Myers ME Installation Manual

MYER

S

SUBMERSIBLE SUMP EFFLUENT

& SEWAGE PUMPS

MWH50 MW200 SERIES ME50 ME150 SERIES

ENGLISH: 3-18 FRENCH: 21-36 ESPANOL: 39-54

SINGLE SEAL PUMP

INSTALLATION AND

OPERATION MANUAL

pentair.com

DOUBLE SEAL PUMP

23833A278 (02-13-20) ©2020 Pentair. All Rigths Reserved.

TABLE OF CONTENTS:

ENGLISH

Safety Instructions ..................................................................................................................................................................................3

Description ..............................................................................................................................................................................................4

Installation ...............................................................................................................................................................................................5

Diagrams ............................................................................................................................................................................................. 6-8

Maintenance .......................................................................................................................................................................................9-10

Specications ........................................................................................................................................................................................11

Dimension Charts .............................................................................................................................................................................. 12-13

Single Seal Pump Specications .......................................................................................................................................................14-15

Single Seal Pump Specications ....................................................................................................................................................... 16-17

Standard Limited Warranty ................................................................................................................................................................... 18

FRENCH

Instructions de sécurité ........................................................................................................................................................................ 21

Description...................................................................................... ................................................................................................. 22

Installation .............................................................................................................................................................................................23

Diagrammes .................................................................................................................................................................................... 24-26

Entretien ......................................................................................................................................................................................... 27-28

Spécications .......................................................................................................................................................................................29

Tableaux de dimensions ...................................................................................................................................................................30-31

Spécications pour les pompes à joint simple ................................................................................................................................. 32-33

Spécications pour les pompes à joint simple ................................................................................................................................. 34-35

Garantie limitée standard ......................................................................................................................................................................36

SPANISH

Instrucciones de seguridad ...................................................................................................................................................................39

Descripción .......................................................................................................................................................................................... 40

instalación ............................................................................................................................................................................................. 41

Diagramas .......................................................................................................................................................................................42-44

Mantenimiento .................................................................................................................................................................................45-46

Especicaciones ................................................................................................................................................................................... 47

Tablas de dimensiones ....................................................................................................................................................................48-49

Especicaciones de bomba de sello único .......................................................................................................................................50-51

Especicaciones de bomba de sello doble ...................................................................................................................................... 52-53

Garantía limitada estándar ....................................................................................................................................................................54

2

23822A278 (02-13-20)

SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS - This manual contains important

instructions that should be followed during installation,

operation, and maintenance of the product. Save this manual

for future reference.

This is the safety alert symbol. When you see this symbol on

your pump or in this manual, look for one of the following signal

words and be alert to the potential for personal injury!

indicates a hazard which, if not avoided, will result in

death or serious injury.

indicates a hazard which, if not avoided, could result

in death or serious injury.

indicates a hazard which, if not avoided, could result

in minor or moderate injury.

NOTICE

addresses practices not related to personalinjury.

CALIFORNIA PROPOSITION 65 WARNING

This product and related accessories contain

chemicals known to the State of California to cause cancer,

birth defects or other reproductive harm.

WHEN OVERLOAD CURRENT PROTECTION IS PROVIDED BY

INSTALLER:

USE WITH APPROVED MOTOR CONTROL THAT MATCHES

MOTOR INPUT IN FULL LOAD AMPERES WITH OVERLOAD

ELEMENT(S) SELECTED OR ADJUSTED IN ACCORDANCE WITH

CONTROL INSTRUCTIONS.

WHEN MOTOR HAS BUILT-IN OVERLOAD PROTECTION:

USE WITH APPROVED MOTOR CONTROL THAT MATCHES

MOTOR INPUT IN FULL LOADAMPERES.

ELECTRICAL RISKS

Pumps with a single seal are supplied with a grounding

conductor and grounding-type attachment plug on the power

cord. To reduce the risk of electric shock:

Be certain that it is connected only to a properly grounded,

grounding-type receptacle.

DO NOT cut off ground pin or use an adapter fitting.

DO NOT use an extension cord with this pump.

Entire plug may be cut off if a control panel is used.

Wh

en wiring this pump follow all local electrical and safety

codes and ordinances as well as the most recent National

Electric Code (NEC-ANSI/NFPA 70).

All pumps have a GROUND WIRE that is connected to a screw

in the metal motor housing. This wire goes to the receptacle

or control box which must be connected to a good outside

GROUND such as a metal water pipe or GROUND STAKE driven

at least 8 feet into theground.

23822A278 (02-13-20)

3

DESCRIPTION

DESCRIPTION

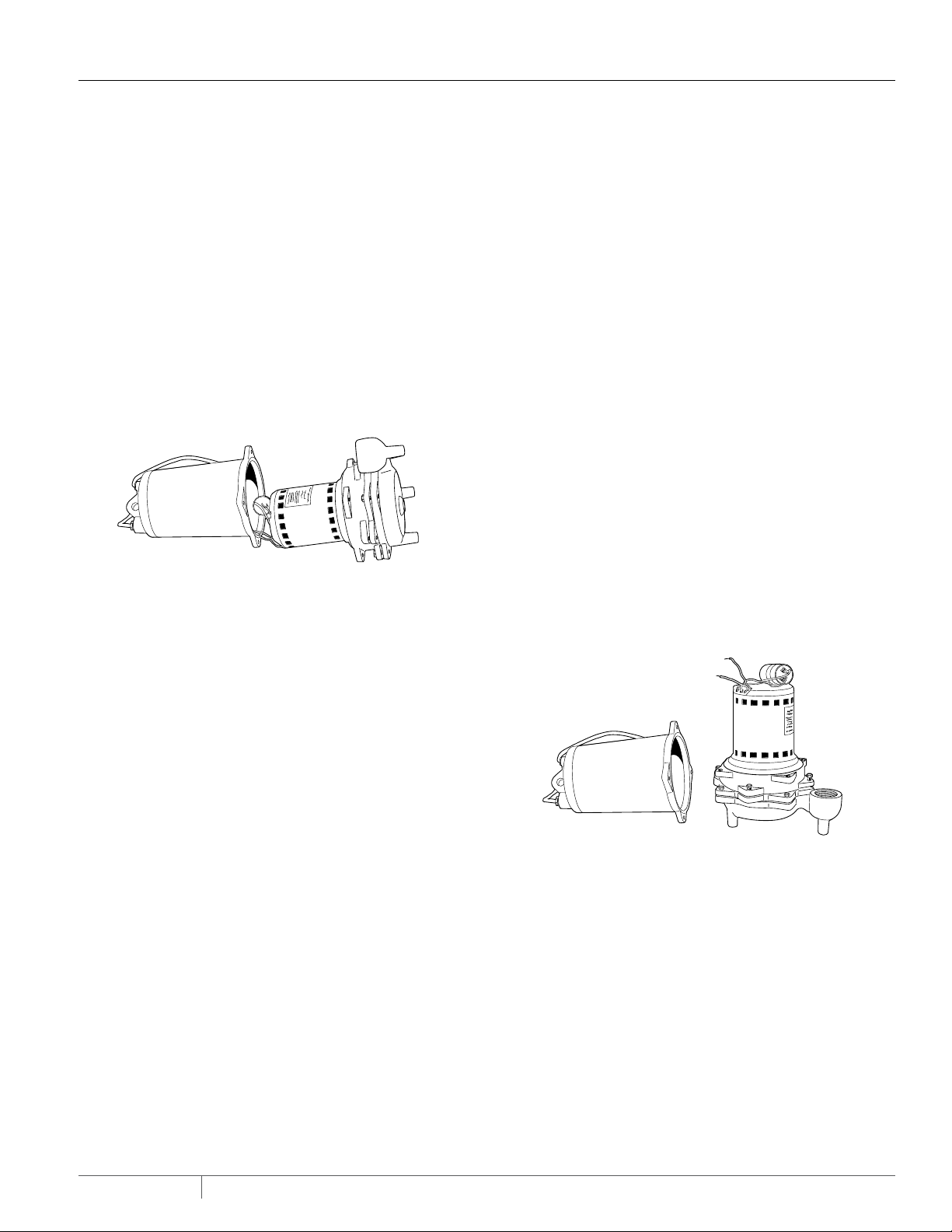

Myers ME and MW series pumps are available in both a single

seal as well as a double seal design with leak detector. The

ME50-ME150 models are designed for effluent dosing, Septic

Tank Effluent Pumping (S.T.E.P.) or normal sump and general

dewatering applications where higher pressure is required.

These units are designed to handle ¾” spherical solids.

The MWH50-MW200 models are designed for raw sewage

applications and can pass 2” spherical solids. These units can

also be used for sump and general dewatering applications

where larger solids capabilities are required.

When used in effluent dosing or S.T.E.P. applications, the pump

must be installed in a separate tank or compartment at the

discharger side of the septic tank. Never install pump in tank

where sludgecollects.

These pumps are available in single phase and three phase,

and either in single seal or double seal with seal leak detector.

All three phase units, all double seal units and all duplex

installations must be used with a control box. All power cords

and seal leak detector cords are 20 feet long.

The ME model impellers are enclosed two vane type to handle

¾” spherical solids and are available made of engineered

thermoplastic or optional naval bronze. All pumps have a 2” NPT

discharge tapping.

single phase pumps can be made automatic by attaching MFLC

or MFS controls to the pump. These switches have a fixed draw

off level of 8 to 10 inches and can be used up to 1 HP. For higher

horsepower ratings two mercury switches (or SMNO) controls

with a magnetic starter can be used. Simplex systems may

also use on/off pilot mercur y control switches (when permitted

by code) with control box and magnetic starter. The ALC and

AWS-1 controls can be used for simplex single phase pumps with

ratings up to 2 HP. All duplex systems must use pilot mercur y

control switches with control box and magnetic starters.

