2202MYJE-MY-C8-N_2018.02.

Compound 2-stage Screw Compressor

3225 * * C Instruction Manual

3225LLLC/3225LLMC/3225LLSC/3225LLC/3225LMC/3225LSC

3225MLC/3225MMC/3225MSC/3225SLC/3225SMC/3225SSC

CAUTION

Before operating, servicing, or inspecting this product, read this manual thoroughly to fully

understand the contents.

Keep this Instruction Manual in a safe, designated place for future reference whenever the

manual is needed.

Specifications of this product and contents of this manual are subject to change without

prior notice due to technical improvements, and the like.

2202MYJE-MY-C8-N_2018.02.

Preface

Compound 2-stage Screw Compressor 3225**C

i

Preface

Thank you for purchasing the C-series compound 2-stage screw compressor 3225**C

(hereinafter referred to as "this product").

This Instruction Manual (hereinafter referred to as "this manual") provides safety information and

operation and maintenance procedures, so that users correctly understand how to handle this product

and, as a result, can use it safely and efficiently. This manual is applicable to the following models:

3225LLLC-*B*-51

3225LLLC-*B*-61

3225LLMC-*B*-51

3225LLMC-*B*-61

3225LLSC-*B*-51

3225LLSC-*B*-61

3225LLC-*B*-51

3225LLC-*B*-61

3225LMC-*B*-51

3225LMC-*B*-61

3225LSC-*B*-51

3225LSC-*B*-61

3225MLC-*B*-51

3225MLC-*B*-61

3225MMC-*B*-51

3225MMC-*B*-61

3225MSC-*B*-51

3225MSC-*B*-61

3225SLC-*B*-51

3225SLC-*B*-61

3225SMC-*B*-51

3225SMC-*B*-61

3225SSC-*B*-51

3225SSC-*B*-61

* -51 (-61) may not be written. For more information, see 2.2 "Model designation of the compressor"

in this manual Chapter 2.

Make sure you read this manual before installing or using this product.

Keep this manual in a safe place near this product for quick reference.

Revision History

Title

Document No.

First edition issue date

3225**C Instruction Manual

2202MYJE-MY-C8-N_2018.02.

Nov. 14, 2014

Revision

No.

Issue date

Major Contents of revisions

Created/approved by:

00

Nov. 14, 2014

Overall review associated with reissue as

electronic document, document No. change

Ikehara / Hirao

01

Apr. 30, 2015

Modified the constitution of Chapter 4 and

Chapter 5. Correction of describing, etc.

Ikehara / Muta

02

Feb.28.2018

Corrected Table 2-1&2-2, Figure 2-1~12, Table

7-1&7-2. Corrected other errors. Deleted

Contact Information

Takenouchi・Ito/Kato

2202MYJE-MY-C8-N_2018.02.

Warranty and Disclaimer

Compound 2-stage Screw Compressor 3225**C

ii

Warranty and Disclaimer

Warranty

MAYEKAWA shall repair or replace parts of this product for no charge if any failure resulting from

defects in design or manufacture occurs, under normal use with the purpose and method that are in

accordance with the specifications of this product and this manual, within the warranty period.

The warranty period is "12 months from factory shipment of this product". If there is a separate

agreement, that agreement shall prevail in principle.

MAYEKAWA is not liable for production or man-made disaster compensation due to malfunction or

damage of this product.

Disclaimer of Warranty

Although MAYEKAWA warrants the clauses mentioned above, the following clauses are exempted.

Malfunction or damage of this product caused by natural disaster, or other accidental forces

(such as fire, thunderbolt, windstorm, intense rainfall, flood, tidal wave, earthquake, land

subsidence, etc.).

Malfunction or damage caused by misusage described below.

Malfunctions, damage, or deterioration of this product due to abnormal or improper use

(including improperly storing this product outdoors or under too hot/humid conditions,

unexpected inspections, tests, operations, too frequent liquid flow-back operation*, and

too frequent start-stop cycles, etc.).

Malfunction or damage caused by devices or equipments not provided by MAYEKAWA

including operation control methods of those devices.

Malfunction or damage caused by refrigerants, gases, or refrigerant oils, and operating

conditions (design conditions) not approved for this product.

Malfunction or damage caused by maintenance or inspection not recommended by

MAYEKAWA.

Malfunction or damage caused by parts that are not genuine.

Malfunction or damage caused by remodeling the product without approval of

MAYEKAWA.

Malfunction or damage caused by unexpected misusage

"Liquid flow-back operation" is ・・・

Normally, while the compressor sucks in the refrigerant liquid only after vaporizing it in the

evaporator, it may directly sucks it in because of the faulty adjustment or failure of the

expansion valve. We call this state of compressor operation "liquid flow-back operation".

No compressor can compress a liquid. The compressor may be damaged should the liquid be

sucked in.

2202MYJE-MY-C8-N_2018.02.

Important Information

Compound 2-stage Screw Compressor 3225**C

iii

Important Information

Intended Use of This Product

This product is a general-purpose screw compressor for refrigeration, cold storage and various gases

compression. Do not use this product for any other purposes that are not intended for or which depart

from the specifications. For specifications of this product, refer to "2.3 Compressor Specifications".

Please perform the maintenance items described in this manual by using safe and assured procedures.

For Safe Use of This Product

Although MAYEKAWA has paid a lot of attention to safety measures for this product, all hazards

including potential hazards caused by human errors, or due to environmental conditions can not be

anticipated.

As there are too many items to be strictly observed or prohibited when using this product, it is

impossible to inform all of them through this manual. Therefore, when operating this product, pay

extreme caution on personnel safety as well as on items described in this manual.

Important rules for safety work with this product that apply to all workers including managers and

supervisors are listed below.

Please read this manual before using this product. Fully understand the instructions provided there,

and be sure to perform the safety procedures described in this manual.

Operation, maintenance, and inspection of this product should be performed by qualified

personnel educated about the fundamentals of this product and trained about hazards

involved and measures to avoid danger.

Do not allow any person other than those educated on the fundamental expertise of this

product and trained about hazards involved and measures to avoid dangers to approach this

product while it is operating or during maintenance.

Observe all related federal/national and local codes and regulations.

To prevent accidents, do not carry out any operation or maintenance other than those

described in this manual. Do not use this product for any purpose other than intended.

Replace the parts with genuine parts.

Not only workers but also managers should actively participate safety and health activities in

the workplace to prevent accidents.

When closing or opening a valve during work, make sure to apply lockout/tagout to prevent

the valve from being accidentally closed or opened during the work.

[Lockout] To lock with a key in order to keep people, except the workers involved, from

operating the product.

Lockout means disconnecting or keeping disconnected machines and devices by locking their energy

(power) sources. Lockout is not just simply turning off the power switches to stop the supply of power,

but includes immobilizing them with a key or similar device to keep any blocked switches from being

operated.

Lockout devices are devices such as keys, covers, and latches, to immobilize switches, valves,

opening and closing levers, etc., with a state of being locked.

[Tagout] To prevent any inappropriate work by hanging tag plates indicating "work in progress".

Tagout means to clearly indicate, by hanging tag plates, that a device is in lockout and that operation of

the device is prohibited. Tag plates forbidding operation, starting, opening, etc. are warnings clearly

stating to not operate energy (power) sources, and are not for stopping blocking devices.

2202MYJE-MY-C8-N_2018.02.

Important Information

Compound 2-stage Screw Compressor 3225**C

iv

Observe the following precautions when performing maintenance work on electrical control.

Electrical maintenance of the product must be performed by certified/qualified personnel and

only those educated about the electrical control of the product.

Before servicing or inspecting the electrical equipment or devices, turn "OFF" the motor main

power and control power, and perform lockout/tagout to prevent the power from being turned

on during work.

Even when the motor main power and control power are turned "OFF", this product may be turned on if

the power is supplied from outside the package unit. Make sure the power supply on the power source

side is shut off, and perform lockout/tagout to prevent the product from being turned on during work.

About This Manual

This product may be modified without prior notice. Therefore, the appearance of actual

machine may differ from the descriptions in this manual. If you have any questions, contact

our sales offices or service centers. For each sight of MAYEKAWA, refer to following URL.

http://www.mayekawa.com/about/network/

This manual is in English. If any other language is required, it is the customers’ responsibility

to prepare a manual for safety education and operation instructions.

This manual is copyrighted. Drawings and technical references including this manual shall not,

in whole or part, be copied, photocopied, or reproduced into any electronic medium or

machine-readable form without prior permission from MAYEKAWA.

Photographs or drawings included in this manual may differ from the appearance of actual

product.

If this manual is lost or damaged, immediately request our local sales offices or service

centers for a new manual. Using this product without the manual may result in safety issues.

If you resell this product, never fail to attach this manual to this product.

Construction of This Manual

Title of section and chapter

Description details

Preface

Describes the outline of this manual and how to read this manual.

Warranty and Disclaimer

Describes what MAYEKAWA warrants and what are covered by

the warranties. Warranty exemption is stated as disclaimer.

Important Information

Describes important information related to this product and this

manual.

1. Safety

Describes safety information for the worker, safety rules for this

product, and management details regarding the work safety that

is required for handling this product.

2. Compressor Specifications and

Structure

Describes the main components of this product, functional

information, specification, and operating limits.

3. Installation

Describes the installation procedure of this product.

4. Compressor and Package Unit

Operation

Describes the precautions for operating this product.

5. Maintenance and Inspection

Describes sections and period for inspecting, and assembly and

disassembly of this product.

6. Troubleshooting

Describes troubleshooting methods for this product in case

problems occur during operation of this product.

7. Related Documents

Describes documents such as exploded views and parts list.

2202MYJE-MY-C8-N_2018.02.

Table of Contents

Compound 2-stage Screw Compressor 3225**C

v

Table of Contents

Preface .................................................................................................................... ⅰ

Revision History ..................................................................................................... ⅰ

Warranty and Disclaimer ....................................................................................... ⅱ

Important Information ............................................................................................ ⅲ

Intended Use of This Product ........................................................................................... ⅲ

Important Information for Safe Use of This Product .......................................................... ⅲ

About This Manual ............................................................................................................. ⅳ

Construction of This Manual .............................................................................................. ⅳ

Table of Contents ................................................................................................... ⅴ

Chapter 1 Safety

1.1 Strict Requirements and Prohibitions ........................................................ 1-1

1.1.1 Strict Requirements (Do’s)................................................................................... 1-1

1.1.1.1 Do’s on Operation ........................................................................................ 1-1

1.1.1.2 Do’s on Maintenance ................................................................................... 1-1

1.1.1.3 Do’s on Lockout/Tagout after Shutting Off the Power ................................. 1-1

1.1.1.4 Do’s about Personal Protective Gear .......................................................... 1-2

1.1.1.5 Do’s about Handling of Hazardous and Toxic Substances .......................... 1-2

1.1.1.6 Do’s about Handling Emergency Situations ................................................ 1-2

1.1.1.7 Do’s about Waste Oil, Fluid, and Materials ................................................. 1-2

1.1.1.8 Other Do’s .................................................................................................... 1-3

1.1.2 Prohibitions (Don’ts) ......................................................................................... 1-3

1.2 Warnings ....................................................................................................... 1-3

1.3 Residual Risks ............................................................................................. 1-4

1.4 Safety Devices .............................................................................................. 1-6

1.4.1 Emergency Stop Button ....................................................................................... 1-6

1.4.2 Breakers of motor main power and control power

(with Lockout/Tagout Mechanism) ...................................................................... 1-6

1.4.3 Compressor Protective Devices .......................................................................... 1-7

Chapter 2 Compressor Specifications and Structure

2.1 Overview of the 3225**C ............................................................. 2-1

2.2 Model Designation of the Compressor ................................................... 2-1

2.3 Compressor Specifications ........................................................................ 2-2

2.3.1 Standard Specifications ....................................................................................... 2-2

2.3.2 Operation Limits ................................................................................................... 2-4

2.3.3 Outer Dimensions ................................................................................................ 2-5

2.4 Structure of Compressor .......................................................................... 2-17

2.4.1 Sectional View ................................................................................................... 2-17

2202MYJE-MY-C8-N_2018.02.

