Myford ML7, ML7-R, Super 7 User Manual

Gearboxes supplied for

subsequent fitting only Far M

L7 lathes prior to K125240 and

Super 7 lathes prior to

SK124461 instead of screws

267 (paragraphs 9, 11S and

11M also parts list) use 1/2"

B.S.F. x 3/4". If far your

machine you need the 1/4"

B.S.F. screws, return the metric

screws to us for exchange.

No. 712V

QUICK CHANGE

GEARBOX

Nos, 1480 (ML7) and 1680 (ML7-R) and Super 7)

INSTRUCTIONS FOR

INSTALLATION AND OPERATION

WITH

PICTORIAL PARTS LIST

Myford Ltd, Wilmot Lane, Chilwell Road, Beeston, Nottingham NG9 I

ER Telephone: 01 15 925 4222 • Fax: 01 15 943 1299 email address:

Myford@btinternet.com

MYFORD QUICK CHANGE GEARBOX

CAUTION

IT IS OF THE UTMOST IMPORTANCE THAT THE WHOLE

GEARBOX AND TRANSMISSION MECHANISM SHALL ROTATE

MISALIGNMENT OF LEADSCREW OR TIGHTNESS IN ANY OF

THE BEARINGS (GEAR TRAIN-GEARBOX-OR LEADSCREW) WILL

IMPOSE HEAVY LOADS ON THE GEAR TRAIN AND MAY LEAD TO

SERIOUS DAMAGE.

THE CUTTING OF UNUSUALLY COARSE PITCHES IN EXCESS

OF .125"), EXERTS EXCESSIVE PRESSURE ON THE LEADSCREW

AND GEAR MECHANISMS. GREAT CARE SHOULD BE TAKEN SO

AS TO MINIMISE THE LOADS IMPOSED.

N.B. When changing to the slotted quadrant (page 6 fig. 5) or

back to the standard quadrant (page 3 fig. 2) it may be

necessary to reset the anchor pin No. 03 (see page 15

paragraph 22) in order to line up the driven gear on the

first stud with the driver on the tumbler stud.

