2203M4JE-MY-iS2-N_2017.04.

i-Series Screw Compressor

Instruction Manual

i125S / i125L

i160S / i160M / i160L

CAUTION

Before operating, servicing, or inspecting this product, read this manual thoroughly to

fully understand the cont ents.

Keep this instruction manual in a safe, designated place for future reference whenever

the manual is needed.

Specifications of this product and contents of this manual are subject to change without

prior notice due to technical im pr ovements, and the like.

This manual is applied to each compressor after the serial number

shown below.

i125S: 8750303 i125L: 8770301

i160S: 8710055 i160M: 8720018 i160L: 8730030

2203M4JE-MY-iS2-N_2017.04.

Preface

Screw Compressor i-series

i

Preface

Thank you for purchasing our

i-series screw compressor (hereinafter referred to as "this

product").

This instruction manual (hereinafter referred to as "this manual") provides safety information and

operation and maintenanc e procedures , so that users correct ly understand how t o handle this pr oduct

and, as a result, can use it safely and efficiently.

Before installing or using this product, make sure you read this manual.

Keep this manual in a safe place near this product for quick reference.

Revision History

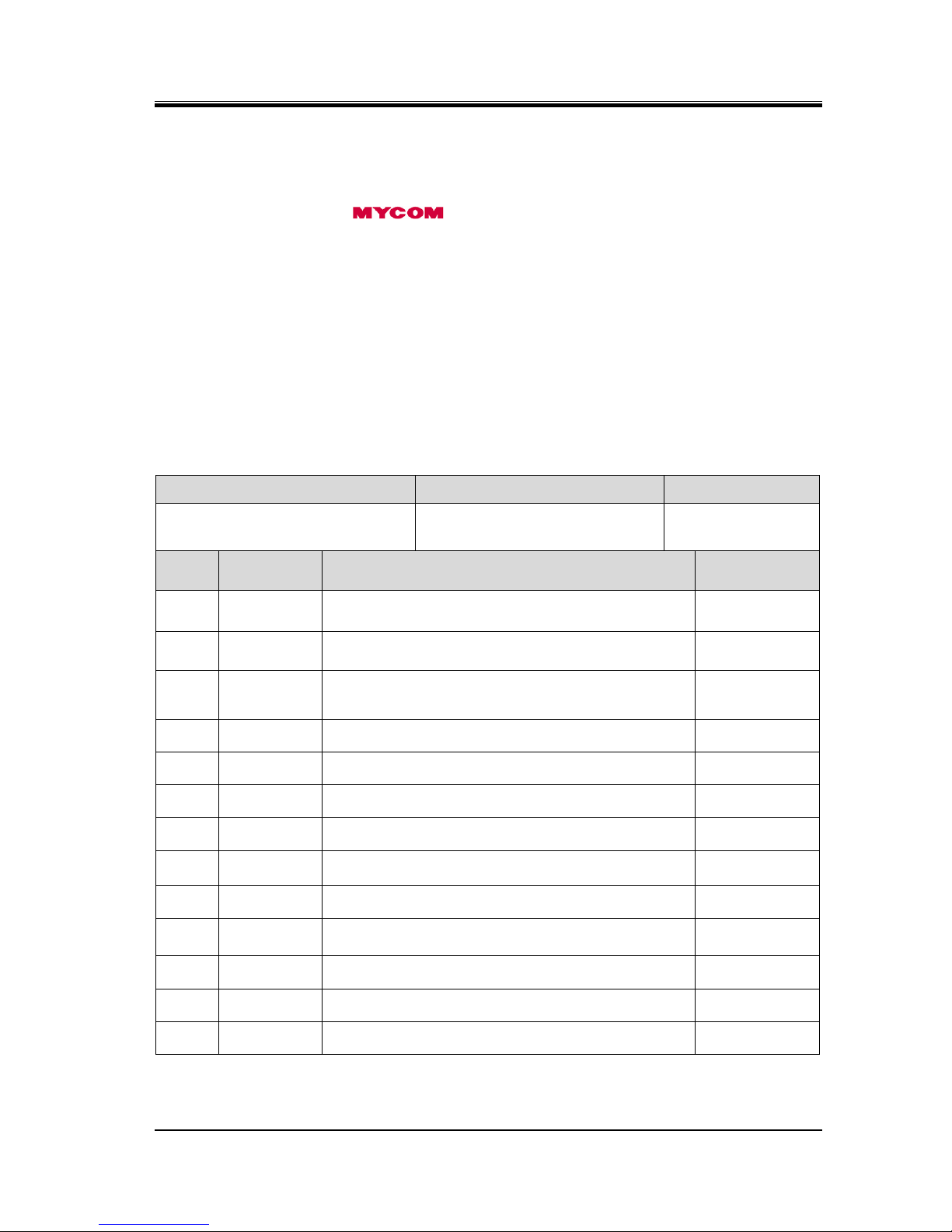

Title Document No. First edition issue date

i-Series Screw Compressor

Instruction manual

2203M4JE-MY-iS2-N_2017.04.

April 28, 2014

Revision

No.

Issue Date Major contents of revisions

Created

/ approved by:

00 April 28, 2014

Newly is

sued as applicable to the product after May

2014, due to modification of the i-series specifications.

Muta

/ Ikeda, Hirao

01 Sep. 24, 2014 Added models for IEC motor flange specifications.

Amanuma, Kato /

Ikeda, Hirao

02

June 01, 2015

Modified the constitution of Chapter 4 and Chapter 5.

Added the basic multi-packaging points using plural

i-sereis compressors.

Kitahara,

Fujimoto / Ikeda

03

April 30, 2017

Corrected 2.3.1 Standard Specifications, 2.4.3 Parts

Configuration Table . Deleted Contact Information.

Takenouchi,

Ito / Kato

2203M4JE-MY-iS2-N_2017.04.

Warranty and Disclaimer

Screw Compressor i-series

ii

Warranty and Disclaimer

Warranty Clauses

MAYEKAWA shall repair or replace parts of this product for no charge if any failure resulting from

defects in design or m anufacture occurs, und er normal use with th e purpose and method t hat are in

accordance with the specifications of this product and this manual, within the warranty period.

The warranty period is "12 months from factory shipment of this product". If there is a separate

agreement, that agreement shall prevail in principle.

MAYEKAWA is not liable for production or m an-made disaster compensation due to malfunction or

damage of this product.

Disclaimer of Warranty

Although MAYEKAWA warrants the clauses mentioned above, the following clauses are exempted.

Malfunction or damage of this product caused b y natural disaster, or other accidental forces

(such as fire, thunderbolt, windstorm, intense rainfall, flood, tidal wave, earthquake, land

subsidence, etc.).

Malfunction or damage caused by misusage described below.

• Malfunctions, damage, or deteri oration of this product due to abn ormal or improper use

(including improperly storing this product outdoors or under too hot/humid conditions,

unexpected inspections , tests, operations, too frequent liquid flow-back operation*, and

too frequent start-stop cycles, etc.).

• Malfunction or damage c aused by devices or equipm ents not provided by MAYEKAWA

including operation control methods of those devices.

• Malfunction or damage c aused by refrigerants, gases, or refr igerant oils, and operating

conditions (design conditions) not approved for this product.

• Malfunction or damage caused by maintenance or inspection not recommended by

MAYEKAWA.

• Malfunction or damage caused by parts that are not

genuine.

• Malfunction or damage caused by remodeling the product without approval of

MAYEKAWA.

• Malfunction or damage caused by unexpected misusage

"Liquid flow-back operation" is ・・・

Normally, while the compressor suc ks in the refrigerant liquid only after vaporizing it in th e

evaporator, it may directly sucks it in because of the faulty adjustment or failure of the

expansion valve. We call this state of compressor operation "liquid flow-back operation".

No compressor can compress a liquid. The compressor may be damaged should the liquid be

sucked in.

2203M4JE-MY-iS2-N_2017.04.

Important Information

Screw Compressor i-series

iii

Important Information

Intended Use of this Product

This product is a general-p ur pose s c rew compressor for refrigeratio n and c o ld sto r age. Do not use this

product for any other purpos es that are not intended for or which depart f rom the specifications. For

specifications of this product, refer to "2.3 Compressor Specifications".

Please perform the maintenance items described in this manual by using safe and assured procedures.

Important Information for Safe Use of this Product

Although MAYEKAWA has paid a lot of attention to safety measures for this product, all hazards

including potential ha zards caused by human errors, or due to environmental cond itions can not be

anticipated.

As there are too many items to be strictly observed or prohibited when using this product, it is

impossible to inform all of them through t his m anual or war ning lab els. Theref ore, when operat ing this

product, pay extreme caution on personnel safety as well as on items described in this manual.

Important rules for safety work with this product that apply to all workers including managers and

supervisors are listed below.

Please read this manual b efore using this product. Fully understand the instructions provided there,

and be sure to perform the safety procedures described in this manual.

Operation, maintenance, and inspection of this product should be performed by qualified

personnel educated about the fundamentals of this product and trained about hazards

involved and measures to avoid danger.

Do not allow any person other than those educated on the fundamental expertise of this

product and trained about hazards invol ved and m eas ures to avoid dangers to ap proach this

product while it is operating or during maintenance.

Observe all related federal/national and local codes and regulations.

To prevent accidents, do not carry out any operation or maintenance other than those

described in this manual. Do not use this product for any purpose other than intended.

Replace the parts with the

genuine parts.

Not only workers but also m anagers should acti vely participate saf ety and health activities in

the workplace to prevent accidents.

When closing or opening a valve during work , make sure to apply lock out/tagout to prevent

the valve from being accidentally closed or opened during the work.

[Lockout] To lock with a key in order to keep people, except the workers involved, from

operating the product.

“Lockout” m eans disc onnec ting or k eepi ng disc onnec ted m ac hines and d evices b y lock ing their

energy (po wer) sources. Lockout is not just simpl y turning off the power switches to stop the

supply of power, but includes immobilizing them with a key or similar device to keep any blocked

switches from being operated.

Lockout devices are devices such as keys, covers, and latches, to immobilize switches, valves,

opening and closing levers, etc., with a state of being locked.

2203M4JE-MY-iS2-N_2017.04.

Important Information

Screw Compressor i-series

iv

[Tagout] To prevent any inappropriate work by hanging tag plates indicating "work in

progress".

“Tagout” means to clearly indicate, by hanging tag plates, that a device is in lockout and that

operation of the device is prohibited. Tag plates forbidding operation, starting, opening, etc. are

warnings clearl y stating to not operate energ y (power) sources, and ar e not for stopping block ing

devices.

Observe the following precautions when performing maintenance work on electrical control.

Electrical maintenanc e of the pr oduct m ust be perform ed by certif ied/qual ified p ersonnel a nd

only those educated about the electrical control of the product.

Before servicing or insp ecti ng the el ectrical equipm ent or devices , turn "OFF" th e m otor main

power and control power, and perform lock out/tagout to prev ent the power from bein g turned

on during work.

Even when the motor main power and control power are turned "OFF", this product may be turned on if

the power is supplied from outside the package unit in which this product is used. Make sure the power

supply on the power source sid e is shut off, and perform lock out/tagout to prevent the product from

being turned on during work.

About This Manual

This product may be modified without prior notice. Therefore, the appearance of actual

machine may differ fr om the descriptions in th is manual. If you have any questions, contact

our sales offices or service centers. F or each sight of MAYEKAWA, refer to following URL.

http://www.mayekawa.com/about/network/

This manual is in English. I f an y other lan guage is requ ired, it is th e customers’ responsibility

to prepare a manual for safety education and operation instructions.

This manual is copyrighted. Drawings and technical references including this manual shall not,

in whole or part, be copied, photocopied, or reproduced into any electronic medium or

machine-readable form without prior permission from MAYEKAWA.

Photographs or drawings i ncluded in this manual may differ from the appear ance of actual

product.

If this manual is lost or dam aged, immediately request to one of our local sales offices or

service centers for a new m anual. Us ing this pr oduct without the m anual m ay res ult in saf ety

issues.

When you resell this product, be sure to transfer this manual to the next owner.

2203M4JE-MY-iS2-N_2017.04.

Important Information

Screw Compressor i-series

v

Structure of This Manual

Chapter/Section Title Description

Preface Describes the outline of this manual and how to read this manual.

Warranty and Disclaimer

Describes what MAYEKAWA warrants and what

are covered by the

warranties.

Warranty exemption is stated as disclaimer.

Important Information Describes important information related to this product and this manual.

1. Safety

Describes safety information for the worker, safety rules for this product,

and management details regar ding the work safety that is r equired for

handling this product.

2. Compressor

Specifications and

Configuration

Describes the main com ponents of this product, func tional

information,

specification, operating limits, drawings, and parts list.

3. Installation Describes the installation procedure of this product.

4. Compressor and Package

Unit Operation

Describes the precautions for operating this product

and the package

unit..

5. Maintenance and

Inspection

Describes sections and period for inspecting, and assembly and

disassembly of this product.

6. Troubleshooting

Describes troubl

eshooting methods for this product in case problems

occur during operation of this product.

7. Related Documents List of disassembly tools for i-series compressor, and other information

Appendix 1 :

Packaging Points 1

Describes basic points for the design and manufacture of a i-

series

compressor package unit.

Appendix 2:

Packaging Points 2

Describes basic multi-packaging points using plural i-sereis

compressors.

2203M4JE-MY-iS2-N_2017.04.

Table of Contents

Screw Compressor i-series

vi

Table of Contents

Preface .................................................................................................................. ⅰ

Revision History ................................................................................................... ⅰ

Warranty and Disclaimer ...................................................................................... ⅱ

Important Information .......................................................................................... ⅲ

Intended Use of This Product ........................................................................................... ⅲ

Important Information for Safe Use of This Product .......................................................... ⅲ

About This Manual ............................................................................................................. ⅳ

Structure of This Manual .................................................................................................... ⅴ

Table of Contents ................................................................................................. ⅵ

1 Safety

1.1 Strict Requirements and Prohibitions ....................................................... 1-1

1.1.1 Strict Requirements (Do's) ................................................................................... 1-1

1.1.1.1 Do's on Operation ........................................................................................ 1-1

1.1.1.2 Do's on Maintenance ................................................................................... 1-1

1.1.1.3 Do's on Lockout/Tagout after Shutting Off the Power ................................. 1-2

1.1.1.4 Do's about Personal Protective Gear .......................................................... 1-2

1.1.1.5 Do's about the Handling of Hazardous and Toxic Substances.................... 1-2

1.1.1.6 Do's about Handling Emergency Situations ................................................ 1-2

1.1.1.7 Do's about Waste Oil, Fluid, and Materials ................................................. 1-2

1.1.1.8 Other Do's .................................................................................................... 1-2

1.1.2 Prohibitions (Don'ts) ............................................................................................ 1-3

1.2 Warnings ..................................................................................................... 1-3

1.3 Residual Risks ............................................................................................ 1-4

1.4 Safety Devices ............................................................................................ 1-6

1.4.1 Emergency Stop Button ....................................................................................... 1-6

1.4.2 Circuit Breakers of Motor Main Power and Control Power

(with Lockout/Tagout Mechanism) ....................................................................... 1-6

1.4.3 Compressor Protective Devices ................................................................ 1-7

Chapter 2 Compressor Specifications and Configuration

2.1 Features of

i-Series Compressor ........................................ 2-1

2.2 Model Designation of the Compressor ..................................................... 2-1

2.3 Compressor Specifications ....................................................................... 2-2

2.3.1 Standard Specifications ....................................................................................... 2-2

2.3.2 Operation limits .................................................................................................... 2-3

2203M4JE-MY-iS2-N_2017.04.

