mycom V- Handling Manual

V SERIES

REFRIGERATION DIVISION

SCREW COMPRESSOR HANDLING MANUAL

New V-Series

Screw Refrigeration Compressor

Handling Manual

Supersedes all previous version. This information is for reference use only and subject to change without notice

Revision 2 (June 05,2000) Page 1 of 61

V SERIES

REFRIGERATION DIVISION

SCREW COMPRESSOR HANDLING MANUAL

1. General Description of Mycom V-Series Compressor

Introduction

1.1 Refrigerant Compression Mechanism

1.2 Explanation of Vi (Internal Volumetric Ration)

1.3 Reasons for Adjusting Vi

1.4 Variable Vi Mechanism

1.5 External Adjustment of Vi

1.6 Other Component Mechanisms

2. Exploded View of V-Series Screw Compressor

2.1 Parts List

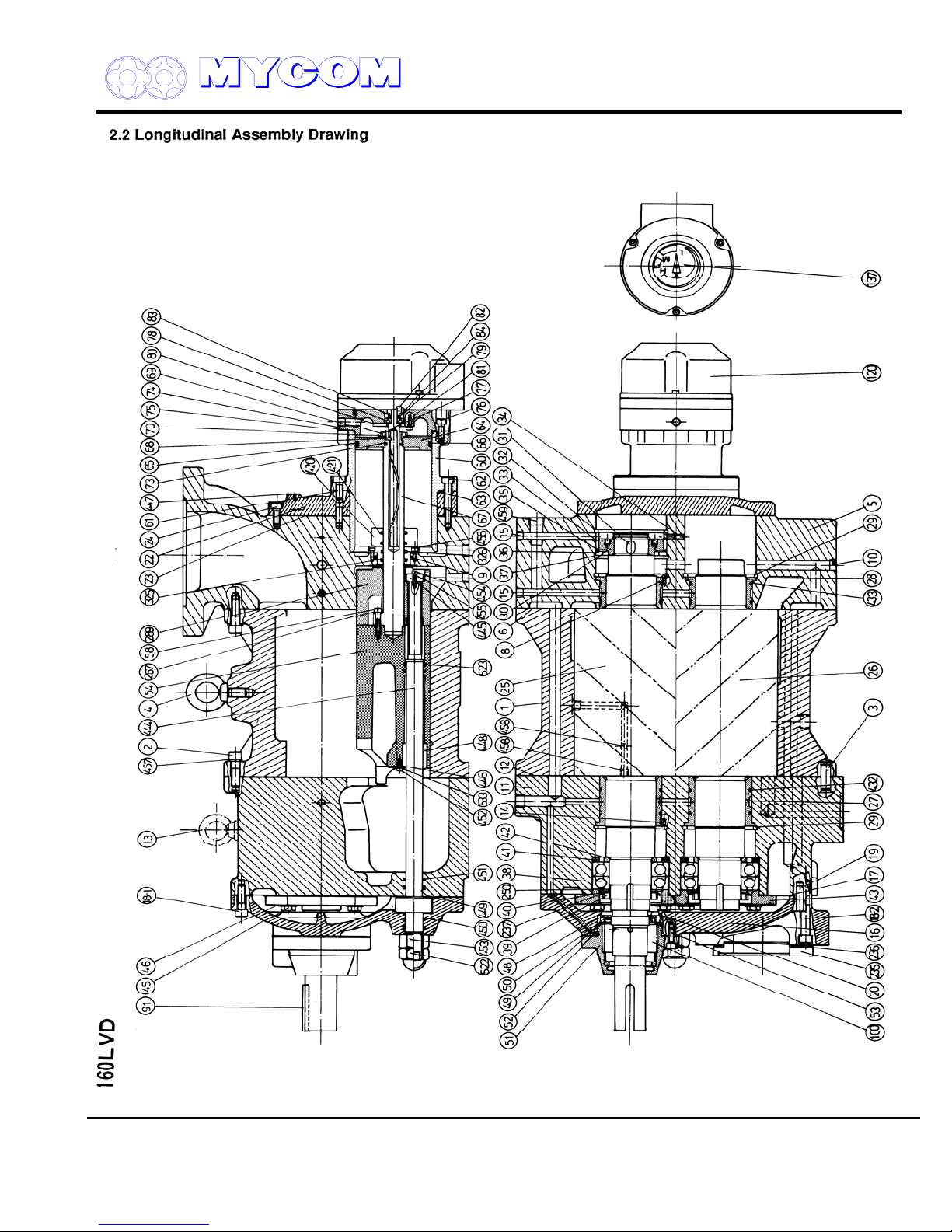

2.2 Longitudinal Assembly Drawing

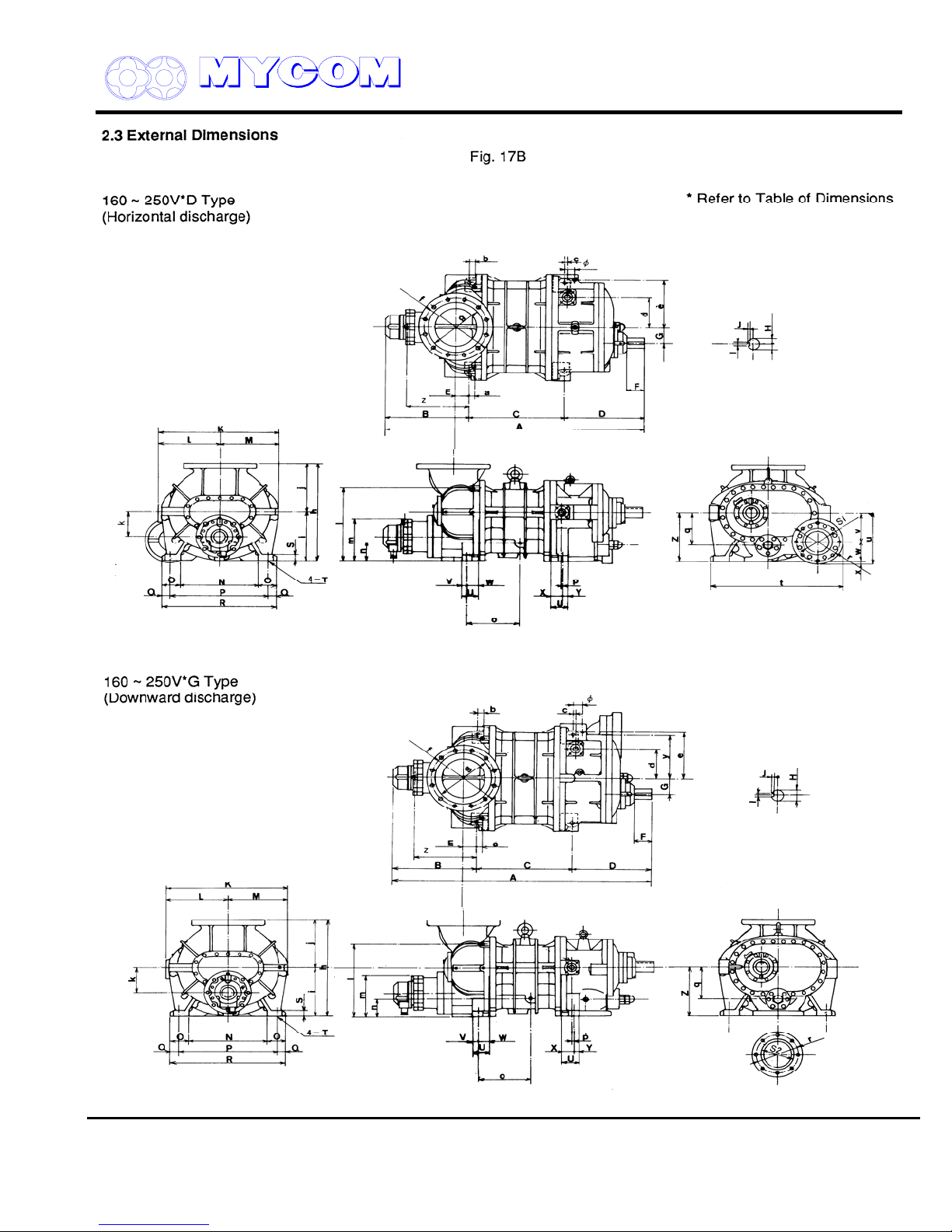

2.3 External Dimensions

3. Disassembly of V-Series

3.1 Preparations for Disassembly

3.2 Hand Tool Kit

3.3 Removing Compressor

3.4 Disassembly Sequence

3.4.1 Mechanical Seal

3.4.2 Unloader Indicator

3.4.3 Unloader Cover

3.4.4 Unloader Piston and Unloader Cylinder

3.4.5 Blind Cover

3.4.6 Balance Piston and Balance Piston Sleeve Portion

3.4.7 Bearing Cover

3.4.8 Thrust Bearing

3.4.9 Suction Cover and Side Bearing

3.4.10 Rotor, Rotor Casing and Variable Vi Slide Valve

3.4.11 Bearing Head and Main Bearing

4. Reassembly

4.1 Bearing Head and Main Bearing

4.2 Rotor Casing, Unloader Slide Bearing, Variable Vi Slide Valve and Bearing Head

4.3 Rotor Casing and Rotors

4.4 Suction Cover

4.5 Thrust Bearing

4.6 Bearing Cover

4.7 Blind Cover, Unloader Cylinder and Unloader Piston

4.8 Unloader Cover

4.9 Mechanical Shaft Seal

5. Disassembly and Adjustment of Unloader Indicator

5.1 Disassembly of Unloader Indicator

5.2 Inspection

5.3 Assembly and Adjustment

6. Standards of Components

Supersedes all previous version. This information is for reference use only and subject to change without notice

Revision 2 (June 05,2000) Page 2 of 61

V SERIES

REFRIGERATION DIVISION

SCREW COMPRESSOR HANDLING MANUAL

1. General Description of MYCOM V-Series Screw Compressor

Introduction

The MYCOM V-Series Screw Compressor (referred to hereafter as the “V Series”) incorporates

numerous improvements. A variable Vi mechanism allows these compressors to be adjusted readily

for most operating conditions and a new tooth profile (0 profile) has been introduced to further

improve performance.