Plug-in cords can be used on all the single phase pumps with

a single seal (does not have a seal leak detector). This cord

has a GROUND pin that plugs into a grounded receptacle. The

grounded receptacle cannot be used in the wet sump or basin

due to DANGER of current leakage. Sealed junction boxes must

be used in wet sumps or basins to make connections to motor

cord. The AWS-1 control also acts as a sealed junction box for

connecting power cord to pump cord.

DOUBLE SEAL PUMPS

All pumps in this series “ME—D” or “MW—D” have two seals with

an oil chamber between the seals so that the seal faces of

both the lower and upper seals are oil lubricated for longer life

and greater protection against water leaking into the motor

windings. These double seal units are all made with a seal leak

de tector.

The MW model impellers are enclosed two vane non-clog

style, designed to handle 2” spherical solids. The MW pumps

are available with standard cast iron or optional naval bronze

impellers.

These pumps are NOT for use in swimming pools orfountains.

AIR LOCKING

A sump pump is said to be air locked if water traps air in the

pump and it cannot get out, thus preventing the pump from

operating.

In installation of this type a 1/8” hole should be drilled in the

discharge pipe just above the pump discharge and a check valve

should be installed 12 to 18 inches above pump discharge. Do not

put check valve directly into pump discharge opening - follow

local code.

PACKAGING

Each pump is packaged separately in a carton marked with a

catalog number and the Myers engineering number.

LEVEL CONTROLS

All pumps must use sealed level control switches for automatic

operation. MLC and MFLC controls have sealed switches that

are 1 HP rated at 230 volts. ALC and AWS-1 controls have sealed

mechanical switches that are rated 2 HP at 230 volts.Simplex

The leak detector in the oil seal chamber detects any water

leakage into the chamber and turns on a red signal light in

the control panel. Pumps should be removed from the sump

and seals replaced after the seal light shows in the panel.

Control panels must be used for pumps having the seal leak

detectors, and seal leak detectors must be wired as illustrated

in theseinstructions.

D ESIGN OF PRESSURE SEWER SYSTEMS

MYERS has available complete computer SOFTWARE for

designing PRESSURE SEWER SYSTEMS. This gives pipe sizes to

use and gives exact flow from any pump or group of pumps in the

system when operating simultaneously. This design DISK for IBM

or COMPATIBLE computers is available to engineers onrequest.

4

23822A278 (02-13-20)

INSTALLATION

MOTOR TYPE

Motors are ¾ frame, 1/2 – 2HP single or three phase, 60 Hertz,

3450 R.P.M. with class B insulation. All single phase motors are

permanent split-capacitor (PSC) type with built-in on-winding

overload protection and do not require a start switch or start

relay. The three phase pump motors require a magnetic starter

with 3 leg overload protection. All motors have upper and lower

ball bearings and all are oil-cooled and lubricated.

Breathing hazard. Basin or tank must be vented in

accordance with local plumbing codes. These pumps are not

designed for and CANNOT be installed in locations classified as

hazardous in accordance with the National Electric Code ANSI/

NFPA 70.

Never enter pump chamber after sewage or effluent

has been in basin. Sewage water can give off methane,

hydrogen sulfide and other gases which are highly

poisonous.

Myers recommends installing ME series effluent pumps with

a quick removal system. The quick removal system may be a

union or quick-release coupling if the pipe or discharge hose

is within reach from the surface, or a rail system type quick

disconnect on deeper installations. See installation drawings for

suggestedinstallation.

The dosing tank or pumping chamber must be constructed

of corrosion resistant materials and must be capable of

withstanding all anticipated internal and external loads. It also

must not allow infiltration or exfiltration. The tank must have

provisions for anti-buoyancy. Access holes or covers must be

of adequate size and be accessible from the surface to allow

for installation and maintenance of the system. Access covers

must be lockable or heavy enough to prevent easy access

by unauthorized personnel. The pumping chamber holding

capacity should be selected to allow for emergency conditions.

The discharge pipe must be the same size as the pump

discharge (2 inches) or larger. In order to insure sufficient fluid

velocity to prevent any residual solids from collecting in the

discharge pipe, it is recommended that a minimum flow of 2 feet

per second be maintained. (21 GPM through 2” pipe and 46 GPM

through 3” pipe). It is recommended that PVC or equal pipe is

used for corrosion resistance.

A full flow (ball or gate) shut off valve must be installed to

prevent back flow of effluent if the pump must be removed for

service. A check valve must be installed on pressure sewer

systems and on other systems where conditions allow to

prevent backflow and to reduce wear on the pump system.

A high water alarm must be installed on a separate circuit from

the pump circuit. The alarm should have the ability to be tested

for proper operation.

S PECIAL INSTRUCTIONS FOR THREE PHASE PUMPS

1. Myers recommends three phase pumps to be installed by

qualified personnel.

2.

strain relief. Do not connect conduit topump.

3. Three phase pumps are always installed with control boxes

having magnetic starters with 3 leg overload protection. DO

NOT TRY TO RUN THREE PHASE PUMPS DIRECTLY ACROSS

THE LINE.

4. To Connect Pump: Run wire from pump to the bottom

of control box or appropriate junction box suitable for

enclosing splice connections. A hole must be cut into the

control box for the wires. With power to control box off,

connect green (ground) line to ground lug. Connect black

(power) wires to power lead terminals.Note: for a typical CE

style control box, these terminals are marked M1, M2 and

M3. Make sure that all wires are inside control box and not in

a position to be pinched or shorted when the door is closed.

Risk of electric shock. Do not remove cord and

23822A278 (02-13-20)

5

AS

S

DIAGRAMS

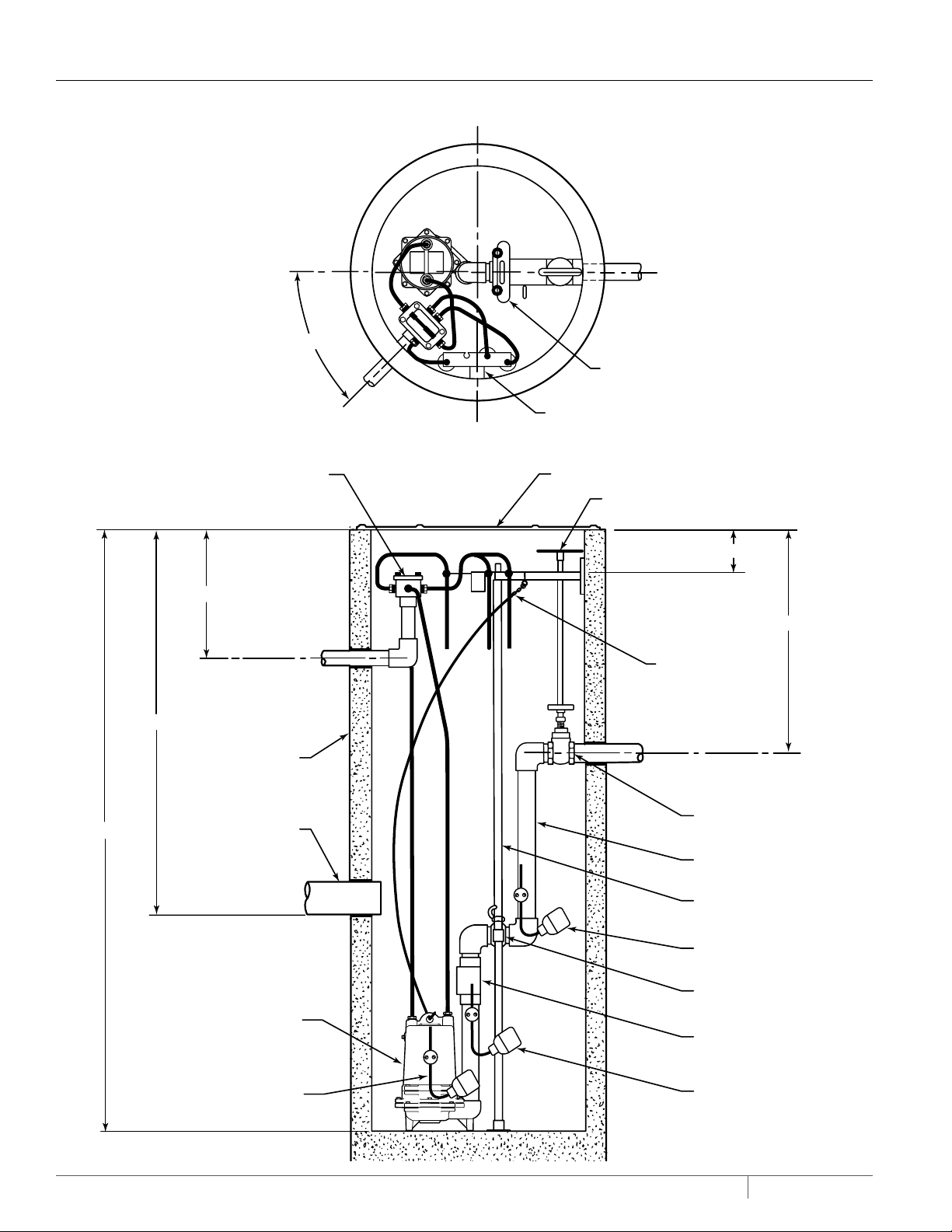

30” Diameter Simplex ME/MW 1/2 – 2 HP

45º

RAIL SUPPORT

CONTROL MOUNTING

BRACKET, SST

REQ’D.

AS REQ’D.

JUNCTION BOX

STRUCT. PLASTIC

18

1-1/2” CONDUIT

REQ’D.

30” DIA.

CONCRETE WELL

INLET HUB

(AS REQ’D.)

30” DIA. BASIN COVER

VALVE EXTENSION HANDLE

6

As Req’d.

LIFT-OUT ROPE

2” DISCHARGE

2” GATE VALVE, BRASS

2” DISCHARGE PIPE, PVC

GUIDE RAILS, 3/4” GALV.

