Mygale M14-F4 FORD User Manual

MYGALE

Technopole

58470 Magny-Cours

France

Tel : +33 (0)3 86 21 86 21

Fax : +33 (0)3 86 21 86 22

Version: V1.2

MYGALE M14-F4 FORD

MSA FORMULA

USER MANUAL

MYGALE

Technopole - 58470 Magny-Cours - France

Tel : +33 (0)3 86 21 86 21

Fax : +33 (0)3 86 21 86 22

2/58

0.0 CONTENT

0.0 CONTENT ....................................................................................................... 2

1.0 CAR VIEWS ..................................................................................................... 3

2.0 CAR SPECIFICATIONS ........................................................................................ 4

2.1 Dimensions .................................................................................................... 4

2.2 Weight ........................................................................................................ 4

2.3 Supplied Parts: Partners ..................................................................................... 5

3.0 SET UP AND OPTIONS ........................................................................................ 6

3.1 Geometry information (in baseline set-up) .................................................................. 6

3.2 Set Up Adjustment ........................................................................................... 7

3.3 Kinematics – Graphical Representation ..................................................................... 18

3.4 Springs ....................................................................................................... 22

3.5 Dampers ...................................................................................................... 23

3.6 Anti-Roll Bars ............................................................................................... 25

3.7 Aero Set Up ................................................................................................. 27

3.8 Brake bias ................................................................................................... 29

3.9 Pedal box adjustment ....................................................................................... 30

3.10 Set-up sheet Baseline Proposal ........................................................................... 33

3.11 Ballast ...................................................................................................... 34

3.12 Paddle shift ................................................................................................ 35

3.13 Gear box ratios ............................................................................................ 36

3.14 Data acquisition ............................................................................................ 37

3.15 Brake pads ................................................................................................. 37