Table of Contents

Screw Compressor i-series

vii

2.3.3 Alarm Set Values ................................................................................................. 2-4

2.3.4 Outer Dimensions ................................................................................................ 2-5

2.4 Configuration of Compressor .................................................................. 2-18

2.4.1 Secti ona l Vie ws ................................................................................................. 2-18

2.4.2 Exploded Views ................................................................................................. 2-24

2.4.3 Parts Configuration Table .................................................................................. 2-26

2.5 Mechanisms .............................................................................................. 2-33

2.5.1 Basics of the Screw Compressor ...................................................................... 2-33

2.5.2 Sucti on Pr oces s ................................................................................................. 2-33

2.5.3 Compression Process ........................................................................................ 2-34

2.5.4 Disc har ge Proc es s ............................................................................................. 2-34

2.5.5 About Volume Ratio (Vi) .................................................................................... 2-34

2.5.6 Capac ity Control Mechanism ............................................................................. 2-36

Chapter 3 Installation

3.1 General Precautions for Installation ......................................................... 3-1

3.2 Installation Works....................................................................................... 3-1

3.2.1 Unpacking ............................................................................................................ 3-1

3.2.2 Storage ................................................................................................................ 3-1

3.2.3 Transportation ...................................................................................................... 3-1

3.2.4 Preparation for Installation ................................................................................... 3-3

3.2.5 Installation ............................................................................................................ 3-3

3.2.5.1 Piping Connection ....................................................................................... 3-3

3.2.5.2 Equipment and Devices for Protection of the Compressor ......................... 3-4

3.2.6 Airtightness Test .................................................................................................. 3-4

3.2.7 Lubricating Oil Charge ......................................................................................... 3-4

3.2.7.1 Initial Charge of Lubricating OIL .................................................................. 3-5

3.2.7.2 Additional Charge of Lubricating Oil ............................................................ 3-5

3.2.8 Charge of Refrigerant .......................................................................................... 3-5

3.2.9 Check after Installation ........................................................................................ 3-5

Chapter 4 Compressor and Package Unit Operation

4.1 Lubricating Oil (Refrigerant Oil) ................................................................ 4-1

4.1.1 Precautions for Selecting the Lubricating Oil....................................................... 4-1

4.1.2 Recommended Lubricating O ils .......................................................................... 4-2

4.1.2.1 Recommended Lubricating Oils for Ammonia Refrigerant .......................... 4-2

4.1.2.2 Oils for Systems Using Hydrofluorocarbon (HFC) Refrigerants .................. 4-3

4.1.3 Change of Lubricating Oil Brand ......................................................................... 4-3

4.1.4 Precautions for Handling Lubricating Oil ............................................................. 4-4

4.1.5 Lubricating Oil Management Criteria ................................................................... 4-4

4.1.6 Lubricating Oil Replacement Timing .................................................................... 4-5

2203M4JE-MY-iS2-N_2017.04.

Table of Contents

Screw Compressor i-series

viii

4.1.6.1 After Starting the Initial Operation .............................................................. 4-5

4.1.6.2 During Normal Operation ........................................................................... 4-5

4.2 Precautions for Operation ......................................................................... 4-6

4.2.1 Prevention of Liquid Flow-back ........................................................................... 4-6

4.2.2 Purging of Non-Condensable Gases ................................................................... 4-6

4.3 When Stopping the Compressor for a Long Time .................................... 4-7

Chapter 5 Maintenance and Inspection

5.1 Precautions for Maintenance and Inspection ........................................... 5-1

5.2 Maintenance and Inspection List .............................................................. 5-3

5.2.1 Dai l y Management ............................................................................................... 5-3

5.2.2 Periodic Inspection .............................................................................................. 5-5

5.2.3 Guidelines for Compressor Overhaul Interval ..................................................... 5-6

5.3 Compressor Disassembly Preparation ..................................................... 5-7

5.3.1 Disassembly Tools and Work Place .................................................................... 5-7

5.3.2 Replacement Parts .............................................................................................. 5-8

5.3.3 Refrigerant Gas Treatment ................................................................................ 5-10

5.3.3.1 Valves Used ............................................................................................... 5-10

5.3.3.2 Refrigerant Gas Recovery ......................................................................... 5-10

5.3.4 Removing Parts Connected to the Unit ............................................................. 5-11

5.3.5 Removing and Lifting the Compressor .............................................................. 5-11

5.3.6 Removing Oil from Compressor ........................................................................ 5-11

5.4 Disassembly and Inspection ................................................................... 5-12

5.4.1 Shaft Seal Block ................................................................................................ 5-12

5.4.1.1 Disassembly .............................................................................................. 5-12

5.4.1.2 Inspection .................................................................................................. 5-13

5.4.2 Bear ing Co ver .................................................................................................... 5-14

5.4.2.1 Disassembly .............................................................................................. 5-14

5.4.2.2 Inspection ................................................................................................... 5-14

5.4.3 Balanc e Pist on ................................................................................................... 5-15

5.4.3.1 Disassembly .............................................................................................. 5-15

5.4.3.2 Inspection .................................................................................................. 5-15

5.4.4 End Cover .......................................................................................................... 5-15

5.4.5 Thrust Bearing Block ......................................................................................... 5-16

5.4.5.1 Disassembly .............................................................................................. 5-16

5.4.5.2 Inspection .................................................................................................. 5-16

5.4.6 Bear ing Hea d ..................................................................................................... 5-17

5.4.6.1 Disassembly .............................................................................................. 5-17

5.4.6.2 Inspection .................................................................................................. 5-17

5.4.7 Rotors ................................................................................................................ 5-17

5.4.7.1 Disassembly .............................................................................................. 5-17

5.4.7.2 Inspection .................................................................................................. 5-17

5.4.8 Radial Be ar ings ................................................................................................. 5-18

5.4.8.1 Disassembly .............................................................................................. 5-18

2203M4JE-MY-iS2-N_2017.04.

Table of Contents

Screw Compressor i-series

ix

5.4.8.2 Inspection .................................................................................................. 5-18

5.4.9 Sucti on Str ai ner and Check Valve ..................................................................... 5-18

5.4.9.1a Disassembly (i125*) ................................................................................... 5-18

5.4.9.1b Disassembly (i160*) ................................................................................... 5-18

5.4.9.2 Inspection .................................................................................................. 5-19

5.4.10 Unloader ............................................................................................................ 5-19

5.4.10.1 Disassembly .............................................................................................. 5-19

5.4.10.2 Inspection .................................................................................................. 5-19

5.5 Reassembly .............................................................................................. 5-20

5.5.1 Unloader ............................................................................................................ 5-21

5.5.2 Rotor and Inner Race of Radial Bearing ............................................................ 5-21

5.5.3 Bear ing Hea d ..................................................................................................... 5-22

5.5.4 Outer Race of Radial Bearing ............................................................................ 5-22

5.5.5 Suction Strainer and Check Valve ..................................................................... 5-23

5.5.5.1 i125*........................................................................................................... 5-23

5.5.5.2 i160*........................................................................................................... 5-23

5.5.6 Adjustment of Thrust Bearing and End Clearance ............................................ 5-24

5.5.6.1 End Clearance Measurement .................................................................... 5-26

5.5.6.2 End Clearance Adjustment ........................................................................ 5-27

5.5.6.3 Tightening after End Clearance Adjustment .............................................. 5-27

5.5.7 Balanc e Pist on ................................................................................................... 5-28

5.5.8 Bear ing Co ver .................................................................................................... 5-28

5.5.9 Shaft Seal Block ................................................................................................ 5-29

5.5.10 End Cover .......................................................................................................... 5-31

Chapter 6 Troubleshooting

01: Compressor does not start up ................................................................................ 6-1

02: Compressor stops immediately after startup .......................................................... 6-1

03: Abnormally low pressure (decrease of suction pressure) ...................................... 6-2

04: Low oil pressure (low oil supply pressure) ............................................................. 6-2

05: Abnormally high pressure (abnormal discharge pressure) .................................... 6-3

06: Discharge temperature is abnormally high ............................................................. 6-4

07: Leak from mechanical seal part ............................................................................. 6-6

08: Squeaking sound from mechanical seal ................................................................ 6-6

09: Capacity control malfunction .................................................................................. 6-6

10: Compressor generates abnormal vibration and/or sound ...................................... 6-6

2203M4JE-MY-iS2-N_2017.04.

Table of Contents

Screw Compressor i-series

x

Chapter 7 Related Documents

7.1 Tightening Angles for Lock Nuts .............................................................. 7-1

7.2 Disassembly Tools ..................................................................................... 7-2

7.3 Flange Motor and Connection Flange Size ............................................. 7-3

Appendix 1: Basic Points for Design and Manufacturing for the

Compressor Package

1-1 Basic Flow of the Package Unit ........................................................... Appendix 1-1

1-2 Basic Flow of the Oil Cooler ................................................................ Appendix 1-2

1-3 Oil Temperature Control ...................................................................... Appendix 1-3

1-4 Economizer .......................................................................................... Appendix 1-3

1-5 Oil Separator ....................................................................................... Appendix 1-4

1-6 Protection Devices ............................................................................... Appendix 1-4

1-7 Power Supply and Control Devices ..................................................... Appendix 1-5

Appendix 2: Basic Points for Design and Manufacturing for the

Compressors Multi-package

2-1 Preface ................................................................................................ Appendix 2-1

2-2 Reference Flow and Configuration Components for Multi-package ... Appendix 2-1

2-2-1 Package Flow Representative Example ......................................... Appendix 2-1

2-2-2 Oil Separator ................................................................................... Appendix 2-2

2-2-3 Pressure Regulator for Differential Oil Supply Press ure ............... Appendix 2-2

2-2-4 Oil Cooler ........................................................................................ Appendix 2-2

2-2-5 Oil Filter and Oil Line ....................................................................... Appendix 2-2

2-2-6 Stop Valves and Safety Valves ....................................................... Appendix 2-2

2-3 Economizer .......................................................................................... Appendix 2-3

2-4 Protection Devices and Control Devicess ........................................... Appendix 2-3

2203M4JE-MY-iS2-N_2017.04.

Chapter 1 Safety

Screw Compressor i-series 1.1 Strict Requirements and Prohibitions

1-1

Chapter 1 Safety

1.1 Strict Requirements and Prohibitions

1.1.1 Strict Requirements (Do’s)

1.1.1.1 Do’s on Operation

Make sure to attach safety and protective devices to the package unit.

The safety devices and protection systems must be regularly checked for their normal

operation.

If any safety device or protection system does not function normally or this product operates in

an abnormal manner, immediately stop the work and contact your supervisor. When the

system is to be restarted, you must observe the decision and instruction of the supervisor.

If this product has stopped operation due to an unknown cause, immediately contact your

supervisor. Before restarting the system , you must seek the decision and instruction of the

supervisor.

Depending on the type of refrigerant used, its leakage may generate a bad smell or poisonous

gas. Be sure to sufficiently ventilate the room while the machine is operated.

Regarding the characteristics of the refrigerant and lubricating oil, e.g., corrosiveness,

degradability, and toxicity, be sure to obtain the Safety Data Sheet (SDS) of the m and follow

the instructions given.

When this produc t is not to be used for some peri od of time, close the suction (side) and

discharge (side) stop valves and shut off the m otor power source, heat er power, and control

power.

1.1.1.2 Do’s on Maintenance

Prepare work procedures based on a work plan. Be sure to perform danger forecasting before

starting the work.

If two or more peo ple are to work together, be sure to mutuall y check the work details and

procedures before the work. During the work, always keep track of the other workers’ actions.

Before working on any troubleshooting during operation, before setting up this product, before

cleaning work, and before conducting maintenance or inspec ti on wor k, be sure to shut off the

motor power source, control power, and power to other equipment, perform lock-out and

tag-out procedur es, and take effective measures to p revent any accidental power -on during

the work.

Before working on any troubleshooting during operation, before setting up this product, before

cleaning work, and bef ore conducting m aintenance or inspection work, be sure t o check that

the internal pressure of this product and the refrigeration/cold storage unit is at the

atmospheric pressure.

Depending on the t ype of refrigerant used, it ma y generate a bad smell or poiso nous gas or

could cause an oxygen deficient atmosphere. Before starting the work , measure the ox ygen

content in the work area, as appropriate, and provide sufficient ventilation. The ventilation

must be continued steadily until the work is completed.

For the properties of refrigerant and lubricating oil (corrosiveness, decomposability or toxicity),

be sure to obtain the Safety Data Sheet (SDS) and follow the relevant information.

After work, the tools us ed must be returned to the predefined locat ion. Be sure not to leave

them inside the package unit.

2203M4JE-MY-iS2-N_2017.04.

Chapter 1 Safety

Screw Compressor i-series 1.1 Strict Requirements and Prohibitions

1-2

1.1.1.3 Do’s on Lockout/Tagout afte r Shutting Off the Power

A lock-out/tag-out mechanism must be installed for the main circuit breakers that supply power

to the motor and po wer to the control system . T he lock-out/tag-out after power do w n is a v er y

effective means to ensur e t he s af et y wh en two or more work ers ar e work ing on t he system at

the same time, as it can prevent p ossible i njury of workers t hat ma y be caused b y accidenta l

power-on of the driving source by one of the workers.

If there is a risk of danger, especially during cleaning, maintenance/inspection, or

troubleshooting work , be sure to l et the work ers per form the lock -out/tag-out pr ocedures after

the motor main power and control power has been shut off.

Because the workers m ay neglect to perform the lock-out/tag-out proced ures or cut-off the

power in the following situations, be sure to instruct them to strictly follow the correct

procedure by clearly identifying the work that require lock-out/tag-out and the reasons why it is

needed.

• As it is a cumbers ome task for the workers to cut off the motor m ain power and control

power and use lock -out/tag-out devices before starting the w ork , they m ight negl ec t to do

it.