HIGH WATER “ALARM” LEVEL

ME 1/2 – 1-1/2 HP

EFFLUENT PUMP

MW 1/2 – 2 HP

SEWAGE PUMP

PUMP “OFF” LEVEL

6

PITLESS DISCONNECT, BRAS

2” SWING CHECK VALVE, PVC

PUMP “ON” LEVEL

23822A278 (02-13-20)

DIAGRAMS

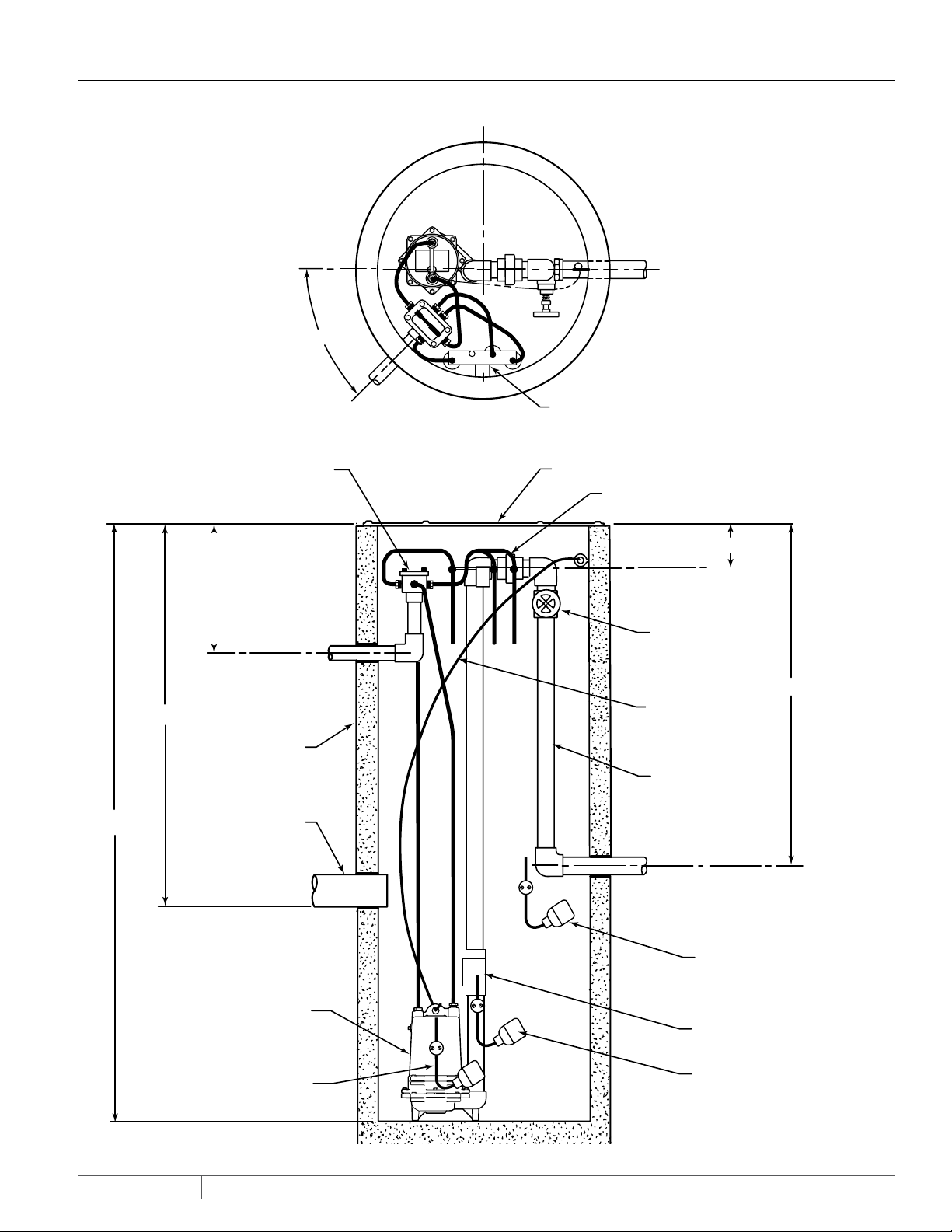

30” Diameter Simplex Union System ME/MW 1/ - 2 HP

45º

CONTROL MOUNTING

BRACKET, SST

AS REQ’D.

AS REQ’D.

JUNCTION BOX

STRUCT. PLASTIC

18

1-1/2” CONDUIT

REQ’D.

30” DIA.

CONCRETE WELL

INLET HUB

(AS REQ’D.)

30” DIA. BASIN COVER

2” UNION, PVC

6

2” GATE VALVE,

BRASS

AS REQ’D.

LIFT-OUT ROPE

2” DISCHARGE

PIPE, PVC

2” DISCHARGE

23822A278 (02-13-20)

ME 1/2 – 1-1/2 HP

EFFLUENT PUMP

MW 1/2 – 2 HP

SEWAGE PUMP

PUMP “OFF” LEVEL

HIGH WATER “ALARM” LEVEL

2” SWING CHECK VALVE, PVC

PUMP “ON” LEVEL

7

CONTROL MOUNTING

AS REQ’

SEWAGE PUMP

, BRASS

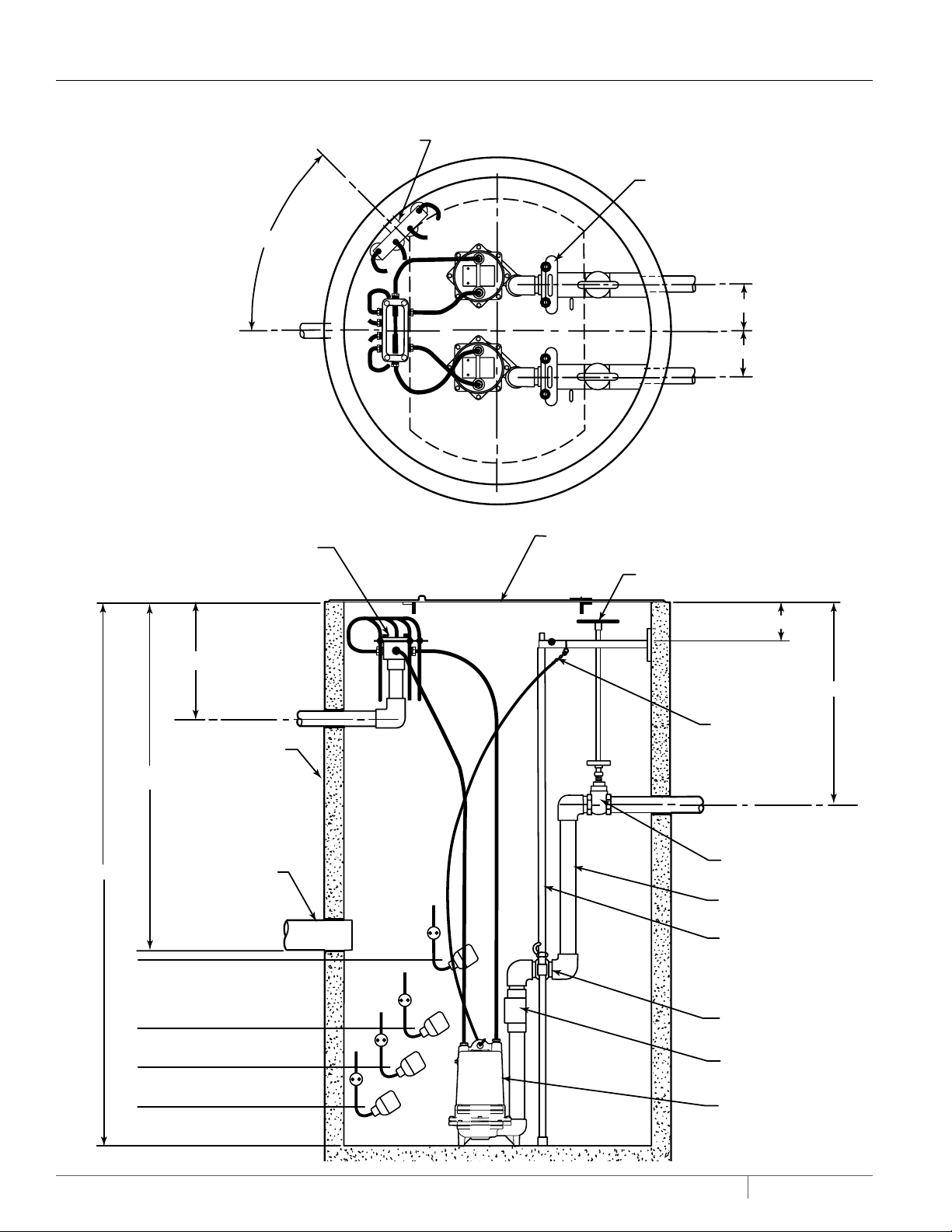

DIAGRAMS

48” Diameter Duplex ME/MW 1/2 – 2 HP

BRACKET, SST

RAIL SUPPORT

45º

71/8

71/8

JUNCTION BOX

STRUCT. PLASTIC

18

2” CONDUIT

REQ’D.

48” DIA.

CONCRETE WELL

AS REQ’D.

D.

HIGHWATER “ALARM” LEVEL

INLET HUB

(AS REQ’D.)

48” BASIN COVER W/HINGED HATC H

& LOCK HASP EPOXY COAT ED 1/4” STEEL

VALVE EXTENSION HANDLE

6

AS REQ’D.

LIFT-OUT ROPE

2” DISCHARGE

2” GATE VALVE, BRASS

2” DISCHARGE PIPE, PVC

GUIDE RAILS, 3/4” GALV.

