MYERS WHR, WHRH, WHRE, WHR-DS, WHR-SD L/D Installation And Servicing Instructions

...

WHR/WHRH

and WHRE

WASTE HANDLING

SUMP PUMPS

Installation and Servicing Instructions

for Myers WHR/WHRH and WHRE

Submersible Sump Pumps

Single & Three Phase Power

Single & Double Seal

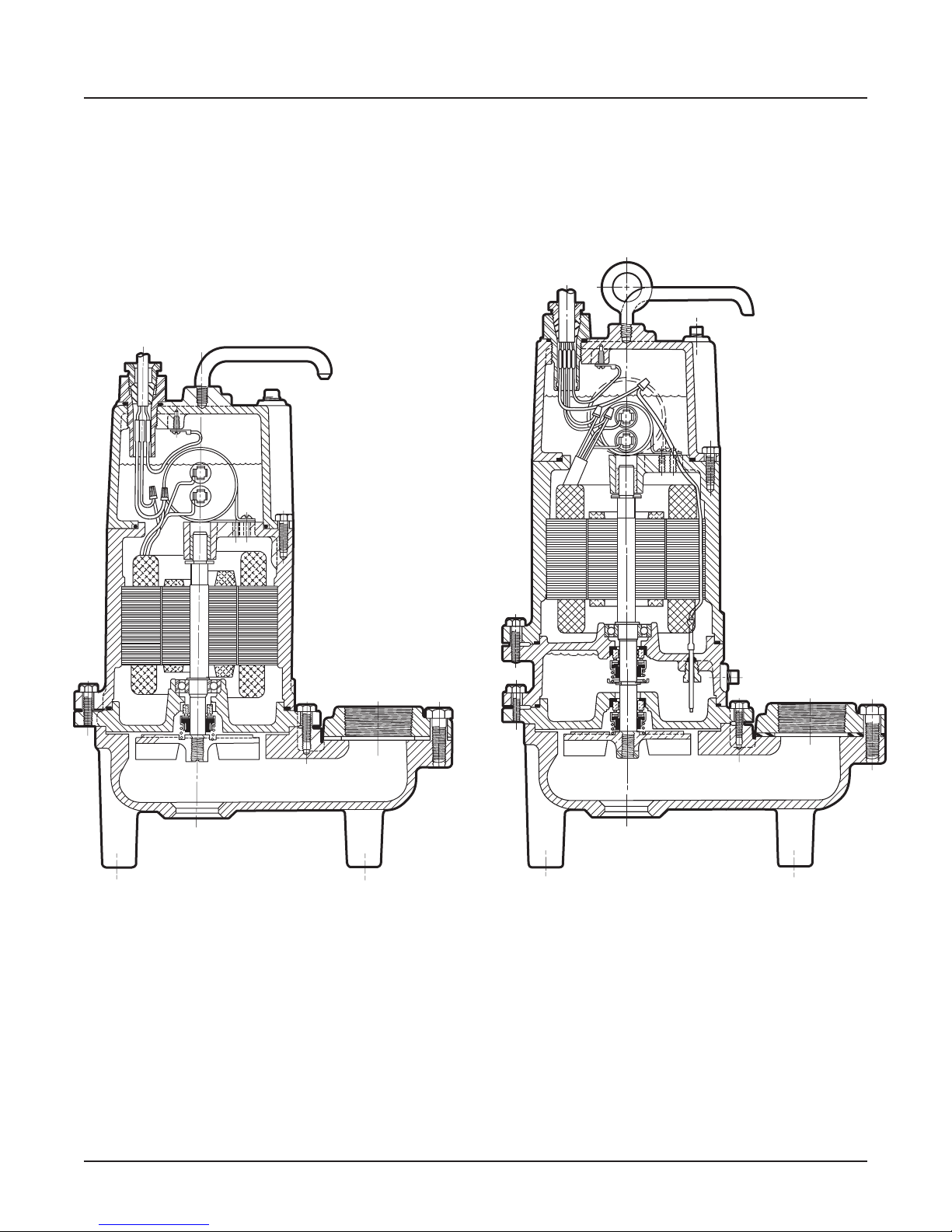

SINGLE SEAL PUMPS

23833A201 (Rev. 6/09)