The basic construction of the V Series is the same as standard MYCOM compressors except for the

addition of the variable Vi mechanism.

The operator should have a thorough knowledge of the compressor and the system it is incorporated

into before attempting to disassemble the unit for inspection. Read this instruction manual carefully

before undertaking any work on the system.

This screw compressor is classified as a positive displacement rotary type. It compresses the

refrigerant gas continuously using the volume change between two rotating screw profile rotors.

Refrigerant gas is trapped in the clearance between the two mated rotors and pressure increased by

decreasing the volume. The refrigerant is then discharged as a high-pressure gas

Supersedes all previous version. This information is for reference use only and subject to change without notice

Revision 2 (June 05,2000) Page 3 of 61

V SERIES

REFRIGERATION DIVISION

1.1 Refrigerant Compression Mechanism

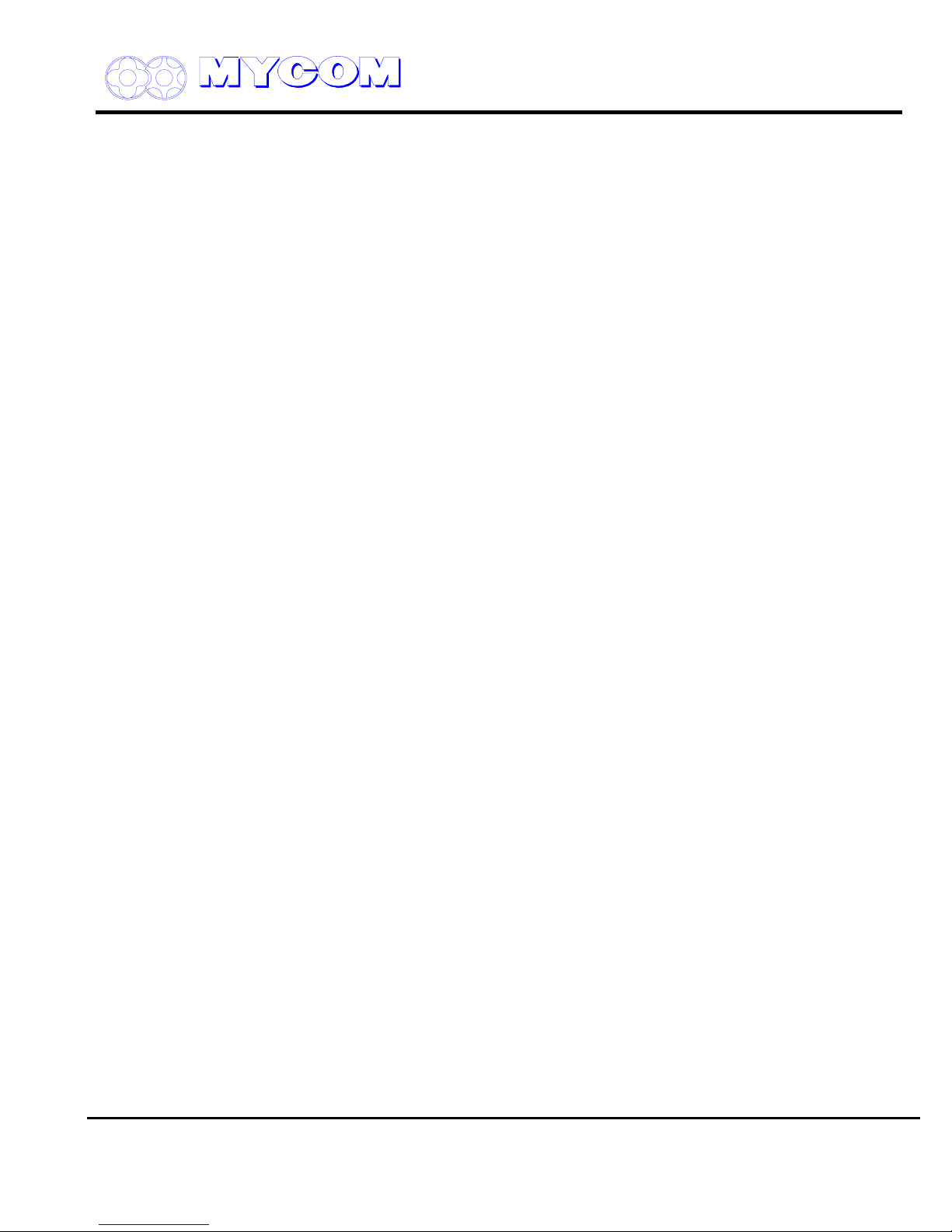

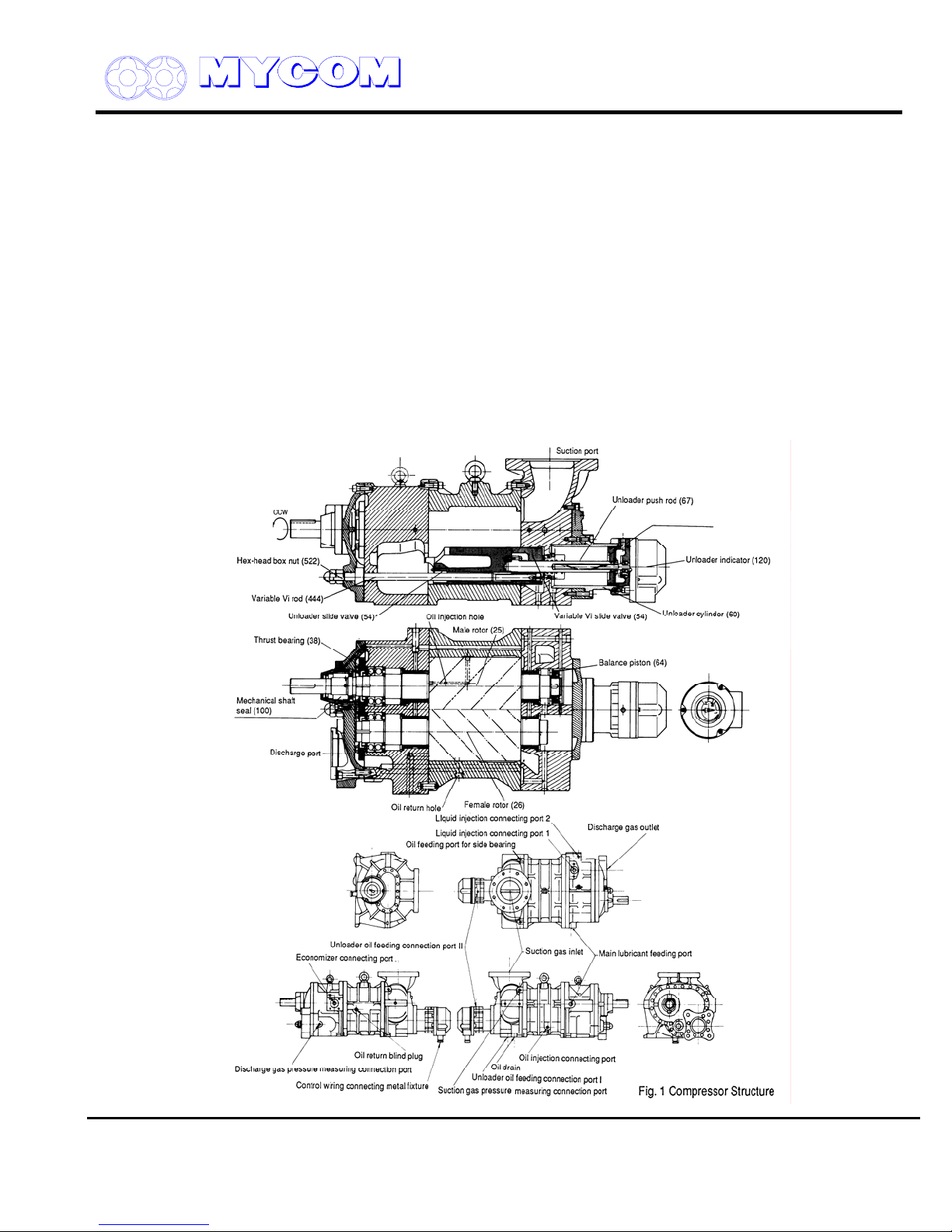

As shown in Figs. 1 and 2, a pair of mated helical gears, or rotors, are mounted in the compressor

casing. The rotor having the four-lobe section is called the male (M) rotor while the one with the sixlobe section is called the female (F) rotor.

A two-pole motor connected directly to the M rotor drives the compressor at speeds of 2,950 rpm or

3,550 rpm (50 Hz or 60 Hz)

Compressor efficiency is directly related to the shape of the rotor lobes. In the case of the V-Series,

the rotors have unsymmetrical profiles in contrast to conventional screw compressor rotor lobes. This

unsymmetrical design reduces the triangular blow off hole between the casing and the rotors to 60%,

minimizing leakage due to the pressure difference.