Table of Contents

Compound 2-stage Screw Compressor 3225**C

vi

2.5 Mechanisms ............................................................................................... 2-18

2.5.1 Basics of the Screw Compressor ...................................................................... 2-18

2.5.2 Suction Process ................................................................................................. 2-18

2.5.3 Compression Process ........................................................................................ 2-19

2.5.4 Discharge Process ............................................................................................. 2-19

2.5.5 About Volume Ratio (Vi) .................................................................................... 2-19

2.5.6 Capacity Control Mechanism ............................................................................. 2-21

2.5.7 Bearings and Balance Piston ............................................................................ 2-21

2.5.8 Shaft Seal Block ................................................................................................ 2-21

2.6 Gas and Oil Flow ........................................................................................ 2-22

Chapter 3 Installation

3.1 General Precautions for Installation .......................................................... 3-1

3.2 Installation Works ........................................................................................ 3-1

3.2.1 Unpacking ............................................................................................................ 3-1

3.2.2 Storage ................................................................................................................ 3-1

3.2.3 Transportation ...................................................................................................... 3-1

3.2.4 Preparation for Installation ................................................................................... 3-4

3.2.5 Installation ............................................................................................................ 3-5

3.2.5.1 Installation .................................................................................................... 3-5

3.2.5.2 Shaft Alignment between the Compressor and Driving Machine ................ 3-5

3.2.5.3 Piping Connection ....................................................................................... 3-6

3.2.5.4 Equipment and Devices for Protection of the Compressor ......................... 3-6

3.2.6 Airtightness Test .................................................................................................. 3-7

3.2.7 Lubricating Oil Charge ......................................................................................... 3-7

3.2.7.1 Initial Charge of Lubricating Oil ................................................................... 3-7

3.2.7.2 Additional Charge of Lubricating Oil ............................................................ 3-7

3.2.8 Charge of Refrigerant .......................................................................................... 3-7

3.2.9 Check after Installation ........................................................................................ 3-7

Chapter 4 Compressor and Package Unit Operation

4.1 Lubricating Oil (Refrigerant Oil) ................................................................. 4-1

4.1.1 Precautions for Selecting the Lubricating Oil....................................................... 4-1

4.1.2 Recommended Lubricating Oils .......................................................................... 4-1

4.1.2.1 Recommended Lubricating Oils for Ammonia Refrigerant .......................... 4-1

4.1.2.2 Oils for systems using Hydrofluorocarbon refrigerants ............................... 4-2

4.1.3 Change of Lubricating Oil Brand ......................................................................... 4-3

4.1.4 Precautions for Handling lubricating Oil .............................................................. 4-4

4.1.5 Lubricating Oil Management Criteria ................................................................... 4-5

4.1.6 Lubricating Oil Replacement Timing .................................................................... 4-6

4.1.6.1 After Starting the Initial Operation ............................................................... 4-6

4.1.6.2 During Normal Operation............................................................................. 4-6

2202MYJE-MY-C8-N_2018.02.

Table of Contents

Compound 2-stage Screw Compressor 3225**C

vii

4.2 Precautions for Operation ........................................................................... 4-7

4.2.1 Prevention of Liquid Flow-back Operation ........................................................... 4-7

4.2.2 Purging of Non-Condensable Gases ................................................................... 4-7

4.3 When Stopping the Compressor for a Long Time .................................... 4-8

Chapter 5 Maintenance and Inspection

5.1 Precautions for Maintenance and Inspection ............................................ 5-1

5.2 Maintenance and Inspection List................................................................ 5-3

5.2.1 Daily Management ............................................................................................... 5-3

5.2.2 Periodic Inspection .............................................................................................. 5-5

5.2.3 Guidelines for the Timing of Compressor Overhaul ............................................ 5-6

5.3 Compressor Disassembly Preparation ...................................................... 5-7

5.3.1 Disassembly Tools and Workplace ..................................................................... 5-7

5.3.2 Replacement Parts .............................................................................................. 5-8

5.3.3 Refrigerant Gas Recovery ................................................................................. 5-11

5.3.4 Removal of Connections to the Unit .................................................................. 5-12

5.3.5 Removal and Lifting the Compressor ................................................................ 5-13

5.3.6 Draining Oil from the Compressor ..................................................................... 5-13

5.4 Disassembly and Inspection ..................................................................... 5-14

5.4.1 Unloader Indicator ............................................................................................. 5-15

5.4.1.1 Disassembly .............................................................................................. 5-15

5.4.1.2 Inspection .................................................................................................. 5-17

5.4.2 Unloader Cover .................................................................................................. 5-18

5.4.2.1 Disassembly .............................................................................................. 5-18

5.4.2.2 Inspection .................................................................................................. 5-19

5.4.3 Unloader Piston and Unloader Cylinder ............................................................ 5-20

5.4.3.1 Disassembly .............................................................................................. 5-20

5.4.3.2 Inspection .................................................................................................. 5-21

5.4.4 Shaft Seal Block ................................................................................................ 5-22

5.4.4.1 Disassembly .............................................................................................. 5-22

5.4.4.2 Inspection .................................................................................................. 5-23

5.4.5 Bearing Cover .................................................................................................... 5-24

5.4.5.1 Disassembly .............................................................................................. 5-24

5.4.6 Separating High-stage and Low-stage Blocks................................................... 5-25

5.4.6.1 Disassembly .............................................................................................. 5-25

5.4.7 Gear Coupling .................................................................................................... 5-25

5.4.7.1 Disassembly .............................................................................................. 5-25

5.4.7.2 Inspection .................................................................................................. 5-26

5.4.8 Removing Oil Injection Pipe............................................................................... 5-27

5.4.8.1 Disassembly ............................................................................................... 5-27

5.4.9 Balance Piston ................................................................................................... 5-28

5.4.9.1 Disassembly .............................................................................................. 5-28

5.4.9.2 Inspection .................................................................................................. 5-28

5.4.10 High-stage Suction Cover and Side Bearings ................................................... 5-29

2202MYJE-MY-C8-N_2018.02.

Table of Contents

Compound 2-stage Screw Compressor 3225**C

viii

5.4.10.1 Disassembly .............................................................................................. 5-29

5.4.10.2 Inspection .................................................................................................. 5-30

5.4.11 Low-stage Suction Cover and Side Bearings .................................................... 5-31

5.4.1 1.1 Disassembly .............................................................................................. 5-31

5.4.11.2 Inspection .................................................................................................. 5-31

5.4.12 Thrust Bearing Block ......................................................................................... 5-32

5.4.12.1 Disassembly of the High-stage Thrust Bearing Block ............................... 5-32

5.4.12.2 Disassembly of the Low-stage Thrust Bearing Block ................................ 5-33

5.4.12.3 Inspection (High-stage and Low-stage) ..................................................... 5-33

5.4.13 High-stage Rotors and Main Rotor Casing ........................................................ 5-34

5.4.13.1 Disassembly .............................................................................................. 5-34

5.4.13.2 Inspection .................................................................................................. 5-35

5.4.14 Low-stage Rotors and Main Rotor Casing ......................................................... 5-35

5.4.15 High-stage Bearing Head and Main Bearings ................................................... 5-36

5.4.15.1 Disassembly .............................................................................................. 5-36

5.4.15.2 Inspection .................................................................................................. 5-36

5.4.16 Low-stage Bearing Head and Main Bearings .................................................... 5-37

5.4.16.1 Disassembly .............................................................................................. 5-37

5.4.16.2 Inspection .................................................................................................. 5-37

5.5 Reassembly ................................................................................................ 5-38

5.5.1 Unloader Slide Valve and Guide Block .............................................................. 5-40

5.5.2 Bearing Head and Main Bearings ...................................................................... 5-41

5.5.3 Bearing Head and Main Rotor Casing ............................................................... 5-42

5.5.4 Installing the Rotors ........................................................................................... 5-43

5.5.5 Suction Cover and Side Bearings ...................................................................... 5-44

5.5.6 Balance Piston Sleeve ....................................................................................... 5-45

5.5.7 Installing the Suction Cover ............................................................................... 5-46

5.5.8 Thrust Bearing Block ......................................................................................... 5-48

5.5.8.1 End Clearance Measurement .................................................................... 5-50

5.5.8.2 End Clearance Adjustment Procedure ...................................................... 5-51

5.5.8.3 Tightening after Finishing the End Clearance Adjustment ........................ 5-52

5.5.8.4 Installing the Balance Piston ..................................................................... 5-53

5.5.9 Balance Piston Cover and High-stage Unloader Cylinder ................................. 5-53

5.5.10 Bearing Cover .................................................................................................... 5-56

5.5.11 Shaft Seal Block ................................................................................................ 5-57

5.5.12 Low-stage Unloader Cylinder ............................................................................ 5-60

5.5.13 Unloader Cover .................................................................................................. 5-61

5.5.14 Coupling the High-stage and Low-stage Blocks ................................................ 5-62

5.5.15 Unloader Indicator ............................................................................................. 5-64

5.5.15.1 Potentiometer ............................................................................................ 5-64

5.5.15.2 Micro-switches and Micro-switch Cam ...................................................... 5-64

5.5.15.3 Reassembly ............................................................................................... 5-65

2202MYJE-MY-C8-N_2018.02.

Table of Contents

Compound 2-stage Screw Compressor 3225**C

ix

Chapter 6 Troubleshooting

01: Compressor does not start up ............................................................................ 6-1

02: Compressor stops immediately after startup ................................................... 6-1

03: Unusually low pressure (decrease of suction pressure) ................................. 6-2

04: Low oil pressure (low lubricating oil supply pressure) ................................... 6-2

05: Intermediate pressure is unusually high ........................................................... 6-3

06: Unusually high pressure (abnormal discharge pressure) ............................... 6-4

07: Discharge temperature is abnormally high ....................................................... 6-5

08: Leak from mechanical seal ................................................................................. 6-6

09: Squeaking of mechanical seal ............................................................................ 6-7

10: Capacity control position is indicated incorrectly ........................................... 6-7

11: Capacity control malfunction.............................................................................. 6-8

12: Compressor generates abnormal vibration and/or sound .............................. 6-9

Chapter 7 Related Documents

7.1 Exploded Views, Assembly Sectional Views ............................................ 7-1

7.2 Parts Configuration Table ......................................................................... 7-27

7.3 Tightening Torques for Bolts and Nuts ................................................... 7-34

7.4 About the O-rings Used ............................................................................. 7-36

7.4.1 List of O-rings Used ........................................................................................... 7-36

7.4.2 O-ring Materials Used for Screw Compressor ................................................... 7-36

7.5 Tools for Disassembly............................................................................... 7-37

2202MYJE-MY-C8-N_2018.02.

Chapter 1 Safety

Compound 2-stage Screw Compressor 3225**C 1.1 Strict Requirements and Prohibitions

1-1

Chapter 1 Safety

1.1 Strict Requirements and Prohibitions

1.1.1 Strict Requirements (Do’s)

1.1.1.1 Do’s on Operation

Make sure to install safety and protective devices on the package unit.

Regularly inspect the safety and protective devices if they function properly.

If the safety or protective devices do not work properly or if this product operates abnormally,

immediately stop the operation and report to the supervisor. Obtain his/her approval and

direction before restarting the compressor.

If this product stops for unknown reasons, immediately inform your supervisor of it. Obtain

his/her approval before restarting the compressor.

Some types of refrigerants emit bad smell or toxic gases when they leak. Make sure to

ventilate the air during operation.

For the properties of refrigerant and lubricating oil (corrosiveness, decomposability or toxicity),

be sure to obtain the Safety Data Sheet (SDS) and follow the relevant information.

When stopping the operation of this product, close the suction and discharge side shut-off

valves and turn "OFF" the motor (main power), heater power, and control power.

1.1.1.2 Do’s on Maintenance

Prepare work procedures based on a work schedule. Be sure to perform danger forecasting

before starting the work.

Before performing the work together with at least one other person, thoroughly confirm each

other's work details and procedures to acknowledge the other worker's movement.

When troubleshooting during operation or before performing setup, cleaning, maintenance,

or inspection of this product, always turn OFF the main power to the motor and control power

and other devices. Also, lock and tag out them to prevent the power from being supplied

erroneously during operation.