3.16 Steering system adjustments ............................................................................. 38

4.0 ASSEMBLY AND MAINTENANCE ............................................................................ 39

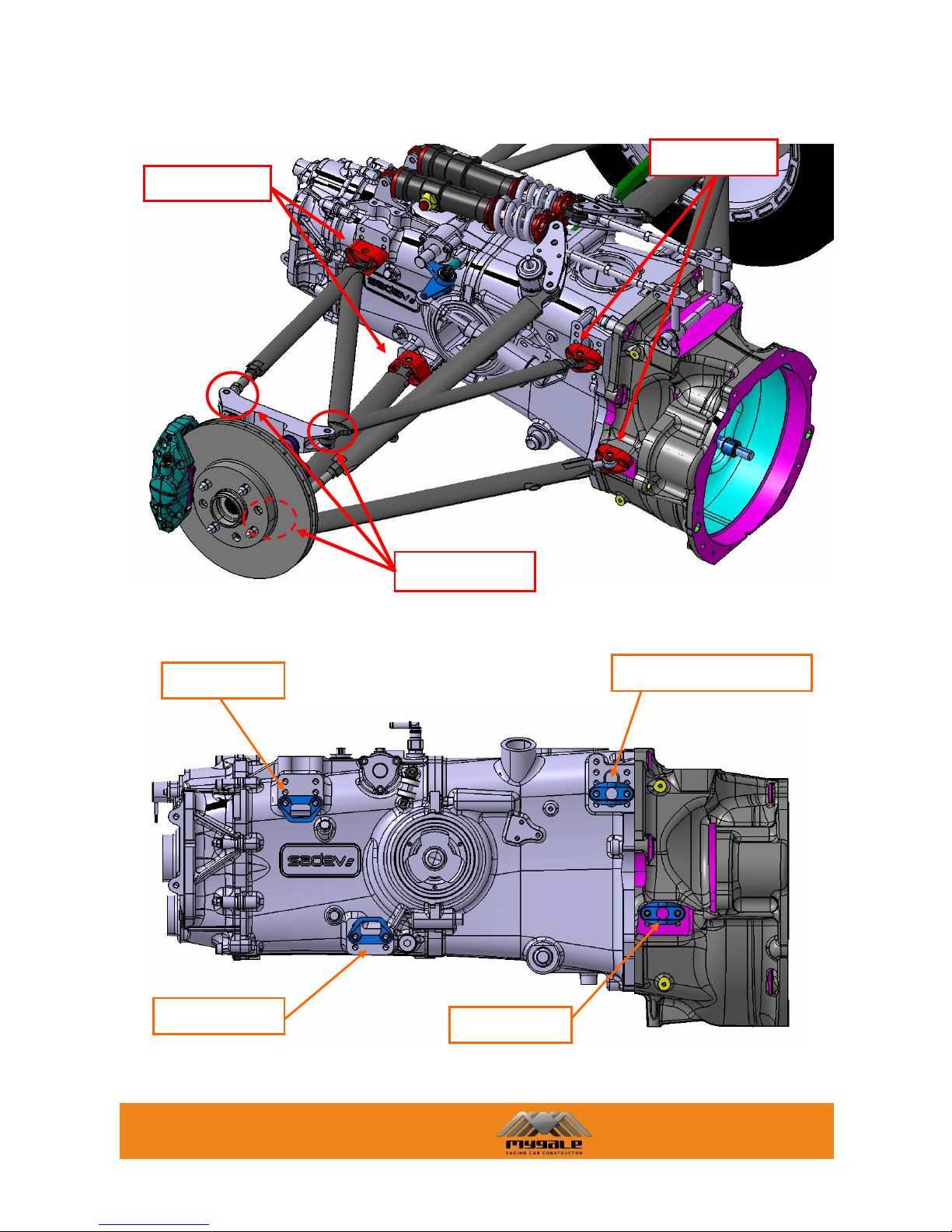

4.1 Engine ........................................................................................................ 39

4.2 Transmission ................................................................................................. 39

4.3 Steering System ............................................................................................. 40

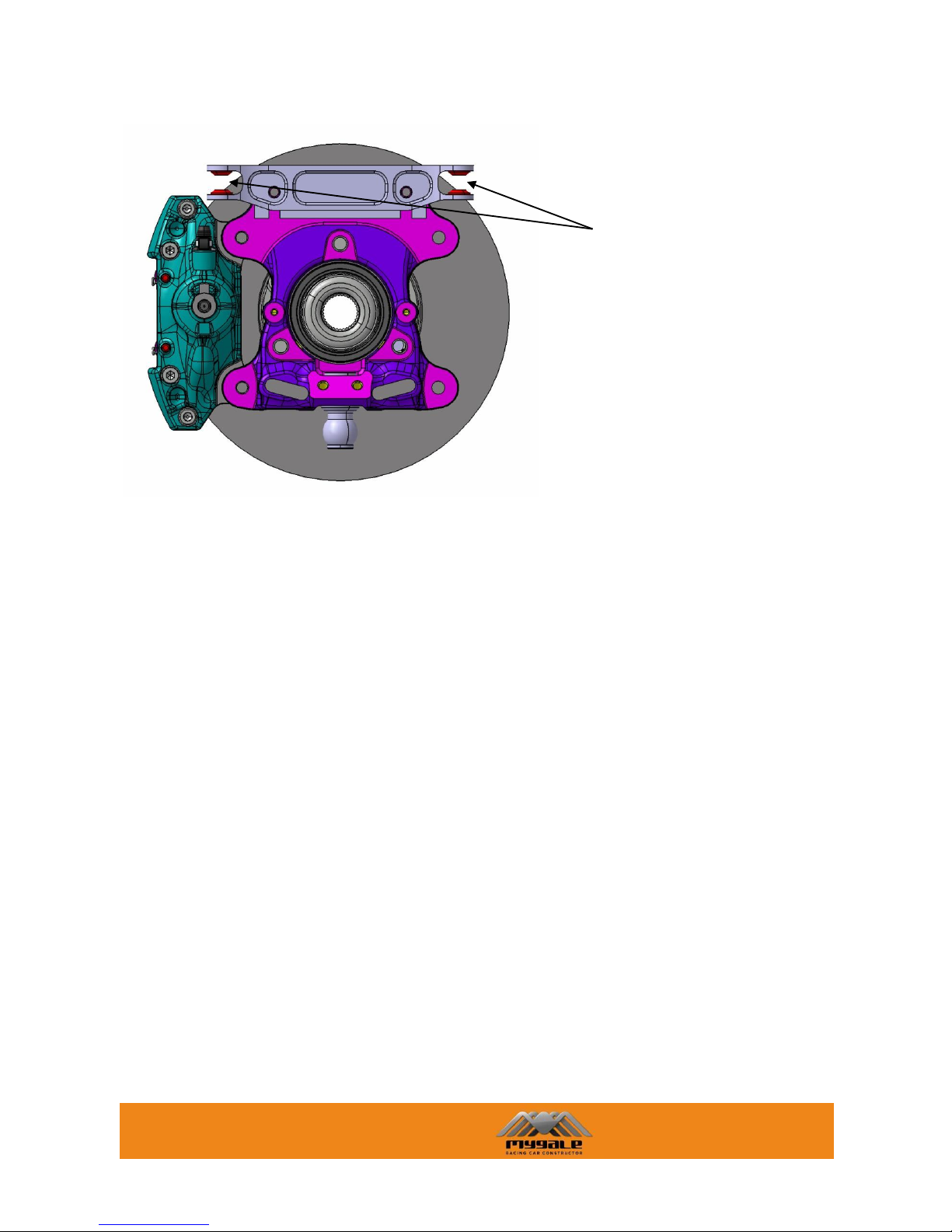

4.4 Hub Assembly ................................................................................................ 42

4.5 Bottom Front Wishbones .................................................................................... 43

4.6 Wheel Cables ................................................................................................ 43

4.7 Heat protection .............................................................................................. 44

4.8 Brake line protection ........................................................................................ 44

4.9 Electricity .................................................................................................... 44

4.10 Wings ....................................................................................................... 44

4.11 Head restraint ............................................................................................. 45

4.12 Monocoque Chassis and Crash Boxes ...................................................................... 45

4.13 Bodywork repairs ........................................................................................... 45

4.14 Extractible seat cut for loom ............................................................................. 45

4.15 Fire extinguisher ........................................................................................... 46

4.16 Markings and holograms ................................................................................... 46

4.17 Screws ...................................................................................................... 46

4.18 Fuel system ................................................................................................. 47

4.19 Cooling system .............................................................................................. 48

4.20 Filling fluids ................................................................................................ 51

4.21 Accident data recorder .................................................................................... 52