LAG PUMP “ON” LEVEL

LEAD PUMP “ON” LEVEL

PUMP “OFF” LEVEL

8

PITLESS DISCONNECT

2” SWING CHECK VALVE, PVC

ME 1/2 – 1-1/2 HP

EFFLUENT PUMP

MW 1/2 – 2 HP

23822A278 (02-13-20)

MAINTENANCE

BEFORE DISMANTLING PUMP FOR REPLACEMENT OF PARTS

Clean pump thoroughly. Knock off all scale and deposits. Use

sandblast if possible. Submerge complete unit in dilute bleach

solution for one hour beforedisassembly.

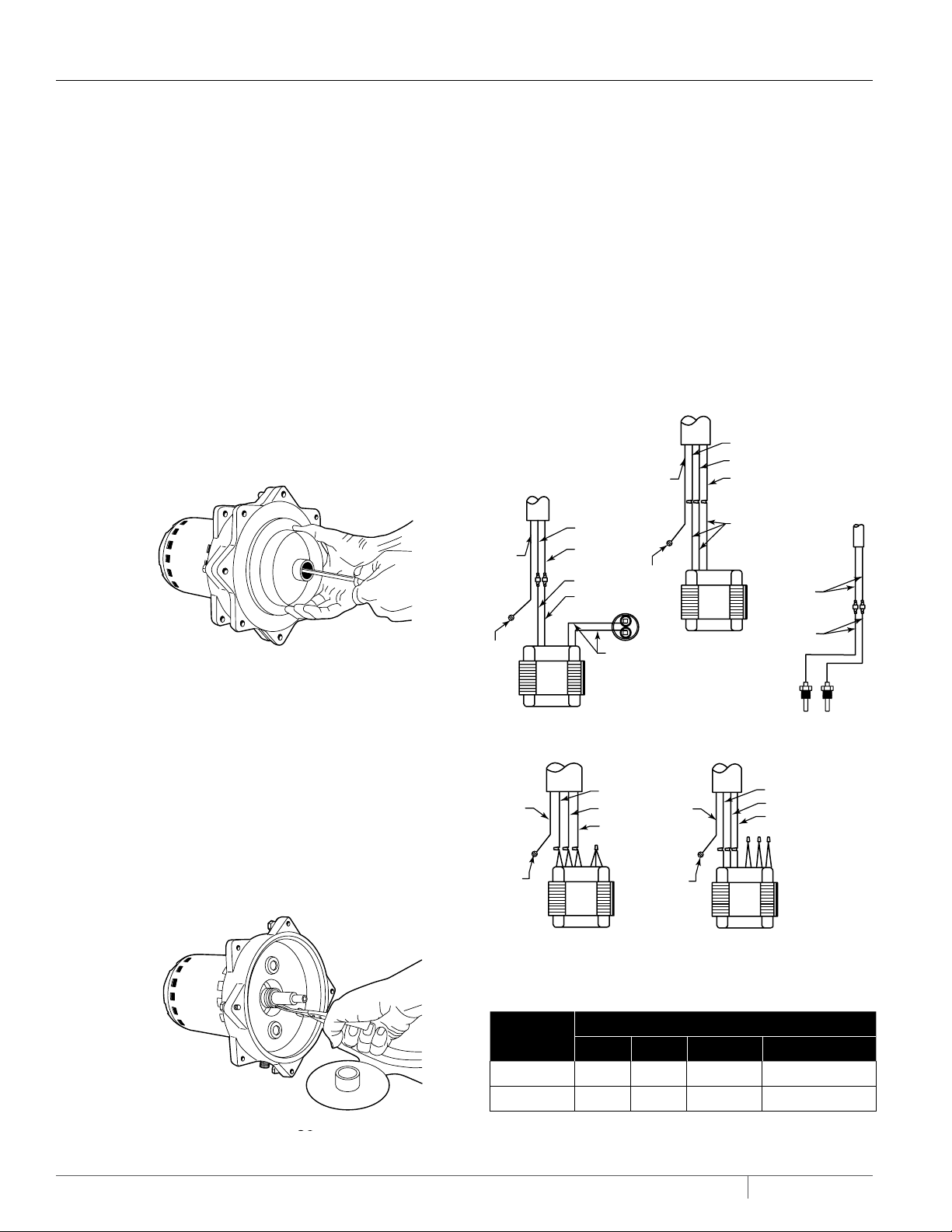

TO REPLACE CAPACITORS ONLY

All of the single phase motors are of the permanent split

capacitor type and have no relays or starting switch. They have

only a starting capacitor that is in the circuit for both starting

and running conditions.

1. Remove oil fill plug near the top of the motor and pour the oil

out.

2. Loosen the pug nuts around the cords until they are loose

enough to push the cords down inside of the motor housing.

3. Remove the four bolts from the motor housing and bump the

housing with a plastic hammer to loosen. Lay the pump on

its side.

4. Remove the housing carefully to be sure that enough cord is

pushed into the housing to create no tension on the cords.

5. Slide motor housing up far enough to expose the capacitor

and to be able to lay the housing down.

6. Disconnect wiring from capacitor and loosen capacitor

clamp and slide out capacitor. Replace with new capacitor,

tighten and re-connect. Wiring diagram is given in these

instructions.

7. Check all wiring connectors to be sure they aresecure.

8. Be sure tetraseal gasket is in place.

9. Slide motor housing back onto pump while pulling the cords

out slowly. Assemble the motor housing with the four bolts.

10. Re-assemble cord nuts. Be sure washers are seated and

cords are pulled up to stop against the washers. Tighten

nuts securely.

11. Put pump upright and refill motor with refined paraffinic

transformer oil, ¹Shellflex™ 2210 or equivalent. DO NOT

OVER FILL WITH OIL. With pump upright fill oil to bottom of

oil fill tapping. Replace oil fill plug

¹ Shel l Oil Compan y, Texas

12. Be sure pump turns freely before connecting to power. Turn

pump on side and turn impeller, using screwdriver in slotted

shaft. Plug pump into receptacle to test operation. Pump

must run quiet and free of vibration.

TO REPLACE POWER CORD AND/OR SEAL LEAK

DETECTOR CORD

Remove motor housing as described above. Disconnect the

push-together terminals and remove the ground screw from the

power cord if beingreplaced.

Completely unscrew cord bushing to be replaced and remove

cord assembly from housing. Be sure remaining terminals are

secure on the wires.

Replace with proper cord with fittings. Push cord into the motor

housing far enough to make proper connections. Reconnect

ground wire if replacing power cord and securely connect the

wires correctly. See wiring diagram in these instructions.

Assemble cords and motor housing as described in Capacitor

Replacement. Fill with oil as noted and be sure pump turns

freely before connecting topower.

T O REPLACE MOTOR STATOR AND SHELL

1. Remove motor housing as described above.

2. Disconnect all leads from power and seal leak cords and

ground wire and set pump upright.

3. Loosen the four long screw holding the motor and remove

slowly. If unit has seal leak probes, be sure to feed the wires

through the slots as the motor is being removed.

4. Either remove previous capacitor and clamp from old motor

and assemble onto new stator and shell or replace with a

new capacitor and assemble the two capacitor leads per

wiring diagram.

5. Position bearing spring washer on top of upper ball bearing.

6. Tighten terminal screws of seal leak probes and feed wires

through the motor slots.

7. Position the “stator with shell” into place and line up screws

with the bosses and tighten the (4) long screws. Extend

probe wires out through the slots. Lay unit down in line with

motor housing.

8. Be sure pump turns freely with screwdriver in impeller end

of shaft.

9. Reconnect all terminals securely per wiringdiagram.

10. Be sure tetraseal gasket is in place.

11. Reassemble motor housing and fill with oil as noted above in

capacitor replacement.

NOTICE On three phase motors always check unit for proper

rotation. With pump on its side apply power by turning on, then

off, quickly. Impeller must turn counter-clockwise when looking

into the impeller inlet. If not, interchange any two leads in the

control box.

23822A278 (02-13-20)

9

MAINTENANCE

SHAFT SEAL REPLACEMENT

1. Remove plugs in motor housing and in seal housing (for

double seal units) and drain oil.

2. Remove four bolts holding the volute case and bump with a

plastic hammer to loosen and removecase.

3. Hold impeller and unscrew impeller locking screw. Turn

counterclockwise to loosen.

4. Pry off seal bellows and ceramic seat. Break seats if

necessary to get out since they must be replaced with new

parts.

5. NEVER USE OLD SEAL PARTS - USE ONLY COMPLETELY

NEW SEALS. (Do not use seal spring retainer plate on single

seal pump or lower seal of double seal pump.)

6. For single seal pumps or if only replacing the lower seal

of a double seal pump, it is not necessary to disassemble

further. On a double seal pump, it is not necessary to drain

oil out of the motor housing, just the seal housing.

10. Check HUVA cup seal in volute case inlet. If worn,replace.

11. Be sure tetraseal gasket is in position (replace if worn) and

reassemble.

12. Replace oil in motor housing and seal chamber. Use only

Myers submersible oil.

13. Be sure pump turns freely before connecting to power. After

connecting, check for proper rotation noted under

Stator Replacement.

WIRING DIAGRAM

BLACK

WHITE

RED

BLACK

BLACK

GREEN

BLACK

WHITE

BLACK

WHITE

GREEN

GROUND

7. On a double seal pump, to remove the upper seal, remove

four bolts holding the bottom plate and remove bottom

plate.

8. Remove snap ring with snap ring pliers. Pry off upper seal

bellows and ceramic seat.

9. If no water has entered motor housing (check winding with

ohmmeter or megger) wipe seal chambers thoroughly and

replace seals. (Use seal retainer plate on upper seal only; do

not use on lower seal.) Clean seal faces and use light on face

before installing bellows part of seal.

YELLOW

575V. - 3 PHASE

GREEN

GROUND

(DOUBLE SEAL ON LY)

BLACK

WHITE

RED

460V. - 3 PHAS E

TYP. FOR 1 & 3Ø

GROUND

115V ., 208V. OR 230V.

