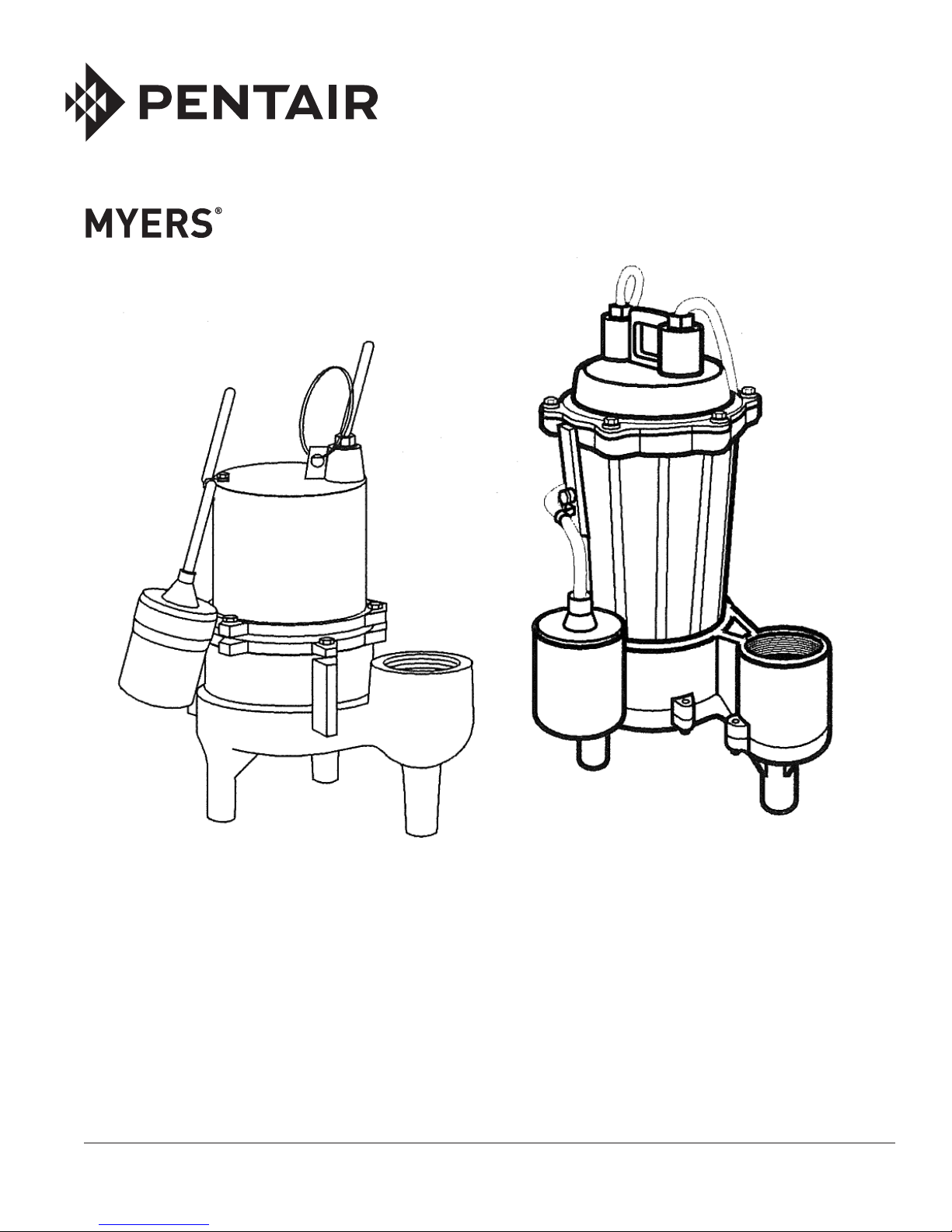

MYERS SR1830, CMV1830, SR1830I Installation And Service Manual

SR1830I

SR1830 CMV1830

MODELS SR1830 and CMV1830

SUBMERSIBLE SEWAGE PUMPS

INSTALLATION AND SERVICE MANUAL

NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible

party who maintains the system.