4.22 Exploitation tools ........................................................................................... 52

5.0 ANNEXES ...................................................................................................... 56

5.1 Tightening torques (general) ................................................................................ 56

5.2 Tightening torques (F4 mounting): .......................................................................... 57

MYGALE

Technopole - 58470 Magny-Cours - France

Tel : +33 (0)3 86 21 86 21

Fax : +33 (0)3 86 21 86 22

3/58

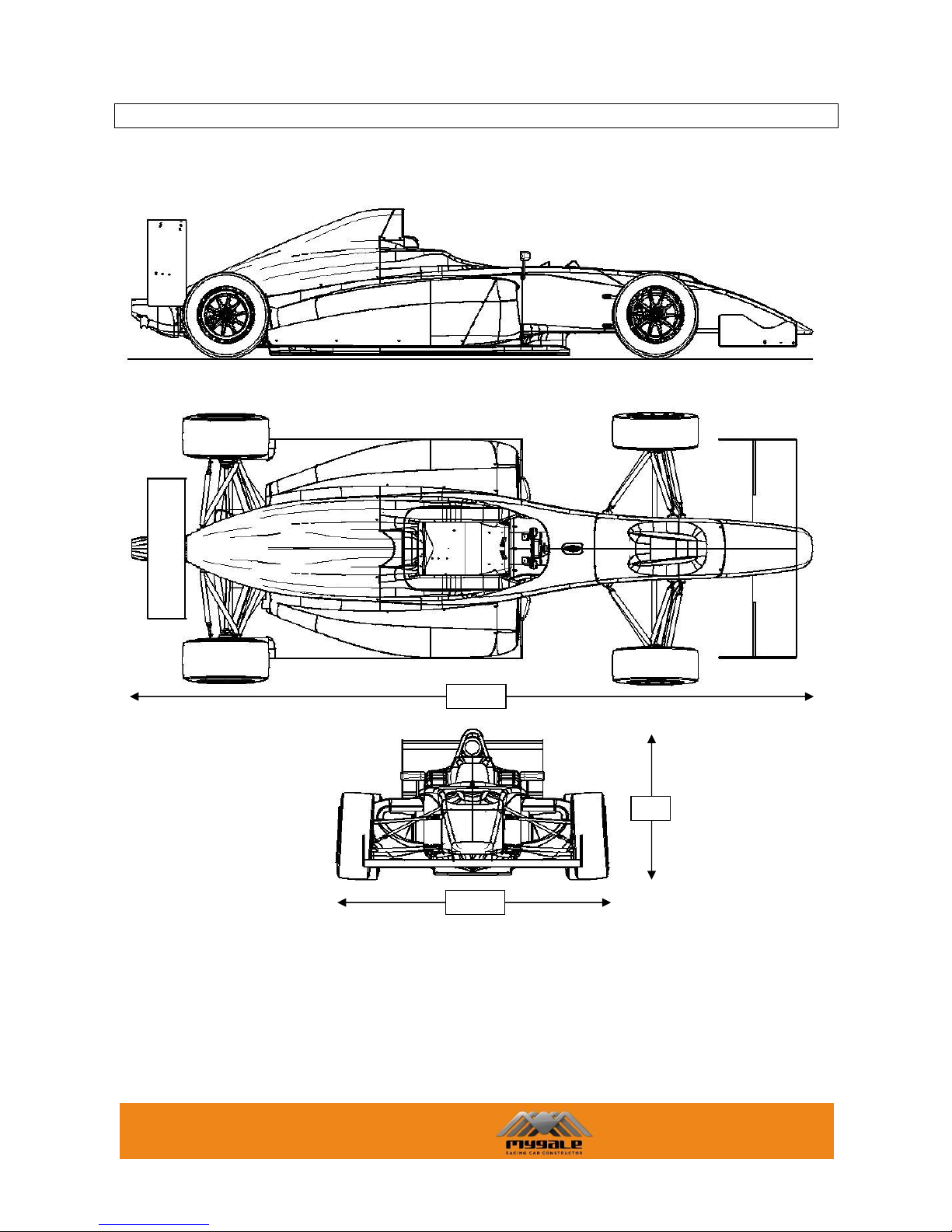

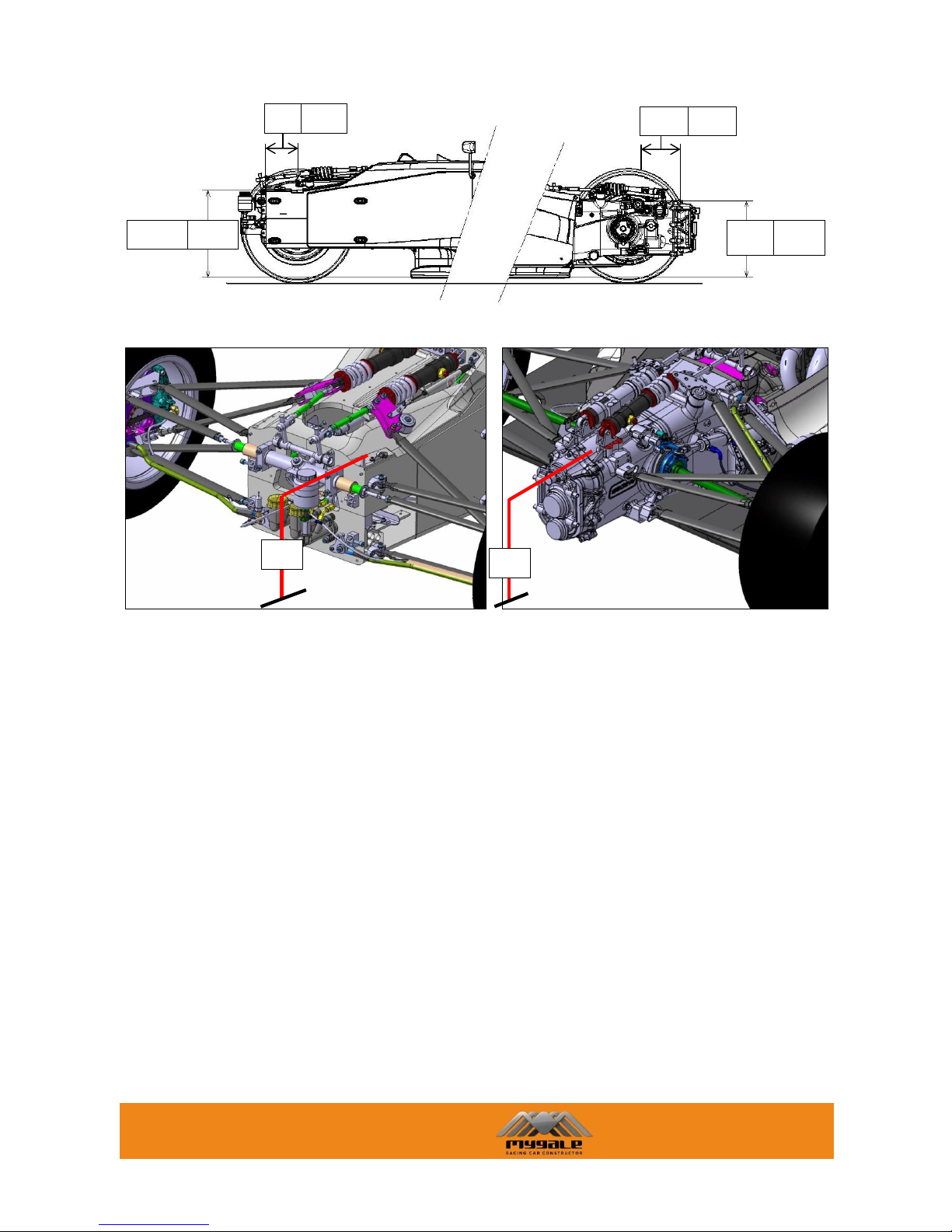

1.0 CAR VIEWS

1738

4341

958

MYGALE

Technopole - 58470 Magny-Cours - France

Tel : +33 (0)3 86 21 86 21

Fax : +33 (0)3 86 21 86 22

4/58

2.0 CAR SPECIFICATIONS

2.1 DIMENSIONS

Description

Reference Dimensions

Length

mm

4341

Height

mm

958

Front ride height

mm

20

Rear ride height

mm

30

Wheelbase

mm

2742

Front overhang

mm

1000

Rear overhang

mm

600

Front overall width

mm

1725 *

Rear overall width

mm

1715 *

Front track

mm

1493.5

Rear track

mm

1430.4

Front wing assy width

mm

1400

Rear wing assy width

mm

898

* depending tyres

2.2 WEIGHT

The minimum allowed weight is specified by sporting regulations of the championship.

The weight of the car should be adjusted by mean of appropriate ballast to ensure that the specified

minimum weight is reached with the driver at any time during the event.

MYGALE

Technopole - 58470 Magny-Cours - France

Tel : +33 (0)3 86 21 86 21

Fax : +33 (0)3 86 21 86 22

5/58

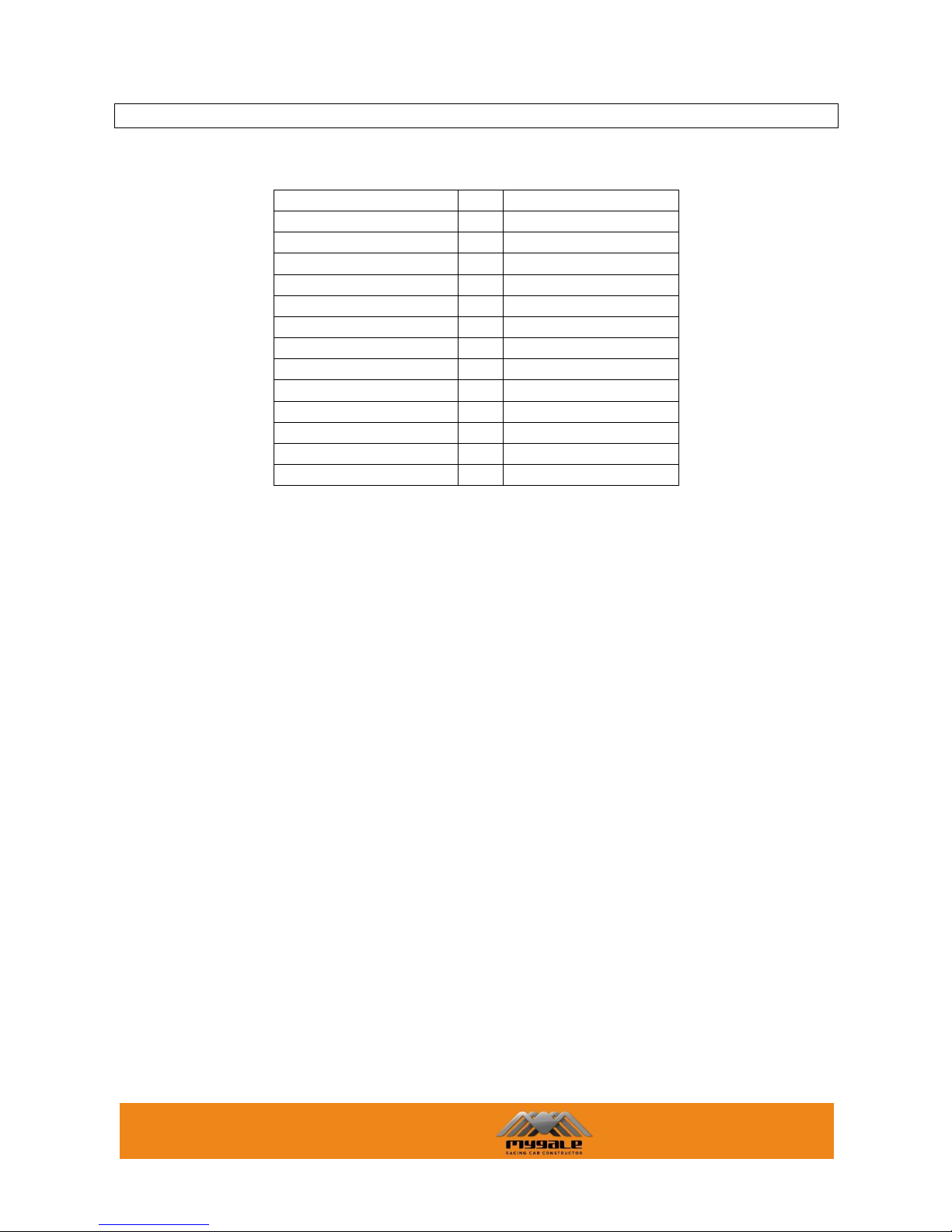

2.3 SUPPLIED PARTS: PARTNERS

Gearbox, driveshaft: Sadev

Steering rack: Titan

Springs, dampers: Sachs

Fuell cell, fuel pump: Premier Fuel

Brake pads: Ferrodo

Brake discs, callipers: Brembo

Extinguisher : OMP

Harness : TRS Motrosports

Rims : Team Dynamics

MYGALE

Technopole - 58470 Magny-Cours - France

Tel : +33 (0)3 86 21 86 21

Fax : +33 (0)3 86 21 86 22

6/58

3.0 SET UP AND OPTIONS

3.1 GEOMETRY INFORMATION (IN BASELINE SET-UP)

The standard set up of the car is:

dimension

FRONT

REAR

Ride Height

mm

24

37

Camber

deg

-3.3

-2.2

Toe

deg

0.00

0.00

Castor

deg

8.21

-22.81

Castor Offset (wheel centre)

mm

5.64

---

Castor Offset (ground)

mm

31.23

---

King Pin

deg

15.46

---

King Pin Offset (wheel centre)

mm

69.1

---

King Pin Offset (ground)

mm

15.4

---

Damper-Spring / Wheel

ratio

0.68

0.71

Anti Roll Bar (deg) / Wheel

ratio

0.69

0.48

Anti Dive % 14.45

22.13

Ackermann

deg

19.9

---

Roll Center Z

mm

17.8

34.5

Mechanical Trail1

mm

30.87

---

1

Mechanical Trail

The perpendicular distance in side elevation between the steering axis and the centre of tyre contact.

It is considered positive when the steering axis is forward of the tyre contact centre and negative

when it is rearward.