• The workers m ight determ ine by th em selves th at it sh ould b e OK j ust to c ut off th e m otor

main power and control power, and not use any lock-out/tag-out devices.

1.1.1.4 Do’s about Personal Protective Gear

Prepare and use protective gear com pl ying wit h the safety standards of the regulations.

Check the function of each protective gear before using.

Wear designated clothes such as work outfits, with their cuffs tightly closed.

Do not wear an y neck ties or jewelry as there is a ris k of being entangled by a movable part or

rotating part. Put on a helmet as your hair may get entangled.

Do not have anything in your pocket to prevent objects from falling into the machine.

1.1.1.5 Do’s about Handling of Hazardous and Toxic Substances

Obtain Safety Data Sheet (SDS) from manufacturers of hazardous and toxic substances.

Check the MSDS and fol low the han dling instr uctions recomm ended b y the manuf acturers to

handle and store those substances.

1.1.1.6 Do’s about Handling Emergency Situations

Formulate an emer gency action plan complying with the regulatio ns, and post it on a safe

place.

1.1.1.7 Do’s about Waste Oil, Fluid, and Materials

Disposing of refrigerant and oil used for this product are subject to a number of regulations for

the environmental protecti on purposes. Follow the local, state, federal acts and regula tions

and your company's rules when disposing of such waste oil, fluid and materials.

1.1.1.8 Other Do’s

Keep clean the floor around the entire package unit. Provide a safety passage.

Walk only on the areas set up as a work f loor. Also, do not lea ve too ls and c lea ning sol utions

in that area.

If water or oil is spi lled on this pr oduct or the f loor, immediately wipe it off to pr event work ers

from slipping and getting injured.

2203M4JE-MY-iS2-N_2017.04.

Chapter 1 Safety

Screw Compressor i-series 1.2 Warnings

1-3

1.1.2 Prohibitions (Don’ts)

Do not remove or relocate any safety device, including electrical interfaces.

Do not disable any safety device by short-c irc ui tin g or bypassing with out any permission.

Do not leave this pro duct unsafe and unattended, b y removing a safet y cover or some other

measures.

Do not touch, clean or lubricate any part of this product which is moving.

Do not touch rela ys or electr ic systems such as terminal b lock with bare hands when t urning

on the power.

1.2 Warnings

The warning messages described in this manual warn dangerous situations that may arise during work

by using the following four categories.

Neglecting such warnings may cause accidents, resulting in personal injury or even death.

Also, this product or its auxili ary equipment may be heavily damaged. T herefore, be sure to always

observe the instructions of the warnings.

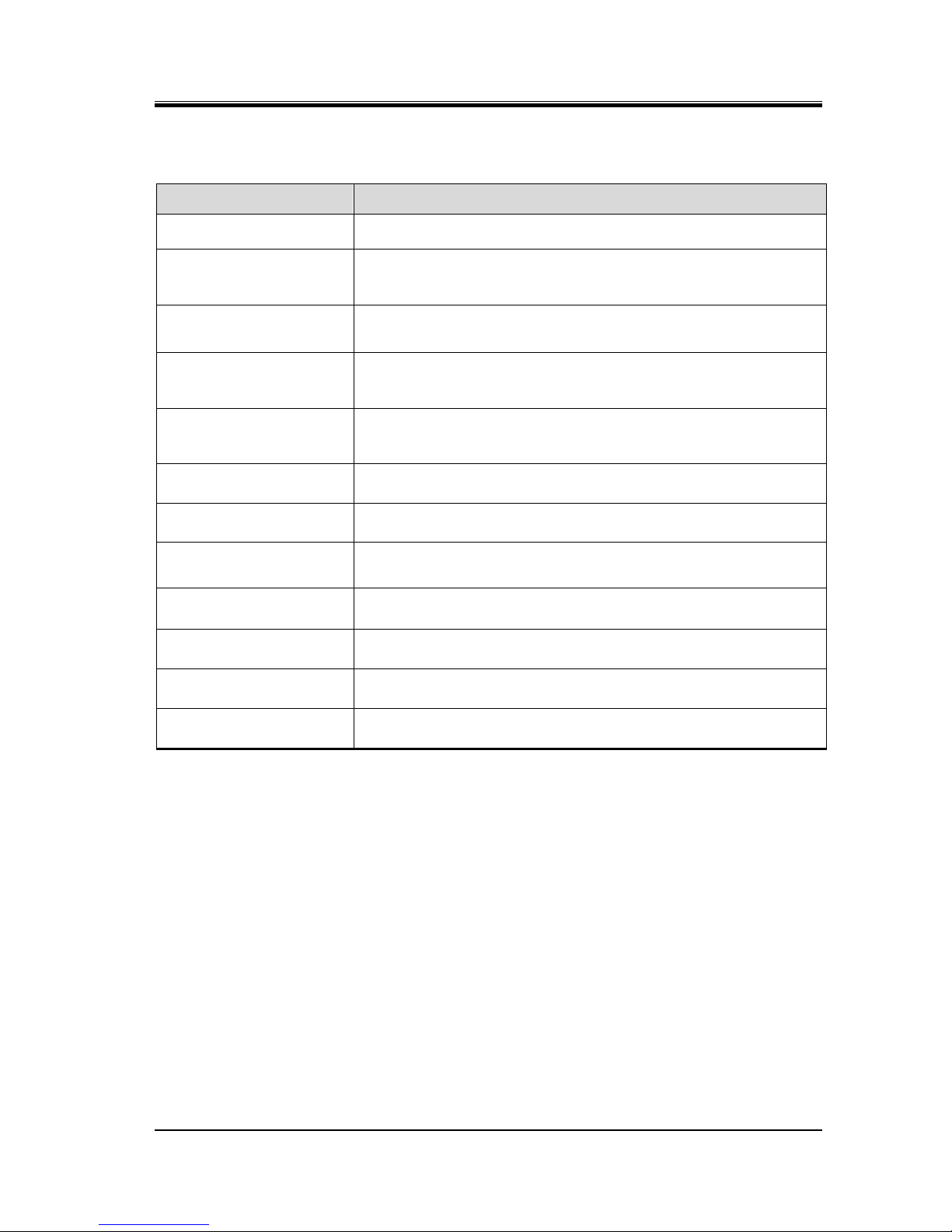

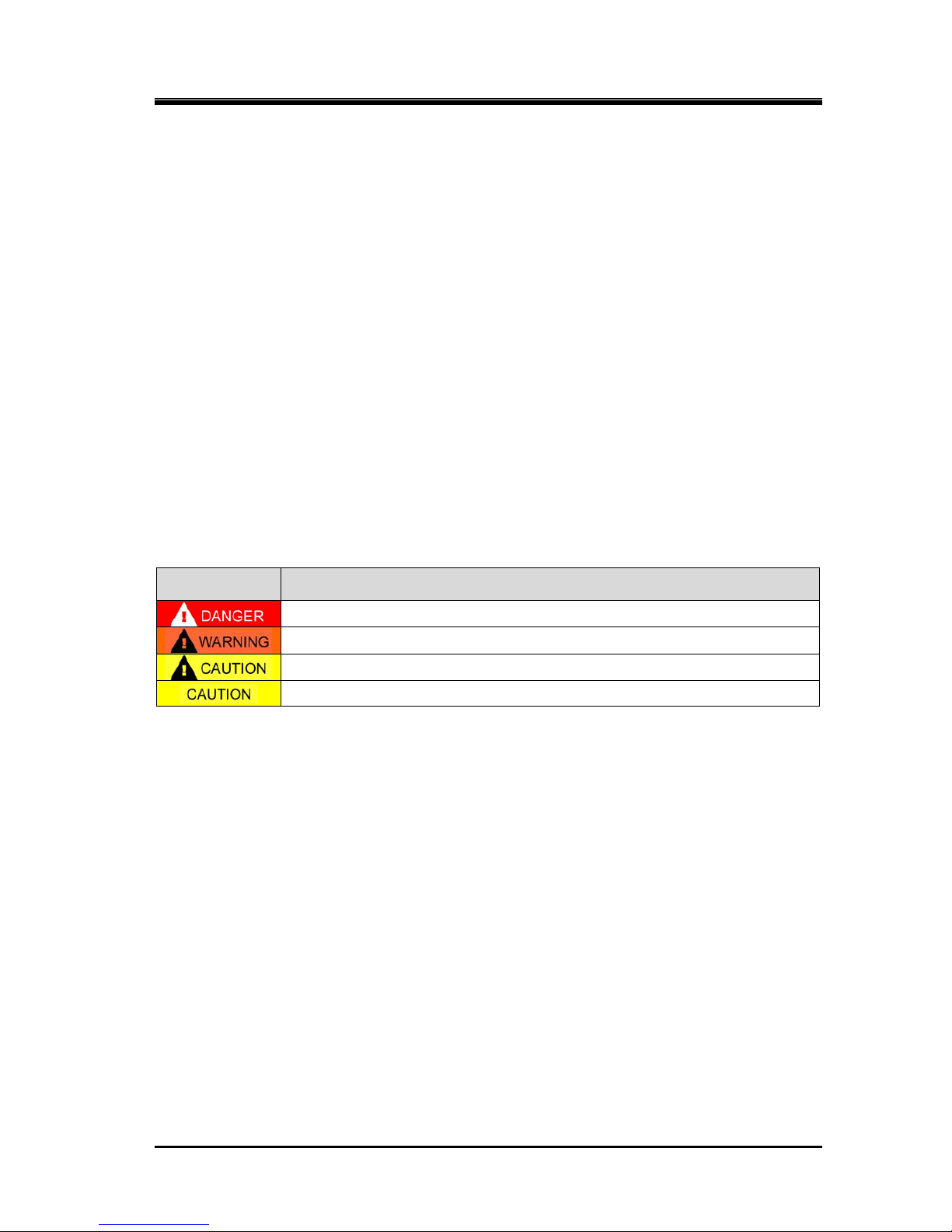

Table 1-1

Types and Meanings of Warnings

Symbol Meaning

Indicates that there is a high risk of death or severe injury if it is not avoided.

Indicates that there is a potential risk of death or severe injury if it is not avoided.

Indicates that there is a risk of light or medium injury if it is not avoided.

Indicates that there is a potential risk of property damage if it is not avoided.

2203M4JE-MY-iS2-N_2017.04.

Chapter 1 Safety

Screw Compressor i-series 1.3 Residual Risks

1-4

1.3 Residual Risks

The following inform ation assumes that this pr oduct is operated or i nspected/maintained as part of a

general package unit for refrigeration/cold storage. It is impossible to predict all the risk sources

involved in actual use of the package unit.

Devise appropriate countermeasures for hazardous sources in your systems.

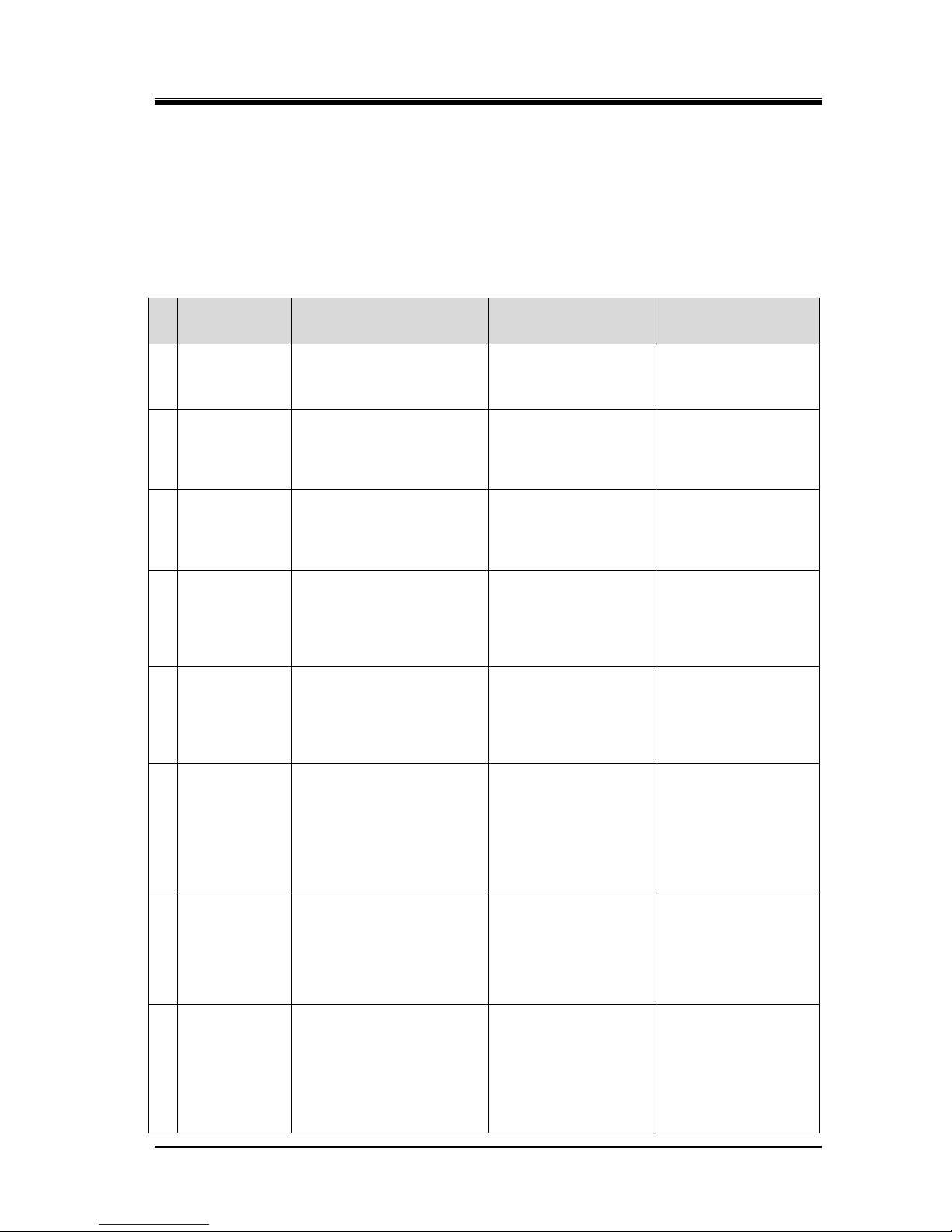

Table 1-2

Hazardous Sources

Hazardous

sources

Predicted hazard

Measures to be taken

in operation

Countermeasures in

cleaning, inspection,

and parts replacement

A

Motor and

compressor

coupling

Caught in or entangled in

due to contact

Install cover on the

opening of coupling,

or prohibit opening.

Keep away.

Turn off motor main

power and control

power, and conduct

lockout/tagout.

