MAXDTC-BTFamilyUserManual

Description

The MAXDTC-BT is a fully programmable industrial temperature controller. The

controller is configurable and monitorable thru a Bluetooth connection from your Android

bluetooth enabled smartphone or tablet. The MAXDTC6-BT can run 6 independent

programmable temperature control rules. The MAXDTC2-BT can run 2 programmable

temperature control rules. All controllers have FLASH memory for saving and restoring

configuration after power loss.

The controllers have either 2 or 6 external temperature sensor inputs (-40F - 300F / -40C

- 150C) and 2 or 6 dry relay contact outputs (120/240VAC @ 3A, 0-30VDC @ 3A) for switching

MAXDTC-BT User Manual - Rev A www.mydtcstore.com 1

both AC and DC loads depending on model. The controllers are din rail mounted and powered

by 12VDC. They have gray ABS enclosures and screw terminal for all connections.

Applications

● Differential Heating and Cooling (Solar hot water heating, root cellar cooling, attic

cooling)

● Industrial Heat and Cool Thermostat/Alarming (-40F - 300F / -40C - 150C setpoints)

● Outdoor Reset Control for Wood Boilers, with programmable one shot restart timer

● Multi Input/Output Industrial Temperature Alarming

● Remote control of all outputs from smart phone with one shot timer capability.