MYGALE

Technopole - 58470 Magny-Cours - France

Tel : +33 (0)3 86 21 86 21

Fax : +33 (0)3 86 21 86 22

7/58

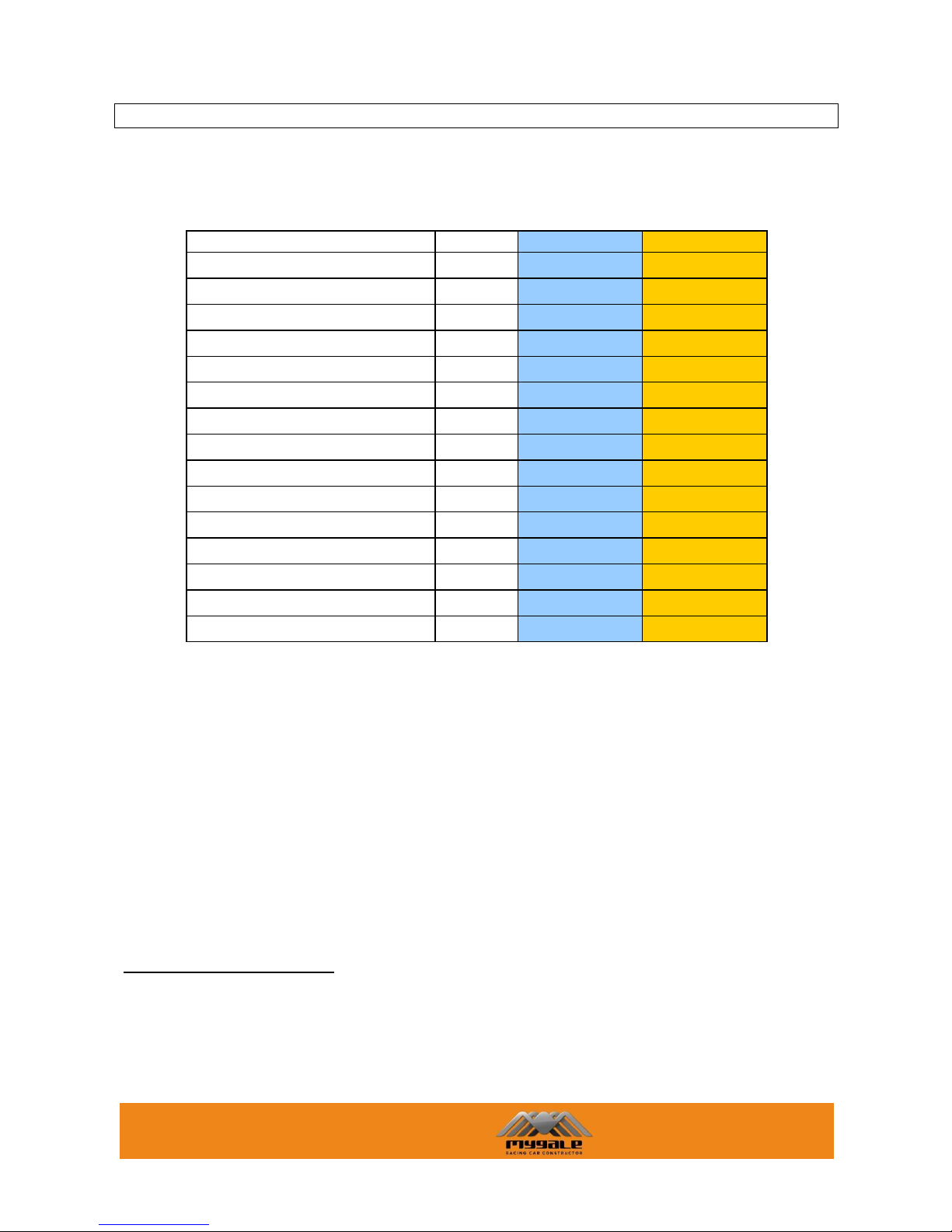

3.2 SET UP ADJUSTMENT

Values are theoretical, assembly dispersion is possible.

3.2.1 RIDE HEIGHT CHECK & ADJUSTMENT

The reference points for calculating the ride height are shown below.

The vehicle reference plane is the lower side of the wood floor. The skid block is below this. The

choice of ride height needs to take account of the skid block thickness which is a maximum of 5mm

below the reference plane (and minimum 2mm).

The diagrams refer to the dimensions from the chassis reference point to the reference plane.

At the front two ride height adjustment screws (F.41.35.001) must be fix on the two reference pads

which are machined into the upper surface of the monocoque and are accessible with the damper cover

removed.

At the rear the reference surfaces are machined pads on the gearbox upper surface, at the level of

the damper bracket and are accessible with the engine cover removed.

Front reference Rear reference

The front reference dimension A1 is 441mm.

The rear reference dimension A2 is 369mm.

MYGALE

Technopole - 58470 Magny-Cours - France

Tel : +33 (0)3 86 21 86 21

Fax : +33 (0)3 86 21 86 22

8/58

b

To set up front and rear ride height values at the level of the front and rear axle centre lines (H1 and

H2 respectively), use the following calculation:

X1 = A1*cos(α) - B1*sin(α) + H1

X2 = A2*cos(α) + B2*sin(α) + H2

(Dimensions in mm)

Where α is the car pitch angle, α = arcsin((H2-H1)/2741.6 in rad.

B1

165

369

A2

A1

441

B2

230

X1

X2

MYGALE

Technopole - 58470 Magny-Cours - France

Tel : +33 (0)3 86 21 86 21

Fax : +33 (0)3 86 21 86 22

9/58

Ride height adjustment:

Front:

Lengths (ball centre to ball centre) for a 20mm ride height: Pushrod 554.6mm.

1 face on the adjuster changes the ride height by 0.95mm.

1 turn on the adjuster changes the ride height by 5.70mm.

For 1mm ride height, 1/6 turn on the adjuster.

Rear:

Lengths (ball centre to ball centre) for a 30mm ride height: Pushrod 527.5mm.

1 face on the adjuster changes the ride height by 1.00mm.

1 turn on the adjuster changes the ride height by 6.00mm.

For 1mm ride height, 1/6 turn on the adjuster.

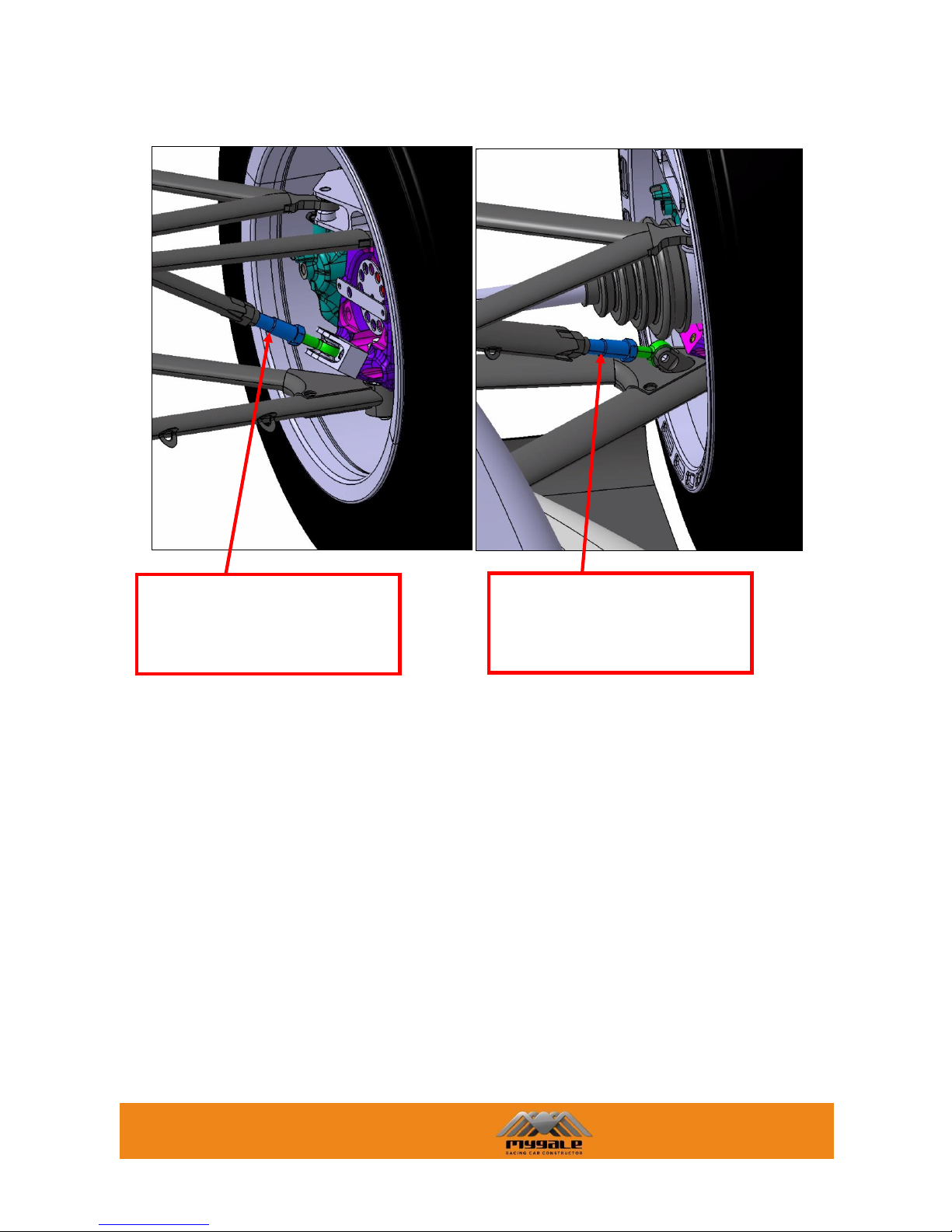

Front ride height adjustment

Lengthen adjuster to raise car.

