MYERS E54-30, E70-23V, E54-30L, E70-23VL, E80-20V Safety Instructions

...

CALL 1-800-577-8111 FOR SALES AND SUPPORT

E Series

Reciprocating Pump (Shaft Drive)

Safety Instructions and Service Manual

E54-30 Part No. 26866F000

E54-30L Part No. 26866F010

E70-23V Part No. 26866F100

E70-23VL Part No. 26866F110

E80-20V Part No. 26866F300

E80-20VL Part No. 26866F310

E110-14 Part No. 26866F200

E110-14L Part No. 26866F210

1

26850A003

CALL 1-800-577-8111 FOR SALES AND SUPPORT

Table of Contents

SPECIFICATIONS ............................................................................................................................... 3

DIMENSIONS ...................................................................................................................................... 4

BELT DRIVE (Dimensions) .................................................................................................................. 4

STARTING THE PUMP ........................................................................................................................ 4

SUGGESTED MAINTENANCE SCHEDULE ..................................................................................... 5

LUBRICATION ..................................................................................................................................... 5

ADDITIVES FOR CRANKCASE OIL .................................................................................................. 5

SERVICING THE PUMP:

REMOVING PISTON ...................................................................................................................... 5

INSTALLING THE PACKING ............................................................................................................ 6

REMOVING THE CYLINDERS ...................................................................................................... 6

CYLINDER INSTALLATION .......................................................................................................... 6

REMOVING THE SEATS: Wing Guided Valves ............................................................................. 6

REPLACEMENT OF VALVES ........................................................................................................ 7

REPLACING PISTON ROD SEALS .............................................................................................. 7

REMOVING CRANKSHAFT AND PINION SHAFT ...................................................................... 7

REPLACING PINION SHAFT & SHIMMING BEARINGS ............................................................ 8

REPLACING CRANKSHAFT & SHIMMING BEARINGS ............................................................. 8

RECONDITIONED CRANKSHAFTS ............................................................................................ 9

SERVICING CONNECTING LINKS .............................................................................................. 9

CROSSHEAD AND PISTON RODS ............................................................................................. 9

RECOMMENDED TORQUE (Foot-pounds) .................................................................................. 9

VALVE LIFTERS ........................................................................................................................... 10

SERVICE CHART & TROUBLE-SHOOTING ............................................................................. 11

CROSS-SECTIONAL VIEWS OF PUMPS:

SIDE VIEW – PRE JUNE 1, 2008 E70-23, E80-20 ..................................................................... 14

SIDE VIEW – POST JUNE 1, 2008 E70-23V, E80-20V ............................................................. 15

POWER-END ............................................................................................................................... 16

PARTS LIST ................................................................................................................................. 17

2

26850A003

GPM

1800 PSI

2100 PSI

2400 PSI

2700 PSI

3000 PSI

LPM

124 BAR

145 BAR

165 BAR

186 BAR

207 BAR

30 37 43 49 55 62

113 28 32 36 41 46

36 44 52 59 66 74

136 33 39 44 49 55

42 51 60 59 79 86

158 38 45 51 59 64

48 59 69 79 89 98

181 44 51 59 66 73

54 66 79 89 100 111

204 49 59 66 75 83

E-54-30

1417

1620

1823

Horsepower

/Kilowatts Required For:

RPM

1012

1215

GPM

1900 PSI 2000 PSI 2100 PSI 2200 PSI 2300 PSI

LPM

131 BAR 138 BAR 145 BAR 152 BAR 159 BAR

30 39 41 43 45 47

113 29 31 32 34 35

40 52 55 57 60 63

151 39 41 42 45 47

50 65 69 72 75 80

189 48 51 54 56 60

60 78 82 86 90 95

227 58 61 64 67 71

70 91 96 100 105 110

265 68 72 75 78 82

Horsepower

/Kilowatts Required For:

RPM

914

1143

E70-23V

1371

1600

1828

GPM

1200 PSI 1400 PSI 1600 PSI 1800 PSI 2000 PSI

LPM

83 BAR 97 BAR 110 BAR 124 BAR 138 BAR

40 33 38 44 49 55

151 24 29 33 37 41

50 41 48 55 62 69

18931364146

51

60 49 58 66 74 82

227 37 43 49 55 61

70 58 67 77 86 96

265 43 50 57 64 72

80 66 77 88 99 110

303 49 57 65 74 82

Horsepower

/Kilowatts Required For:

