SATURN

USER’S GUIDE

WM00177

SATURN SPA

User’s manual

_____________________

Version: 02.2014

Standard Specification:

Shell material PU reinforced antimicrobial acrylic

(6,3 mm)

Total number of bathers 5 Prs.

Lounge beds 2 Prs.

Seats 3 Prs.

Water volume 1400 l

Net weight ~350 kg

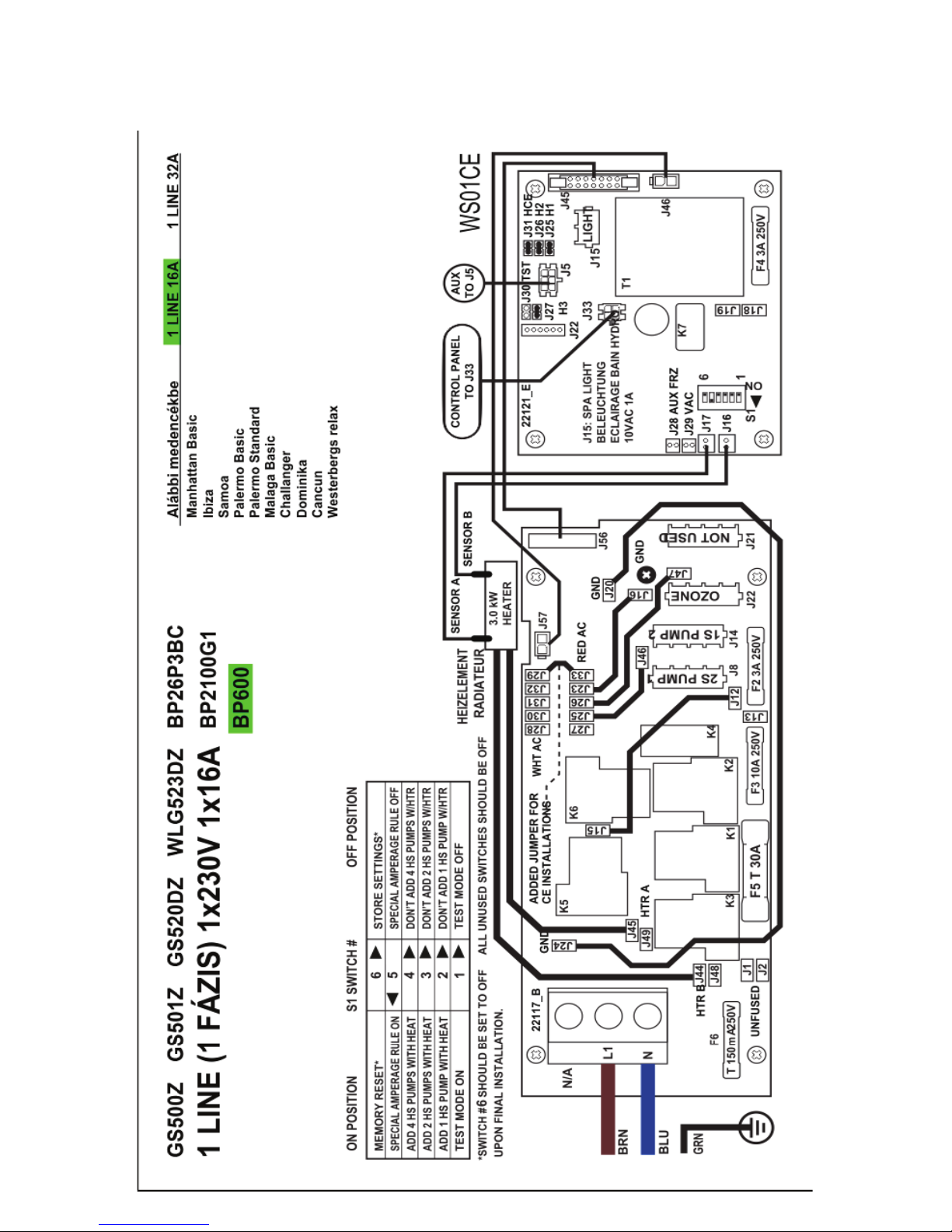

Power requirement 1 ×32 A (230V/50Hz) optimum

1 ×16 A (230V/50Hz) minimum

Total number of jets 50

Hydro massage pump 1×2 HP 2 speed (230V/50Hz)

1×2 HP (230V/50Hz)

Diverter 1

Ozonator 1

Filter 2

Chromotherapy lighting 18×1 LED

Heating unit 1 (3kW/230V/50Hz)

Air inlet regulator 5

Controller TP600

3/4” Drain 1

Cabinet Maintenance-free Synthetic

Spa cover Thermal cover with child locks

Headrests 3

2300 × 2300 × 900 mm

Warranty letter

Serial number:...............................................

Model: .............................................................

2014 MyLine Spa Limited Warranty

WARRANTY FOR EXPORT Warranty;

Limitations of Liability and Damages.

Company oers a limited warranty comprised of replacement of faulty parts and oers no

reimbursement for labour of repairs outside any abnormal failure rates to be determined by

both parties.

5 years on spa shell: WELLIS warrants the structure of the spa shell against defects in workmanship and material for a period of 5 years, subject to the limitations and conditions listed

in this Warranty.

3 years on spa shell surface: The acrylic spa shell is warranted against cracking, blistering or

delaminating due to defects in materials or workmanship for three years from the original

date of delivery.

Distributor Retailer

Date of buying: Date of buying:

Signature: Signature:

(stamp) (stamp)

2 years on spa plumbing: Spa ttings and plumbing are warranted against leaks due to defects in materials or workmanship for two years from the original date of delivery. There is no

labour coverage on internal jet parts replacement, cleaning or adjusting.

2 years on standard and optional spa equipment – Balboa Control Systems, Jet Pump(s),

Laing Circulation Pump, Heater, Wi-Fi module, IR receiver: The spa equipment systems are

warranted against failure due to defects in materials or workmanship for two years from the

date of delivery. Fuses, bulbs, and seals are not covered.

2 years on Pulsar hydrotherapy system: The factory installed Pulsar hydrotherapy systems are

warranted against failure due to defects in materials or workmanship for one year from the

original date of delivery.

2 years on spa cabinets/skirts: The factory installed spa cabinets/skirts are warranted against

failure due to defects in materials or workmanship for one year from the original date of

delivery.

2 years on ozone generator: The ozone generator is warranted against failure due to defects

in materials or workmanship for one year from the original date of delivery.

2 years on audio system components: The factory installed audio components (i.e. power

supply, speakers, wires, etc.) are warranted against failure due to defects in materials or workmanship for one year from the original date of delivery. There is no in-eld labour service on

these items.

2 years on LED lights: The factory installed LED lights are warranted against failure due to

defects in materials or workmanship for one year from the original date of delivery.

2 years on UV-C sanitizer lamp: The factory installed UV-C sanitizer lamps are warranted

against failure due to defects in materials or workmanship for one year from the original date

of delivery.

2 years on I.S.I.S. water disinfection system: The factory installed I.S.I.S. water disinfection systems are warranted against failure due to defects in materials or workmanship for one year

from the original date of delivery.

1 year on blower: The blower is warranted against failure due to defects in materials or workmanship for one year from the original date of delivery.

1 year on thermo cover: The thermo cover is warranted against failure due to defects in materials or workmanship for one year from the original date of delivery.

1 year on WELLIS Spa Umbrella: The factory installed WELLIS Spa Umbrellas are warranted

against failure due to defects in materials or workmanship for one year from the original date

of delivery.

1 year on LCD TV system: The factory installed LCD TV systems are warranted against failure

due to defects in materials or workmanship for one year from the original date of delivery.

90 days on skimmer house: Skimmer houses are subject to water chemistry variation and

are warranted for ninety days from the original date of delivery. NO warranty on lters, spa

pillows and skimmer house tops.

WARRANTY PERFORMANCE

1. This warranty does not cover cleaning or adjusting spa or for customer error in following

correct procedures.

2. WELLIS Magyarország Kft. reserves the right to substitute a spa or component of equivalent value, either new or factory reconditioned and any such repair or replacement

shall assume as its warranty only the remaining portion of the warranty on the original

product.