When troubleshooting during operation or before performing setup, cleaning, maintenance,

or inspection of this product, confirm that the pressure inside this product and the package unit

is at atmospheric pressure.

Some refrigerants in use generate bad smell or toxic gases, or may cause deficiency of

oxygen. Before starting work, measure oxygen concentration in the work area as necessary.

Ventilate the area well. Be sure to keep the area well ventilated until the work is finished.

For the properties of refrigerant and lubricating oil (corrosiveness, decomposability or toxicity),

be sure to obtain the Safety Data Sheet (SDS) and follow the relevant information.

After using tools always restore to designated place and never leave tools in the package unit

1.1.1.3 Do’s on Lockout/Tagout after Shutting Off the Power

Attach lockout/tagout mechanism to the main breakers of motor main power and control power.

Lockout/tagout after power off is a very effective means to secure safety. It can prevent the

power source from being turned on by accident by two or more workers which may cause

injury to other worker(s).

2202MYJE-MY-C8-N_2018.02.

Chapter 1 Safety

Compound 2-stage Screw Compressor 3225**C 1.1 Strict Requirements and Prohibitions

1-2

If there are any possibilities of danger during works (especially during cleaning, maintenance

and inspection, and troubleshooting), turn "OFF" the motor main power and control power, and

perform lockout/tagout.

In the following situations, workers may neglect to perform power source shutoff or

lockout/tagout. Clearly notify the workers of the necessity of lockout/tagout.

It is assumed that workers do not perform lockout/tagout before starting work because it is

troublesome, and only turn "OFF" the main motor and control power.

It is assumed that workers only turn off the main motor and control power and do not

lockout/tagout the main motor and control power, because they judge that there is no

danger.

1.1.1.4 Do’s about Personal Protective Gear

Prepare and use protective gear complying with the safety standards of the regulations.

Check the function of each protective gear before using.

Wear designated clothes such as work outfits, with their cuffs tightly closed.

Do not wear any neckties or jewelry as there is a risk of being entangled by a movable part or

rotating part. Put on a helmet as your hair may get entangled.

Do not have anything in your pocket to prevent objects from falling into the machine.

1.1.1.5 Do’s about Handling of Hazardous and Toxic Substances

Obtain the Safety Data Sheet (SDS) from manufacturers of hazardous and toxic substances.

Check the SDS and follow the handling instructions recommended by the manufacturers to

handle and store those substances.

1.1.1.6 Do’s about Handling Emergency Situations

Formulate an emergency action plan complying with the regulations, and post it on a safe

place.

1.1.1.7 Do’s about Waste Oil, Fluid, and Materials

Disposing of refrigerant and oil used for this product are subject to a number of regulations for

the environmental protection purposes. Follow the local, state, federal acts and regulations

and your company's rules when disposing of such waste oil, fluid and materials.

1.1.1.8 Other Do’s

Clean the floor around the entire refrigerating/cold storage/gas compression package unit.

Provide a safety passage.

Walk only on the areas set up as a work floor. Also, do not leave tools and cleaning solutions

in that area.

If water or oil is spilled on this product or the floor, immediately wipe it off to prevent workers

from slipping and getting injured.

2202MYJE-MY-C8-N_2018.02.

Chapter 1 Safety

Compound 2-stage Screw Compressor 3225**C 1.2 Warnings

1-3

1.1.2 Prohibitions (Don’ts)

Do not remove or relocate any safety device, including electrical interfaces.

Do not disable any safety device by short-circuiting or bypassing without any permission.

Do not leave this product unsafe and unattended, by removing a safety cover or some other

measures.

Do not touch, clean or lubricate any part of this product which is moving.

Do not touch relays or electric systems such as terminal block with bare hands when turning

on the power.

1.2 Warnings

The warning messages described in this manual warn dangerous situations that may arise during work

by using the following four categories.

Neglecting such warnings may cause accidents, resulting in personal injury or even death.

Also, this product or its auxiliary equipment may be heavily damaged. Therefore, be sure to always

observe the instructions of the warnings.

Table 1-1 Warning Symbols and their Meanings

Symbol

Meaning

Indicates a hazardous situation which, if not avoided, could very likely cause

serious injury or death.

Indicates a potentially hazardous situation which, if not avoided, may cause serious

injury or death.

Indicates a potentially hazardous situation which, if not avoided, may cause minor

or moderate injury.

Indicates a potentially hazardous situation which, if not avoided, may result in

property damage.

2202MYJE-MY-C8-N_2018.02.

Chapter 1 Safety

Compound 2-stage Screw Compressor 3225**C 1.3 Residual Risks

1-4

1.3 Residual Risks

The following information assumes that this product is operated or inspected/maintained while being

used in general refrigerating/cold storage/gas compression package units.

Note that all hazardous sources cannot be predicted for the applications mentioned.

Devise appropriate countermeasures for hazardous sources in your systems.

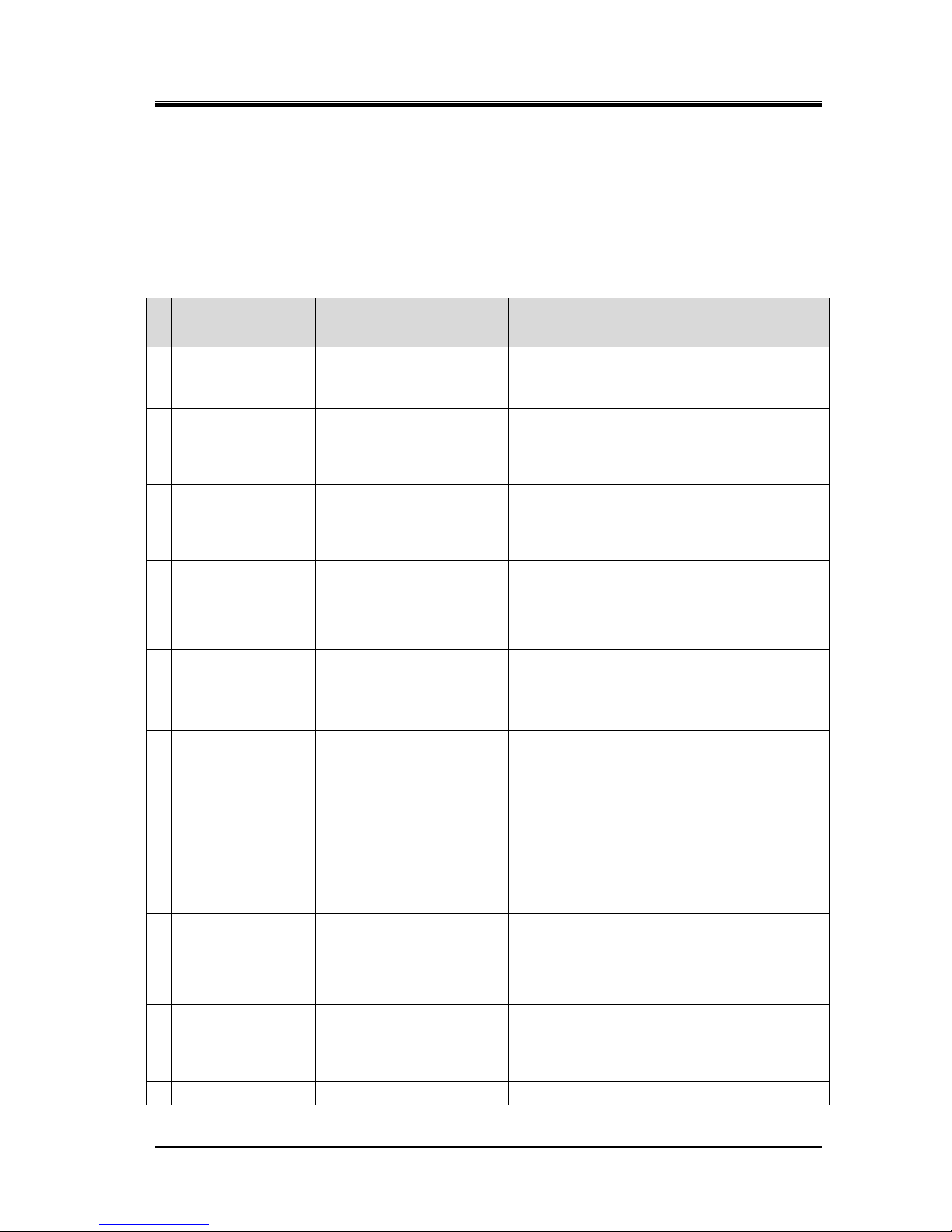

Table 1-2 Hazardous Sources

Hazardous sources

Predicted hazard

Countermeasures in

operation

Countermeasures in

cleaning, inspection,

and parts exchange

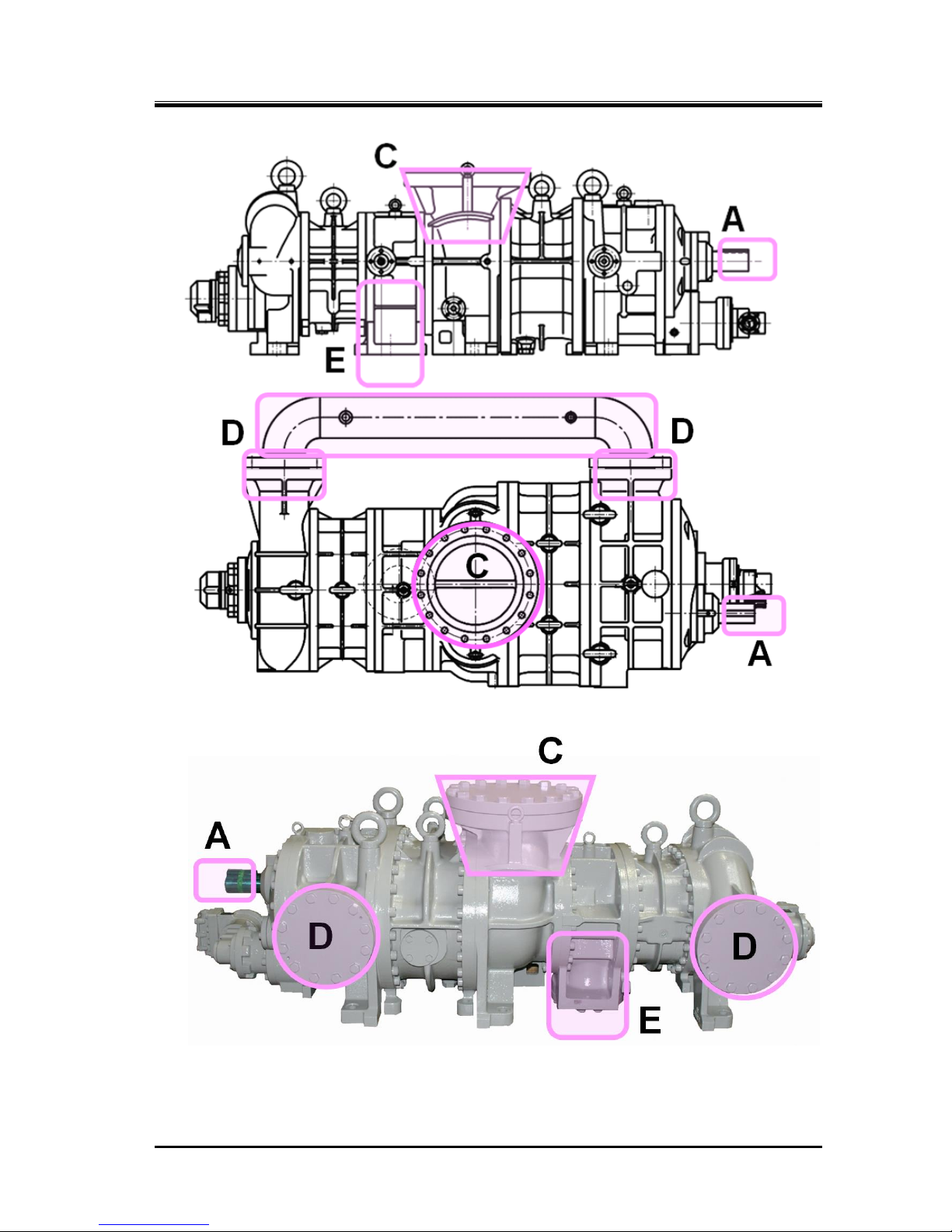

A

Motor and

compressor coupling

Refer to Figure 1-1

Caught in due to contact

Install coupling cover

and prohibit opening.