DOUBLE SEAL PUMPS

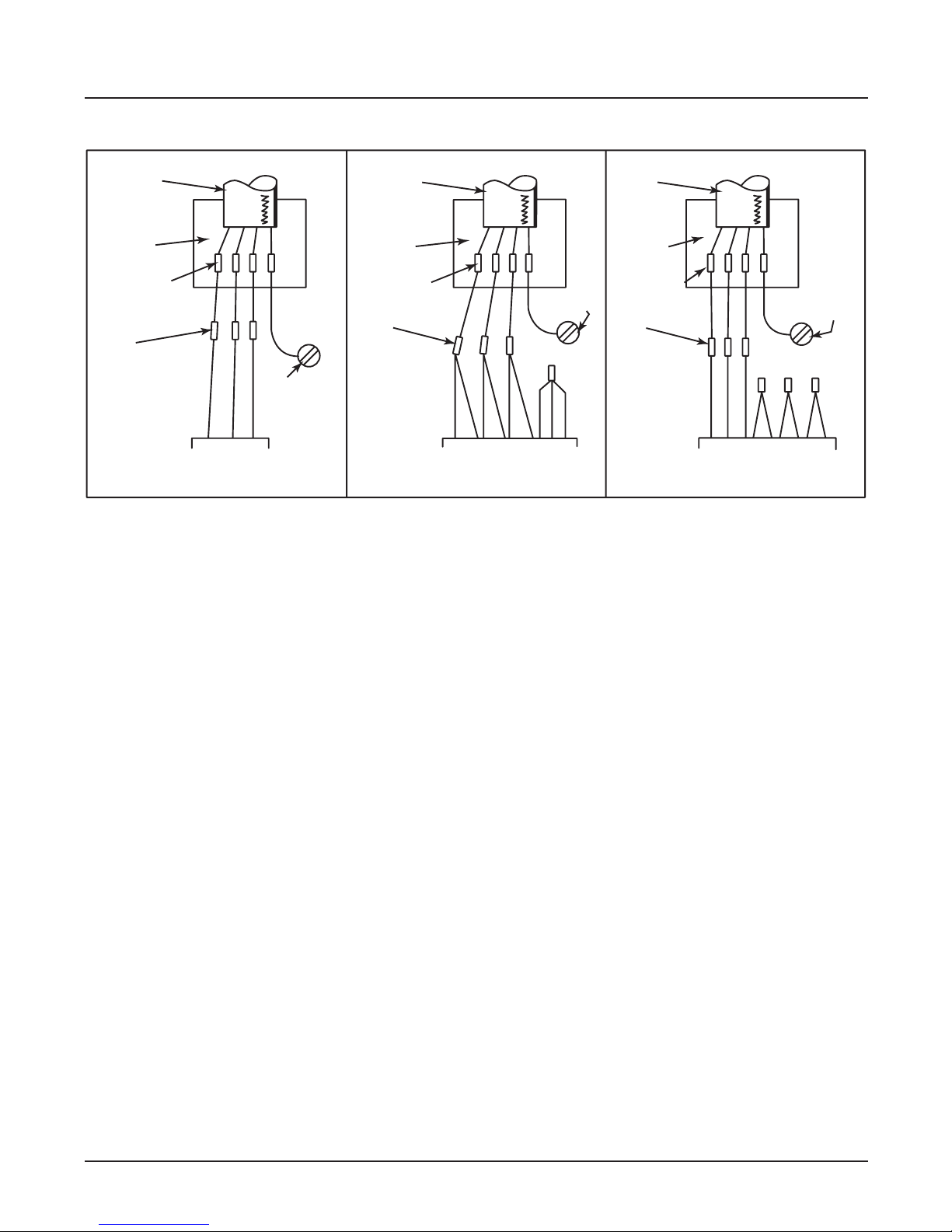

TYPICAL SECTIONAL DRAWINGS

FOR WHR/WHRH AND WHRE

SINGLE AND DOUBLE SEAL WASTE HANDLING PUMPS

SINGLE SEAL

FIG. 1

WHR

WHRH

WHRE

23833A201 2

DOUBLE SEAL

FIG. 2

WHR-DS WHR-SD L/D

WHRH-DS WHRH-DS L/D

WHRE-DS WHRE-DS L/D

GENERAL DESCRIPTION AND USES

The WHR and WHRH Series are solids handling

pumps that can be used to pump RAW SEWAGE

for COMMERCIAL and DOMESTIC use, but are

not intended to handle large rags, mop heads, or

strings. All pumps can be used for normal sump

duty where extra capacity is required.