3. WELLIS Magyarország Kft. is not liable for any costs associated with in-ground, in-deck,

or in-home installations or removal. Costs associated with installations other than

standard residential portable spa use will be the sole responsibility of the spa owner.

The spa owner is responsible for any freight and/or delivery and set up charges for a

replacement spa.

4. The radio reception is not covered under warranty due to the following: The radio signal

reception may be impaired by the positioning of the spa next to or near structures, high

power lines, main power lines or metallic towers. The signal reception may be impaired

if the spa is located near hills or it is in a valley or simply outside the broadcasting range

of the radio stations. The position of the spa and radio may be “out of phase with the

bandwidth” or the radio frequency. External signal reception assistance may be required

and is not part of this warranty.

5. WELLIS Magyarország Kft. shall not be liable for any incidental or consequential damages for breach of any expressed or implied warranty, breach of contract, negligence, strict

liability, or any other legal theory related to this product. All consequential expenses

including loss of use, damages, or contingent liabilities arising out of any alleged deciencies of the spa are specically excluded from this warranty.

6. Warranty coverage is only extended to the original buyer. Spas purchased from anyone

other than a current WELLIS Spas Authorized Dealer are specically excluded from any

warranty coverage. To obtain warranty service, please notify your WELLIS Spas Authorized Dealer in writing within 14 days of the problem (with problem details, original

proof of purchase).

7. The Authorized Dealer will repair or replace any component found defective under the

terms of this warranty – and permitted by WELLIS Magyarország Kft. Travelling expenses

may apply outside of every European cities.

8. If the Authorized Dealer doesn`t supply the customer with proper service, please notify

WELLIS Magyarország Kft. by mail within 10 days of the problem.

9. Electrical connection: All electrical connections are required to be done by a qualied

electrician solely. The spa has to be connected to separate current circuit equipped with

suitable power switch and life safety relay. Omission of these electrical conditions/requirements entails immediate loss of the warranty.

10. Water connection: All water connections are required to be done by a qualied plumber

solely. If the spa is placed indoor make allowances for the following special requirements: The water accumulates around the spa so the socket cover has to be in possession of a suitable drainage. This arrangement hinders the water in collecting.

11. WELLIS Magyarország Kft. oers a limited warranty as described in the Warranty Letter.

12. Warranty claim is enforceable with this warrant letter. Irregular establishing of this

warrant letter doesn`t aect to the validity of warranty obligation. If customer doesn`t

get this warrant letter from the Authorized Dealer, it doesn`t aect to the validity of

warranty obligation.

SPA WARRANTY COVERAGE WILL BE VOID

UNDER THE FOLLOWING CONDITIONS

1. If damages caused by inecient maintenance of water and/or chemical dosage.

Terms of water hardness (limits): between 6-10 German degrees.

2. If the spa surface or equipment has been damaged or discoloured as a result of improper water chemistry maintenance, including sanitizers such as trichlor type chlorine,

calcium hypochlorite, sodium hypochlorite, and any other chemicals or a chemical

dispenser that may rest on the spa surface. Some household cleaners can damage the

spa shell or equipment and will void this warranty completely. Use only products that

are recommended for spas.

3. If damage to the spa has resulted from an Act of God, force majeure, moving of the

spa, improper installation, unstable power conditions, customer negligence, customer

abuse, weather and sunlight damage or damage caused in shipment.

4. If damage to the spa has resulted from operation outside – temperature exceed 45°C.

5. If the spa has been subjected to any alterations, after-market product installations, misuses, abuses, or if any repairs are attempted by anyone other than its authorised dealers.

6. If damage to the spa has resulted from improper use of thermo cover.

7. If damage to the spa has resulted from clogged, dirty and/or clogged lter. The spa warranty will be void if the owner does not follow all the instructions in the owner’s manual

regarding the proper use and care of the spa. Warranty doesn`t apply to lters!

8. If damage to the spa has resulted from improper electrical installation, voltage drop,

peak voltage and/or operation is outside the pale of + / - 10% voltage range.

Electrical conditions:

For electrical installation it is required to build a 30mA circuit breaker (life safety relay),

which is just connected to the spa (not allowed to connect any other devices). This 30

mA circuit breaker is not permitted to be installed in the same place as the spa.

Required to install IEC, RCCB system in spa`s common surroundings.

Length of cable is 3 meters at the place of spa installed.

It is obligatory to observe all information, details and requirements which are in the

product`s installation diagram regarding electricity demand and drain installation.

These information can be found in the user manual, or able to download from www.

wellis.eu. If you didn`t get the document from your dealer, please contact support@

wellis.eu.

If damage to the spa has resulted from debris in jets (i.e. sand, dirty calcium, leaves etc.).

9. Warranty doesn`t extend to the waste water manifold (drain hose), pillows, lters, bulbs

and/or pump sealing.

LIMITATIONS

The Warranty expressions specied excludes any other implied or oral undertakings. Purchasers also have current rights under statute which will be respected by WELLIS Magyarország

Kft. After a period of 12 months, for the purpose of assessing WELLIS Magyarország Kft.

liability, all aspects covered by this Warranty will be treated on a pro-rata basis. WELLIS

Magyarország Kft. or its agents will not be liable for any incidental or consequential loss or

injury. Nor will WELLIS Magyarország Kft. be liable for costs associated with but not limited to

building alterations or nishes and under no circumstances will be liable for greater expense

than the amount paid for the product.

THE SPA OWNER MUST DO EVERYTHING STATED IN THE SPA OWNERS MANUAL

AND WARRANTY LETTER TO SAFEGUARD AND MAINTAIN THE SPA!

MANUFACTURER OF YOUR SPA:

WELLIS Magyarország Kft.

Registered:....................................31/C, Budaörsi út, H-1118 Budapest, HUNGARY

Central premise:..........................hrsz: 0417, Mánteleki út, H-2371 Dabas, HUNGARY

AUTHORIZED DEALER OF YOUR SPA

Company in charge of your spa

Company name:.........................................................................................................................................................

Registered: ...................................................................................................................................................................

Central premise: .......................................................................................................................................................

Place of complaint: ................................................................................................................................................

E-mail address: ..........................................................................................................................................................

Website: ......................................................................................................................................................................

Phone number: .........................................................................................................................................................

Fax: ..................................................................................................................................................................................

Person in charge of installation: ..........................................................................................................................

Date of installation: .................................................................................................................................................

Service-work

The announcement date of damage: _____________________________

Date of received goods/parts for repair: _____________________________

Date of the return of repaired goods/parts: _____________________________

Date of site service: _____________________________

Improved error: _____________________________

Mode of repair: _____________________________

Failed component: _____________________________

New deadline for the warranty: _____________________________

A

STAMP

The announcement date of damage: _____________________________

Date of received goods/parts for repair: _____________________________

Date of the return of repaired goods/parts: _____________________________

Date of site service: _____________________________

Improved error: _____________________________

Mode of repair: _____________________________

Failed component: _____________________________

New deadline for the warranty: _____________________________

B

STAMP

The announcement date of damage: _____________________________

Date of received goods/parts for repair: _____________________________

Date of the return of repaired goods/parts: _____________________________

Date of site service: _____________________________

Improved error: _____________________________

Mode of repair: _____________________________

Failed component: _____________________________

New deadline for the warranty: _____________________________

C

STAMP

The announcement date of damage: _____________________________

Date of received goods/parts for repair: _____________________________

Date of the return of repaired goods/parts: _____________________________

Date of site service: _____________________________

Improved error: _____________________________

Mode of repair: _____________________________

Failed component: _____________________________

New deadline for the warranty: _____________________________

D

STAMP

SAFETY INSTRUCTIONS

ATTENTION: PLEASE READCAREFULLY AND FOLLOW THE INSTRUCTIONS

AVOIDING THE RISK OF INJURY OF CHILDREN

1. In order to reduce the risk of injury to children, do not allow children to use this spaalone

unless they are carefully supervised at all the times.

2. Lower water temperatures arerecommended for young children. Please test the water

temperature with yourhands before allowing children to get into the spa, and make sure

it iscomfortable for children’s usage.