RPM

914

1143

E80-20V

1371

1600

1828

GPM

800 PSI

1000 PSI

1200 PSI

1400 PSI

LPM

55 BAR

69 BAR

83 BAR

97 BAR

70 38 48 58 67

265 28 36 43 50

80 44 55 66 77

302 33 41 49 57

90 49 62 74 86

340 37 46 55 64

100 55 69 82 96

378 41 51 61 72

110 60 75 90 106

416 45 56 67 79

Horsepower

/Kilowatts Required For:

E110-14

1487

1652

1817

RPM

1157

1322

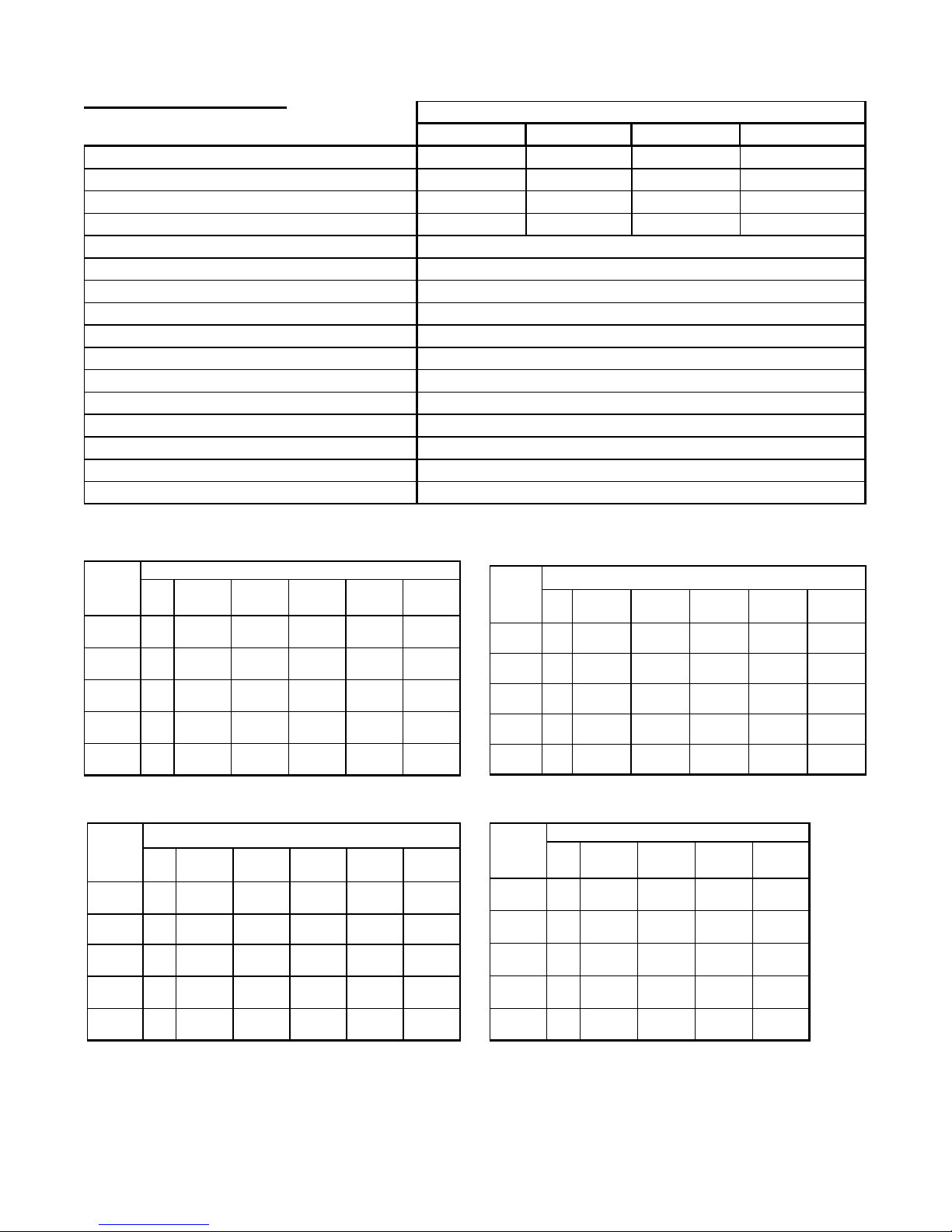

E54-30 E70-23V E80-20V E110-14

RATED MAX CAPACITY (G.P.M.) 54 70 80 110

PINION SHAFT RPM @ MAX. CAPACITY 1823 1807 1828 1817

PRESSURE RATING (PSI) 3000 2300 2000 1400

CYLINDER BORE DIA. (INCHES) 1.750 2.000 2.125 2.500

PISTON STROKE LENGTH (INCHES)

GEAR REDUCTION RATIO

TEMPERATURE RATING, MAX.