The WHRE Series is for pumping sump water

and EFFLUENT from septic tanks only. DO NOT

USE FOR RAW SEWAGE.

Plug in cords can be used on all the single phase

pumps without seal leak detector. The cord

has a GROUND pin that plugs into a grounded

receptacle. The grounded receptacle cannot be

used in the wet sump or basin due to DANGER

of current leakage.

Sealed junction boxes must be used in wet sumps

or basins to make connections to motor cord. The

AWS-1 control also acts as a sealed junction box

for connecting power cord to pump cord.

RECESSED IMPELLERS

All of the pumps are of the recessed impeller

type that provides a clear volute passage for

solids as no solids pass through the impeller.

All of the pumps listed can be used to pump

septic tank EFFLUENT or GROUND sewage as

used in some pressure sewer systems.

DOUBLE SEAL PUMPS

All double seal models have two seals with an oil

chamber between the seals so that seal faces of

both lower and upper seals are oil lubricated for

longer life and greater protection against water

leaking into the motor windings. These double

seal units are made with and without a seal leak

probe. The leak probe in the oil seal chamber

detects any water leakage into the chamber and

turns on a red signal light in the control panel.

Pumps should be removed from sump and seals

replaced after seal light shows in the panel.

Control panels must be used for pumps having

the seal leak probe.

Double seal pumps without the seal leak probe,

should be pulled and seal leak checked in 12 to

18 months.

LEVEL CONTROLS

All pumps must use sealed level control switches

for automatic operation. MLC and MFLC controls

have sealed mercury* switches that are 1 H.P.

rated at 230 volts. ALC and AWS-1 controls have

sealed mechanical switches that are rated 2 H.P.

at 230 volts.

Simplex single phase pumps can be made

automatic by attaching MFLC or MLC controls

to pump. These switches have a fixed draw off

level of 8 to 10” and can be used up to 1 H.P. For

higher H.P. ratings two mercury* switch (or SMNO)

controls with a magnetic starter can be used.

The ALC and AWS-1 controls can be used for

simplex single phase pumps with ratings up to 2 H.P.

SAFETY WARNING

All pumps single or three phase must have a

GROUND WIRE that is connected to a screw

in the metal pump housing. This wire goes to

the control box and is connected to a good

outside GROUND such as a metal water pipe or

GROUND STAKE driven at least 6 feet into the

ground.

MOTOR TYPES

All single phase pump motors are of the

permanent split capacitor type that do not

require a start switch or start relay.

Automatic reset overload switches are attached

directly to the motor windings.

Three phase pump motors require a magnetic

starter with 3 leg overload protection.