3. Remember that wet surfaces can be slippery, please remind children to be careful when

entering or exiting the spa.

4. Don’t permit children to climb onto the spa cover.

AVOIDING THE RISK OF INJURY OF BATHERS

1. In order to reducing the risk of injury to bathers, do not remove or lose anysuction ttings. Never operate spa if the suction tting are broken or missing.

2. Remember that wet surfaces can be very slippery. Take care of a danger ofslipping and

falling when entering or exiting the spa.

3. For the sake of health, people with infectious diseases should not be allowed touse the

spa.

4. Keep any loose articles of clothing or hanging jewelry away from rotating jets orother

moving components.

5. The use of drugs, alcohol or medicine before or during spa use may lead to unconsciousness with the possibility of drowning. Persons using medicines shouldconsult a physician

before using spa; some medicine may cause a user to becomedrowsy. While other medicine may aect heart beating, blood pressure changing and circulation problem.

6. Pregnant women should consult a doctor before using the spa.

AVOIDING TNE RISK OF ELECTROCUTION

1. Test the ground fault circuit interrupters before use. Must always to be connectedto a

circuit protected by a ground fault interrupt.

2. Check the power cables cord, a damaged power cord may result in death, or seriouspersonal injury due to electrocution. Do not use the spa with damaged power cable, change

that immediately before using and need to disconnect the spa from power supply.

3. Do not permit any electrical appliances, such as a light, telephone, radio, or television

within 1,5m of a spa. Keep a safe distance from spa, because this failure may result indeath, or serious injury due to electrocuting if the appliance should fallinto the spa.

4. Install your spa in such a way that drainage is away from the electricalcompartment and

from all electrical components.

5. Disconnect the spa from the power supply before servicing the electricalcomponents.

NOTICE:

Your spa is anequippedwith two/three massage pumps that allow you tooperate eachpart of

the jet system separately or all valves simultaneously.

Do not connect power to an empty spa. Otherwise the components such ascontroller, heater,

circulation pump, and other systems could be damaged.

INSTALLATION INSTRUCTIONS

SITE PREPARATION

1. INDOOR/BASEMENT INSTALLATION

If you take it place your spa indoors, be aware of some special requirements. Water

willaccumulate around the spa, so the ooring materials must provide a good grip

whenwet proper drainage is essential to prevent a build-up of water around the spa.

When building a new room for the spa it is recommended that a oor drain isinstalled.

The humidity will naturally increase with the spa installed water may getinto woodwork

and produce rot, mildew or otherproblems. Check for airborne moisture’s eects on

exposed wood, paper, etc in theroom .To minimize these eects, it is best to provide

plenty of ventilation to the spa area.

2. OUTROOR AND PATIO INSTALLATION

It is important that you have solid foundation to support the new spa when youinstall

it .Tobe certain your deck or foundation can support your spa. You mustknow the deck

maximum load capacity. Consult a qualied building contractor orstructural engineer.

To nd the weight of your spa, its contents and occupants, please refer to the spa specication chart. This weight per square foot must notexceed the structure’s rated capacity:

otherwise serious structural damages couldresult,if you install the spa outdoors we

recommend a reinforced concrete pad a tleast four inches thick. Don’t forget to install

some oor drains around your spa sothat it can take the water away during and after the

heavy rain.

INSTALLATION

1. Please read and study the OWNER’S MANUAL carefully. Please nda professional people

to install and setup for rst time.

2. Remove the package, and take down the new spa on the prepared foundation.

3. Open the control box compartment under the display by loosenthe screw and then

open the control box. Prepare the accordingly cooper cable(the length will be enough

to connect to the power supply), with electricalplug one side and another side without

plug and then take the empty side of cablefrom electrical cable. Lead the cable through

the pump compartment to the channelof control box compartment.Connect the electrical cable to control box according by electrical drawing in user manual.

4. Your spa has been thoroughly tested duringthe manufacturing process to ensure reliability. So there is a small amount of water even within some grease may have remained

in the plumbing after testing, as a result,may have spotted the spa shell or the spa siding

prior thedelivery so before lling spa.

OPERATING INSTRUCTIONS

1. Close the drain stub and ll the spa with water

After closing the drain stub, and ll up the tub with soft water to theindicated line inside

of the body. If you see any leak(orood) anywhere, stop the lling procedure until it will be

xed.

2. Power up your spa

First check the main house CIRCUIT INTERRUPTORY that controls the electricto the spa

are functioning properly. Then connect the spa plug to the power supply.

3. Trail open and test

Your controller with a factory‘s rst setup already. push the button of PUMP/JET andAIR

BLOWER to make jets run for some minutes to check the operations of the jetsystem and

purge any remaining air from the heating system. once the jet systemfully operational, priming of the spa is complete. Check and make sure the all aircontroller and all jets are open.

Possible symptom is an AIR LOCK on the first starting or when fills up with new

water.

It can cause the jets to appear not work well or at all. It happens when you are lling the spa

up fairly rapidly, and air can get trapped in the pipe system that goes to the suction ttings

and to the jets. The water level rises up past the openings in the spa, but air becomes locked

in the pipes, and then when you start the spa pump, it tries to air bubble(s) still in water, but

only air is in the pipes. Sometimes the pump cannot prime itself at that point, so it just runs,

but does not pump any water.

Solution:

1. Open the door of pump compartment.

2. Loosen the quick disconnecttting (white rim on the pump) in front of the pump a

little.

3. Let some air get in and it will break the air lock that has developed, and then see

some water start to come out.

4. Re-tighten the tting.

5. Turn the pump on again. It will surge for a few seconds and then start to pump

properly.

If it still does not work, please contact a local spa professional to check it for you.

CLEANING

GENERAL INFORMATION:

Water recirculation-ltering

The basic conditions for keeping the water of the spa clean are the removal of mechanical

dirt and the blending of the chemicals in the water with continuous water recirculation.

In all our spa’s appliances comprising of a pump and a lter are used for this purpose.

- The lter removes the dirt oating in the water or at the surface of the water. Filters with

paper or textile lter medium are used in the spa. The dirt settled at the bottom of the spa is

ltered out with the aid of the suction and stirring created by the massage pumps.

Protecting the spa

Don’t leave the spa expose to the sun without water or the cover. Exposure to direct sunlight

can cause solar distress of the shell material. Use a spa cover when spa is not in use, whether

it is empty or full. Try to keep your spa away from rain and snow. If possible, build a gazebo

for your spa.

1. Don’t attempt to open the electrical control box. There are no user serviceable parts

inside.

2. Drain, clean and rell your spa with fresh water on a regular schedule.

3. Clean the lter cartridge at least once a month.

4. Have spa users bathe before entering the spa water, showering without soap prior to

enter the spa, and using only the rinse cycle when laundering your bathing suit, will

help avoiding detergent and soap residue in spa water.

FILTER CARTRIDGE RMOVAL AND CLEANING

You spa lter cartridge can become clogged with mineral particles of calcication from hard

water. Which may result in reduced water ow. We recommend to clean the lter cartridges

every month.

1. Remove lter grid.

2. Unscrew lter cartridge.

3. Clean with high pressure nozzle to remove all debris that clinging the lter.

4. Soak lter in warm water and WELLIS Alga Shock to remove all body oils and grime.

Never use chlorine to clean the lter!

The chemical equilibrium of the water

The water of the spa will be clean and clear if its chemical components are in equilibrium.

1. pH-value:

The rst important indicator is the pH value of the water. pH is measured in a scale

between 0-14 where 7 is the neutral value. Below this level the water is acidic, above it

is alkaline. The pH value of the human eye is around 7.5, below 7.2 and above 7.8 the

water will sting the eyes of the bather. Experiences have shown that most problems are

caused by a too high pH value. An improper value reduces the eect of the disinfectant.

2. Water hardness:

Water hardness is determined by the quantity of calcium and magnesium salts dissolved

in the water.

Hard waters contain too much of these dissolved salts and thus, left alone, scale will

form. Scales can cause signicant damage both to the walls of the spa, to the piping,

lter and to the heating and engineering units. In Hungary waters are medium hard.