B

Motor

terminals

Electric shock caused by

contact with live wires or

electrical leakage

Keep away.

Do not open terminal

boxes.

Do not touch

terminal boxes.

Turn off motor main

power and control

power, and conduct

lockout/tagout.

C

Compressor

suction casing

Frostbite due to contact

Contact with or inhalation

of hazardous substances

generated by leakage of

refrigerant or the like

Keep away and do

not touch.

Wear protective

gear.

Detect gas leakage.

Wear protective

gear.

Work under room

temperature.

D

Compressor

economizer

and/or liquid

injection port

around and

piping

Burn injury due to contact

Contact with or inhalation

of hazardous substances

generated by leakage or

spout of refrigerant or the

like

Keep away and do

not touch.

Wear protective

gear.

Detect gas leakage.

Wear protective

gear.

Work at a

temperature of not

higher than 40°C.

E

Compressor

discharge

casing and

discharge

piping

Burn injury due to contact

Contact with or inhalation

of hazardous substances

generated by leakage or

spout of refrigerant or the

like

Keep away and do

not touch.

Wear protective

gear.

Detect gas leakage.

Wear protective

gear.

Work at a

temperature of not

higher than 40°C.

F

Solenoid valve

for controlling

compressor

capacity

Electric shock caused by

contact with live wires or

electrical leakage

Install protective

cover on terminals,

and prohibit

opening.

Keep away and do

not touch.

Wear protective

gear.

Turn off each

breaker and the

control power, and

conduct

lockout/tagout.

Wear protective

gear.

G

Package Unit

Check valve,

service valve

and joint in

each section

Contact with or inhalation

of hazardous substances

generated by mishandling

or leakage

Frostbite or burn due to

contact

Sufficient ventilation

Indicate valve

open/close state.

Keep away and do

not touch.

Wear protective

gear.

Sufficient ventilation

Wear protective

gear.

Tagout for controlled

valve

H

Package Unit

Solenoid valve

or motor

operated

valve

Electric shock caused by

contact with live wires or

electrical leakage

Pinched due to contact

with driving part

Install protective

cover on terminals,

and prohibit

opening.

Keep away and do

not touch.

Wear protective

gear.

Turn off each

breaker and the

control power, and

conduct

lockout/tagout.

Wear protective

gear.

2203M4JE-MY-iS2-N_2017.04.

Chapter 1 Safety

Screw Compressor i-series 1.3 Residual Risks

1-5

Hazardous

sources

Predicted hazard

Measures to be taken

in operation

Countermeasures in

cleaning, inspection,

and parts replacement

I

Package Unit

Electric

components in

each part (oil

heater,

protective

device, etc.)

Electric shock caused by

contact with live wires or

electrical leakage

Pinched due to contact

with driving part

Install protective

cover on terminals,

and prohibit

opening.

Keep away and do

not touch.

Wear protective

gear.

Turn off each

breaker and the

control power, and

conduct

lockout/tagout.

Wear protective

gear.

J

Package Unit

Oil drain

Contact with hazardous

substances generated by

leakage or spout

Burn caused by contact

with high-temperature

fluid

Sufficient ventilation

Keep away and do

not touch.

Wear protective

gear.

Sufficient ventilation

Wear protective

gear.

Work at a

temperature of not

higher than 40°C.

K

Noises

Damage caused by noise

Wear protective

gear.

—

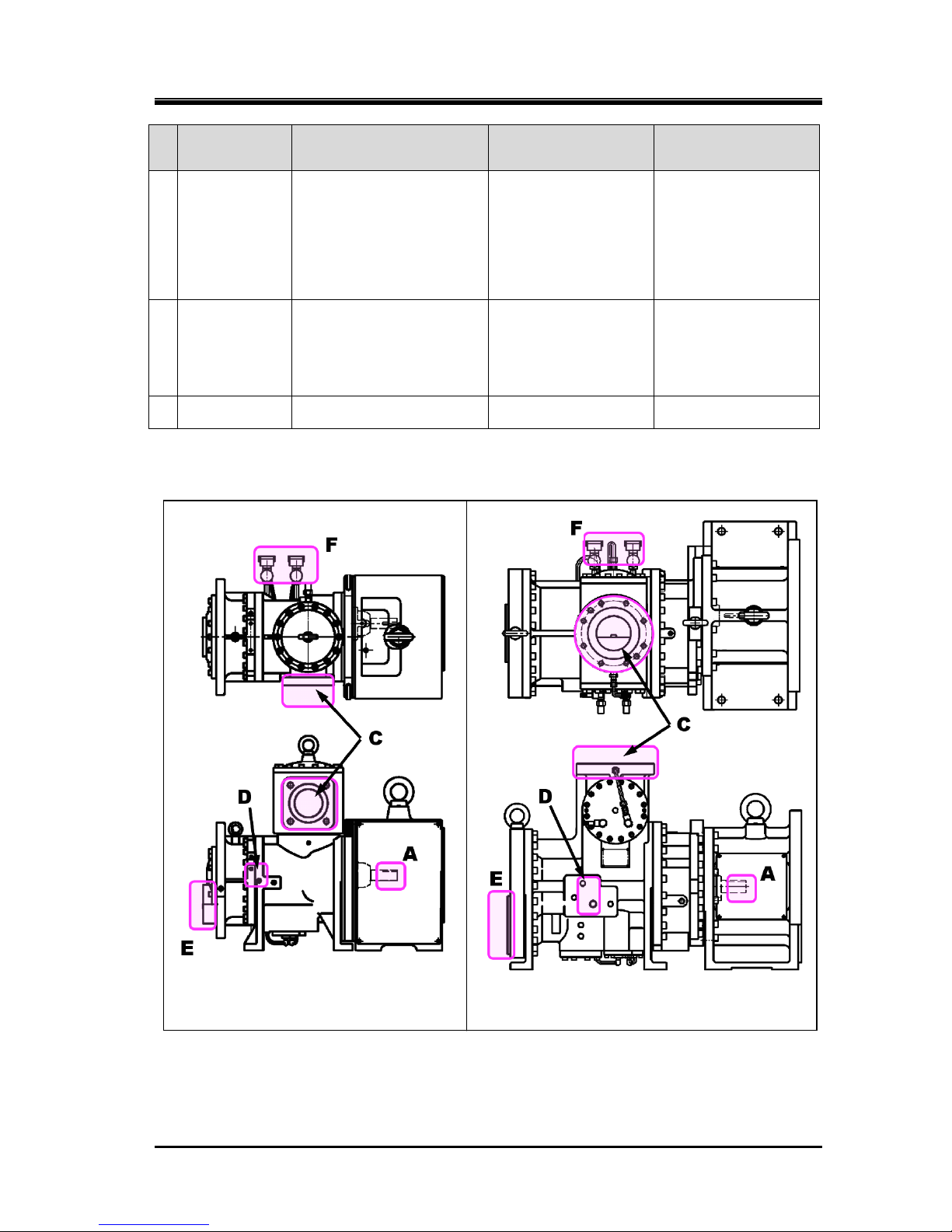

i125L with Spacer for NEMA i160L with Spacer for NEMA

(example) (example)

Figure 1-1 Locations of Hazardous sources (Compressor)

2203M4JE-MY-iS2-N_2017.04.

Chapter 1 Safety

Screw Compressor i-series 1.4 Safety Devices

1-6

1.4 Safety Devices

For safe use and protection of this produc t, make sure to attach safet y devices to this produc t in

accordance with the regulations and the following instructions.

Safety devices cannot be kept in normal condition unless inspected and maintained at regular

intervals. Their maintenance and inspection need to be performed as an important part of the

maintenance/inspectio n work project. Provide users of this product with necessary information on

the safety devices, for example, types of the safety devices, installation position, function, and

inspection method of safety related devices.

Check the safety devices after turning on the power and before operation of this

product. If they do not operat e normally, immediately take countermeasures.

1.4.1 Emergency Stop Button

Overview/Function/Purpose

The emergency stop buttons are used for emergency shutdown of this product when an emergency

situation arises.

Installation Positions

On the control board and in the operation control room

Stop/Restoration Methods

The operating procedures for the emergency stop button, i.e., how to stop the operation and

restore the normal operatin g c ondit io n, must be clearly defined and the inf ormation provided to the

user of this product.

Inspection Method/Interval

The emergency stop buttons mus t be tested befor e commissioning a nd must also be periodicall y

re-tested after that.

The inspection procedures and the inspection interval for the emergency stop button must be

clearly defined and the information provided to the user of this product

1.4.2 Circuit Breakers of Motor Main Power and Control Power

(with Lockout/Tagout Mechanism)

Overview/Function/Purpose

Turn off the main motor and control power, and if there is an y possibility of danger during work

(especially during cle aning, maintenance, inspection, or tr oubleshooting), lockout/tagout devices

must be used on the br eak ers of the m ain m otor and cont rol po wers t o prevent injuries to work ers

in case the power is turned on accidentally during work .

Methods of Performing and Releasing Lockout/Tagout

Make sure to clearly notify methods of performing and releasing lockout/tagout referring to the

regulations created by Occupational Safet y & Health Administration (OSHA) or local governing

body.

Inspection Method/Interval

The inspection procedures and the inspection interval for the lockout/tagout devices must be clearly

defined and the information provided to the user of this product.

2203M4JE-MY-iS2-N_2017.04.

Chapter 1 Safety

Screw Compressor i-series 1.4 Safety Devices

1-7

1.4.3 Compressor Protective Devices

Be sure to adjust the set values and check operation of the protective devices before

the commissioning.

Install necessary protection devices shown in section 2.3.3 "Alarm Set Values" in this manual chapter 2.

Also, install the following protection devices that are not indicate in section 2.3.3, as occasion

demands.

• Protection from motor over current (OCR)

This device activates an d applies appropr iate contro l when the c urrent e qual to or higher t han

the set level flows. In some cases, this device stops the compressor operation.

For more information about setting and installation of this device, please refer to the instruction

manual of the motor.

• Protection from oil level decrease

In case of the oi l supp ly by different ial pr essure, install a prot ection device to the oil separator

for protect form oil level decrease. Since there is a possibility that alarm for protection from

lubricating differential press ure decr ease do es not act ivat e even if the amount of lubricat ing oil

is insufficient.

• No Water Alarm

If you use water cooling oil cooler and/or water cooling condenser, a suspension of water

supply protection is necessary.

For more inform ation about setting and install ation of this protectio n d ev ice, pl eas e r ef er to the

instruction manual of the motor or the like used in the cooling water system.

Connection Positions and Settings

Specify the connection position and set ting f or e ach co m pressor protecti ve de vice, an d m ake s ure

to provide users of this product with them.

Inspection Method/Interval

Compressor protect ive devices require operat ion tests and co nfirmation of the settings c alibration

before commissioning as well as at regular intervals.

Specify the inspect ion methods/inter vals of the com pressor protect ion devices, and m ake sure to

provide users of this product with such information.

In the operation test, check that alarms and switches operate normally by using

devices such as pressure tester. Do not operate the compressor with all the valves

closed, or in any other dangerous conditions.

If the protection from oil pressure (OP) or high pressure (HP) activates, do not restar t

operation until the cause of activation is remove d.

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.1 Features of i-Series Compressor

2-1

Chapter 2 Compressor Specif i c a t ions and Configuration

2.1 Features of

i-series Compressor

i-series compressor enables designers to design highly reliable and most compact

refrigerating unit. It has a lot of features.

Centering is made unnecessary by mounting the motor using a flange.

By mounting the motor using a flange eliminates the need of the troublesome motor centering before

starting the equipment.

Suction strainer and check valve built-in compressor

This compressor has built-in suction strainer and check valve which enable easy maintenance.

No oil pump required in differential pressure oil supply system

This compressor em ploys roller bearings which let lubrication oil res erved in part even when the

machine is stopped. Ac cordingly, no lubrication failure will occur ev en with differential press ure oil

supply system which has no oil pump installed.

3-step (100%, 75%, 50%) unloader

As it has a 3-step (100%, 75%, 50%) unloader built-in, flow adjustment can be done easily.

In addition, inverter-controlled speed control is available.

High efficiency, and low vibration and noise

Use of original screw rotor profile attains high efficiency, and low vibration and noise.

2.2 Model Designation of the Compressor

This manual describes i125*-* and i160*-* models.

The meaning of the type designation, which is engraved on the MODEL column of the compressor

nameplate, is as follows.

i 1 2 5 * - *

Specifications of Vi (volume ratio) of the discharge port, which is L (Vi=2.63), M (Vi=3.65)

or H (Vi=5.80)

Specifications of rotor length, which is S or L (i125) and S, M or L (i160)

Rotor diameter, which is 125 or 160

Indicates i-series.