1 PHASE, P.S.C.

GREEN

GROUND

208/230V. - 3 PHAS E

BROWN

BLACK

WHITE

RED

3 PHASE DUAL VOLTAGE WINDING

Voltage

Black White Red Toge ther

208 & 230 1 & 7 2 & 8 3 & 9 4 & 5 & 6

460 1 2 3 4 & 7, 5 & 8, 6 & 9

Leads

SEAL LEAK

DETECTOR

10

23822A278 (02-13-20)

INCOMING 115V, 1 PH

1

3

11.47

A

CAPACITY LITERS PER MINUTE

CAPACITY GALLONS PER MINUTE

TOTAL HEAD IN FEET

TOTAL HEAD IN METERS

SPECIFICATIONS

M OISTURE SENSOR SEAL PROBE CIRCUIT

7

2

RI

6

5

TO SEAL LEAK

PROBES

Relay: SSAC Inc. #LLC44A5A

Socket: Standard 8-pin plug-in type

If Myers panel is used see below.

Pumps: ME50D-11,

ME75D-11

Required Panel:

CMEP(SL)-11S, -11SW,-11D, or -11DW

Pumps: ME50D-01, ME50D-21,

ME75D-01, ME75D-21,

ME100D-01, ME100D-21,

ME150D-01, ME150D-21,

MWH50D-01, MWH50D-21,

MW100D-01, MW100D-21,

MW150D-01, MW150D-21,

MW200D-01, MW200D-21

Required Panel:

CMEP(SL) -21S, -21SW,-21D, or -21DW

Pumps: ME50D-03, ME50D-23,

ME75D-03, ME75D-23,

ME100D-03, ME100D-23,

ME150D-03, ME150D-23,

MWH50D-03, MWH50D-23,

MW100D-03, MW100D-23,

MW150D-03, MW150D-23,

MW200D-03, MW200D-23

Required Panel:

CMEP(SL) -23S, -23SW,-23D, or -23DW

Pumps: ME50D-43,

ME75D-43,

ME100D-43,

ME150D-43,

MWH50D-43,

MW100D-43,

MW150D-43,

MW200D-43

Required Panel:

CMEP(SL)-43S, -43SW,-43D, or -43DW

RI

TO AUDIBLE OR

VISUAL ALARM

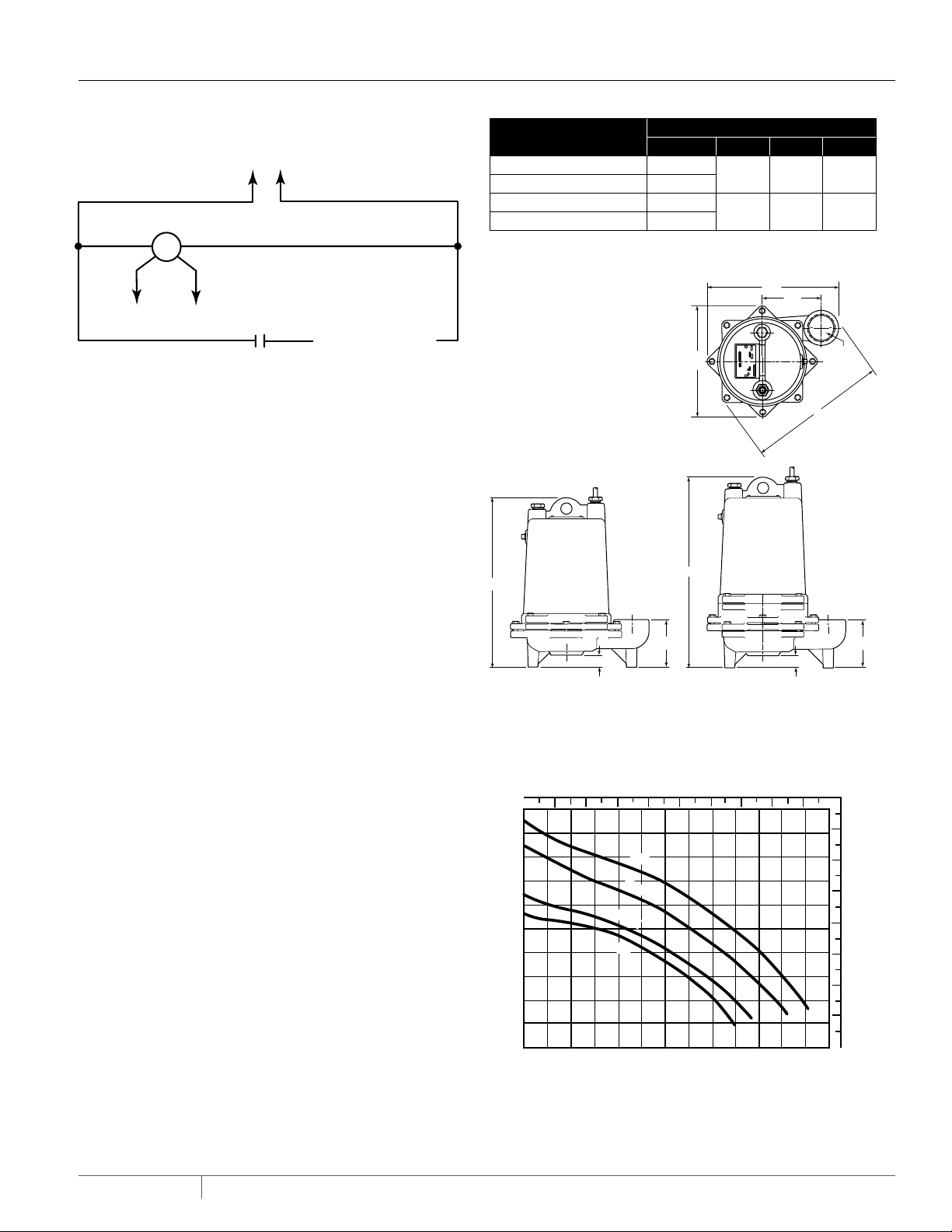

ME SERIES DIMENSIONS

Model Series

ME50S 16.8 (427)

ME50D 18.6 (47 2)

ME75S, ME100S, ME150S 16.8 (427)

ME75D, ME100D, ME150D 18.6 (47 2)

C

Inches (milimeters)

A B C F

4.09

(104)

4.0

(102)

9.63

(245)

A

B

ME PERFORMANCE CURVE

0 50 100 150 200 250 300 350 400 450

100

90

80

70

60

50

40

30

20

10

0

0 10 20 30 40 50 60 70 80 90 100 110 120 130

ME 150

ME 100

ME 75

ME 50

(291)

1.03

(26)

1.06

(27)

5.12

(130)

C

F

12.13

(308)

12.5

(318))

2” NPT

Discharge

B

28

24

20

16

12

8

4

0

23822A278 (02-13-20)

11

CAPACITY LITERS PER MINUTE

CAPACITY GALLONS PER MINUTE

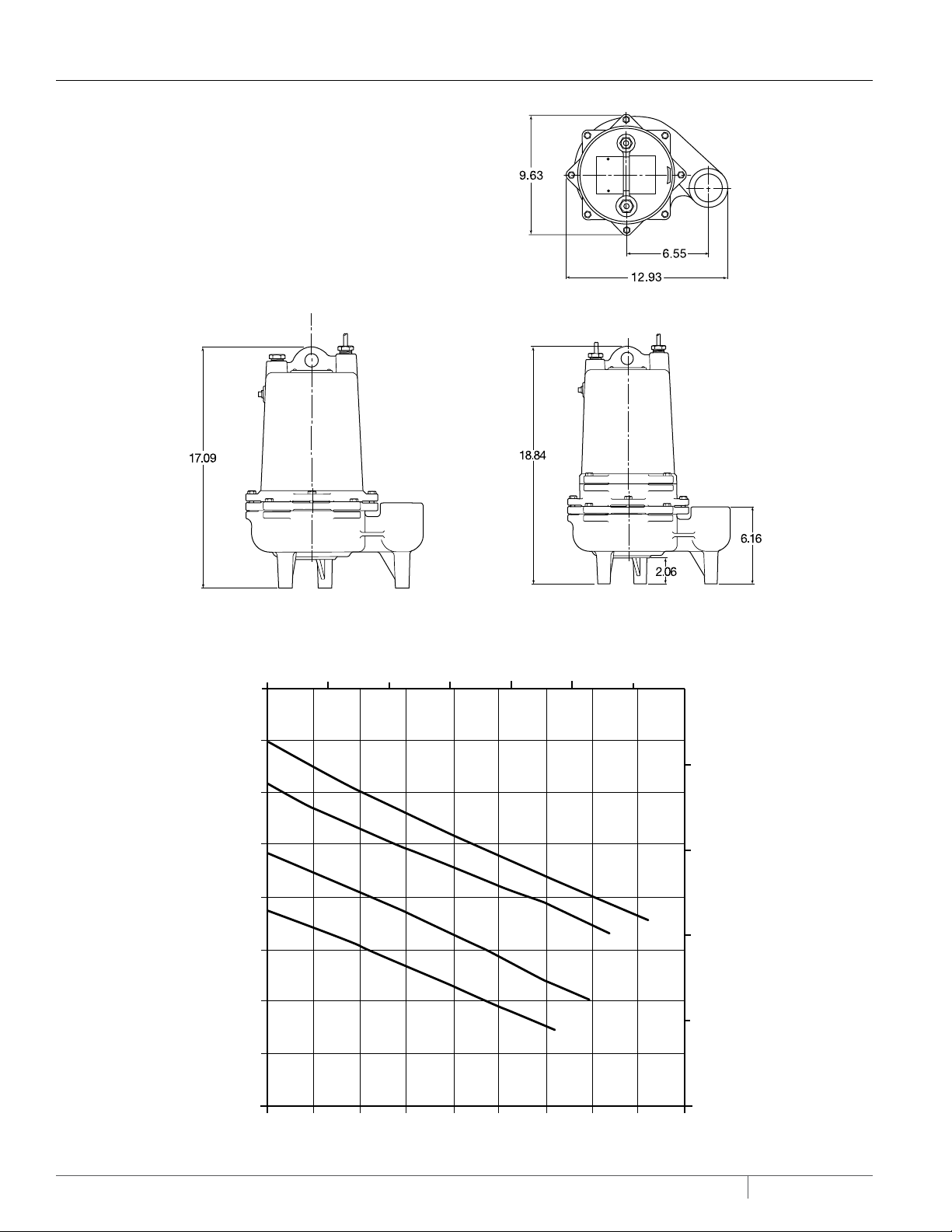

DIMENSION CHARTS

MW SERIES DIMENSIONS

MW PERFORMANCE CURVE

TOTAL HEAD IN FEET

0 100 200 300 400 500 600

80

70

60

MW200

50

40

30

20

10

MWH50

MW150

MW100

20

15

10

TOTAL HEAD IN METERS

5

12

0

0 20 40 60 80 100 120 140 160 180

0

23822A278 (02-13-20)