Water hardness cannot be reduced by the addition of chemicals, but the formation of

scales can be prevented.

3. Disinfection:

Disinfectant is the chemical that eliminates or neutralises the microorganisms (bacteria, algae, fungi, viruses) present in the water. Microorganisms are small, microscopic

organisms, which cannot be detected with the naked eye and are continuously getting

into the water through rain, wind and the body of the bathers. If they are not eliminated

they pass from one person to the other through the water (and may cause sickness,

infection). Organic matter turns the water of the spa opaque and cloudy. Most often – as

we are dealing with warm water spas – bromine or active oxygen is used.

4. Frothing:

Froth is the smaller-bigger agglomeration of the bubbles and colloid contaminants

found on the surface of the water. It is mostly caused by the mixing of the dirt, cosmetics, body care lotions, etc. that soak out of the human skin and the chemicals. It endangers the conservation of the aesthetic appearance and cleanliness of the water.

5. Water analysers:

There are several dierent types of water analysers, which are mostly used to measure

chemical and disinfectant eect. Chemical (pH); Disinfectant (Br, O

3

)

Tester types:

- Box containing tablets and graduated measuring glass.

- Litmus paper indicators in a box.

Chemicals should always be loaded into the lter housing.

Then proper disinfection of the spa balance, if the chemical levels are not at least 48 hours

below the specied value.

Even with the most accurate disinfection after 2-3 months, the water quality is no longer

maintain and necessary replace the full water quantity.

Then proposed a large swimming pool, shock-like disinfection.

REPLACING UNDERWATER LIGHT

1. Turn o the power of the spa.

2. Remove plastic panel behind where the underwater light

is situated.

3. There is a plug with two wires going into the back of the

light.

4. Remove this plug by turning anticlockwise.

5. Replace faulty light globe with a new one.

6. Replace parts and put the plastic panel back on.

TROUBLESHOOTING

Problem Probable causes Solutions

Cloudy Water Dirty filters.

Improper sanitization.

Suspended particles/organic

matter.

Overused water.

Clean filters.

Shock spa with sanitizer.

Add sanitizer.

Adjust PH andl or alkalinity to recommended range.

Run jet pump(s) and clean filters.

Drain and refill the spa.

Water Odor Excessive organics in water.

Improper sanitization.

Low PH level.

Shock spa with sanitizer.

Add sanitizer.

Adjust PH or refill the spa.

Chlorine Odor Chloramines level too high.

Low PH level.

Shock spa with sanitizer.Adjust PH to

recommended range.

Musty Odor Bacteria or algae growth. Shock spa with sanitizer id problem is

visible or persistent drain, clean and

refill the spa.

Organic build-up/

scum ring around

spa

Build-up of oils and dirt. Wipe off scum with clean rag-if

severe.

Drain the spa.

Use a spa surface cleaner to remove

the scum, and refill the spa.

Algae Growth High PH level.

Low sanitizer level.

Shock spa with sanitizer and adjust

PH level.

Shock spa with sanitizer and maintain

sanitizer level.

Eye irritation Low PH level.

Low sanitizer level.

Ajust PH level.

Shock spa with sanitizer and maintain

sanitizer level.

Skin irritation/rash Unsanitary water.

Free chlorine level above

5ppm.

Shock spa with sanitizer and maintain

s anitizer level.

Allow free chlorine level to drop

below 5ppm before spa use.

Stains Total alkalinity andl or PH

too low high iron or copper

in source water

Adjust total alkalinity and/or PH level.

Use a metal deposit inhibitor.

Scale High calcium content in

water-total alkalinity and PH

level too high.

Adjust total alkalinity and PH level.

If scale requires removal, drain the

spa, scrub off the scale, refill the spa

and balance the water.

Problem Probable causes Solutions

Entire spa is inoperative.

Power failure.

GFCI tripped heater

high-limit thermostat

tripped.

Check power source.

Reset GFCI, call for service if not reset.

Disconnect power for at least thirty

second to reset heater high limit.

If it will not reset check for clogged

filters. If tripping continues, call for

service.

Spa does not heat

jets and light operate (Ready, and

power indicators

are blinking.

Integrated pressure switch

open Circulation pump

thermal cut-off tripped.

Check for cartridge filters. Integrated

pressure switch will reset when the

flow of water through the heater has

been retored Call for ervice if the

heater trips frequently.

Check for cartridge filters or are looks

in plumbing Disconnected power to

the spa, allow circulation pump to

cool Circulation pump thermal cut off

will reset when pump has cooled and

power is reapplied. Call for service if

circulation pump thermal cutoff trips frequently.

Jets weak or surging.

Spa water level too low.

Filters clogged.

Air regulator is closed.

Jet closed.

Add water.

Clean filters.

Open air regulator.

Open the jet.

Light inoperative. Light wiring or assembly is

faulty.

Replace light assembly.

Power indicator is

blinking. (Entire

spa inoperative)

Heater high-limit thermostat

tripped.

Disconnect power for at least thirty

seconds to reset heater high limit. If it

will not reet. Check for clogged filters

if tripping continues, call for service.

Ready indicator

blinking.

Temperature sensor problem.

Disconnect power for at feast thirty

second problem if blinking continues,

call for service.

TP600 Control Panel

User Interface and Programming Reference – Standard Menus

System Model: BP-Series Systems are BP5XX, BP6XX, BP1XXX, BP2XXX.

Software Version: 7.0 and later

Panel Model: TP600 Series

Software Version: 2.3 or later

Power-up Screens

Each time the System powers up, a series of numbers is displayed.

After the startup sequence of numbers, the system will enter Priming Mode (See Page 3).

Indicates Flashing or Changing Segment

Key

A temperature button, used for “Action”

Light or dedicated “Choose” button, depending on control panel con

guration

Indicates Alternating or Progressive Message - every 1/2 second

Waiting time that keeps the last change to a menu item.

Waiting time (depends on menu item) that reverts to original setting and

Navigation

Navigating the entire menu structure is done with 2 or 3 buttons on the control panel.

Some panels have separate WARM (Up) and COOL (Down) buttons, while

others have a single Temperature button. In the navigation diagrams

Temperature buttons are indicated by a single button icon.

Panels that have two Temperature buttons (Warm and Cool) can

use both of them to simplify navigation and programming where

a single Temperature icon is shown.

The LIGHT Button is also used to

choose the various menus and navigate each section.

Typical use of the Temperature button(s) allows changing the

Set Temperature while the numbers are flashing in the LCD.

Pressing the LIGHT button while the numbers are flashing will

enter the menus.

The menus can be exited with certain button presses. Simply waiting for

several seconds will return the panel operation to normal.

Main Menus

Indicates Flashing or Changing Segment

Key

A temperature button, used for “Action”

Light or dedicated “Choose” button, depending on control panel

conguration

Indicates Alternating or Progressive Message - every 1/2 second

Waiting time that keeps the last change to a menu item.

Waiting time (depends on menu item) that reverts to original

setting and

ignores any change to that menu item.

*****

Main Screen

P

SET

RANGE

SET

While the Temperature is

ng, press Light.

SET

RANGE

READY

RANGE

FLTR1

SET

READYSET

1

2

Light Cycle if enabled

Power-up Screens

Each time the System powers up, a series of numbers is displayed.

After the startup sequence of numbers, the system will enter Priming Mode (See Page 3).

If Time of Day is not set

“SET TIME” will

appear in this menu.

Indicates Flashing or Changing Segment

Key

A temperature button, used for “Action”

Light or dedicated “Choose” button, depending on control panel con

Indicates Alternating or Progressive Message - every 1/2 second

Waiting time that keeps the last change to a menu item.

Waiting time (depends on menu item) that reverts to original setting and

ignores any change to that menu item.

*****

Navigation

Navigating the entire menu structure is done with 2 or 3 buttons on the control panel.

Some panels have separate WARM (Up) and COOL (Down) buttons, while

others have a single Temperature button. In the navigation diagrams

Temperature buttons are indicated by a single button icon.

Panels that have two Temperature buttons (Warm and Cool) can

use both of them to simplify navigation and programming where

a single Temperature icon is shown.