Normally, an oil film seals the clearance between the leading edges of the rotor lobes and the casing.

With the V-Series, however, a change has been incorporated to raise the pressure of the oil film and

the clearance between the casing and the lobe leading edges is wedge shaped.

SCREW COMPRESSOR HANDLING MANUAL

Fig. 2 Screw Compressor cross sectional view Fig. 3 Rotor Rotation & the Compression Cycle

Supersedes all previous version. This information is for reference use only and subject to change without notice

Revision 2 (June 05,2000) Page 4 of 61

V SERIES

REFRIGERATION DIVISION

1.1.1 Suction Phase (refer to Figs. 4 and 5)

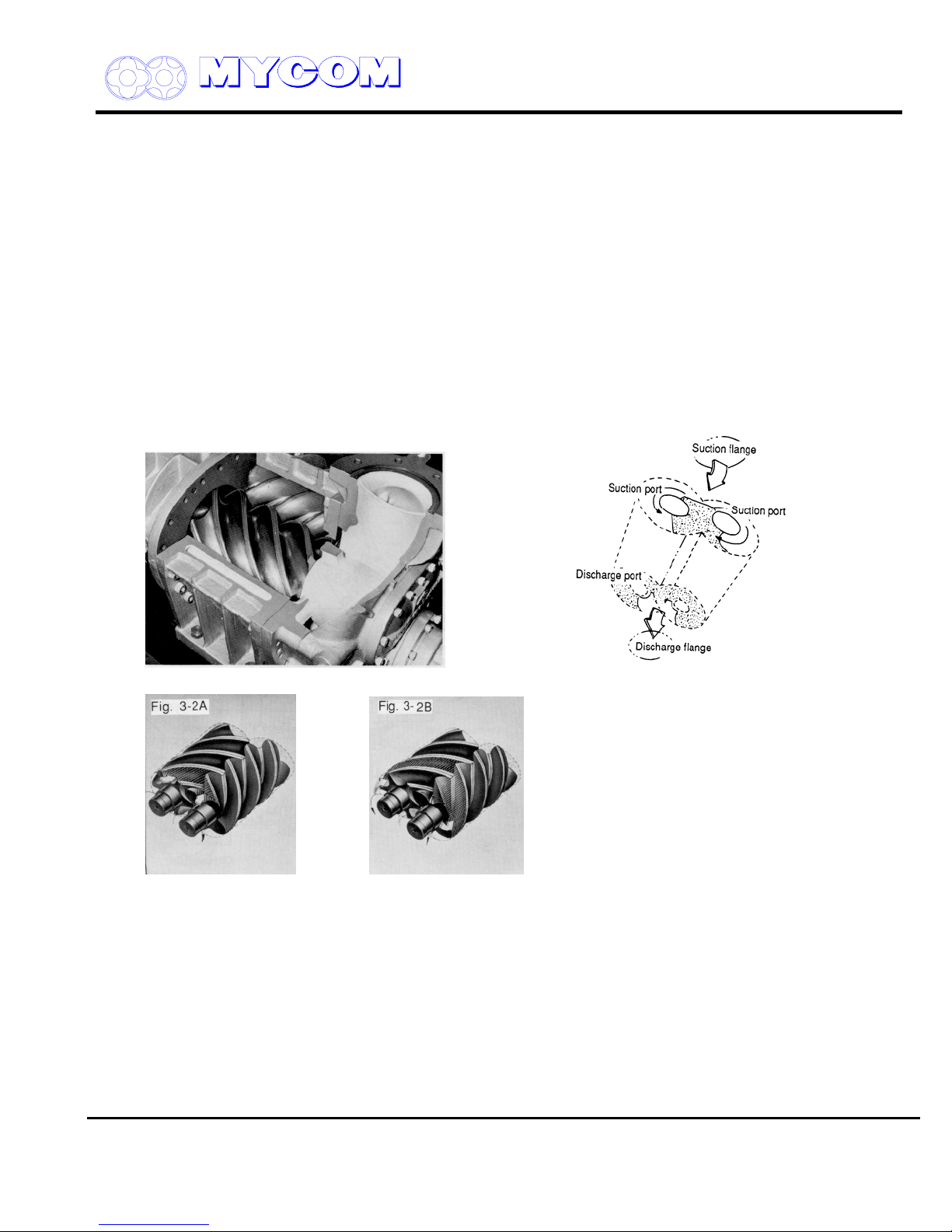

As shown in Fig. 4, the rotors of different lobe shape mate and the clearance between the M and F

rotors and the casing expands gradually from the suction side as the rotors rotate.

When the clearance reaches maximum as the rotors rotate further, it is sealed by the walls at both

ends of the rotor and becomes independent.

Fig. 4 Suction Phase Fig. 5 Suction Side Sealing

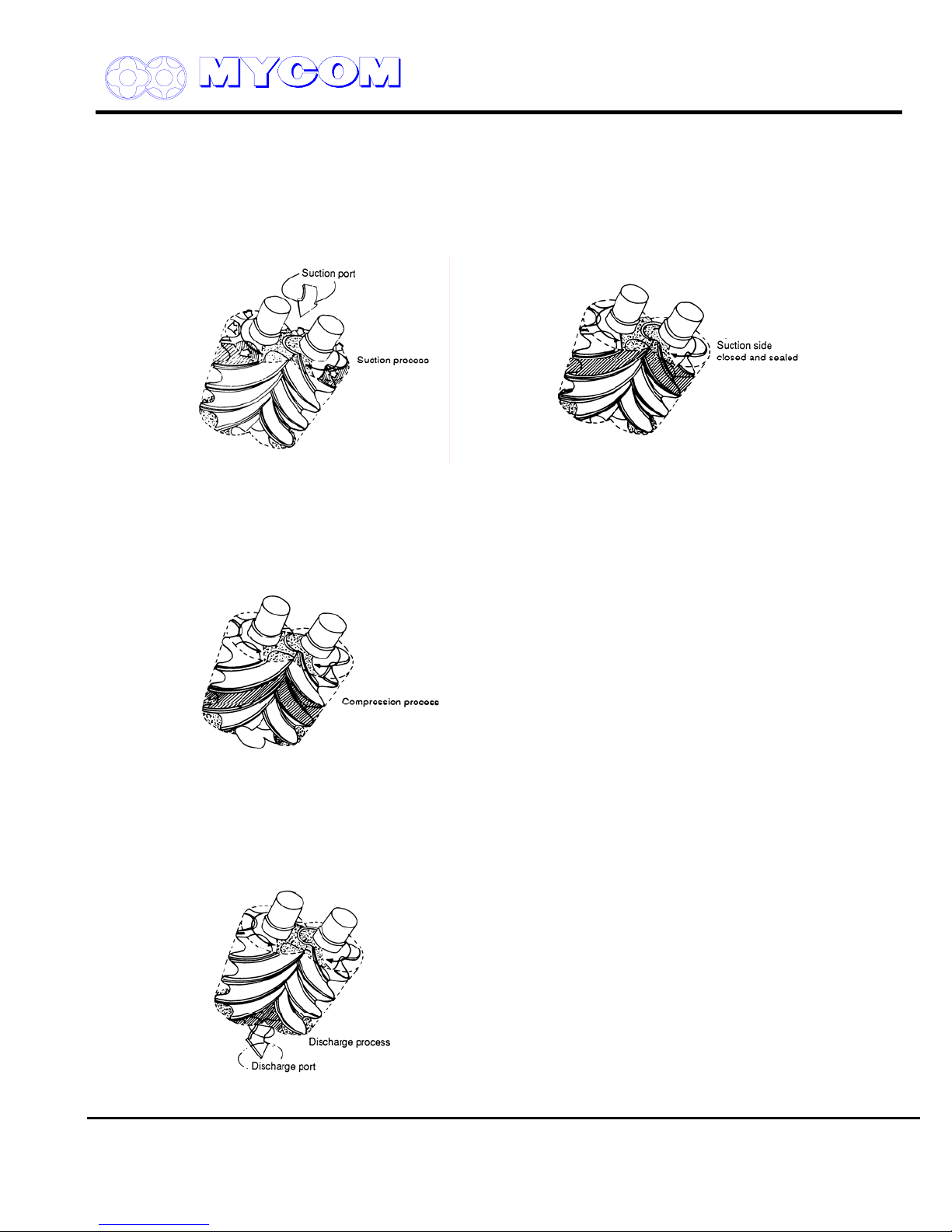

1.1.2 Compression Phase (refer to Fig. 6)

As the rotors further rotate, the suction side of the clearance is sealed by the mating of the lobes and

the volume between the lobes decreases while the sealing line moves toward the discharge side.

SCREW COMPRESSOR HANDLING MANUAL

Fig. 6 Compression Phase

1.1.3 Discharge Phase (refer to Fig. 7)

When the volume is decreased to the designated Vi, the clearance between the discharge port and

the rotors is linked and the refrigerant is pushed to the discharge side.

Fig. 7 Discharge Phase

Supersedes all previous version. This information is for reference use only and subject to change without notice

Revision 2 (June 05,2000) Page 5 of 61

V SERIES

REFRIGERATION DIVISION

SCREW COMPRESSOR HANDLING MANUAL

1.2 Explanation of Vi (Internal Volumetric Ratio)

In the case of a reciprocating compressor, the volume of the refrigerant sucked into the cylinder

decreases and the refrigerant pressure increases as the piston ascends. When the pressure exceeds

the discharge side pressure plus the force of the spring on the discharge plate valve, the refrigerant in

the cylinder pushes open the valve and passes to the discharge side.