● Greenhouse / hydroponics temperature control and alarming

Device Capabilities

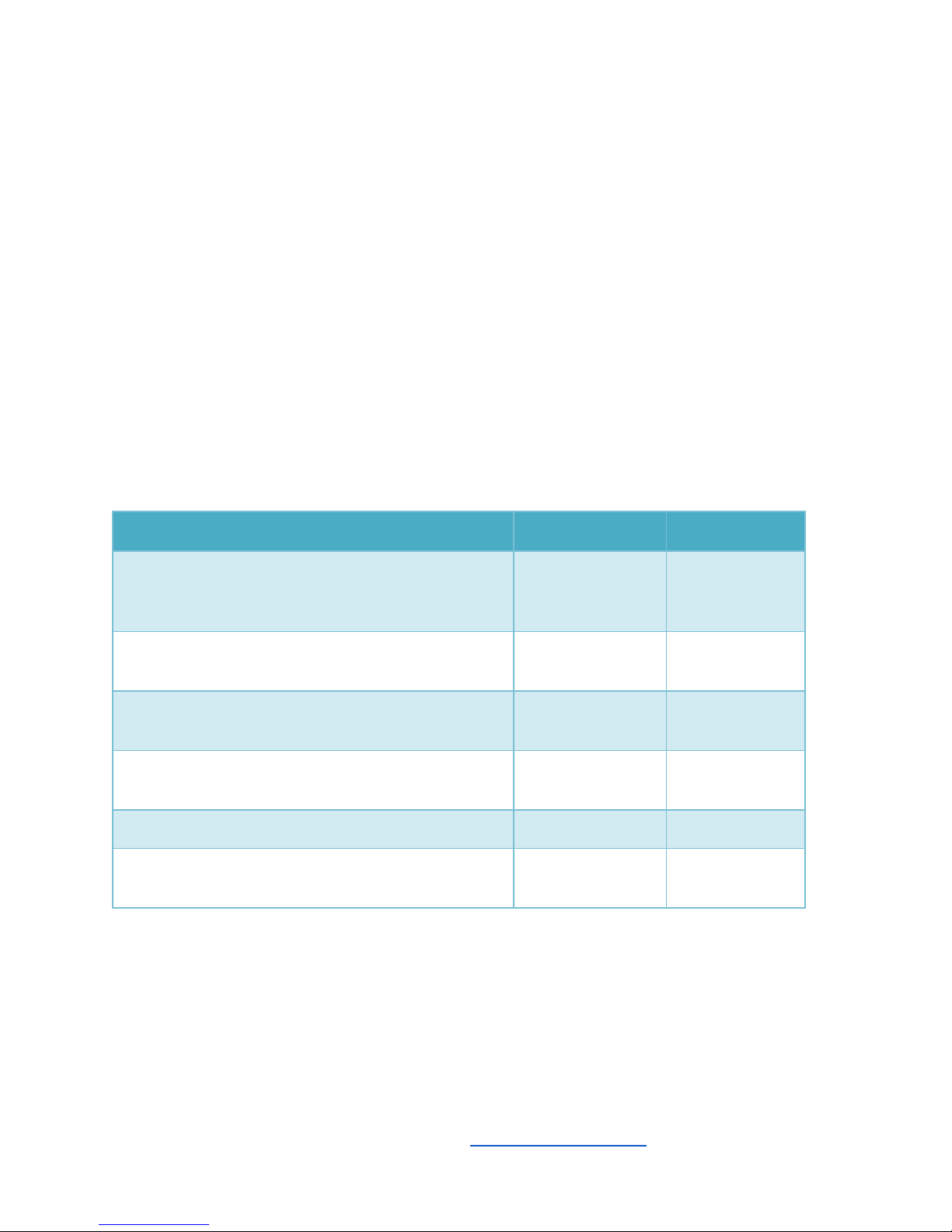

Number of Control Rules Supported

MAXDTC2-BT

MAXDTC6-BT

Differential Temperature Control

(Solar Heating or Root Cellar / Attic Cooling)

(2 Inputs / 1 Output)

1

3

Thermostat (Heat or Cool) (-40 - 300F range)

(1 Input / 1 Output)

2

6

Outdoor Reset Control (wood stove boiler)

(2 Inputs / 1 Output)

1

3

Periodic Timer

(0 Inputs / 1 Output)

2

6

Manual On/Off

2

6

Time Controlled One-Shot

Boiler Reset / Remote Control Timed Run

2

6

MAXDTC-BT User Manual - Rev A www.mydtcstore.com 2

Controller Specifications

Specifications

Relay Outputs: 0-240VAC/ 0-30VDC, 3 amps

Temperature Inputs: -40F - 300F Range, NTC 10K thermistor 1%

Power Input Voltage: 12vdc nominal (10.8V - 14V)

Power Input Current: 40mA + 16.7ma per active relay

Mounting: DIN RAIL

Indicator: Green LED

Communication: Bluetooth 2.0, Range: ~50ft line of site (nominal)

Configuration Memory: Non-Volatile, power fail safe

Enclosure / Size:

MAXDTC2-BT:

ABS/PC Blend, Gray, 1.429" L x 3.551" W (36.30mm x 90.20mm) X 2.264" (57.51mm)

MAXDTC6-BT:

ABS/PC Blend, Gray, 2.795" L x 3.551" W (70.99mm x 90.20mm) X 2.264" (57.51mm)

MAXDTC-BT User Manual - Rev A www.mydtcstore.com 3

Installing a Bluetooth Terminal Program

In order to communication with the MAXDTC-BT controllers, you will need to load a Bluetooth

Terminal program on your android smartphone or tablet. The program is free and can be

downloaded for the Google Play Store.

The program that works best is Bluetooth Terminal HC-05 from mightyIT.

You can search for it and download it from the Google Play Store. Here is a link for it as well:

https://play.google.com/store/apps/details?id=project.