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.3 Compressor Specifications

2-2

2.3 Compressor Specifications

2.3.1 Standard Specifications

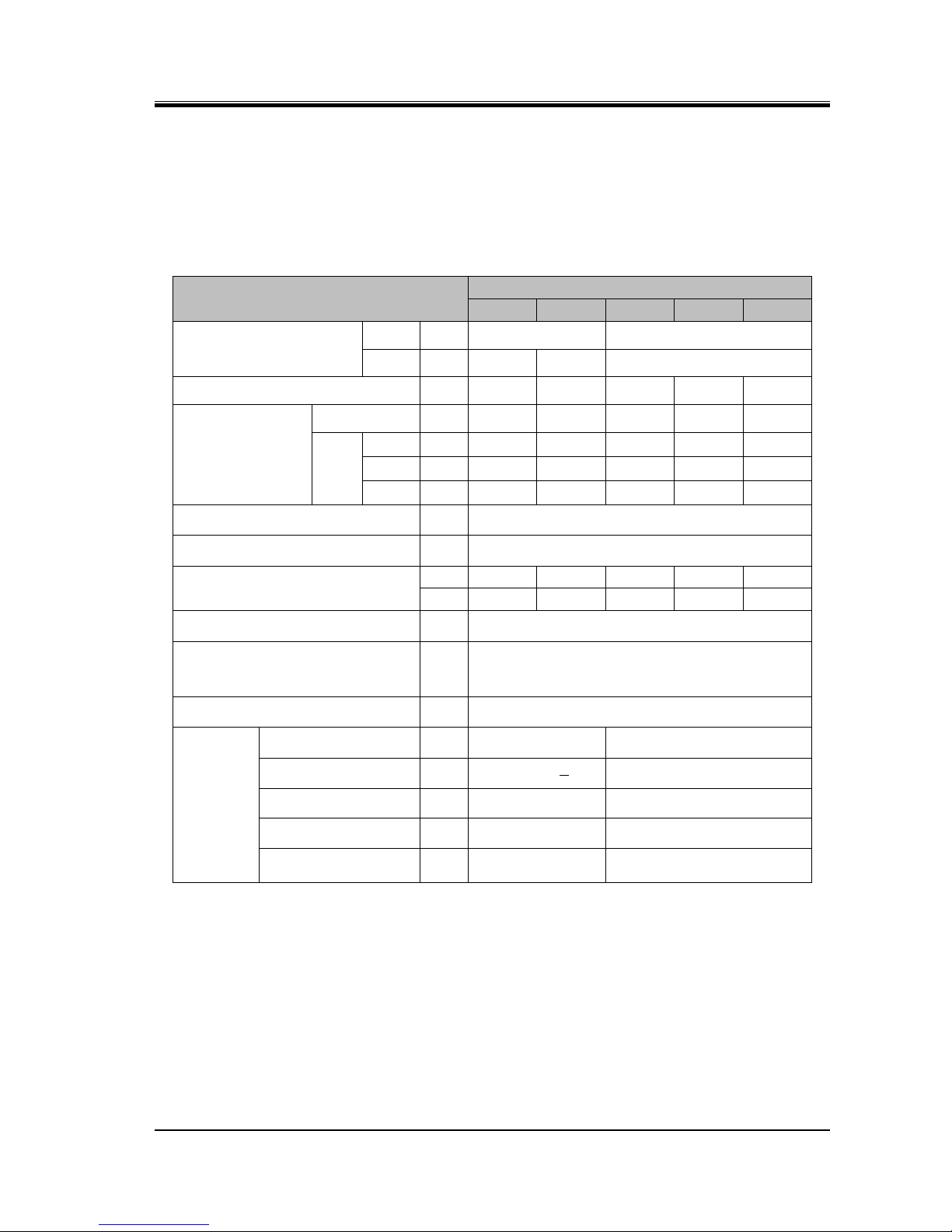

Table 2-1 Specifications of i-series Compressor

Items

Model

i125S

i125L

i160S

i160M

i160L

Flange motor connection

NEMA — 3**C, 40*C 3**D, 4**D

IEC — FF400 FF500 FF500 / FF600

Product mass (Compressor only)

kg

330 350 520 560 600

Mass of

compressor with

motor spacer

for NEMA

kg

490 510 670 710 750

for

IEC

FF400

kg

440 — — — —

FF500

kg — 480

630

670

710

FF600

kg — —

660

700

740

Standard speed 50Hz/60Hz min-1 2950/3550

Rotation direction — Clockwise as viewed from motor

Swept volume 50Hz/60Hz

m3/h

197/237

296/356

415/499

519/624

622/749

CFM 116/139 174/210 244/294 305/367 366/441

Refrigerant

—

R717 / R404A / R507A / R134a

Design pressure *Note MPa

2.6

(Applies to i-series compressors manufactured

and shipped in May 2014 or after.)

Capacity control — 3-step (100%, 75%, 50%) unloader

Connected

pipe size

Suction flange —

MYCOM 100A (4")

ANSI #300 5"

Discharge flange

—

MYCOM 65ACD ANSI #300 3"

Oil inlet port

— Rc1/2 MYCOM 65A

Economizer — Rc3/8 Rc3/4

Aquamizer

(Liquid injection)

— Rc1/4 Rc1/2

Unless otherwise noted, the pressure unit MPa represents the gauge pressure in this manual.

For limits of working temperature and pressure, see Section 2.3.2 "Operation Limits" in this

Chapter.

*Note: The design pressure varies according to each area, laws and ordinances of the country.

The design pressure of this list is the maximum value of the compressor. Therefore, the

real design pressure may become less than this value according to the law.

Please confirm real pressure on a name plate and individual specifications.

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.3 Compressor Specifications

2-3

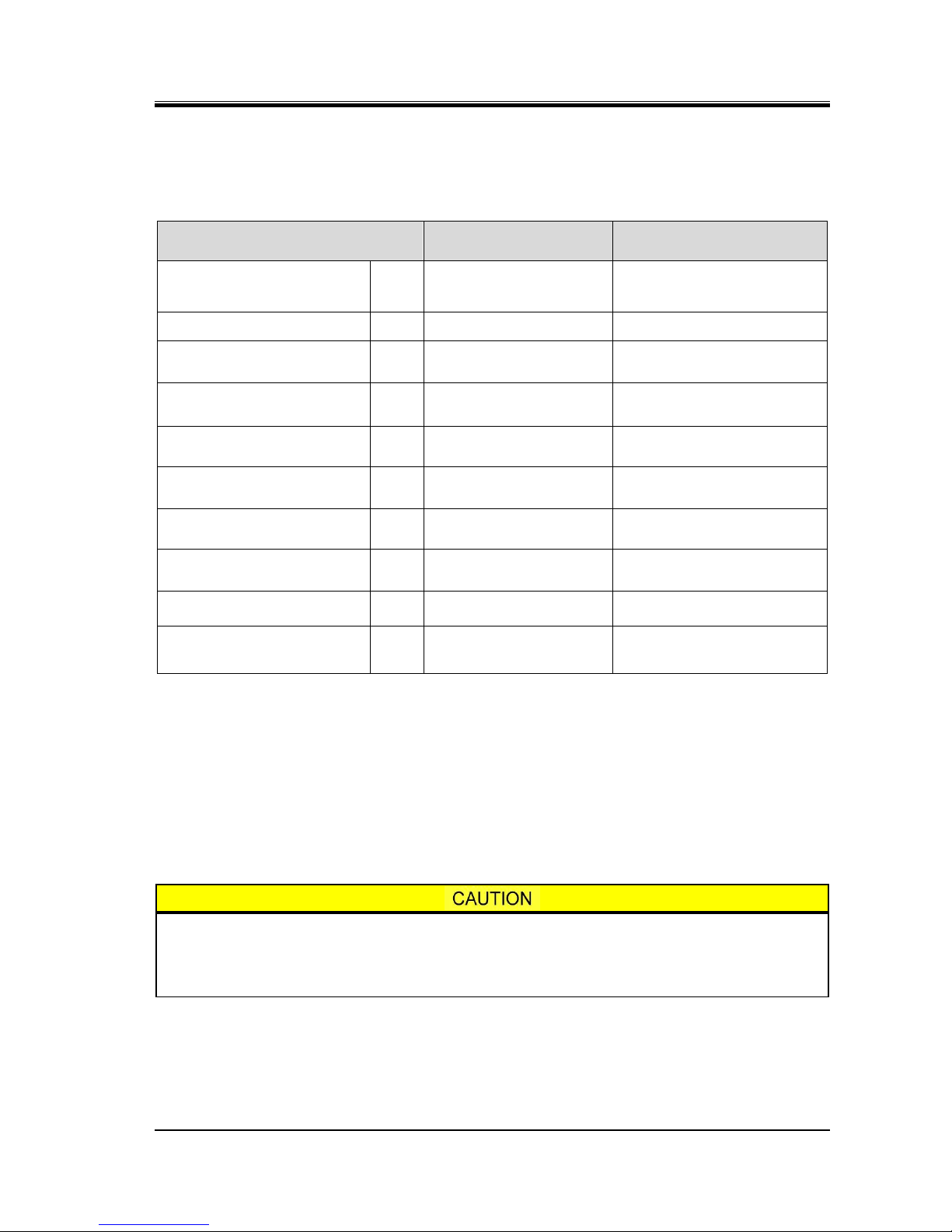

2.3.2 Operation Limits

Table 2-2 Operation Limits of i-series Compressor

Item

Normal operation range

*Note 1

Permissible limit

Speed

min-1

2950 @50 Hz

3550 @60 Hz

125S, 160S: Max. 4500 *Note 2

125L, 160M, 160L : Max. 3550

Discharge pressure

MPa

1.0 to 1.9 Max. 1.9

Suction pressure

MPa

0.02 to 0.35

Max. 0.6

Min. -0.05

Differential pressure for

lubrication (Po - Ps)

*Note3

MPa

≥ 0.5 Min. 0.5 *Note 4

Discharge gas temperature

°C

Condensing temperature +

15 to 90

Max. 90

Superheating degree of

suction gas

°C

5 to 20 —

Oil supply temperature

°C

30 to 60

Max. 80 BBSE

*Note 2

Min. 30

Supply oil viscosity

(kinematic viscosity)

mm2/s

13 to 40

Min. 13

Max. 300 (At start-up time)

Vibrat ion standar d value at

shipment

μm

(Half amplitude) 20 —

Noise standard value at

shipment

dB (A)

125S, L, 160S, M: 84

160L: 85

—

Unless otherwise noted, the pressure unit MPa represents the gauge pressure in this manual.

*Note 1: For operations outside the normal operation ranges, consult our compressor manufacturing

division.

*Note 2: When performing a speed-increasing operation by inverter at 70 °C or a bove oil temperature,

contact our compressor manufacturing division to confirm the temperature on the mechanical

seal sliding surface.

*Note 3: Po = Oil supply pressure, Ps = Suction pressure

*Note 4: This value excludes the start-up of the compressor. Refer to Note 2 in the next section.

Repeated startup and stop in a short period is harmful not for the startup devices and

electric machinery but also for the compressor itself. For information on the start/stop

limitations, refer to each instruction manual.

Wait at least 15 mi nutes after sto pping the compressor before restarting i t .

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.3 Compressor Specifications

2-4

2.3.3 Alarm Set Values

To protect the compressor, please set the alarm shown in the table below.

Table 2-3 Application Limits of i-series Compressor *

Note 1

Item

Unit Alarm

Stop

Rotation speed min-1

High

—

i125S, i160S: 4550 (0 sec.)

i125L, i160M, i160L: 3650 (0 sec.)

Low — 1450 (0 sec.)

Discharge pressure MPa

High

1.9 (0 sec.)

2.0 (0 sec.)

Low — —

Suction pressure MPa

High

0.6 (30 sec.)

0.6 (60 sec.)

Low -0.05 (30 sec.) -0.05 (60 sec.)

Differential pressure for

lubrication

(Po - Ps) *Note 2

MPa

High — —

Low 0.6 (30 sec.) 0.5 (30 sec.) *Note 3

Discharge temperature °C

High

90 (5 sec.)

95 (0 sec.)

Low — —

Suction temperature °C

High

60 (60 sec.)

—

Low -58 (30 sec.) -60 (30 sec.)

Discharge superheat °C

High — —

Low 15 (60 sec.) 10 (60 sec.)

Suction superheat °C

High —

—

Low 0 (30 sec.) 0 (60 sec.)

Lubrication temperature °C

High

80 (60 sec.)

85 (60 sec.)

Low 30 (60 sec.) 25 (60 sec.)

Unless otherwise noted, the pressure unit MPa represents the gauge pressure in this manual.

*Note 1: The values in the parentheses are the maximum operation delay times.

The values have been set to protect the compressor.

*Note 2: Po = Oil supply pressure, Ps = Suction pressure

*Note 3: This alarm stop is set for normal operation. At the time of the start-up of the compressor,

it is not necessary to perform this alarm monitoring after start until 300 seconds.

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.3 Compressor Specifications

2-5

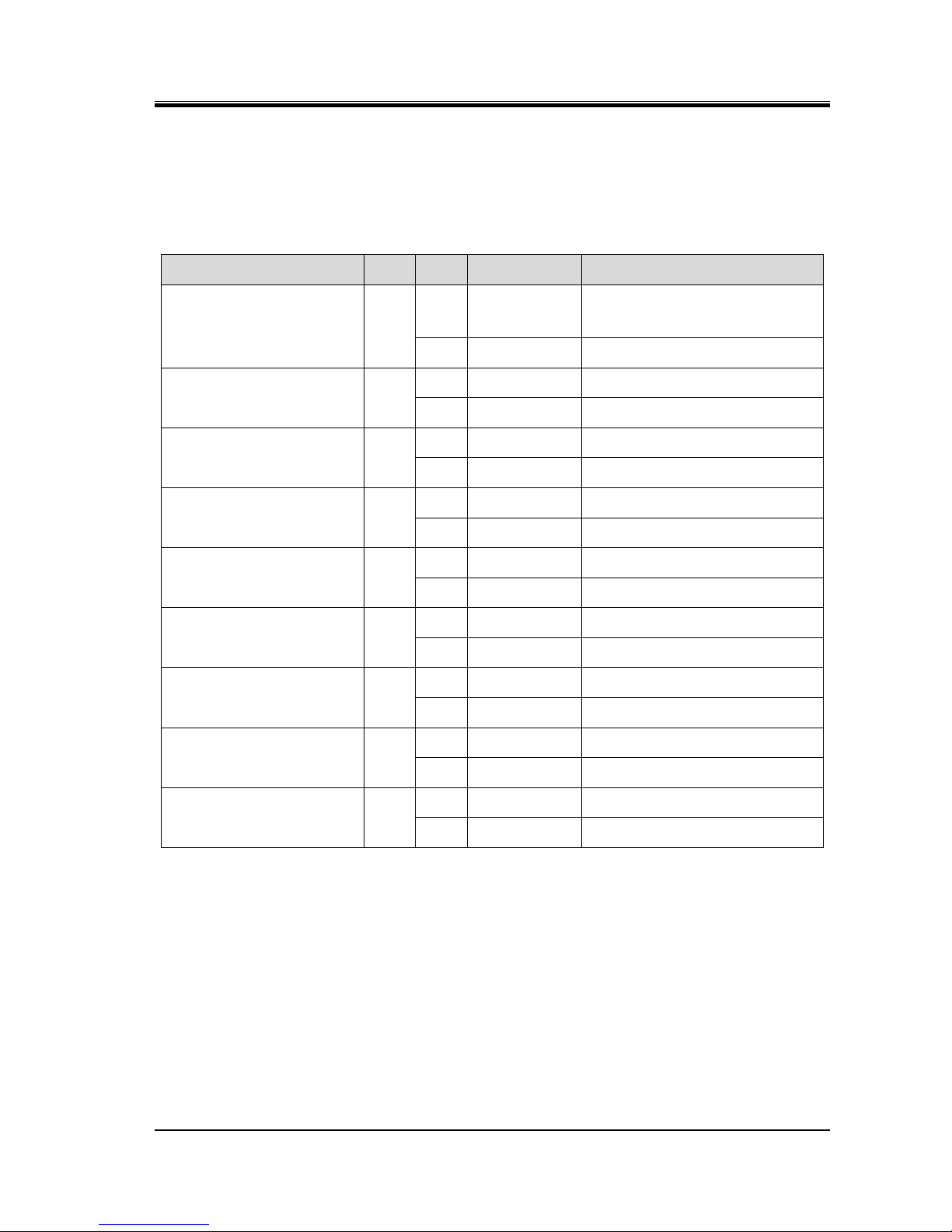

2.3.4 Outer Dimensions

Figure

2-1 i125S Outer Dimensions with a Spacer for Flange Motor (NEMA)