DIMENSION CHARTS

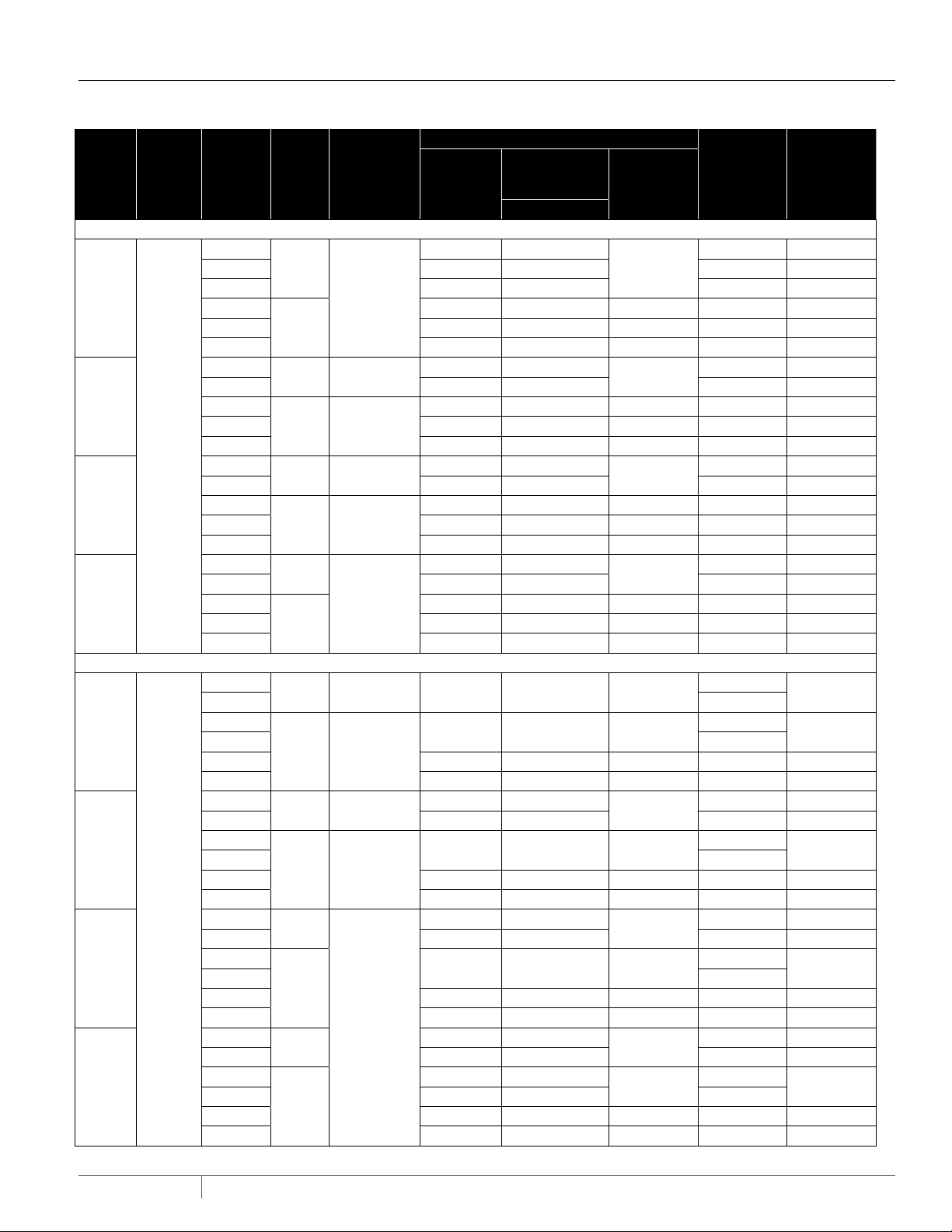

MO TOR DATA CH ART

H.P. Speed Volts Phase Stack Height

ME Series

115

1

3

1 2-1/4

3 2

1 2-3/4 -

3 2-1/2

1

3

1 2-1/4 4.5 12.0 -

3 2

1 2-3/4

3 2-1/2

1

3

1

3

1/2

3/4

1

1-1/2

MW Series

1/2

1

1-1/2

2

3450

3450

208 6.7 16.5

230 9.8 19.7 6.0 15.0

208/230

460 45.4 45.4 45.4 1.6 6.4

575 71.0 71.0 71.0 1.3 5.1

115

208/230 4.5 12.0 7.6 /6.9 16.2

208/230

460 30.1 30.1 30.1 2.3 10.1

575 47.0 47. 0 47.0 1.9 8.1

208

230 3.0/2.6 16/14 9.3 19.0

208/230

460 21.2 21.2 21.2 3.0 14.5

575 33.1 33.1 33.1 2.4 11.6

208

230 2.4 12.0 12.8 23.0

208/230

460 16.0 16.0 16.0 4.0 15.0

575 25.0 25.0 25.0 3.2 12.0

208

230 6.9

208

230 4.7

460 30.1 30.1 30.1 2.3 10.1

575 47.0 47. 0 47.0 1.9 8.1

208

230 2.8 15.0 9.3 19.0

208

230 6.0

460 21.2 21.2 21.2 3.0 14.5

575 33.1 33.1 33.1 2.4 11.6

208

230 1.6 7.4 12.8 33.4

208

230 7.0

460 18.0 18.0 18.0 3.5 15.0

575 28.0 28.0 28.0 2.8 12.0

208

230 1.6 7.4 13.1 33.4

208

230 4.5 4.5 7.7

460 18.0 18.0 18.0 3.9 15.0

575 28.0 28.0 28.0 3.1 12.0

1-5/8

2-3/4

2-3/4

Winding Resistance In Ohms

Main

Black To

White

.9 /.8 14.7

11.3 11.3 11.3 3.5/3.2 12.8

.85 4.9

7.6 7.6 7.6 5.2 /4.7 20.2

5.3 5.3 5.3 6.6/6.0 29.0

4.5 4.5 4.5 8.8/8.0 30.0

7.6 7.6 7.6

2.2 11.5

5.3 5.3 5.3

2.1 9.3

4.5 4.5 4.5

2.1 9.3

4.5 4.5

Start - 1Ø

Brn. To Brn. Or

Black To Red - 3Ø

Purple

White To Red

-

-

-

-

-

-

4.5

Max. Amps

12.1 29.6

13.8 30.4

10.3 21.0

14.1

7.6

5.2

10.3 21.0

6.6

14.8 39.9

7.7

15.3 39.9

8.5

Locked Rotor

Amps

16.2

20.2

29.0

30.0

30.0

23822A278 (02-13-20)