bluetoothterminal&hl=en

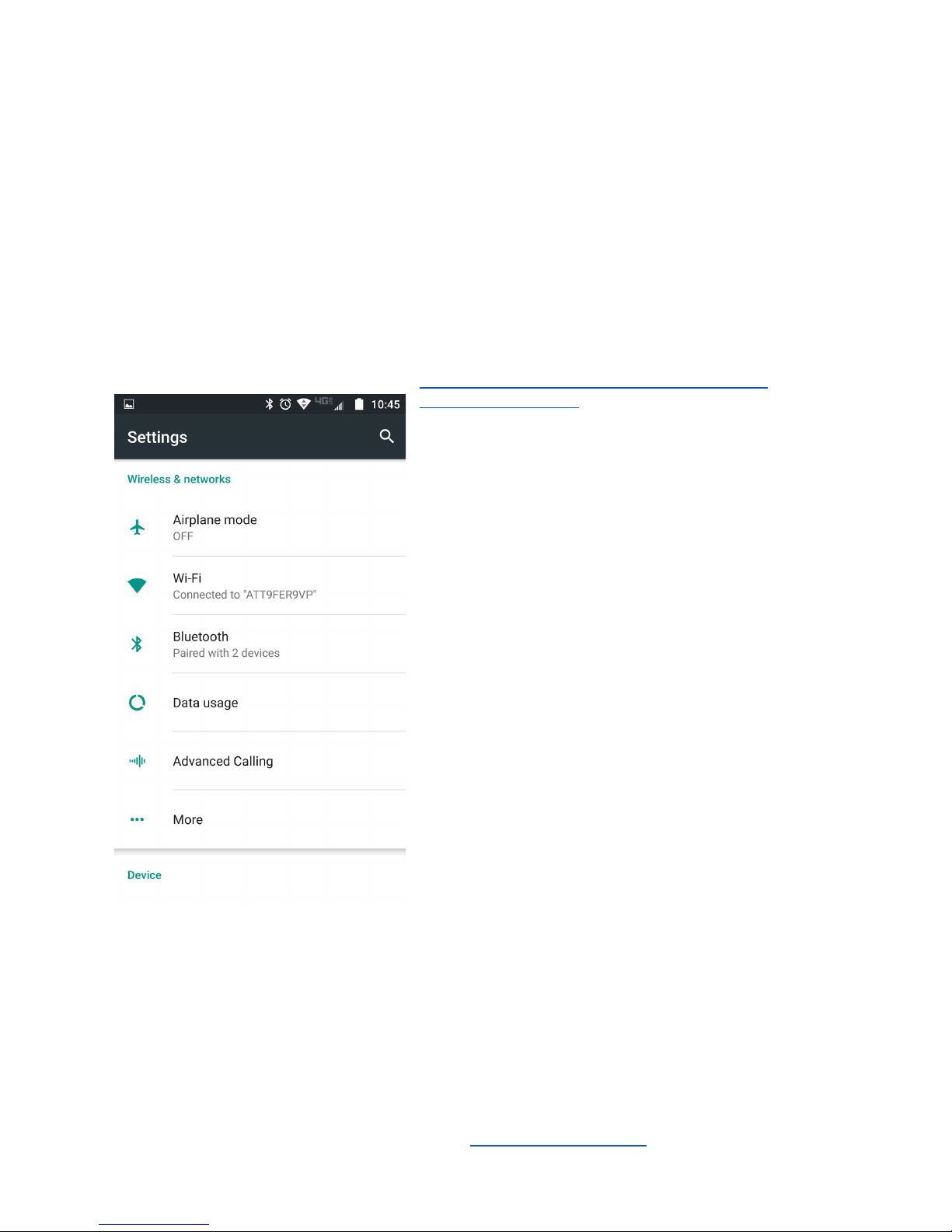

First Connect to Bluetooth

with Android

Before you can connect to the controller via the

Bluetooth Terminal HC-06 program, you need to

connect to the controller via the Bluetooth settings on

your phone. You can navigate to the Bluetooth

settings screen by going to Settings then selecting

Bluetooth. Once here, have the phone or tablet

check for available devices. You will want to have

the controller powered up for a minute before doing

this. When you scan for available devices, you should

be able to find the controllers onboard bluetooth device

which shows up as HC-06 or BT04-A. Once you see

this, go ahead and select it to connect to the device.

Once your phone has found and connected to the

controller in this way, you are ready to connect to the

controller with the Bluetooth Terminal HC-05

application.