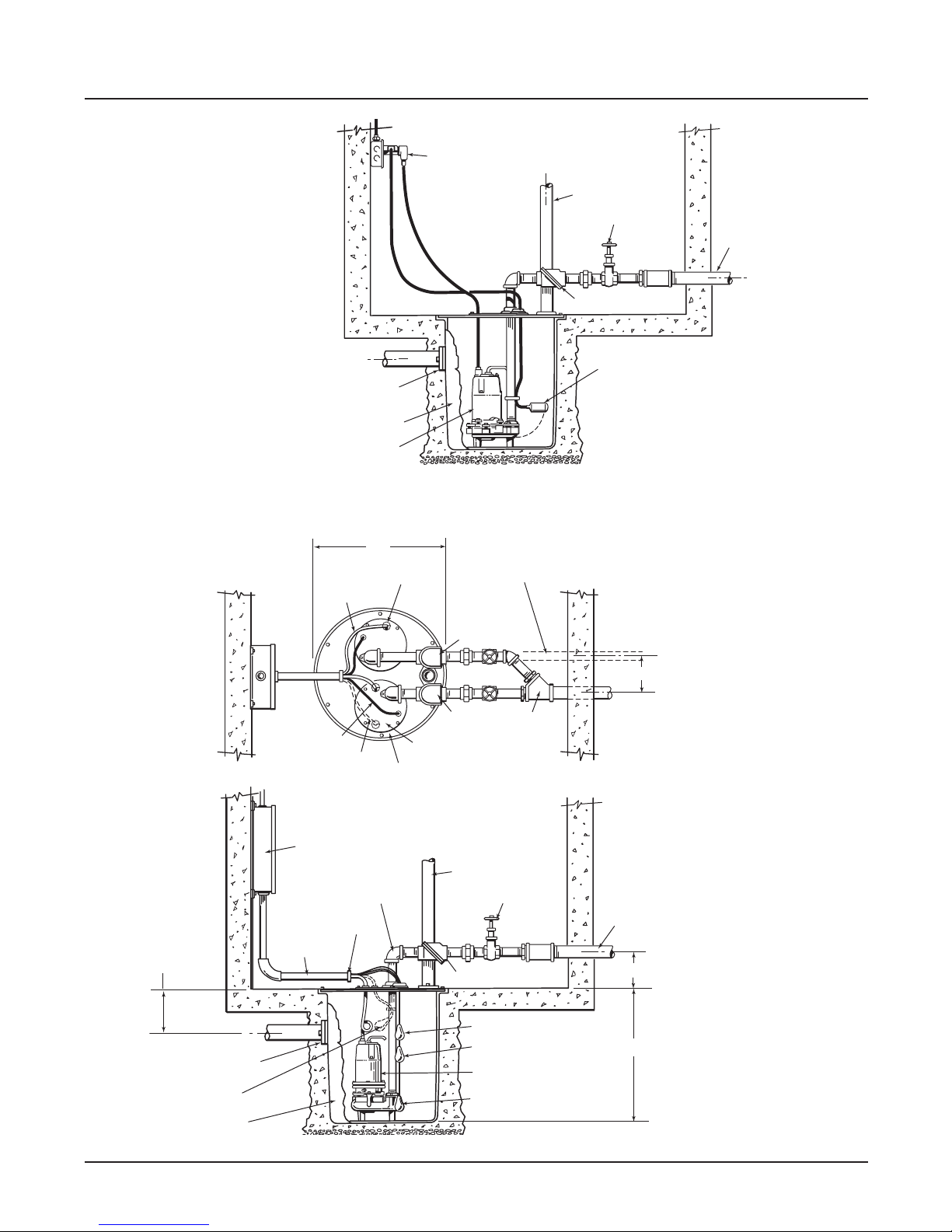

INSTALLATION

Pumps can be installed inside sealed basin

with proper venting for either simplex or duplex

systems. SIMPLEX or DUPLEX basin systems

are available. See Figs. 3 and 4.

It is not recommended that basins be used for

RAW SEWAGE inside the home, but are for use

in office buildings and small industrial buildings

and factories.

*This product contains mercury and must be disposed of according to local

3 23833A201

and federal codes.

“O” RING SEAL INLET

FLANGE FOR 4

PLASTIC PIPE

FIBERGLASS BASIN

WHR – WHRH – WHRE

SEWAGE PUMP

SINGLE PHASE

1

/2-3/4-1-2 HP

1

/2” O.D.

PUMP CORD PLUGS INTO

SERIES SWITCH CORD FOR

AUTOMATIC OPERATION

3” VENT PIPE

GATE VALVE

MYERS FREE FLOW

CHECK VALVE

MLC or MFLC

LEVEL CONTROL

WITH SERIES PLUG

SIMPLEX SYSTEM WITH

ALC LEVEL CONTROLS.

DISCHARGE PIPE

FIG. 3

NOT MORE THAN 14”

HEIGHT

TO SUIT

“O” RING SEAL INLET

FLANGE FOR 41/2” O.D.

PLASTIC PIPE

OPTIONAL ALARM

CONTROL

30” DIA. x 36” DEEP

FIBERGLASS BASIN

PUMP CORD

LEVEL CONTROL

CORD

OPTIONAL ALARM

CORD

NEMA 1 DUPLEX

CONTROL BOX

2” PUMP PIPING,

CAN BE 3” IF

REQUIRED

1

1

/2” CONDUIT

BUSHING

1

1

/2” CONDUIT

35”

SPLIT RUBBER

SEAL BUSHING

PUMP 1

CAST IRON PUMP COVER

SEALS WITH RUBBER GASKET

STEEL BASIN COVER EPOXY

COATED. SEALED TO BASIN

WITH CAULKING COMPOUND

SEPARATE 2” DISCHARGE

PIPE CAN BE RUN FROM

EACH PUMP IF DESIRED

PUMP 2

3”– 45º TEE

3” VENT PIPE

2” GATE VALVE

CV-200 CHECK VALVE

OVERRIDE CONTROL

START CONTROL

WASTE HANDLING PUMPS

STOP CONTROL

10”

3” DISCHARGE

PIPE

10”

REMOTE CONTROL BOX.