13

SINGLE SEAL PUMP SPECIFICATIONS

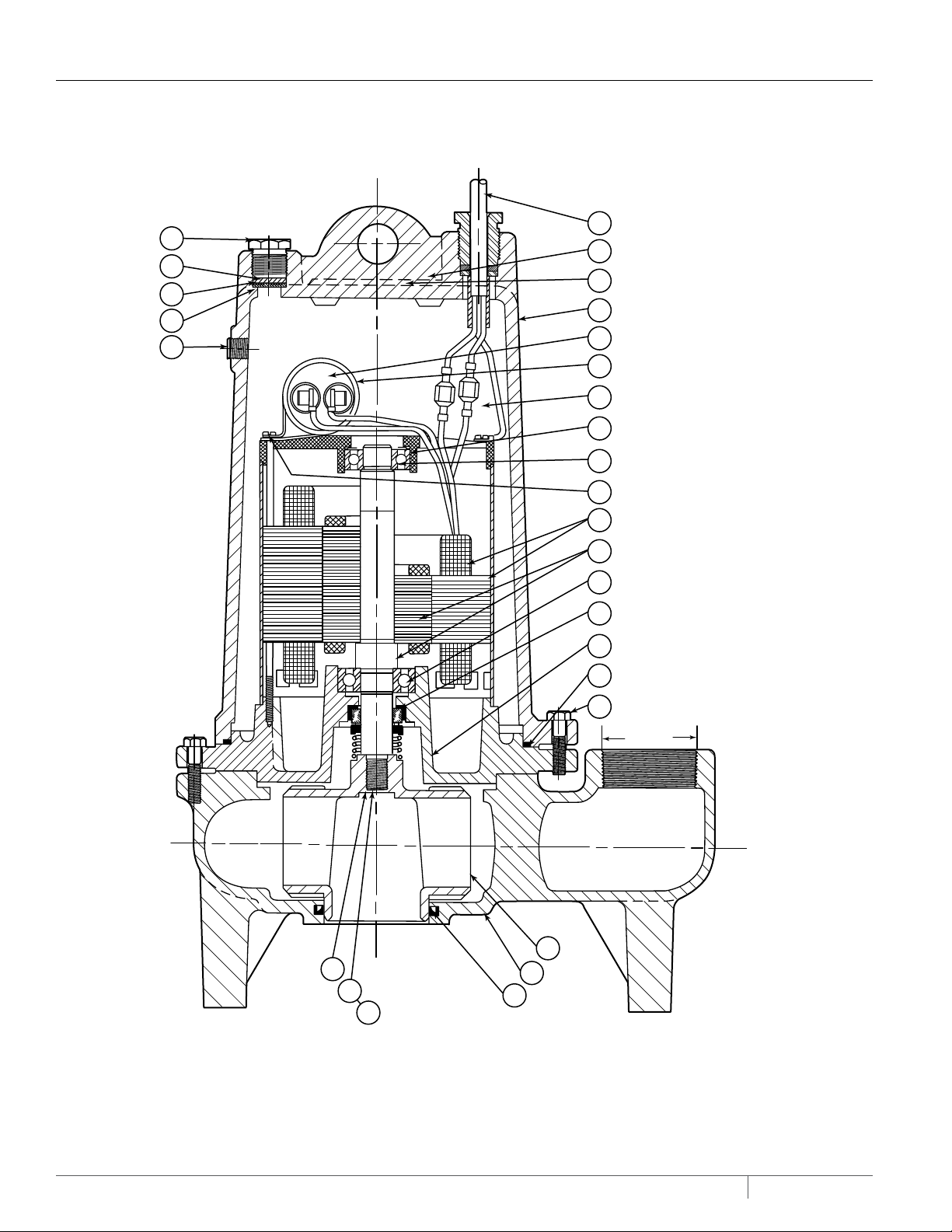

TYPICAL SECTION DRAWING FOR ME/MW50-200 SINGLE SEAL PUMPS

1

2

3

4

5

OIL LEVEL

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

26

27

21

22

2” NPT

23

24

25

28

14

23822A278 (02-13-20)

SINGLE SEAL PUMP SPECIFICATIONS

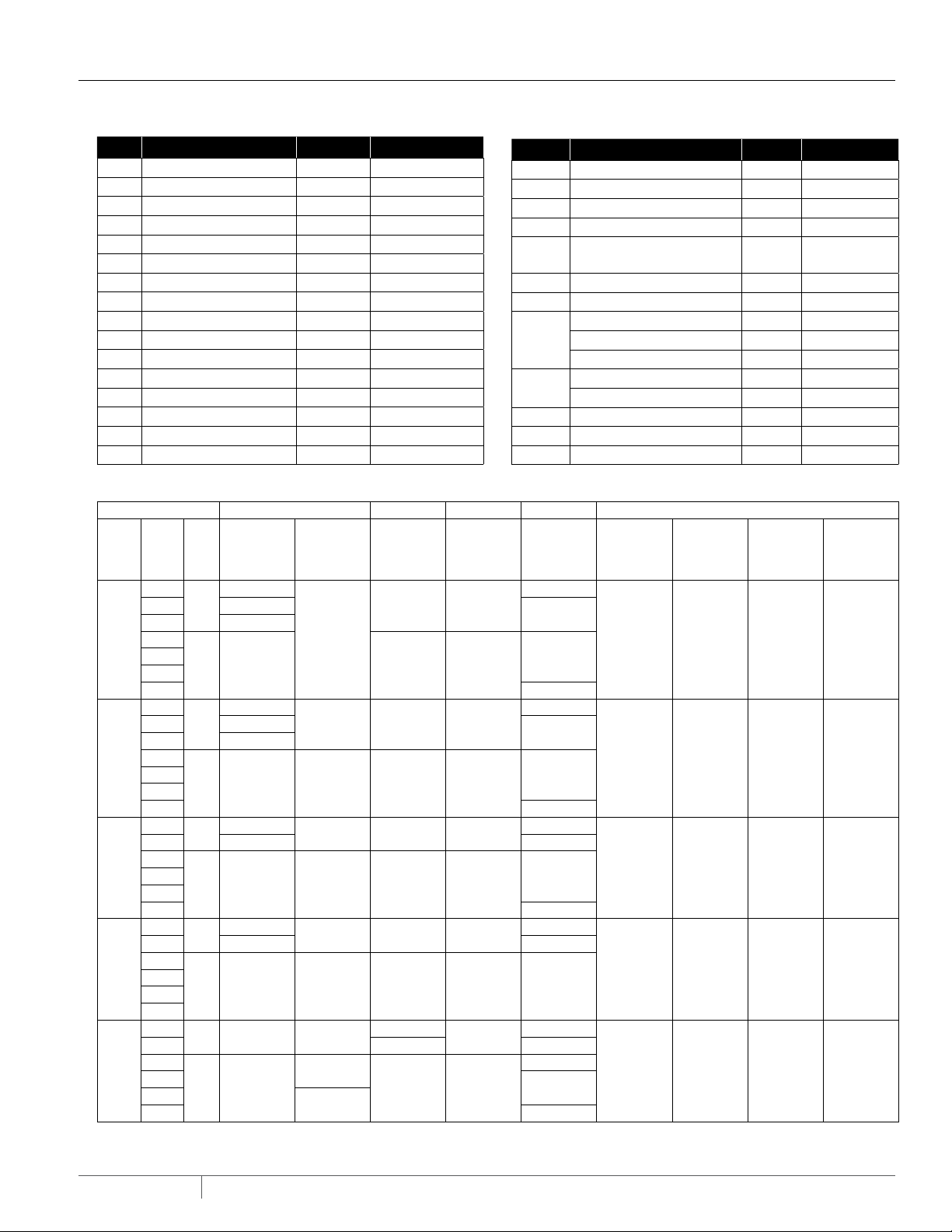

SINGLE SEAL REPAIR PARTS LIST

Ref. Description Qty. Part Numbers

1 Nut, cord plug, solid 1 25341A002

2 Washer, 1/32” Thk. 1 05030A234

3 Gasket, Rubber 1 05014A193

4 Washer, 3/32” Thk. 1 05030A235

5 Plug, 1/4” pipe 1 05022A009

6 Cord, Power 1 See Chart

7 Screw, drive 2 05160A004

8 Name Plate 1 N/A

9 Housing, Motor 1 25327D000

10 Capacitor (1Ph only) 1 See Chart

11 Clip, capacitor (1 Ph only) 1 See Chart

12 Oil, Transformer .8-1 gal 11009A006

12A Connectors (3 Ph only) 3-6 15781A001

13 Washer, bearing 1 19331A005

14 Bearing, ball, upper 1 08565A013

15 Screw, st, #10 x 3/8 2 09822A032

Unit manufactured prior to Aug-2007 contact factory for repair parts.

Item Number 6 10 11 16 & 17 23

HP Volts PH

115

208

230 25338B005

1/2

208

460

575 25484D103

115 25338B000

208

230 25338B001

3/4

208

460

575 25484D103

208

230 25338B001 25484D105

208

1

460

575 25484D107

208

230 25338B001 25484D105

208

1-1/2

230

460

575

208

230 26520A000 25484D109

208

2

230

460

575 25484D112

Power Cord

W/Plug

25338B004

1

3

3 25338B003

1 25338A002 23838A000 20333A004

3 25338B003

1 25338B002 23838A000 20333A004

3 25338B003 25484D106

1 25338B009

3

Power Cord

No Plug

25338B006

25338B002 23839A000 20333A006

25338B008

25338B003

Capacitor

23839A000 20333A006

23839A000

Capacitor

Clip

20333A006

Ref. Description Qty. Part Number

16 & 17 Stator, Rotor shaft with shell 1 See Chart

18 Bearing, ball, lower 1 08565A022

19 Seal, shaft 1 25370A000

20 Plate, brg & seal 1 25367D000

21

22 Screw, cap, 5/16 x 1-1/4 8 19100A012

23 Impeller 1 See Chart

24

25

26 Washer, Impeller Retainer 1 05030A242

27 Screw, Machine #10 x 3/8 1 06106A042

28 Sealant 1 14550A001

Stator Rotor

& Shaft Ass’y

25484D100

25484D101

25484D102230

25484D100

25484D101

25484D102230

25484D104

25484D106230

25484D104

25484D108

25484D110

25484D111

Gasket, tetraseal, 7x6-

3/4x1 /8

Case, volute (ME50) 1 25357D000

Case, volute (ME75-150) 1 25331D000

Case, volute (MWH5-200) 1 26057D000

Cup, U, HUVA (ME50-150) 1 22835A005

Cup, U, HUVA (MWH50-200) 1 22835A009

ME

Impeller

Plastic

25333B025 25348B121 26029B013 26029B113

25348B020 25348B120

25348B010 25348B110 26029B012 26029B112

25348B000 25348B100 26029B011 26029B111

Naval Bronze

ME

Impeller

Optional

1 05014A181

MW

Impeller DI

26029B000 26029B100

MWH Impeller

Optional

Naval Bronze

23822A278 (02-13-20)