Shorten adjuster to lower car

Rear ride height adjustment

Lengthen adjuster to raise car.

Shorten adjuster to lower car

MYGALE

Technopole - 58470 Magny-Cours - France

Tel : +33 (0)3 86 21 86 21

Fax : +33 (0)3 86 21 86 22

10/58

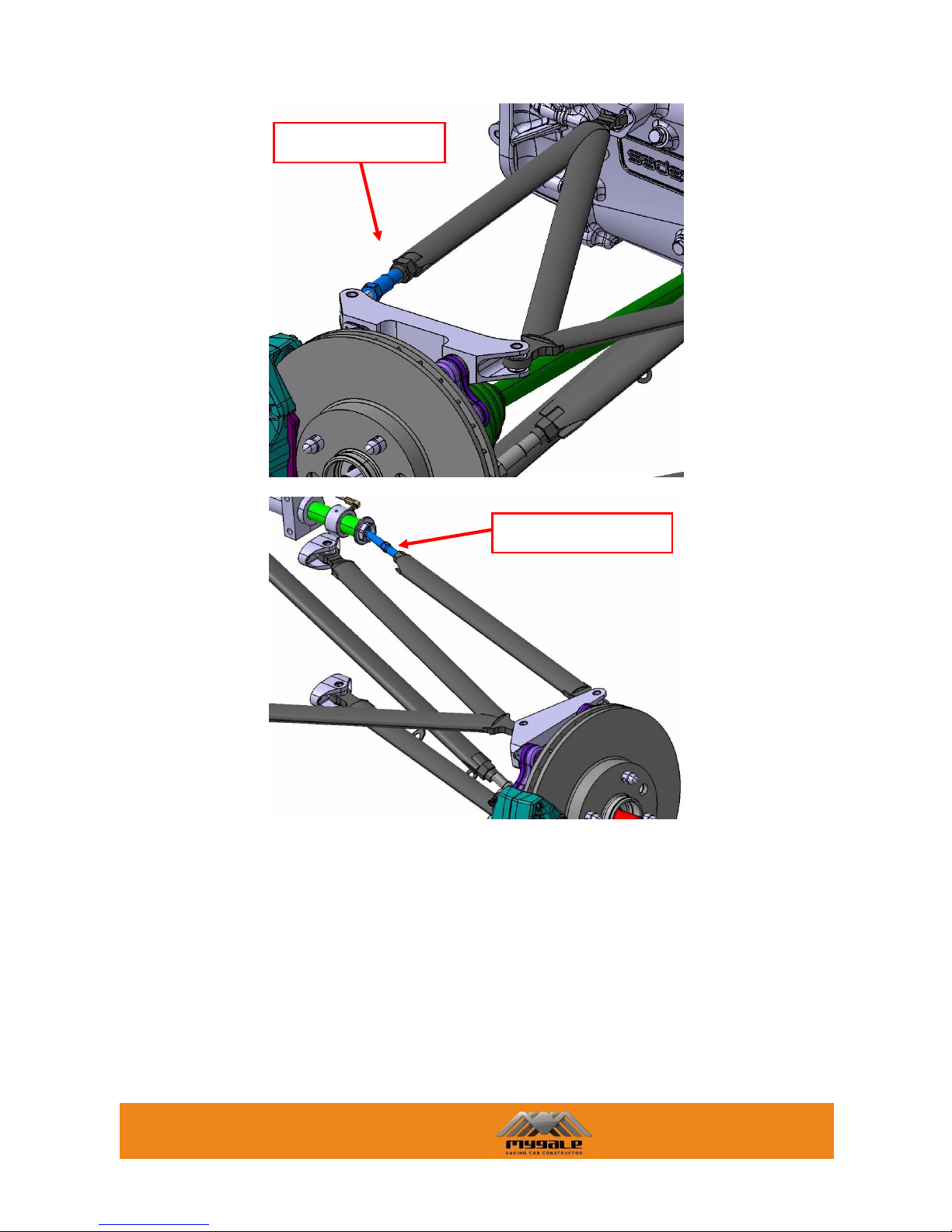

3.2.2 CASTOR CHECK & ADJUSTMENT

The castor angle is the angle, in side elevation, between the steering axis and the vertical. It is

considered positive when the steering axis is inclined rearward.

You can check the castor angle in the same way in the front and in the rear suspension. The castor

angle can be calculated as follows:

Measure the angle of the steering arm plane for the front (or the wishbone mount plane for the rear)

to the horizontal; this is the measured castor angle (MCA). Positive inclined down to rear, negative

inclined down to front. Calculate the true castor angle (TCA) as following:

Front Castor Angle

Rear Castor Angle

True castor angle

= MCA + 7.08°

= MCA - 25.41°

Base settings

8.21°

-22.81°

Base set up length, wishbone

ball centre to ball centre

556.4mm

578.9mm

The Castor angle influences the Castor Offset, the Mechanical Trail and therefore the force to turn

the wheel.

Castor Offset, (mm)

The distance in side elevation between the point where the steering axis intersects the ground, and

the centre of tyre contact. The offset is considered positive when the intersection point is forward of

the tyre contact centre and negative when it is rearward. (Base setting: FRT=31.23mm)

Mechanical Trail, (mm)

The perpendicular distance in side elevation between the steering axis and the centre of tyre contact.

It is considered positive when the steering axis is forward of the tyre contact centre and negative

when it is rearward. (Base setting: FRT=30.87mm)

The Castor Offset is along the ground plane while the Mechanical Trail is perpendicular to the steering

axis.