In the case of the screw compressor, a volume of refrigerant is sucked into the groove between the

rotors and the volume decreases while pressure increases as the rotors rotate. The process up to this

point is the same as for a reciprocating compressor. When the volume is decreased to the designed

Vi, the groove is linked to the discharge port and the refrigerant is pushed out. The groove is linked to

the discharge port according to the volume of the groove and is not dependent on internal pressure.

Vi (internal volumetric ratio) is used to represent the value of the decreased volume of suction

refrigerant when the groove aligns with the discharge port (or is discharged).

This can be expressed as follows:

Vi =

Volume of suction refrigerant when compression begins

Volume of same quantity of refrigerant at discharge port

In other words, Vi is the ratio of the groove volume after competition of suction to the volume when the

discharge port opens.

Conventional screw compressors have three fixed Vi values, that is 2.63, 3.65 and 5.80, termed “L

port,” “M port” and “H port,” respectively.

The relationships are:

Vi = (P

d/Ps

1/k

)

or Vik = Pd/P

Consequently, the Vi corresponding to the compression ratio changes according to the refrigerant

used.

For approximate values, refer to the graph given in Fig. 12. The new V-Series, Maximizer Series

Screw Compressors, are designed so that the Vi can be adjusted on site according to operating

conditions.

1.3 Reasons for Adjusting Vi

Operating conditions of refrigeration systems are not always constant. As well, the same model of

compressor may be operated under a variety of pressure conditions, e.g., air conditioning, cold

storage and freezing applications. In the case of air conditioning and cold storage, the conditions will

vary depending on the need for cooling, heating, low and high temperature.

Needless to say, compressors must be operated at maximum efficiency under various conditions. The

drawback of the conventional compressor is that a fixed Vi is established for the compressor during

production. This Vi can later be changed by machining the compressor but is limited to change from a

higher to a lower value only. Variable Vi screw compressors in the Maximizer Series were developed

as an answer to this drawback. Many compressors of this type are used in special reefer carrier

applications, but because of the sophisticated structure and relatively high cost, they have not been

popular for general applications.

The V-Series, which incorporates a variable Vi, has consequently been developed for these general

applications.

s

The Vi of the V-Series can be readily changed between L, M and H at the installation plant according

to operating conditions.

Supersedes all previous version. This information is for reference use only and subject to change without notice

Revision 2 (June 05,2000) Page 6 of 61

V SERIES

REFRIGERATION DIVISION

SCREW COMPRESSOR HANDLING MANUAL

With the fixed Vi of a conventional compressor, maximum efficiency can only be obtained when the

system is operating at a pressure equivalent to the designed Vi. Unnecessary power is consumed,

however, when pressure conditions diverge from the designed value. For example, if low compression

ratio (high compression pressure or low discharge pressure) operation is carried out using a

conventional M port compressor (designed for a medium compression ratio), compression will exceed

discharge pressure and power will be wasted.

Fig. 8 Internal Volume Ratio Fig. 9 Relationship between design and

operating conditions

Conversely, if the same M port compressor is used under high compression conditions (high suction

pressure or high discharge pressure), the discharge port opens before internal pressure has

increased sufficiently, allowing refrigerant to flow back from the discharge port. Power is also wasted.

Obviously, if a compressor is to be operated for an extended period under varying conditions, a

variable Vi design is preferable to a fixed Vi type. For a conventional compressor with a high Vi, the

discharge port can be machined to lower the Vi but a unit with a low Vi cannot be changed to a high

Vi type. If a higher Vi is needed, the compressor must be replaced with a new one.

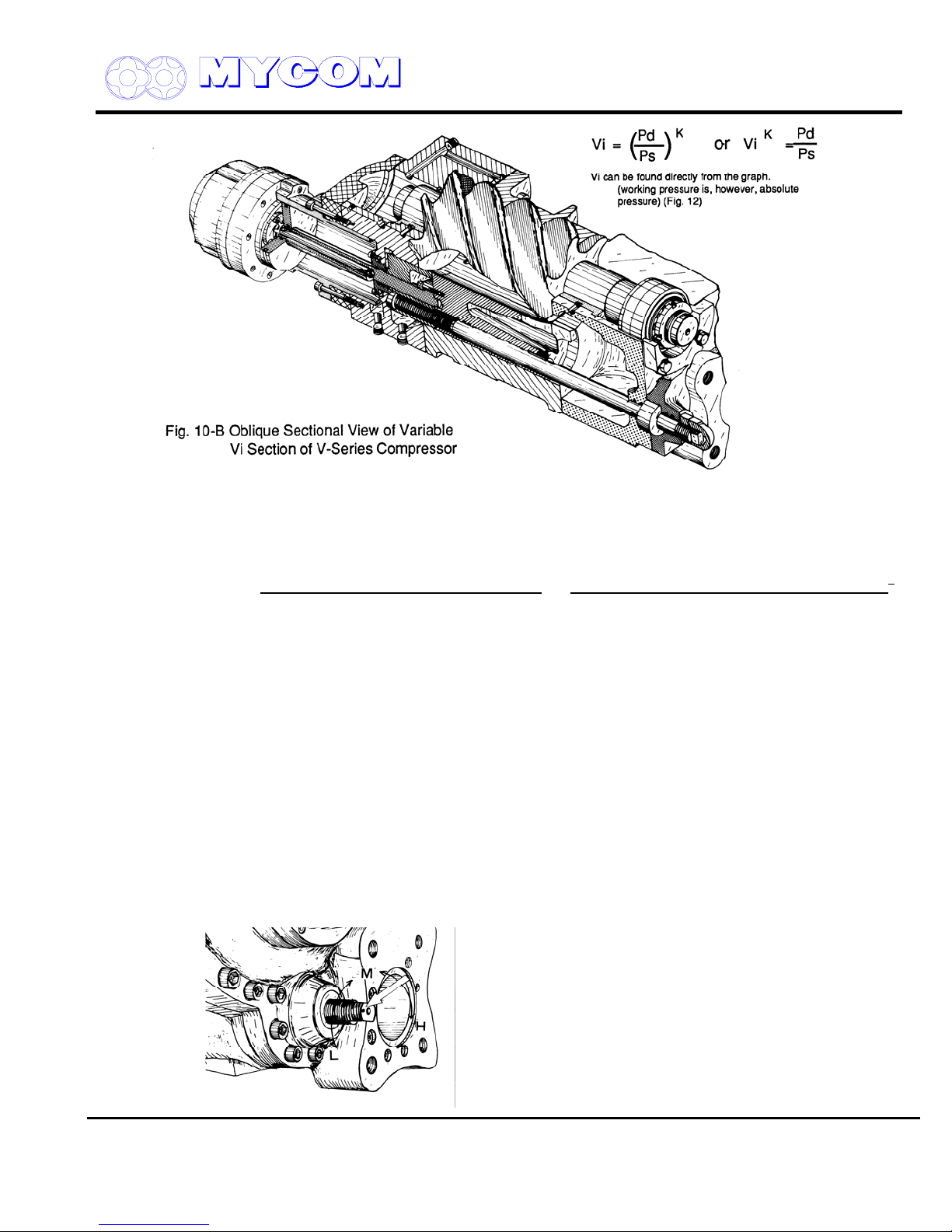

1.4 Variable Vi Mechanism

The Vi of a conventional screw compressor is determined by the combination of the axial discharge

port of the rotors on the bearing head and the radial discharge port of the shaft (radial discharge port

on the unloader slide valve). In the case of a conventional model, the axial and radial elements are

combined to exhibit particular characteristics at partial load. In the case of V-Series compressors, the

Vi can be changed by altering the size of the radial port while maintaining the axial port at Vi 5.10.

Supersedes all previous version. This information is for reference use only and subject to change without notice