MAXDTC-BT User Manual - Rev A www.mydtcstore.com 4

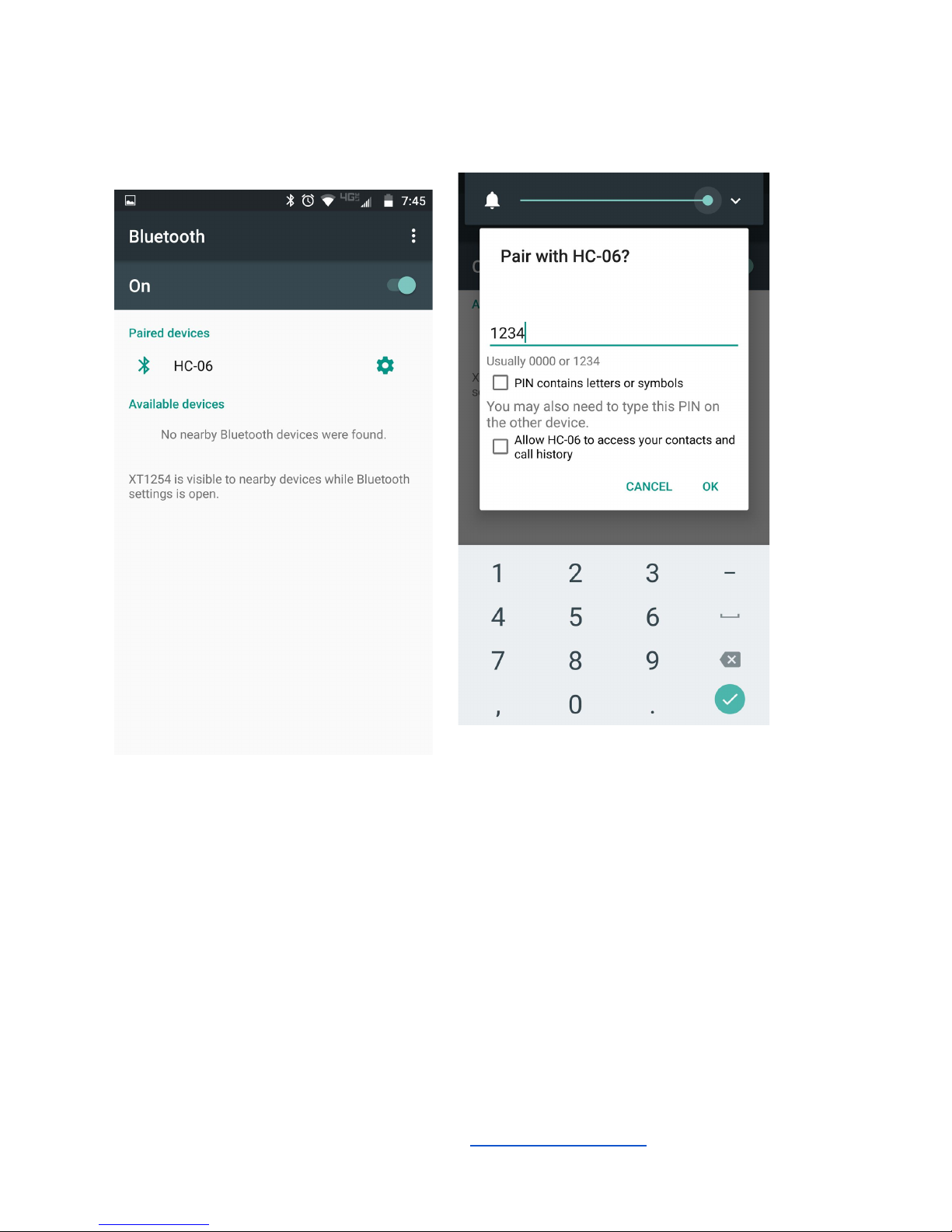

In the bluetooth settings go ahead and pair with the discovered HC-06 device. You will need to

enter a password to do this. The password for the HC-06 and BT04A bluetooth is 1234.

After pairing with the controllers bluetooth, you are ready to connect to it with the terminal

application program.