The LIGHT Button is also used to

choose the various menus and navigate each section.

Typical use of the Temperature button(s) allows changing the

Set Temperature while the numbers are flashing in the LCD.

Pressing the LIGHT button while the numbers are flashing will

enter the menus.

The menus can be exited with certain button presses. Simply waiting for

several seconds will return the panel operation to normal.

Indicates a Menu Item that

Depends on a Manufacturer

Con

guration and

may or may not appear.

Main Menus

guration

Indicates a Menu Item that

Depends on a Manufacturer

Con

guration and

may or may not appear.

Main Screen

P

SET

RANGE

SET

While the Temperature is

ng, press Light.

SET

RANGE

READY

RANGE

FLTR1

Main Screen

READY

RANGE

FLTR1

SET

READYSET

1

2

Light Cycle if enabled

Power-up Screens

Each time the System powers up, a series of numbers is displayed.

After the startup sequence of numbers, the system will enter Priming Mode (See Page 3).

Waiting Several Seconds in the Main Menu

will allow the display to revert to the Main Screen.

Most changes are not saved unless Light is pressed.

Refer to Key above.

If Time of Day is not set

“SET TIME” will

appear in this menu.

Indicates Flashing or Changing Segment

Key

A temperature button, used for “Action”

Light or dedicated “Choose” button, depending on control panel con

Indicates Alternating or Progressive Message - every 1/2 second

Waiting time that keeps the last change to a menu item.

Waiting time (depends on menu item) that reverts to original setting and

ignores any change to that menu item.

*****

Navigation

Navigating the entire menu structure is done with 2 or 3 buttons on the control panel.

Some panels have separate WARM (Up) and COOL (Down) buttons, while

others have a single Temperature button. In the navigation diagrams

Temperature buttons are indicated by a single button icon.

Panels that have two Temperature buttons (Warm and Cool) can

use both of them to simplify navigation and programming where

a single Temperature icon is shown.

The LIGHT Button is also used to

choose the various menus and navigate each section.

Typical use of the Temperature button(s) allows changing the

Set Temperature while the numbers are flashing in the LCD.

Pressing the LIGHT button while the numbers are flashing will

enter the menus.

The menus can be exited with certain button presses. Simply waiting for

several seconds will return the panel operation to normal.

Indicates a Menu Item that

Depends on a Manufacturer

Con

guration and

may or may not appear.

Preparation and Filling

Fill the spa to its correct operating level. Be sure to open all valves and jets in the plumbing system before filling to allow

as much air as possible to escape from the plumbing and the control system during the filling process.

After turning the power on at the main power panel, the top-side panel display will go through specific sequences. These

sequences are normal and display a variety of information regarding the configuration of the hot tub control.

Priming Mode – M019*

This mode will last for 4-5 minutes or you can manually exit the priming mode after the pump(s) have primed.

Regardless of whether the priming mode ends automatically or you manually exit the priming mode, the system will automatically return to normal heating and filtering at the end of the priming mode. During the priming mode, the heater is

disabled to allow the priming process to be completed without the possibility of energizing the heater under low-flow or

no-flow conditions. Nothing comes on automatically, but the pump(s) can be energized by pushing the “Jet” buttons.

If the spa has a Circ Pump, it can be activated by pressing the “Light” button during Priming Mode.

Priming the Pumps

As soon as the above display appears on the panel, push the “Jet” button once to start Pump 1 in low-speed and then

again to switch to high-speed. Also, push the Pump 2 or “Aux” button, if you have a 2nd pump, to turn it on. The pumps

will now be running in high-speed to facilitate priming. If the pumps have not primed after 2 minutes, and water is not

flowing from the jets in the spa, do not allow the pumps to continue to run. Turn o he pumps and repeat the process.

Note: Turning the power o

nd back on again will initiate a new pump priming session. Sometimes momentarily turning

the pump o nd on will help it to prime. Do not do this more than 5 times. If the pump(s) will not prime, shut o he

power to the spa and call for service.

Important: A pump should not be allowed to run without priming for more than 2 minutes. Under NO circumstances should

a pump be allowed to run without priming beyond the end of the 4-5 minute priming mode. Doing so may cause damage to

the pump and cause the system to energize the heater and go into an overheat condition.

Exiting Priming Mode

You can manually exit Priming Mode by pressing a “Temp” button (Up or Down). Note that if you do not manually exit the

priming mode as described above, the priming mode will be automatically terminated after 4-5 minutes. Be sure that the

pump(s) have been primed by this time.

Once the system has exited Priming Mode, the top-side panel will momentarily display the set temperature but the display

will not show the temperature yet, as shown below. This is because the system requires approximately 1 minute of water

flowing through the heater to determine the water temperature and display it.

Fill it up!

READY

RANGE

READY

RANGE

or

*M019 is a Message Code. See “General Messages” Pages.

Pumps

Press the “Jets 1” button once to turn pump 1 on or o, and to shift between low- and high-speeds if equipped.

If left running, the pump will turn o after a time-out period. The pump 1 low-speed will time out after 30 minutes. The

high-speed will time out after 15 minutes.

On non-circ systems, the low-speed of pump 1 runs when the blower or any other pump is on. If the spa is in Ready Mode

(See page 6), Pump 1 low may also activate for at least 1 minute every 30 minutes to detect the spa temperature (polling)

and then to heat to the set temperature if needed. When the low-speed turns on automatically, it cannot be deactivated

from the panel, however the high speed may be started.

Circulation Pump Modes

If the system is equipped with a circ pump, it will be configured to work in one of three dierent ways:

1, The circ pump operates continuously (24 hours) with the exception of turning o for 30 minutes at a time when the

water temperature reaches 3°F (1.5°C) above the set temperature (most likely to happen in very hot climates).

2, The circ pump stays on continuously, regardless of water temperature.

3, A programmable circ pump will come on when the system is checking temperature (polling), during filter cycles, during

freeze conditions, or when another pump is on.

The specific Circulation Mode that is used has been determined by the Manufacturer and cannot be changed in the field.

Filtration and Ozone

On non-circ systems, Pump 1 low and the ozone generator will run during filtration. On circ systems, the ozone will run with

the circ pump.

The system is factory-programmed with one filter cycle that will run in the evening (assuming the time-of-day is properly

set) when energy rates are often lower. The filter time and duration are programmable. (See page 10)

A second filter cycle can be enabled as needed.

At the start of each filter cycle, the blower (if there is one) or Pump 2 (if there is one) will run briefly to purge its plumbing to maintain good water quality.

Freeze Protection

If the temperature sensors within the heater detect a low enough temperature, then the pump(s) and the blower automatically activate to provide freeze protection. The pump(s) and blower will run either continuously or periodically depending

on conditions.

In colder climates, an optional additional freeze sensor may be added to protect against freeze conditions that may not

be sensed by the standard sensors. Auxiliary freeze sensor protection acts similarly except with the temperature thresholds

determined by the switch. See your dealer for details.

Clean-up Cycle (optional)

When a pump or blower is turned on by a button press, a clean-up cycle begins 30 minutes after the pump or blower is

turned o or times out. The pump and the ozone generator will run for 30 minutes or more, depending on the system. On

some systems, you can change this setting. (See the Preferences section on page 12)

Spa Behavior

the LCD stops flashing, the spa will heat to the new set temperature when required.

If the panel has a single temperature button, pressing the button will cause the temperature to flash. Pressing the button

again will cause the temperature to change in one direction (e.g. UP). After allowing the display to stop flashing, pressing

the Temperature Button will cause the temperature to flash and the next press will change the temperature in the opposite

direction (e.g. DOWN).

Press-and-Hold

If a Temperature button is pressed and held when the temperature is flashing, the temperature will continue to change

until the button is released. If only one temperature button is available and the limit of the Temperature Range is reached

when the button is being held, the progression will reverse direction.

Dual Temperature Ranges

This system incorporates two temperature range settings with independent set temperatures. The High Range designated in

the display by an “up” arrow, and the Low Range designated in the display by a “down” arrow.

These ranges can be used for various reasons, with a common use being a “ready to use” setting vs. a “vacation” setting.