Revision 2 (June 05,2000) Page 7 of 61

V SERIES

REFRIGERATION DIVISION

SCREW COMPRESSOR HANDLING MANUAL

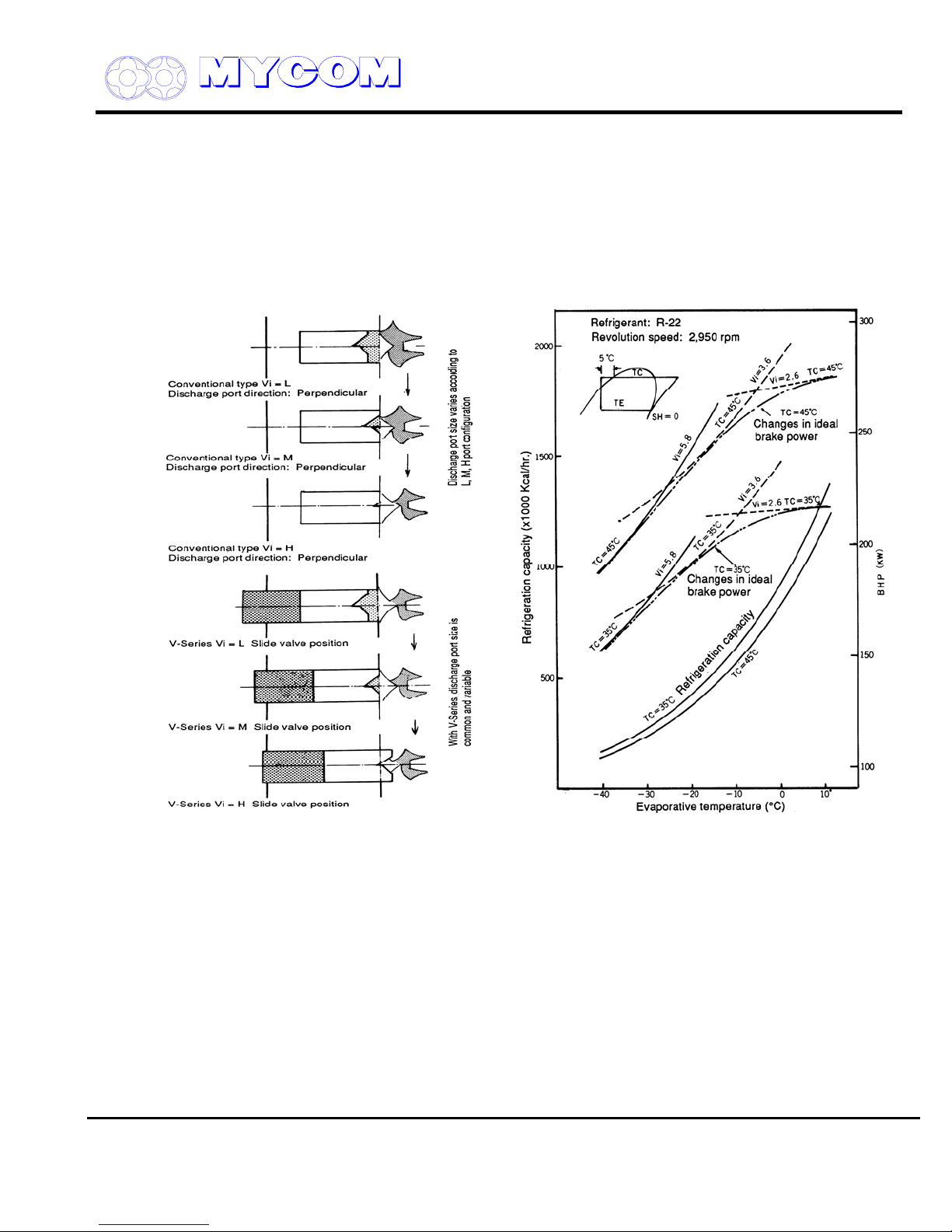

As shown in Fig. 10A, the radial port of a conventional model becomes larger as Vi becomes smaller.

In the case of V-Series compressors, the stop position of the variable Vi unloader slide valve moves to

the discharge side and changes Vi by reducing the size of the radial port at full load operation.

As Fig. 11 shows, the refrigeration capacity changes only slightly under various Vi and other

conditions. Refrigeration capacity is influenced considerably by shaft power but changes little in

response to slight changes in operating conditions, as the diagram shows, consequently, once Vi is

adjusted to the operating conditions, it is not necessary to alter it in response to slight changes in

operating conditions.

Fig. 10-A Difference between Conventional Fig. 11 Conventional Screw Capacity Curve

Discharge Port and V-Series Discharge Port

The Vi must be adjusted only when there are major changes in operating conditions such as a change

in the application of the compressor. For instance, when the operating conditions of the compressor

are changed from cooling at approx. 0qC evaporative temperature to refrigeration at -40q C

evaporative temperatures with the compressor Vi set to the L port configuration, shaft power must be

double. In such a case it is advisable to change the Vi to the H port configuration. Similarly, if the

compressor is to be used for refrigeration at an evaporative temperature of 0qCa-30qC, it is advisable

to set the Vi to the M port configuration.

Temperature drops and the compression ratio “Vi” increases as refrigeration progresses but Vi should

not be changed according to the varying conditions. The Vi should be fixed during operation (when Vi

must be changed according to operating conditions, a Maximizer Screw Compressor, namely a new

V-Series unit, should be used).

Supersedes all previous version. This information is for reference use only and subject to change without notice

Revision 2 (June 05,2000) Page 8 of 61

V SERIES

REFRIGERATION DIVISION

1.5 External Adjustment of Vi

SCREW COMPRESSOR HANDLING MANUAL

a) Determine P

P

= Absolute value of discharge pressure = Discharge gauge pressure + 1.033 kgf/cm

d/Ps

Absolute value of suction pressure Suction gauge pressure + 1.033 kgf/cm

during operation based on the anticipated operating conditions of the system.

d/Ps

2

2

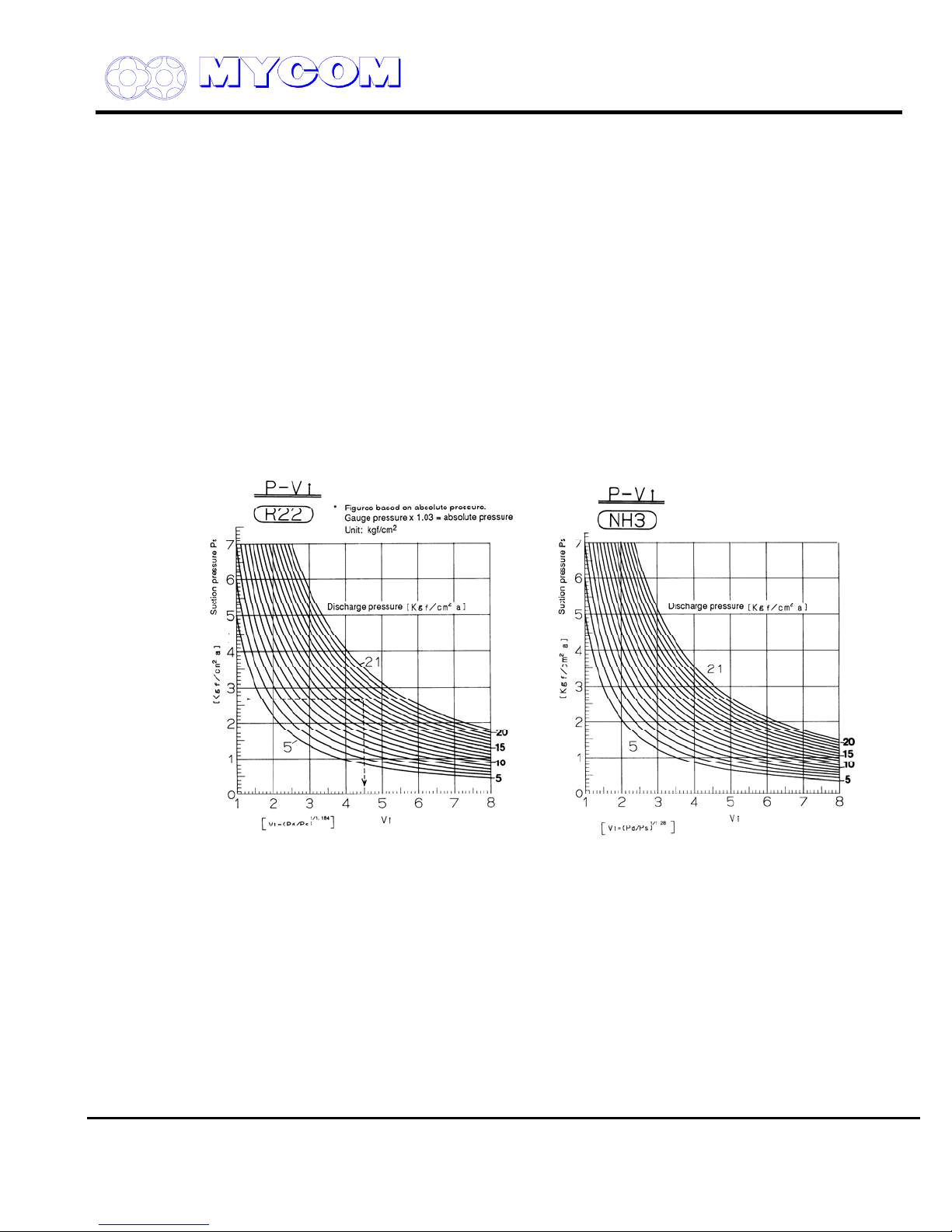

b) Find Vi from the compression ratio

1/k

)