SUCTION SIZE (INCHES) NOMINAL

DISCHARGE SIZE (INCHES) NOMINAL

INPUT SHAFT DIAMETER (INCHES)

KEYWAY (INCHES)

WEIGHT (Lbs.)

FLUID-END CASTING MAT'L

VALVE MAT'L

VALVE SPRING MAT'L

CYLINDER MAT'L STAINLESS STEEL/CERAMIC OXIDE COATING

525

DUCTILE IRON

17-4 PH with POLYURETHANE INSERT

STAINLESS STEEL

3" NPT

1 1/4 NPT

1.6250/1.6245

3/8 X 3/16

TRIPLEX PUMP MODELS

3.75

3.95 to 1

160F

CALL 1-800-577-8111 FOR SALES AND SUPPORT

SPECIFICA

TIONS

NOTE: Flow (GPM/LPM) based on 100% volumetric efficiency. Horsepower and kilowatts required are based on 85% overall efficiency.

Horsepower requirements are at Myers pump input shaft. The efficiency of the hydraulic pump, hydraulic motor, etc. must be considered to

determine horsepower required to drive complete system.

3

26850A003

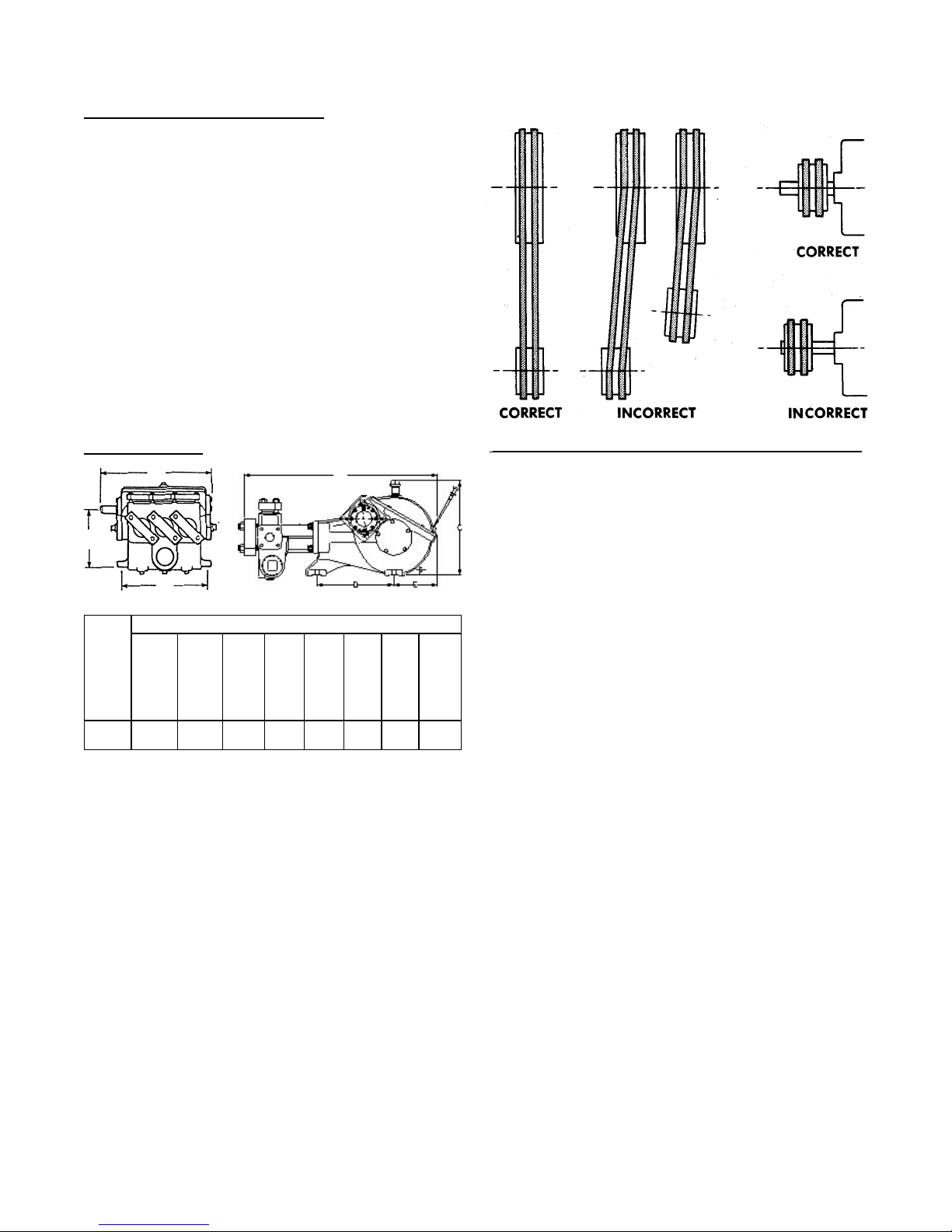

A B C D E F G

Diameter of

Mounting Hole

21 36.25 17 14 7.5 16 10.38 0.75

533.4 920.75 431.8 355.6 190.5 406.4 263.7 19.05238

Weight Lbs.

(Kg)

Dimensions in Inches

(Millimeters)

525

CALL 1-800-577-8111 FOR SALES AND SUPPORT

GENERAL INSTRUCTIONS

CAUTION: Positive Displacement Pumps must

have a proper size and operable type of pressure

regulating valve or pressure relief valve piped into

the discharge line. This is mandatory to prevent

damage to pump and piping or possible injury to

personnel. DO NOT install any valves or shut-off

devices in the bypass line from pressure regulator

to tank or supply.

DIMENSIONS

A

G

F

B

BELT DRIVE SEWER CLEANERS

With belt drives, pulley on both engine and pump should

be located as closely as possible to bearing to reduce

bearing and shaft bending loads. Make sure that all

bolts, nuts, set screws, and keys are properly tightened.

PULLEY

TION ON PUMP

LOCA

AND MOT

OR SHAFT

STARTING PUMP

A. Before Starting:

1. Read all instructions carefully.

2. Fill pump crankcase with recommended oil to

level mark on oil saber. Oil recommendations are