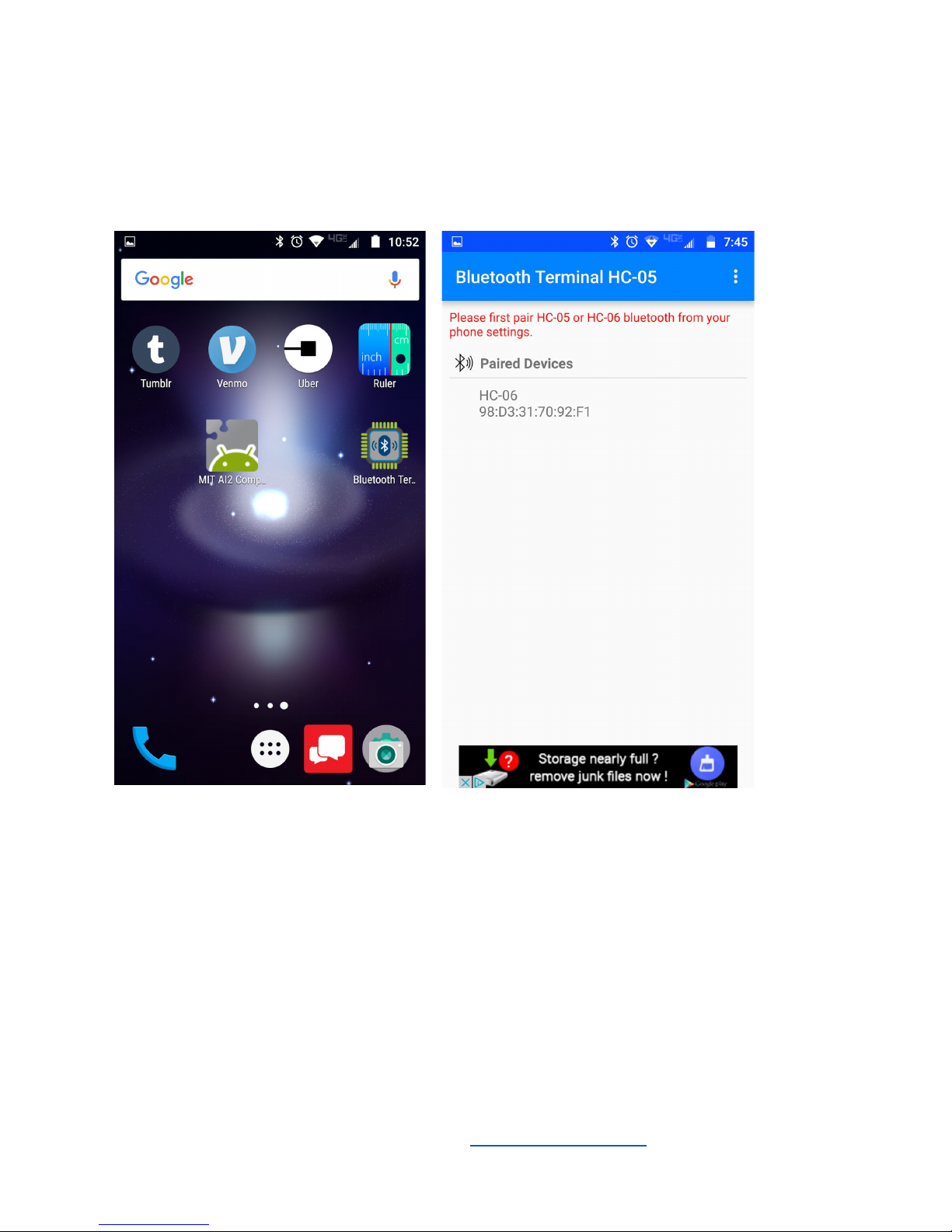

Assuming you have loaded the serial terminal program, go ahead and run the Bluetooth

Terminal HC-05 application..

MAXDTC-BT User Manual - Rev A www.mydtcstore.com 5

Here is the Bluetooth terminal application on one of the startup screens on the phone. When

you run it you should see a connection choice for HC-06 or BT04-A like below if your have

connected with the phone’s bluetooth settings previously.

After running the app it will show you a list of paired devices. Select the HC-06/BT04-A device.

Once selected, the smartphone will attempt to connect to the controller. It should flash a

connecting / connected message and take you to the terminal screen like shown below.

Go ahead and tap the enter command tab and hit an ‘s’ and then the Send button. The

controller should respond with a Status display and the main menu. At this point you can

monitor and configure your controller thru the application.