Keep away.

Turn off motor main

power and control

power, and conduct

lockout/tagout.

B

Motor terminals

Electric shock caused by

contact with live wires or

electrical leakage

Keep away.

Do not open terminal

boxes.

Do not touch terminal

boxes.

Turn off motor main

power and control

power, and conduct

lockout/tagout.

C

Compressor

low-stage side

suction casing

Refer to Figure 1-1

Frostbite due to contact

Contact with or inhalation of

hazardous substances

generated by leakage of

refrigerant or the like

Keep away and do not

touch.

Wear protective gear.

Detect gas leakage.

Wear protective gear.

Work under room

temperature.

D

Compressor

intermediate piping

(low-stage discharge

port to high stage

suction port)

Refer to Figure 1-1

Burn injury due to contact

Contact with or inhalation of

hazardous substances

generated by leakage or

spout of refrigerant or the like

Keep away and do not

touch

Wear protective gear

Gas leakage detection

Wear protective gear

Work in temperatures

below 40 °C

E

Compressor

high-stage side

discharge casing and

discharge piping

Burn injury due to contact

Contact with or inhalation of

hazardous substances

generated by leakage or

spout of refrigerant or the like

Keep away and do not

touch.

Wear protective gear.

Detect gas leakage.

Wear protective gear.

Work at a temperature

of not higher than 40°C.

F

Check valves/service

valves and joints on

each section of the

package unit

Contact with or inhalation of

hazardous substances

generated by mishandling or

leakage

Frostbite or burn due to

contact

Sufficient ventilation

Indicate valve

open/close state.

Keep away and do not

touch.

Wear protective gear.

Sufficient ventilation

Wear protective gear.

Tagout for controlled

valve

G

Solenoid

valves/electric valves

on each section of the

package unit

Electric shock caused by

contact with live wires or

electrical leakage

Pinched due to contact with

driving part

Install protective cover

on terminals, and

prohibit opening.

Keep away and do not

touch.

Wear protective gear.

Turn off each breaker

and the control power,

and conduct

lockout/tagout.

Wear protective gear.

H

Electric components

in each section of the

package unit (oil

heater, protective

switch, etc.)

Electric shock caused by

contact with live wires or

electrical leakage

Pinched due to contact with

driving part

Install protective cover

on terminals, and

prohibit opening.

Keep away and do not

touch.

Wear protective gear.

Turn off each breaker

and the control power,

and conduct

lockout/tagout.

Wear protective gear.

I

Package unit oil

drains

Contact with hazardous

substances generated by

leakage or spout

Burn caused by contact with

high-temperature fluid

Sufficient ventilation

Keep away and do not

touch.

Wear protective gear.

Sufficient ventilation

Wear protective gear.

Work at a temperature

of not higher than 40°C.

J

Noises

Damage caused by noise

Wear protective gear.

—

2202MYJE-MY-C8-N_2018.02.

Chapter 1 Safety

Compound 2-stage Screw Compressor 3225**C 1.3 Residual Risks

1-5

Figure 1-1 Locations of Hazardous Sources (compressor)

Photo 001 Locations of Hazardous Sources (compressor)

2202MYJE-MY-C8-N_2018.02.

Chapter 1 Safety

Compound 2-stage Screw Compressor 3225**C 1.4 Safety Devices

1-6

1.4 Safety Devices

For safe use and protection of this product, make sure to attach safety devices to this product in

accordance with the regulations and the following instructions.

Safety devices cannot be kept in normal condition unless inspected and maintained at regular intervals.

Their maintenance and inspection need to be performed as an important part of the

maintenance/inspection work project. Provide users of this product with necessary information on the

safety devices, for example, types of the safety devices, installation position, function, and inspection

method of safety related devices.

Check the safety devices after turning on the power and before operation of this

product. If they do not operate normally, immediately take repair or replace

safeties before starting this product.

1.4.1 Emergency Stop Button

Overview/Function/Purpose

The emergency stop buttons are used to stop the compressor operation immediately if an

emergency occurs in this product.

Installation Positions

On the control board and in the operation control room

Stop/Restoration Methods

The operating procedures for the emergency stop button, i.e., how to stop the operation and restore

the normal operating condition, must be clearly defined and the information provided to the user of

this product.

Inspection Method/Cycle

The emergency stop buttons must be tested before commissioning and must also be periodically

re-tested after that. The inspection procedures and the inspection interval for the emergency stop

button must be clearly defined and the information provided to the user of this product.

1.4.2 Breakers of Motor Main Power and Control Power

(with Lockout/Tagout Mechanism)

Overview/Function/Purpose

Turn off the main motor and control power, and if there is any possibility of danger during work

(especially during cleaning, maintenance, inspection, or troubleshooting), lockout/tagout devices

must be used on the breakers of the main motor and control powers to prevent injuries to workers in

case the power is turned on accidentally during work.

Methods of Performing and Releasing Lockout/Tagout

Make sure to clearly notify methods of performing and releasing lockout/tagout referring to the

regulations created by Occupational Safety & Health Administration (OSHA) or local governing

body.

Inspection Method/Cycle

The inspection procedures and the inspection interval for the lockout/tagout devices, must be

clearly defined and the information provided to the user of this product.

2202MYJE-MY-C8-N_2018.02.

Chapter 1 Safety

Compound 2-stage Screw Compressor 3225**C 1.4 Safety Devices

1-7

1.4.3 Compressor Protective Devices

Be sure to adjust the set values and check operation of the protective devices at

the commissioning.

Overview/Function/Purpose

These protective devices are used to protect this product.

Protecting from discharge temperature rise (DT)

This device activates and stops the compressor operation when the compressor discharge

temperature gets equal to or higher than the set value.

Install a temperature sensing port to the discharge pipe.

Protecting from oil temperature rise (OT)

This device activates and stops the compressor operation when the compressor oil

temperature gets equal to or higher than the set value.

Install a temperature sensing port to the oil supply pipe of the package unit (after the oil

cooler).

Protecting from high pressure (HP)

This device activates and stops the compressor operation when the compressor discharge

pressure gets abnormally high due to mishandling of the compressor or suspension of water

supply to the condenser. This device prevents explosion of the equipment and components.

Install a pressure sensing port to the discharge pipe.

Protecting from intermediate pressure (IP)

This device activates when the intermediate pressure of the compressor gets equal to or

higher than the set value and properly controls the compressor. In some cases, this device

stops the compressor operation. Install a pressure output port to the package unit's

intermediate gas pipe (or compressor's intermediate gas pressure output port).

Protecting from suction pressure drop (LP)

This device activates and stops the compressor operation when the compressor suction

pressure gets equal to or lower than the set value.

Install a pressure sensing port to the suction pipe.

Protecting from oil pressure (OP)

This device activates and stops the compressor operation when the differential pressure to

supply oil to the compressor (= lubrication oil supply pipe pressure − compressor discharge

pressure) gets equal to or lower than the set value, due to insufficient lubricating oil, clogged

filter or mixture of refrigerant into the lubrication oil. This device prevents the sliding portion

from being abnormally worn or seized.

Install a pressure sensing port to the package unit's oil supply pump (after the oil pump) and

the discharge pipe.

Protecting from motor over-current (OCR)

This device activates and applies appropriate control when the current gets equal to or higher

than the set level flows. In some cases, this device stops the compressor operation.

This device is normally installed inside the control panel.

2202MYJE-MY-C8-N_2018.02.

Chapter 1 Safety

Compound 2-stage Screw Compressor 3225**C 1.4 Safety Devices

1-8

Connection Positions and Settings

Specify the connection position and setting for each compressor protective device, and make sure

to provide users of this product with them.

Make sure that the set values do not exceed the operating limits shown in Chapter 2, section 2.3.2

and Table 2-2 in this manual.

Inspection Method/Cycle

Compressor protective devices require operation tests and confirmation of the settings calibration

before commissioning as well as at regular intervals.

Specify the inspection methods/intervals of the compressor protection devices, and make sure to

provide users of this product with such information.

In the operation test, check that alarms and protective devices operate normally

by using devices such as pressure tester. Do not operate the compressor with all

the valves closed, or in any other dangerous conditions.

If the protection from oil pressure (OP), high pressure (HP) activates, do not

restart operation until the cause of activation is removed.

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.1 Overview of MYCOM 3225**C

2-1

Chapter 2 Compressor Specifications and Structure

2.1 Overview of the 3225**C

The 2-stage compression system, which has hitherto required two units of standard-type screw

compressor for its embodiment, can now be realized by a single unit of compound 2-stage screw

compressor.

Generally, screw compressors use oil injection to keep discharge temperature at a low level during

operation without loss of volumetric efficiency even at high compression ratios. It can, therefore, be

operated with a single-stage compression system even at evaporative temperatures near -40°C.

However, for normal use at low temperatures, a 2-stage compression system is applied in order to

improve kW/RT (ratio of power consumption versus cooling ability). If the 2-stage compression system

is configured with standard-type screw compressors, at least two screw compressor units need to be

installed, one on the high-stage and the other on the low-stage, which inevitably requires double

installation of the entire system including machinery, motors, utilities, etc.

This 2-stage screw compressor is produced to solve this problem. It is a single unit that has two

single-stage compressor units combined into one.

The 3225**C model has a capacity control mechanism for startup load reduction on the high-stage, and

a capacity control mechanism for coping with load change on the low-stage.

In addition, there are four rotor lengths for the low-stage and three rotor lengths for the high-stage.

Moreover, customer is able to select each low-stage and high-stage volume ratio from two

specifications. Employing these combinations of each specification, 3225**C is providing a high

versatility that can satisfy a wide range of operation conditions required by different applications at the

load side. Therefore, the 3225**C models are the long-selling products which last to

more than 30 years since the developed in 1982 as the large sized compound 2-stage screw

compressor.

2.2 Model Designation of the Compressor

This manual describes 3225**C-*B*-51 and 3225**C-*B*-61 models.

The meaning of the type designation, which is engraved on the MODEL column of the compressor

nameplate, is as follows.

*3225**C-*B*-51/61

5: Power frequency (6: 60Hz)

1: Indicates that it is a motor directly connected type.

* Unless specifically specified, machines manufactured in

September, 2010 or after do not have this indication engraved

on their nameplate.