covered in lubrication section of pump instructions.

3. Replace all drain plugs in pump and piping.

4. Inspect tank to be sure that no foreign material is

in tank or suction line.

5. Fill tank at least half full or connect suction to

water supply. Open valve (if present) in suction

line. Avoid prolonged dry operation which may

cause excessive wear on cylinders and piston

packing. Be sure that an operating pressure

gauge is located in discharge line.

6. Make sure all valves, including spray gun or

nozzles, are open in discharge line. Spray gun

may be anchored to discharge back into tank.

7. Completely back off pressure adjusting screw on

pressure regulating valve.

B. Starting the Unit:

1. After starting, close discharge valve or spray gun

slowly while watching pressure gauge to make

sure relief valve or unloader is operating properly.

2. Adjust relief valve or unloader to desired pressure. See regulator instructions.

3. Cycle nozzles or gun on and off to be sure that

pressure adjustment and regulator operation is

satisfactory.

NOTE: Nozzle capacity should not exceed 90% of

pump capacity for satisfactory regulator operation.

AVOID FREEZING by draining all water from pump and

system in cold weather.

4

26850A003

CALL 1-800-577-8111 FOR SALES AND SUPPORT

SUGGESTED MAINTENANCE SCHEDULE

OPERATION INTERVAL

Check oil level Daily

Drain and change oil 300 hr. (1)

Replace piston packing 500 hr. (2)

Inspect valves and springs 500 hr. (3)

Inpsect connecting link bearing inserts 1000 hr. (4)

Inspect crankshaft tapered roller bearings 2000 hr.

(1) Drain at operating temperature to prevent contamina-

tion from setting.

(2) Inspect frequently for leakage; replace before 500

hours if any cylinder exceeds 10 drops per minute

leakage. Packing may not look badly worn but will

often be shiny and hard and won’t seal well.

(3) Replace if cracks and heavy wear are present.

(4) Replace at first signs of fatigue or wear to prevent

damage to crankshaft.