MCA

TCA

MCA

TCA

Car direction

Horizontal and

vertical lines

MYGALE

Technopole - 58470 Magny-Cours - France

Tel : +33 (0)3 86 21 86 21

Fax : +33 (0)3 86 21 86 22

11/58

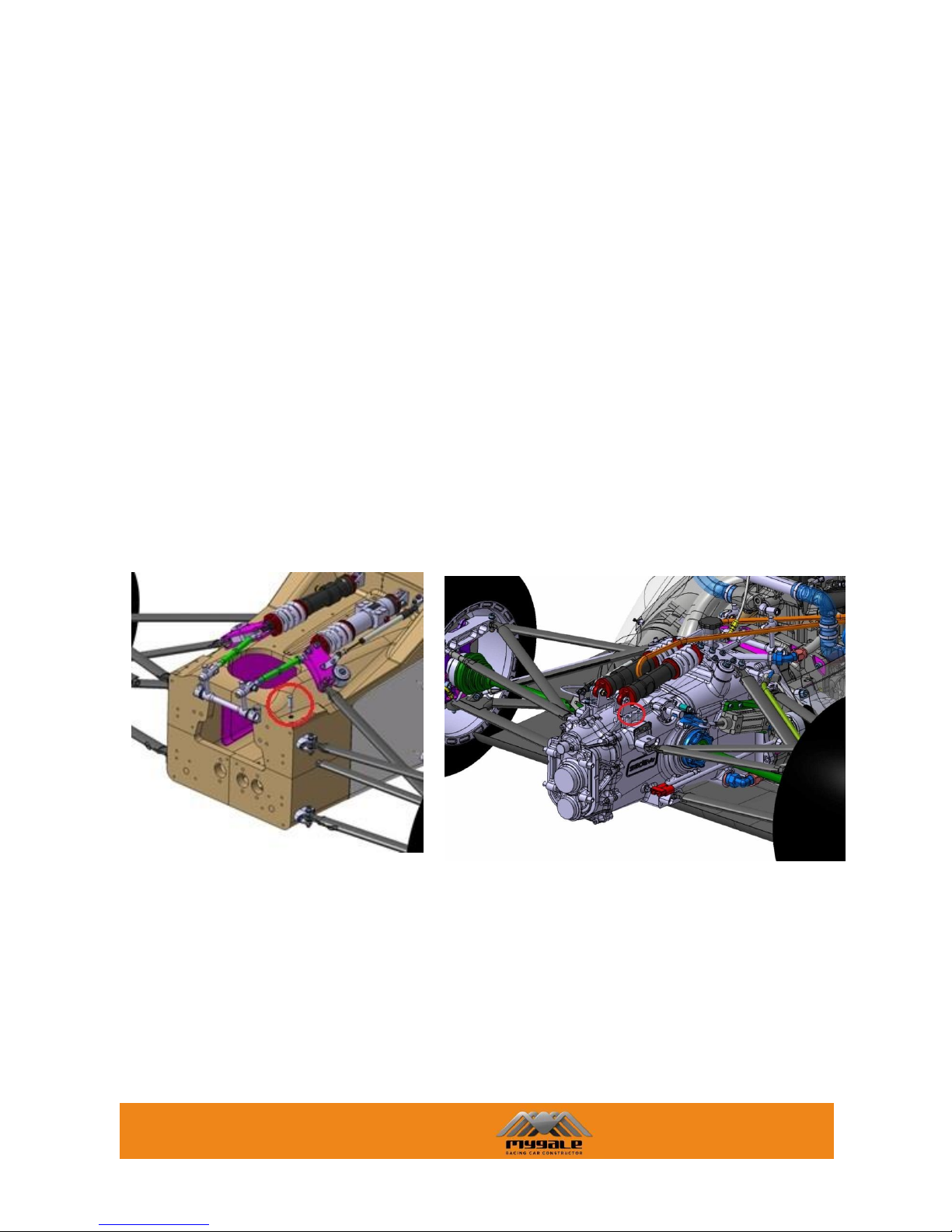

Castor adjustment:

Adjust the castor angle with the rod end bearings as shown in the following pictures:

Front castor adjustment

Rear castor adjustment

MYGALE

Technopole - 58470 Magny-Cours - France

Tel : +33 (0)3 86 21 86 21

Fax : +33 (0)3 86 21 86 22

12/58

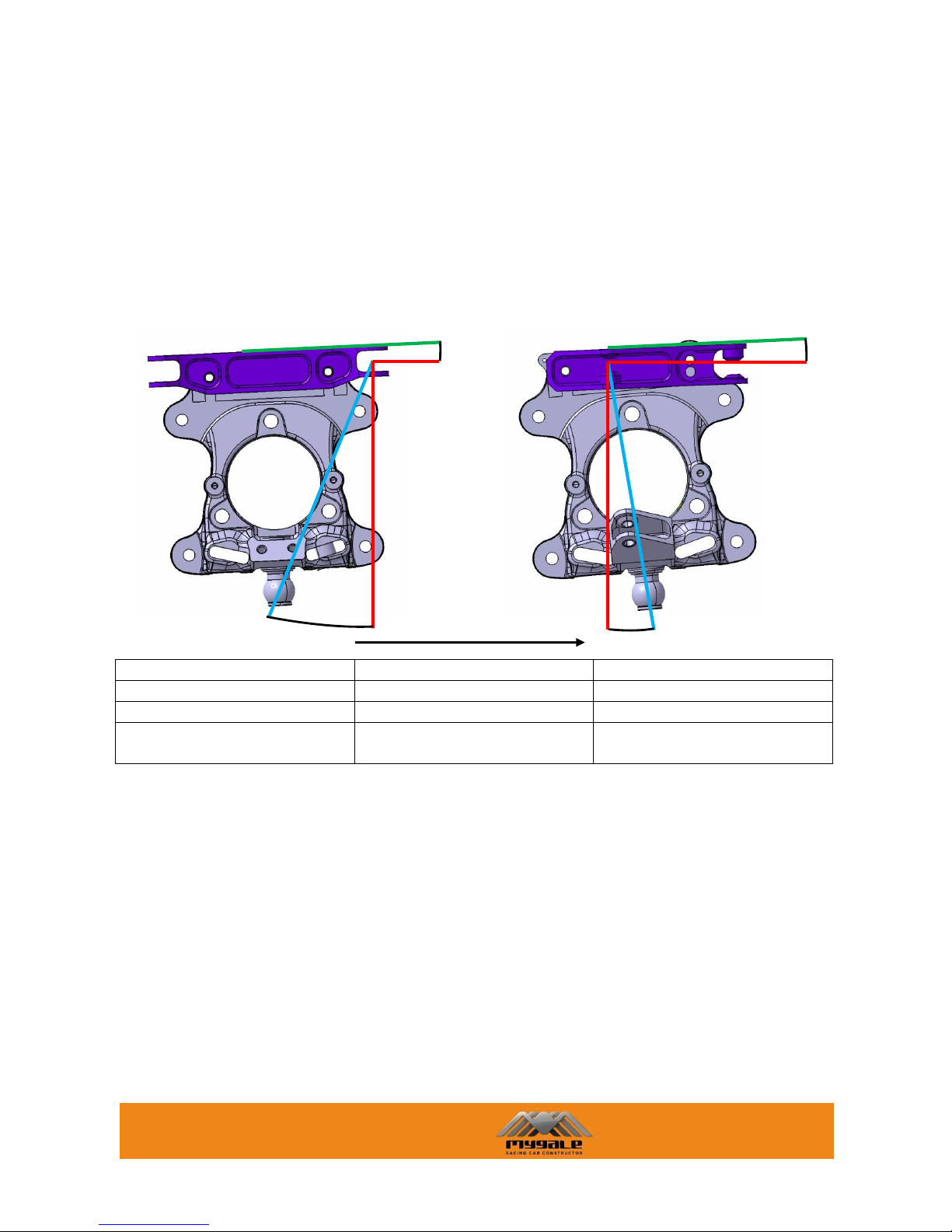

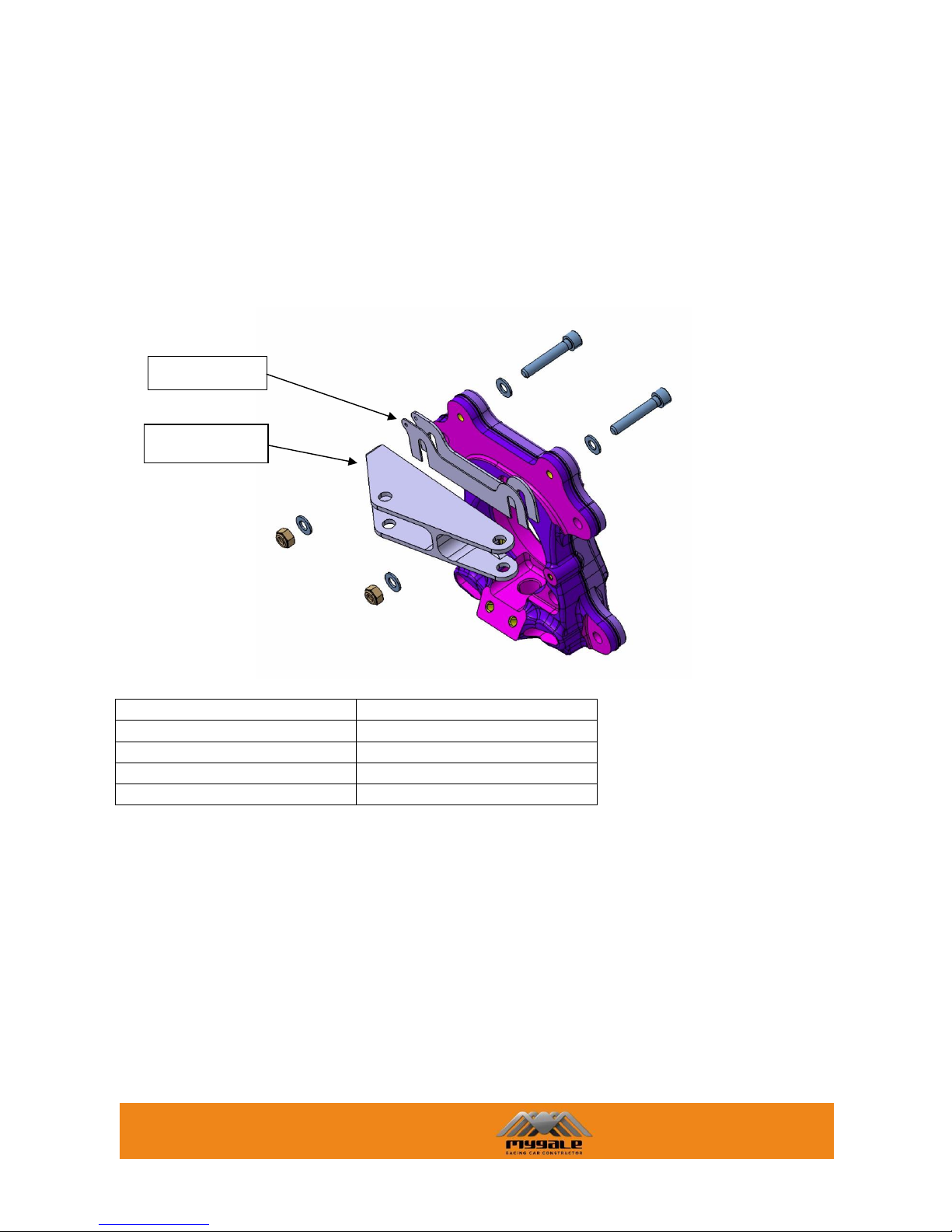

3.2.3 CAMBER ADJUSTMENT

The Camber Angle is the inclination of the wheel plane to the vertical. It is considered positive when

the wheel leans outward at the top and negative when it leans inward.

The Camber can be adjusted by releasing the fixing bolts and adding or removing shims between the

steering arm and the upright. A change of shim has no influence on the toe setting.

Front (Rear similar)

Available shims:

Part Number

Description

F.41.14.055.A

Camber shim 1 mm

F.41.14.056.A

Camber shim 1.5 mm

F.41.14.057.A

Camber shim 2 mm

F.41.14.058.A

Camber shim 4 mm

Front

Recommended base setting: -3,3°, 2mm of shim

Adjustment: 0.325°/mm

1.5mm for 0.5°

Rear

Recommended base setting: -2.2°, 4.5mm of shim (2mm + 1.5mm+1mm)

Adjustment: 0.300°/mm

1.5mm for 0.5°

Steering arm

Camber shim

MYGALE

Technopole - 58470 Magny-Cours - France

Tel : +33 (0)3 86 21 86 21

Fax : +33 (0)3 86 21 86 22

13/58

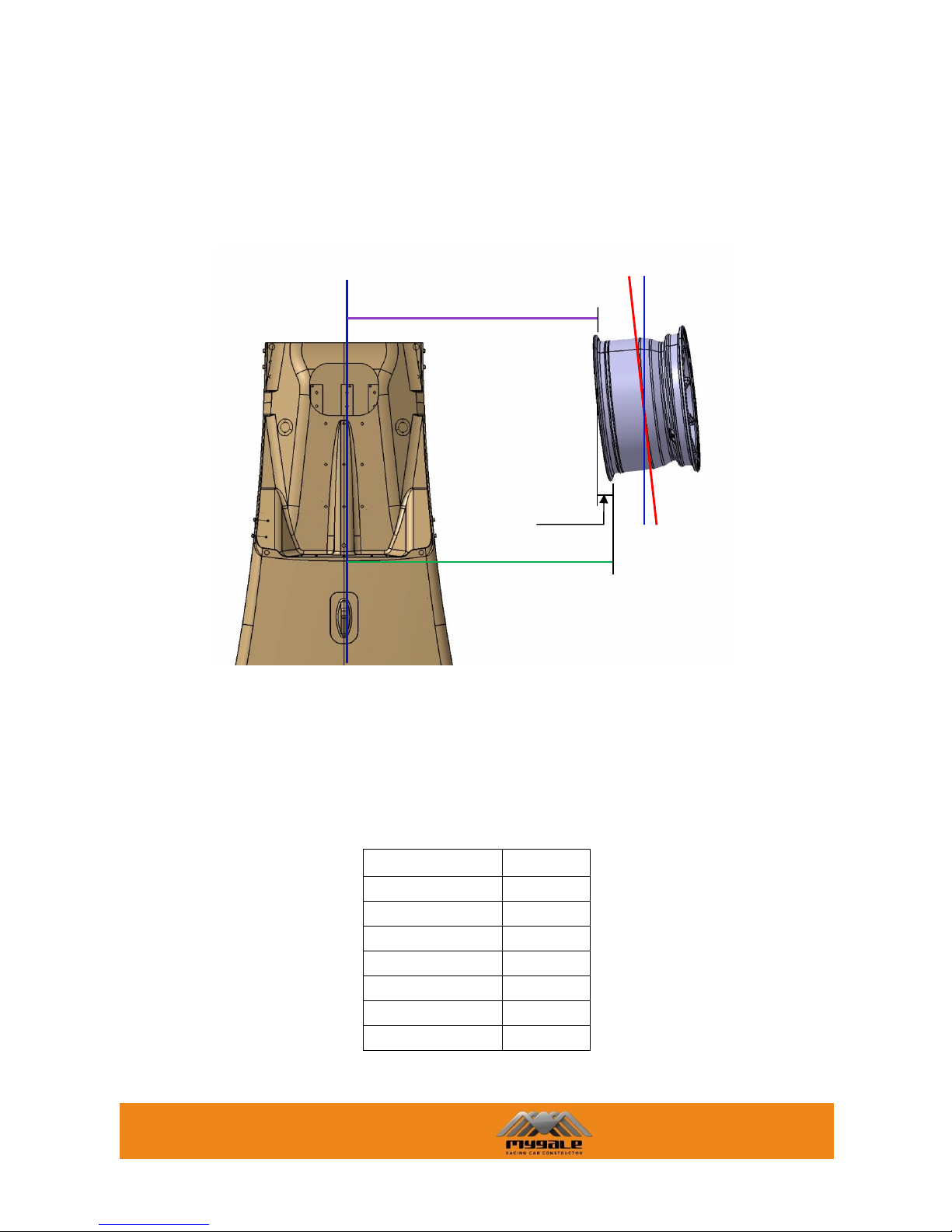

3.2.4 TOE CHECK & ADJUSTMENT

The toe angle is the angle between a longitudinal axis of the vehicle and the line of intersection of the

wheel plane and the road surface. The wheel is ”toed-in” if the forward portion of the wheel is turned

towards a central longitudinal axis of the vehicle, and “toed-out” if turned away.

Checking the distance between the wheel forward and rearward points in the front suspension is

possible to measure the Toe.

The Toe can be measured with the following formula:

Toe = B/2 – A/2

The correlation between degrees and the value B/2-A/2 is :

B/2-A/2 (mm)

Toe (deg)

18 3 12 2 6 1 0 0 -6

-1

-12

-2

-18

-3

In this table, negative toe corresponds to “toe out”, positive toe corresponds to “toe In”. The Toe

angle can be adjusted with the track rod.