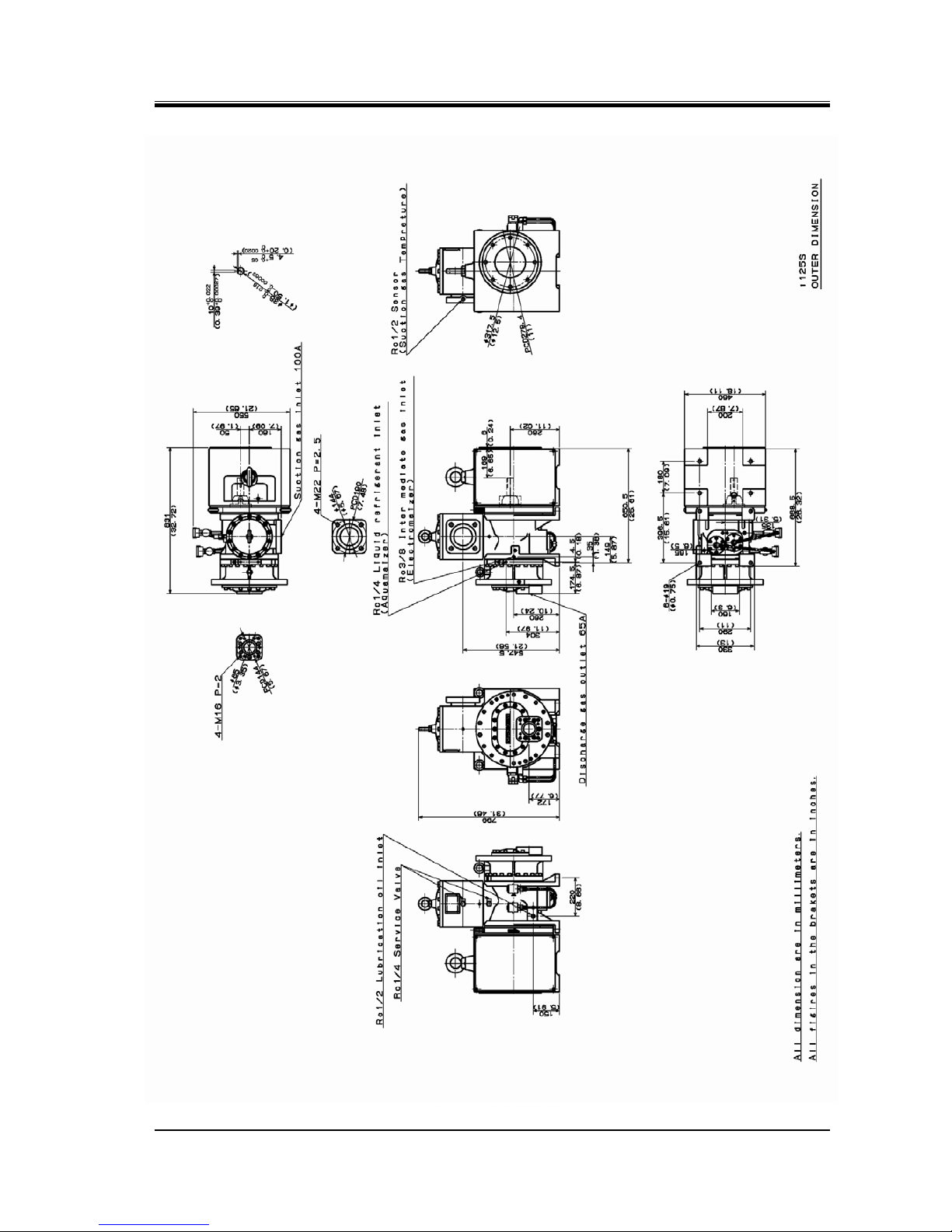

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.3 Compressor Specifications

2-6

Figure

2-2 i125S Outer Dimensions with a Spacer for Flange Motor (IEC FF400)

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.3 Compressor Specifications

2-7

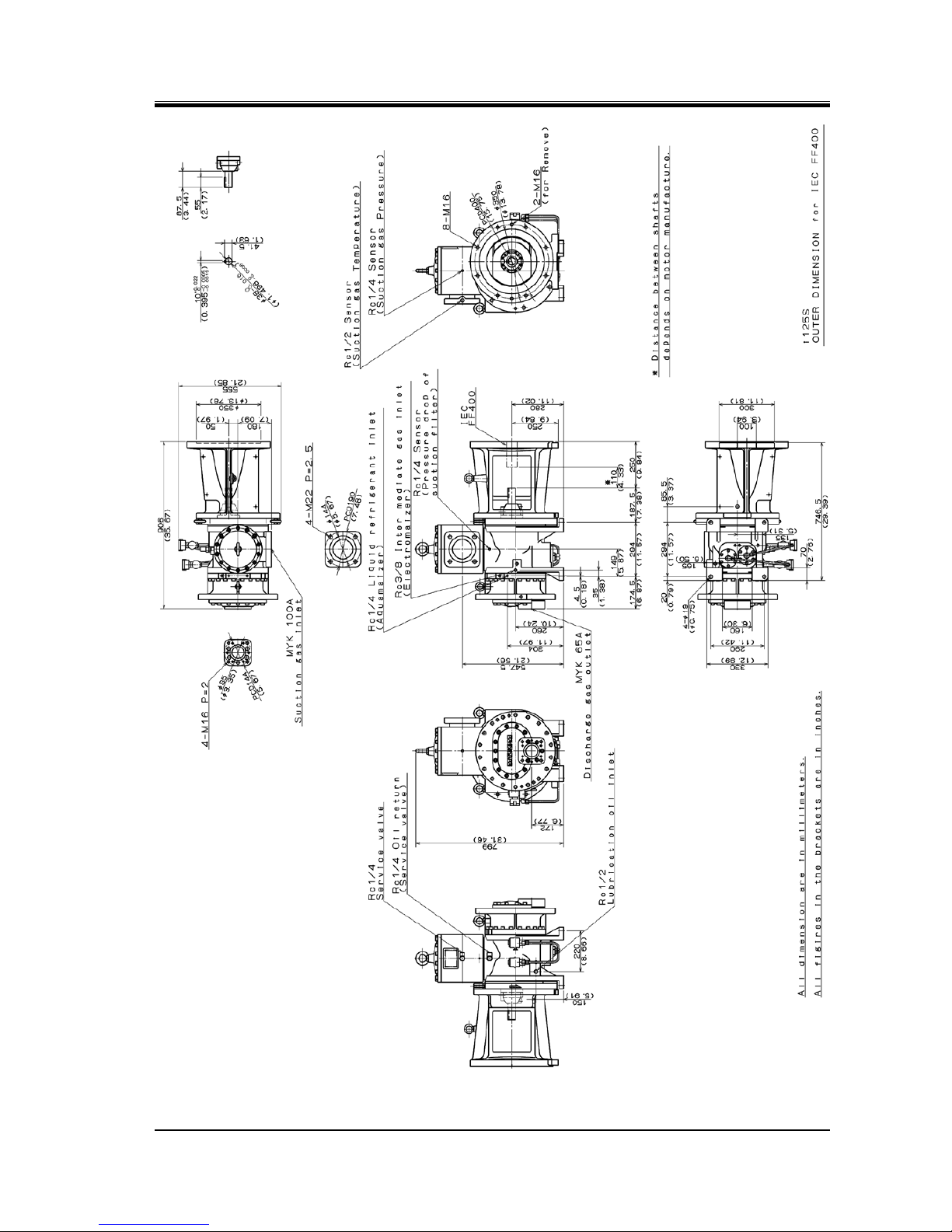

Figure

2-3 i125L Outer Dimensions with a Spacer for Flange Motor (NEMA)

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.3 Compressor Specifications

2-8

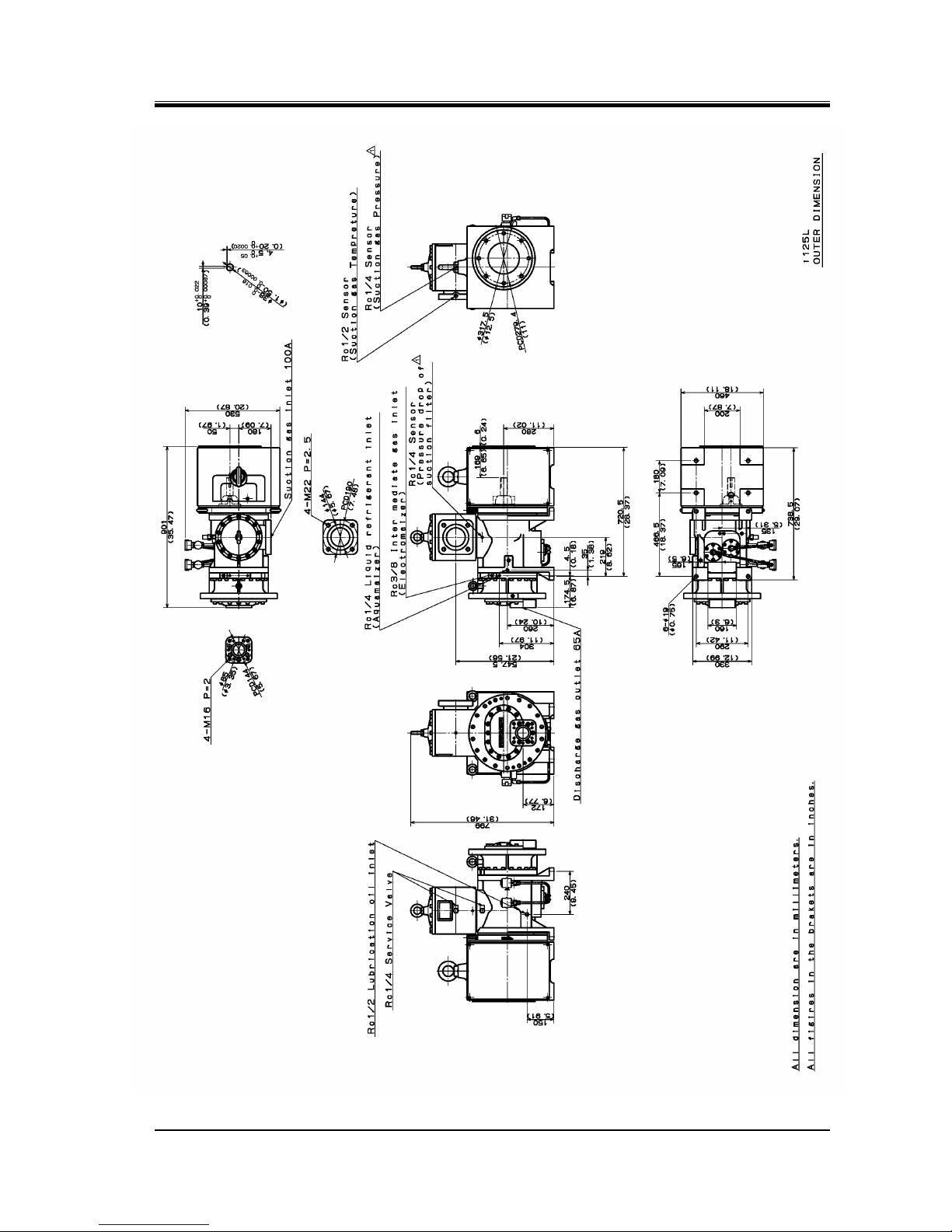

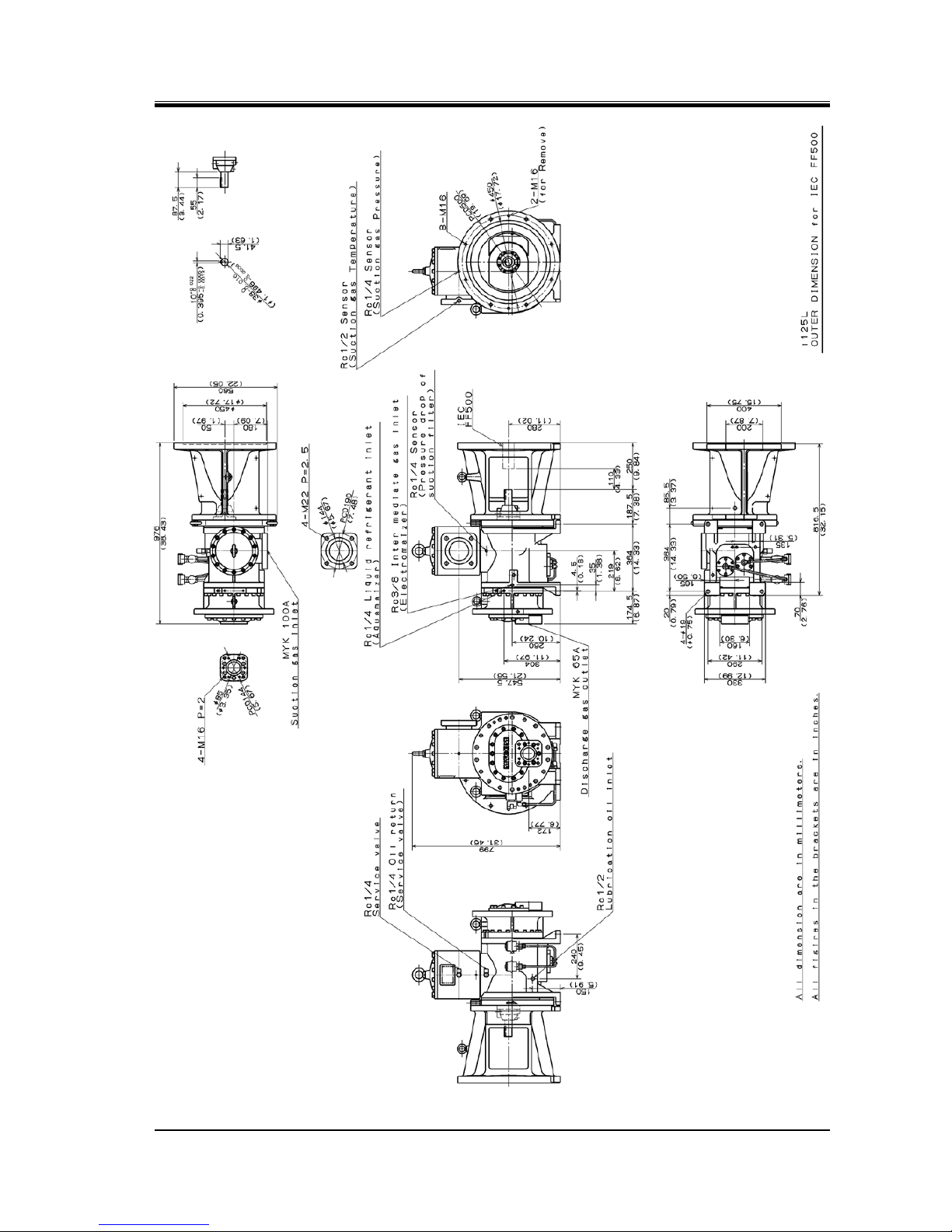

Figure

2-4 i125L Outer Dimensions with a Spacer for Flange Motor (IEC FF500)