Part # 25581A043 | © 2014 Pentair Ltd. | 05/07/14

MODELS SR1830 AND CMV1830

Your SR1830 or CMV1830 is designed to operate

automatically or manually and for simple and quick

installation. Its preset fluid level control allows for

efficient operation when installed in a standard

18" x 30" sewage basin.

Before installing your pump, check carefully for

shipping damage. Any claim for shipping damage

must be made with your supplier at the point of

purchase. The manufacturer cannot make shipping

damage adjustments.

CALIFORNIA PROPOSITION 65 WARNING:

This product and related

accessories contain chemicals known to the

State of California to cause cancer, birth

defects or other reproductive harm.

INSTALLATION

This is a sewage handling pump and must be vented

in accordance with local plumbing codes. This

pump is not to be installed in locations classified as

hazardous in accordance with National Electric Code,

ANSI/NFPA 70.

The motor in your new submersible sewage pump is

oil-filled for efficient operation. DO NOT loosen the

three motor housing screws.

Place sewage pump on the bottom of the basin and

position it to allow float to rise in center of basin.

Check that nothing interferes with the float switch.

Slip cover over discharge pipe and power cord.

Bolt cover securely to basin (be sure to use a cover

gasket). Install discharge compression fitting and cord

seal grommet.

CHECK VALVE

A properly designed full-flow check valve MUST

be used on every installation. A series CV-200P is

provided. It eliminates back-flow, reduces vibration

and acts as a pipe union for easy servicing. Install on

discharge pipe (make certain that arrow on valve body

points in flow direction). Connect outlet of check valve

to the plumbing line leading to the sanitary sewer

system.

ELECTRICAL INFORMATION

WARNING: Risk of electric shock. This pump

is supplied with a grounding conductor and

grounding-type attachment plug. To reduce

the risk of electric shock, be certain that it is

connected only to a properly grounded, groundingtype receptacle. Read instructions before installing

pump. This pump has not been investigated for

use in swimming pools.

Never touch the sewage pump, switch or

discharge pipe when the pump is connected to

electrical power.

Check the electrical circuit to make sure it meets the

voltage and amperage requirement listed on the motor

nameplate.

Your electrical service outlet should meet the National

Electric Code and/or local codes. Your pump should

have a separate branch circuit, properly fused and

grounded. The outlet should be 4' above the floor and

close enough to your pump that the original cord can

reach it. Never use an extension cord.

Plug the switch power cord into a properly grounded

outlet. Plug the pump power cord into the back of

the switch cord plug. Tape the power cords to the

discharge pipe every 12 inches to make sure any

movement will not damage the insulation.

To test the system, add water to the sewage basin

until the float switch operates normally.

Your pump has thermal overload protection. If the

impeller becomes locked because of a foreign object,

the motor will overheat and the thermal overload

switch will cut off the electricity. Unplug pump and

remove the foreign object immediately. See that the

impeller turns freely.

SWITCH ADJUSTMENT AND

REPLACEMENT INSTRUCTIONS

CAUTION: Always disconnect the pump and

switch from the electrical power source before

doing any maintenance! This pump is equipped

with a float switch and does not control both

sides of the electrical circuit. To reduce the risk

of electric shock it is essential that it be wired in

series with the hot side of the electrical circuit.

Make sure your outlets are wired according to your

local electrical code.

1. Inspect the pump to be certain that there are no

rocks, lint, etc. clogging the openings where water

enters the pump housing. Remove any debris.

Check to see that the impeller turns freely.

2. Plug the pump power cord into a properly

grounded, 3 hole outlet. If the pump works

(impeller turns and air is blowing out of discharge

opening), proceed to step 3. If the pump does not

work, it must be replaced.

3. If the pump works, (1) unplug pump and (2) replug

into back of switch plug and (3) plug the assembly

into the electrical outlet. Raise switch by hand to

activate pump. If pump turns on, pump and switch

are OK-no need to replace. If pump does not turn

25581A043 05/07/14

2

Loading...

Loading...