Vi (volume ratio) specified for the high-stage discharge port,

standard value of which is L or M

Means a booster (low-stage machine)

Vi (volume ratio) specified for the low-stage discharge port, standard

value of which is L or M

Stands for Compound (compound 2-stage machine)

Specifications of high-stage rotor length, which is L, M or S

Specifications of low-stage rotor length, which is LL, L, M or S

High-stage rotor diameter of 250

Low-stage rotor diameter of 320

Indicates working fluid

(Example: N = Ammonia, F= Fluorocarbon, P = Propane, HE = Helium)

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.3 Compressor Specifications

2-2

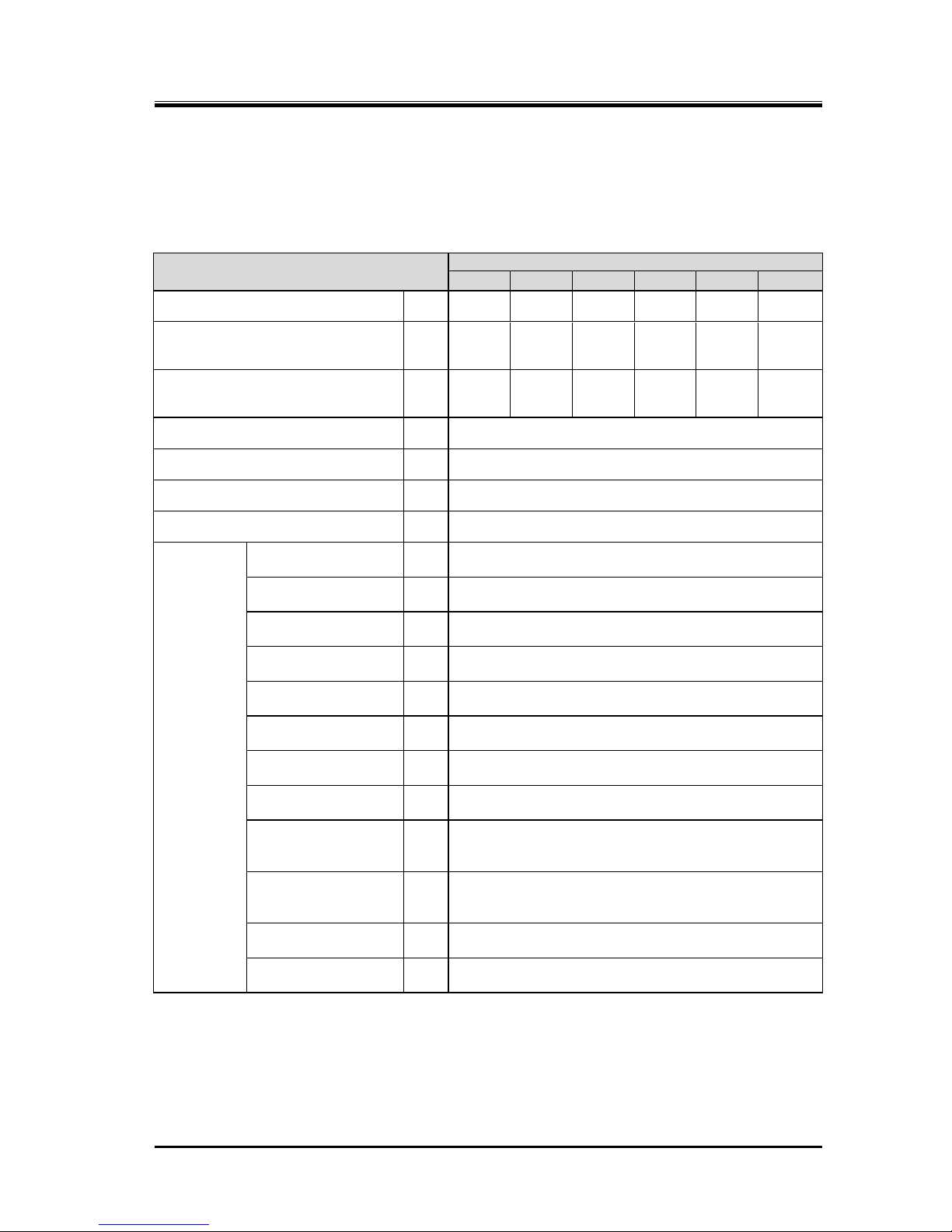

2.3 Compressor Specifications

2.3.1 Standard Specifications

Table 2-1 3225**C Screw Compressor Specifications (1/2)

Items

Model

LLLC

LLMC

LLSC

LLC

LMC

LSC

Product mass

kg

4150

4100

4020

3440

3390

3310

Low-stage swept volume

@3550 min-1 /2950 min-1

m3/h

6740

/5600

6740

/5600

6740

/5600

5700

/4740

5700

/4740

5700

/4740

High-stage swept volume

@3550 min-1 /2950 min-1

m3/h

2840

/2360

2380

/1980

1900

/1580

2840

/2360

2380

/1980

1900

/1580

Working fluid (Refrigerant)

-

Ammonia, Hydrofluorocarbon, etc.

Design pressure

MPa

2.6

Capacity control (Actual load)

%

10 to 100

Rotation direction

-

Counterclockwise viewed from motor

Connected

pipe size

Low-stage suction

flange

-

JIS 20K 350A (14”)

Low-stage discharge

flange

-

JIS 20K 200A (8”)

High-stage suction

flange

-

JIS 20K 200A (8”)

High-stage discharge

flange

-

JIS 20K 150A (6”)

Journal lubrication

(low-stage)

-

JIS 20K 40A (1-1/2”)

Journal lubrication

(High-stage)

-

JIS 20K 25A (1”)

Oil injection

lubrication

-

JIS 20K 20A (3/4”)

Oil return Inlet

(Rotor casing)

-

JIS 20K 32A (1-1/4”)

Oil return outlet

(Low-stage Bearing

cover)

-

JIS 20K 32A (1-1/4”)

Oil return outlet

(High-stage Suction

cover)

-

JIS 20K 20A (3/4”)

Low-stage capacity

control

-

Load: Rc3/8, Unload: Rc3/8

High-stage capacity

control

-

Load: Rc3/8・Rc1/2, Unload: Rc3/8

Unless otherwise noted, the pressure unit MPa represents the gauge pressure

in this manual.

For limits of working temperature and pressure, see "2.3.2 Operation Limits" in

this manual.

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.3 Compressor Specifications

2-3

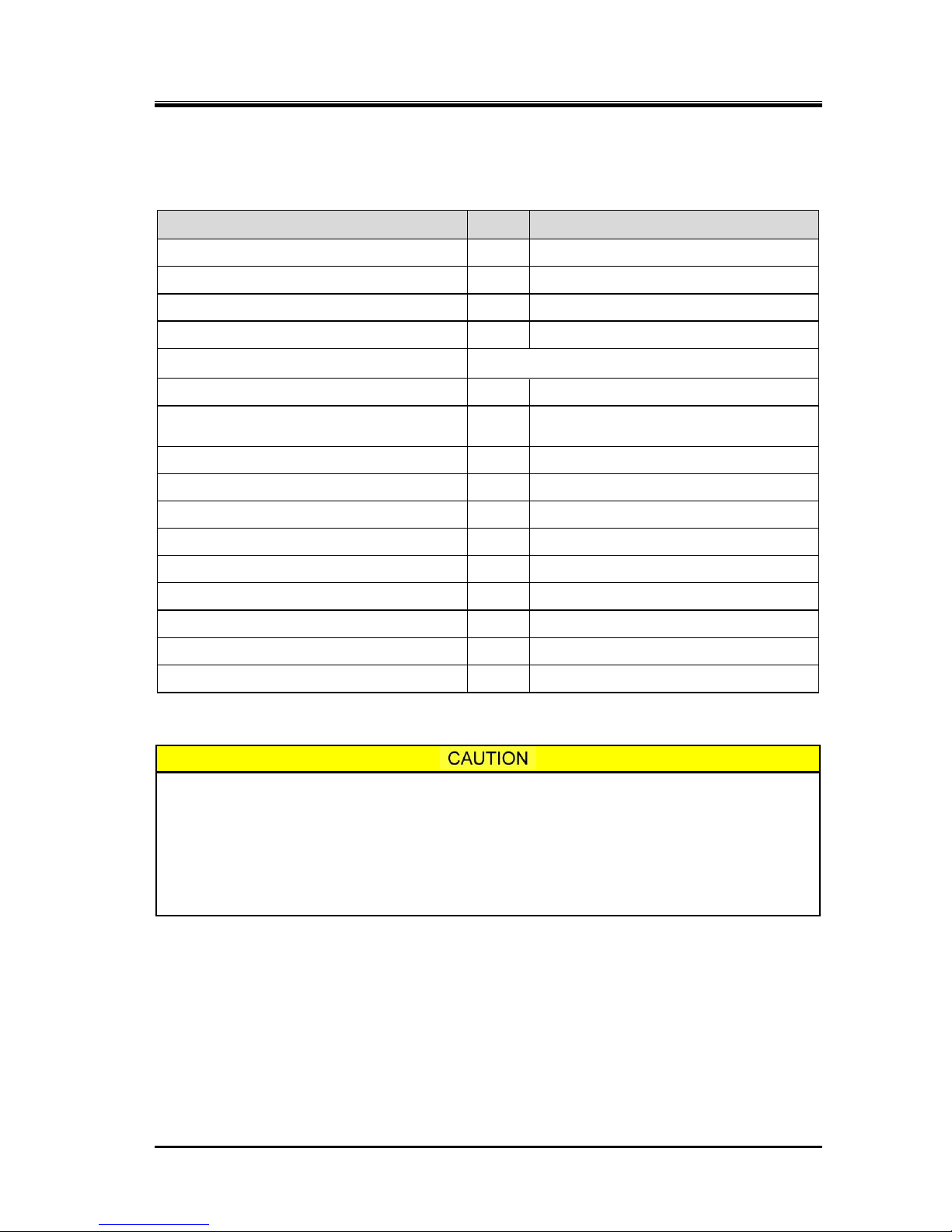

Table 2-2 3225**C Screw Compressor Specifications (1/2)

Items

Model

MLC

MMC

MSC

SLC

SMC

SSC

Product mass

kg

3290

3240

3160

3150

3100

3020

Low-stage swept volume

@3550 min-1 /2950 min-1

m3/h

4760

/3960

4760

/3960

4760

/3960

3820

/3170

3820

/3170

3820

/3170

High-stage swept volume

@3550 min-1 /2950 min-1

m3/h

2840

/2360

2380

/1980

1900

/1580

2840

/2360

2380

/1980

1900

/1580

Refrigerant - Ammonia, Hydrofluorocarbon, etc.

Design pressure

MPa

2.6

Capacity control (Actual load)

%

10 to 100

Rotation direction

-

Counterclockwise viewed from motor

Connected

pipe size

Low-stage suction

flange

-

JIS 20K 350A (14”)

Low-stage discharge

flange

-

JIS 20K 200A (8”)

High-stage suction

flange

-

JIS 20K 200A (8”)

High-stage discharge

flange

-

JIS 20K 150A (6”)

Journal lubrication

(low-stage)

-

JIS 20K 40A (1-1/2”)

Journal lubrication

(High-stage)

-

JIS 20K 25A (1”)

Oil injection

lubrication

-

JIS 20K 20A (3/4”)

Oil return Inlet

(Rotor casing)

-

JIS 20K 32A (1-1/4”)

Oil return outlet

(Low-stage Bearing

cover)

-

JIS 20K 32A (1-1/4”)

Oil return outlet

(High-stage Suction

cover)

-

JIS 20K 20A (3/4”)

Low-stage capacity

control

-

Load: Rc3/8, Unload: Rc3/8

High-stage capacity

control

-

Load: Rc3/8・Rc1/2, Unload: Rc3/8

Unless otherwise noted, the pressure unit MPa represents the gauge pressure

in this manual.

For limits of working temperature and pressure, see "2.3.2 Operation Limits" in

this manual.

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.3 Compressor Specifications

2-4

2.3.2 Operation Limits

Table 2-3 Operation Limits of 3225**C

Items

Operation Limits

Maximum discharge pressure

MPa

1.96

Minimum suction pressure

MPa

−0.080

Maximum intermediate pressure

MPa

0.588

Minimum intermediate pressure

-

> Suction pressure

Oil supply pressure

・ Maximum journal lubrication pressure

MPa

Discharge pressure + 0.39

・ Minimum journal lubrication pressure

MPa

Discharge pressure +0.049 and

Suction pressure +0.49

・ Minimum oil injection lubrication pressure

MPa

Suction pressure +0.49

Maximum Suction temperature

°C

85

Minimum suction temperature

°C

−60

Maximum low-stage discharge temperature

°C

90

Maximum high-stage discharge temperature

°C

100

Maximum oil supply temperature

°C

60

Minimum oil supply temperature

°C

30

Maximum male rotor rotation speed

min-1

3600

Minimum male rotor rotation speed

min-1

1450

Note : Unless otherwise noted, the pressure unit MPa represents the gauge pressure in this manual.

If operation at partial load, which is not greater than 30 % of the indicated load, is

continued for a long time except when starting up the machine, abnormal noises

or vibration may be generated. So avoid such operation.

Repeated startup and stop in a short period is harmful not for the startup devices

and electric machinery but also for the compressor itself. For information on the

start/stop limitations, refer to each instruction manual. Wait at least 15 minutes

after stopping the compressor before restarting it.