36”

DUPLEX SYSTEM WITH

FLOAT CONTROLS AND

FIG. 4

23833A201 4

Basins can be used inside the home where extra

capacity sump pumps are required for water

softeners and wash water.

If raw sewage must be pumped in the home use

outside basins that connect with pressure sewer

mains or gravity sewers, or run to septic tanks.

If an inside basin is used it is usually installed at

time of pouring the concrete floor.

Pumps can be installed in a compartment of septic

tanks for pumping to pressure sewer mains, gravity

sewers, leach fields, or evaporation mounds. See

Figs. 5, 6 and 7.

PROPER VENTING FOR BASINS

INSTALLED INSIDE

All inside sealed basins must have a 2” or 3” vent

pipe installed in accordance with local codes.

Sumps for handling softener water, wash or

drainage water do not have to be sealed or vented.

Outside basins are usually of fiberglass and from

4 to 8 feet deep and have a sealed cover. Pump

is usually installed with a lift out rail system so

that pump can be removed without disturbing the

discharge piping. The check valve comes out with

pump for servicing. Complete LIFT OUT SYSTEMS

mounted in fiberglass basins are available to meet

customer’s specifications.

WARNING: Sump basin must be vented in accordance with local plumbing codes. These pumps

are not designed for and CANNOT be installed in

locations classified as hazardous in accordance

with the National Electric Code ANSI/NFPA 70.

PIPING

Pumps are fitted with 2” or 3” female threaded

pipe flange. Galvanized or PVC plastic pipe can be

used. Plastic pipe is preferred for raw sewage or

septic tank effluent.

CHECK VALVES AND SHUT-OFF VALVES

All pumps must have check valves and shut-off

valves in the discharge line. Check valves must be

flapper type with outside spring or ball type. Shutoff valves can be ball or gate type. Plastic construction for both check and shut-off valves is preferred.

STARTING SIMPLEX SYSTEMS

1. For single phase pumps with MLC or MFLC

control, plug cords piggy back into receptacle

and run water into sump until pump starts. Allow

pump to make several on/off cycles. Leave

power cord plugged in. If pump runs but does

not pump it may be air locked. Unplug cord and

crack union in the discharge line then restart

pump, this should vent off any trapped air.

Re-tighten union.

AIR LOCKING

A sump pump is said to be air locked if water traps in the pump and

it cannot get out, thus preventing pump from operating.

ALL MYERS SUMP PUMPS HAVE A SMALL AIR VENT HOLE IN

THE IMPELLER CHAMBER TO LET OUT TRAPPED AIR. IF THIS

HOLE BECOMES PLUGGED, PUMP MAY AIR LOCK. THIS

USUALLY HAPPENS ON PUMPS THAT ARE USED MAINLY IN THE

SEASONS. IN SUMMER MONTHS, THE PUMP MAY BE TURNED

OFF AS SUMP WATER DRIED UP. WHEN PUMP IS TURNED ON

AGAIN AND WATER COMES UP IN SUMP, THE AIR WILL TRAP IN

PUMP IF NOT VENTED.

AS A SECONDARY PRECAUTION IN INSTALLATIONS OF THIS

TYPE – 1/8” HOLE SHOULD BE DRILLED IN THE DISCHARGE PIPE

BELOW THE CHECK VALVE. THE CHECK VALVE SHOULD BE 12

TO 18 INCHES ABOVE PUMP DISCHARGE. DO NOT PUT CHECK

VALVE DIRECTLY INTO PUMP DISCHARGE OPENING.

In normal sumps where the pump is operating daily, air locking

rarely occurs.

2. With 2 float controls turn on power at the control

box and run water into sump. When level gets

above top control pump should start and

continue to pump until level drops to lower

control stopping pump. Run pump through

several cycles. If pump runs but does not pump,

check air lock as in 1. Leave power on for

automatic operation.