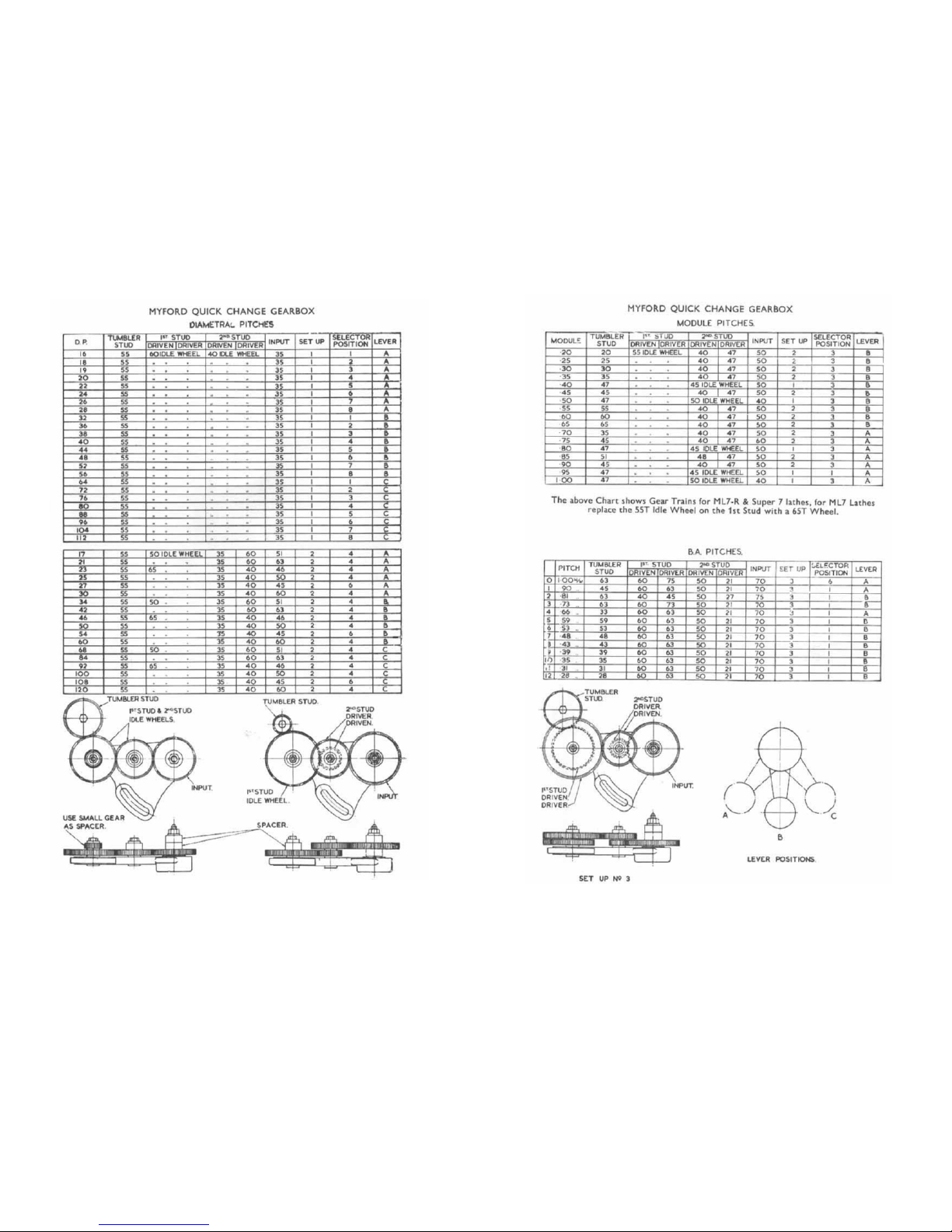

The chart for diametral pitches has been included for the

benefit of users wishing to cut wor ms t o mes h wi th

wormwheels whose pitch is expressed as D.P. The table of

module pitches has been included for the s am e rea so n.

Wh e r e a s diametral pitch is the ratio of the number of teeth

to the pitch diameter (in inches), module is the ratio of the

pitch diameter (in millimetres) to the number of teeth.

Before operating the lathe, remove the level plug

(at the right-hand end of the boxy, and fill to

just s ho rt o f plug level with 80025, Esso Febis

K68 oil. Replenish the oil ba th oc ca si ona ll y. A t

lon

g

intervals, flush with 800127, Esso Nuto

The tumbler reverse gear pins and quadrant gear

pins should be lubricated frequently. Occasional

application of the oil gun to the oil nipples on the

gear box will be sufficient.

Illustrations not bindin

g

in detail.

MYFORD QUICK CHANGE

OPERATION

The Myford Quick Change Gear Box permits instant

selection of 48 Englis h threads and feeds without the necessity for

setting-up gear trains. A conversion set is available fo r cutting

Metric , B.A. , and thou sands of oth er odd pitches, using ordinary

changewheels in conjunction with the gear box.