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.3 Compressor Specifications

2-5

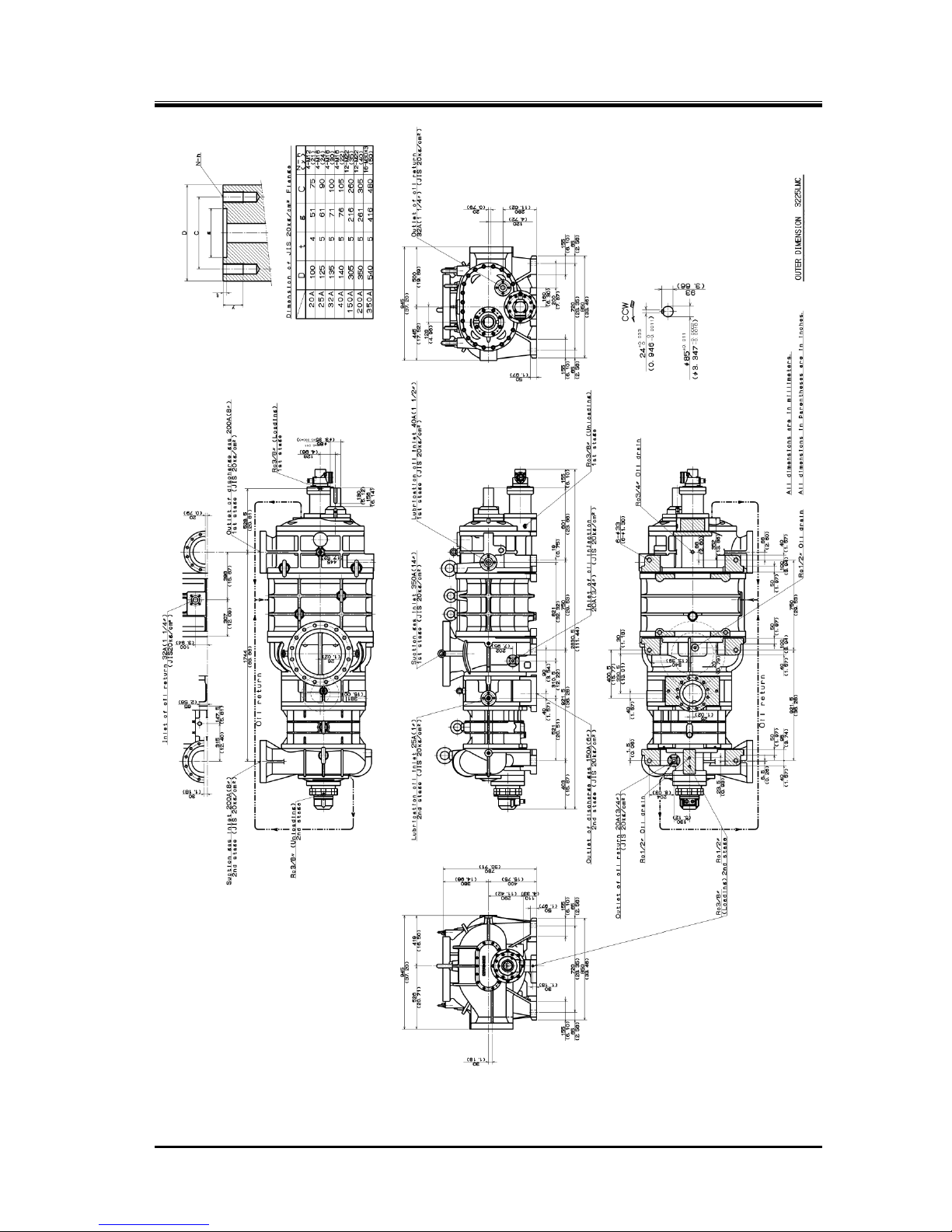

2.3.3 Outer Dimensions

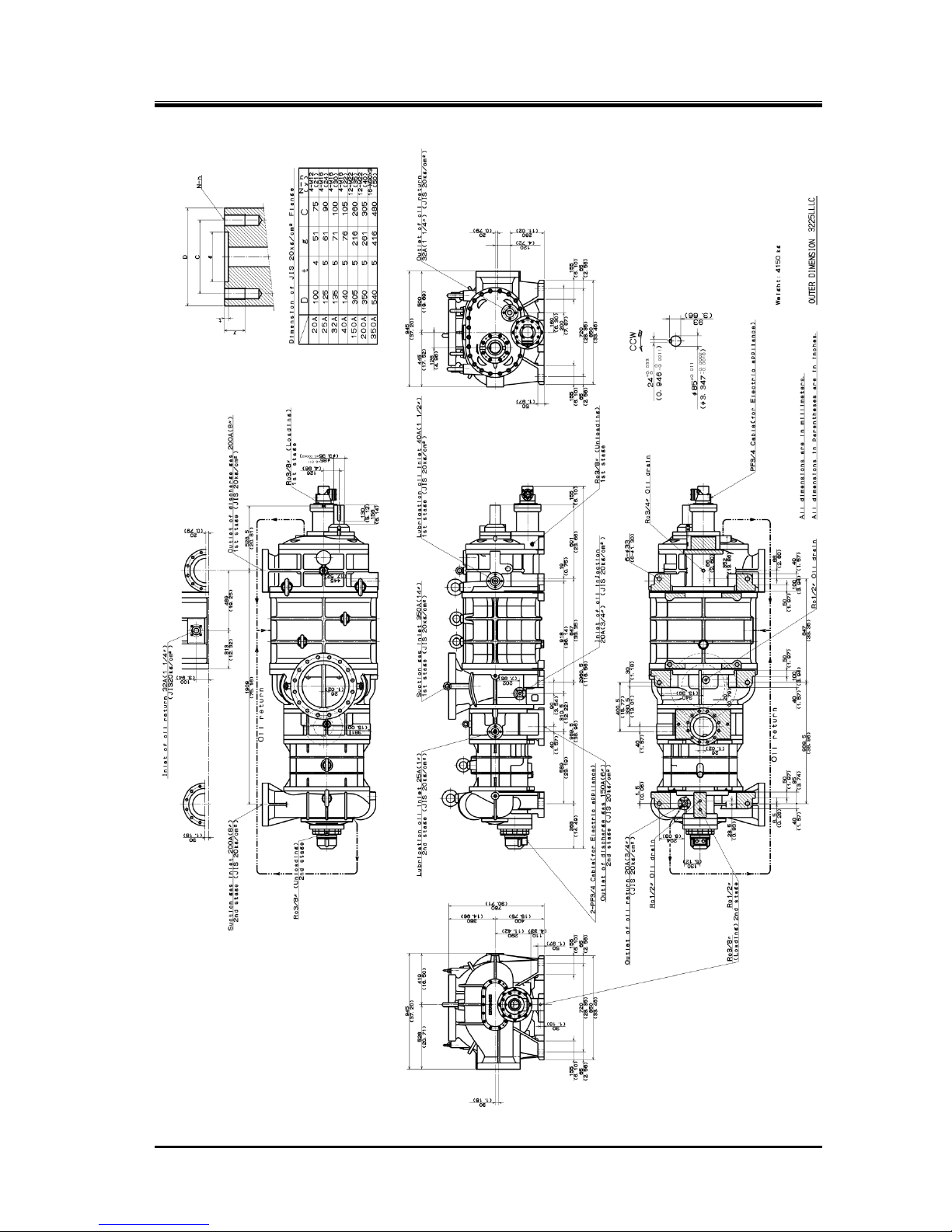

Figure 2-1 Outer Dimension 3225LLLC

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.3 Compressor Specifications

2-6

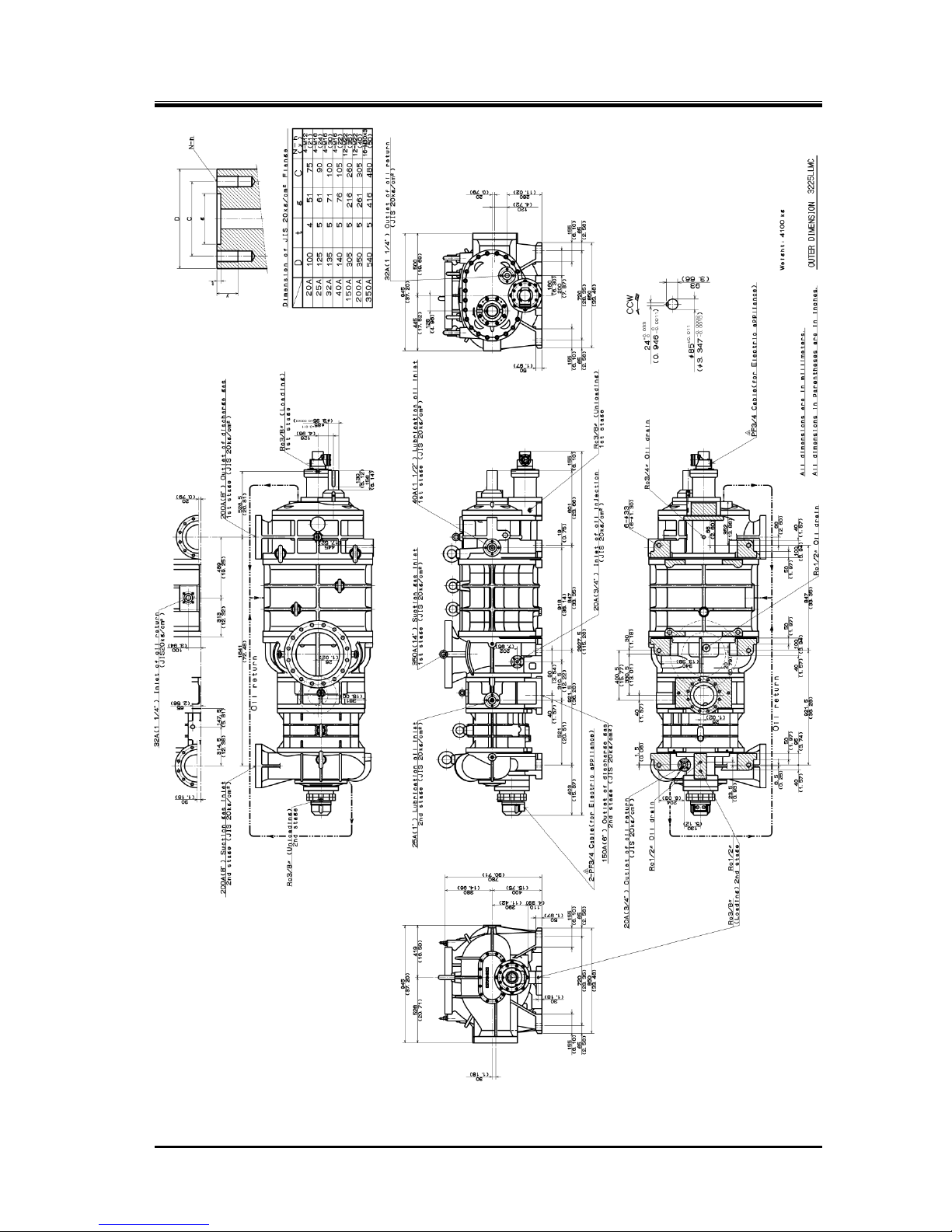

Figure 2-2 Outer Dimension 3225LLMC

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.3 Compressor Specifications