3. Where ALCL or AWS-1 controls are used plug

in cord or turn on power and run water into

sump, when level is about half way up on upper

weight pump should start and run until level

drops until about half the lower weight is above

water, stopping pump. Check 1, if pump does

not operate properly. For all cases if motor does

not start when water level is up check for proper

plug in or that start switch is on, or if fuse is

blown. ALWAYS HAVE ELECTRICTIAN MAKE

ELECTRICAL CHECKS.

STARTING PUMP “WHE-P” (AUTOMATIC)

USING MECHANICAL SWITCH WITH

SERIES PLUG-SIMPLEX SYSTEM

1. These pumps have a mechanical (mercury-free)

float switch with a 20 ft. cord and 115 volt or 230

volt series piggy-back plug on ½ H.P. with switch

mounted to the pump. On ¾ H.P. and 1 H.P., it

requires 20 ft. cord and 230 volt only.

2. Plug the switch cord plug into a proper voltage

properly grounded outlet.

3. Plug the pump power cord into the back of the

switch cord series plug.

4. Tape the cords to the discharge pipe every 12”.

5. Run water into sump until pump starts. Be sure

discharge line valve is open.

6. Allow pump to operate through several on/off

cycles.

7. If pump does not operate properly, see trouble

shooting service chart for remedy.

5 23833A201

HOW TO SET CONTROLS AND START

DUPLEX SYSTEMS

CONTROL BOX MUST BE USED ON ALL

DUPLEX SYSTEMS

1. 4 float controls are used for duplex systems.

Set turn-on control 6” to 8” above pumps. Set

turn-off control 8” to 10” above bottom of

sump. Set override control 6” to 8” above turn on control. Set high level alarm control about 6”

to 8” above override control. Mark all control

cords so that they can be

connected correctly in

the control box. See Fig. 4.

2. Turn Hand-Off-Auto switches to OFF position

and close circuit breaker.

3. Turn H-O-A switches to the AUTO position and

run water into sump. When level floats up and

activates the turn-on switch one pump should

start and run, pump will continue to run until

lower control is exposed stopping pump.

4. Run water into sump again and when level

floats up turn-on control, opposite pump will

start and run until level drops exposing lower

control, stopping pump.

5. Run this test several times to be sure pumps

are alternating properly.

LEVEL CONTROL SYSTEMS AVAILABLE

1. Simplex single phase packaged automatic

system. This system has the MLC or MFLC

float switch attached directly to the

pump. This system has a fixed pump-off level

of 8” to 10” and is usually used for drainage

water and is good up to and including 1 H.P.

2. Simplex single phase pumps can use the ALC

or AWS-1 controls which are mounted separate

from the pump. These controls can be used up

to 2 H.P. motors. See Fig. 3

3. Simplex pumps can use two float controls

mounted separate from the pump. These

controls must be used with a control box and

magnetic contactor. These controls can be

spaced apart for any draw off level required and

can be used for 2 H.P. or larger motors.

4. Duplex pump systems must use only the

float controls with electrical control box.

These control boxes mounted remote from the

sump tank are generally of plastic construction

for best corrosion resistance. See Fig. 4.

MOTOR OVERLOAD PROTECTION

All single phase motors have built-in automatic

reset overload switches fastened directly to the

motor windings.

All 3 phase motors must be installed with magnetic

starters having 3 leg overload protection.

HOW TO SET CONTROLS AND START

SIMPLEX SYSTEMS

1. Automatic systems – These systems have the

MLC, MFLC, or ALC switches mounted on the

pump, so pump is installed in the sump and

motor cord is plugged into GROUNDED

receptacle. For sealed sump cover, power cord

is brought through a split rubber plug in the

sump cover.

2. Where 2 float controls are used the turn on

control is set 3” to 6” above top of motor,

and the turn-off control is set about 6” to *’

above bottom of sump. If a high level alarm

control is used it is set about 6” above upper

control. If sump depth will not allow these

settings closer spacing can be used.

3. Where ALLC or AWS-1 controls are used the

DISPLACEMENT WEIGHTS are set so that turn on weight is 4” to 6” above top of motor and

lower weight is set about 6” above sump bottom.

4. Repeat this operation with one pump off which

will duplicate a failed pump condition. When

the level reaches the override control the pump

that is turned on should start and run and

pump down sump level.

