended for indoor use. Please,

be careful when interacting with the printer

in any way. It is an electrical device with the moving and hot parts. Do not expose the printer

to the rain, snow and frost. Always use the printer

in a dry environment and at a minimum distance

of 50 cm from other objects.

Always place the printer on a stable place with

sucient load capacity, e.g. on a at oor or table

with no threat of fall or tilting of the device.

Electrical Parameters

The printer is powered by 230 V,

50 Hz, 12 V power sockets. Never

connect the printer to a voltage source dierent than that delivered to

you, it could result in malfunction or damage.

Place the power cord so as not to stumble over

it, step on it, or expose it to any damage. Make

sure that the power cord is not mechanically

or otherwise damaged. Immediately stop using

the cord that is damaged and replace it. When

disconnecting the power cord, pull the cord

from the socket by holding the socket itself, not

by pulling only the cable out, thus reducing the

risk of damage to the socket or network sockets.

Ensure that persons without proper electrotechnical qualication (lay persons) make no

unauthorized interference into the electrical

equipment. Never disassemble the voltage source on the printer; it does not contain any parts

that an unskilled worker could repair. If any

troubles occur, always hand the printer over to

a qualied service engineer. Make sure that the

print head temperature is around 200-260 °C.

4

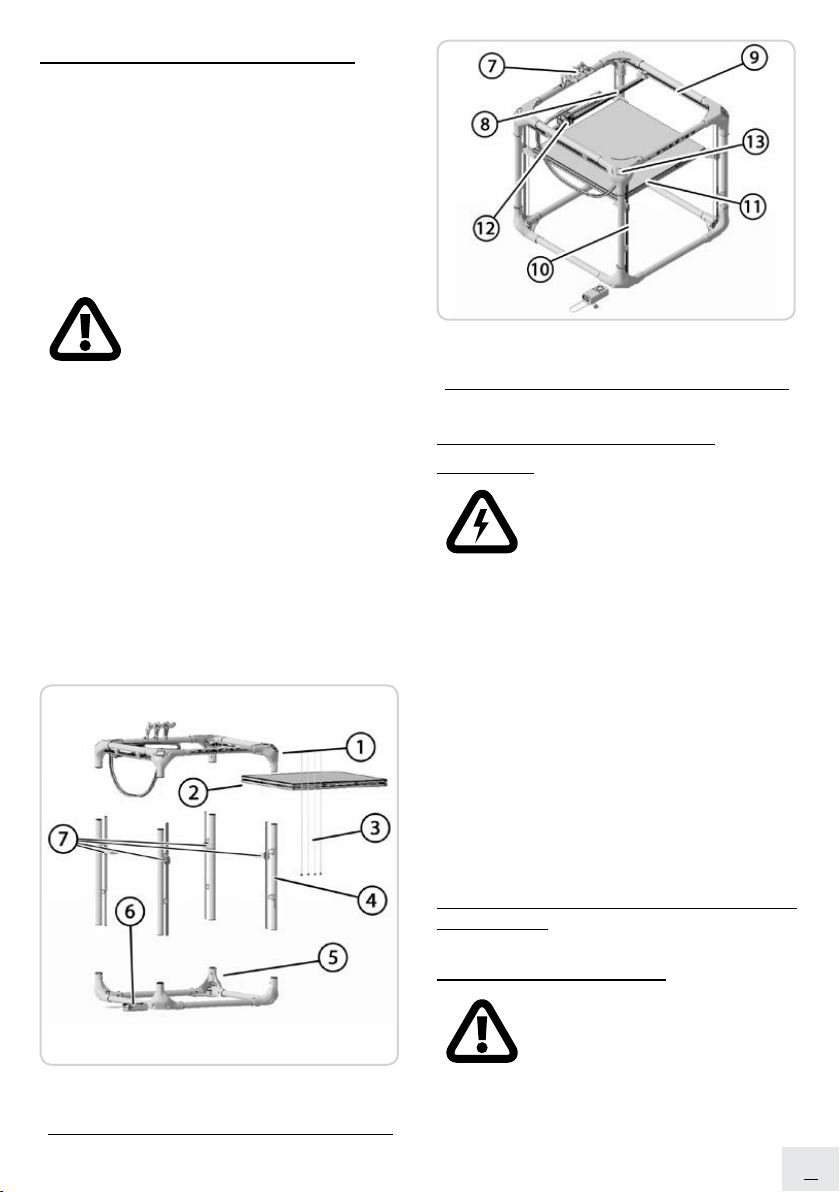

Quadron Printer Assembly

Start assembling the printer by placing the part 5

(Figure 1) on a stable horizontal surface. Insert vertical axes in its corners (Figure 1). In the clockwise

order, start with the corner containing the power

supply. Insert the part 1 on the vertical axes.

At the same time, plug the cable from the display

to the lower corner containing the power supply.

Lead the connector from the bottom corner and

connect it to the other connector.

When inserting the part 1 on the ver-

tical axes, make sure that part 1 does

not cross. There are holes on the

inner sides of the corners of the part

1 and part 2 ready for screwing.

Figure 2: (7) Filament holder, (8) X axis, (9) Y axis,

(10) Z axis, (11) Adjustment rollers of the print surface,

(12) Double extruder, (13) Display

There are hexagonal holes in the part 5 of the

engine gearboxes where, again, insert the threaded rods in the clockwise direction, beginning

with the rod 1 at the corner of the display. At

the same time, insert the corner rods into the

holders on the print pad placed on the pillars.

Mount the lament holder at the back of the

part 1.

Place the print pad (part 2) on the holders (part

7). Plug the printer to the power supply.

Figure 1: (1) Top section, (2) Printing pad, (3)

Threaded rods, (4) Pillars, (5) Bottom section, (6) Power

source with the switch, (7) Holders to the printing pad

Movement of Electrical

Devices

When operating the electrical

device, the operator must follow

the relevant instructions, rules and

local operating regulations for its

use, and ensure that the device is not

overloaded or otherwise damaged. Maintain

the electrical device in line with the manufacturer's instructions. When the electrical device is

switched o, you can move and extend the movable inlets by means of the connecting cables

equipped with the respective connecting parts.

The device must be switched o immediately

in the following cases: insulation damage,

the smell of burns, smoke, extremely unsmooth

or impact operation of the electrical device,

severe contusion, jerking launch, overheating

of some parts of the electrical device.

THE DAMAGED ELECTRICAL DEVICE SHOULD

NOT BE USED!

Safety Information

The device contains movable and

rotating parts; reduced caution du-

ring its operation and improper han-

dling can result in injury. Prevent

unaccompanied children from accessing

the printer, even if not in operation. The user is

required keep the electrical devices in a perma-

5

Loading...

Loading...