Vi = (P

Vi can be found directly from the graph. (Working pressure is, however, absolute pressure)(Fig. 12)

d/Ps

or Vik = Pd/P

s

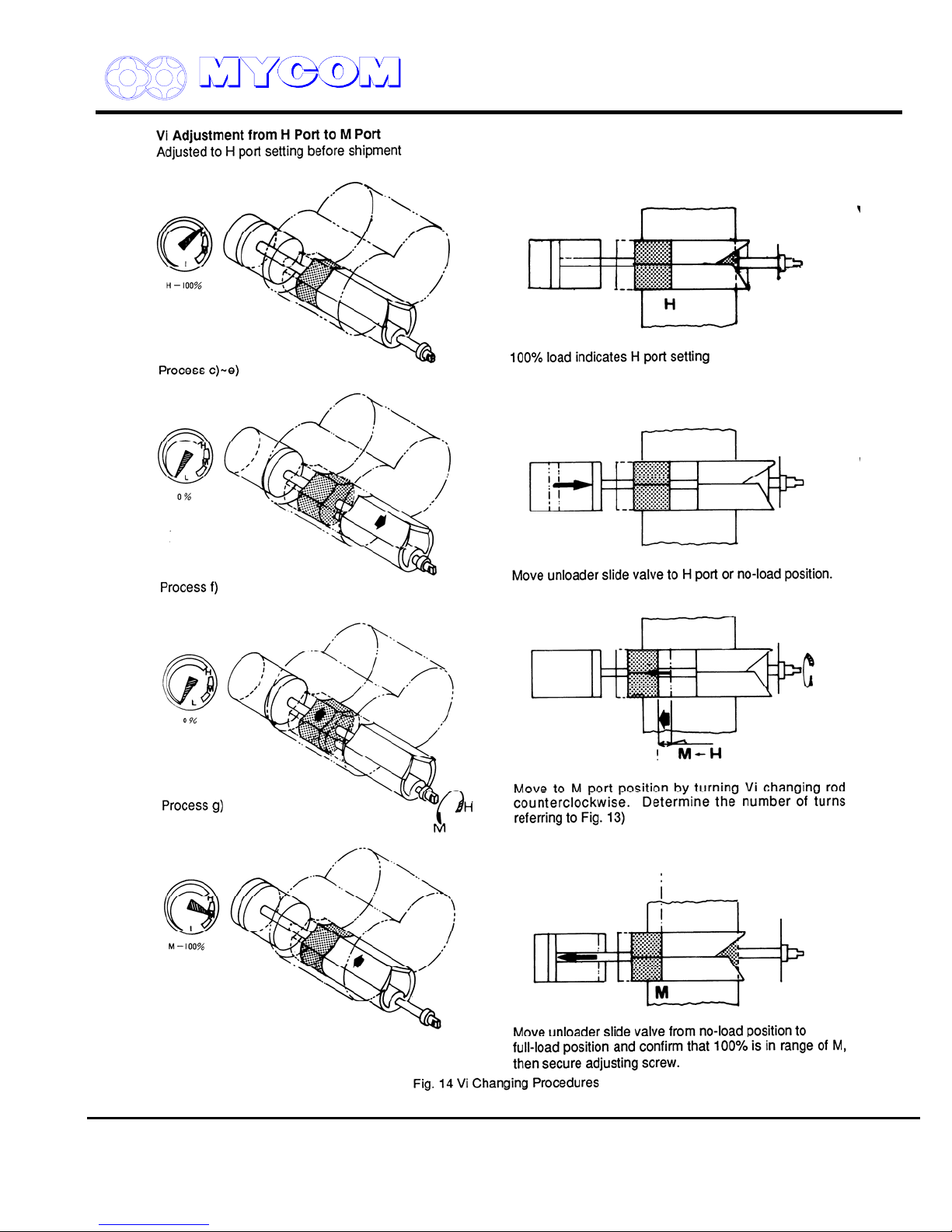

c) After determining the port, set the capacity control mechanism to the unload position.

d) Determine the number of turns needed on the Vi changing rod for the particular compressor as

given in Fig. 13.

e) Remove the cap seal on the Vi changing rod and loosen the lock nut.

Turn the Vi changing rod clockwise (CW) and confirm that the variable Vi slide valve is at the

maximum Vi position and that the Vi changing rod does not rotate (unreasonable force should

be avoided when turning the Vi changing rod). (Adjusted to H port configuration before

shipment). In case of medium port (M port), turn the Vi changing rod clockwise (CW) until it

stops and set the variable Vi slide valve to the H port position.

Supersedes all previous version. This information is for reference use only and subject to change without notice

Revision 2 (June 05,2000) Page 9 of 61

V SERIES

REFRIGERATION DIVISION

SCREW COMPRESSOR HANDLING MANUAL

f) Next, record the position of operation start (confirm the position of the stamp on the screw

head).

Turn the Vi changing rod counterclockwise the number of rotations indicated for the particular

compressor as given in Fig. 13.

After adjusting, secure the lock nut (approx. 1/12 of a turn after contact with the casing). When

securing the lock nut, be sure that the Vi changing rod does not rotate out of position.

g) Set the capacity control mechanism to the full load position.

If the needle pointer of the capacity control indicator indicates the specified porti range on the

dial, proper adjustment is confirmed.

An amplitude is provided between the M and H graduations on the indicator dial because the

M and H positions shift depending on whether the compressor is a 160SML, 200 SML or 250

SML model as well as on the rotor length, of which there are nine. Since the graduations on

the dial are common to all models, an amplitude is provided. When the Vi changing rod is

adjusted the correct number of turns and the needle pointer position is within the specified

range, adjustment can be considered correct.

Fig. 12 Graphs for determining Vi from Operating Suction and Discharge Pressure (R22, NH3)

h) Secure the hex head cap nut (453) for the Vi changing rod securely (rotate approx. 1/12 turn

after contacting casing).

Supersedes all previous version. This information is for reference use only and subject to change without notice

Revision 2 (June 05,2000) Page 10 of 61

V SERIES

REFRIGERATION DIVISION

SCREW COMPRESSOR HANDLING MANUAL

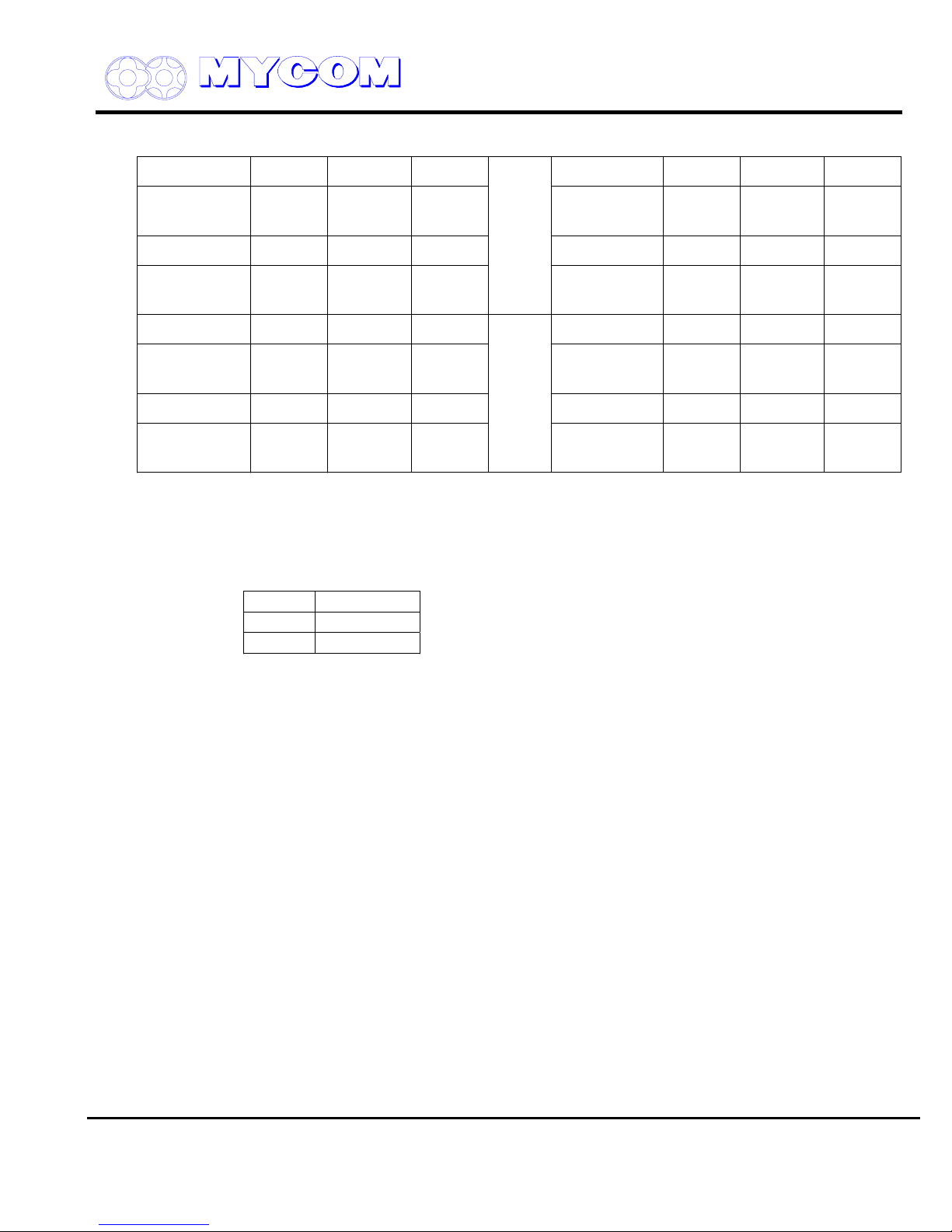

H port ĺ M port H port ĺ L port

H ĺ M 160VS* 160VM* 160VL* H ĺ L 160VS* 160VM* 160VL*

Distance

No. of Turns

18mm

7.2

23mm

9.9

27mm

10.8

Distance

No. of Turns

37mm

14.0

45mm

18.0

55mm

22.0

H ĺ M 200VS* 200VM* 200VL* H ĺ L 200VS* 200VM* 200VL*

Distance

No. of Turns

23mm

6.6

28mm

8.0

34mm

9.7

Distance

No. of Turns

46mm

13.0

57mm

16.0

69mm

19.0

H ĺ M 250VS* 250VM* 250VL* H ĺ L 250VS* 250VM* 250VL*

Distance

No. of Turns

29mm

7.3

36.5mm

9.1

43mm

10.8

Distance

No. of Turns

58mm1472.5mm1887mm

21

H ĺ M 320VS* 320VM* 320VL* H ĺ L 320VS* 320VM* 320VL*

Distance

No. of Turns

Fig. 13 Vi Changing Rod Adjustment By Model

Reference:

Dimensions of screw used to change Vi.