2-7

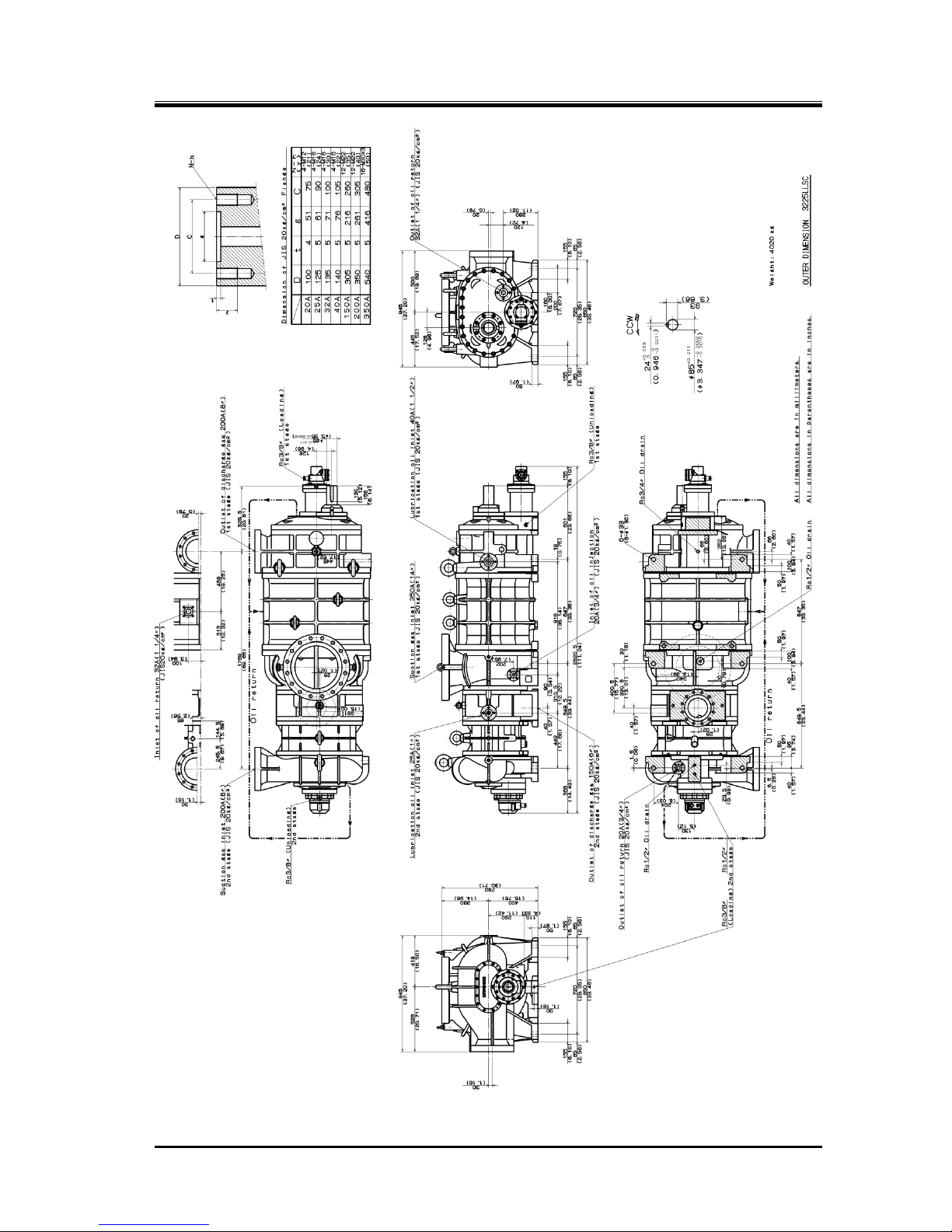

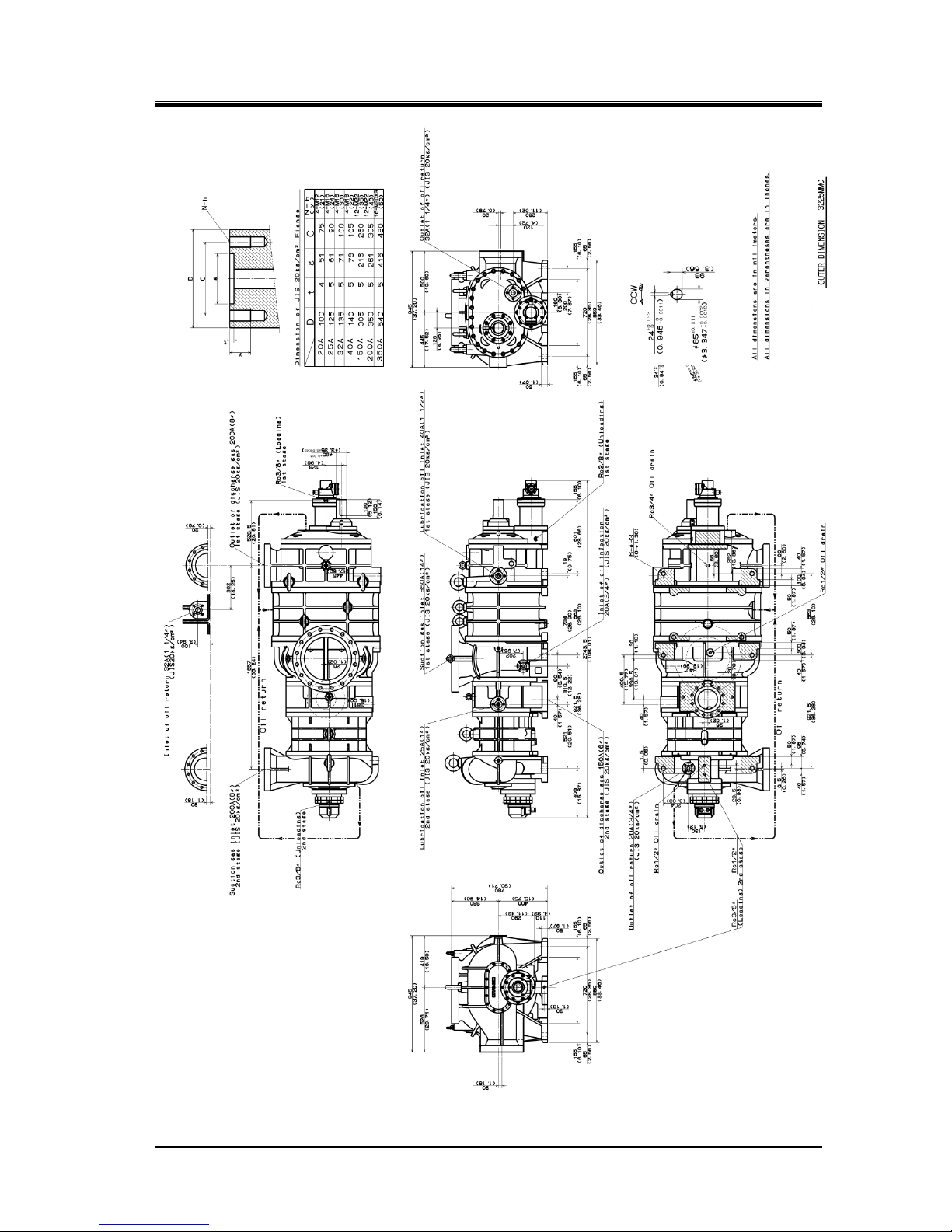

Figure 2-3 Outer Dimension 3225LLSC

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.3 Compressor Specifications

2-8

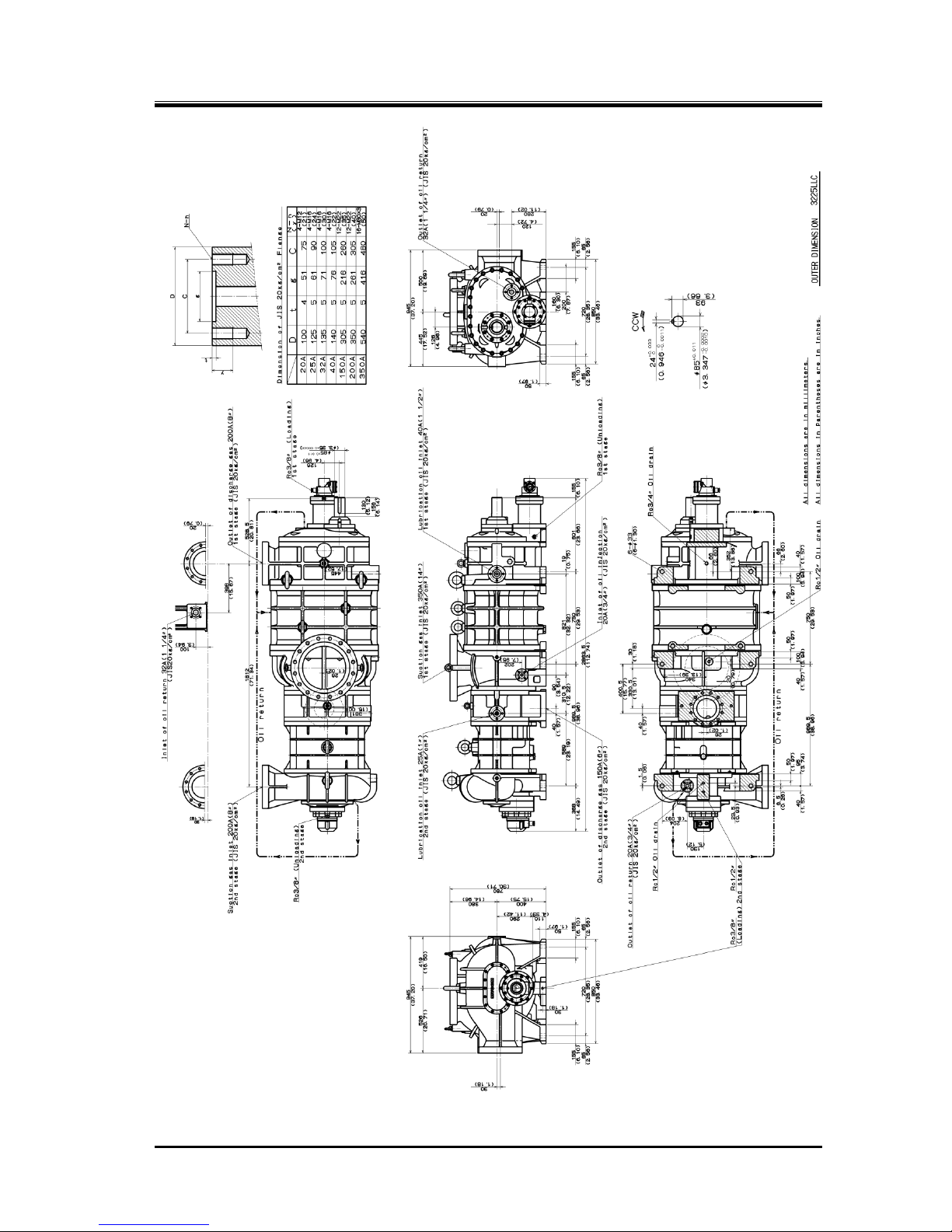

Figure 2-4 Outer Dimension 3225LLC

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.3 Compressor Specifications

2-9

Figure 2-5 Outer Dimension 3225LMC

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.3 Compressor Specifications

2-10

Figure 2-6 Outer Dimension 3225LSC

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.3 Compressor Specifications