LUBRICATION

Fill gear case with Mobilgear 630 or equivalent 80W90

oil to capacity listed in chart. Note oil level on oil

dipstick, and maintain at this level.

NOTE: Slow speed operation of Myers Reciprocating

Pumps can be accomplished by adding additional oil to

the crankcase (see chart). The higher level compensates for lack of splash lubrication at slow speeds.

Some slight leakage may occur around crossheads and

dipstick/vent area with additional oil.

For further information, please consult the factory.

Volume of liquid MoS2 concentrate required at various speeds

VOLUME MoS2, CONCENTRATE

PINION RPM GEAR CASE OR DISPERSION “M” FOR

RANGE CAPACITY 5% 10%

1600 - 1800 6½ Qts. 7 Fl. Oz. 14 Fl. Oz.

1000 - 1599 6½ Qts. 9 Fl. Oz. 18 Fl. Oz.

600 - 999 6½ Qts. 10 Fl. Oz. 20 Fl. Oz.

The MoS2 fluid concentrate is marketed by Dow Corning,

Phone (517)-496-6000 or www.molykote.com/iam under the

designation “Molykote M Gear Guard.” Several other

brands are available. Follow instructions of manufacturer.

SERVICE

CAUTION: Disengage clutch, disconnect electrical

leads to motor, or remove spark plug leads on engine.

Following work on any internal pump parts, it is important

to tighten all clamps, caps and assemblies to specific

torque ratings, refer to Recommended Torque chart.

CAUTION: Also inspect cylinders for linear grooving by

running your thumbnail circumferentially around bore of

cylinder. If any grooving is detected also replace cylinders.

New packing will rapidly cut or wear out in grooved cylinders.

SERVICE

CAUTION: Disengage clutch, disconnect electrical leads to

motor, or remove spark plug leads on engine. Following

work on any internal pump parts” it is important to tighten all

clamps, caps and assemblies to

specific torque ratings, ‘refer to Recommended Torque

chart.

: After first 30 hours of operation drain oil

IMPORT

ANT

from gear case (preferably drain at operating temperature), replace plug and refill crankcase with new oil as

above. Change oil every 300 hours thereafter. Check

oil level daily and add oil as needed.

ADDITIVES FOR CRANKCASE OIL

Use of Molybdenum Disulfide (MoS2) is optional as an

additive to the petroleum-based gear case oil in back

geared pumps and speed reducers manufactured by

Myers. Do not use this additive with synthetic oil. It

appears to be so effective in reducing wear and friction

that power train life may be doubled between overhauls.