Accordingly:

Number of turns x pitch = Variable Vi slide valve distance change

59mm1350mm

11

47mm

10

Distance

No. of Turns

98mm

21.5

98mm

21.5

105mm

23

160v**

200v**

250v**

M20 x P2.5

M30 x P3.5

M36 x P4

Precautions when changing Vi.

1. The Vi should be changed only when the compressor is stopped and the capacity control

mechanism is set to the no-load position.

2. Unreasonable force should not be applied to the mechanism provided on L port and M port

compressors.

3. If the Vi needs to be positioned midway between two different ports, select the best port

referring to the capacity chart. Do not use variable Vi except for L, M and H ports.

4. The Vi should not be changed frequently in an attempt to adjust to small changes in the

compression ratio, which may arise during normal operations. If no substantial change in

operating conditions (e.g., a change in evaporative temperature) is required, the Vi should be

changed only in the autumn and spring following the respective summer and winter seasons.

Supersedes all previous version. This information is for reference use only and subject to change without notice

Revision 2 (June 05,2000) Page 11 of 61

V SERIES

REFRIGERATION DIVISION

SCREW COMPRESSOR HANDLING MANUAL

Supersedes all previous version. This information is for reference use only and subject to change without notice

Revision 2 (June 05,2000) Page 12 of 61

V SERIES

REFRIGERATION DIVISION

1.6 Other Component Mechanisms

a) The radial load of the compressor is absorbed by white meal-lined bearings while the axial

thrust load on the rotors is absorbed by an angular contact ball bearing.

The balance piston of the V-Series compressor M rotor is somewhat larger in diameter than

that of a conventional screw compressor in order to allow for a decrease in the oil pressure

load which is used for pressure difference lubrication.

b) A new, single balance type mechanical shaft seal is used on the drive shaft to protect the shaft

from refrigerant leakage.

The mechanical seal utilizes O-ring packing to allow service with various different refrigerants.

A combination of carbon and metal is used to assure the durability of the frictional parts and

the sealing effect.

c) A cam is provided to indicate the position of the variable Vi slide valve and unloader slide

valve. The capacity control ratio is shown on the dial indicator. Capacity control indication can

be output to a remote indicator using the electric circuit provided.

d) Compressor oil flow

Oil for lubrication and for injection is supplied from a high pressure side oil tank by the

pressure difference with the low pressure side or by an additional pump. Regarding oil

injection, conventional compressors have oil injected into the triangular blow hole in the mating

portion of the unloader slide valve but V-Series compressors utilize a system whereby oil is

supplied from a fixed position on the M rotor side rotor casing.

SCREW COMPRESSOR HANDLING MANUAL

e) Unlike with conventional screw compressors, oil is also supplied to the F rotor side bearing

directly from the suction cover.

Supersedes all previous version. This information is for reference use only and subject to change without notice

Revision 2 (June 05,2000) Page 13 of 61

V SERIES

Oil Flow

REFRIGERATION DIVISION

SCREW COMPRESSOR HANDLING MANUAL

Fig. 15 Schematic Diagram of Lubrication System

Supersedes all previous version. This information is for reference use only and subject to change without notice

Revision 2 (June 05,2000) Page 14 of 61

V SERIES

REFRIGERATION DIVISION

SCREW COMPRESSOR HANDLING MANUAL

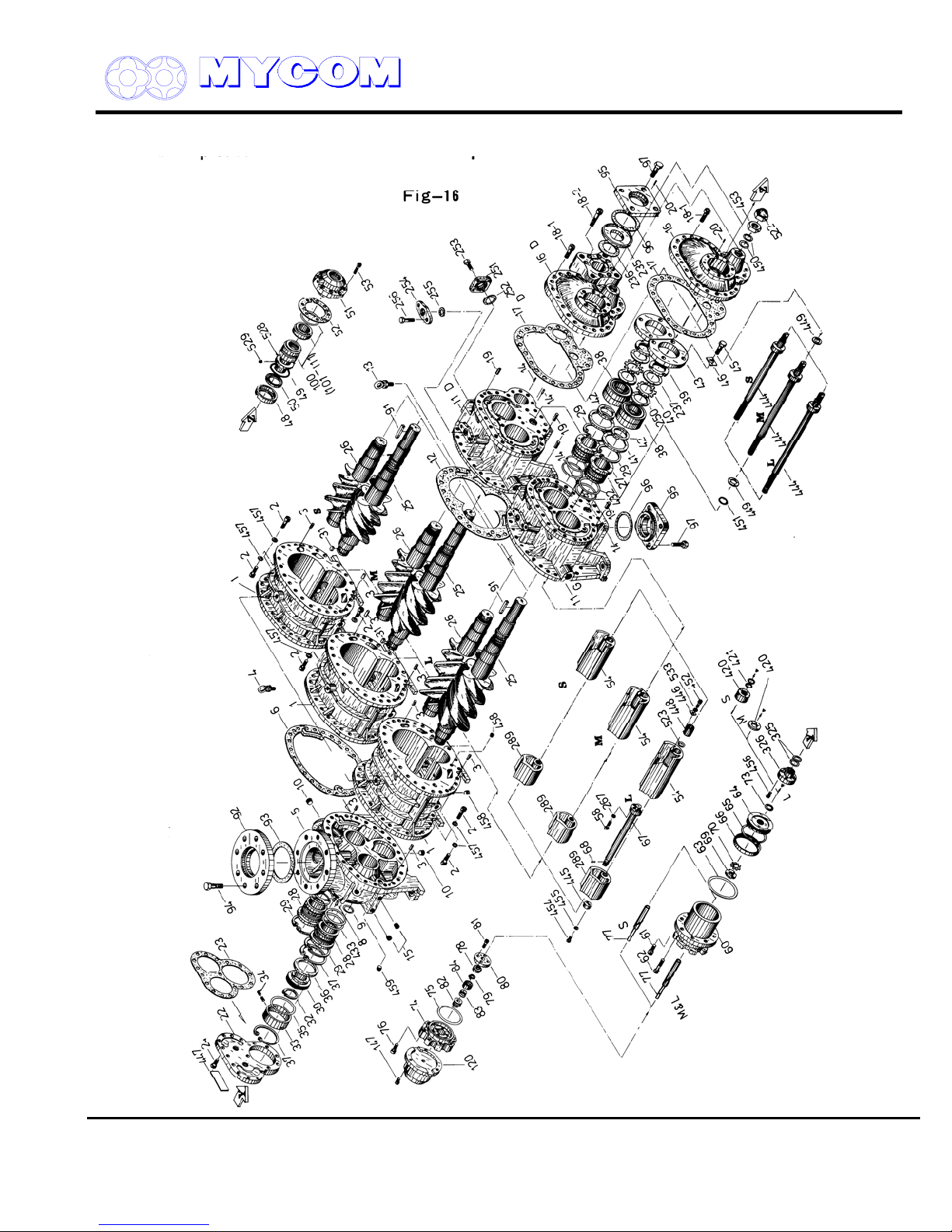

2. Exploded View of V-Series Screw Compressor

Supersedes all previous version. This information is for reference use only and subject to change without notice