2-11

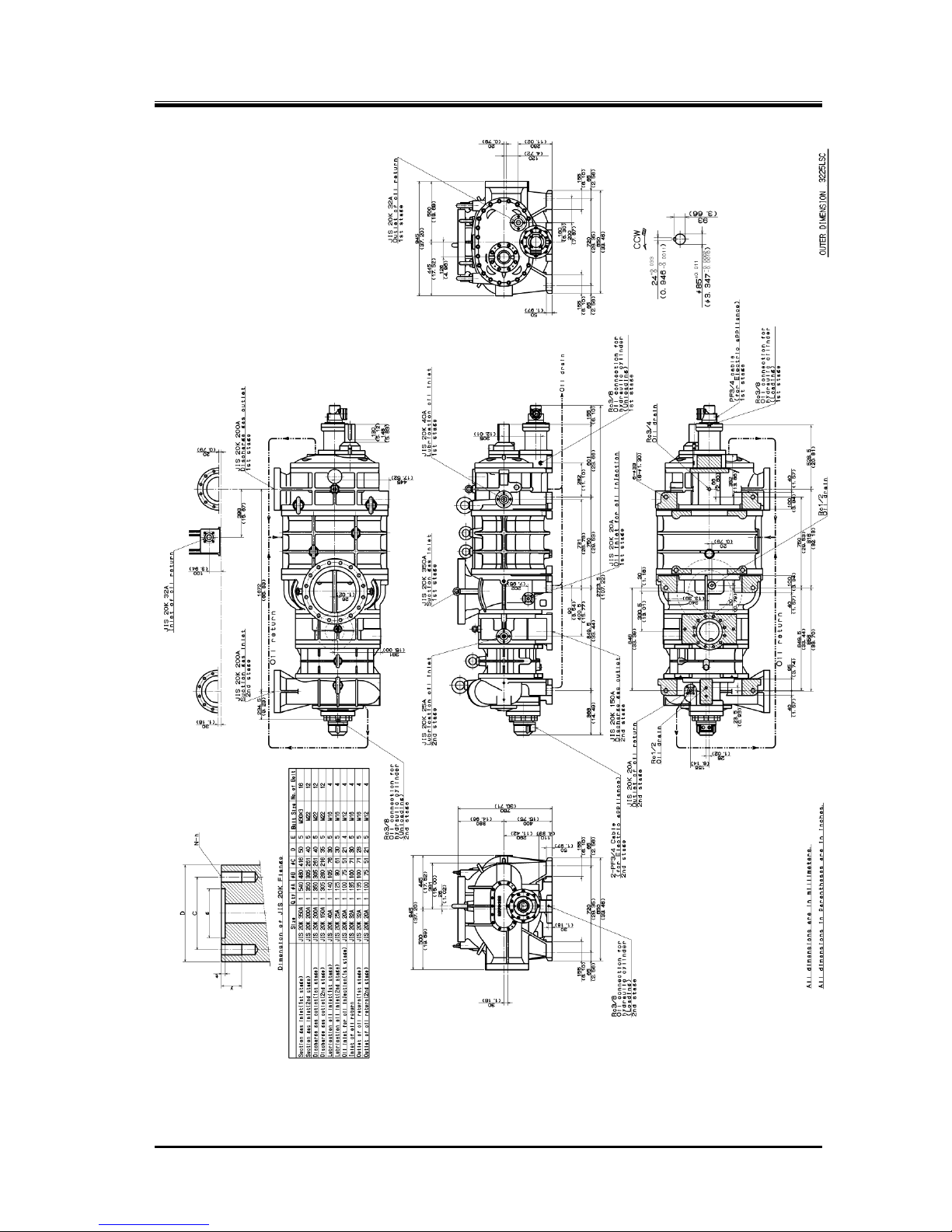

Figure 2-7 Outer Dimension 3225MLC

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.3 Compressor Specifications

2-12

Figure 2-8 Outer Dimension 3225MMC

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.3 Compressor Specifications

2-13

Figure 2-9 Outer Dimension 3225MSC

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.3 Compressor Specifications

2-14

Figure 2-10 Outer Dimension 3225SLC

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.3 Compressor Specifications

2-15

Figure 2-11 Outer Dimension 3225SMC

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.3 Compressor Specifications

2-16

Figure 2-12 Outer Dimension 3225SSC

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.4 Structure of Compressor

2-17

2.4 Structure of Compressor

For names and locations of each part of the compressor, refer to Section 7.1 "Exploded Views,

Assembly Sectional Views" and Section 7.2 "Parts Configuration Table" in this manual.

2.4.1 Sectional View

Figure 2-13 3225**C Screw Compressor Sectional Views

The 3225**C model, a compound 2-stage compressor, consists of two compressors, (i) a low-stage

compressor which suctions gas, working fluid, from the refrigerating unit and compresses (pressure-raises)

the gas and (ii) a high-stage compressor which furthermore compresses the gas that has been

pressure-raised by the low-stage compressor and sends the resulting gas to the equipment side.

In each casing (low-stage, high-stage), two screw rotors are supported on both ends by bearings. They are

meshed with each other in a joint assembly. These two screw rotors are a set of a male rotor having 4

protruding lobe profiles (M rotor) and a female rotor having 6 concave lobe profiles (F rotor). They conduct

compressing according to the mechanism explained below.

The standard compressor's M rotor is driven by a 2-pole motor; it operates at 3000 min-1 (50 Hz) or 3600

min-1 (60 Hz). F rotor operates at 2000 min-1 (50 Hz) or 2400 min-1 (60 Hz), conforming to the operation of M

rotor.

* The actual speed of a motor is less than its calculated speed (synchronous speed). This difference is

caused by slipping of the motor rotor.

The shaft of the low-stage compressor's M rotor which is linked with the motor has a shaft seal block that

keeps gas and lubricating oil from escaping from inside the compressor.

For high efficient operation, the 3225**C model has a capacity control mechanism for coping with load

change on the low-stage, and a capacity control mechanism for reducing startup load on the high-stage.

Discharge port

Low-stage

capacity control

mechanism

High-stage capacity

control mechanism

Low-stage

compressor

High-stage compressor

Shaft seal block

Low-stage

discharge port

High-stage suction port

Suction port

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.5 Mechanisms

2-18

2.5 Mechanisms

2.5.1 Basics of the Screw Compressor

The screw compressor is categorized as a positive displacement rotary compressor.

As shown in Figure 2-14, the refrigerant (gas) is continuously compressed by the 3-dimensional spaces

that are formed by a pair of male and female screw rotors (with different sectional profiles) and the

casing, as the spaces change continuously.

The rotor having 4 protruding lobe profiles is called a male or M rotor, and the rotor having 6 concave

lobe profiles is called a female or F rotor. In this manual, they are referred to as M rotor and F rotor.

The compressor is driven by the motor connected to the shaft of the M rotor.

Figure 2-14 Compressor Mechanism

2.5.2 Suction Process

As shown in Figure 2-15, the rotors with different lobe profiles are engaged. As the rotors turn, the

volume between the M and F rotor lobe profiles and the compressor casing gradually increases starting

from the suction side.

As the rotation continues, at a certain point when the volume reaches its maximum, the rotors isolate

the gas (volume), which is enclosed by the rotors and the compressor casing, from the suction port and

then continues rotation.

Figure 2-15 Suction Process

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.5 Mechanisms

2-19

2.5.3 Compression Process

As the rotors rotate further, the volume between the rotor lobes decreases while the sealing line moves

toward the discharge side, which compresses the trapped refrigerant gas.

2.5.4 Discharge Process

The volume between the rotor lobes decreases to a level predetermined by the discharge port. With the

rotations of the rotors, the compressed refrigerant gas is pushed out to the discharge port.

2.5.5 About Volume Ratio (Vi)

Volume ratios (Vi) of C-series screw

compressors are indicated in performance tables

or catalogs by using port symbols L and M.

The volume ratio represented by each symbol is

as follows:

L=2.63, M=3.65.

Which volume ratio (L or M) should be used is

decided according to operating conditions. If the

compressor is used with a volume ratio that does

not match operating conditions, operation will go

inefficiently wasting the power.

The relationship between volume ratios and

generally used compression ratios is as follows:

Figure 2-18 Volume Ratio

(Vi)

κ

= πi =Pd/Ps κ= Cp/Cv of refrigerant gas

Vi = Design volume ratio πi = Design compression ratio

As Vi is affected by the constant of the refrigerant gas, its value that corresponds to the compression

ratio will change depending on the refrigerant gas.

Figure 2-16 Compression Process

Figure 2-17 Discharge Process

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.5 Mechanisms

2-20

(A) Properly adapted Vi to load condition

(B) Improperly adapted Vi to load condition

Figure 2-19 Relationship between Volume ratio (Vi) and Operation Conditions

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.5 Mechanisms

2-21

2.5.6 Capacity Control Mechanism

The capacity control mechanism, by moving a slide valve, lets suction gas (immediately before

compressed) bypass and advance to the suction side, to help shorten the rotor portion used for

compression. The slide valve is located at the bottom of the casing in which the rotors mesh together,

and is constructed to move parallel to the rotor shaft. This movement is changed by a cam mechanism

into rotation movement. Its position (namely, capacity control ratio) is indicated externally and, at the

same time, fed back to the automatic control circuit by changing the electric resistance.

Figure 2-20 Capacity Control Mechanism

2.5.7 Bearings and Balance Piston

For the load acting on the rotor perpendicular to the shaft, sleeve-type white metal-lined bearing is used.

For the load acting along the shaft direction, face-to-face combination type of angular contact ball

bearings is used.

Special care is taken to cope with the load acting along the shaft direction. Because the M rotor is a

kind of helical gear and also because the thrust force produced by discharge pressure is larger than

that for F rotor, the load applied onto the M rotor is reduced by using not only a thrust bearing but also a

balance piston that applies pressure from the opposing direction.

2.5.8 Shaft Seal Block

To prevent refrigerant gas and oil leakage, a mechanical seal assembly is used for the shaft seal of the

M rotor.

Mechanical seal assembly is mainly composed of "rotating ring" installed on the rotor shaft and

"stationary ring" installed in the seal cover. Rotating ring rotates with the shaft, and slides each other

with the stationary ring while maintaining a micron class gap. The sliding each other place is called as

the sliding surface.

For example, the BBSE (Balance Bellow Single Seal) which is currently used as standard seal,

employs a stationary ring (mating ring) made of special cast iron, a rotating ring made from carbon, and

O-rings for the packing.

Figure 2-21 Slide Valve in the

Main Rotor Casing

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.6 Gas and Oil Flow

2-22

2.6 Gas and Oil Flow

The compression process of the screw compressor is as described in the preceding paragraphs.

Gas of the compound 2-stage screw compressor 3225**C is sent from the evaporator, and passes

through the strainer and check valve. It is drawn in from the upper central area (1) of the compressor,

compressed at the low-stage side (2), and then discharged at (3).

(3) and (4) are connected with a pipe. At the mid point of the pipe, that gas is mixed with the gas from

liquid cooler which was used for super-cooling.

Lubricating oil injected at the low-stage is, while kept mixed with gas, suctioned from (4) into the

high-stage.

After being compressed at (5), the gas mixed with lubricating oil is discharged from (6), and is sent from

the oil separator to the condenser.

Even if without intermediate gas cooling, oil provides cooling effect.

So, the high-stage discharge temperature is maintained at a temperature not higher than 90°C.

Figure 2-22 Gas Flow

2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.6 Gas and Oil Flow

2-23

Oil Supply Route

As shown in Figure 2-23, lubricating oil is split into five flows. After completing each role, the oil

flows to the rotor messing part of the high-stage, and in addition to return to the low-stage rotor

meshing part through the external piping. At last, both oil mixed with compressed gas and

discharged from the compressor.

In standard configuration, oil injection is not performed at the high-stage.

Figure 2-23 3225**C Oil Supply Route

2202MYJE-MY-C8-N_2018.02.

Chapter 3 Installation

Compound 2-stage Screw Compressor 3225**C 3.1 General Precautions for Installation

3-1

Chapter 3 Installation

3.1 General Precautions for Installation

This chapter (Installation) assumes that the compressor is installed to a standard refrigeration /

cold storage/gas compression package unit.

If the package unit you are actually using is not the standard type refrigeration/cold storage/gas

compression package unit, prepare a proper installation manual by referring to the description in

this chapter and paying due consideration to safety, before installing the compressor.

If there are any questions, please contact our local sales offices or service centers.

In some cases, it may be required that installation is performed by qualified personnel. Make

sure that the work is performed by qualified personnel in compliance with local laws,

ordinances and other regulations/requirements.

Before installing the compressor, please read this chapter and related documents attentively

and fully understand their contents.

Electrical works should be performed only by electrical engineers.

3.2 Installation Works

3.2.1 Unpacking

Confirm whether a compressor does not have abnormality including the damage.

If there are abnormalities or deficient parts on the compressor, please contact our sales offices

or service centers immediately.

Unnecessary packing materials should be discarded according to the laws and ordinances, or

your company's rules.

3.2.2 Storage

If you need to store the compressor before installation, perform the followings:

Store it indoors.

Infuse nitrogen gas into the compressor and seal it. (Pressure: Approximately 0.15 Mpa )

3.2.3 Transportation

Dropping of the lifted compressor may cause death or serious injury to the worker.

Do not stand under the lifted compressor.

1. For lifting the compressor within the safety limit, use lifting equipment and tools appropriate for the

mass of compressor.

2. Secure sufficient space for safe lifting.

3. Always check the wire ropes before using them. Thoroughly check the wire ropes for problems

such as kinks, knots and broken strands. Do not perform lifting before confirming the safety of the

wire ropes. If you cannot make a correct evaluation or judgment, entrust an expert to check.

2202MYJE-MY-C8-N_2018.02.

Chapter 3 Installation

Compound 2-stage Screw Compressor 3225**C 3.2 Installation Works

3-2

4. To lift the compressor, attach the wire ropes to the appended eye bolts by using appropriate

shackles and hooks. Refer to Figure 3-1 and Photo 002 in next page.