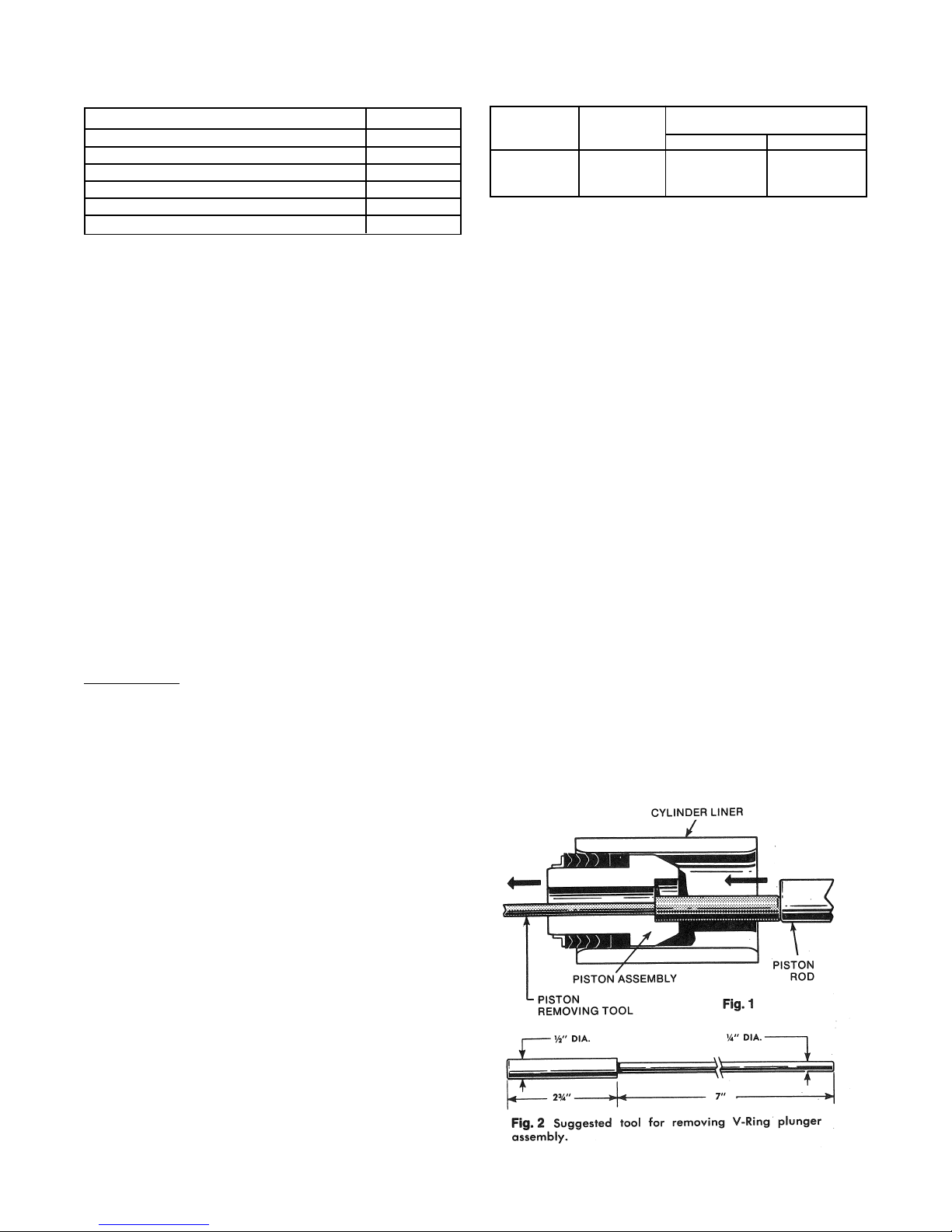

REMOVING PACKiNG

Move assembly to front end of cylinder (top dead center).

Remove valve assembly if required to provide clearance.

Remove cap screw with an Allen wrench. (Allen wrench,

Part No. 8574A11). Retract piston rod and insert tool as

shown. Pull packing assembly out or push by rotating

crankshaft by hand.

5

26850A003

CALL 1-800-577-8111 FOR SALES AND SUPPORT

CAUTION: Also inspect cylinders for linear grooving by

running your thumbnail circumferentially around bore of

cylinder. If any grooving is detected also replace

cylinders. New packing will rapidly cut or wear out in

grooved cylinders.

INSTALLING PACKING

Assemble V-Rings onto stud as shown. Lubricate the

outside of the assembly with Molykote or other grease

for ease in insertion – do not use a graphite type grease.

When installing each V-Ring assembly, rotate crankshaft

until piston rod is at forward position. Place copper

gasket 5030A128 in position in stud using a small

amount of Permatex to hold in place. NOTE: Apply

Loctite RC35 to capscrew prior to piston installation.

Follow instructions on label and make certain threads in

piston rod are clean and free of any grease or oil.

Assemble capscrew, etc., into piston assembly and

push into cylinder. Torque the capscrew to 50 ft. lb. using

a hexagonlal socket attachment 3/8" across flats.

REMOVING CYLINDERS, (Fig. 5)

1. First remove packing as outlined previously.

2. Rotate crankshaft until piston rod is in rear position.

3. Insert puller (3) through inside of cylinder and pilot over

piston rod.

4. Insert disc (4) into slots on puller (3).

5. Slip plate (2) over threads on puller (3) as shown.

6. Screw nut (1) on thread on puller (3) and snug up.

7. Tighten nut (1) until liner breaks loose.

8. Loosen nut (1) and slip disc (4) out of slots.

9. Remove puller (3) and repeat to remove other

cylinders.

Reasonable care and judgment should be used when

installing the new cylinder. Clean out any accumulation

of loose rust or corrosion in cylinder body. Install a new

O-ring in groove on tapered portion of cylinder, lubricate

O-ring with oil or grease for ease in insertion. Position

cylinder carefully by hand to avoid cutting the O-ring.

Drive into position firmly with a wooden block and mallet.

Never use a hydraulic press; excessive force can cause

damage and make cylinders very difficult to remove for

later replacement.