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.3 Compressor Specifications

2-9

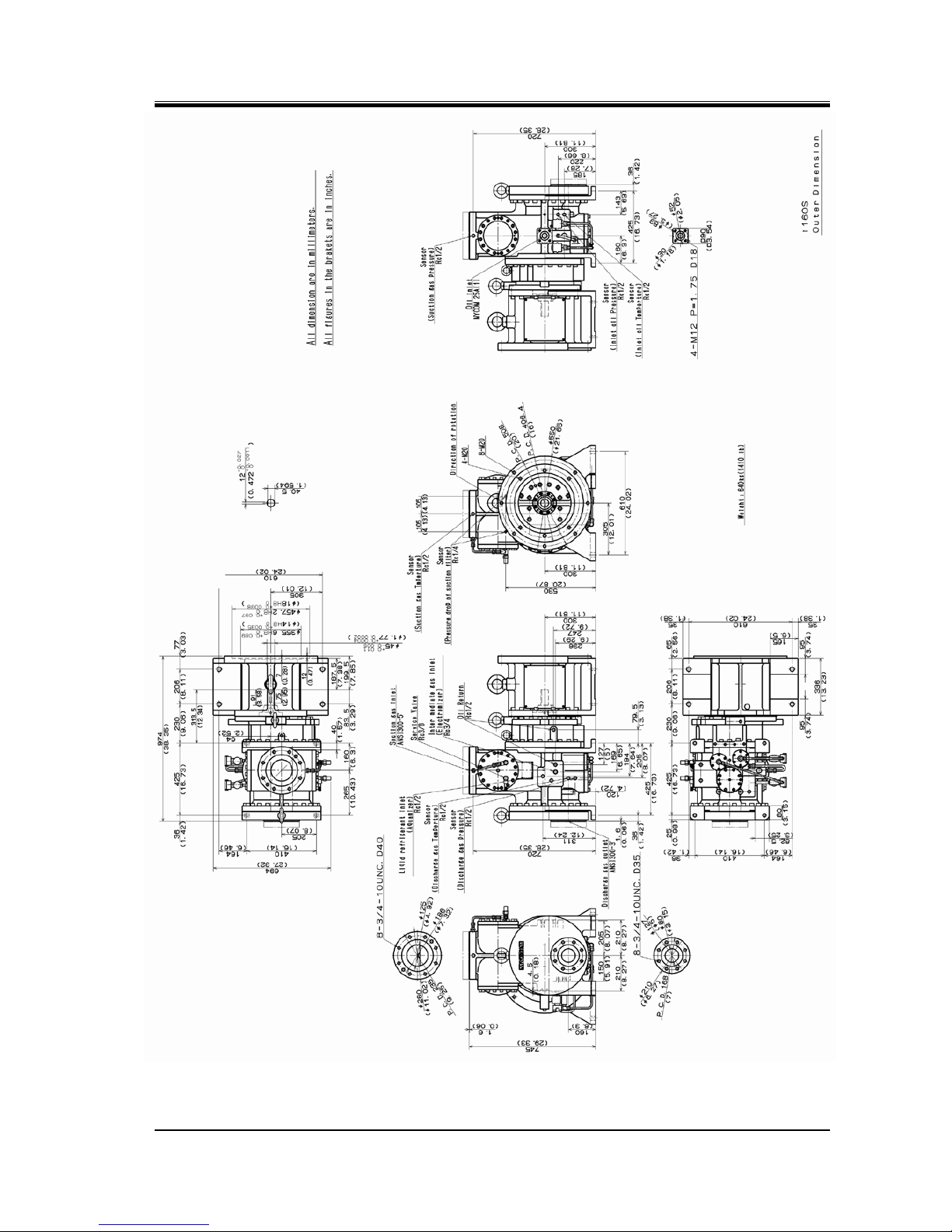

Figure

2-5 i160S Outer Dimensions with a Spacer for Flange Motor (NEMA)

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.3 Compressor Specifications

2-10

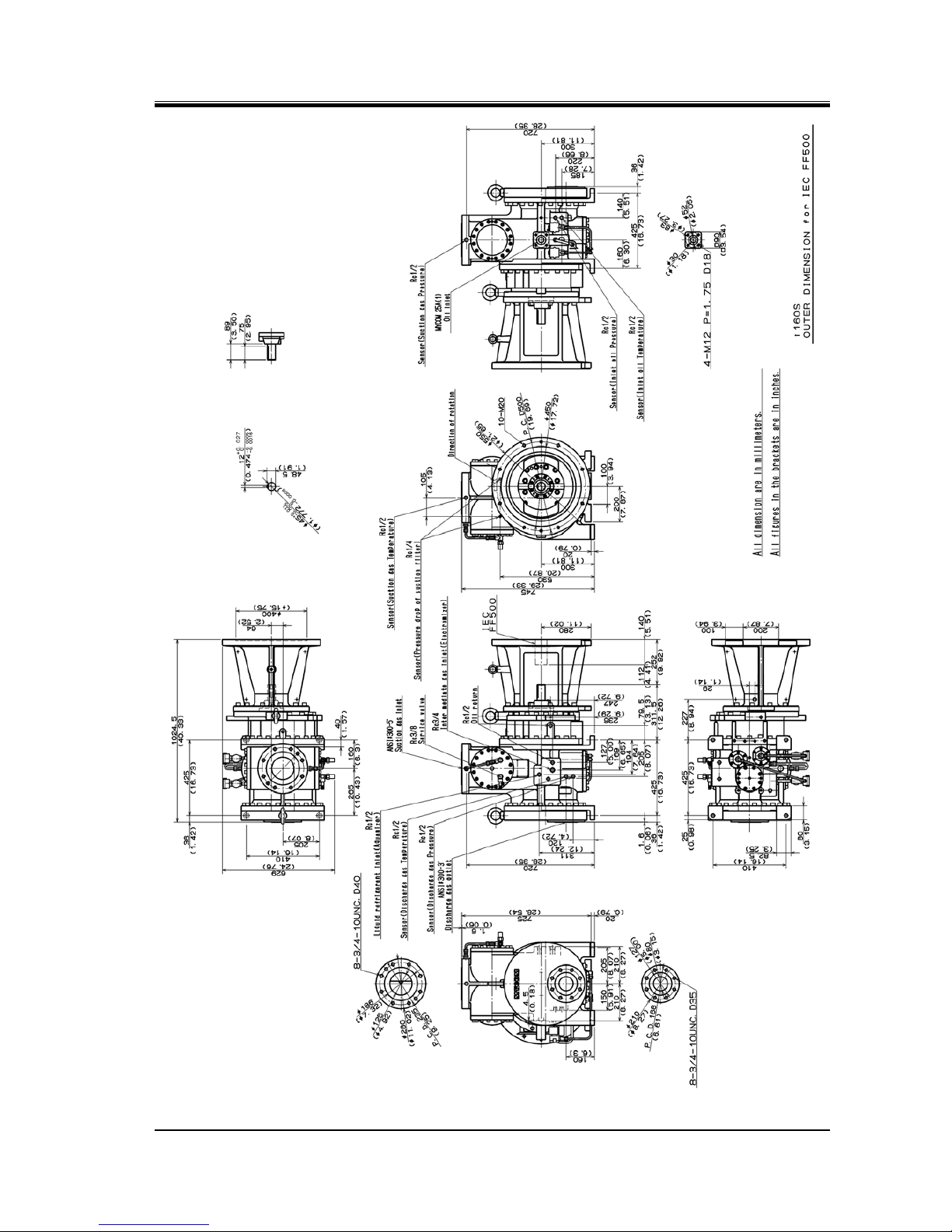

Figure

2-6 i160S Outer Dimensions with a Spacer for Motor Flange (IEC FF500)

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.3 Compressor Specifications

2-11

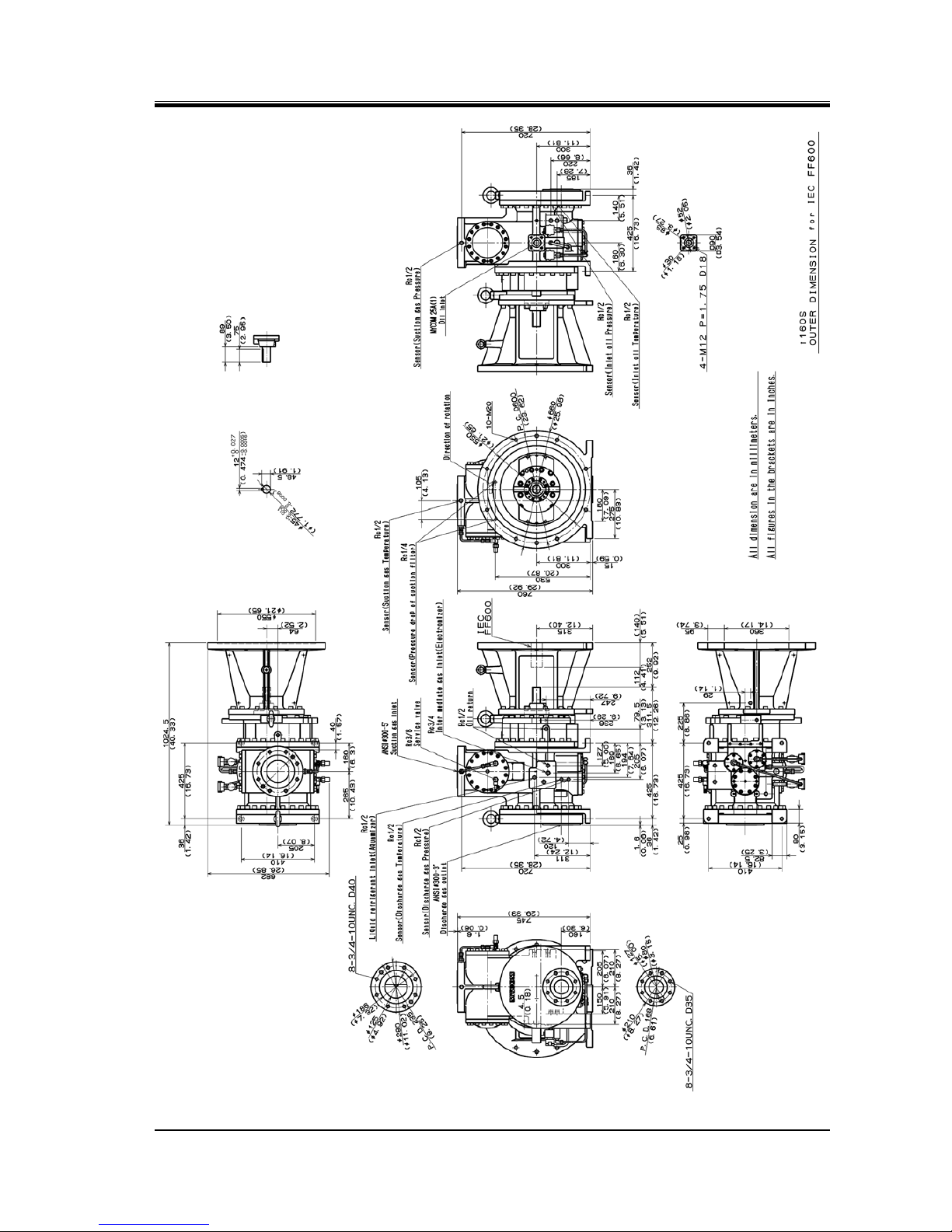

Figure

2-7 i160S Outer Dimensions with a Spacer for Flange Motor (IEC FF600)

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.3 Compressor Specifications

2-12

Figure

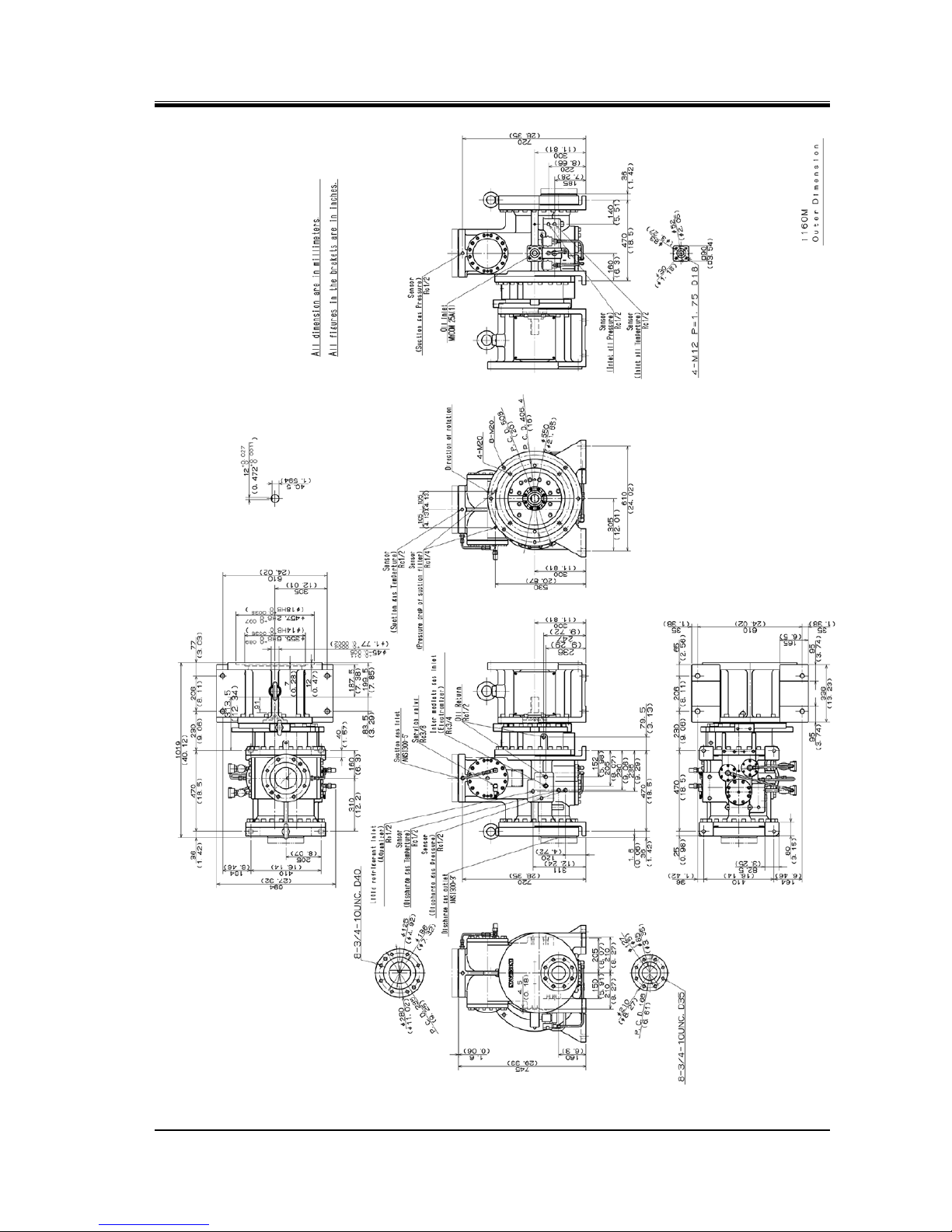

2-8 i160M Outer Dimensions with a Spacer for Flange Motor (NEMA)