MAXDTC-BT User Manual - Rev A www.mydtcstore.com 6

Configuring the Controller

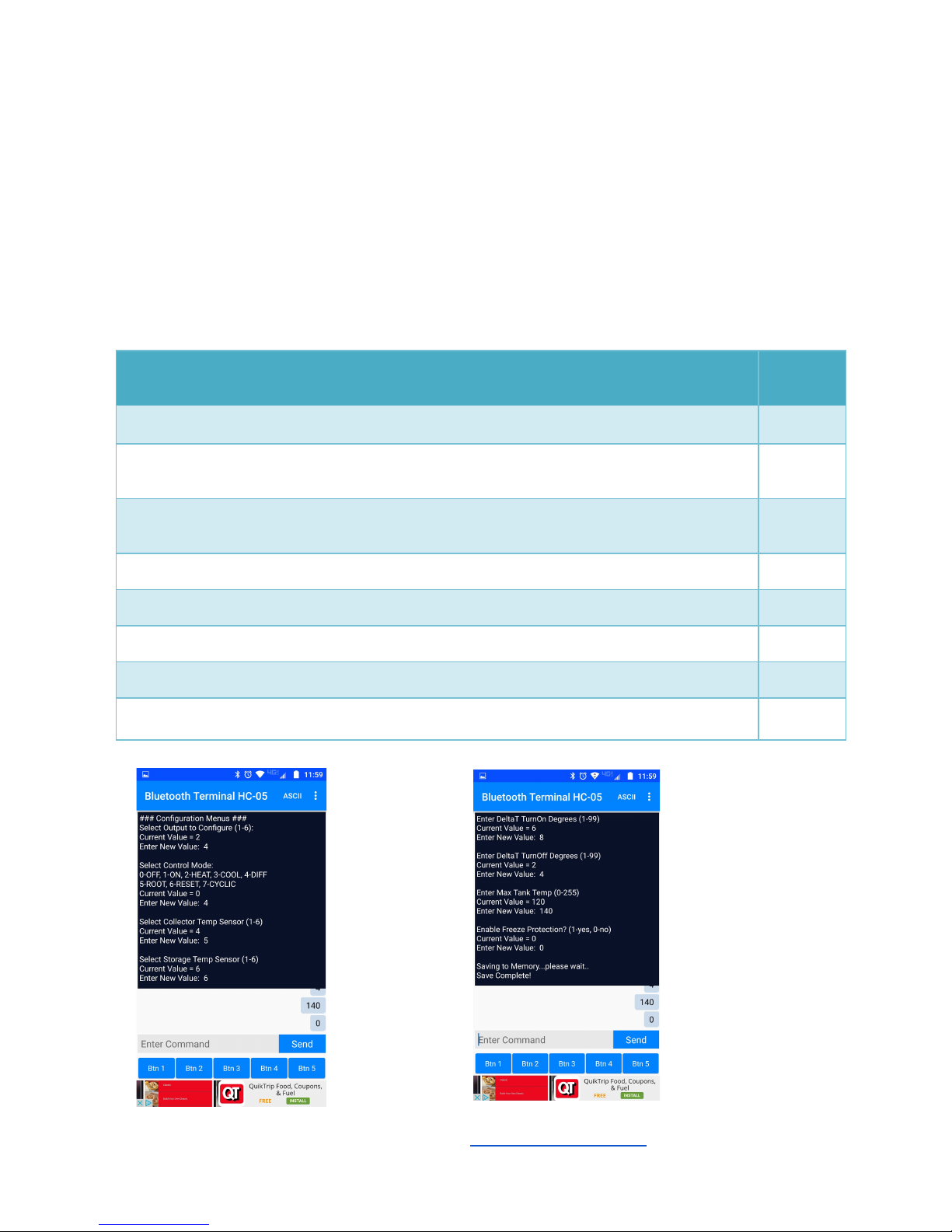

Differential Heating and Root Cellar Modes (DIFF / ROOT)

These modes are used for solar hot water and air heating and root cellar or attic cooling. DIFF

mode is used for heating. ROOT mode is used for differential cooling applications like root

cellars..

Configure Differential or Root Cellar Menu Descriptions

Value

Range

Select Output to Configure (1-6):

1-6

Select Control Mode: 0-OFF, 1-ON, 2-HEAT, 3-COOL, 4-DIFF

5-ROOT, 6-RESET, 7-CYCLIC

4-5

Select Collector Temp Sensor (1-6):

(ROOT Mode) Select Outside Temp Sensor (1-6):

1-6

Select Storage Temp Sensor (1-6) or (Root Mode) Select Cellar Temp Sensor (1-6):

1-6

Enter DeltaT TurnOn Degrees (1-99):

1-99

Enter DeltaT TurnOff Degrees (1-99):

1-99

Enter Max Tank Temp (0-255) or (Root Mode) Enter Min Cellar Temp (0-255):

0-255

Enter Freeze Protection? (1-yes, 0-no) or (ROOT Mode: None)

0-1

MAXDTC-BT User Manual - Rev A www.mydtcstore.com 7

Outdoor Reset Mode (RESET)

Outdoor reset mode is used to automatically adjust the setpoint for a wood boiler based on

outdoor temperature. The controller will automatically adjust the setpoint higher when the

outside temperature gets very cold as well as reduce the setpoint when the outdoor temperature

warms up. This reduces wood consumption and enhances comfort.

Reset_setpoint = 70 + ( ( 70 - Outside Temp ) * SLOPE / 10) - Fahrenheit

Reset_setpoint = 21 + ( ( 21 - Outside Temp ) * SLOPE / 10) - Celsius

Here is a link to a spreadsheet for comparing calculated setpoints vs outside temperature and

the slope setting:

https://docs.google.com/spreadsheets/d/1uj_T8KyJOKdhtVgsXukm8cQ8C06riTzFjORUtoDk3Fk

/edit?usp=sharing

Configure Outdoor Reset Menu Descriptions

Value

Range

Select Output to Configure (1-6):

1-6

Select Control Mode: 0-OFF, 1-ON, 2-HEAT, 3-COOL, 4-DIFF

5-ROOT, 6-RESET, 7-CYCLIC

7

Select Outside Ambient Temp Sensor (1-6):

1-6

Select Boiler Temp Sensor (1-6):

1-6

Enter Slope Value (x10) (1-99):

1-99

Enter Reset Hysteresis (1-99):

1-99

Enter Maximum Boiler Temp (0-255):