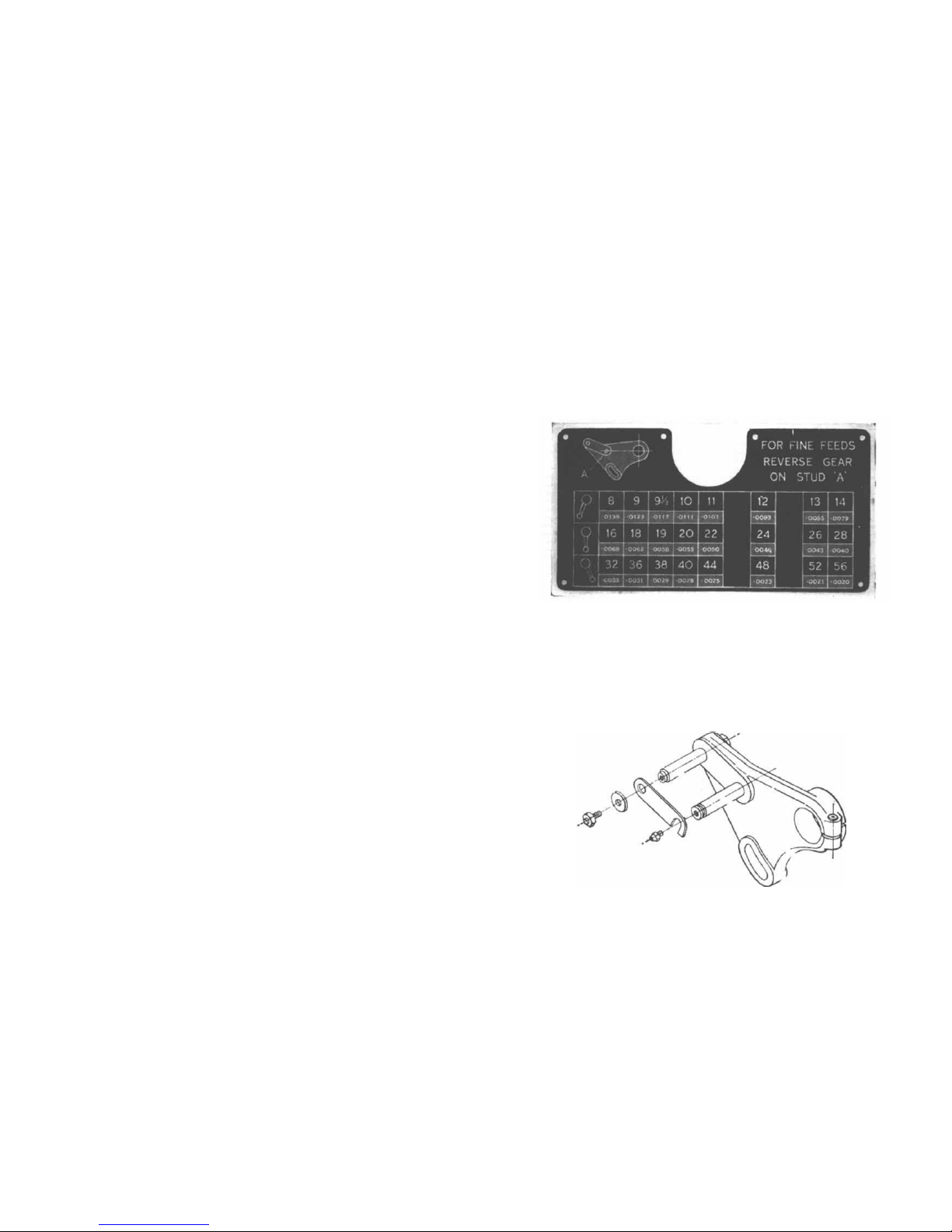

Fig. 1. Gear Box Chart showing English threads and feeds.

Reference to the gear box chart Fig. 1, will show that all

the commonly used English pitches are covered. In view

of this the gear pins on the normal quadrant (as supplied

with the gear box), are placed at fixed centres. This permits

the advantage of mounting the driving train of gears on pins

which are considerably greater in diameter, and more robust

than the movable type of changewheel stud.

Fig. 2. Normal

SET UP No 1 SET UP No 2

Fig. 3. Chart showing Changewheel Trains for Diametral Threads. (The four diagrams on

pages 4 and 5 apply to Diametral, Module and B.A. Charts).

Fig. 4. Chart showing Changewheel Trains for Module and B.A. Threads. (The

four diagrams on pages 4 and 5 apply to Diametral, Module and B.A. Charts).

Loading...

Loading...