Innovative Solutions

SENTIR KS4 UNIVERSAL EDGE

The KS4 Universal Edge comes with 8.2K, 10K and Normally Open

(non-monitored) termination resistors to enable it to work with a

variety of equipment to meet UL325 standards, plus all legacy

non-monitored applications.

An

The One Edge Solution!

Kit includes: contact edge,

aluminum channel, and all

components to assemble a

complete edge.

Industry

First!

Included Termination Plugs

8.2K 10K

Normally Open

(non-monitored installs)

Available at a CPSG branch near you or buy online.

ASK

The Access

Experts!

National Sales 877-531-6122

Technical Support 877-531-6123

ControlledProducts.com

Available Lengths

4ft

1.2”

5ft

6ft

Stay connected at MyCPSG.com

EVENTS PRODUCTS SUPPORT CAREERS

1”

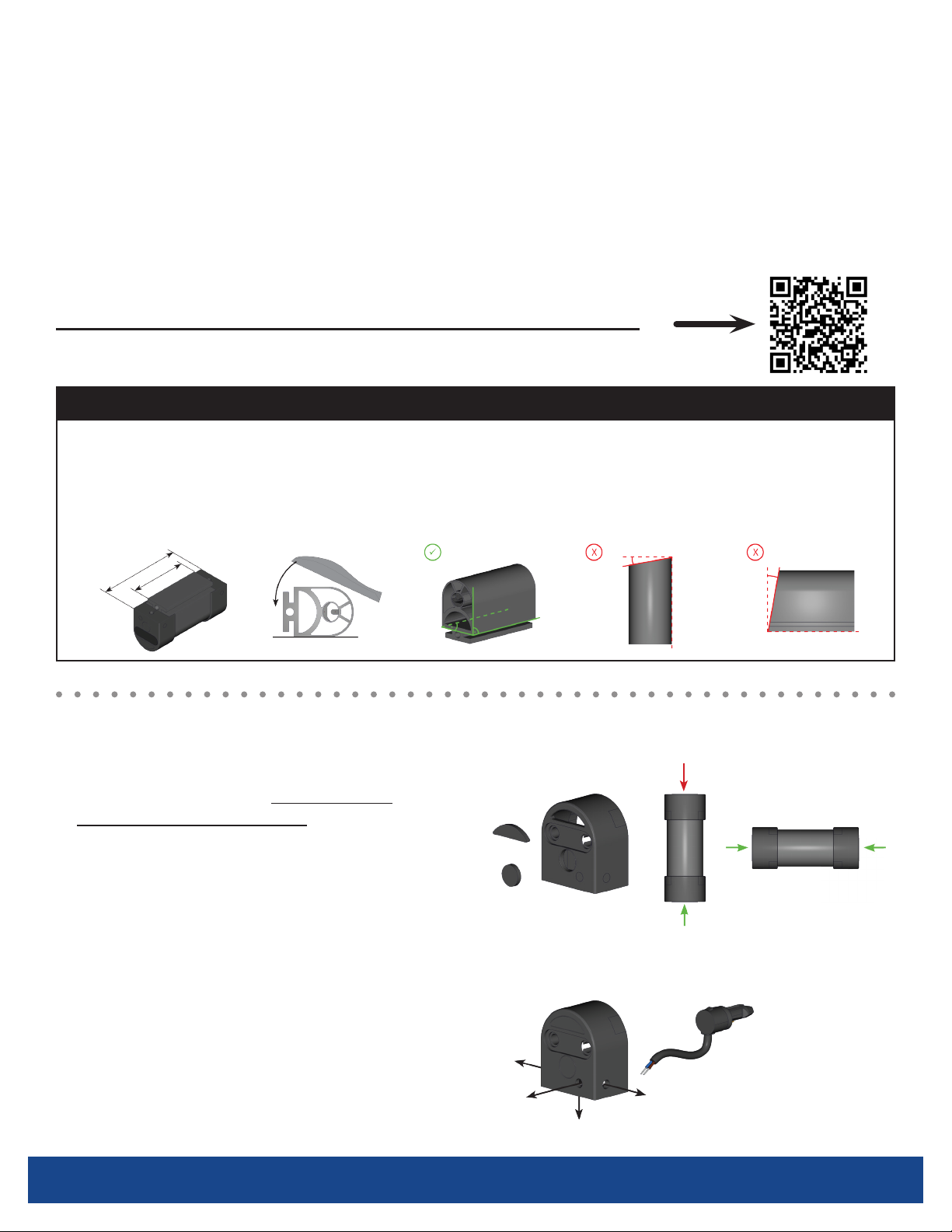

Assembly Instructions

The KS4 Universal Edge comes with 8.2K, 10K and Normally Open (non-monitored) termination

resistors to enable it to work with a variety of equipment to meet UL325 standards, plus all legacy

non-monitored applications.

This edge is easily assembled and comes in pre-cut lengths of 4ft, 5ft and 6ft.

Safety contact edges may only be assembled and installed by authorized personnel!

ASO GmbH excludes all liability for damage caused of an incorrect assembly and installation of the contact edges!

Click to watch the assembly instruction video or scan the QR code.

THIS STEP IS ONLY NECESSARY IF TRIMMING IS REQUIRED

Cutting the safety-contact-edge

The safety-contact-edge is cut 1 inch shorter than the nal length dimension to allow for the length of the end caps

on each end. The aluminum channel should be cut to the nal length dimension. Make sure that the cut surfaces are

rectangular and clean, so the cut should be made starting at the chamber side of the safety edge. The scissors or

table lever blade offered by ASO should be used for this purpose.

(L)ength

L - 1”

1) Preparing end caps

A) Water drain plugs - It is necessary

to remove water drain plugs. For vertical

mounting, remove the two marked areas

in the lower end cap, for horizontal

mounting, remove the two marked areas

in both end caps.

B) Connection cable - Choose desired

cable exit of end cap. If necessary, stitch

through the marks.

DO NOT remove drain plugs from

!

the top of a vertically mounted edge.

MyCPSG.com

2

Assembly Instructions

2) Insert lock cap

Press the clamp straight into the hollow chambers around the

internal switching chamber until it is tightly against the surface

of the prole. Then check whether the outer wall of the switching

chamber abuts the clamp. Slight rotational movements of the clamp

can cause misalignment.

3) Insert the contact plugs

(Wired plug at one end and termination plug at the other.)

Choose the termination plug that ts your application

(8.2K, 10K, or NO). For the required sealing, press

both the termination plug and wired plug straight

and rmly into the switching chambers on each end.

The stop point on the plug should be as close as

possible to the end face of the clamp. Then press

the plug a second time to ensure a proper t.

4) Put on end caps

Push the end cap onto the safety edge and x

it with the clip until it rests in the predetermined

position of the end cap and noticeably locks in the

clamp. Then press the xation clip a second time.

Termination Plugs

8.2K 10K

Normally Open

(non-monitored

installs)

5) Electrical testing of the safety contact edge

Measure the contact edge with a multimeter. In

rest position, the resistance value has to be 8.2kΩ,

or 10kΩ ± 500 Ω. When edge is activated, the

resistance should not exceed 500 Ω.

MyCPSG.com

3

Loading...

Loading...