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.3 Compressor Specifications

2-13

Figure

2-9 i160M Outer Dimensions with a Spacer for Motor Flange (IEC FF500)

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.3 Compressor Specifications

2-14

Figure

2-10 i160M Outer Dimensions with a Spacer for Flange Motor (IEC FF600)

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.3 Compressor Specifications

2-15

Figure

2-11 i160L Outer Dimensions with a Spacer for Flange Motor (NEMA)

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.3 Compressor Specifications

2-16

Figure

2-12 i160L Outer Dimensions with a Spacer for Flange Motor (IEC FF500)

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.3 Compressor Specifications

2-17

Figure

2-13 i160L Outer Dimensions with a Spacer for Flange Motor (IEC FF600)

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.4 Configuration of Compressor

2-18

2.4 Configuration of Compressor

2.4.1 Sectional Views

Figure

2-14 i125L Longitudinal Sectional View

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.4 Configuration of Compressor

2-19

Figure

2-15 i125L Cross-Sectional View

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.4 Configuration of Compressor

2-20

Figure 2-16

i125* Longitudinal Sectional View of Suction/Capacity Control Section

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.4 Configuration of Compressor

2-21

Figure

2-17 i160S Longitudinal Sectional View

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.4 Configuration of Compressor

2-22

Figure

2-18 i160S Cross-Sectional View

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.4 Configuration of Compressor

2-23

Figure 2-19

i160* Longitudinal Sectional View of Suction/Capacity Control Section

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.4 Configuration of Compressor

2-24

2.4.2 Exploded Views

Figure 2-20

Exploded View of i125S/L Parts with Motor Spacer

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.4 Configuration of Compressor

2-25

Figure 2-21

Exploded View of i160S/L Parts with Motor Spacer

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.4 Configuration of Compressor

2-26

2.4.3 Parts Configuration Table

Table 2-4 i125S/L Parts Configuration Table

P/N Part name Code No. Remarks Qty

1

Main Rotor Casing

-

i125S-* port

S:1

1

Main Rotor Casing

-

i125L-* port

L:1

2-1 Hexagon Socket Head Cap Screw NB35412-050 M12×50 SCM435 45

2-2

Hexagon Socket Head Cap Screw

NB35412-035

M12×35 SCM435

39

3

Alignment Pin NE242A13-050A

Φ13×50 with internal thread

and slot

4

3

Alignment Pin NE242A13-050A

Φ13×50 with internal

thread and slot for Motor

Spacer

2

4-1

Eye Bolt

NB600-16

M16 3 4-2

Eye Bolt

NB600-20

M20 1 4-3

Eye Bolt

NB600-30

M30 1 5-1

Suction Adapter -

i125

1

5-2

Strainer Cover

CS00510-I125

i125 1 6-1

Gasket, Suction Adapter

CS00600-I125

i125 t=0.5

1

6-2

Gasket, Strainer Cover

CS00900-I125

i125 t=0.5

1 7 O-ring

PA12-140

JIS B 2401 G140

1

10-1

Hexagon Socket Head Cap Plug

NF06-004

R1/8 S45C

5

10-2

Hexagon Socket Head Cap Plug

NF06-008

R1/4 S45C

10

10-3

Hexagon Socket Head Cap Plug

NF06-010

R3/8 S45C

S:6 L:5

10-4

Hexagon Socket Head Cap Plug

NF06-015

R1/2 S45C

1

11

Bearing Head

CS01100-I125

i125 1 12

Gasket, Bearing Head

CS01200-I125

i125 t=0.5

1

16

Bearing Cover -

i125 1 17

Gasket, Bearing Cover

CS01700-I125

i125 t=0.5

1

18-1

Hexagon Socket Head Cap Screw

NB35416-055

M16×55 SCM435

7

20

Spring Pin

NE3203-008

Φ3×8

1

22

End Cover

CS02200-I125

i125 1 23

Gasket, End Cover

CS02300-I125

i125 t=1.0

1

25

Male Rotor -

i125SM/SF FCD S:1set

26

Female Rotor

-

25

Male Rotor

CS02500-I125L

(M,F ASSY)

i125LM/LF FCD L:1set

26

Female Rotor

27-1

Radial Bearing

CS02800-FM125M

NU2308ET7

2

27-2

Radial Bearing

CS02800-FM125F

NU2309ET7

2

29-1

Snap Ring

NG11-090

H90 C type-Internal

1

29-2

Snap Ring

NG11-100

H100 C type-Internal

1

29-3

Snap Ring

NG12-040

S40 C type-External

1

30

Balance Piston

CS03000-I125

i125

1

31

Slotted Set Screw

NA14708-016

FM160 (M8×16)

1

32

Snap Ring

NG12-045

S45 C type-External

1

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.4 Configuration of Compressor

2-27

P/N Part name Code No. Remarks Qty

33

Sleeve, Balance Piston

CS03300-I125

i125

1

34

Spring pin

NE3206-015

FM160 (Φ6×15)

1

35

O-ring

PA11-016

JIS B 2401 P16

1

38-1

Thrust Bearing M

CS03800-I125MP

Shared with i125M,FM11S

1

38-2

Thrust Bearing F

CS03800-125FP

Shared with i125F,125

1

39-1

Lock Nut

NG31-008

AN8 1 39-2

Lock Nut

NG31-009

AN9

1

40-1

Lock Washer

NG32-008

AW8 1 40-2

Lock Washer

NG32-009

AW9 1 41-1

Spacer, Thrust Bearing Outer Race M

CS25000-FM11S

FM11S Thrust Washer

1

41-2

Spacer, Thrust Bearing Outer Race F

CS04100-I125F

i125F

1

42-1

Spacer, Thrust Bearing Alignment M

CS04200-I125M

i125M

1

42-2

Spacer, Thrust Bearing Alignment F

CS04200-125

125***

1

43-1

Thrust Bearing Gland M

CS04300-I125M

i125M

1

43-2

Thrust Bearing Gland F

CS04300-I125F

i125F 1 45

Hexagon Head Bolt

NB111008-035

M8X35-10.9 SCM435

8

46

Spring Was her

ND320-008

M8

8

48

Retainer, Oil Seal

CS04800-125

125*** 1 49

O-ring

PA12-085

JIS B 2401 G85

1

50

Oil Seal

CS05000-125D

125*** Rareflon

1

51 Seal Cover CS05100-125BBS

Shared with 125*** seal pot

specifications

1

52

Gasket, Seal Cover

CS05200-125N

125*** 1 53

Hexagon Socket Head Cap Screw

NB35406-020

M6×20 SCM435

8

58

Hexagon Socket Head Cap Screw

NB35408-030

M8X30 SCM435

12

91

Coupling Key

CS09100-125

125L** 1 92

Suction Flange with hole

CS74000-100

MYK 100A (Male)

1

92

Suction Cover Flange

CS71400-P100

MYK 100A(Male)

1

93

Gasket, Suction Flange

CR72000-100N

MYK 100A

1

94

Hexagon Head Bolt, Suction Flange

NB12022-060

M22×60 SCM435

S:4 L:8

95

Discharge Flange with hole

CS71400-065CDMK

MYK 65CD (Male)

1

235

Discharge Flange Spacer

FX101-125

65CD for 125

1

236

Gasket, Suction Flange Spacer

CS23600-125N

65CD for 125

1

96

Gasket, Discharge Flange

CS23600-125N

MYK 65CD

1

97

Hexagon Head Bolt, Discharge Flange

NB12016-045

M16×45 SCM435

S:4 L:8

100

Mechanical Seal Assembly

CS10002-125EBS

BBSE 125***

1set

235-1

Motor Spacer

-

for NEMA Motor Flange

1

CS23500-I125IEC40

for IEC FF400

CS23500-I125IEC50

for IEC FF500

235-2

Plate, Motor Spacer

CS23510-I125

i125

2

-

for IEC FF400 (1), (2)

2

-

for IEC FF500 (1), (2)

2

235-3

Hexagon Socket Head Cap Screw

NB35406-010

M6×10 SCM435

8

237-1

Torsional Slip Washer M

CS23700-FM125M

FM125 M

1

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.4 Configuration of Compressor

2-28

P/N Part name Code No. Remarks Qty

237-2

Torsional Slip Washer F

CS23700-125

125L**

1

250-1

Thrust Washer M CS04200-I125M

i125M Spacer, thrust

bearing alignment

1

250-2

Thrust Washer F

CS25000-125

125***

1

391 Unloader Piston CS39100-I160 i160* 2

392

Spring

CS39200-F125

FM125

2

393

Unloader Cover

CS39300-I160

i160* 2 395

Gasket, Unloader Cover

CS39500-I160

i160*

2

480

Strainer Element

CS48000-I160

i160* 1 481

Retainer, Strainer Element

CS48100-I125

i125

1

482

Hexagon Socket Head Cap Screw

NB35406-015

M6×15 SCM3

2

485

Check Valve Spring

CS48500-F125

FM125

1

486

Hexagon Nut

NC622-10

U-NUT M10

1

487

Plain Washer ND193-10

JISB1256 small-sized,

round-shaped 10-22H

1

488-1

Seat Stopper (1)

CS48800-F125

FM125

1

488-2

Seat Stopper (2)

CS48800-F1252

FM125

1

489

Valve Seat

CS48900-I125

i125 1 490

Valve Plate

CS49000-I125

i125

1

491

Check Valve Shaft

CS49100-I125

i125 1 495

O-ring

PA11-007

JIS B 2401 P7

1

533 Solenoid Valve

KF711-XOF1

SPOLAN XOF-120V

2

KF711-XOF2

SPOLAN XOF-240V

534

Nipple (High Pressure)

NN410-080

R3/8 Sch40 80L

2

535

Connection (L-type)

NJ3-0803NE

L-Φ8-R3/8 JO4060

2

536

Connection (L-type)

NJ3-0802KNNT

L-Φ8-R1/4 JO4050

2

538

Piping

QA11-08

Φ8 STS

2

546

Wave Washer

ND91-016

FM125 BW16

1

555

Angle Valve

NF042-0302N

R1/4×Rc1/4

2

795

Cover Plate, Discharge Flange

CS71500-I1251

i125 4.5x84D

1

795

Cover Plate, Suction Flange

CS71500-I1252

i125 4.5x123D

1

The part code of the O-ring is the one assigned to NBR-70-1 which is standard

material. When the material of the O-ring is other than NBR, a different part code is

used for each material.

If you are using O-rings made from other than the standard material, please

contact MAYEKAWA when pl acing an order.

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.4 Configuration of Compressor

2-29

Table 2-5 i160* Parts Configuration Table

P/N

Part name Code No. Remarks

Qty

1

Main Rotor Casing

-

i160S-* port (L, M, H)

S:1

1

Main Rotor Casing

-

i160M-* port (L, M, H)

M:1

1

Main Rotor Casing

-

i160L-* port (L, M, H)

L:1

2

Hexagon Socket Head Cap Screw

NB35416-055

M16×55 SCM435

71

3 Alignment Pin NE242A13-050A

13×50L With internal thread

and slot

4

3 Alignment Pin NE242A13-050A

13×50L With internal thread

and slot for Motor Spacer

2

4-1

Eye Bolt

NB600-12

M12 3 4-2

Eye Bolt

NB600-24

M24 1 4-3

Eye Bolt

NB600-24

M24 1 5

Strainer Cover

CS00500-I160

i160

1

6

Gasket, Strainer Cover

CS00900-I160

i160 t=0.5

2

7-1

O-ring

PA12-150

JIS B 2401 G150

1

7-2

O-ring

PA12-140

JIS B 2401 G140

1

8

Check Valve Cover

CS00800-I160

i160 1 10-1

Hexagon Socket Head Cap Plug

NF06-004

R1/8 S45C

5

10-2

Hexagon Socket Head Cap Plug

NF06-008

R1/4 S45C

9

10-3 Hexagon Socket Head Cap Plug NF06-010 R3/8 S45C

S,L:3

M:4

10-4 Hexagon Socket Head Cap Plug NF06-015 R1/2 S45C

S, L:15

M:14

10-5

Hexagon Socket Head Cap Plug

NF06-020

R3/4 S45C

1

10-6

Hexagon Socket Head Cap Plug

NF06-025

R1 S25C

2

11

Bearing Head

CS01100-I160

i160 1 12

Gasket, Bearing Head

CS01200-I160

i160 t=0.5

1

16

Bearing Cover

CS01600-I160

i160 1 17

Gasket, Bearing Cover

CS01700-I160

i160 t=0.5

1

18-1

Hexagon Socket Head Cap Screw

NB35412-040

M12×40 SCM435

40

20

Spring Pin

NE3203-010

3×10L

1

22

End Cover

CS02200-I160N

i160 1 23

Gasket, End Cover

CS02300-I160N

i160 t=1.0

1

25 Male Rotor

-

i160SM/SF FCD S:1set

26 Female Rotor -

25

Male Rotor

-

i160MM/MF FCD M:1set

26 Female Rotor

-

25 Male Rotor -

i160LM/LF FCD L:1set

26

Female Rotor

-

27-1

Radial Bearing M

CS02800-FM160M

NU2311ET7

2

27-2

Radial Bearing F

CS02800-FM160FCT

NU2312ET7

2

29-1

Snap Ring

NG11-120

H120 C type-Internal

1

29-2

Snap Ring

NG11-130

H130 C-type-Internal

1

29-3

Snap Ring

NG12-060

S60 C type-External

1

30 Balance Piston CS03000-I160 i160 1

2203M4-JE-MY-iS2-N_2017.04.

Chapter 2 Compressor Specifications and Configuration

Screw Compressor i-series 2.4 Configuration of Compressor

2-30

P/N

Part name Code No. Remarks

Qty

30