The Ranges are chosen using the menu structure below. Each range maintains its own set temperature as programmed by

the user. This way, when a range is chosen, the spa will heat to the set temperature associated with that range.

For example:

High Range might be set between 80°F and 104°F.

Low Range might be set between 50°F and 99°F.

More specific Temp Ranges may be determined by

the Manufacturer.

Freeze Protection is active in either range.

See Ready and Rest on Page 6

for additional heating control information.

High-Range vs.

Low-Range Temp Choice

Press a Temp Button repeatedly to change the temperature.

Pressing and holding a Temp Button will also change the temperature.

Pressing and holding a Temp Button will also change the temperature.

Toggle the Range arrows in the LCD.

SET

RANGE

SET

RANGE

Set Temp will Show & Flash

Set Temp will Show & Flash

SET

RANGE

FLTR

1

SET

RANGE

FLTR

1

SET

RANGE

FLTR1

SET

RANGE

SET

RANGE

Waiting

Several Seconds

Reverts to Original Setting

To Set

*****

SET

RANGE

While

temperature

is ashing...

To next item in Main Menu

Main Screen

READY

RANGE

FLTR1

Main Screen

READY

RANGE

FLTR1

Several Seconds

OR

Main Screen

READY

RANGE

FLTR1

Press a Temp Button repeatedly to change the temperature.

Several Seconds

OR

Main Screen

READY

RANGE

FLTR1

Main Screen

READY

RANGE

FLTR

1

Indicates Flashing or Changing Segment

Key

A temperature button, used for “Action”

Light or dedicated “Choose” button, depending on control panel

conguration

Indicates Alternating or Progressive Message - every 1/2 second

Waiting time that keeps the last change to a menu item.

Waiting time (depends on menu item) that reverts to original

setting and

ignores any change to that menu item.

*****

Adjusting the Set Temperature

When using a panel with Up and Down buttons (Temperature buttons), pressing Up or Down will cause the temperature to

flash. Pressing a temperature button again will adjust the set temperature in the direction indicated on the button. When

the LCD stops flashing, the spa will heat to the new set temperature when required.

If the panel has a single temperature button, pressing the button will cause the temperature to flash. Pressing the button

again will cause the temperature to change in one direction (e.g. UP). After allowing the display to stop flashing, pressing

the Temperature Button will cause the temperature to flash and the next press will change the temperature in the opposite

direction (e.g. DOWN).

Press-and-Hold

If a Temperature button is pressed and held when the temperature is flashing, the temperature will continue to change

until the button is released. If only one temperature button is available and the limit of the Temperature Range is reached

when the button is being held, the progression will reverse direction.

Dual Temperature Ranges

This system incorporates two temperature range settings with independent set temperatures. The High Range designated in

the display by an “up” arrow, and the Low Range designated in the display by a “down” arrow.

These ranges can be used for various reasons, with a common use being a “ready to use” setting vs. a “vacation” setting.

The Ranges are chosen using the menu structure below. Each range maintains its own set temperature as programmed by

the user. This way, when a range is chosen, the spa will heat to the set temperature associated with that range.

For example:

High Range might be set between 80°F and 104°F.

Low Range might be set between 50°F and 99°F.

More specific Temp Ranges may be determined by

the Manufacturer.

Freeze Protection is active in either range.

See Ready and Rest on Page 6

for additional heating control information.

Temperature and Temp Range

Indicates Flashing or Changing Segment

Key

A temperature button, used for “Action”

Light or dedicated “Choose” button, depending on control panel

conguration

Indicates Alternating or Progressive Message - every 1/2 second

Waiting time that keeps the last change to a menu item.

Waiting time (depends on menu item) that reverts to original

setting and

ignores any change to that menu item.

*****

Indicates Flashing or Changing Segment

Key

A temperature button, used for “Action”

Light or dedicated “Choose” button, depending on control panel

conguration

Indicates Alternating or Progressive Message - every 1/2 second

Waiting time that keeps the last change to a menu item.

Waiting time (depends on menu item) that reverts to original

setting and

ignores any change to that menu item.

*****

In order for the spa to heat, a pump needs to circulate water through the heater. The pump that performs this function is

known as the “heater pump.”

The heater pump can be either a 2-Speed Pump 1 or a circulation pump.

If the heater pump is a 2-Speed Pump 1, READY Mode will circulate water every 1/2 hour, using Pump 1 Low, in order to

maintain a constant water temperature, heat as needed, and refresh the temperature display. This is known as “polling.”

REST Mode will only allow heating during programmed filter cycles. Since polling does not occur, the temperature display

may not show a current temperature until the heater pump has been running for a minute or two.

Circulation Mode (See Page 4, under Pumps, for other circulation modes)

If the spa is configured for 24HR circulation, the heater pump generally runs continuously. Since the heater pump is always

running, the spa will maintain set temperature and heat as needed in Ready Mode, without polling.

In Rest Mode, the spa will only heat to set temperature during programmed filter times, even though the water is being

filtered constantly when in Circulation Mode.

Mode – Ready and Rest

In order for the spa to heat, a pump needs to circulate water through the heater. The pump that performs this function is

known as the “heater pump.”

The heater pump can be either a 2-Speed Pump 1 or a circulation pump.

If the heater pump is a 2-Speed Pump 1, READY Mode will circulate water every 1/2 hour, using Pump 1 Low, in order to

maintain a constant water temperature, heat as needed, and refresh the temperature display. This is known as “polling.”

REST Mode will only allow heating during programmed filter cycles. Since polling does not occur, the temperature display

may not show a current temperature until the heater pump has been running for a minute or two.

Circulation Mode (See Page 4, under Pumps, for other circulation modes)

If the spa is configured for 24HR circulation, the heater pump generally runs continuously. Since the heater pump is always

running, the spa will maintain set temperature and heat as needed in Ready Mode, without polling.

In Rest Mode, the spa will only heat to set temperature during programmed filter times, even though the water is being

filtered constantly when in Circulation Mode.

Mode – Ready and Rest

READYSET

SET

REST

READY Mode will allow the spa to Poll and determine a need for heat. The panel will maintain a “current” temperature display.

REST Mode will not Poll and will only heat during lter cycles. The panel will not display a current temperature at all times.

The Main Screen will display RUN PUMP FOR TEMP if the ltration pump has not run for over 1 hour.

The Main Screen will display normally during Filter Cycles or when the spa is in use.

If the ltration pump has been o for an hour or more, when any function button, EXCEPT Light, is pressed on the panel,

the pump used in conjuncton with the heater will run so that temperature can be sensed and displayed.

1 Hour

REST

RANGE

REST

RANGE

REST

RANGE

REST

R

ANGE

REST

RANGE

While the Temperature is

still ashing, press Light

repeatedly until MODE

appears in the LCD.

SET

RANGE

Main Screen

READY

RANGE

FLTR1

Main Screen

REST

RANGE

FLTR1

Main Screen

REST

RANGE

FLTR1

Toggle between READY and REST

Pressing Light when the display is toggled will go to Main Screen.

To next item in

Main Menu

If not toggled

Waiting

Several Seconds

Reverts to Original Setting

To Set

*****

Indicates Flashing or Changing Segment

Key

A temperature button, used for “Action”

Light or dedicated “Choose” button, dependin

g on control panel conguration

Indicates Alternating or Progressive Messag

e - every 1/2 second

Waiting time that keeps the last change to a m

enu item.

Waiting time (depends on menu item) that r

everts to original setting and

ignores any change to that menu item.

*****

In order for the spa to heat, a pump needs to circulate water through the heater. The pump that performs this function is

known as the “heater pump.”

The heater pump can be either a 2-Speed Pump 1 or a circulation pump.

If the heater pump is a 2-Speed Pump 1, READY Mode will circulate water every 1/2 hour, using Pump 1 Low, in order to

maintain a constant water temperature, heat as needed, and refresh the temperature display. This is known as “polling.”

REST Mode will only allow heating during programmed filter cycles. Since polling does not occur, the temperature display

may not show a current temperature until the heater pump has been running for a minute or two.