0-255

Enter Minimum Boiler Temp (0-255):

0-255

MAXDTC-BT User Manual - Rev A www.mydtcstore.com 8

Thermostat Heat and Cool Modes (HEAT / COOL)

Configure COOL / HEAT Thermostat Menu Descriptions

Value Range

Select Output to Configure (1-6):

1-6

Select Control Mode: 0-OFF, 1-ON, 2-HEAT, 3-COOL, 4-DIFF

5-ROOT, 6-RESET, 7-CYCLIC

2 or 3

Select Thermostat Temp Sensor (1-6):

1-6

Select Setpoint Temperature (-40-300F):

-40 - 300

Enter Hysteresis / Dwell Degrees (1-99):

1-99

Use HEAT or COOL mode to provide thermostat

heating or cooling or provide temperature alarming

for motors or refrigeration.

Setpoints from -40F to 300F (or celsius equivalent)

are supported by the controller.

Programmable Hysteresis and Dwell temperature

from (0 - 99F) (or celsius equivalent) is also

provided to adjust the run time and depth of

temperature cycling required.

The inputs sensor selection for these modes will

allow multiple thermostats to be controlled by the

same temperature input if desired for controlling

multiple output devices from one sensor.

The controller will print Saving to Memory when

the settings are committed to memory.

MAXDTC-BT User Manual - Rev A www.mydtcstore.com 9

Cyclic Timer Mode (CYCLIC)

Configure Cyclic Timer Menu Descriptions

Value

Range

Select Output to Configure (1-6):

1-6

Select Control Mode: 0-OFF, 1-ON, 2-HEAT, 3-COOL,

4-DIFF

5-ROOT, 6-RESET, 7-CYCLIC

7

Enter Cyclic On Time (1-32000):

1-32000

Enter Cyclic Off Time (1-32000):

1-32000

Cyclic Timer is used for things like hot water

recirculation pumps, misting systems, buffer tanks.

Configure the On time in seconds followed by the off

time in seconds. The controller will turn the output

on for the on time setting, then off for the off time

setting then repeat.

The controller will print Saving to Memory when

the settings are committed to memory.

MAXDTC-BT User Manual - Rev A www.mydtcstore.com 10

Changing the Controller Preferences

Preferences Menu Descriptions

Value Range

Enter Temperature Units (0-Fahrenheit, 1-Celsius):

0-1

Enter One Shot Time Seconds (1-32000)

1-32000

In preferences you can change the temperature

units that the controller uses to display the

temperature sensors. It will not automatically

change the parameters you have entered when

changing units. You will have to change those

setting manually.

The settings will not be saved to nonvolatile

memory until you have changed all the settings in

the menu group (Temperature Units, One Shot

Time Seconds).

The controller will print Saving to Memory when

the settings are committed to memory.

This configuration screen is activated by entering a

‘p’ character.

MAXDTC-BT User Manual - Rev A www.mydtcstore.com 11

Status and Monitoring the Controller

Info Screen

The Info screen provides the SW revision of the

controller, Total Runtime in hours and days,

Runtime since last reset, currently selected

temperature units and one shot timer

seconds configured.

This screen is activated by entering a ‘i’

character.

MAXDTC-BT User Manual - Rev A www.mydtcstore.com 12

Rules Screen

The rules screen shows a snapshot of all the relay control rules you have entered and their

parameter values. It is accessed by entering an ‘r’ at anytime.

The rules screen shows the mode, temperature

inputs selected, setpoints and parameters for

each relay control rule configured. For outdoor

reset it also shows the calculated reset setpoint

temperature.

MAXDTC-BT User Manual - Rev A www.mydtcstore.com 13

Status Screen

The status screen shows a snapshot of all the relay control inputs temperatures and output

state for each relay. It is accessed by entering an ‘s’ at anytime. It shows the controlling

variables and any overtemp / under-temp status states. As an example below the R1: Root

Cellar Mode, Outside and Cellar temps (O/C) are shown, the calculated deltaT, and output relay

is OFF.

Across the top it shows current temperature

readings of all inputs. From there is shows the

relay control rules configured mode, controlling

input values, and relay output state at the end.

If an under or over temp state is overriding the

control rule it will show which one. On R6 a reset

control rule is setup and MINT value indicates

that the minimum temperature is being violating

and forcing the output on. The RSP value is the

reset setpoint calculated and being used based

on the ambient temperature and slope you have

selected. This value is bounded by the Min

Temperature and Max temperatures you

configured for the rule.