Revision 2 (June 05,2000) Page 15 of 61

V SERIES

REFRIGERATION DIVISION

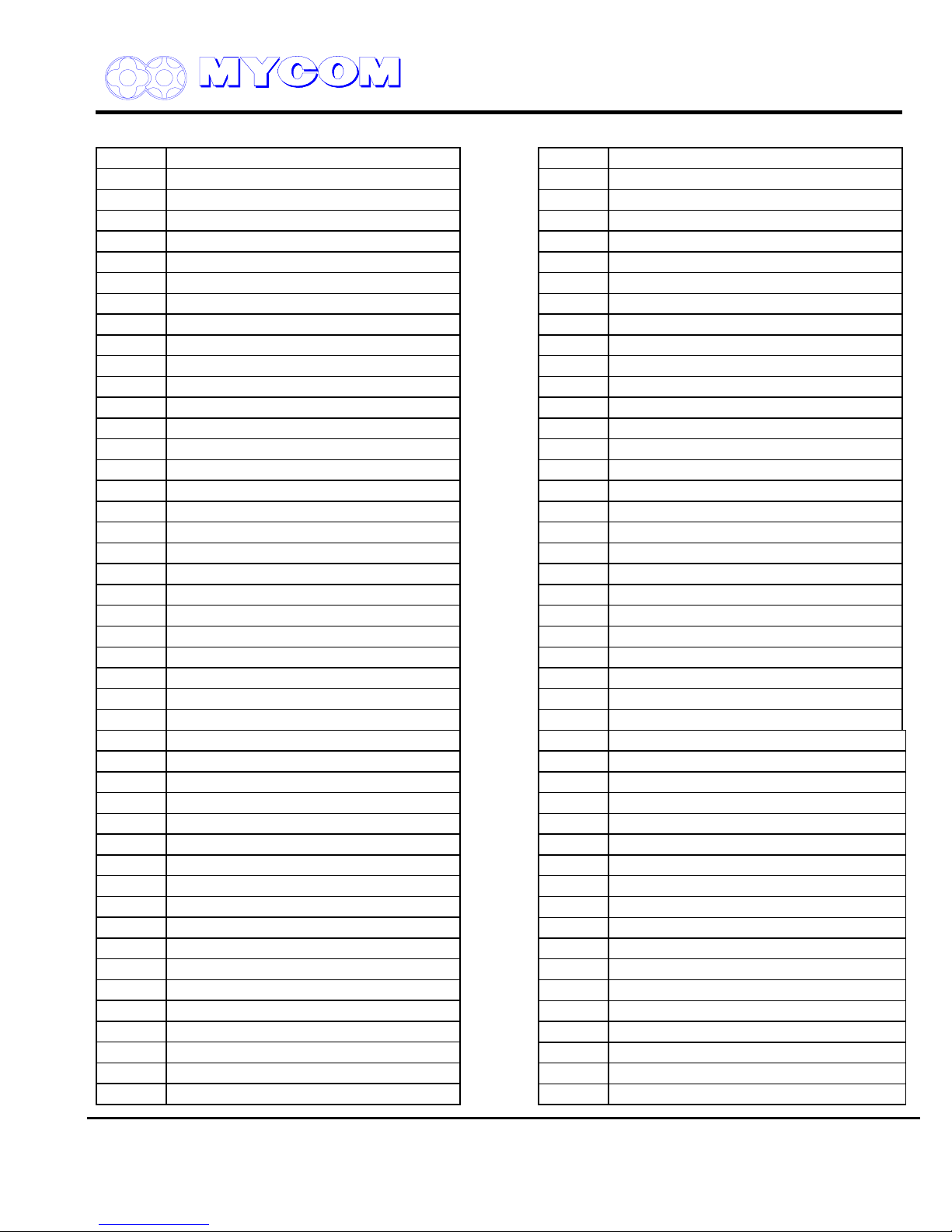

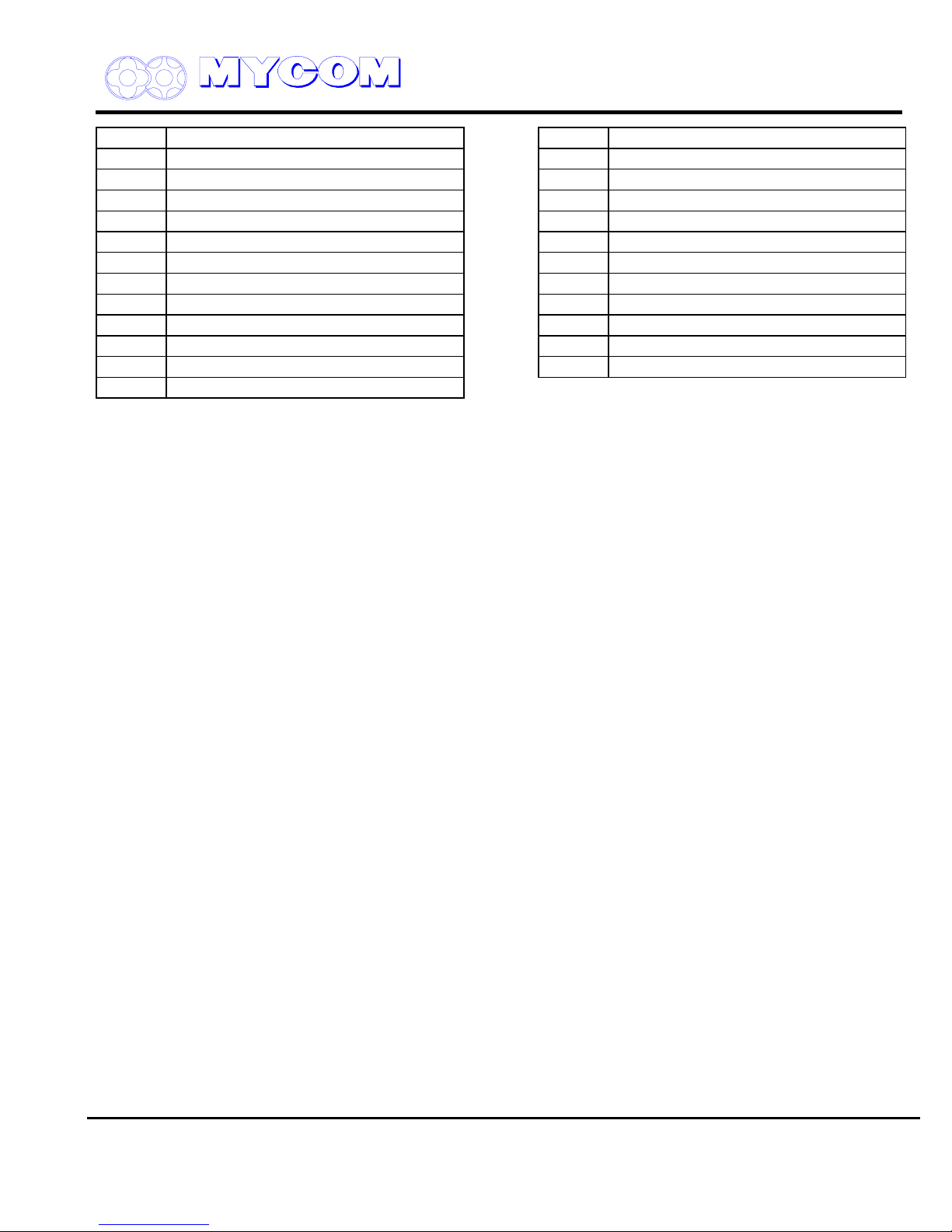

2.1 Parts List

No. Parts Name

1 Main Rotor Casing

2 Hexagon Socket Head Cap Screw

3 Alignment Pin

4 Hanger Bolt

5 Suction Cover

6 Gasket, Suction Cover

8 Spring Pin

9 "O"Ring

10-A Plug

10-B Plug

10-C Plug

10-D Plug

11 Bearing Head

12 Gasket, Bearing Head

13 Hanger Bolt

14 Spring Pin

16 Bearing Cover

17 Gasket, Bearing Cover

18-1 Hexagon Socket Head Cap Screw

18-2 Hexagon Socket Head Cap Screw

19 Alignment Pin

20 Spring Pin

21 Plug

22 Balance Piston Cover

23 Gasket, Balance Piston Cover

24 Hexagon Socket Head Cap Screw

25 Male Rotor

26 Female Rotor

27 Main Bearing

28 Side Bearing

29 Stop Ring

30 Balance Piston

31 Key, Balance Piston

32 Stop Ring

33 Sleeve, Balance Piston

34 Set Screw

35 "O"Ring

36 Spacer

37 Stop Ring

38 Thrust Bearing Assembly

No. Parts Name

39 Lock Nut

40 Lock Washer

41 Spacer, Thrust Bearing Outer Race

42 Spacer, Thrust Bearing Alignment

SCREW COMPRESSOR HANDLING MANUAL

43 Thrust Bearing Gland

45 Hexagon Head Bolt

46 Lock Washer

48 Retainer, Oil Seal

49 "O"Ring

50 Oil Seal

51 Seal Cover

52 Gasket, Seal Cover

53 Hexagon Socket Head Cap Screw

54 Unloader Slide Valve

58 Hexagon Socket Head Cap Screw

60 Unloader Cylinder

61 Hexagon Socket Head Cap Screw

62 Hexagon Socket Head Cap Screw

63 "O"Ring

64 Unloader Piston

65 "O"Ring

66 Cap Seal

67 Push Rod, Unloader Slide Valve

68 Guide Pin

69 Lock Nut

70 Lock Washer

73 "O"Ring

74 Unloader Cover

75 "O"Ring

76 Hexagon Socket Head Cap Screw

77 Unloader Indicator Cam

78 Ball Bearing

81 Hexagon Socket Head Cap Screw

82 "V"Ring

83 Spring

84 Retainer

91 Shaft Key

100 Assembly, Mechanical Seal

120 Assembly, Unloader Indicator

137 Unloader Indicator

237 Torsional Slip Washer

No. Parts Name

250 Washer, Thrust Bearing

267 Spring Washer

289 Vi Slide Stop

325 "O"Ring

326 Gland, "O"Ring

420 Unloader Spacer

421 "O"Ring

432 "O"Ring

Supersedes all previous version. This information is for reference use only and subject to change without notice

Revision 2 (June 05,2000) Page 16 of 61

V SERIES

REFRIGERATION DIVISION

433 "O"Ring

444 Vi Adjusting Rod

445 Washer

446 Vi Square Washer

447 Name Plate

448 Bushing

449 Thrust Washer

450 "O"Ring

451 "O"Ring

452 Hexagon Socket Head Cap Screw

453 Hexagon Nut

454 Hexagon Socket Head Cap Screw

455 Spring Washer

SCREW COMPRESSOR HANDLING MANUAL

456 Hexagon Socket Head Cap Screw

457 Spring Washer

458 Plug

459 Plug

522 Domed Cap Nut

523 "O"Ring

528 Sleeve, Oil Seal

529 Set Screw

533 Spring Washer

605 Plug

No Parts Name

607 Plug

Supersedes all previous version. This information is for reference use only and subject to change without notice

Revision 2 (June 05,2000) Page 17 of 61

V SERIES

REFRIGERATION DIVISION

SCREW COMPRESSOR HANDLING MANUAL

Supersedes all previous version. This information is for reference use only and subject to change without notice

Revision 2 (June 05,2000) Page 18 of 61

V SERIES

REFRIGERATION DIVISION

SCREW COMPRESSOR HANDLING MANUAL

Supersedes all previous version. This information is for reference use only and subject to change without notice

Revision 2 (June 05,2000) Page 19 of 61

Loading...

Loading...