5. To check high level alarm, again turn both

switches to OFF and fill sump until level is above

the alarm control. Turn switches to Auto position

and ALARM BUZZER should sound and alarm

light should come on. When level drops below

the alarm control buzzer should stop.

6. If pumps operate as described then set both

H-O-A to Auto and pumps are ready to operate

automatically.

7. If pumps do not operate properly then check as

described for simplex systems. See page. 13.

CAUTION – NEVER WORK ON PUMPS OR

CONTROL BOXES UNTIL CIRCUIT BREAKERS

ARE TURNED OFF.

Always have a qualified ELECTRICIAN make

electrical connections and service checks.

23833A201 6

SPECIAL INSTRUCTIONS FOR

THREE PHASE PUMPS

1. WARNING! Only qualified persons shall

conduct services and installations of this

pump. The pump must be wired by a

qualified electrician, using an approved

starter box and switching device.

CAUTION! Risk of electric shock. Do not

connect conduit to pump

2. Three phase pumps are always installed with

control boxes having magnetic starters with

3 leg overload protection. DO NOT

TRY TO RUN THREE PHASE PUMPS

DIRECTLY ACROSS THE LINE.

3. To Connect Pump: Run wire from pump to the

bottom of control box or appropriate junction

box suitable for enclosing splice connections.

A hole must be cut into the control box for the

wires. With power to control box off, connect

green (ground) line to ground lug. Connect

black (power) wires to power lead terminals.

Make sure that all wires are inside control box

and not in a position to be pinched or shorted

when the door is closed. See wiring diagrams,

page 8.

4. All three phase motors can run either direction,

ROTATION can be changed by interchanging

any two line leads at magnetic starter. BE

SURE CIRCUIT BREAKER IS OFF BEFORE

MAKING THIS CHANGE.

To find if rotation is correct operate pumps

and check delivery operation. If flow and head

is low (refer to pump curves shown in this

manual) the rotation is wrong. With duplex

pumps check operation of both pumps.

All pump impellers either single or three phase

must turn counterclockwise when looking

into pump inlet. If uncertain of rotation, TURN

OFF POWER and lift pump from basin with

cord connected and lay pump on side so

impeller can be seen. Turn on power and start

pump using hand position of H-O-A switch.

Turn on and off fast so that coast of impeller

can be seen.

ON THE IMPELLER.

leads at the magnetic starter to change rotation.