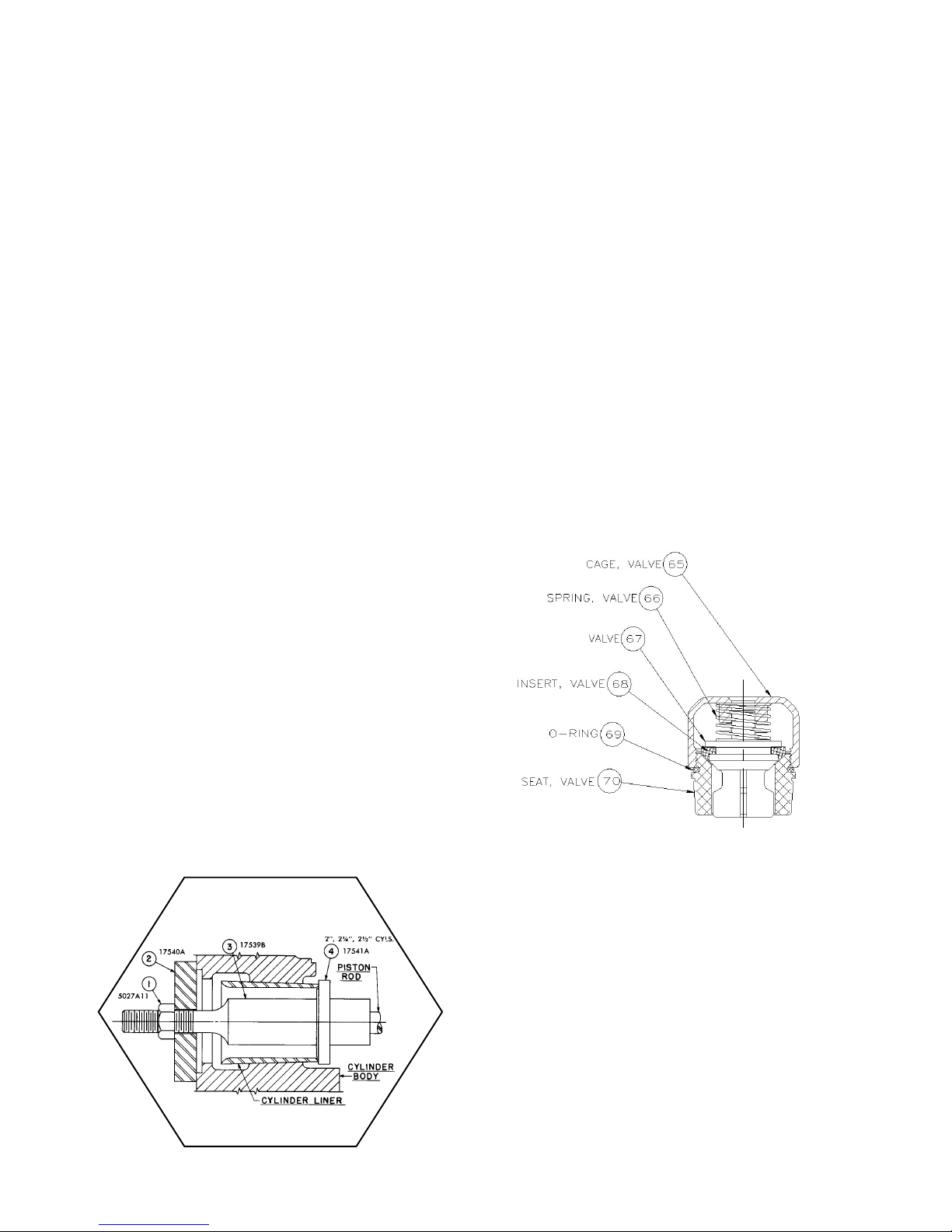

REMOVING SEATS: Wing Guided Valves

A. First remove valve caps, (61) and cylinder

caps, (72) which provide access to suction and

discharge valves. Remove the stainless steel cage

which serves as a valve guide and spring retainer.

Remove cage (65), spring (66), and valve (67), from

the pump fluid end. (Fig. 6)

. Suction valve seats are removed as above except

two stud lengths are joined using coupling

CYLINDER INSTALLATION

1¾”,

Fig. 5

Fig. 6

SUCTION & DISCHARGE VALVE ASSEMBLY

Part No. (TS18-AR0-AC0714)

6

26850A003

Loading...

Loading...