Circulation Mode (See Page 4, under Pumps, for other circulation modes)

If the spa is configured for 24HR circulation, the heater pump generally runs continuously. Since the heater pump is always

running, the spa will maintain set temperature and heat as needed in Ready Mode, without polling.

In Rest Mode, the spa will only heat to set temperature during programmed filter times, even though the water is being

filtered constantly when in Circulation Mode.

Ready-in-Rest Mode

READY/REST appears in the display if the spa is in Rest Mode and Jet 1 is pressed. It is assumed that the spa is being used

and will heat to set temperature. While Pump 1 High can be turned on and o, Pump 1 Low will run until set temperature

is reached, or 1 hour has passed. After 1 hour, the System will revert to Rest Mode. This mode can also be reset by entering

the Mode Menu and changing the Mode.

Mode – Ready and Rest

READYSET

SET

REST

READY Mode will allow the spa to Poll and determine a need for heat. The panel will maintain a “current” temperature display.

REST Mode will not Poll and will only heat during lter cycles. The panel will not display a current temperature at all times.

The Main Screen will display RUN PUMP FOR TEMP if the ltration pump has not run for over 1 hour.

The Main Screen will display normally during Filter Cycles or when the spa is in use.

If the ltration pump has been o for an hour or more, when any function button, EXCEPT Light, is pressed on the panel,

the pump used in conjuncton with the heater will run so that temperature can be sensed and displayed.

1 Hour

REST

RANGE

REST

RANGE

REST

RANGE

REST

R

ANGE

REST

RANGE

While the Temperature is

still ashing, press Light

repeatedly until MODE

appears in the LCD.

SET

RANGE

Main Screen

READY

RANGE

FLTR1

Main Screen

REST

RANGE

FLTR1

Main Screen

REST

RANGE

FLTR1

Toggle between READY and REST

Pressing Light when the display is toggled will go to Main Screen.

To next item in

Main Menu

If not toggled

Waiting

Several Seconds

Reverts to Original Setting

To Set

*****

Indicates Flashing or Changing Segment

Key

A temperature button, used for “Action”

Light or dedicated “Choose” button, depending on control panel conguration

Indicates Alternating or Progressive Message - every 1/2 second

Waiting time that keeps the last change to a menu item.

Waiting time (depends on menu item) that reverts to original setting and

ignores any change to that menu item.

*****

Main Screen

REST

RANGE

Main Screen

READY

/ REST

RANGE

J

Indicates Flashing or Changing Segment

Key

A temperature button, used for “Action”

Light or dedicated “Choose” button, depending on control panel

conguration

Indicates Alternating or Progressive Message - every 1/2 second

Waiting time that keeps the last change to a menu item.

Waiting time (depends on menu item) that reverts to original

setting and

ignores any change to that menu item.

*****

Show and Set Time-of-Day

Be sure to set the Time-of-Day

Setting the time-of-day can be important for determining filtration times and other background features.

When in the TIME menu, SET TIME will flash on the display if no time-of-day is set in the memory.

24-hour time display can be set under the PREF menu.

Show and Set Time-of-Day

P

P

SET

P

SET

P

SET

P

SET

P

To next item in

Main Menu

While the Temperature is

still ashing, press Light

repeatedly until TIME

appears in the LCD.

If Time of Day is not actually programmed due to a power cycle,

SET TIME will appear in the menu instead of just TIME.

SET

RANGE

Main Screen

READY

RANGE

FLTR1

Main Screen

READY

RANGE

FLTR1

Several Seconds

Main Screen

READY

RANGE

FLTR1

Waiting

Several Seconds

Reverts to Original Setting

To Set

*****

Be sure to set the Time-of-Day

Setting the time-of-day can be important for determining filtration times and other background features.

When in the TIME menu, SET TIME will flash on the display if no time-of-day is set in the memory.

24-hour time display can be set under the PREF menu.

Indicates Flashing or Changing Segment

Key

A temperature button, used for “Action”

Light or dedicated “Choose” button, depending on contr

ol panel conguration

Indicates Alternating or Progressive Messag

e - every 1/2 second

Waiting time that keeps the last change to a menu item.

Waiting time (depends on menu item) that reverts to origin

al setting and

ignores any change to that menu item.

*****

Indicates Flashing or Changing Segment

Key

A temperature button, used for “Action”

Light or dedicated “Choose” button, depending on control panel

conguration

Indicates Alternating or Progressive Message - every 1/2 second

Waiting time that keeps the last change to a menu item.

Waiting time (depends on menu item) that reverts to original

setting and

ignores any change to that menu item.

*****

Show and Set Time-of-Day

P

P

SET

P

SET

P

SET

P

SET

P

To next item in

Main Menu

While the Temperature is

still ashing, press Light

repeatedly until TIME

appears in the LCD.

If Time of Day is not actually programmed due to a power cycle,

SET TIME will appear in the menu instead of just TIME.

SET

RANGE

Main Screen

READY

RANGE

FLTR1

Main Screen

READY

RANGE

FLTR1

Several Seconds

Main Screen

READY

RANGE

FLTR1

Waiting

Several Seconds

Reverts to Original Setting

To Set

*****

Be sure to set the Time-of-Day

Setting the time-of-day can be important for determining filtration times and other background features.

When in the TIME menu, SET TIME will flash on the display if no time-of-day is set in the memory.

24-hour time display can be set under the PREF menu.

Note:

If power is interrupted to the system, Time-of-Day is not stored. The system will still operate and all other user settings

will be stored. If filter cycles are required to run at a particular time of day, resetting the clock will return the filter times

to the actual programmed periods.

When the system starts up, it defaults to 12:00 Noon, so another way to get filter times back to normal is to start up the

spa at noon on any given day. SET TIME will still flash in the TIME Menu until the time is actually set, but since the spa

started at noon, the filter cycles will run as programmed.

Flip (Invert Display)

Indicates Flashing or Changing Segment

Key

A temperature button, used for “Action”

Light or dedicated “Choose” button, depending on control panel conguration

Indicates Alternating or Progressive Message - every 1/2 second

Waiting time that keeps the last change to a menu item.

Waiting time (depends on menu item) that reverts to original setting and

ignores any change to that menu item.

*****

Show and Set Time-of-Day

P

P

SET

P

SET

P

SET

P

SET

P

To next item in

Main Menu

While the Temperature is

still ashing, press Light

repeatedly until TIME

appears in the LCD.

If Time of Day is not actually programmed due to a power cycle,

SET TIME will appear in the menu instead of just TIME.

SET

RANGE

Main Screen

READY

RANGE

FLTR1

Main Screen

READY

RANGE

FLTR1

Several Seconds

Main Screen

READY

RANGE

FLTR1

Waiting

Several Seconds

Reverts to Original Setting

To Set

*****

Be sure to set the Time-of-Day

Setting the time-of-day can be important for determining filtration times and other background features.

When in the TIME menu, SET TIME will flash on the display if no time-of-day is set in the memory.

24-hour time display can be set under the PREF menu.

Note:

If power is interrupted to the system, Time-of-Day is not stored. The system will still operate and all other user settings

will be stored. If filter cycles are required to run at a particular time of day, resetting the clock will return the filter times

to the actual programmed periods.

When the system starts up, it defaults to 12:00 Noon, so another way to get filter times back to normal is to start up the

spa at noon on any given day. SET TIME will still flash in the TIME Menu until the time is actually set, but since the spa

started at noon, the filter cycles will run as programmed.

Flip (Invert Display)

Several Seconds

or

SET

SET

Toggle the inversion of the segmented characters

Pressing Light when the display is toggled will go to Main Screen.

READY

RANGE

FLTR1

While the Temperature is

still ashing, press Light

repeatedly until FLIP

appears in the LCD.

SET

RANGE

Main Screen

Main Screen

READY

RANGE

FLTR

1

To next item in

Main Menu

If not toggled

Indicates Flashing or Changing Segment

Key

A temperature button, used for “Action”

Light or dedicated “Choose” button, depending on control panel conguration

Indicates Alternating or Progressive Message - every 1/2 second

Waiting time that keeps the last change to a menu item.

Waiting time (depends on menu item) that reverts to original setting and

ignores any change to that menu item.