NEVER PUT HAND OR FINGERS

Interchange any two line

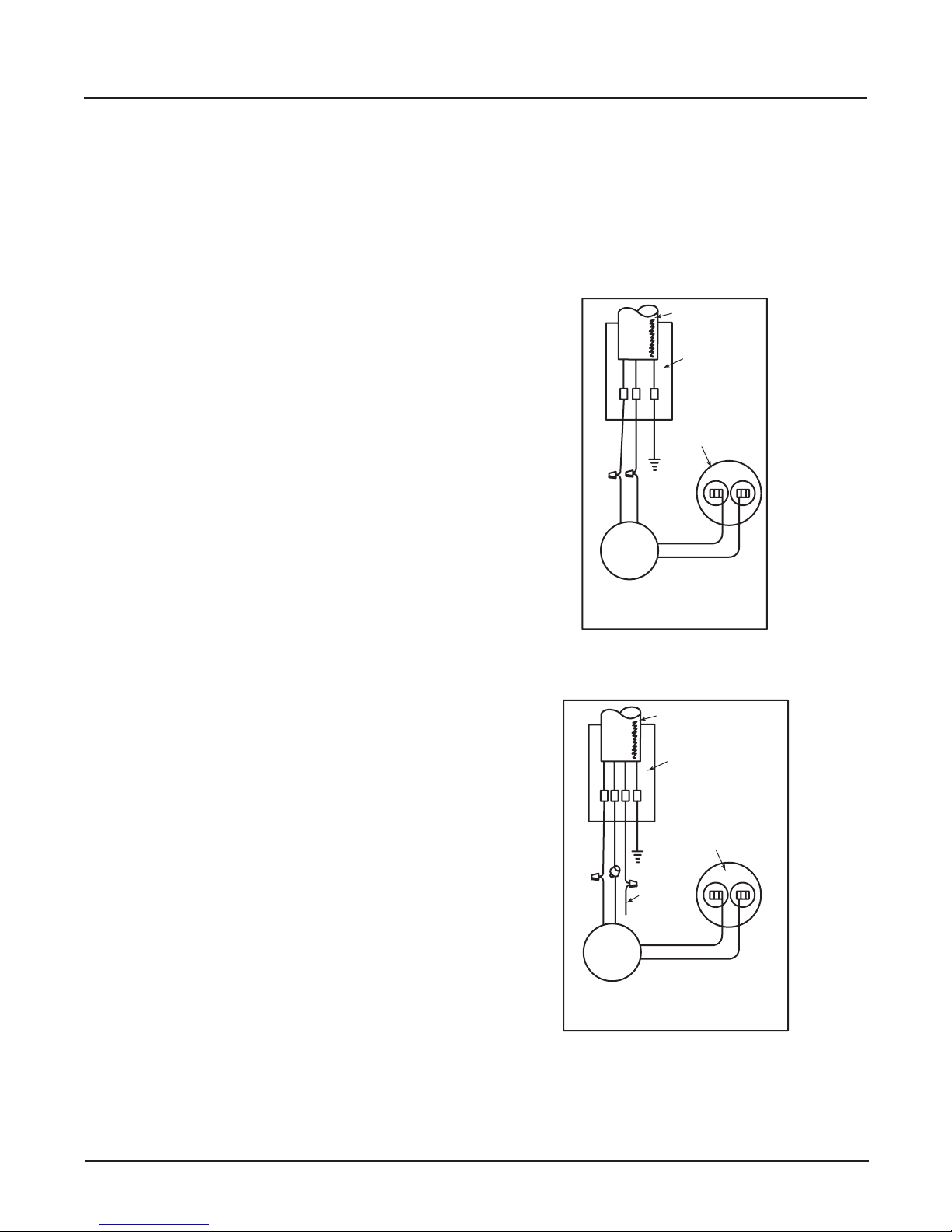

WIRING DIAGRAMS SINGLE PHASE MOTORS

SINGLE PHASE PUMPS

WARNING – Risk of electric shock. This pump

is supplied with a grounding conductor and

grounding-type attachment plug. To reduce

the risk of electric shock, be certain that it

is connected only to a properly grounded,

grounding-type receptacle.

POWER CORD

POTTING

RESIN

CAPACITOR

GRN.

BLACK

WHT. OR YELL

WHITE

BLACK

STATOR

115 VOLT OR

200 or 230 VOLT - 1 PHASE

SINGLE VOLTAGE P.S.C. MOTOR

BROWN

BROWN

SINGLE SEAL PUMPS AND DOUBLE SEAL

PUMPS WITHOUT SEAL LEAK PROBE

POWER CORD

POTTING

RESIN

GRN.

RED

BLACK

WHT. OR YELL

SEAL

LEAK

RED

BLACK

WHITE

ELECTRODE

STATOR

115 VOLT OR

200 or 230 VOLT - 1 PHASE

SINGLE VOLTAGE P.S.C. MOTOR

CAPACITOR

BROWN

BROWN

7 23833A201

DOUBLE SEAL PUMPS WITH

SEAL LEAK PROBE

(RED CONDUCTOR IN POWER CORD

IS FOR SEAL LEAK PROBE)

WIRING DIAGRAMS FOR 3 PHASE MOTORS

POWER

CORD

POTTING

RESIN

SPLICES

B

B

B

CONNECTORS

B

B

B

MOTOR STATOR

200 or 575 VOLT - 3 PHASE

FOR SINGLE SEAL PUMPS AND DOUBLE SEAL PUMPS

GREEN

GROUND

SCREW

POWER

CORD

POTTING

RESIN

SPLICES

CONNECTORS

T9

B

B

T8

T3

GROUND

B

SCREW

GREEN

T7

T6

T5

T1

T2

T4

MOTOR STATOR

230 VOLT - 3 PHASE

WITHOUT SEAL LEAK PROBE

POWER

CORD

POTTING

RESIN

SPLICES

CONNECTORS

MOTOR STATOR

460 VOLT - 3 PHASE

B

B

B

T1

T2

T3

T9

GREEN

T6

GROUND

SCREW

T5

T8

T7

T4

23833A201 8

Loading...

Loading...