You will see a trigger one shot status with

amount of time left if you do a one shot trigger on

any of the outputs in this display as well.

MAXDTC-BT User Manual - Rev A www.mydtcstore.com 14

History Screen

The history screen displays the high and low temps read on the inputs since the last history

reset. They are displayed in the units you have selected in the preferences. It is accessed by

entering an ‘h’ at anytime. Hitting a ‘1’ at the prompt resets the high and low readings to current

readings.

Power LED

The green LED should like and blink once a second when the controller is operating properly. If

the LED is not lit, check the power inputs and verify you are providing +12VDC and Ground to

the power inputs located next to the LED. Verify polarity is correct.

When power is first applied, it can take approximately 6 seconds to initialize.

Installation and Wiring Info

Temperature Sensor Inputs and Wiring

The temperature sensors sold with the controller are matched in characteristic to the controller

and will provide the most accurate readings. Using other 10K NTC thermistors is not

recommended. There are water-proof versions of the temp sensor available as well.

Temperature sensors may be extended 50 ft with twisted pair telephone cable or CAT5 cable

without dramatically affected the reading accuracy. Do not include power wiring in the bundle to

other devices as it may put noise on the temperature reading. Always separate measurement

sensor wiring from power / load device power wiring where possible.

The sensor inputs are wired with a common terminal between each two inputs. This common

wire should have one wire from each temp sensor input adjacent to it.

MAXDTC-BT User Manual - Rev A www.mydtcstore.com 15

Temperature Sensors for MAXDTC-BT Controller

There are two types of temperature sensors available for use with the MAXDTC-BT. The

Standard Temp sensor and a waterproof temp sensor are both available from the website.

These sensors are matched to the controller and will provide the most accurate readings.

Each controller comes with two standard temp sensors.

Additional sensors are available for purchase off the wesite: www.mydtcstore.com

MAXDTC-BT User Manual - Rev A www.mydtcstore.com 16

Power Input (12VDC)

The power input to the controller requires 12VDC input, which is on the top right side of the

controllers. It is recommended to use a DIN rail type 12vdc power supply with a well regulated

output for the best performance and reliability of the controller. These are available off the

website, but do not come standard with the controllers.

If you need to run large DC pump, you will need to have a higher current capacity power supply

(3-5 Amp recommended). These supplies have an adjustable output voltage trimmer as well.

MAXDTC-BT User Manual - Rev A www.mydtcstore.com 17

Controller Output Relay Wiring to Load Devices

Wiring load devices to the controller relay outputs is simple. Connect the Hot or Positive power

source wire to one side of a relay output, connect the other side of the relay output to the Hot or

Positive power input of the load device. The controller will switch the power to the load device

by closing the relay.

It’s always a good idea to put a fuse on the output of the controller to the input of the load

device.

MAXDTC-BT User Manual - Rev A www.mydtcstore.com 18

Controller Temperature Sensor Wiring

The temp sensors are wired to T1-T6 sensor inputs (T1-T2 on smaller MAXDTC2-BT version).

Each group of two temperature sensor inputs shares a common ground terminal that both

temperature sensors share in common. See diagram.

The temperature sensors can be extended 50ft with twisted pair telephone wire or equivalent

CAT5 type cable with no appreciable reading error. Avoid running temperature sensor wires

near AC or power connections to load devices which can create noise on the temperature

sensor input.

MAXDTC-BT User Manual - Rev A www.mydtcstore.com 19

External DIN Rail Relay Info

If you need to switch larger power loads than the 5amp onboard relays can handle, consider

purchasing an external DIN rail mountable relay and control it with the onboard controller relay.

Just switch 12VDC power to the external relay coil to support upto 10A load devices.

MAXDTC-BT User Manual - Rev A www.mydtcstore.com 20

Ordering Information and Pre-configuration Options

MAXDTC-BT Controllers can be ordered off the www.mydtcstore.com website. More

information and accessory equipment such as additional temperature sensors, waterproof

sensors, fuses, DIN rail power supplies, terminal blocks, additional DIN rail, and external high

current relays are available for purchase on the website.

If you would like the controller preconfigured to your application before shipment, please contact

us for details.

For OEM inquiries, contact Brian Smith at this email address: smith100griggs@gmail.com .

Have Technical Questions? Send us an email!

Have a question on how the controller works? Send me an email and I will try to answer your

question: Brian Smith - smith100griggss@gmail.com

MAXDTC-BT User Manual - Rev A www.mydtcstore.com 21

Loading...

Loading...