*****

Show and Set Time-of-Day

P

P

SET

P

SET

P

SET

P

SET

P

To next item in

Main Menu

While the Temperature is

still ashing, press Light

repeatedly until TIME

appears in the LCD.

If Time of Day is not actually programmed due to a power cycle,

SET TIME will appear in the menu instead of just TIME.

SET

RANGE

Main Screen

READY

RANGE

FLTR1

Main Screen

READY

RANGE

FLTR1

Several Seconds

Main Screen

READY

RANGE

FLTR1

Waiting

Several Seconds

Reverts to Original Setting

To Set

*****

Be sure to set the Time-of-Day

Setting the time-of-day can be important for determining filtration times and other background features.

When in the TIME menu, SET TIME will flash on the display if no time-of-day is set in the memory.

24-hour time display can be set under the PREF menu.

Note:

If power is interrupted to the system, Time-of-Day is not stored. The system will still operate and all other user settings

will be stored. If filter cycles are required to run at a particular time of day, resetting the clock will return the filter times

to the actual programmed periods.

When the system starts up, it defaults to 12:00 Noon, so another way to get filter times back to normal is to start up the

spa at noon on any given day. SET TIME will still flash in the TIME Menu until the time is actually set, but since the spa

started at noon, the filter cycles will run as programmed.

Note:

Some panels may have a dedicated FLIP button,

which allows the user to flip the display with a single button-press.

Flip (Invert Display)

Several Seconds

or

SET

SET

Toggle the inversion of the segmented characters

Pressing Light when the display is toggled will go to Main Screen.

READY

RANGE

FLTR1

While the Temperature is

still ashing, press Light

repeatedly until FLIP

appears in the LCD.

SET

RANGE

Main Screen

Main Screen

READY

RANGE

FLTR

1

To next item in

Main Menu

If not toggled

Indicates Flashing or Changing Segment

Key

A temperature button, used for “Action”

Light or dedicated “Choose” button, depending on control panel conguration

Indicates Alternating or Progressive Message - every 1/2 second

Waiting time that keeps the last change to a menu item.

Waiting time (depends on menu item) that reverts to original setting and

ignores any change to that menu item.

*****

Restricting Operation

The control can be restricted to prevent unwanted use or temperature adjustments.

Locking the panel prevents the controller from being used, but all automatic functions are still active.

Locking the Temperature allows Jets and other features to be used, but the Set Temperature and other programmed settings

cannot be adjusted.

Temperature Lock allows access to a reduced selection of menu items.

These include Set Temperature, FLIP, LOCK, UTIL, INFO and FALT LOG.

Restricting Operation

LOCK will remain on the display

for 3 seconds and then revert to the normal display.

When the Temperature is locked, the panel will display the Set Temperature

by pressing a Temperature Button, as ususal.

LOCK will appear if an attempt to reset the temperature is made with a subsequent button press.

Adjustable settings in the menus are also locked.

Other function buttons will operate normally.

Panel Locked

Temperature Locked

Any

Button

Press

Locks all function buttons.Locks Temp. and Settings.

SET

SET

SET

SET

READY

RANGE

FLTR1

READY

RANGE

FLTR1

While the Temperature is

still ashing, press Light

repeatedly until LOCK

appears in the LCD.

SET

RANGE

Main Screen

Main Screen

READY

RANGE

FLTR1

Main Screen

READY

RANGE

FLTR1

Main Screen

READY

RANGE

FLTR1

Main Screen

READY

RANGE

FLTR1

READY

RANGE

FLTR1

Main Screen

READY

RANGE

FLTR1

SET

Several Seconds

To next item in

Main Menu

Several

Seconds

Several

Seconds

RANGE

Waiting

Several Seconds

Reverts to Original Setting

To Set

*****

Indicates Flashing or Changing Segment

Key

A temperature button, used for “Action”

Light or dedicated “Choose” button, depending on control pa

nel conguration

Indicates Alternating or Progressive Message - every 1/2 seco

nd

Waiting time that keeps the last change to a menu item.

Waiting time (depends on menu item) that reverts to origin

al setting and

ignores any change to that menu item.

*****

The control can be restricted to prevent unwanted use or temperature adjustments.

Locking the panel prevents the controller from being used, but all automatic functions are still active.

Locking the Temperature allows Jets and other features to be used, but the Set Temperature and other programmed settings

cannot be adjusted.

Temperature Lock allows access to a reduced selection of menu items.

These include Set Temperature, FLIP, LOCK, UTIL, INFO and FALT LOG.

Indicates Flashing or Changing Segment

Key

A temperature button, used for “Action”

Light or dedicated “Choose” button, depending on control panel

conguration

Indicates Alternating or Progressive Message - every 1/2 second

Waiting time that keeps the last change to a menu item.

Waiting time (depends on menu item) that reverts to original

setting and

ignores any change to that menu item.

*****

Restricting Operation

LOCK will remain on the display

for 3 seconds and then revert to the normal display.

When the Temperature is locked, the panel will display the Set Temperature

by pressing a Temperature Button, as ususal.

LOCK will appear if an attempt to reset the temperature is made with a subsequent button press.

Adjustable settings in the menus are also locked.

Other function buttons will operate normally.

Panel Locked

Temperature Locked

Any

Button

Press

Locks all function buttons.Locks Temp. and Settings.

SET

SET

SET

SET

READY

RANGE

FLTR1

READY

RANGE

FLTR1

While the Temperature is

still ashing, press Light

repeatedly until LOCK

appears in the LCD.

SET

RANGE

Main Screen

Main Screen

READY

RANGE

FLTR1

Main Screen

READY

RANGE

FLTR1

Main Screen

READY

RANGE

FLTR1

Main Screen

READY

RANGE

FLTR1

READY

RANGE

FLTR1

Main Screen

READY

RANGE

FLTR1

SET

Several Seconds

To next item in

Main Menu

Several

Seconds

Several

Seconds

RANGE

Waiting

Several Seconds

Reverts to Original Setting

To Set

*****

Unlocking

Indicates Flashing or Changing Segment

Key

A temperature button, used for “Action”

Light or dedicated “Choose” button, depending on control panel conguration

Indicates Alternating or Progressive Message - every 1/2 second

Waiting time that keeps the last change to a menu item.

Waiting time (depends on menu item) that reverts to original setting and

ignores any change to that menu item.

*****

This Unlock sequence may be used from any screen that may be displayed on a restricted panel.

The control can be restricted to prevent unwanted use or temperature adjustments.

Locking the panel prevents the controller from being used, but all automatic functions are still active.

Locking the Temperature allows Jets and other features to be used, but the Set Temperature and other programmed settings

cannot be adjusted.

Temperature Lock allows access to a reduced selection of menu items.

These include Set Temperature, FLIP, LOCK, UTIL, INFO and FALT LOG.

Restricting Operation

LOCK will remain on the display

for 3 seconds and then revert to the normal display.

When the Temperature is locked, the panel will display the Set Temperature

by pressing a Temperature Button, as ususal.

LOCK will appear if an attempt to reset the temperature is made with a subsequent button press.

Adjustable settings in the menus are also locked.

Other function buttons will operate normally.

Panel Locked

Temperature Locked

Any

Button

Press

Locks all function buttons.Locks Temp. and Settings.

SET

SET

SET

SET

READY

RANGE

FLTR1

READY

RANGE

FLTR1

While the Temperature is

still ashing, press Light

repeatedly until LOCK

appears in the LCD.

SET

RANGE

Main Screen

Main Screen

READY

RANGE

FLTR1

Main Screen

READY

RANGE

FLTR1

Main Screen

READY

RANGE

FLTR1

Main Screen

READY

RANGE

FLTR1

READY

RANGE

FLTR1

Main Screen

READY

RANGE

FLTR1

SET

Several Seconds

To next item in

Main Menu

Several

Seconds

Several

Seconds

RANGE

Waiting

Several Seconds

Reverts to Original Setting

To Set

*****

While pressing and holding the Temperature Button (or UP button, if available),

Slowly press and release the Light Button two times.

READY

RANGE

FLTR

1

Main Screen

A Few

Seconds

Unlocking

Indicates Flashing or Changing Segment

Key

A temperature button, used for “Action”