A/2

semi forward track

B/2

semi rearward track

T.A. = Toe

To

MYGALE

Technopole - 58470 Magny-Cours - France

Tel : +33 (0)3 86 21 86 21

Fax : +33 (0)3 86 21 86 22

14/58

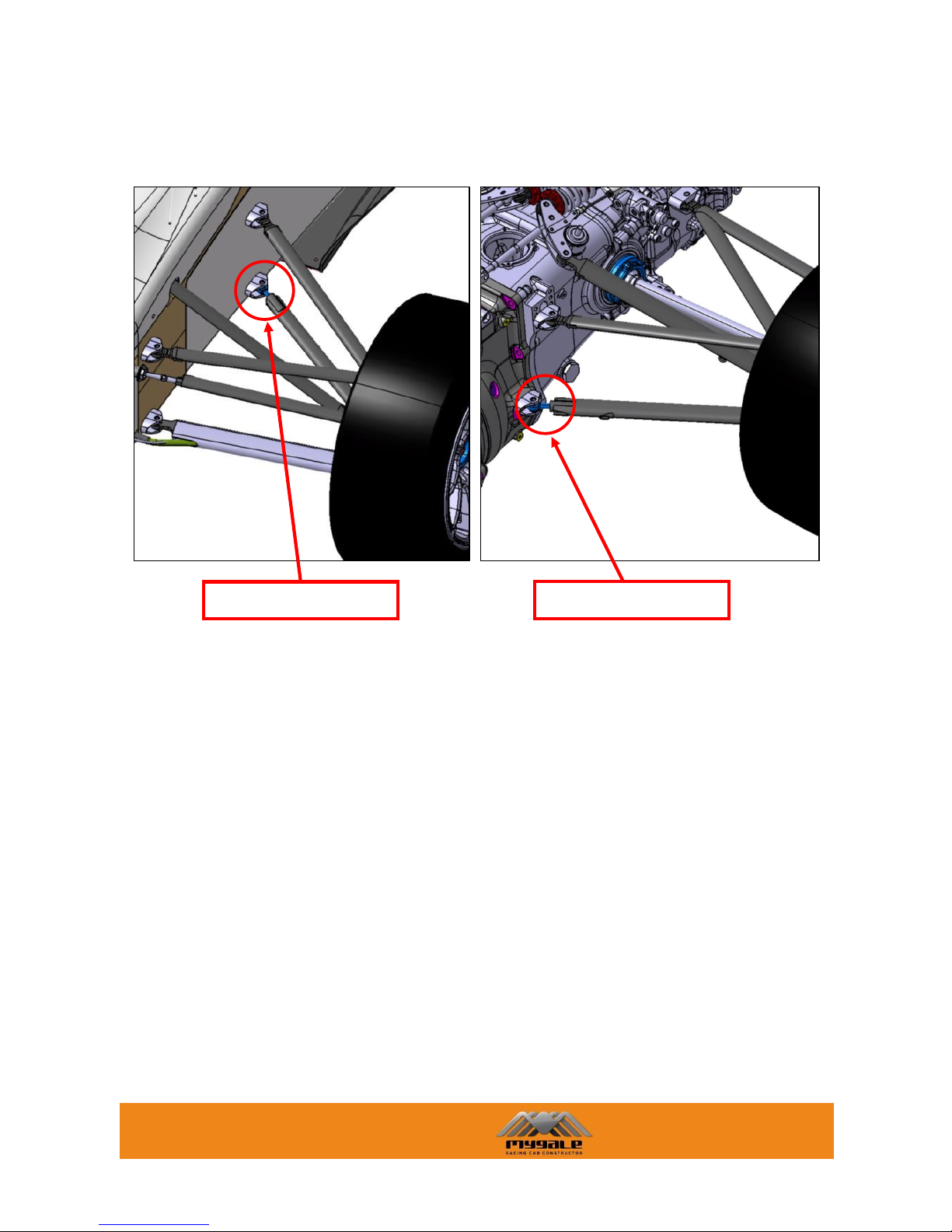

Base starting set up lengths for toe adjustment (ball centre to ball centre)

Front trackrod assembly: 474.9mm for (toe 0° and 0mm)

±1 turn on the bearing = ±3.84mm

±1 face turn on the bearing = ±0.64mm

For 1mm toe: 1.6 faces bearing

Rear trackrod assembly: 478.7mm for (toe 0° and 0mm)

±1 turn on the adjuster = ±4.70mm

±1 face turn on the adjuster = ±0.43mm

For 1mm toe: 2.4 faces adjuster

Rear toe adjustment

Front toe adjustment

MYGALE

Technopole - 58470 Magny-Cours - France

Tel : +33 (0)3 86 21 86 21

Fax : +33 (0)3 86 21 86 22

15/58

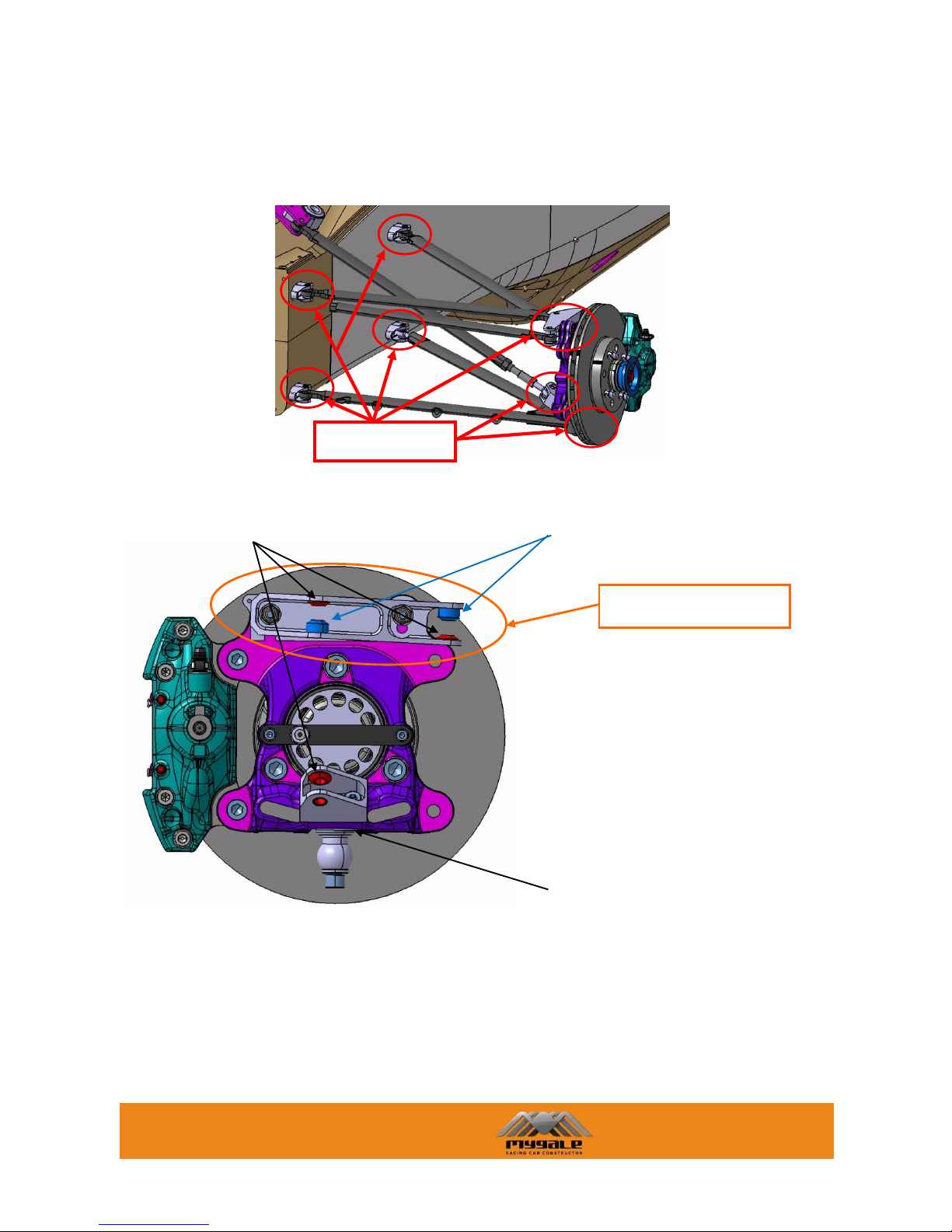

3.2.5 SUSPENSION POINTS

Front suspension points

The following picture shows the mandatory position of the front upright points:

Fixation points

Steering arm position

Ref. F.41.14.064.B (x2)

Ref. F.41.14.063.B (x4)

Spacer Ref. F.41.14.097.A

MYGALE

Technopole - 58470 Magny-Cours - France

Tel : +33 (0)3 86 21 86 21

Fax : +33 (0)3 86 21 86 22

16/58

Rear suspension points

The following picture shows the mandatory position of the rear wishbone brackets:

2nd hole from the bottom

Lower position

Upper position

Middle position

Fixation points

Fixation points

Fixation points

MYGALE

Technopole - 58470 Magny-Cours - France

Tel : +33 (0)3 86 21 86 21

Fax : +33 (0)3 86 21 86 22

17/58

The following picture shows the mandatory position of the rear upright points:

Ref. F.41.14.063.B (x4)

MYGALE

Technopole - 58470 Magny-Cours - France

Tel : +33 (0)3 86 21 86 21

Fax : +33 (0)3 86 21 86 22

18/58

3.3 KINEMATICS – GRAPHICAL REPRESENTATION

All the following graphs represent the kinematics in standard setup.

Loading...

Loading...