15

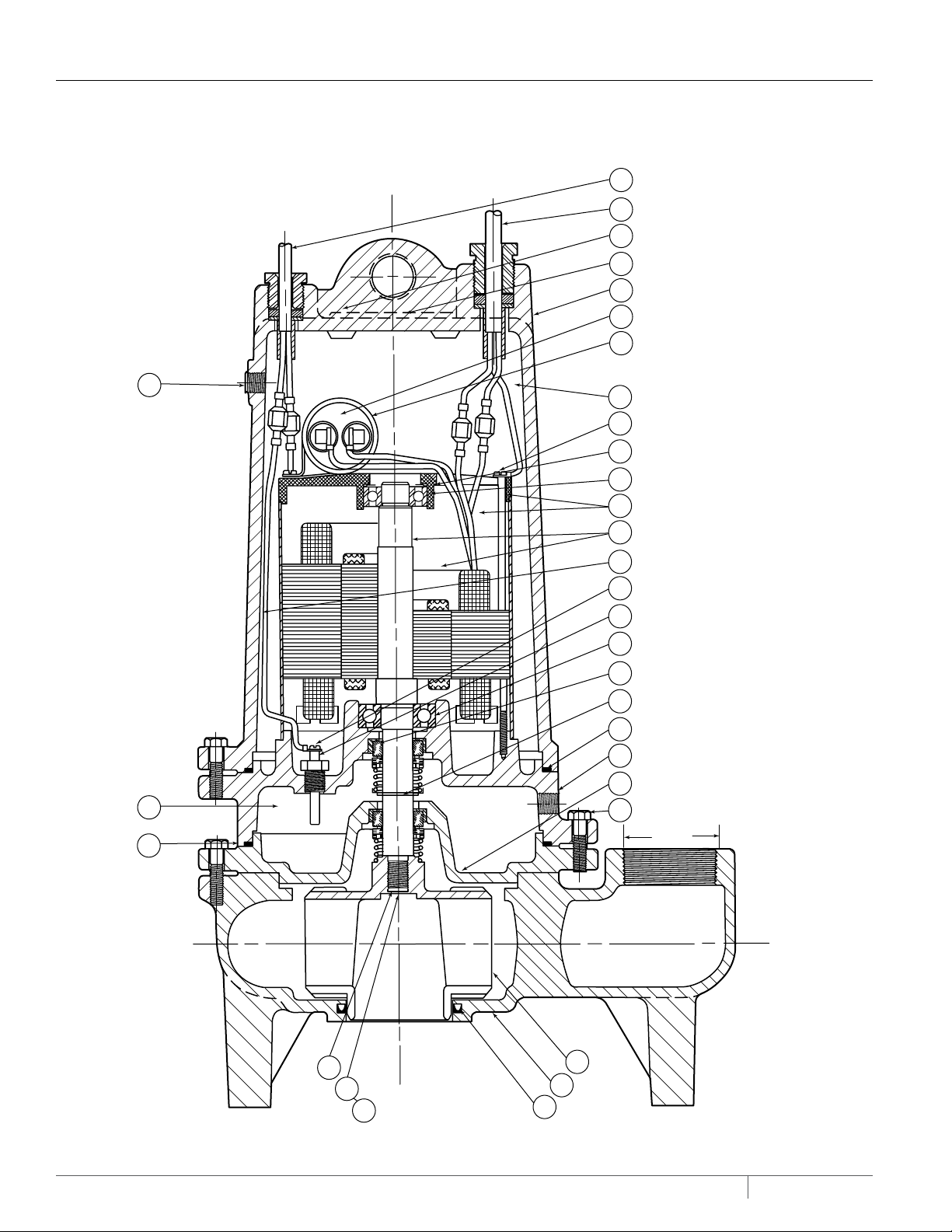

DOUBLE SEAL PUMP SPECIFICATIONS

TYPICAL SECTION DRAWING FOR ME/MW50-200 DOUBLE SEAL PUMPS

1

2

3

4

5

6

7

21

8

9

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

2” NPT

16

28

29

30

25

26

27

23822A278 (02-13-20)

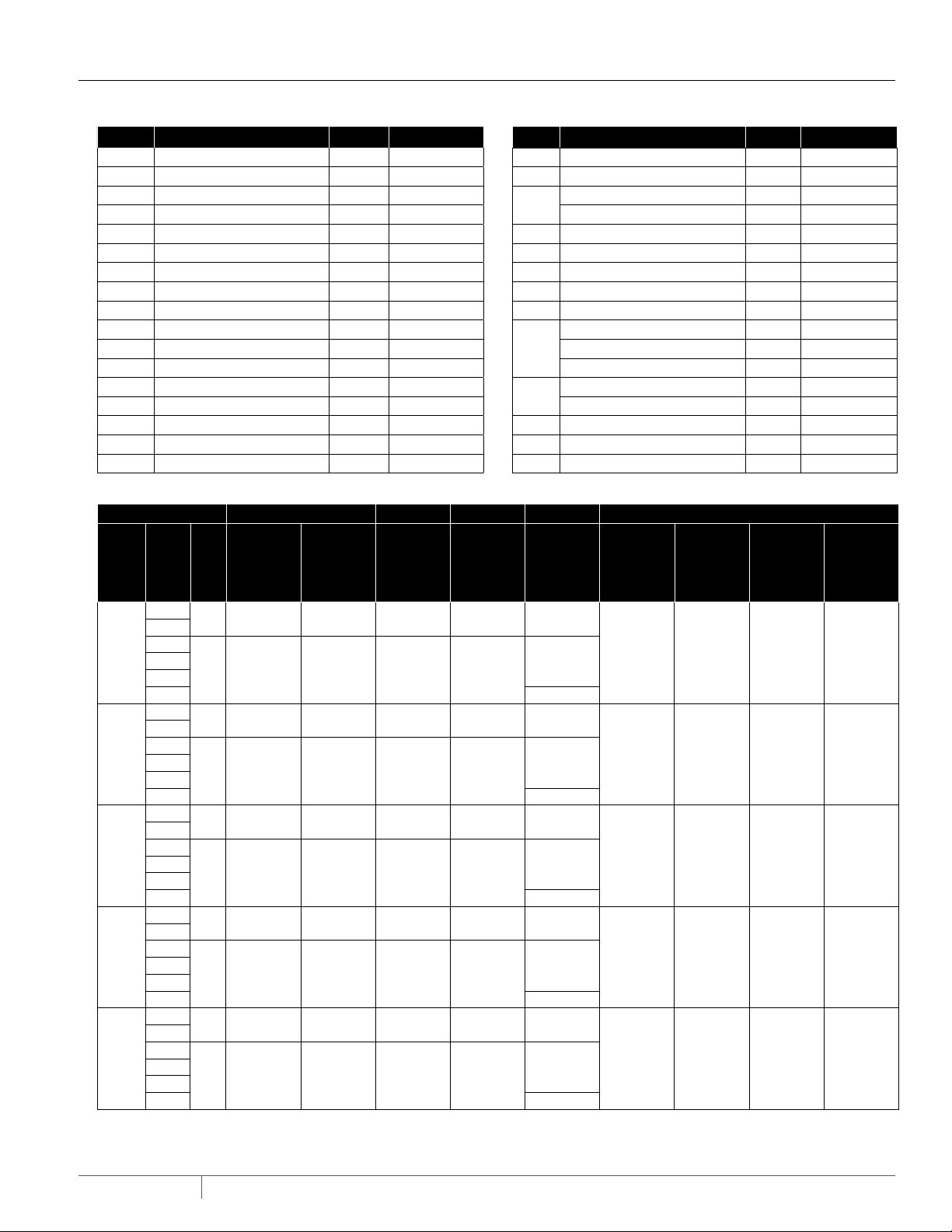

DOUBLE SEAL PUMP SPECIFICATIONS

DOUBLE SEAL REPAIR PARTS LIST

Ref. Description Qty. Part Number

1 Cord, Sensor 1 25339B000

2 Cord, Power 1 See Chart

3 Screw, drive 2 05160A004

4 Name Plate 1 N /A

5 Housing, Motor 1 25327D000

6 Capacitor (1Ph only) 1 See Chart

7 Clip, capacitor (1 Ph only) 1 See Chart

8 Plug, 1/4” pipe 1 05022A009

9 Oil, Transformer 1.12 ga l 11009A006

9A Connectors (3 Ph only) 3-6 15781A001

10 Screw, st, #10 x 3/8 2 09822A032

11 Washer, bearing 1 19331A005

12 Bearing, ball, upper 1 08565A013

13 & 14 Stator, Rotor shaft with shell 1 See Chart

15 Wire, electrode 2 21792A004

16 Screw, #6 x 1/4 2 05434A025

17 Seal Probe 2 25343A000

Unit manufactured prior to Aug-2007 contact factory for repair parts.

Item Number 2 6 7 13 & 14 25

HP Volts PH

208

230

208

1/2

460

575 25484D203

208

230

208

3/4

460

575 25484D203

208

230

208

1

460

575 25484D207

208

230

1-1/2

208

460

575 25484D207

208

230

208

2

460

575 25484D212

Power Cord

W/Plug

1 25338B005 25338B006 23839A000 20333A006 25484D201

3 25338B003

1 25338B001 25338B002 23839A000 20333A006 25484D201

3 25338B003

1 25338B001 25338B002 23838A000 20333A004 25484D205

3 25338B003

1 25338B001 25338B002 23838A000 20333A004 25484D205

3 25338B003

1 25338B001 25338B002 26520A002 25484D209

3 25338B003

Power Cord

No Plug

Capacitor

Capacitor

Clip

Ref. Description Qt y. Part Number

18 Bearing, ball, lower 1 08565A022

19 Seal, shaf t 1 25370A000

20

21 Gasket, tetraseal, 7x6-3/4x1/8 2 05014A181

22 Housing seal 1 25369D000

23 Plate, bottom 1 25368D000

24 Screw, cap 5/16 x 1-1/4 12 19100A012

25 Impeller 1 See Chart

26

27

28 Washer, Impeller Retainer 1 05030A242

29 Screw, Machine #10 x 3/8 1 06106A042

30 Sealant 1 14550A001

Stator

Rotor &

Shaft Ass’y

25484D202230

25484D202230

25484D206230

25484D206230

25484D211230

Ring, retaining 2 12558A021

Ring, retaining 1 12558A033

Case, volute (ME50) 1 25357D000

Case, volute (ME75-150) 1 25331D000

Case, volute (MWH50-200) 1 26057D000

Cup, U, HUVA (ME50-150) 1 22835A005

Cup, U, HUVA (MWH50-200) 1 22835A009

ME

Impeller

Plastic

25333B025 25348B121 26029B013 26029B113

25348B020 25348B120

25348B010 25348B110 26029B012 26029B112

25348B000 25348B100 26029B011 26029B111

ME

Impeller

Optional

Naval

Bronze

MWH

MW

Impeller DI

26029B000 26029B100

Impeller

Optional

Naval

Bronze

23822A278 (02-13-20)

17

Loading...

Loading...